Page 1

WASHING MACHINE

OWNERS HANDBOOK

CUSTOMER CARELINE

08705 168299

Page 2

W A S H I N G M A C H I N E

Customer Careline: 08705 168299

SM1507

Page 3

W A S H I N G M A C H I N E

Thank you for purchasing a Servis Washing Machine.

The responsibility for correctly installing your washing machine rests entirely

with you, the owner, so please read the safety and installation instructions

carefully. Remember, it may be necessary to pull your appliance from its working position for servicing so do not make the water and electrical connections

too short.

Do not tamper with the appliance until you have read and understood the

instructions fully.

INDEX

INTRODUCTION

Safety Instructions 4

INSTALLATION

Unpacking Instructions 5

Electrical Information 6

Levelling the Appliance 8

Plumbing Installation 9

OPERATION

How to Do a Wash 13

Laundry Preparation 15

Loading the Appliance 15

HINTS & ADVICE

Detergents and Additives 16

Care of Your Appliance 17

Stain Removal 19

Troubleshooting 21

AFTER SALES SERVICE 22

SM1507

3

Page 4

W A S H I N G M A C H I N E

SAFETY INSTRUCTIONS

1 Please read the installation and connection instructions before attempting to install this appliance.

2 Ensure you have followed the ‘Unpacking Instructions’ section carefully.

3 You should run an initial wash cycle without laundry to remove residues of factory-applied grease from

the drum and tub. We suggest a rinse and spin programme with a small amount of detergent.

4 It is important that when you have selected a rinse and spin programme, you attend the machine through-

out the cycle, which will also ensure that all installation connections have been correctly made.

5 It is also recommended after seven days use, that the connections to the outlet hoses are checked at

the taps and the appliance.

6 You may fi nd some water deposits in the tub; this is the residue from the thorough testing, which your

appliance was subjected to in the factory.

7 Before using your appliance for the fi rst time, please make sure that the mains voltage and supply in-

dicated on the rating plate (situated inside the fi lter door on the front bottom right hand corner of the

appliance) agree with the mains voltage where the machine is to be used.

8 Before cleaning or care and maintenance work, make sure that the appliance is switched off. For safety

reasons we strongly advise that you pull the mains plug out of the socket, switch off at the power point

or completely remove the fuse box servicing the circuit (see Electrical Information).

9 Never direct water onto the outer casing of the appliance.

10 Never use the supply lead to pull the mains plug out of the socket. Pull the plug.

11 Never operate the machine if the appliance shows visible signs of damage to the control panel, worktop

or bottom plinth.

12 We advise that for your safety and the continued trouble free operation of your appliance, all repairs and

maintenance should be carried out by an approved Servis UK engineer using only genuine parts.

13 Children may not realise the dangers of improper use of electrical appliances. Therefore, please ensure

that children are kept away at all times.

14 During certain programmes, the glass on the porthole door could become very hot, please ensure there-

fore that children are kept away at all times.

15 When it is fi nally time to replace your washing machine, please make sure that you de-activate the door

lock and cut the electrical supply lead, (after disconnecting) and dispose of the lead and plug safely.

16 If you operate this appliance incorrectly or use it for any purpose other than that for which it is intended,

we cannot accept liability for any possible damage caused.

17 When cleaning the stainless steel drum, never use any iron-containing scouring agents or steel wool.

18 If the supply cord is damaged, it must be replaced by the manufacturer or its service agent.

19 The appliance must be positioned so that its plug is easily accessible. It is also important that your ap-

pliance has adequate ventilation and that air fl ow underneath the appliance is not impeded.

WARNING! Socket outlets are not permitted in bathrooms, neither should any provision be made for connecting moveable electrical appliances. No stationary appliance is to be installed within reach of a person

using a bath or shower.

Cold fi ll only machines improve the performance of biological detergents as well as increasing stain

removal capabilities: all contributing to an “A” wash performance. Apart from having lower water consumption and energy costs, it also offers the convenience of a one pipe installation connection.

4

SM1507

Page 5

W A S H I N G M A C H I N E

UNPACKING INSTRUCTIONS (ACCORDING TO MODEL)

1 Washing Machine

2 Owners Handbook

3 Hot and Cold High Pressure Hoses

4 Plastic Hole Plugs

5 Water Inlet Cap

6 Rubber Washers

7 Mesh Filters

8 Hose Crook

The machine must be installed by professionally qualifi ed technicians, according to the manufacturer’s indications. Incorrect installation may result in damage to persons and property.

The machine can be installed anywhere, provided the temperature in the place of installation is not below

3°C and the cables and hoses at the rear of the machine are not crushed in any way.

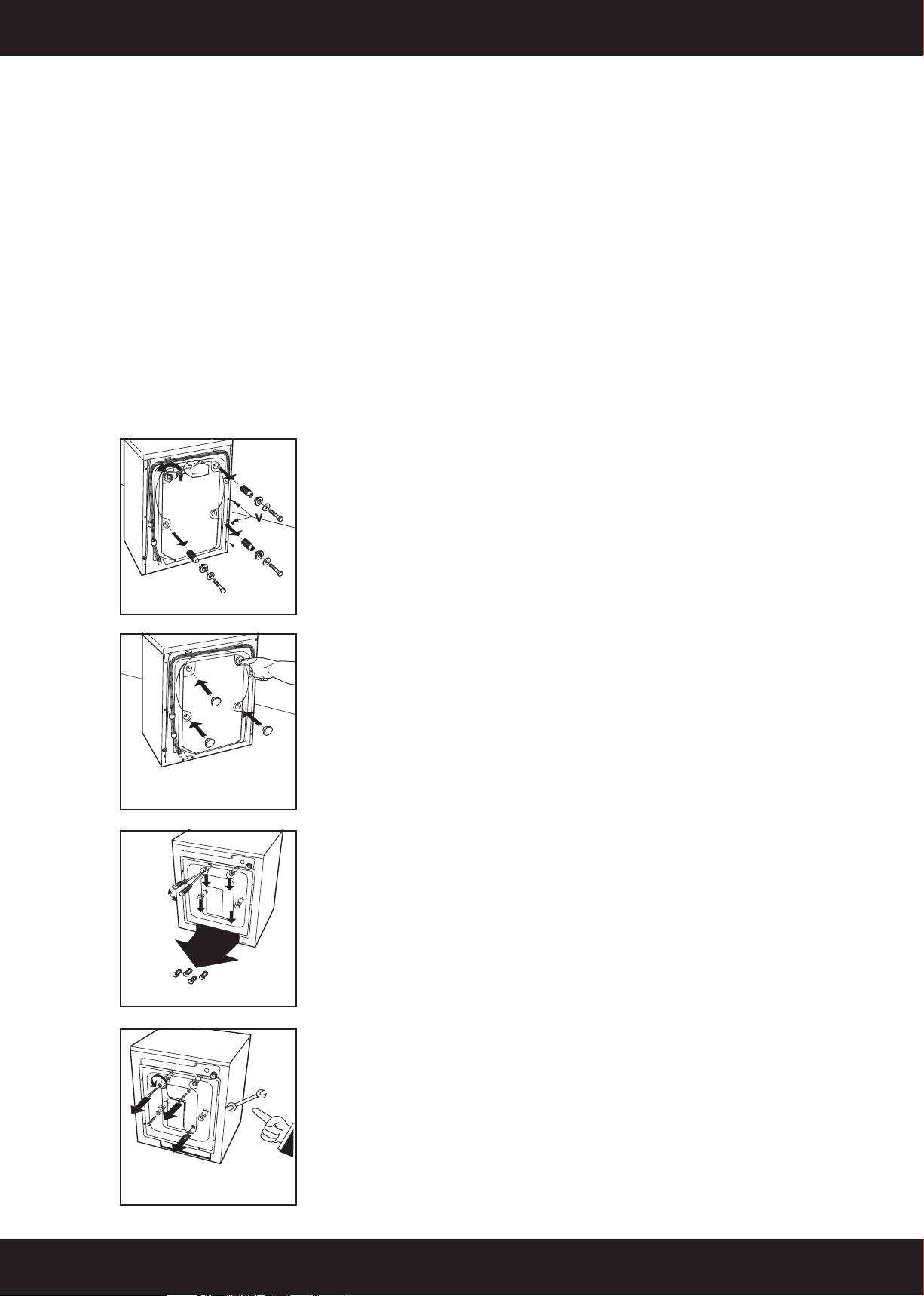

For transport purposes the swinging unit in the machine is blocked using 4

spacers with screws. Before starting the machine these spacers and lock

screws must be removed, and stored for use in the event of a possible change

of location.

Fig 1

Fig 2

Fig 1A

Block off the holes with the plugs provided, which can be found in the bag

containing the documents.

For transport purposes the swinging unit in the machine is blocked using

4 spacers with screws. Before starting the machine these screws must be

removed using a screwdriver.

Fig 2A

SM1507

Insert a screwdriver in the holes and proceed as shown in the fi gure to recover

the 4 plastic spacers.

5

Page 6

W A S H I N G M A C H I N E

ELECTRICAL INFORMATION

Before using this appliance ensure that the voltage in your home corresponds with the voltage indicated on

the machine rating plate, which can be found inside the fi lter door - front bottom right hand corner.

Warning – This appliance must be earthed.

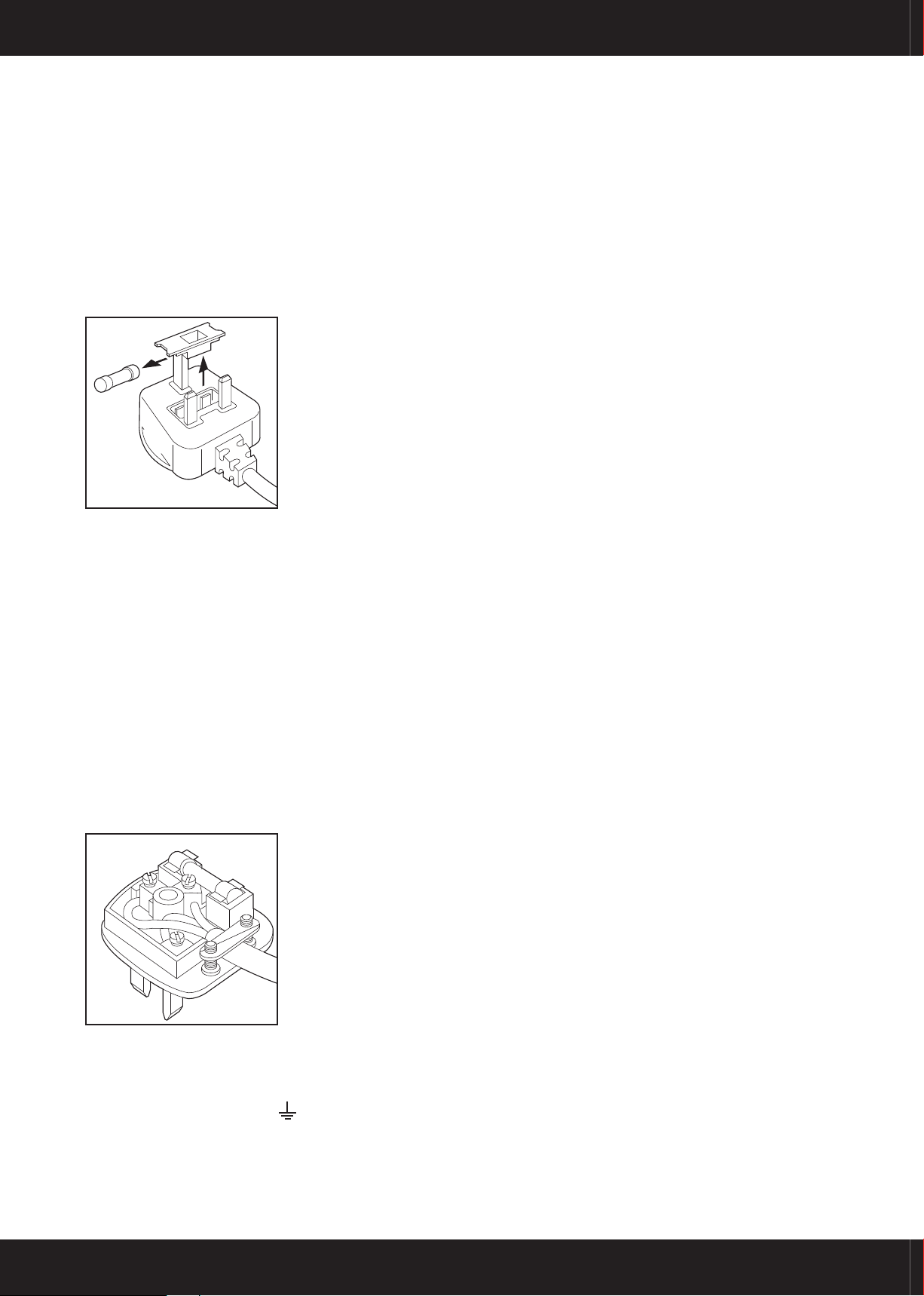

The mains lead of the appliance is fi tted with a BS 1363A 13 amp fused plug.

To change a fuse in this type of plug, proceed as follows:

1 Remove the fuse cover (A) and the fuse (Fig 3).

Fig 3

2 Fit a replacement fuse which should be BS 1362 13 amp.

Important:

1 The fuse cover must be replaced after changing a fuse.

2 In the event of a fuse cover being misplaced, the plug must not be used until a correct replacement is fi tted.

3 Please ensure that the replacement fuse cover is of the same colour as the insert or has the colour em-

bossed in words on the base of the plug.

4 For replacement fuse covers please consult your local electrical store.

Please state the colour of your plug insert.

If the fi tted plug is not suitable for your socket outlets, it should be cut off and disposed of immediately to

avoid a possible shock hazard should it be inserted into a 13 amp fuse elsewhere. A suitable alternative plug

should then be fi tted to a cable.

Warning – This appliance must be earthed.

Important: The wires of the mains lead fi tted to this appliance are coloured in accordance with the following code:

1 GREEN AND YELLOW – EARTH

Fig 4

2 BLUE – NEUTRAL

3 BROWN – LIVE

As the colour of the wires in the mains lead fi tted to this appliance may not correspond with the coloured

markings identifying the terminals in the plug 9 (Fig 4), proceed as follows:

1 The GREEN & YELLOW wire must be connected to the terminal in the plug which is marked with the ‘E’

or by the earth symbol or coloured green or green and yellow.

2 The BLUE wire must be connected to the terminal, which is marked with the ‘N’ or coloured black.

3 The BROWN wire must be connected to the terminal in the plug, which is marked with the ‘L’ or coloured red.

4 If the terminals in the plug are unmarked or if you are in any doubt as to the correct connections, consult

a qualifi ed electrician.

6

SM1507

Page 7

W A S H I N G M A C H I N E

For the Republic of Ireland only

The information given in respect of Great Britain will frequently apply, but a third type of plug and socket is

also used, the 2-pin, side earthed type. In this case, the wire, which is coloured green and yellow must be

connected to the earth contact and the other two wires to the two pins, irrespective of colour. The supply to

the socket must be fi tted with a 16 amp fuse.

Warning

Do not plug a tumble dryer and washing machine into an adaptor for connection to a single socket outlet.

Plug the dryer and washing machine into separate socket outlets.

On completion of the installation, the appliance must be connected to the mains supply through a two-pole

switch.

Special Electronic System

Your appliance is fi tted with a special electronic system that allows your appliance to spin at very high speed if

the load is distributed correctly. Prior to spin, the electronic system allows the drum to rotate in both clockwise

and anti-clockwise directions to distribute the wash load evenly. If this doesn’t happen, sometimes large towels

and sheets tangle into a ball, the electronic system will recognise the imbalance in the drum and reduce the

spin cycle. This will result in the wash items being more damp than usual.

Where the imbalance is signifi cant and could be detrimental to the appliance the system will automatically

halt the spin cycle. The wash items will therefore be wet.

If this happens, wait until the door safety inter-lock has released the door catch, remove the clothes, spread

them out inside the drum and then reset the appliance to the spin programme.

Note: If your appliance stops and your wash items are wet or more damp than usual, this is not a fault.

The electronic system is there to protect your appliance against excessive movement and vibration.

SM1507

7

Page 8

W A S H I N G M A C H I N E

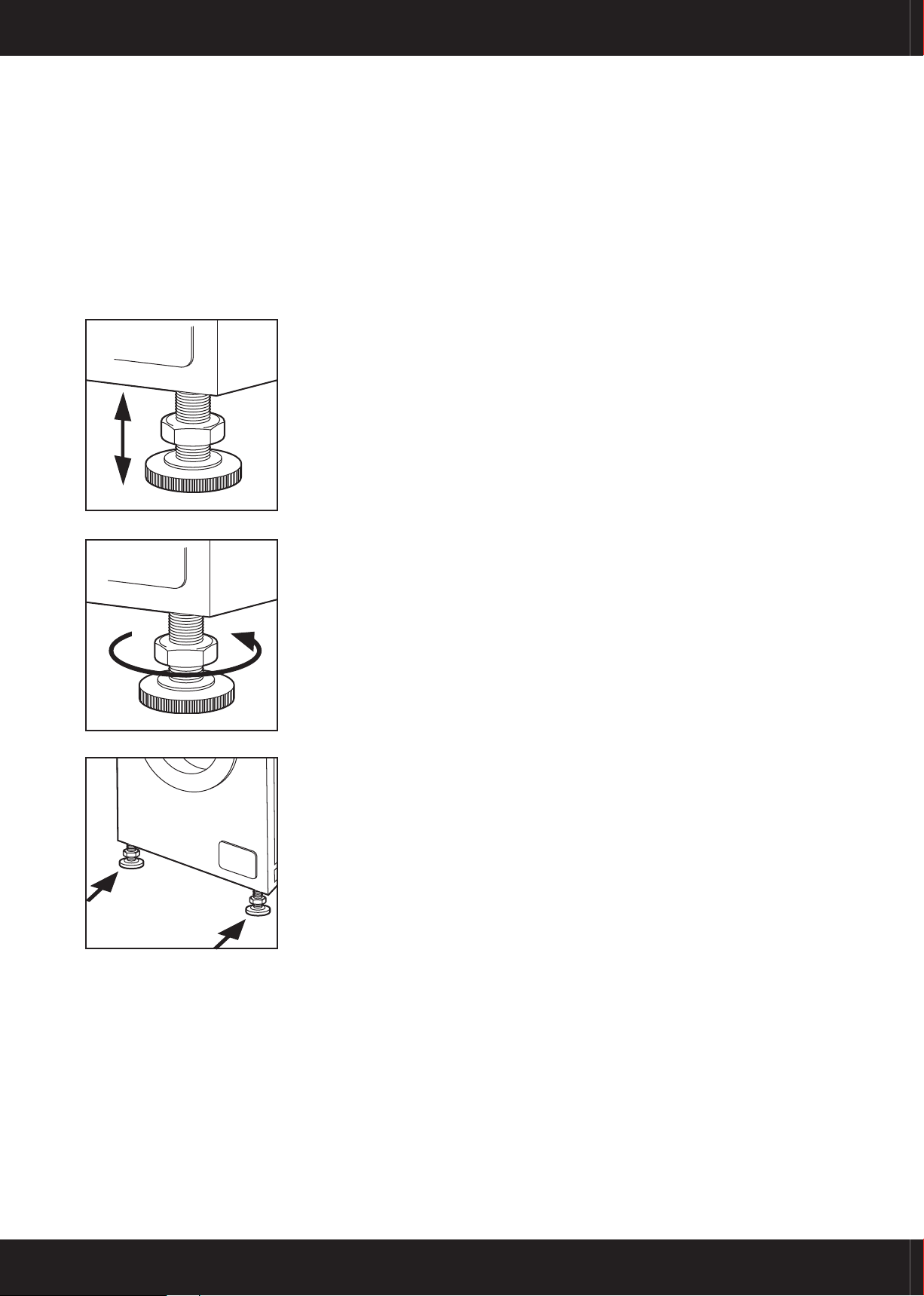

LEVELLING THE APPLIANCE

Having completed the electrical connections, move your appliance to its operating position. To minimise

vibration and noise during spinning your appliance must be level and in fi rm contact with a well supported

or preferably solid fl oor. Failure to level the appliance could lead to instability and consequent damage to

adjacent equipment.

Suspended, wooden fl oors or plinths might be needed to distribute the weight evenly.

Fig 5

Fig 6

1 One or both of the front feet should be adjusted in order to level the ap-

pliance. The back feet also need to be secured by adjusting the nuts.

(Fig 5).

2 Screw the foot up or down until the appliance is level in both front to rear

and side to side directions. Turn feet clockwise to lower the appliance

(Fig 6).

3 Lock the feet by screwing up the nuts using a 16mm spanner so that

they are in fi rm contact with the underside of the machine (Fig 7).

8

Fig 7

SM1507

Page 9

W A S H I N G M A C H I N E

PLUMBING INSTALLATION

Location

Modern washing machines spin at high speed. To avoid excessive vibration during spinning, install the appliance on a properly supported fl oor.

Always leave at least 5cm of space on each side of the appliance to allow for possible vibration during spinning of unbalanced loads.

Space for servicing and fi tting

Allow space on either side of the appliance for access and servicing.

Water Board Regulations

These instructions are intended only as a general guide and local by-laws and water board regulations regarding the water connections and drainage from the appliance must be observed.

Water Pressure

The appliance will operate within a wide range of water pressures.

Cold Water minimum 5 N/cm2 (0.5 bar) (7 psi)

Bleu Coloures maximum 100 N/cm2 (10 bar) (150 psi)

Hot Water (if fi tted) minimum 5 N/cm2 (0.5 bar) (7 psi)

Red Coloures maximum 100 N/cm2 (10 bar) (150 psi)

N.B.: Use the new pipe supplied with the machine and do not re-use theold one.

The height of the storage tank in the house must be a minimum of 8 feet above the top of the appliance to

meet the minimum pressure requirements.

Permanent plumbing for Hot and Cold fi ll machines only. (Two water valve connection)

Fig 8

Both the hot and cold hoses are provided with a standard 3/4 “ B.S.P female

connector which is to be fi tted to a suitable tap. The hot water inlet can be

identifi ed by the red coloured fi lter inside the inlet valve. Remember to

fi t the rubber washers into the ends of the hoses prior to connection to the

supply or appliance.

If only cold water supply is available it will be necessary to fi t a special adaptor (Fig 8).

Cold fi ll Only ( one water valve connection )

Fit the hose to cold water supply

Water Supply

1 Most domestic hot water systems are suitable.

2 Multi-point gas heaters can be used if suffi cient water pressure is available (check with manufacturer).

3 Single point instantaneous gas water heaters MUST NOT BE USED.

4 If you are in any doubt about the suitability of your hot water system, consult the manufacturer of the

heating appliance or the Gas or Electricity Board.

Water Connections

All the connections and adaptors mentioned in this section can be purchased from your local builder, plumber

or from large DIY stores and electrical outlets.

Filling hoses

Fig 9

SM1507

All our washing machines are supplied with special high pressure fi lling hoses

complete with a 3/4” BSP (19mm) female coupling.

Important: Under no circumstances should this coupling be removed from

the hoses (Fig 9).

We will not accept any responsibility for failure of the hoses or water connections if the factory fi tted couplings are removed. The hoses are designed to

be long enough to stay connected while the appliance is pulled forward for

cleaning and servicing.

9

Page 10

W A S H I N G M A C H I N E

38mm (11/2")

Min

Air gap

Inspection Elbow

600 - 900mm

(23”-1/2";35”-1/2")

Fitting the hose or hoses

Important: Remove the hoses from their storage in the drum and fi t them to the inlet valves situated on the

rear panel of the appliance. Remember to fi t the red hose to the red valve and to insert the rubber washers

into the couplings.

Insert the fi lter washers (Fig 11/12) in the other end of the fi lling hoses as shown. Screw the red hose to the

hot tap and the other hose to the cold tap.

You should not need tools to make a satisfactory seal; excessive force may

Fig 10

damage the connections (Fig 10). It should be suffi cient to fi rmly tighten

them by hand.

Permanent Plumbing

Please make provisions to shut off the water supply to the appliance completely. A separate isolation valve

Fig 11

Fig 12

should be fi tted. This will:

1 Avoid the possibility of fl ooding when the machine is not in use.

2 Allow the appliance to be moved for cleaning and servicing. If you do

not have an existing installation for connecting your appliance, consult

a qualifi ed plumber. There are various methods available.

NB: the appliance is to be connected to the water mains using new hosesets and old hose-sets should not be reused.

10

Discharge into a standpipe - drainage

Fig 13

The top of the standpipe should be approximately 610mm (24”) from the

ground. The dimensions from the fl oor to the underneath of the bend in the

drain hose, should be between 600 - 900mm (23”-1/2”;35”-1/2”) (Fig 13).

The take off pipe must be capable of taking a fl ow of 6 gallons (27 litres) per

minute. The minimum diameter of the standpipe must be 3.81cm (11/2”)

and there must be an air gap around the appliance drain hose when fi tting

into the standpipe.

Recommended way to plumb in a washer dryer from a combined

waste trap

SM1507

Page 11

W A S H I N G M A C H I N E

Note: All flexible hose connections to be secured with 'Jubilee Clips'

Washing Machine

Washing machine

flexible discharge

hose

Anti-syphon unit

WM4 washing

machine trap

with hose

adaptor

Sink waste to

S.V. pipe

Sink

Spare flexible hose length

for W/M withdrawal

365mm

510mm

Unit Height 900mm

Critical dimension not

to exceed 670mm

Temporary connections

Fig 14

It is best to avoid temporary connections where possible. When the appliance runs from sink taps, it can

mean that you are unable to use the sink for over an hour while the appliance completes a programme. In

addition, very hot water will be discharged from the drain hose into the sink and this could be a safety hazard,

especially if you have children close by.

If you must make a temporary connection, be sure that you check the condition of your tap and

keep children away from the discharge area.

The closing of the water valve in automatic appliances is instantaneous and will cause back pressure to the

tap. It is therefore essential that your taps are in good condition or they may leak during use. Even though

your taps may be adequate for everyday use, it is advisable to check the spindle sealing gland of the tap

before connecting your appliance for the fi rst time. To do this, connect the appliance fi ll hoses to the tap using your chosen adaptor, making sure the hose sealing washer is in place. If water escapes from the top of

the tap, the gland may need tightening or replacing.

Tap adapters

Tap adapters are available to fi t the majority of tap designs. Always ensure that the mesh fi lter is correctly

positioned in the fi ll hose coupling. These taps are normally fi tted with 5/8” BSP threads (17mm). An adapter

to convert the tap thread to the required 3/4” (19mm) is available from you local builder/plumber merchant.

DO NOT CONNECT TO MIXER TAPS!

Fig 15

SM1507

11

Page 12

W A S H I N G M A C H I N E

Temporary drainage connection

The end of the drain hose should be placed over the edge of the sink (Fig 16). Ensure that:

Fig 16

1 The hose cannot be easily displaced (a piece of string or wire can be threaded through the hole in the

plastic moulded hose crook and then attached to the tap).

2 The water level in the sink cannot cover the end of the drain hose.

3 The plug is removed and the water is able to drain.

4 Children are kept away from the sink while the machine is in operation.

12

SM1507

Page 13

W A S H I N G M A C H I N E

HOW TO DO A WASH

IMPORTANT

You should run an initial wash cycle without laundry to remove residues of factory-applied grease

from the drum and tub. We suggest a rinse and spin programme with a small amount of detergent.

Fig 17

Use of detergents

The washing machine is fi tted with a three-compartment detergent drawer:

Compartment on the right is for the pre-wash soap powder

Compartment on the left is for liquid detergent or soap powder for the main

wash

The centre compartment is for the softener, perfume, starch or bleach

Fig 19

Fig 18

NOTE: When using a liquid detergent (recommended for programs without

pre-wash) proceed as follows: remove the baffl e from its housing at the front

of compartment 2 and insert it in the guides near the centre of the same

compartment.

Remember to replace it in its front housing when using soap powder.

Close the detergent drawer before starting the wash.

WARNING! Do not attempt to remove the detergent drawer while the appliance is operating, as this may cause water to fl ow out.

Load the laundry

Open the door by pulling the catch outwards. Load the items to be washed

one at a time and close the door (Fig 19).

Fig 20

SM1507

Add the detergent

Open the detergent drawer by pushing the lower section of the drawer

front

Measure the required quantity of washing powder and pour it into the detergent compartment (Fig 20) or directly into the drum of the appliance if you

are using a wash ball. (See section on Detergents and Additives).

13

Page 14

W A S H I N G M A C H I N E

Fig 21

Start up

Fig 22

How to remove the detergent drawer

open the drawer, press on the word push and use the other hand to pull it

out (Fig.21).

Check that:

1 The appliance is plugged in.

2 The water taps are on.

3 The drain hose is correctly positioned. Then push the ON/OFF button

(Fig 22) then the start button

The end

At the end of a programme the appliance automatically stops. Push the ON/OFF button to turn the appliance

OFF. The door is controlled by a safety device.

Open the door once the safety catch is released and remove all the articles of clothing. When the programme

has fi nished, you are advised to unplug the appliance and turn off the water taps.

NOTE: Should you turn past the required programme continue to turn the dial to reset. Do not turn the programme selector dial whilst the machine is switched on and working, if necessary switch off the machine

before attempting to move the dial.

14

SM1507

Page 15

W A S H I N G M A C H I N E

LAUNDRY PREPARATION

Before you start washing, sort out your laundry into washing loads according to type of fabric, degree of soiling, colour fastness, drip dry, etc. All the articles in a load must be able to be washed at the same temperature.

You will then obtain the best washing results.

NOTE: Clothing care labels on all clothes must be adhered to at all times.

1 Check the clothing care label on all articles; if in doubt refer to the sections on main wash programmes

& fabric guide.

2 Fasten zips – these can cause damage to other articles.

3 Tears and open seams should be mended before washing.

4 Secure loose buttons.

5 Empty pockets of all contents, coins, keys, etc. can cause internal damage to your appliance.

6 Put lace, belts and children’s clothes (bootees, etc.) into a pillowcase to prevent tangling around clothes.

7 Treat any stains before washing (see section on “Stain removal”).

8 If you are unsure about the colour fastness of fabrics, wash in low temperature at 40oC.

9 New denims should be washed separately in case of colour run. Afterwards they can be washed

according to instructions.

10 Bulky articles – sleeping bags, quilts etc, should be washed on the wool programme to get best results.

Wash one at a time.

LOADING THE APPLIANCE

How much is in a load? Your appliance will wash the following dry weights. (On selected models).

Cottons and Linens 5kg 11lbs 6kg 13.3lbs 7kg 15.4lbs 8kg 17.6lbs

Absorbent materials, towels, nappies, fl annelette

Manufactured fi bres 2kg 4.4lbs 2.5kg 5.5lbs 3kg 6.6lbs 3.5kg 7.7lbs

Machine washable woollens 2kg 4.4lbs 2.5kg 5.5lbs 3kg 6.6lbs 3.5kg 7.7lbs

A guide to the approximate dry weight of articles.

Double sheet 907gm

Single sheet 680gm

Table cloth 453gm

Bath towel 453gm

Hand towel 227gm

Tea towel 113gm

Skirt 340gm (3/4 lb)

Pyjamas 340gm (3/4 lb)

Underwear 113gm (3/4 lb)

Aprons 113gm (3/4 lb)

Blouses 113gm (3/4 lb)

Nightdresses 113gm (3/4 lb)

Two typical loads:

Programme 2 (Load 10lbs) Programme 4 (Load 5 lbs)

2 tea towels, 1 tablecloth, 5 pairs pants, 3 blouses,

2 bath towels, 2 hand towels, 2 nightdresses, 3 shirts

1 single sheet, 2 double sheets. 2 pairs pyjamas, 1 apron.

2.5kg 5.5lbs 3kg 6.6lbs 3.5kg 7.7lbs 4kg 8.8lbs

IMPORTANT!

DONOTOVERLOAD

Overloading will affect the effi ciency of the wash and in the long term, it can damage the appliance. This is

particularly important with machine washable wool, and with man made fi bres, such as Acrilan, Bri-nylon,

Terylene, Crimplene, Dralon, Trevira and Courtelle. They need plenty of room, so keep within the weight limit.

Take them out of the appliance as soon as possible after the wash programme is completed.

DO NOT UNDERLOAD

To ensure smooth running, avoid spinning heavy items. Spinning underloaded may cause excessive vibration.

So, if you do not have enough items in a particular group to make a reasonable load add a few towels.

SM1507

15

Page 16

W A S H I N G M A C H I N E

DETERGENTS AND ADDITIVES

How much and where?

Deciding on the soil level of your clothes is very diffi cult. However it is also very important to make sure you

dose the correct amount of detergent. to help you, we have included the soil level symbols as you see them

on the Ariel pack. We have also explained what these soil levels mean and have included garment types and

items which fall into each category.

Soil levels

Light soil - No stains are noticeable on the garments, youwould just like to refresh the

clothes you’ve been wearing. (eg: sweaters, curtains, jackets).

Normal soil - Garment that have been worn for a dy and which may show some stains,

although not all stains are visible (eg: blouses, shirts).

Heavy soil - Garments that have been worn for at least one day or are owrn in hgh body

soil areas (eg: underwear, towels, socks, baby clothes).

Very heavy soil - Items which are very dirty (for example kitchen towels) or garments

which have tough stains on them such as mud, grass, motor oil (eg: tea towels, bed linen,

sportswear).

Getting the right dosage

For the best laundry results, it’s important to use the right amount of detergent. Modern washing machines

use less water and some people believe it is okay to use less detergent. This is not true and will lead to

problems in the wash. Detergent dosage is based on the amount of soil on the laundry and the hardness of

the water.

As well as ingredients designed to remove stains, detergents also contain ingredients which hold the removed

stains in solution. Underdosing the detergent will result in too little of this ingredient being able to hold all of

the removed stains in solution. This will build-up with time resulting in laundry which is not as white or bright

as it should be.

Underdosing: will result in limescale build-up in your machine thus reducing its effi ciency and increas-

ing the running cost.

Overdosing: the detergent is uneconomical and may result in rinsing problems.

By following the dosing table on your Ariel pack, you should be able to work out the correct amount of detergent for your particular wash load.

NOTE: Always follow the recommended dosages of detergent, which can be found on every pack.

Servis recommend the use of Ariel, Ariel Color and Ariel Non-Bio in their washing machines, all of these

products are available in powder, liquid, tablet or liquitab form to kep you clothes looking newer for longer.

16

SM1507

Page 17

W A S H I N G M A C H I N E

CARE OF YOUR APPLIANCE

Successful washing and smooth running of your appliance depends on routine maintenance, which should

be carried out on a regular basis.

IMPORTANT: You must unplug the appliance before all cleaning and maintenance operations.

Decalcifi cation

The water we normally use contains lime; therefore, it is a good idea to occasionally use a water softener

powder in the appliance (more frequently in hard water areas). Add the powder according to the manufacturer’s instructions. This will prevent the formation of lime deposits, which can affect the performance of your

appliance.

After each wash

Leave the door slightly open. This helps prevent mould and stagnant smells forming inside the appliance.

Turn the drum slowly so that no small items have been overlooked. Wipe the inside of the drum and door seal

with a dry cloth (It is normal if a certain amount of water has collected in the rim of the door seal).

Fig 23

Cleaning the drawer

The drawer should be cleaned when there is a build-up of residual detergent.

To remove the drawer, press on the plastic part of the conditioner grill marked

‘PUSH’ (Fig 23) then clean it by running it under warm water.

External cleaning

Use soap and water only and then dry thoroughly.

Cleaning the fi lter

A clean fi lter is important for correct functioning of the washing machine, so should therefore be cleaned

periodically

Fig 24

1 Open the panel, which is situated at the bottom, right corner on the front

of the machine and place a container underneath to catch any spillage (It

is normal for a certain amount of water to collect in the fi lter) (Fig 24).

Fig 25

SM1507

2 Unscrew the fi lter – 2 turns anticlockwise (Fig.25) remove and rinse.

3 Replace the fi lter carefully, putting it on its guides, push in and screw it

in fi rmly until black seal is not showing.

17

Page 18

W A S H I N G M A C H I N E

If the fi lter is blocked and the appliance is unable to drain, you will need to remove the water from the appliance at this stage. To do this:

1 Unhook the drain hose from the standpipe or sink.

2 Hold the end of the hose over the bowl on the fl oor. The water should drain by gravity into the bowl.

3 When the bowl is full, hook the hose back up and empty. Repeat the procedure until the water stops

fl owing.

4 Clean the fi lter in the normal way.

NOTE: Never remove the fi lter during a wash cycle, always wait until the appliance has fi nished its cycle

and is empty. When replacing the fi lter ensure that it is securely retightened. This will prevent leaks and stop

young children from being able to undo the fi lter.

18

SM1507

Page 19

W A S H I N G M A C H I N E

STAIN REMOVAL

Here are some common stains, their nature and the ideal reagent to use to remove the stain.

A = absorbed, B = built up, C = compound.

STAIN TYPE TREATMENT

Ballpoint Ink C Methylated spirit

Beer A Hydrogen peroxide, dilute if necessary to avoid bleaching

Blood C Soak in washing powder

Chocolate C Remove excess chocolate and treat any remaining stains with hydrogen perox-

ide

Coffee A Soak in washing powder

Chewing Gum B Hold an ice cube against the gum until it can be crumbled away

Candle Wax B Scrape off excess and iron between two sheets of white blotting paper, treat with

methylated spirit

Eggs C Soak in washing powder

Grass C Methylated spirit

Gravy C Soak in washing powder

Grease or Oil C Methylated spirit

Ink A A cold water diluted solution of washing up liquid or similar liquid

Rust C Small stains – lemon juice

Heavy stains – proprietary rust remover if suitable for material

Lipstick C Washing up liquid or methylated spirit

Mildew C Hydrogen peroxide

Milk A Washing up liquid or washing powder

Nail Varnish C Acetone (except on triacetates) or nail varnish remover:

hand wash immediately before machine washing

Paint C Emulsion – cold water or Polyclens, hand wash immediately before machine

washing

Gloss or undercoat - Polyclens hand wash immediately before machine wash-

ing

Perspiration A Ammonia followed by hydrogen peroxide if any residual stains

Rubber C Methylated spirit followed by dry cleaning

Scorch Marks C Rub in glycerine and soak for 10-15 mins,

then wash followed by diluted hydrogen peroxide

Soot C Washing up liquid

Tar C Polyclens or washing up liquid wash then treat with hydrogen peroxide

Hand wash immediately before machine washing

Tea A Soak in washing powder rub in a little glycerine leave for 10-15 minutes

before re-washing

Wine A Soak in washing up liquid. If coloured treat with hydrogen peroxide

Warning: Keep all chemicals out of reach of children.

SM1507

19

Page 20

W A S H I N G M A C H I N E

Dealing with stains

There are three types of stains:

1 Absorbed stains – caused by liquids, which penetrate the garment easily, e.g. tea, coffee, wine, beer, etc.

2 Built up stains – stay on the surface and do not fl ow into the fi bres.

3 Compound stains – are absorbed into the fabric and leave residue on the surface, e.g. blood and certain

food stains.

Basic rules

1 Remove all stains as soon as possible after they occur and try to stop the stain setting in by soaking in

cold water, NEVER hot water.

2 Blot off what you can with a clean cloth.

3 Identify the stain and fabric.

4 Try the simplest remedy fi rst.

5 Test the stain removal agent on an unseen part of the garment.

6 Local treatment is best.

Soaking can play a valuable part in the removal of many common stains.

Heavy duty washing products usually contain a bleaching ingredient which removes stains such as tea, coffee and fruit juice by oxidation; some also contain enzymes which break down protein stains such as blood,

gravy, egg yoke and milk. At lower temperatures, enzymes work by tackling protein stains, which could be

fi xed by the use of hot water. Long soaking times allow the dirt to settle back into the fabric. Two half hour

soaks are better than one soak lasting an hour. Soaking works best at 40°C to 50°C.

When soaking

1 Always check each individual garment’s Clothing Care Label.

2 Make sure the stained article is suitable for soaking. Whites and fast coloureds can usually be soaked.

3 NEVER soak silk, wool, leather, garments with metal fasteners or any article with a fl ame resistant fi n-

ish.

4 NEVER soak articles of doubtful colour fastness (see section on testing for colour fastness).

5 Use a container such as a sink or plastic bowl (but NOT an enamel bath) large enough to hold gar-

ments

freely and fi ll it with warm water (40°C) where there are blood, gravy, egg or milk stains. Use hand hot

water (50°C) for other soaking.

6 If using a powder, ensure that it is fully dissolved before putting articles in. After soaking, rinse the arti-

cles

before continuing with the soaking. NOTE: Although modern detergents can deal with most house-

hold

stains, once a stain has set it may be necessary to wash it two or three times.

7 Greasy or oily collar and cuff marks can be pre-treated with neat washing liquid. Work the liquid into the

affected area, and then continue with a normal wash.

Testing for colour fastness

Always test a fabric for colour fastness before trying to remove a stain.

Remember too, that some dyes only stay fast for a limited number of washes. It is therefore well worthwhile to

re-test a coloured fabric even if you have previously found it to be colour-fast, particularly if you are planning

to use a prolonged contact time with the stain removal agent or washing solution.

1 Apply the stain removal solution to an inconspicuous part of the garment (e.g. inside the hem).

2 Place the treated area between two pieces of white cloth and press with a warm iron.

3 Examine the pieces of white cloth. If no colour has been transferred, the dye is fast and you can pro-

ceed.

4 If colour has been transferred, the dye is not fast; advice should be sought from a dry cleaner.

20

SM1507

Page 21

W A S H I N G M A C H I N E

TROUBLESHOOTING

If your appliance fails to operate, to avoid unnecessary and possibly expensive service calls, it is in your own

interest to make the following preliminary checks:

If the appliance does not start

1 Is the electricity on? (Check another appliance in the same socket).

2 Is the plug fi rmly in the socket?

3 Is the fuse in the plug working? (Try another fuse).

4 Is the door closed properly?

5 Is the programme selected properly?

NOTE: If the appliance has just fi lled up with water it is probably just heating up. Wait a few minutes and it

should continue.

If the appliance does not drain or spin

1 Check that the drain hose is not kinked.

2 Check that the fi lter is clear (See section on ‘Care of Your Appliance’).

3 Check that the outlet hose is correctly fi tted and has not been kinked during installation, or if the appli-

ance has moved.

4 If drain hose is connected under a sink, check the connection for an obstruction.

If the appliance does not fi ll with water

1 Check that the taps are turned on.

2 Check that the fi lling hoses are not kinked.

3 Check that the water fi lter inlet is clean.

NOTE: Your appliance is designed to use less water, therefore do not worry if the water is not immediately

visible (Wash results are not affected).

If the appliance is noisy or not sitting evenly on the fl oor

1 Check that the adjustable feet are properly set and the lock nuts are tight

(See section on ‘Levelling the Appliance’).

2 Check that nothing has fallen down the back or side of the appliance

3 Check that the appliance is not touching any pipes or any other appliances.

4 Check that the appliance is not over-loaded or under-loaded

5 Check that the appliance is evenly loaded.

6 Check removal of transit screws, and the suspended fl oor if used.

If the appliance appears to be leaking

1 Check that the water hose connections are tight (switch off electricity fi rst).

2 Check the mesh/washers are fi tted

3 Check that the soap dispenser is not blocked with unused powder.

4 Check that the drain hose is not kinked.

5 Have you remembered to fi t the rubber washers to the water hoses?

6 If installed into as standpipe, check for blockage.

If the appliance still fails to operate, you must call for an engineer. In the event of a power cut during the spinning stage, switch off and reset the programme selector to the appropriate spin position when the power is

restored again. This will ensure that the appliance goes through the set balancing sequence using a slow

spin to evenly distribute the laundry. This is necessary to achieve stability during the fi nal spin.

SM1507

21

Page 22

W A S H I N G M A C H I N E

AFTER SALES SERVICE

If you think your automatic Washer Dryer is not working properly, ensure that you have referred to the following before you call for service. The company reserves the right to charge for a service call if an inspection

reveals that the appliance is in fact in working order. We advise that for your safety and the continued trouble

free operation of your appliance, all repairs and maintenance should be carried out by our authorised agents

using genuine parts.

For advise on the use of your appliance and after sales service calls, telephone the Customer Careline 08705

168299 with the following information:

1 Your name, address and postcode.

2 Your telephone number.

3 Model number for the appliance (See the section on Technical Information).

4 The date you purchased the appliance.

5 Clear and concise details of the fault.

6 The guarantee only covers defects resulting from faulty workmanship or components.

7 To obtain your free in-guarantee service repair, proof of purchase must be provided or a charge will be

made.

This appliance is marked according to the European directive 2002/96/EC on Waste Electrical and Electronic

Equipment (WEEE).

By ensuring this product is disposed of correctly, you will help prevent potential negative consequences for

the environment and human health, which could otherwise be caused by inappropriate waste handling of

this product.

The symbol on the product, or on the documents accompanying the product, indicates that this appliance

may not be treated as household waste. Instead it shall be handed over to the applicable collection point for

the recycling of electrical and electronic equipment.

Disposal must be carried out in accordance with local environmental regulations for waste disposal.

For more detailed information about treatment, recovery and recycling of this product, please contact your

local city offi ce, your household waste disposal service or the shop where you purchased the product.

22

SM1507

Page 23

W A S H I N G M A C H I N E

SM1507

23

Page 24

SERVIS UK LIMITED

P.O. BOX 14, DARLASTON ROAD, WEDNESBURY, WEST MIDLANDS, WS10 7TJ

TEL: 0121 568 8333 FAX: 0121 568 8500

CONSUMER CARELINE: 08705 168299

461305487 STMAPA TLF 04/06/2008 SM1507/10

Loading...

Loading...