ServiceMaster 56113010, PEX 500-SM Information And Operating Instructions

Owner’s Manual: 19630

Title: PEX 500-SM

Serial number:________________

INFORMATION AND

OPERATING

INSTRUCTIONS

INFORMATION ET

MODEL: 5

A-English

B-Français

DIRECTIVES

D’UTILISATION

6113010

ServiceMaster Clean

3839 Forest Hill Irene Road

Memphis, TN 38125

800-756-5656 Option 3

Date: November 2013

Revision: G

ServiceMaster® Manual

Copyright 2013 by

ServiceMaster Clean

All rights reserved

7/11 revised 4/2016 FORM NO. 56091038 REV G

A-2 / ENGLISH

TABLE OF CONTENTS

Page

Introduction ................................................................................... A-3

Parts and Service ........................................................................... A-3

Nameplate ...................................................................................... A-3

Uncrating the Machine .................................................................... A-3

Cautions and Warnings .................................................................. A-4

Grounding Instructions ................................................................... A-5

Know Your Machine.............................................................A-6 – A-7

Know Your Switch Plate .................................................................. A-8

Preparing the Machine for Use .................................................... A-9

Operating the Machine .................................................... A-10 – A-11

After Use

After Using the Machine ............................................................... A-12

Maintenance

Maintenance Schedule ................................................................. A-12

Power Cord Maintenance ............................................................. A-12

Troubleshooting ............................................................................ A-13

Technical Specifi cations ............................................................... A-13

SECTION II – Parts List .................................................................. 27

Decal System ..............................................................................28-29

Pallet System 500-1 ....................................................................30-31

Pallet System 500-2 ....................................................................32-33

Recovery System .............................................................................34

Solution System ................................................................................35

Wiring Diagram ............................................................................36-37

Options & Accessories ......................................................................37

CAUTION: DO NOT OPERATE MACHINE UNTIL YOU HAVE READ

ALL SECTIONS OF THIS INSTRUCTION MANUAL

IMPROPER USE OF THE MACHINE WILL VOID THE WARRANTY

A-2 - FORM NO. 56091038 - PEX 500-SM

ENGLISH / A-3

INTRODUCTION

This manual will help you get the most from your ServiceMaster™ carpet extractor. Read it thoroughly before operating the machine.

This product is intended for commercial use only.

PARTS AND SERVICE

Repairs, when required, should be performed by your Authorized ServiceMaster Service Center, who employs factory trained service personnel, and

maintains an inventory of ServiceMaster original replacement parts and accessories.

Call the SERVICEMASTER DEALER named below for repairs or service. Please specify the Model and Serial Number when discussing your

machine.

MODIFICATIONS

Modifi cations and additions to the cleaning machine which affect capacity and safe operation shall not be performed by the customer or user without

prior written approval from the manufacturer. Unapproved modifi cations will void the machine warranty and make the customer liable for any resulting

accidents.

NAMEPLATE

The Model Number and Serial Number of your machine are shown on the Nameplate, located on the rear base of the machine. This information is

needed when ordering repair parts for the machine. Use the space below to note the Model Number and Serial Number of your machine for future

reference.

MODEL ________________________________________________

SERIAL NUMBER ________________________________________

UNCRATING THE MACHINE

Carefully unpack and inspect your PEX 500-SM for shipping damage. Each machine is tested and inspected before shipping. Any shipping

damage incurred is the responsibility of the carrier. You should notify the carrier immediately if you notice damage to the box or to the machine or

parts.

WARNING!

The Products sold with this Manual contain or may contain chemicals that are known to certain governments (such as the State of

California, as identifi ed in its Proposition 65 Regulatory Warning Law) to cause cancer, birth defects or other reproductive harm. In

certain locations (including the State of California) purchasers of these Products that place them in service at an employment job site

or a publicly accessible space are required by regulation to make certain notices, warnings or disclosures regarding the chemicals

that are or may be contained in the Products at or about such work sites. It is the purchaser’s responsibility to know the content

of, and to comply with, any laws and regulations relating to the use of these Products in such environments. The Manufacturer

disclaims any responsibility to advise purchasers of any specifi c requirements that may be applicable to the use of the Products in

such environments.

revised 7/12

FORM NO. 56091038 - PEX 500-SM - A-3

A-4 / ENGLISH

IMPORTANT SAFETY INSTRUCTIONS

This machine is only suitable for commercial use, for example in hotels, schools, hospitals, factories, shops and offi ces

other than normal residential housekeeping purposes.

When using any electrical appliance, basic precautions should always be followed, including the following:

NOTE: Read all instructions before using this machine.

WARNING!

To reduce the risk of fi re, electric shock, or injury:

• This machine is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack

of experience and knowledge.

• Do not leave the machine unattended when it is plugged in. Unplug the unit from the outlet when; not in use, before cleaning the

machine, prior to servicing or performing any maintenance on the machine, and when replacing parts or converting the machine

to another function.

• To avoid electric shock, do not expose to rain or snow. Store and use machine indoors only, store in a heated location. Do not

let the machine or wand freeze.

• Do not allow to be used as a toy. Close attention is necessary when used near children.

• High pressure cleaners shall not be used by children or untrained personnel.

• Use only as described in this manual. Use only the manufacturer’s recommended attachments.

• Never add water over 130º F/54º C to the solution tank.

• Always use a defoamer when foaming occurs to prevent vacuum motor damage.

• Do not let the pump run dry.

• Do not use with damaged cord or plug. If the machine is not working as it should, has been dropped, damaged, left outdoors or

dropped into water, return it to a service center.

• Turn off all controls before unplugging.

• Do not pull by the cord, use the cord as a handle, close a door on the cord, or pull the cord around sharp edges or corners. Do

not run the machine over the cord. Keep the cord away from heated surfaces. To unplug, grasp the plug, not the cord.

• Do not handle the plug, the cord or the machine with wet hands.

• Extension cords must be 12/3 and no longer than 50 feet. Replace the cord or unplug immediately if the ground prong becomes

damaged.

• Connect to a properly grounded outlet only.

• Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair, and anything that may

reduce air fl ow.

• Keep loose clothing, hair, fi ngers, and all parts of body away from openings and moving parts.

• Do not pick up anything that is burning or smoking, such as cigarettes, matches, or hot ashes, or any health endangering dusts.

Do not use to pick up fl ammable or combustible liquids such as gasoline or use in areas where they may be present.

• Risk of explosion – Do not spray fl ammable liquids.

• Use extra care when cleaning on stairs.

• Wear gloves or use rags when removing quick disconnects to prevent burns.

• Liquid ejected at the spray nozzle could be dangerous as a result of its temperature, pressure, or chemical content.

• High pressure jets can be dangerous if subject to misuse. The jet must not be directed at persons, live electrical equipment or

the machine itself.

• Do not use the machine within range of persons unless they wear protective clothing.

• Do not direct the jet against yourself or others in order to clean clothes or foot-wear.

• High pressure hoses, fi ttings and couplings are important for the safety of the machine. Use only hoses, fi ttings and couplings

recommended by the manufacturer.

• To ensure machine safety, use only original spare parts from the manufacturer or approved by the manufacturer.

• Water that has fl own through backfl ow preventers is considered to be non-potable.

• Do not use the machine if a supply cord or important parts of the machine are damaged, e.g. safety devices, high pressure

hoses, trigger gun.

A-4 - FORM NO. 56091038 - PEX 500-SM

revised 7/12

ENGLISH / A-5

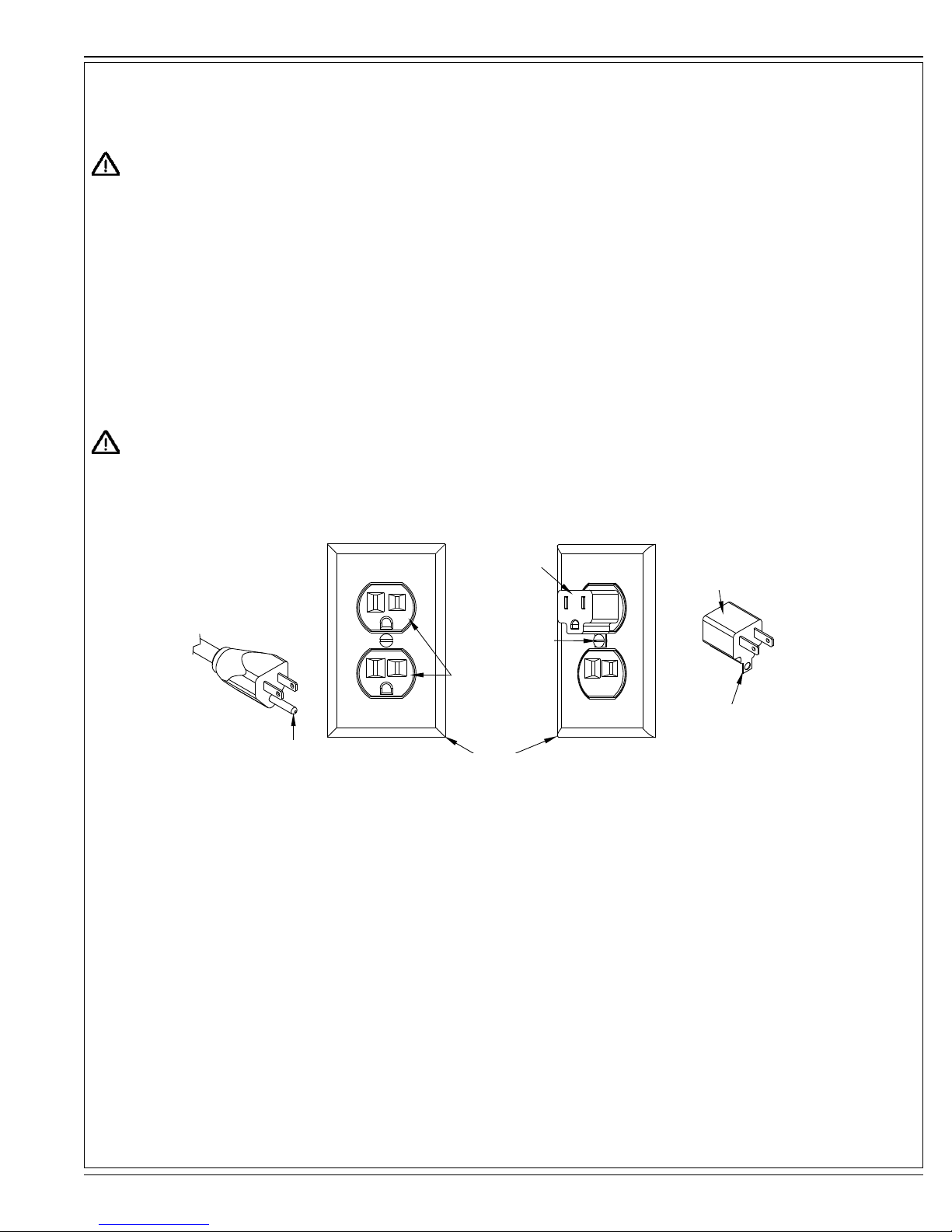

120VAC GROUNDING INSTRUCTIONS

This appliance must be grounded. If it should electrically malfunction, grounding provides a path of least resistance for electric current to reduce

the risk of electric shock. This appliance is equipped with a cord having an equipment-grounding conductor and grounding plug. The plug must be

plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

DANGER!

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualifi ed

electrician or service person if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug

provided with the appliance. If it will not fi t the outlet, have a proper outlet installed by a qualifi ed electrician.

This appliance is for use on a nominal 120-volt circuit, and has a grounding plug that looks like the plug illustrated in Figure 1 below. A temporary

adapter illustrated in Figures 2 and 3 may be used to connect this plug to a 2-pole receptacle as shown in Figure 2 if a properly grounded outlet is

not available. The temporary adapter should be used only until a properly grounded outlet (Figure 1) can be installed by a qualifi ed electrician. The

green-colored rigid ear, tab, or the like extending from the adapter must be connected to a permanent ground such as a properly grounded outlet box

cover. Whenever the adapter is used, it must be held in place by a metal screw. Grounding adapters are not approved for use in Canada.

Replace the plug if the grounding pin is damaged or broken.

The Green (or Green/Yellow) wire in the cord is the grounding wire. When replacing a plug, this wire must be attached to the grounding pin only.

Extension cords connected to this machine should be 12 gauge, three-wire cords with three-prong plugs and outlets. DO NOT use extension cords

more than 50 feet (15 m) long.

WARNING!

• If an extension cord is used, the plug and socket must be of watertight construction.

• Inadequate extension cords can be dangerous.

Grounding Pin

Adapter

Metal Screw

Grounded Outlet

Grounded Outlet Box

FIGURE 1

PLEASE NOTE: FOR NORTH AMERICA ONLY

FIGURE 2

Adapter

Tab for Grounding Screw

FIGURE 3

revised 11/13

FORM NO. 56091038 - PEX 500-SM - A-5

A-6 / ENGLISH

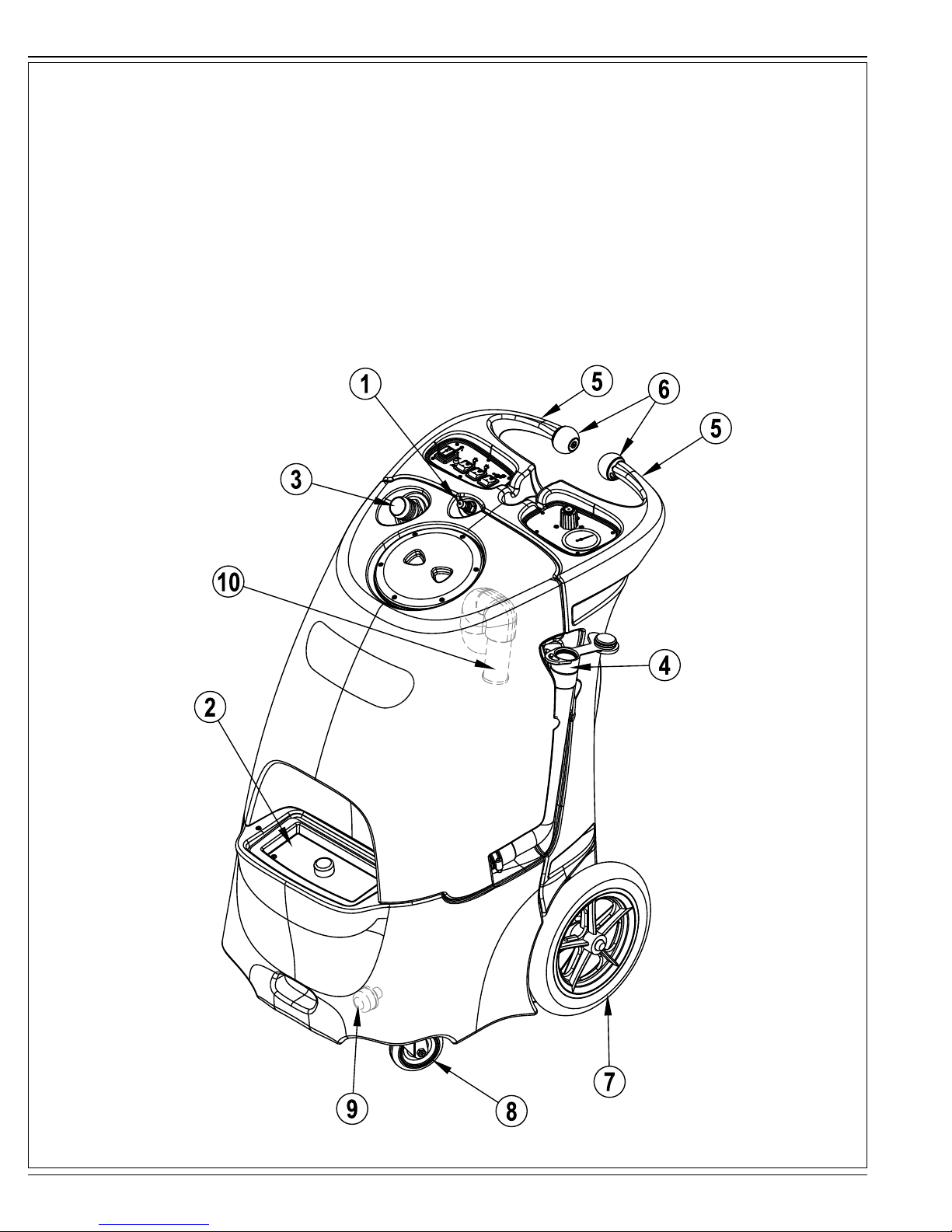

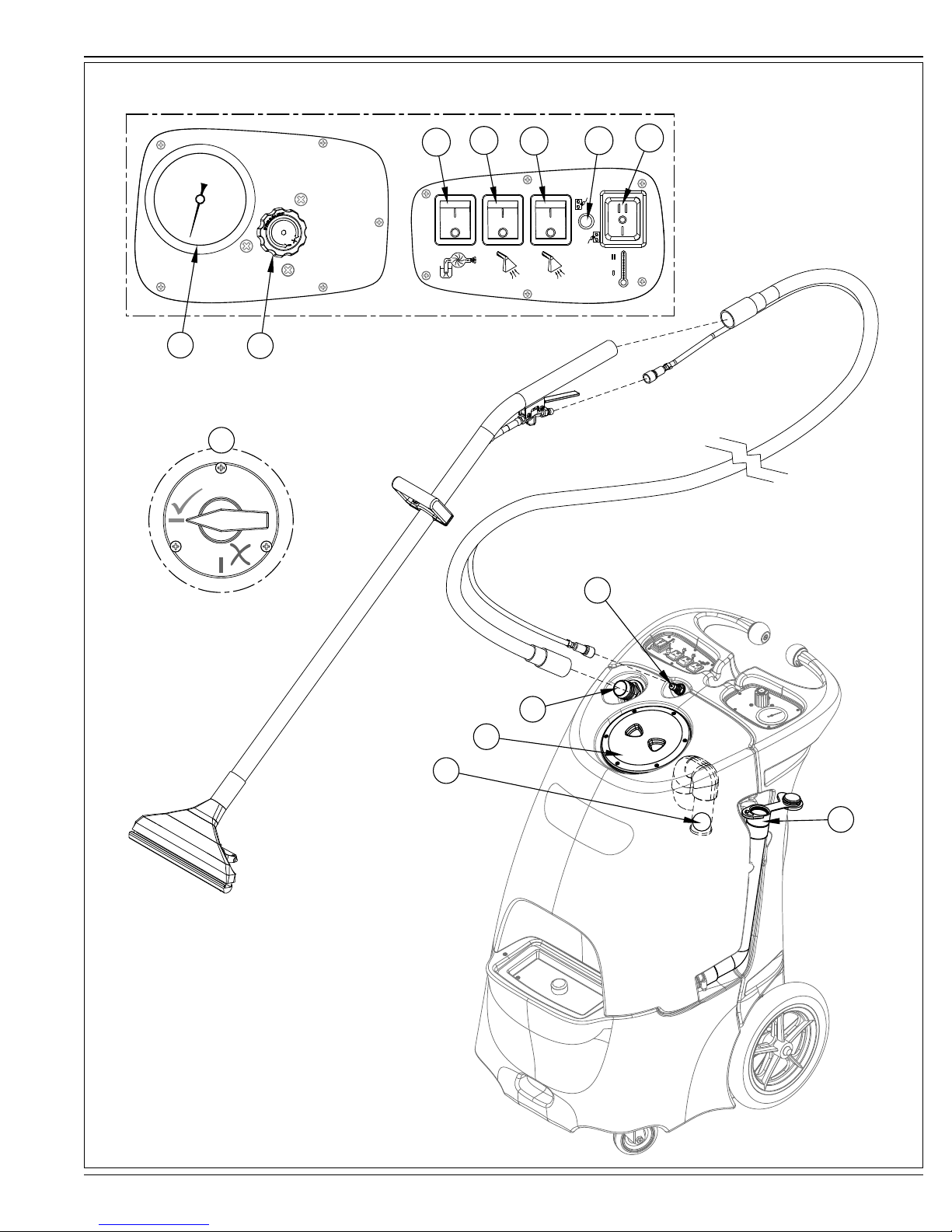

KNOW YOUR MACHINE

1 Solution Hose Quick Disconnect

2 Solution Tank Fill Opening

3 Vacuum Hose Barb

4 Drain Hose

5 Handles

6 Roller Balls

7 Wheel

8 Castor

9 Solution Filter

10 Recovery Tank Shutoff Float

A-6 - FORM NO. 56091038 - PEX 500-SM

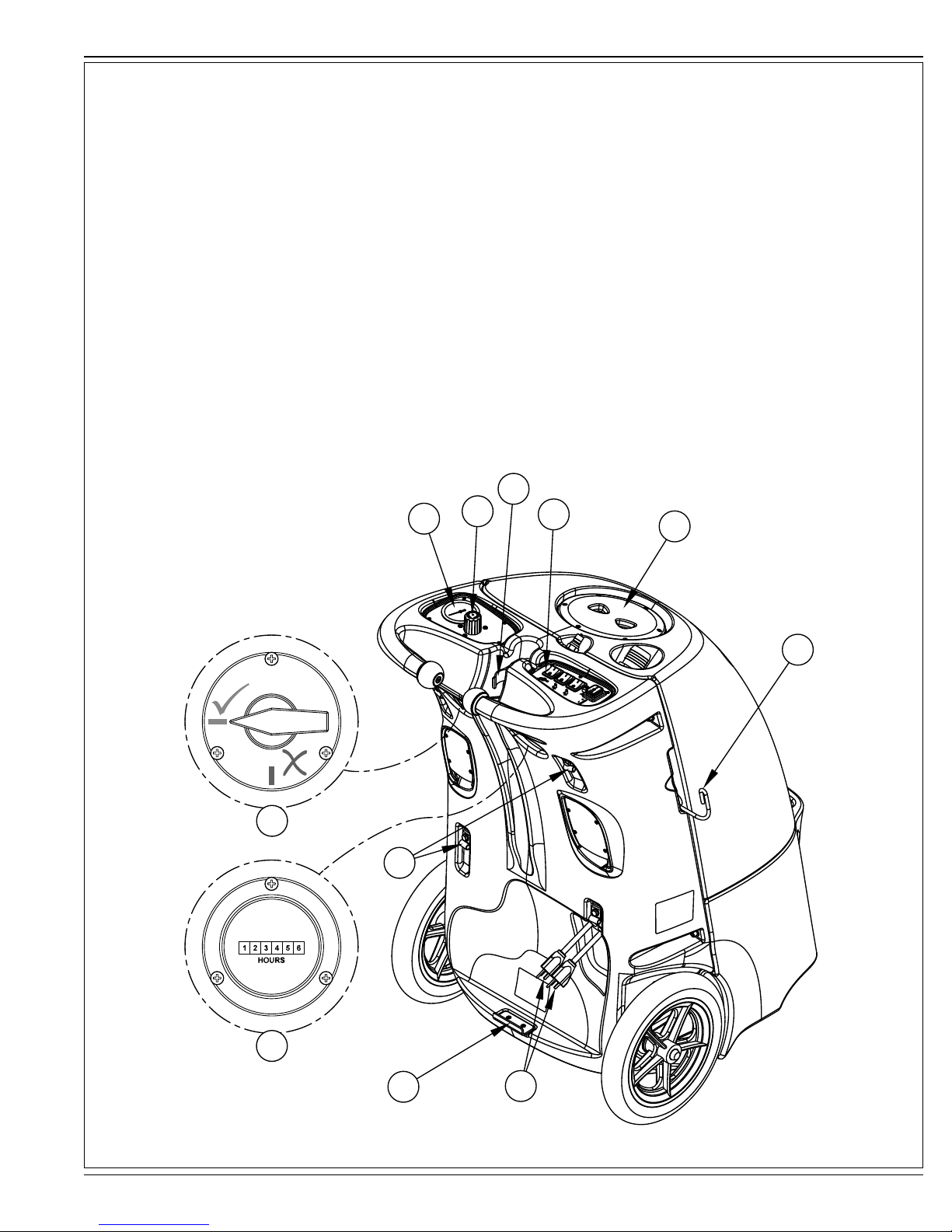

KNOW YOUR MACHINE (CONTINUED)

11 Recovery Tank Lid

12 Switch Plate

13 Wand Storage Clip

14 Pressure Adjustment Knob

15 Pressure Gauge

16 Pressure Relief Valve

17 Cord Retainer Straps (four)

18 Hour Meter (Optional)

19 Wand Retainer Bracket

20 Pigtail Power Cords

21 Hose Hangers (two)

ENGLISH / A-7

16

17

15

14

13

12

11

21

18

19

20

FORM NO. 56091038 - PEX 500-SM - A-7

A-8 / ENGLISH

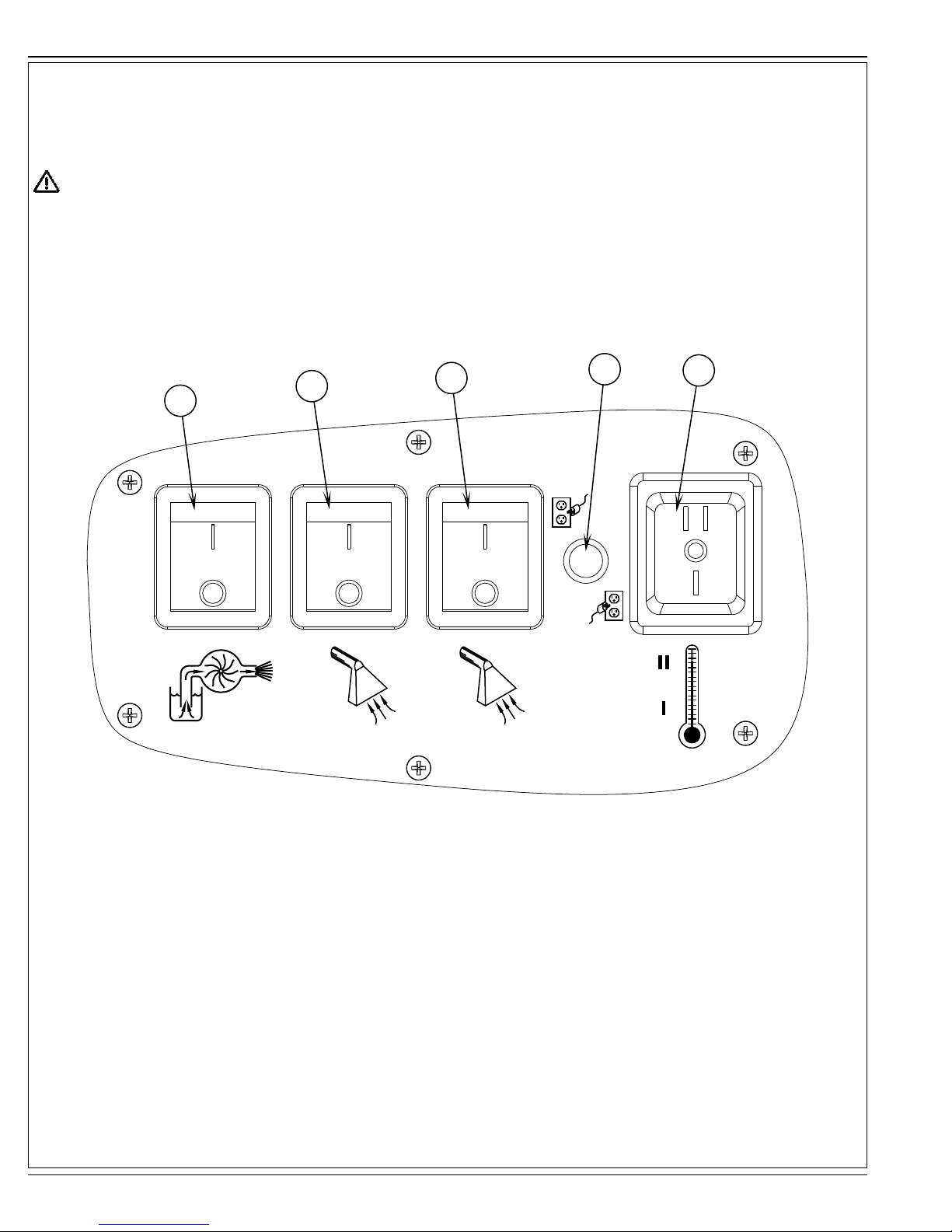

KNOW YOUR SWITCH PLATE

A Solution Pump Switch - This switch turns the solution pump ON and OFF.

B Vacuum Switch - This switch turns the fi rst of the two vacuum motors ON and OFF.

C Vacuum Switch - This switch turns the second of the two vacuum motors ON and OFF.

D Circuit Indicator - When this light is on, it indicates that the two cords are on a separate circuit.

CAUTION!

The circuit breaker in the wall panel can trip if both cords are on the same circuit.

E Heat Switch - This three position switch controls the water temperature. Position (I) is low temperature, Position (O) is OFF and Position (II) is

high temperature.

A

B

C

D

E

A-8 - FORM NO. 56091038 - PEX 500-SM

ENGLISH / A-9

PREPARING THE MACHINE FOR USE

1 Inspect the machine, hoses, and cleaning tools for cleanliness and completeness.

2 Screw the Recovery Tank Lid (11) closed. Ensure the drain cap is closed tightly.

3 Pre-spray spots and heavy traffi c areas before extracting with the detergent of your choice. Mix the pre-spray according to the detergent

manufacturer’s directions.

4 Fill the solution tank with clear water (12 gal. / 45.5 L capacity). If desired, add a detergent or rinse of your choice (we recommend a

CRI approved detergent). If you choose to add a detergent to the solution tank, be sure to mix well, and always follow the use & dilution

instructions on the detergent label. Only use a detergent with a pH between 5 and 10. Although this machine is designed to supply instant

hot water, the addition of warm water to the solution tank would increase heater effi ciency. Never use water above 130º F/54º C in the

solution tank.

CAUTION!

Use low-sudsing, liquid detergents designed for carpet extraction.

FORM NO. 56091038 - PEX 500-SM - A-9

A-10 / ENGLISH

OPERATING THE MACHINE

1 Follow the instructions in the Preparing the Machine for Use section of this manual.

2 Turn off all the switches. Plug the power cords into properly grounded outlets. Do not connect both cords to the same outlet; the green,

Circuit Indicator Light (D) on the switch plate should light up. If the indicator light does not come on, try different outlets until it does. “Do not

connect both cords to the same outlet.”

3 Attach the priming hose to the machine and place the open end into the solution tank.

4 Turn ON the solution pump (A) and let it run until the pump is fully primed (approximately 30 seconds to 1 minute). Once the pump is primed,

turn off the pump and remove the priming hose.

5 Connect a solution line to the Solution Hose Quick Disconnect (1). Attach the other end of the solution line to the cleaning tool.

NOTE: If there is pressure built up in the solution lines, it may be diffi cult to connect a solution line to the Quick Disconnect (1). If this is the case

place the Pump Switch (A) into the OFF (O) position. Momentarily turn the Pressure Relief Valve (16) from the green “checkmark” position to

the red “X” position and back again to the green “checkmark” position, this will relieve the pressure to allow a solution line to be connected to

the quick disconnect port.

CAUTION!

Always operate the machine with the Pressure Relief Valve set to the Green “checkmark” position to avoid possible damage.

6 Connect a vacuum hose to the Vacuum Hose Barb (3). Attach the other end of the vacuum hose to the cleaning tool.

7 To use heated water for cleaning, press the Heat Switch (E) into either the Low Temperature position (I) or the High Temperature position (II).

Wait two minutes for the heat exchanger to reach temperature.

8 Press the Pump Switch (A) to ON (I).

9 Press the Vacuum Switches (B & C) to ON (I). The machine can be used with only one vacuum motor running for less suction i.e. cleaning

upholstery.

10 Spray through your tool a few times to fi ll the lines with solution. Begin cleaning.

11 To adjust the solution spray pressure; rotate the Pressure Adjustment Knob (14) clockwise to increase pressure and counterclockwise to

decrease pressure. The pump spraying pressure will be observable at the Pressure Gauge (15) while spraying. Make sure the cleaning tool is

spraying when adjusting the pressure, otherwise the pressure reading will be inaccurate.

12 Watch the fl uid entering the Recovery Tank Lid (11). If there is a large amount of suds in the recovery tank, add a defoamer chemical to the

recovery tank.

CAUTION!

• Empty the recovery tank before the fl uid or foam enters the vacuum motor.

• If foam or liquid escapes from the machine, switch off immediately.

CAUTION!

Always make sure the fl oat is clean and travels freely before turning on the machine. A fl oat that is stuck will cause the

vacuum motor to suck in water, resulting in vac motor damage.

13 The recovery tank has a Recovery Tank Shutoff Float (10) to block the vacuum system when the recovery tank is full. You can tell when the

fl oat closes by the sudden change in the sound of the vacuum motor. When the fl oat closes, the recovery tank must be emptied. The machine

can continue to dispense solution, but will not pick up water with the fl oat closed.

14 Monitor the water level in the solution tank. Do not let the pump run dry. When the solution tank gets low, turn off the pump and the vacuum

motor(s), refi ll the solution tank with water and the proper ratio of cleaning detergent. Empty the recovery tank and continue cleaning.

15 When the operator has completed the job; vacuum all unused solution from the solution tank into the recovery tank, turn off the pump, vacuum

motor(s) and heat exchanger. Unplug the machine.

16 Push the machine to a designated waste water “DISPOSAL SITE” and empty the recovery tank. To empty, loosen the Velcro strap retaining the

Recovery Tank Drain Hose (4) into its side storage location, then remove the plug (hold the end of the hose above the water level in the tank to

avoid sudden, uncontrolled fl ow of waste water).

17 Follow the instructions in the After Using the Machine section of this manual.

A-10 - FORM NO. 56091038 - PEX 500-SM

OPERATING THE MACHINE

ENGLISH / A-11

15

16

14

A

B

C

D

E

10

1

3

11

4

FORM NO. 56091038 - PEX 500-SM - A-11

A-12 / ENGLISH

AFTER USING THE MACHINE

1 To empty the solution tank, open Solution Tank Fill Opening (2) and vacuum out all unused solution into the recovery tank using the vacuum

hose. Rinse the tank with clean water.

2 Turn all the Power Switches (A, B, C & E) to OFF (O). Unplug the Power Cords (20). Coil the cords and secure them to the rear of the machine

using the four Cord Retainer Straps (17).

3 To empty the recovery tank, loosen the Velcro strap retaining the Recovery Tank Drain Hose (4) into its side storage location. Direct the hose to

a designated waste water “DISPOSAL SITE” and remove the plug (hold the end of the hose above the water level in the tank to avoid sudden,

uncontrolled fl ow of waste water). Rinse the tank with clean water. Inspect the drain hose; replace if kinked or damaged.

4 Disconnect the solution and vacuum hoses from the machine, at the Solution Hose Quick Disconnect (1) and Vacuum Hose Barb (3) respectively.

Flush the vacuum hose with warm water to wash any debris out of the vacuum hose and cleaning tool. Inspect them for damage. Fold down

the Hose Hangers (21) and the hoses can be wrapped around the machine for storage. Set the wand on the Wand Retainer Bracket (19) and

secure to the back of the machine at the Wand Storage Clip (13).

5 Wipe the machine with a damp cloth. Do not use abrasive chemicals or solvents.

6 Perform any required maintenance before storage.

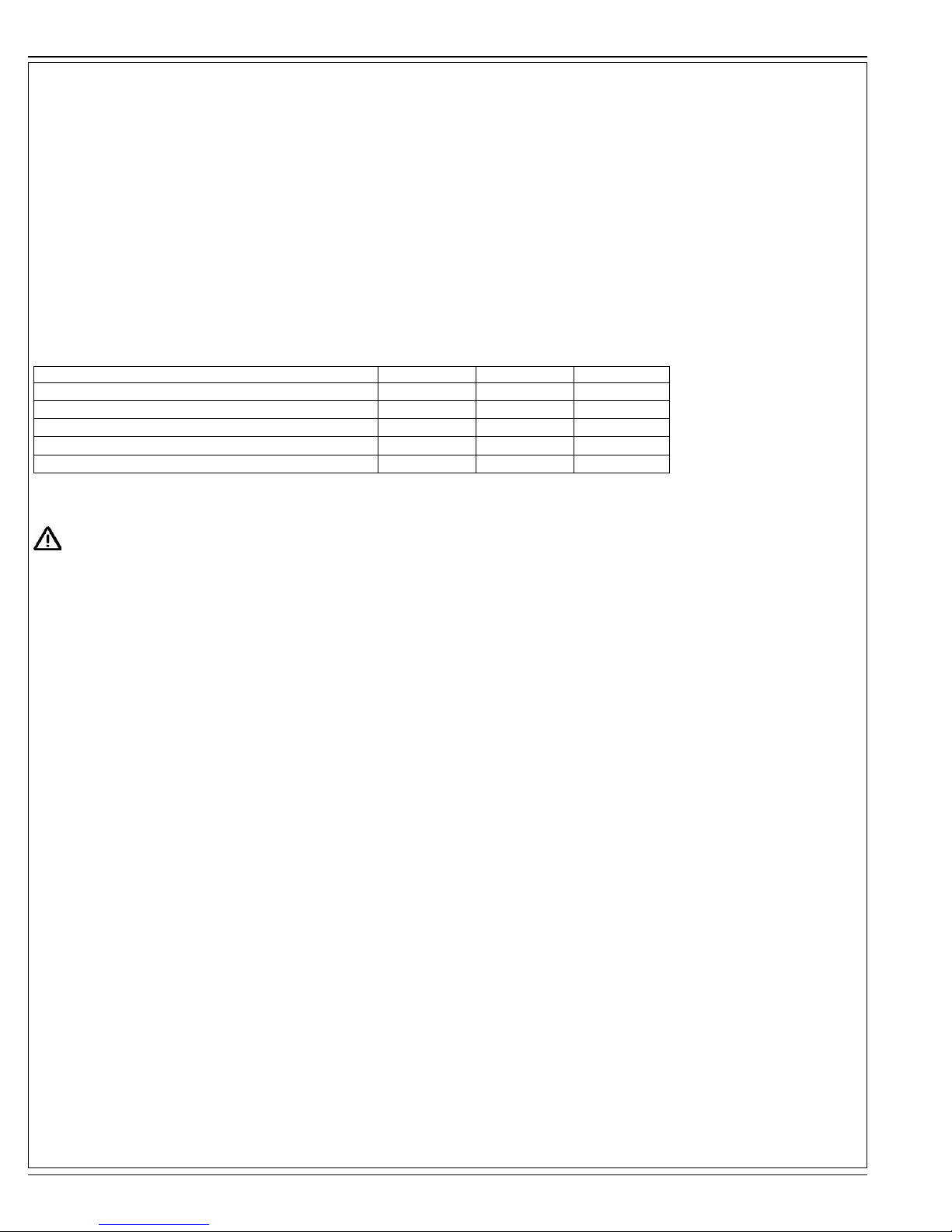

MAINTENANCE SCHEDULE

MAINTENANCE ITEM Daily Weekly Yearly

Check / Clean Tanks & Hoses •

Check / Clean Recovery Tank Shut-Off Float •

Clean Extraction Wand/Tool •

Inspect & Clean Solution Filter •

*Check Carbon Brushes •

* Have a ServiceMaster service technician check the vacuum motor carbon brushes once a year or after 300 operating hours. Check the pump motor

carbon brushes every 500 hours or once a year.

IMPORTANT!

Motor damage resulting from failure to service the carbon brushes is not covered under warranty. See the Limited Warranty

Statement.

7 Store the machine indoors in a clean, dry place with the recovery tank lid open. Keep from freezing.

POWER CORD MAINTENANCE

Once a week (or more often if necessary), check the power cords for cracked or damaged insulation, exposed wires in the cord or plug, and damaged

or missing ground pin. Repair or replace damaged cord or plug immediately.

A-12 - FORM NO. 56091038 - PEX 500-SM

Loading...

Loading...