Page 1

Switched Rack Power

Distribution Unit

Installation and Operations Manual

Firmware Version 7.0

Page 2

Instructions

This symbol is intended to alert the user to the presence of important operating and maintenance (servicing) instructions in

the literature accompanying the appliance.

Dangerous Voltage

This symbol is intended to alert the user to the presence of un-insulated dangerous voltage within the product’s enclosure that may be

of sufficient magnitude to constitute a risk of electric shock to persons.

Protective Grounding Terminal

This symbol indicates a terminal that must be connected to earth ground prior to making any other connections to the equipment.

Life-Support Policy

As a general policy, Server Technology does not recommend the use of any of its products in the following situations:

life-support applications where failure or malfunction of the Server Technology product can be reasonably expected to cause

failure of the life-support device or to significantly affect its safety or effectiveness.

direct patient care.

Server Technology will not knowingly sell its products for use in such applications unless it receives in writing assurances satisfactory

to Server Technology that:

the risks of injury or damage have been minimized,

the customer assumes all such risks, and

the liability of Server Technology is adequately protected under the circumstances.

The term life-support device includes but is not limited to neonatal oxygen analyzers, nerve stimulators (whether used for anesthesia,

pain relief or other purposes), auto-transfusion devices, blood pumps, defibrillators, arrhythmia detectors and alarms, pacemakers,

hemodialysis systems, peritoneal dialysis systems, neonatal ventilator incubators, ventilators (for adults or infants), anesthesia

ventilators, infusion pumps, and any other devices designated as “critical” by the U.S. FDA.

Notices

301-0113-1 Rev U (052016)

Copyright © 2005-2016 Server Technology, Inc. All rights reserved.

1040 Sandhill Drive

Reno, Nevada 89521 USA

All Rights Reserved

This publication is protected by copyright and all rights are reserved. No part of it may be reproduced or transmitted by any means or

in any form, without prior consent in writing from Server Technology.

The information in this document has been carefully checked and is believed to be accurate. However, changes are made

periodically. These changes are incorporated in newer publication editions. Server Technology may improve and/or change

products described in this publication at any time. Due to continuing system improvements, Server Technology is not responsible for

inaccurate information which may appear in this manual. For the latest product updates, consult the Server Technology web site at

www.servertech.com. In no event will Server Technology be liable for direct, indirect, special, exemplary, incidental, or consequential

damages resulting from any defect or omission in this document, even if advised of the possibility of such damages.

In the interest of continued product development, Server Technology reserves the right to make improvements in this document and

the products it describes at any time, without notices or obligation.

The Globe logo is a trademark of Server Technology, Inc., registered in the US. Use of the logos for commercial purposes without

the prior written consent of Server Technology may constitute trademark infringement and unfair competition in violation of federal

and state laws.

Server Technology, the Globe logo, Sentry, Switched CDU, CDU, PRO2, PIPS, POPS, PDU Power Pivot, and StartUp Stick are

trademarks of Server Technology, Inc., registered in the US. EZip is a trademark of Server Technology.

Other trademarks and trade names may be used in this document to refer to either the entities claiming the marks and names or their

products. Server Technology, Inc. disclaims any proprietary interest in trademarks and trade names other than its own.

Please Recycle

Shipping materials are recyclable. Please save them for later use, or dispose of them appropriately.

Page 3

Table of Contents

CHAPTER 1: INTRODUCTION 4

Quick Installation Checklist ............................................................................................................. 4

Technical Support ................................................................ ................................ ............................ 4

PDU Power Pivot .......................................................................................................................... 5

Equipment Overview ....................................................................................................................... 6

IPv6 and Server Technology Products ............................................................................................. 7

CHAPTER 2: INSTALLATION 10

Standard Accessories ..................................................................................................................... 10

Optional Accessories ..................................................................................................................... 10

Additional Required Items ............................................................................................................. 10

Safety Precautions ......................................................................................................................... 11

NEBS GR-1089-Core Information ................................................................................................ 12

Input Power Cord Retention Options for PDUs with IEC C20 Inlets ............................................ 13

Attaching Safety Earth Ground Connection .................................................................................. 14

Mounting the PDU ......................................................................................................................... 15

Attaching the Expansion Module................................................................................................... 16

Connecting to the Power Source .................................................................................................... 16

Connecting Devices ....................................................................................................................... 16

Connecting the Sensors .................................................................................................................. 16

Connecting to the Unit ................................................................................................................... 16

CHAPTER 3: OPERATIONS 19

Interfaces ....................................................................................................................................... 21

Web Interface................................................................................................................................. 22

Command Line Interface ............................................................................................................... 53

CHAPTER 4: ADVANCED OPERATIONS 97

SSL ................................................................................................................................................ 98

SSH .............................................................................................................................................. 100

SNMP/Thresholds ........................................................................................................................ 102

LDAP ........................................................................................................................................... 116

TACACS+ ................................................................................................................................... 126

RADIUS ...................................................................................................................................... 132

Logging ........................................................................................................................................ 136

Upload/Download ........................................................................................................................ 141

Remote Shutdown ........................................................................................................................ 143

CHAPTER 5: APPENDICES 147

Appendix A: Resetting to Factory Defaults ................................................................................. 147

Appendix B: Uploading Firmware............................................................................................... 148

Appendix C: Technical Specifications ......................................................................................... 149

Appendix D: Product Support Information .................................................................................. 156

Page 4

4 Introduction Switched PDU

Installation and Operations Manual

Chapter 1: Introduction

Quick Installation Checklist

The following steps are recommended to quickly install and configure the Switched PDU for use in your data

center equipment cabinet:

1. Mount the Switched PDU.

2. Connect to the power source.

3. Connect the devices.

4. Connect the sensors.

5. Connect to the Switched PDU.

6. Configure the Switched PDU.

Login as the predefined Administrator (admn/admn).

Configure the network settings.

Create new administrative user account.

Configure location and Switched PDU names.

Configure sensor names.

Configure new user account(s).

Remove the predefined Administrator account “admn”.

7. Connect the Switched PDU to the network.

Technical Support

Experience Server Technology's FREE Technical Support

Server Technology understands that there are often questions when installing and/or using a new product. Free

Technical Support is provided from 8 a.m. to 5 p.m. PST, Monday through Friday. After-hours service is provided to

ensure your requests are handled quickly no matter what time zone or country you are located in.

Server Technology, Inc.

1040 Sandhill Drive Tel: 1-800-835-1515 Web: www.servertech.com

Reno, Nevada 89521 USA Fax: 775-284-2065 Email: support@servertech.com

Page 5

Switched PDU

Installation and Operations Manual Introduction 5

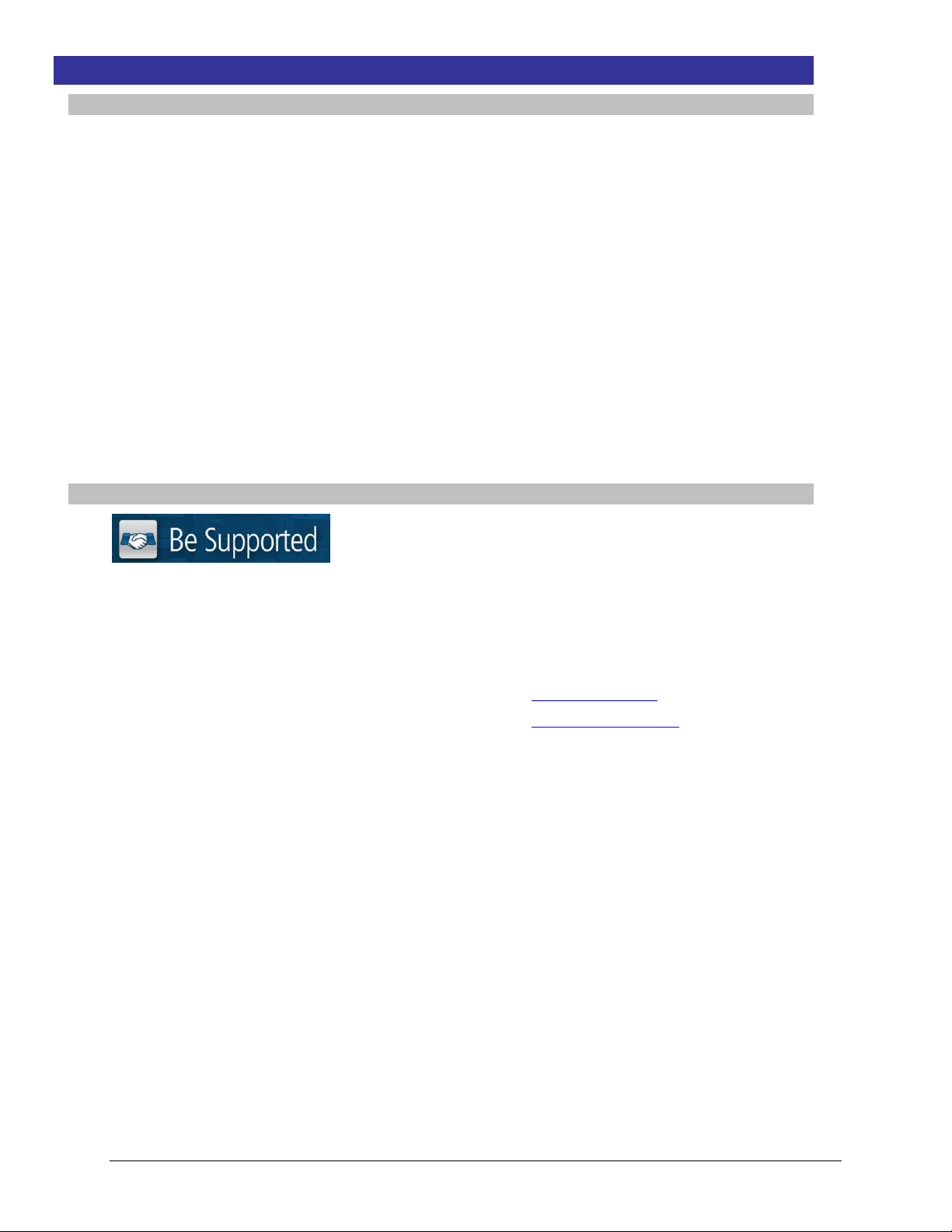

PDU Power Pivot

Server Technology’s PDU Power Pivot flexible infeed provides a simplified power cord routing to the unit with a design that

eliminates bend radius issues.

As illustrated below, the PDU Power Pivot capability can deliver a solution for several types of PDU installations and

mountings, setting the correct cord angle for overhead power, offset overhead power, concrete floor, raised floor, and intra-rack

power.

PDU Power Pivot – Flexible Cord Design

To learn more about PDU Power Pivot and watch a brief video that animates the PDU Power Pivot mounting angles in the

equipment rack, see the Server Technology website at: http://info.servertech.com/PDUpowerpivot

Page 6

6 Introduction Switched PDU

Installation and Operations Manual

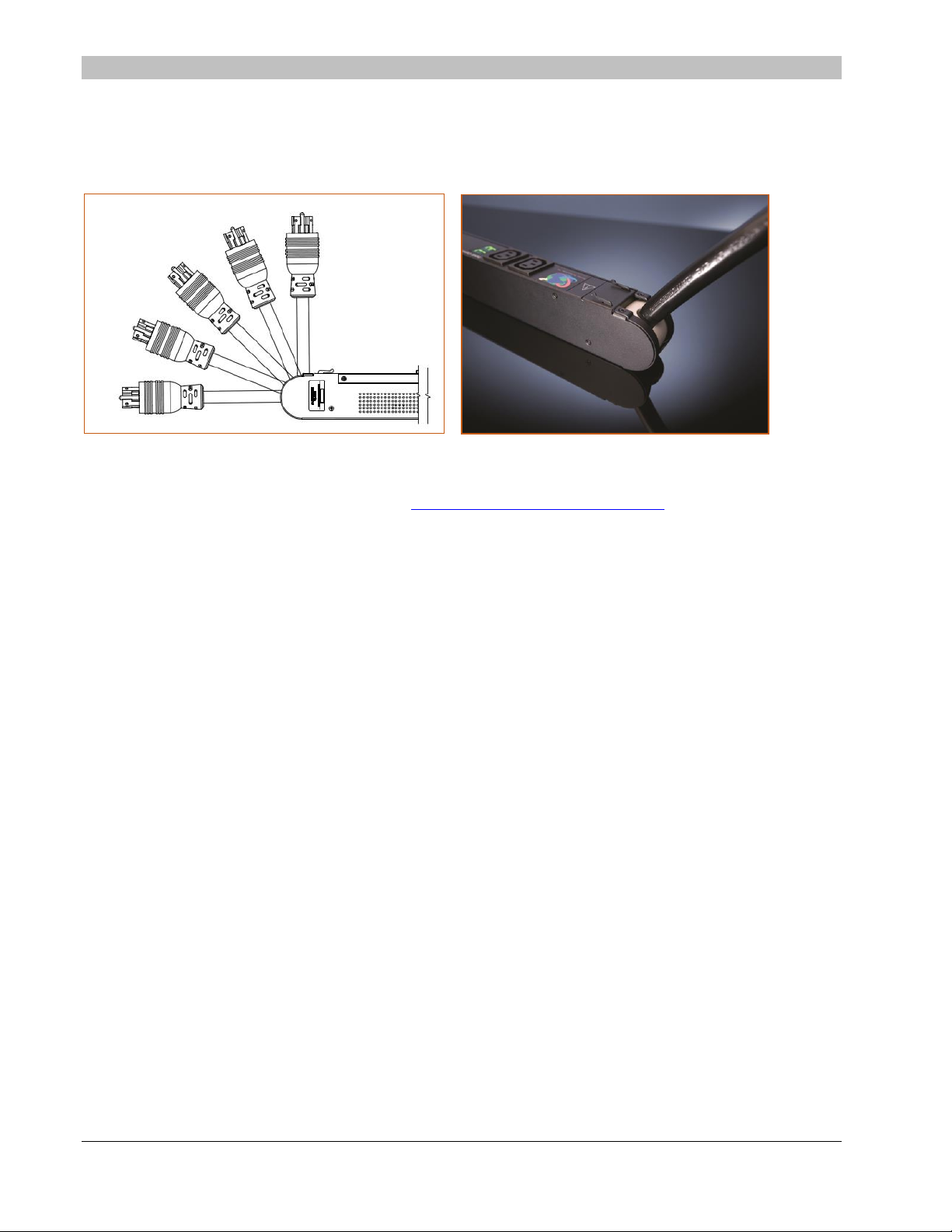

Equipment Overview

1. The power inlet/cord(s) connects the PDU to the electrical power source.

2. The Current LED(s) displays the current load for each infeed, branch or electrical phase per infeed.

3. Two RJ45 connectors for Serial (RS-232) and Ethernet connection.

4. Two mini RJ11 connectors for Temperature/Humidity sensors.

A number is printed above each outlet. These numbers can be used in commands that require an outlet name.

1

2

4

3

4

3

2

1

Switched Rack Power Distribution Unit

Page 7

Switched PDU

Installation and Operations Manual Introduction 7

IPv6 and Server Technology Products

Server Technology is introducing IPv6 “dual stack” support to the PDU product line. IPv6 has been designed to

succeed IPv4 as the dominant communications protocol for internet traffic, to avoid depletions of the IPv4 address

space, and to allow more IP address growth. Many devices already in use support IPv6.

IPv6 has several new operational methods:

Static IPv6 Address: The IPv6 equivalent of Static IPv4.

DHCPv6 Address: The IPv6 equivalent of a DHCP IPv4 address, also known as a “stateful” auto-

configuration of DHCPv6.

IPv6 Stateless Auto-Configured Address – (RFC 4862): An automatically-generated unique link-local IPv6

address used for client based configurations. This address is always present in the Server Technology dual

stack and cannot be disabled.

DHCPv6 Stateless Auto-Configured Address – (RFC 3736): A “stateless” Dynamic Host Configuration

Protocol (DHCP) service for IPv6 (DHCPv6). This address is used by nodes to obtain configuration

information, such as addresses of DNS recursive name servers that do not require the maintenance of any

dynamic state for individual clients.

Firmware – Protocol Support

IPv6 and IPv4 Protocols:

The firmware supports the following network IPv6 and IPv4 protocols:

DNS Ping

FTP (or SFTP) Server SNMPv1/2/3

FTP (or SFTP) Updates SNTP

HTTP or HTTPS

SMTP

Static IPv6 DHCPv6 (stateless and stateful)

Syslog SNMPv1/2/3 Traps

Telnet SSH

IPv4-Only Protocols:

The firmware supports the following network IPv4-only protocols:

Cisco EnergyWise

LDAP

Load Shedding *

RADIUS *

TACACS+

* = may work with IPv6 addresses, but not tested.

Page 8

8 Introduction Switched PDU

Installation and Operations Manual

Network-Enabled Modes

NOTES:

For all network-enabled modes described below, the PDU will set an auto-configured IPv6 address, and if IPv6 router announcements are

active, a stateless DHCP IPv6 address will also be set. Further, in all network-enabled modes, at least one IPv4 or one IPv6 address will

be active.

For maximum backward compatibility, the default network mode is “IPv4 only”.

Network disabled – No IPv4 or IPv6 addresses available.

IPv4 only, DHCP disabled (static IPv4) – If the IPv4 Static Address and Net Mask of the PDU are valid,

they will be set.

IPv4 only, DHCP enabled (DHCP IPv4) – The PDU will try to resolve an IPv4 DHCP address. If a DHCP

address cannot be obtained after 90 seconds, the PDU can: (1) optionally fall back to its static IPv4 settings,

or (2) indefinitely wait to acquire an address based on DHCP configuration settings. This setting is the

default.

Dual IPv6/IPv4, DHCP disabled (static IPv6/IPv4) – If the IPv6 Static Address and prefix of the PDU are

valid, they will be set. Otherwise, the PDU will attempt to use DHCPv6 to obtain an IPv6 address.

In addition, if the IPv4 Static Address and Net Mask of the PDU are valid, they will be set.

Dual IPv6/IPv4, DHCP enabled (DHCP IPv6/IPv4) – The PDU will try to resolve both its IPv6 and IPv4

addresses by DHCP. If both DHCP requests are answered, the primary DNS server of the PDU will become

the primary IPv6 DNS server, and the secondary DNS server of the PDU will become the primary IPv4

DNS server.

If only one of the DHCP requests is answered, the DNS servers of the PDU will map to the primary and

secondary DNS server from that request.

If a DHCP address cannot be obtained after 90 seconds, the PDU can: (1) optionally fall back to its static

IPv4 and/or IPv6 settings, or (2) indefinitely wait to acquire an address based on DHCP configuration

settings.

Page 9

Switched PDU

Installation and Operations Manual Introduction 9

Viewing Network Status

You can obtain the IPv6 network status through the firmware Web Interface or Command Line Interface (CLI). For

the CLI, use the show network command as follows:

Switched CDU: show network

Network Settings

State: DHCP IPv6/IPv4 Network: Dual IPv6/IPv4

Link: Up Negotiation: Auto

Speed: 100 Mbps Duplex: Full

AutoCfg IPv6: FE80::20A:9CFF:FE52:4104/64

IPv6 Address: FD01::1:B51A:E03C/64

IPv4 Address: 10.1.6.230 Subnet Mask: 255.255.0.0

IPv4 Gateway: 10.1.1.1

DNS1: FD01::A01:585

DNS2: 10.1.5.133

Static IPv4/IPv6 Settings

IPv6 Address: FD01::A01:353/64

IPv6 Gateway: ::

IPv4 Address: 10.1.2.253 Subnet Mask: 255.255.0.0

IPv4 Gateway: 10.1.1.1

DNS1: 10.1.5.133

DNS2: 10.1.5.134

DHCP Settings

DHCP: Enabled

FQDN: Enabled [sentry3-524104]

Boot Delay: Enabled

Static Fallback: Enabled

Network Services

Telnet: Enabled Port: 23

SSH: Enabled Port: 22 Auth: Password, Kb-Int

HTTP: Enabled Port: 80

SSL: Enabled Port: 443 Installed Cert: User Encrypted

Access: Optional Stored Files: Cert & Key

User Cert: Enabled User Passphrase: <set>

SNMPv1/2: Enabled Port: 161 TrapPort: 162

SNMPv3: Disabled Port: 161 TrapPort: 162

FTP Server: Enabled Port: 21

SPM Access: Enabled

Command successful

NOTE: The fields IPv4 Address, IPv4 Subnet Mask, IPv4 Gateway, DNS1, and DNS2 are equivalent to existing IPv4 settings except that

current network settings and static settings are displayed separately. This allows you to view both static configuration settings and active

network settings that can be obtained using DHCP. The DNS addresses may be in IPv4 or IPv6 (based on RFC4291) format at this time.

Page 10

10 Installation Switched PDU

Installation and Operations Manual

Chapter 2: Installation

Before installing your Switched Rack Power Distribution Unit, refer to the following lists to make sure you have all

the items shipped with the unit, as well as other items needed for proper installation.

Standard Accessories

Mounting Hardware

Vertical Models:

Button mounting kit with M4 screws.

Horizontal Models:

Two removable L-brackets with four M4 screws.

Expansion Models:

RJ12 to RJ12 crossover cable.

Additional Items for Models with C20 Inlets

Separate power input.

Optional power input retention bracket hardware (can be installed); two removable T-brackets with two 40 mm

screws per input.

Note: This bracket is not compatible with Server Technology Input Power Cords with the self-locking C19

feature. These power cords have the prefix PTCORD-L#.

Optional Accessories

Temperature/humidity sensors (Part Number EMTH-1-1).

Environmental monitor (Part Number EMCU-1-1B).

Vertical mounting brackets; additional mounting options are available in the Accessories section of the

Server Technology website at www.servertech.com.

Additional Required Items

Flathead and Phillips screwdrivers.

Screws, washers, and nuts to attach the PDU to your equipment rack.

Page 11

Switched PDU

Installation and Operations Manual Installation 11

Safety Precautions

This section contains important safety and regulatory information that must be reviewed before installing and using

the Switched Rack Power Distribution Unit.

Only for installation and use in a

Restricted Access Location in

accordance with the following

installation and use instructions.

This equipment should only be

installed by trained personnel.

Destiné à l'installation et l'utilisation dans le

cadre de Restricted Access Location selon

les instructions d'installation et d'utilisation.

Cet équipement est uniquement destiné

à être installé par personnel qualifié.

Nur für Installation und Gebrauch in

eingeschränkten Betriebszonen gemäß der

folgenden Installations-und

Gebrauchsanweisungen.

Dieses Gerät ist nur für den Einbau

durch Personal vorgesehen.

This equipment is designed to be

installed on a dedicated circuit.

The power supply cord shall be a

minimum of 1.5m (4.9ft) and a

maximum of 4.5m (15ft). If using

an extension power cord, the total

length shall also be no more than

the maximum allowed. The plug is

considered the disconnect device

and must be easily accessible.

Cet équipement a été conçu pour être

installé que un circuit dédié. Le cordon

d’alimentation doit être d’au moins 1,5M et

un maximum de 4,5m. Si vous utilisez un

cordon de rallonge, la longueur totale est

également plus que le maximum autorise.

La prise est considérée comme un

dispositif de coupure et doit être facilement

accessible.

Die Geräte sind für eine Installation an

einer fest zugeordneten Leitung ausgelegt.

Die Stromzuleitung hat eine Mindestlänge

von 1,5m, und hochstens 4,5m. Sollten Sie

ein Verlangerrungsnetzkabel, der

Gesamtlange auch nicht mehr als die

maximal zulassige sein. Der Stecker dient

zur Trennung vom Netz und muss einfach

erreichbar sein.

The dedicated circuit must have

circuit breaker or fuse protection.

PDUs have been designed without

a master circuit breaker or fuse to

avoid becoming a single point of

failure. It is the customer’s

responsibility to provide adequate

protection for the dedicated power

circuit. Protection of capacity equal

to the current rating of the PDU

must be provided and must meet

all applicable codes and

regulations. In North America,

protection must have a 10,000A

interrupt capacity.

Le circuit spécialisé doit avoir un disjoncteur

ou une protection de fusible. PDUs ont été

conçus sans disjoncteur général ni fusible

pour éviter que cela devient un seul endroit

de panne. C’est la responsabilité du client

de fournir une protection adéquate pour le

circuit-alimentation spécialisé. Protection de

capacité équivalant à la puissance de

l'équipement, et respectant tous les codes

et normes applicables. Les disjoncteurs ou

fusibles destinés à l'installation en Amérique

du Nord doivent avoir une capacité

d'interruption de 10.000 A.

Der feste Stromkreis muss mit einem

Schutzschalter oder einem

Sicherungsschutz versehen sein. PDUs

verfügt über keinen Hauptschutzschalter

bzw. über keine Sicherung, damit kein

einzelner Fehlerpunkt entstehen kann. Der

Kunde ist dafür verantwortlich, den

Stromkreis sachgemäß zu schützen. Der

Kapazitätsschutz entspricht der aktuellen

Stromstärke der Geräte und muss alle

relevanten Codes und Bestimmungen

erfüllen. Für Installation in Nordamerika

müssen Ausschalter bzw. Sicherung über

10.000 A Unterbrechungskapazität

verfügen.

Models with unterminated power

cords: Input connector must be

installed by qualified service

personnel. Input connector rating

must meet all applicable codes and

regulations.

Modèles avec cordons d'alimentation non

terminées: Le connecteur d’entrée doit être

installé par un personnel qualifié. Entrée

cote de raccordement doit respecter tous

les codes et règlements électriques

applicables.

Modelle mit nicht abgeschlossenen

Netzkabel: Der Eingangsstecker darf nur

von qualifiziertem Wartungspersonal

installiert werden. Eingangsanschluss

Bewertung müssen alle geltenden und

verbindlichen Normen und Vorschriften

entsprechen.

Do not block venting holes when

installing this product. Allow for

maximum airflow at all times.

Ne bloquez pas les orifices d'aération lors

de l'installation de ce produit. Permettre une

circulation d'air maximale à tout moment.

Achten Sie darauf, dass keine

Belüftungslöcher bei der Installation dieses

Produkts. Damit für maximalen Luftstrom

zu allen Zeiten.

Installation Orientation: Vertical

units are designed to be installed

in vertical orientation.

Installation Orientation: Les unités vertical

sont conçues pour être installées dans une

orientation verticale.

Installationsausrichtung: Vertical Einheiten

sind zur vertikalen Installation vorgesehen.

Always disconnect the power

supply cord before servicing to

avoid electrical shock. For

products with two input power

cords, both must be disconnected

before servicing.

Toujours débrancher le cordon

d'alimentation avant de l'ouverture pour

éviter un choc électrique. Pour les produits

avec deux cordons d'alimentation d'entrée,

les deux doivent être déconnectés avant

l'entretien.

Trennen Sie das Netzkabel, bevor Sie

Wartungsarbeiten Öffnung einen

elektrischen Schlag zu vermeiden. Für

Produkte mit zwei Eingangsstromkabel,

sowohl, müssen vor der Wartung

abgeschaltet werden.

WARNING! High leakage current!

Earth connection is essential

before connecting supply!

ATTENTION! Haut fuite très possible! Une

connection de masse est essentielle avant

de connecter l’alimentation !

ACHTUNG! Hoher Ableitstrom! Ein

Erdungsanschluss ist vor dem Einschalten

der Stromzufuhr erforderlich!

WARNING! Cx-xxE-x units double

pole/neutral fusing

ATTENTION! Les unités Cx-xxE-x Double

Pôle/Fusible sur le Neutre

ACHTUNG!: Cx-xxE-x Zweipolige bzw.

Neutralleiter-Sicherung

ATTENTION! Observe precautions

for handling Electrostatic Sensitive

Devices.

Attention ! Respecter les mesures de

sécurité en manipulant des dispositifs

sensibles aux décharges électrostatiques.

Achtung! Vorsichtshinweise zur

Handhabung elektrostatisch empfindlicher

Geräte beachten.

Products rated for 240/415VAC

may be fitted with a plug that is

rated for a higher voltage. Caution

must be taken to assure that the

rating of the unit and the supply

voltage match.

Les produits prévus pour 240/415VAC peut

être équipé d'un bouchon qui est conçu

pour une tension plus élevée. Des

précautions doivent être prises pour assurer

que la cote de l’unité et la tension

d’alimentation correspond.

Produkte die für 240/415VAC zugelassen

sind können mit einem Stecker der für eine

höhere Spannung ausgestattet sein.

Vorsicht ist geboten, um sicherzustellen,

dass die erlaubten Betriebswerte des

Gerätes und der Versorgungsspannung

zueinander passen.

Page 12

12 Installation Switched PDU

Installation and Operations Manual

NEBS GR-1089-Core Information

For NEBS certified products only.

These products are intended to be installed in Network Communications Facilities and in locations where the NEC applies.

This product is suitable for installation in a Common Bonding Network (CBN).

WARNING: The intra-building port(s) of the equipment or subassembly is suitable for connection to intra-building or

unexposed wiring or cabling only. The intra-building port(s) of the equipment or subassembly MUST NOT be metallically

connected to interfaces that connect to the OSP or its wiring.

These interfaces are designed for use as intra-building interfaces only (Type 2 or Type 4 ports as described in

GR-1089-CORE, Issue 5) and require isolation from the exposed OSP cabling. The addition of Primary Protectors is not

sufficient protection in order to connect these interfaces metallically to OSP wiring.

Page 13

Switched PDU

Installation and Operations Manual Installation 13

Input Power Cord Retention Options for PDUs with IEC C20 Inlets

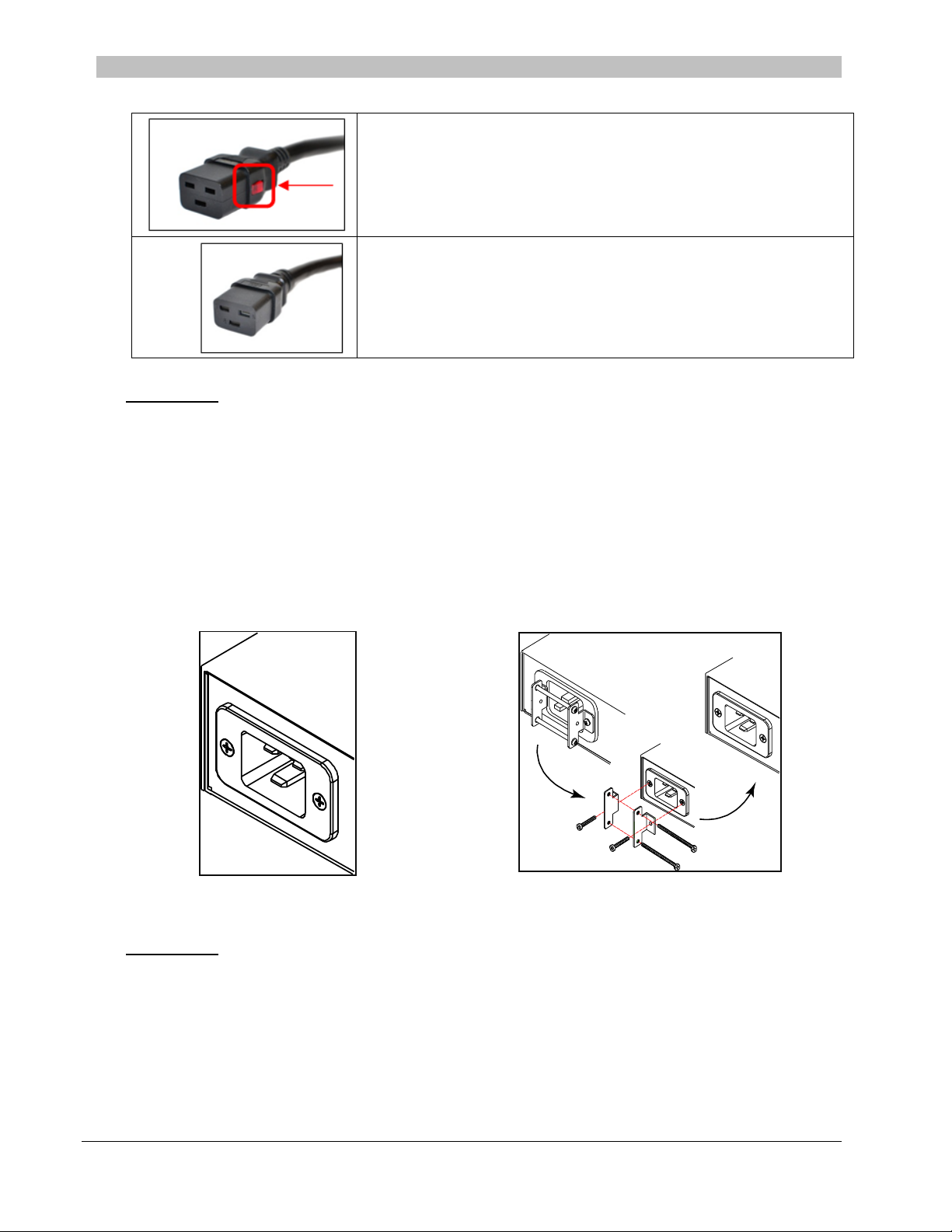

Determine which Detachable Input Cord was supplied with the unit:

For the following Detachable Input Cords with the self-locking

IEC C19 feature, follow Procedure A below.

PTCORD-L1, PTCORD-L2, PTCORD-L3, PTCORD-L5, PTCORD-L6, or

PTCORD-L7.

For the following Detachable Input Cords, follow Procedure B below.

PTCORD-1, PTCORD-2, PTCORD-3, PTCORD-4, PTCORD-5, PTCORD-6,

or PTCORD-7.

Procedure A

If the unit was supplied with a Detachable Input Power Cord with a self-locking IEC C19, install it directly into the

C20 inlet.

1. Verify the Retention Bracket Assembly (part number KIT-0016) is not installed.

a. If KIT-0016 is installed, remove the two screws attaching the bracket to the IEC 60320 C20 inlet

to the enclosure.

b. Remove the Retention Bracket Assembly.

c. Re-attach the two screws to the IEC C20 and securely tighten.

2. Push the C19 from the Detachable Input Cord firmly into the C20 inlet to ensure it is properly seated.

C20 Inlet without Retention Bracket Assembly KIT-0016, Retention Bracket Assembly

Procedure B

If the unit was supplied with a Detachable Input Power Cord without the self-locking C19 feature, install with the

Retention Bracket Assembly (part number KIT-0016), followed by the power cord.

1. Remove the two screws attaching the IEC 60320 C20 inlet to the enclosure.

2. Assemble and attach the Retention Bracket to the enclosure as shown

3. Connect the power cord. Ensure the C19 is fully seated against the C20 inlet. (It may be necessary to loosen

some of the Retention Bracket Assembly screws to allow the C19 plug to be properly installed.)

4. Tighten the Retention Bracket Assembly to restrain the power cord.

Page 14

14 Installation Switched PDU

Installation and Operations Manual

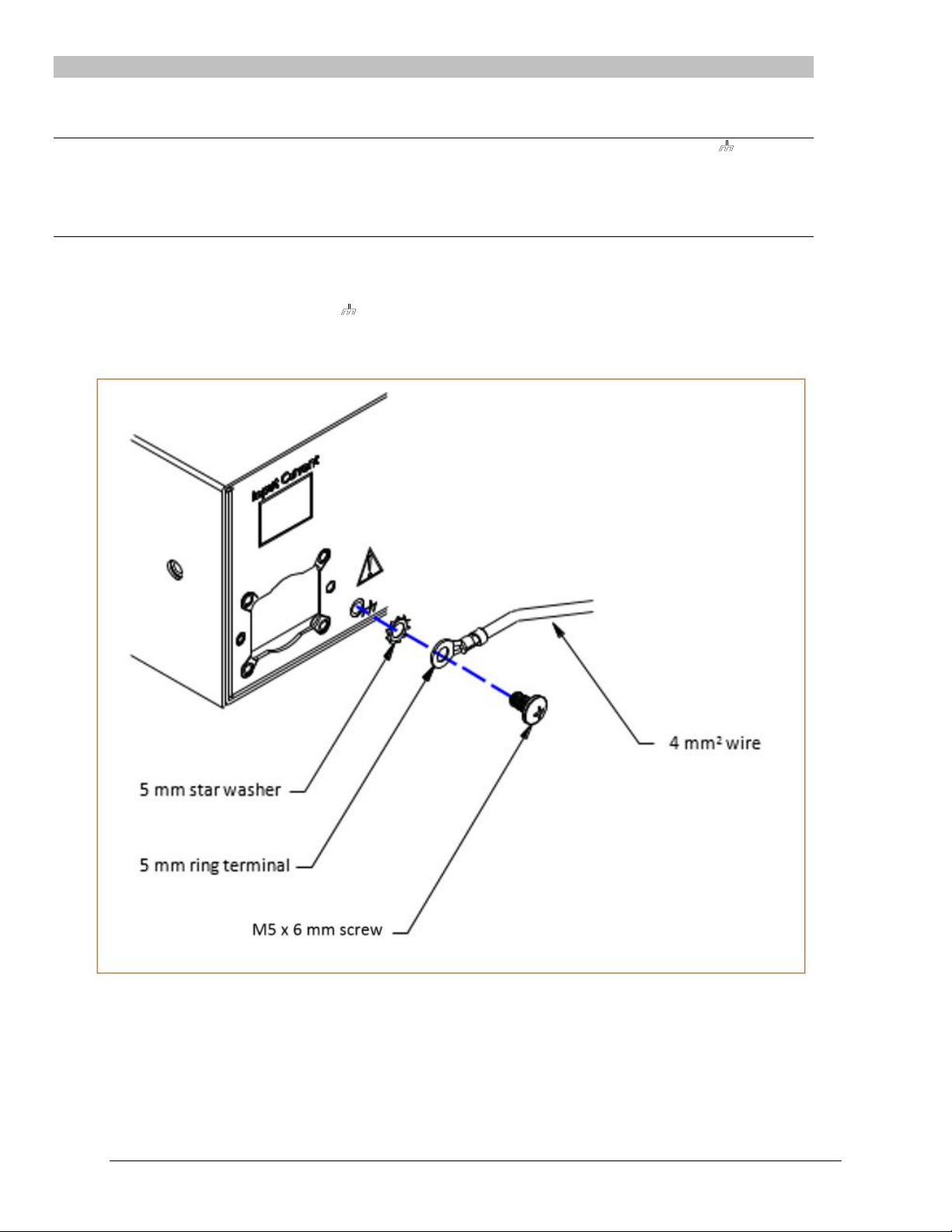

Attaching Safety Earth Ground Connection

Server Technology PDUs are supplied with an external safety ground connection to provide an alternate ground path for fault

currents, and to maintain the same ground reference between it and the equipment rack.

NOTE: The auxiliary external ground location may vary. Most PDUs will have it located near the power cord entry located near the symbol.

User-supplied materials:

One 5 mm internal (or external) tooth star washer;

One 4.0 mm

2

(10 AWG) wire with 5 mm ring terminal;

One metric M5 x 6 mm coarse pitch screw.

Instructions:

1. Connect one end of the ground wire to the equipment cabinet or local ground.

2. Locate the PDU external ground near the symbol.

3. Connect the other end with a ring terminal and a M5 screw to the PDU external ground. To ensure proper grounding

to the chassis, use a star washer between the ring terminal and the PDU.

Page 15

Switched PDU

Installation and Operations Manual Installation 15

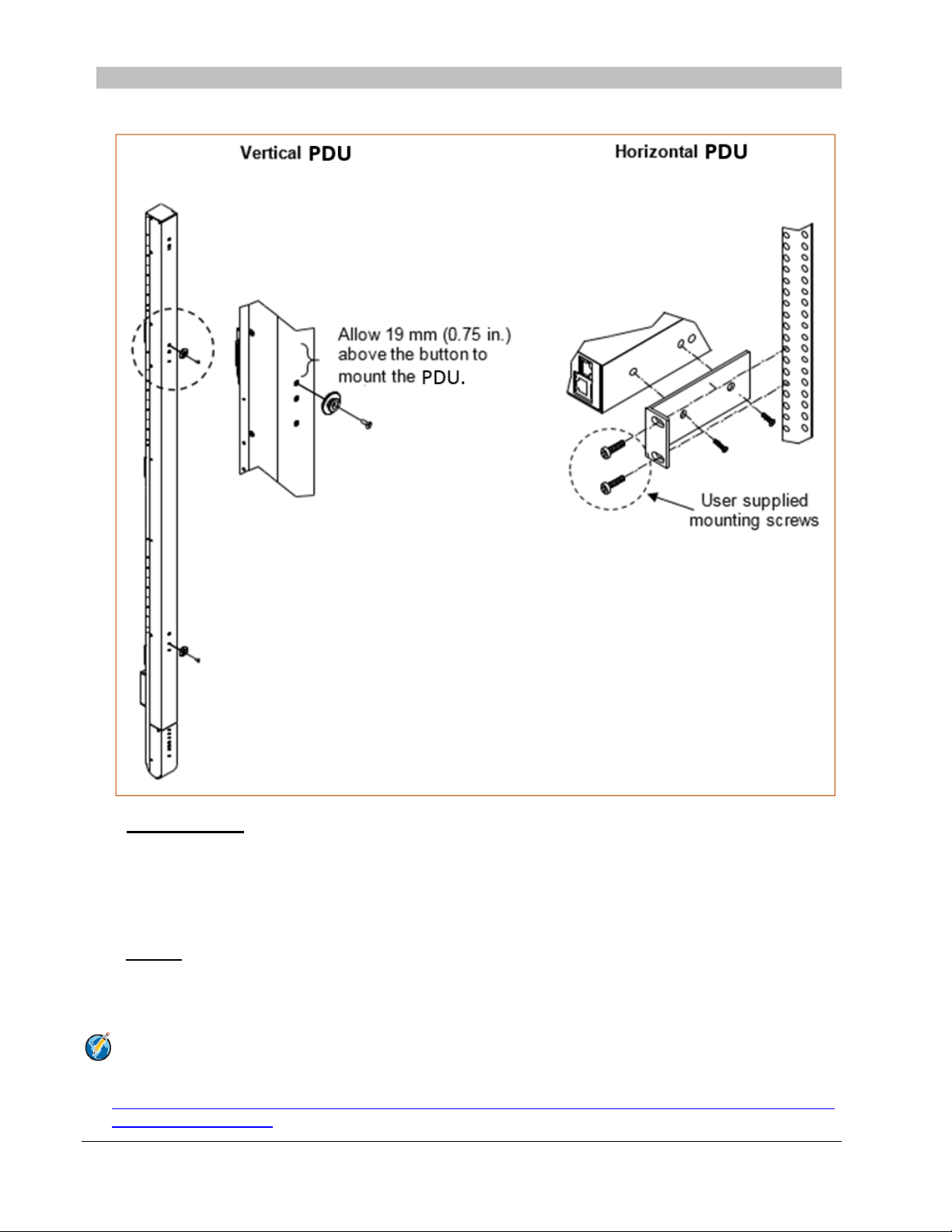

Mounting the PDU

The following illustration shows how to mount the Switched PDU in vertical or horizontal orientation:

Horizontal/Rack

1. Select the appropriate bracket mounting points for proper mounting depth within the rack.

2. Attach the L-brackets to these mounting points with two screws for each bracket.

3. Install the enclosure into your rack, using the slots in each bracket. The slots allow about 6 mm (0.25 inch) of

horizontal adaptability to align with the mounting holes of your rack.

Vertical

The Switched PDU is supplied with button mounting kit(s). Distribute the buttons vertically and attach to the PDU as

appropriate for the cabinet. An additional 19 mm (0.75 inch) of clearance is required at the top of the PDU to allow the

button to mount into the keyholes.

Note: For more information about horizontal/vertical mounting options for the Switched PDU, see the

Server Technology PDU Mounting Bracket Catalog:

http://cdn1.servertech.com/assets/documents/documents/1803/original/Mounting_Bracket_Catalog.201412-30.pdf?1420823515

Page 16

16 Installation Switched PDU

Installation and Operations Manual

Attaching the Expansion Module

Connect the expansion module unit with the provided RJ12 crossover cable at the Link port on the Switched PDU.

NOTE: The overall length of the RJ12 crossover cable should not exceed 10 feet.

Connecting to the Power Source

On 30A units, the input power cord is attached to the base of the unit. On units with a total maximum output <30A,

you must first attach the power cord to the unit before connecting the unit to the power source.

To attach a power cord to the unit:

1. Plug the female end of the power cord firmly into its connector at the base.

2. Use a screwdriver to tighten the two screws on the retention bracket.

To connect to the power source:

Plug the male end of the power cord into the AC power source.

Connecting Devices

To avoid the possibility of noise due to arcing:

1. Keep the device’s on/off switch in the off position until after it is plugged into the outlet.

2. Connect devices to the PDU outlets.

NOTE: Server Technology recommends even distribution of attached devices across all available outlets to avoid exceeding the outlet,

branch or phase limitations.

Always disconnect ALL power supply cords before opening to avoid electrical shock.

Afin d’éviter les chocs électriques, débranchez TOUTES les cables électrique avant d’ouvrir.

Vor dem Offnen immer Netzleitung abziehen um elektrischen Schlag zu vermeiden.

Connecting the Sensors

The Switched PDU is equipped with two mini RJ11 T/H ports for attachment of the Temperature/Humidity sensors.

Attach the mini RJ11 plug of the sensor(s) to the appropriate T/H port.

Connecting to the Unit

Serial (RS232) Port

The Switched Cabinet Distribution Unit is equipped with an RJ45 Serial RS-232 port for attachment to a PC or

networked terminal server using the supplied RJ45 to RJ45 crossover cable and RJ45 to DB9F serial port adapter as

required. For more information about the Serial RS-232 port, see the “Data Connections” section in Appendix C:

Technical Specifications.

Page 17

Switched PDU

Installation and Operations Manual Installation 17

Ethernet Port

The Switched Cabinet Distribution Unit is equipped with an RJ45 10/100Base-T Ethernet port for attachment to an

existing network. This connection allows access to the Switched PDU via Telnet or Web.

The Switched PDU is configured with the following network defaults to allow unit configuration out-of-the-box

through either Telnet or Web:

NOTE: When installed on a DHCP enabled networks, the following network defaults do not apply because the PDU ships with DHCP

support enabled.

IP address: 192.168.1.254

Subnet Mask: 255.255.255.0

Gateway: 192.168.1.1

The local PC network connection must be configured as noted below:

NOTE: For instructions about reconfiguring the network connection, contact your system administrator. A restart may be required for the

reconfiguration of your network to take effect.

IP address: 192.168.1.x (where x is 2-253)

Subnet Mask: 255.255.255.0

Page 18

Page 19

Chapter 3: Operations

INTERFACES 21

Outlet Naming and Grouping 21

Models with a Single Power Infeed ...................................................................................... 21

Models with Multiple Power Infeeds .................................................................................... 21

Usernames and Passwords 21

WEB INTERFACE 22

Logging In 22

System Summary 23

Outlet Control 26

Individual ............................................................................................................................. 26

Group ................................................................................................................................... 26

Power Monitoring 27

Input Feeds........................................................................................................................... 27

System .................................................................................................................................. 27

UPS ...................................................................................................................................... 27

Environmental Monitoring 28

Sensors ................................................................................................................................. 28

Shutdown 28

Outlets .................................................................................................................................. 28

Configuration 28

System .................................................................................................................................. 28

Network ................................................................................................................................ 31

Telnet/SSH............................................................................................................................ 33

HTTP/SSL ............................................................................................................................ 34

Serial Ports .......................................................................................................................... 35

Towers .................................................................................................................................. 37

Input Feeds........................................................................................................................... 38

UPS ...................................................................................................................................... 38

Outlets .................................................................................................................................. 39

Groups ................................................................................................................................. 39

Users .................................................................................................................................... 40

FTP ...................................................................................................................................... 42

SNTP/Syslog ......................................................................................................................... 43

SNMP/Thresholds ................................................................................................................ 44

LDAP ................................................................................................................................... 46

TACACS+ ............................................................................................................................ 48

RADIUS ............................................................................................................................... 50

SMTP/Email ......................................................................................................................... 51

Features ............................................................................................................................... 52

Tools 52

Ping ...................................................................................................................................... 52

Change Password ................................................................................................................ 52

Firmware.............................................................................................................................. 52

View Log .............................................................................................................................. 52

Restart .................................................................................................................................. 52

COMMAND LINE INTERFACE 53

Logging In 53

Operations Commands 56

Administration Commands 61

User Administration ................................................................................................ ............. 61

Outlet Administration ........................................................................................................... 65

Input Feed Administration ................................................................................................... 67

Tower Administration .......................................................................................................... 68

Group Administration .......................................................................................................... 70

Environmental Monitor Administration ............................................................................... 72

Serial Port Administration ................................................................................................... 72

System Administration .......................................................................................................... 75

TCP/IP Administration ........................................................................................................ 83

HTTP Administration ........................................................................................................... 86

Page 20

20 Operations Switched PDU

Installation and Operations Manual

Sentry Power Manager (SPM) Administration .................................................................... 86

Telnet Administration ........................................................................................................... 87

FTP Administration .............................................................................................................. 87

SNTP Administration ........................................................................................................... 89

UPS Administration ............................................................................................................. 91

Feature Administration ........................................................................................................ 95

Page 21

Switched PDU

Installation and Operations Manual Operations 21

Interfaces

The Switched Cabinet Distribution Unit has two interfaces: the Web interface accessed via the HTTP enabled

Ethernet connections, and the command line for serial and Telnet connections.

Outlet Naming and Grouping

Models with a Single Power Infeed

Absolute names are specified by a period (.) followed by a tower letter and outlet number. The tower letter for the

Switched Cabinet Distribution Unit is A and the tower letter for the optional Expansion Module is B.

Models with Multiple Power Infeeds

For units with multiple infeed connectors, absolute names are specified by a period (.) followed by the tower letter,

the infeed letter and outlet number.

Example: The absolute name for outlet 8 on the B infeed of tower A is .AB8.

Outlets can also be included in one or more named groups of outlets, enabling you to issue a command that affects all

outlets in a named group.

Usernames and Passwords

The Switched Cabinet Distribution Unit has one predefined administrative user account (username/password:

admn/admn), and supports a maximum of 112 defined user accounts.

NOTE: For security, Server Technology recommends removal of the predefined administrative user account after a new account with

administrative rights has been created.

Only an administrative-level user can perform operations such as creating/removing user accounts and command

privileges, changing passwords and displaying user information. An administrator can also view the status of all sensors

and power inputs.

Usernames can contain from 1-16 characters and are not case sensitive; spaces are not allowed. Passwords can

contain up to 16 characters, and are case sensitive.

Page 22

22 Operations Switched PDU

Installation and Operations Manual

Web Interface

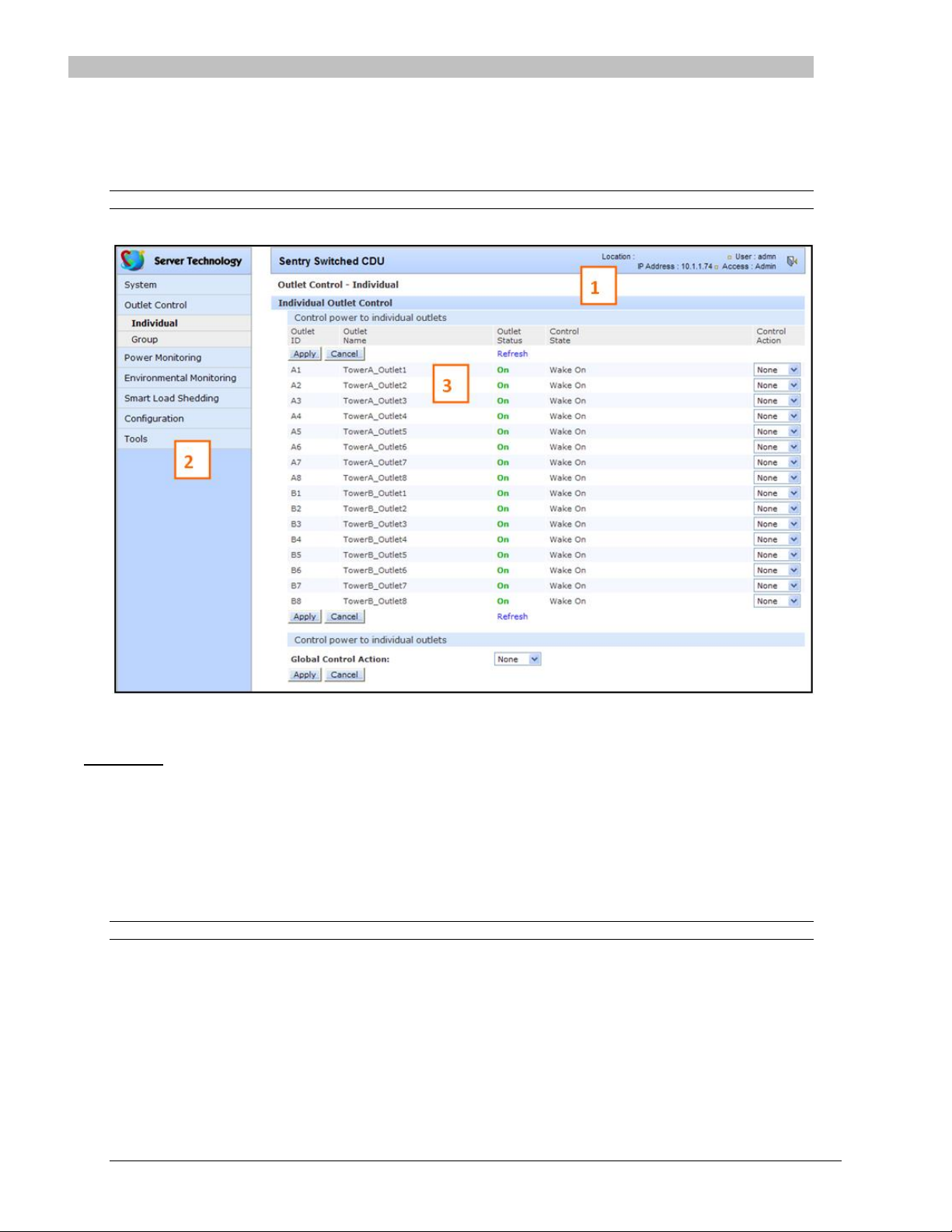

The Web Interface provides web-based access to the firmware. The interface is designed with three major sections,

illustrated below.

1. System Header: Shows PDU description and location, IP address, and user/access.

2. Navigation Bar: Provides access to PDU configuration, control action, or status page.

3. Details Window: Current control/status information based on the page selected from the navigation bar.

NOTE: The blinking of the PDU location string (IP address) in the System Header section may not work with all web browsers.

This example shows the Outlet Control > Individual page:

Example of Firmware Web Interface for the Switched PDU

Logging In

Logging in through the Web interface requires directing the Web client to the configured IP address of the unit.

To log in by Web interface:

In the login window, enter a valid username and password and click OK.

If you enter an invalid username or password, you will be prompted again.

You are given three attempts to enter a valid username and password combination. If all three fail, the session ends

and a protected page will be displayed.

NOTE: The default username/password is admn/admn.

Page 23

Switched PDU

Installation and Operations Manual Operations 23

System Summary

The System Summary is typically displayed as the default page at user login to the firmware Web Interface. If you do

not have environmental monitor access for a PDU, your default page at login will be the Outlet Control page (shown

in Figure 3 above).

Both the System Summary page and the Outlet Control page display automatically at login and do not require

enabling.

The System Summary page contains general system, line, humidity, and temperature status information. The colorcoded sensor graphs shown in the example below provide a quick and efficient real-time view for monitoring

environmental conditions in your PDU network.

Example of System Summary Page

The System Summary page displays precise current and system power consumption in your PDU network. Dynamic

updates (without a full page refresh) allow you to assess critical system statistics with close to instantaneous

feedback. This performance is useful for monitoring new installation or power distribution changes in high-density

computing environments. Power system administrators can also quickly identify thermal and humidity concerns that

might otherwise escalate into costly infrastructure repairs if left unchecked.

As long as the System Summary page is active, the sensor graphs are continually updating system statistics and

threshold values. The data with the most impact on the system is displayed to reduce your analysis and

troubleshooting time. You can quickly analyze and correct a PDU if a sudden operating condition affects your device

network.

NOTE: Because the System Summary page continually requests updated status information from the PDU, the page does not time-out. You

will need to navigate to another page or manually log off.

System Information

Uptime: Displays the cumulative time the PDU has been up and running since the last unit restarted. Uptime shows

continuous, real-time system updates with an approximate 5-second automatic refresh. A manual refresh of the

System Summary page is not required.

Firmware Version: Shows the current firmware version.

Ethernet NIC S/N: Displays the PDU serial number derived from the Ethernet NIC.

Page 24

24 Operations Switched PDU

Installation and Operations Manual

Active Users: Displays the number of active user sessions accessing the firmware. These sessions include serial,

TELNET, SSH, and Web sessions. Active Users also shows sessions that an unauthorized user may be attempting to

access. The number shown in Active Users changes instantly as the number of active user sessions change. A total of

4 concurrent web user sessions are allowed (HTTP or HTTPS).

NOTE: Depending on your web browser, multiple web accesses from the same machine are often treated as one user.

Total Power Consumption: Displays the total system power (in Watts) being distributed by the current PDU

configuration.

Line Status

The Line Status graph displays a blinking warning (yellow), whenever the total input load on an infeed exceeds the

present user set threshold. If an overload occurs, a blinking error condition (red) is displayed. The unit continues to

display these yellow and red states until the condition changes or the problem has been resolved.

The default input feed high load threshold is 80% of the input feed maximum load capacity.

NOTE: The input feed high threshold is user-defined. You must configure this threshold value on the SNMP/Thresholds page or the

Command Line Interface (CLI).

Temperature Status

The Temperature Status graph displays a blinking error whenever temperature exceeds the low or high threshold. The

PDU will continue to display this state until the condition changes or the problem has been resolved.

For the temperature sensor, the default range of low/high temperature values is 5º-45º C (41º-115º F).

Up to four sets of dual temperature/humidity sensors can be displayed in this graph for a total of eight possible

temperature sensor graphs. A thin blue line separates each set based on the tower or environmental monitor.

NOTE: The temperature threshold values are user-defined. You must configure these threshold values on the SNMP/Thresholds page or the

Command Line Interface (CLI).

Humidity Status

The Humidity Status graph displays a blinking error whenever humidity exceeds the low or high threshold. The PDU

will continue to display this state until the condition changes or the problem has been resolved.

For the humidity sensor, the default range of low/high humidity percentage is 0-100% (relative humidity).

Up to four sets of dual temperature/humidity sensors can be displayed in this graph for a total of eight possible

humidity sensor graphs. A thin blue line separates each set based on the tower or environmental monitor.

NOTE: The humidity threshold values are user-defined. You must configure these threshold values on the SNMP/Thresholds page or the

Command Line Interface (CLI).

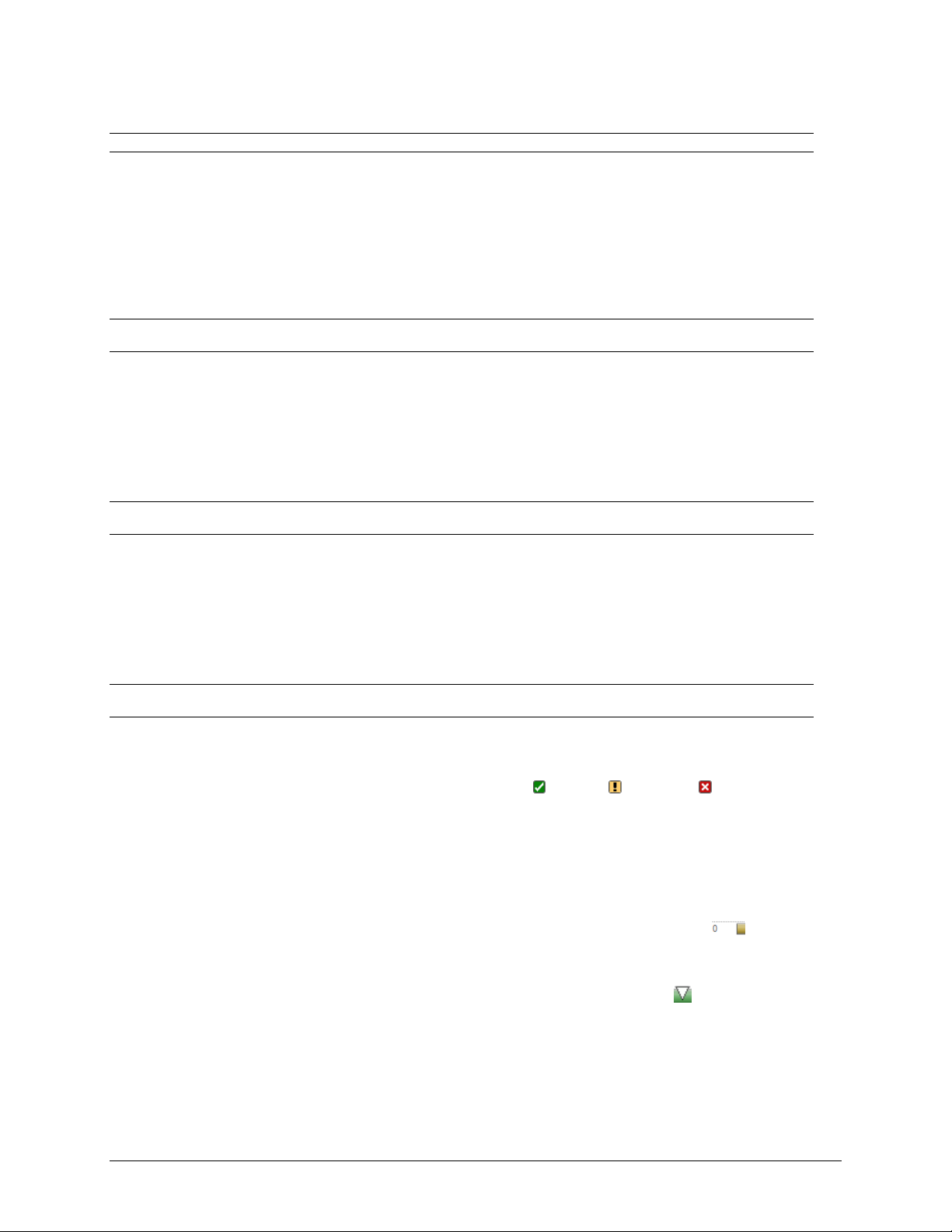

Field Descriptions

The following fields and icons are viewed left to right for Line Status, Temperature Status, and Humidity Status:

Icon: Provides quick viewing of current operational state: Information , Warning and Critical .

ID: Device input feed or sensor identifier.

Name: Descriptive, user-defined name for each input infeed or sensor.

Load, Temp, Humidity: Current state of the reported input load (in amps), current temperature, or current

percentage of relative humidity.

Low Limit: Displays the user-defined low limit of the load, temperature, or humidity graph. These values depend on

the sensor limited and cannot be set by the user. For example, a 0ºC low limit would be displayed as for a

temperature sensor graph in Celsius.

Sensor Graph and Level Indicator: The horizontal sensor graph shows current operating conditions in color-coded

segments. See the section below, “Sensor Graph Color Coding” for details. The level indicator appears across the

graph to indicate the relative position of the current data value with respect to the minimum (low limit) and maximum

(high limit) values displayed at the left and right of the graph.

Page 25

Switched PDU

Installation and Operations Manual Operations 25

High Limit: Displays the high limit of the load, temperature, or humidity graph. These values depend on the sensor

limits are cannot be set by the user. For example, a 100ºC high limit would be displayed as for a temperature

sensor graph in Celsius.

Status: One of several operating conditions:

System Summary – Status Descriptions

Icon Status Description

Reading Unit is reading a new or restored sensor.

Normal Indicates normal operation.

Load High Infeed current load exceeds present High threshold.

Over Load Infeed current load exceeds the measurable range for the infeed.

Temp Low Current temperature falls below present Low threshold.

Temp High Current temperature exceeds present High threshold.

Humid Low Current percentage of relative humidity falls below present Low threshold.

Humid High Current percentage of relative humidity exceeds present High threshold.

Lost The connection was lost to a sensor that was previously detected and the sensor is pulled from the

original environment monitoring statistics. There is no data to report, the graph is meaningless, and

the threshold settings remain displayed but are grayed.

Sensor Graph Color-Coding

The following colors change dynamically on the sensor graphs to communicate operating conditions:

Line (Load) Status:

Green = Normal

Yellow = High load (load configured by user)

Red = Overload (based on device characteristics)

User configures load capacity at Configuration > SNMP/Thresholds > Input Feed Traps and Thresholds

Temperature Status:

Blue = cold; low temperature (threshold configured by user)

Green = acceptable temperature range

Red = hot; high temperature (threshold configured by user)

User configures low/high temperature thresholds at Configuration > SNMP/Thresholds > Sensor Traps and

Thresholds

Humidity Status:

Blue = wet; high humidity (threshold configured by user)

Green = acceptable percentage of relative humidity

Yellow = dry; low humidity (threshold configured by user)

User configures low/high relative humidity thresholds at Configuration > SNMP/Thresholds > Sensor Traps and

Thresholds

Page 26

26 Operations Switched PDU

Installation and Operations Manual

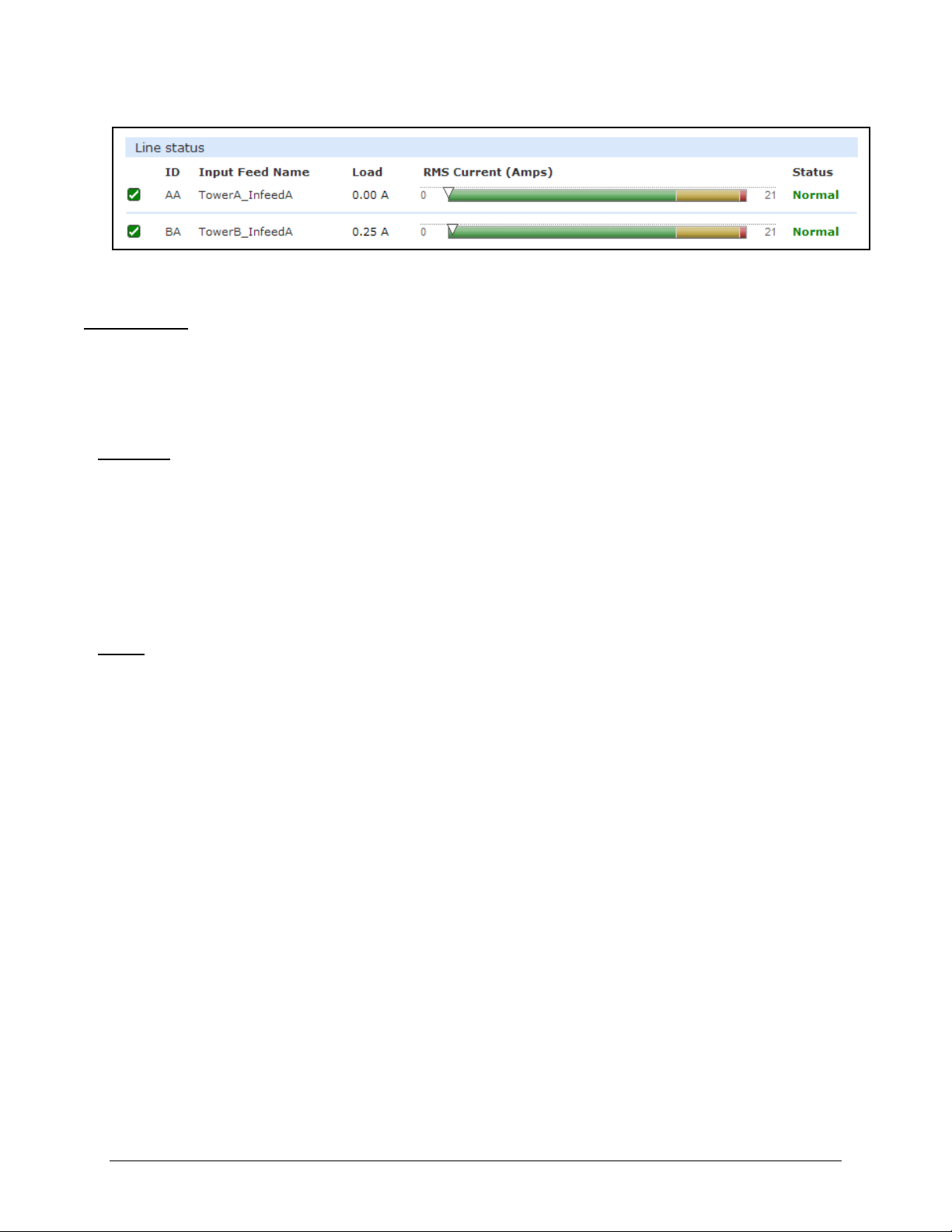

Logical Group Separators

Logical groups are separated by a thin blue line on the System Summary page as shown in the following example

between Tower A_InfeedA and Tower B_InfeedA:

This grouping includes master/link units in addition to some branched units.

Up to three blue line dividers can be displayed on the System Summary page between all sensor groups.

Outlet Control

The Outlet Control section offers access to the Individual and Group outlet control pages. From the Individual and

Group pages, the user can review and manipulate power control functions for all outlets and groups assigned to the

current user. Both pages include the outlet’s absolute and descriptive names, the Outlet Status reported to the PDU by

the outlet, the current Control State being applied by the PDU, and the outlet load in amperes.

Available outlet and group power states can be set to on, off, or reboot.

Individual

The Individual outlet control page displays all outlets assigned to the current user. The user can apply on, off, or

reboot actions to individual, multiple, or all accessible outlets.

To apply actions to individual or multiple outlets:

In the Individual Outlet Control section, select the desired action from the Control Action drop-down menu for each

individual outlet to be changed, and click Apply.

To apply an action to all outlets:

In the Global Control section, select the desired action from the Control Action drop-down menu and click Apply.

Group

The Group outlet control page displays all groups assigned to the current user, as well as the outlets for each group.

To select a group:

Select the group name from the drop-down menu and click Select. The page will refresh to display all outlets

associated to the selected group name.

To apply an action to a group:

Select the desired action from the drop-down menu and click Apply.

Page 27

Switched PDU

Installation and Operations Manual Operations 27

Outlet State/Control State Field Values

Outlet State Control State Description

On On Outlet is on

Off Off Outlet is off

Off Pend On Outlet is off and about to turn on in response to a sequence timer

Off Reboot Outlet is off and a Reboot action has been initiated

On Idle On A restart has occurred – Last Control State has been maintained

Off Idle Off A restart has occurred – Last Control State has been maintained

On Wake On A power-loss has occurred – Wakeup State has been applied

Off Wake Off A power-loss has occurred – Wakeup State has been applied

On/Wait Off Outlet state in transition – Re-query of outlet status required

Off/Wait On Outlet state in transition – Re-query of outlet status required

On/Error varies Error State – Outlet should be off, but current is sensed at the outlet

Off/Error varies Error State – Outlet should be on, but no current is sensed at the outlet

Off/Fuse On Outlet should be on, but a blown fuse has been detected

On/Fuse On Outlet should be on, but a blown fuse has been detected downstream

No Comm varies Communication to the outlet has been lost. Control state will be applied when communication

is re-established.

Power Monitoring

Input Feeds

The Input Feeds page displays:

The absolute and descriptive names of the infeed

Infeed status

Input/branch phase load in amperes

Input Voltage

Calculated power usage in Watts.

Monitor pages (like the Input Feeds page) refresh occasionally to reflect current PDU status.

System

The System page displays:

Calculated power usage for all infeeds in watts

Configured total system area in square feet

Calculated power usage in watts/square feet

Tower monitoring – tower ID, tower name, and tower status

NOTE: For 3-phase systems, if the Out-of-Balance Alerting feature is enabled, and the system goes into a load out-of-balance condition,

the Tower Status field will display the alert “3ph Out-of-Balance”, unless there is a higher priority tower error state to report.

Monitor pages (like the System page) refresh occasionally to reflect current PDU status.

UPS

The UPS page displays the following information for each UPS device associated with the unit:

Status

Voltage

Hostname/IP address

NOTE: The UPS page displays both IPv4 and IPv6 formats in the Hostname/IP field.

Monitor pages (like the UPS page) refresh occasionally to reflect current PDU status.

Page 28

28 Operations Switched PDU

Installation and Operations Manual

Environmental Monitoring

Sensors

The Sensors page displays:

Absolute and descriptive names of the temperature/humidity sensor

Temperature/humidity sensor readings and percentage of relative humidity

Monitor pages (like the Sensors page) refresh occasionally to reflect current PDU status.

Temperature/Humidity Sensor Status

Status Description

Found The PDU found the sensor and connection is established.

Not Found On a fresh reboot, the PDU does not find a sensor.

Lost The connection to a previously found sensor is now lost.

No Comm Communication loss occurred due to a hardware issue (not loss of communication with the probes).1

1

= The ENV part of the sensor supports two Temperature/Humidity (T/H) probes as part of the master unit, two T/H

probes as part of the link unit, and the optional EMCU-1-1 (which can support two T/H probes, four contact-closure

monitoring points, and one water sensor). The “No Comm” sensor status is not loss of communication with probes

themselves.

Shutdown

The Shutdown section offers access to all Remote Shutdown configuration options. This section is available to

administrative level users only. For more information and the configuration requirements, see the “Remote

Shutdown” section.

Outlets

Enabling or disabling Remote Shutdown support:

Select or deselect outlets to enable/disable Remote Shutdown support for in the Shutdown/Delay field and click

Apply.

Setting the Remote Shutdown delay:

Enter the shutdown delay (in seconds) in the outlet Shutdown/Delay field and click Apply. Valid range is 1-900

seconds.

Editing the target server’s Hostname/IP address:

In the outlet Hostname/IP field, enter an IP address or Hostname and click Apply.

Enabling or disabling shutdown script support:

Select or deselect outlet to enable/disable shutdown script support for in the Script/Delay column and click Apply.

Setting the shutdown script delay:

Enter the shutdown delay (in minutes) in the outlet Script/Delay field and click Apply.

Configuration

The Configuration section offers access to all unit configuration options. This section is available to administrative

level users only.

System

The System configuration page is used for reference of system information such as Ethernet NIC Serial Number,

Ethernet MAC address and system firmware and hardware revisions as well as assignment and maintenance of other

system wide configurations.

For descriptive names, up to 24 alphanumeric and other typed characters (ASCII 33-126 decimal) are allowed; spaces

are not allowed.

NOTE: Spaces can be used for the location description only.

Page 29

Switched PDU

Installation and Operations Manual Operations 29

Creating a pre-login banner:

Click the Login Banner link. On the subsequent Login Banner page, type pre-login banner text and click Apply.

NOTES:

The pre-login banner can be up to 2069 characters in length and is displayed prior to the login prompt. If left blank, a system banner will

not be displayed prior to the login prompt.

For an SSH connection, the banner length is truncated to 1500 bytes in SSH packets to avoid failure of the SSH connection when

configured with a long login banner.

The Login Banner displays the following Characters Remaining box to show you in real-time as you type how many of

the 2069 maximum characters are still available for you to complete your banner. The box adjusts dynamically as you

type or delete characters.

If you reach the maximum 2069 characters, the box displays “-1”. To clear your entry and start over, click Cancel.

Creating a descriptive system location name:

Enter a descriptive name and click Apply.

Configuring the Input Current LED display orientation:

Select Normal or Inverted from the drop-down menu and click Apply.

Configuring the LED display orientation:

From the Display Orientation drop-down list, select Normal or Inverted, and click Apply.

NOTES:

Only specific PDU models are equipped with an accelerometer chip that senses device orientation. If equipped, your PDU automatically

aligns the LED display orientation (depending on its current direction), and the option “Auto” displays in the Display Orientation

drop-down list by default. In addition, the actual mounting of the unit, such as “<Normal> or <Inverted>”, appears to the right of

the "Auto" option. However, even if your model does have the sensor for device orientation, you can still select the Normal or

Inverted option from the list to override the capability of the hardware.

If your model does not have the accelerometer chip, you will need to configure the LED display orientation by selecting Normal or

Inverted.

Setting the outlet sequence order:

The PDU lets you configure the power-on sequence of outlets.

The Normal option powers-on outlets in ascending numeric order by outlet number, for example, from outlet 1-8. The

Reversed option powers on outlets in descending order by outlet number; for example, from outlet 8-1.

The Reversed option is useful when the PDU is mounted with inverted orientation and the last outlet (in this example,

outlet 8) is in the first position.

From the Outlet Sequence Order drop-down menu, select Normal or Reversed, and click Apply.

Page 30

30 Operations Switched PDU

Installation and Operations Manual

Enabling or disabling strong password requirements:

The Switched PDU supports enforcement of strong passwords for enhanced security. When enabled, all new

passwords must be a minimum of 8 characters in length with at least one uppercase letter, one lowercase letter, one

number and one special character.

Acceptable strong passwords:

n0tOnmyw@tch

john2STI?

H3reUgo!

NOTE: Strong password requirements also enforce a minimum change of four character positions when defining new strong passwords.

Select Enabled or Disabled from the Strong Passwords drop-down menu and click Apply.

NOTE: The strong password requirement is applied against all new passwords.

Enabling or disabling the configuration reset button:

Select Enabled or Disabled from the Configuration Reset Button drop-down menu and click Apply.

Setting the temperature scale:

Select Celsius or Fahrenheit from the Temperature Scale drop-down menu and click Apply.

Setting the system area (footprint):

Enter a system area value in the Area (Footprint) field and click Apply.

Setting the system area unit of measure:

Select Square Feet or Square Meters from the Area (Footprint) drop-down menu and click Apply.

Setting the power factor:

The Power Factor value calculates the power usage displayed in the Power Monitoring pages.

Type a numeric value in the Power Factor field (from 0.50 to 1.00) and click Apply.

Setting the 3-phase load out-of-balance threshold:

The threshold (percentage) specified determines when the current on the lines of a 3-phase system are out-of-balance

between the three phases of power. If the alerting feature is enabled, an alert will be sent when an out-of-balance condition

occurs.

In the 3-Phase Load Out-of-Balance Threshold field, type a value from 0 to 100%, and click Apply.

Setting the 3-phase load out-of-balance alerting:

This setting enables/disables the sending of an alert when the current on the lines of a 3-phase system are past a pre-set

threshold (percentage) and are out-of-balance between the three phases of power.

From the 3-Phase Load Out-of-Balance Alerting drop-down menu, select Enabled or Disabled, and click Apply.

NOTES:

When a device with 3-phase input voltage is out-of-balance, efficiency is reduced and the unit is prevented from reaching maximum

capacity. When an alert for the out-of-balance condition is received (if the alerting feature is enabled), it may be necessary to adjust

distribution of the loads.

For 3-phase systems, if the Out-of-Balance Alerting feature is enabled, and the system goes into a load out-of-balance condition, the

Tower Status field on the “Power Monitoring – System” web page will display the alert “3ph Out-of-Balance”, unless there is a higher

priority tower error state to report.

Configuring the Command Line Interface (CLI) session timeout:

Enter a timeout period (in minutes) in the CLI Session Timeout field, and click Apply.

The valid timeout range is 1 to 1440 minutes (24 hours); the default is 5 minutes.

Page 31

Switched PDU

Installation and Operations Manual Operations 31

Configuring the web session (Web Interface) timeout:

Enter a timeout period (in minutes) in the Web Session Timeout field.

The valid timeout range is 1 to 1440 minutes (24 hours); the default is 5 minutes.

Enabling/Disabling StartUp Stick :

StartUp Stick is a Server Technology tool for mass configuration of PDU operating parameters.

Select Enabled or Disabled from the StartUp Stick drop-down menu and click Apply.

Creating a descriptive unit name:

Click on the Tower Names link.

On the subsequent Tower Names page, enter a descriptive name and click Apply.

Creating a descriptive input feed name:

Click on the Input Feed Names link.

On the subsequent Input Feed Names page, enter a descriptive name and click Apply.

Creating a descriptive outlet name:

Click on the Outlet Names link which will open the Outlets configuration page. For more information about creating

descriptive outlet names, see the “Outlets” section.

Creating a descriptive serial port name:

Click on the Serial Port Names link which will open the Serial Ports configuration page.

Creating a descriptive environmental monitor name:

Click on the Environmental Monitor Names link.

On the subsequent Environmental Monitor Names page, enter a descriptive name and click Apply.

Creating descriptive sensor names:

Click on the Sensor Names link.

On the subsequent Sensor Names page, enter a descriptive name and click Apply.

Network

The Network configuration page allows the administrator to maintain the network interface by determining IPv6 and

IPv4 status, network state, IP address, gateway, subnet mask, primary/secondary DNS addresses, and the necessary

settings and options for DHCP.

NOTE: For maximum backward compatibility, the default network mode is “IPv4 only”.

Page 32

32 Operations Switched PDU

Installation and Operations Manual

Network:

The Network drop-down menu determines the acquisition method used for the protocol stack, IPv4 address, and IPv6

address. From the Network drop-down menu, select the acquisition method for your network (Disabled, IPv4 only, or

Dual IPv6/IPv4), and click Apply.

State:

The view-only State field shows the current IPv6/IPv4 network status and can display any of the following values:

Current Network States

Acquiring

Disabled

Disconnected

DHCP IPv4

DHCP IPv6

DHCP IPv6/IPv4 (both available)

IPv4 Failed (Static IPv4 problem)

IPv6 Failed (Static IPv6 problem)

Static IPv4

Static IPv6

Static IPv6/IPv4 (both available)

Unknown

Additional network communication values are displayed for viewing only: Link, Speed, Duplex, and Negotiation. Also

displayed for viewing are the IPv6 and IPv4 IP address, subnet mask, gateway, and primary/secondary DNS addresses.

Setting the IPv6 or IPv4 static IP address, gateway, subnet mask, or DSN address:

In the appropriate fields, type the IP address, gateway, subnet mask, or DNS address, and click Apply.

NOTE: IPv6 address formats are accepted in the IPv6 Address field and IPv6 Gateway field. IPv4 formats are accepted in the IPv4-named

Address, Subnet Mask, and Gateway fields.

Enabling Dynamic Host Configuration Protocol (DHCP):

To enable DHCP, check the Enable checkbox. To disable DHCP, uncheck (clear) the checkbox.

Click Apply.

Setting the Fully-Qualified Domain Name (FQDN):

To enable the FQDN, check the Enable checkbox and accept the default name “sentry3-521384” (or type a different

name). To disable the FQDN, uncheck the checkbox.

Click Apply.

Enabling the DHCP boot delay:

To enable the boot delay, check the Enable checkbox. To disable the boot delay, uncheck (clear) the checkbox.

Click Apply.

Enabling the Boot Delay option gives the PDU approximately 100-seconds to establish a connection through a

DHCP server. This interval allows various network component activities to occur as the PDU powers up (such

as obtaining SNTP time stamps for logging). This is the default state.

Disabling the Boot Delay option forces the PDU to boot after approximately 5-seconds regardless of the

DHCP acquisition state. This speeds up a boot when a DHCP server is connected to one of the outlets in the

PDU. In this configuration, SNMP traps, SNTP, and other protocols will not be available until a DHCP

address has been resolved.

NOTES:

The Boot Delay option executes only when DHCP is enabled.

The firmware can detect network link integrity and will wait for network connection. This means that if the network is not currently

connected, the enabled Boot Delay option will be ignored.

Page 33

Switched PDU

Installation and Operations Manual Operations 33

Enabling static address fallback:

NOTE: The Static Address Fallback option executes only when DHCP is enabled.

To enable static address fallback, check the Enable checkbox. To disable, uncheck (clear) the checkbox.

Click Apply.

Enabling the Static Address Fallback option informs the PDU to automatically fall back to a static address if

a DHCP server does not respond after 100-seconds. This is the default state.

Disabling the Static Address Fallback option generates DHCP server requests until the PDU obtains a

dynamic address.

NOTE: If the DHCP server boot time is excessive, you may need to disable the DHCP Static Address Fallback option.

Network defaults

The Switched PDU is configured with the following network defaults to allow unit configuration out-of-the-box

through either Telnet or Web:

IP address: 192.168.1.254

Subnet Mask: 255.255.255.0

Gateway: 192.168.1.1

The initial local PC network connection must be configured as noted below:

NOTE: For instructions about reconfiguring the network connection, contact your system administrator. A restart may be required for the

reconfiguration of your network to take effect.

IP address: 192.168.1.x (where x is 2-253)

Subnet Mask: 255.255.255.0

NOTE: The unit must be restarted after network configuration changes.

Setting the IP address, subnet mask, gateway, or DNS address:

In the appropriate field, enter the IP address, subnet mask, gateway address or DNS address and click Apply.

Telnet/SSH

The Telnet/SSH configuration page enables or disables Telnet and SSH support and configures the port number that

the Telnet or SSH server watches.

Enabling or disabling Telnet or SSH support:

Select Enabled or Disabled from the appropriate Server drop-down menu and click Apply.

Changing the Telnet or SSH server port number:

In the appropriate Port field, enter the port number and click Apply.

Enabling or disabling SSH server authentication methods:

The SSH server supports the Password and the Keyboard-Interactive authentication methods for security.

Password is an authentication method in which the SSH client gathers username/password credentials and makes the

authentication request to the SSH sever with the credentials. The Password method is controlled by the SSH client.

Keyboard-Interactive is an authentication method in which the SSH server controls an information field followed by one

or more prompts requesting credential information from the SSH client. The client gathers credential information keyed-in

by the user and sends it back to the server. The Keyboard-Interactive method is controlled by the SSH server.

Individual enabling and disabling of the Password and Keyboard-Interactive authentication methods are supported to

allow an SSH client to be forced to use a specific method. Although both methods are available, by enabling the

Keyboard-Interactive method and disabling the Password method, the SSH client is forced to used Keyboard-Interactive,

which is required to display the login banner.

NOTE: At least one authentication method must be enabled.

Select the Password checkbox and/or the Keyboard-Interactive checkbox and click Apply.

Page 34

34 Operations Switched PDU

Installation and Operations Manual

HTTP/SSL

The HTTP/SSL page configures HTTP server options, SSL options (including user-defined certificates), and

determines settings for the Sentry Power Manager (SPM) enterprise software product.

Enabling or disabling HTTP or SSL support:

From the HTTP or SSL Server drop-down menu, select Enabled or Disabled, and click Apply.

NOTE: SSL-encrypted (HTTPS) must be used for secure website connections.

Setting SSL secure access:

SSL allows either optional or required connections. The default secure access is optional.

Optional: Both non-secure (HTTP) and SSL-encrypted connections (HTTPS) are allowed access.

Required: Only SSL-encrypted connections (HTTPS) are allowed access.

From the Secure Access drop-down menu, select Optional or Required, and click Apply.

Changing the HTTP server or SSL port number:

In the HTTP or SSL section of the page, in the Port field, type the port number, and click Apply. The HTTP default

port number is 80; the SSL default port number is 443.

Uploading a custom user certificate:

Enabling and disabling user certificates:

In the User Certificate drop-down menu, select Enabled. Provide a passphrase (0-47 characters) for the new

certificate. To change the passphrase, type a new passphrase and check the Change checkbox.

Click Apply.

The Stored Files section displays a message to confirm the upload status of the user certificate and its related public

key.

Custom User Certificate Messages

Message Description and Valid Values/Range