Page 1

Switched PRO2 – User Guide

Introducing the PRO2 • 1

Switched PRO2

User Guide

Firmware 8.0

Page 2

Switched PRO2 – User Guide

Introducing the PRO2 • 2

Instructions

This symbol is intended to alert the user to the presence of important operating and maintenance (servicing) instructions in the literature

accompanying the appliance.

Dangerous Voltage

This symbol is intended to alert the user to the presence of un-insulated dangerous voltage within the product’s enclosure that may be of sufficient

magnitude to constitute a risk of electric shock to persons.

Protective Grounding Terminal

This symbol indicates a terminal that must be connected to earth ground prior to making any other connections to the equipment.

Life-Support Policy

As a general policy, Server Technology does not recommend the use of any of its products in the following situations:

• life-support applications where failure or malfunction of the Server Technology product can be reasonably expected to cause failure of the life-

support device or to significantly affect its safety or effectiveness.

• direct patient care.

Server Technology will not knowingly sell its products for use in such applications unless it receives in writing assurances satisfactory to Server

Technology that:

• the risks of injury or damage have been minimized,

• the customer assumes all such risks, and

• the liability of Server Technology is adequately protected under the circumstances.

The term life-support device includes but is not limited to neonatal oxygen analyzers, nerve stimulators (whether used for anesthesia, pain relief or other

purposes), auto-transfusion devices, blood pumps, defibrillators, arrhythmia detectors and alarms, pacemakers, hemodialysis systems, peritoneal dialysis

systems, neonatal ventilator incubators, ventilators (for adults or infants), anesthesia ventilators, infusion pumps, and any other devices designated as

“critical” by the U.S. FDA.

Notices

301-9999-30 Rev E (102816)

Copyright © 2005-2016 Server Technology, Inc. All rights reserved.

1040 Sandhill Drive

Reno, Nevada 89521 USA

All Rights Reserved

This publication is protected by copyright and all rights are reserved. No part of it may be reproduced or transmitted by any means or in any form, without

prior consent in writing from Server Technology.

The information in this document has been carefully checked and is believed to be accurate. However, changes are made periodically. These changes

are incorporated in newer publication editions. Server Technology may improve and/or change products described in this publication at any time. Due to

continuing system improvements, Server Technology is not responsible for inaccurate information which may appear in this manual. For the latest

product updates, consult the Server Technology web site at www.servertech.com. In no event will Server Technology be liable for direct, indirect, special,

exemplary, incidental, or consequential damages resulting from any defect or omission in this document, even if advised of the possibility of such

damages.

In the interest of continued product development, Server Technology reserves the right to make improvements in this document and the products it

describes at any time, without notices or obligation.

The Globe logo is a trademark of Server Technology, Inc., registered in the US. Use of the logos for commercial purposes without the prior written

consent of Server Technology may constitute trademark infringement and unfair competition in violation of federal and state laws.

Server Technology, the Globe logo, Sentry, Switched CDU, CDU, PRO2, PIPS, POPS, PDU Power Pivot, and StartUp Stick are trademarks of Server

Technology, Inc., registered in the US. EZip is a trademark of Server Technology.

Other trademarks and trade names may be used in this document to refer to either the entities claiming the marks and names or their products. Server

Technology, Inc. disclaims any proprietary interest in trademarks and trade names other than its own.

Please Recycle

Shipping materials are recyclable. Please save them for later use, or dispose of them appropriately.

Page 3

Switched PRO2 – User Guide

Introducing the PRO2 • 3

Table of Contents

Chapter 1: Introducing the PRO2 5

Welcome to the Server Technology Switched PRO2 ................................... 5

What’s the PRO1? ............................................................................................ 6

About Your User Guide ................................................................................... 7

PDU Power Pivot .......................................................................................... 7

Star Linking Technology .................................................................................. 8

Unit Persistence ................................................................................................ 9

Additional PRO2 Resources ............................................................................. 9

Contact Technical Support ............................................................................. 10

Equipment Overview ...................................................................................... 11

Chapter 2: Installing the PRO2 12

Standard Accessories ...................................................................................... 12

Optional Accessories ...................................................................................... 12

Additional Required Items ............................................................................. 12

Safety Precautions .......................................................................................... 13

Input Power Cord Retention Options for PRO2s with IEC C20 Inlets .......... 14

Attaching Safety Earth Ground Connection ................................................... 15

Mounting the PRO2 Unit ............................................................................... 16

Chapter 3: Getting Started with the Firmware 19

On-Board File System .................................................................................... 19

Intuitive and Consistent Terminology ............................................................ 19

Outlet Grouping .............................................................................................. 19

Setting Thresholds .......................................................................................... 19

PRO2 Dashboard View .................................................................................. 20

The User Interfaces......................................................................................... 21

Usernames and Passwords .............................................................................. 21

User Access Rights ......................................................................................... 22

IPv4/IPv6 Support .......................................................................................... 23

Chapter 4: Using the Web Interface 26

Logging In ...................................................................................................... 26

Quick Tour of the GUI ................................................................................... 26

Overview (Viewing the System Dashboard) .................................................. 30

Monitoring (Analyzing Metrics) .................................................................... 34

Control (Managing Outlets) ........................................................................... 48

Configuration (Setting Values) ...................................................................... 52

Network (Setting Up Network Protocols) ...................................................... 92

Access (Managing Users) ............................................................................. 113

Tools (Using Support Functions) ................................................................. 122

Page 4

Switched PRO2 – User Guide

Introducing the PRO2 • 4

Chapter 5: Using the Command Line Interface (CLI) 130

Logging In .................................................................................................... 130

Quick Tour of the Command Line ............................................................... 130

List of Commands ........................................................................................ 133

Command Details ......................................................................................... 139

Appendix A: Product Support Information 204

LED Indicators ............................................................................................. 204

Branch Circuit Protection ............................................................................. 205

Circuit Breaker ............................................................................................. 205

Compact Fuse Holder ................................................................................... 206

Fuse Retractor, Fuse Access Window, and Fuse Access Cover................... 207

Time-Delay Fuses – Class G ........................................................................ 208

PROx Network Interface Card (NIC) Swap ................................................. 209

Appendix B: Regulatory Compliance 210

Product Safety .............................................................................................. 210

Notifications ................................................................................................. 210

Product Recycling ........................................................................................ 211

Appendix C: Product Warranty–Technical Support–RMA 212

Warranty ....................................................................................................... 212

Contact Technical Support ........................................................................... 212

Return Merchandise Authorization (RMA) ................................................. 212

Page 5

Switched PRO2 – User Guide

Introducing the PRO2 • 5

Chapter 1: Introducing the PRO2

Welcome to the Server Technology Switched PRO2

The Switched PRO2 is the latest design in Server Technology’s reliable power distribution units, providing flexibility

for future power management, cost savings, and advanced solutions for data center customers.

Key Product Features

The Switched PRO2 offers many features for the next generation of power management, including:

• PIPS® and (optionally) POPS® high-accuracy measurements for current, voltage, power, and other key

metrics. PIPS is a standard feature on all PRO2 units.

• Auto-Flip LED display gives the proper display orientation no matter how the PRO2 is mounted in the

cabinet.

• Outlet naming on all PRO2 products (for both Switched and Smart products).

• Hot-swappable network interface card (NIC) allows swapping the card in the field without causing a change

in outlet state. The NIC can easily be replaced even when power is applied.

• Support for IPv6 address names and support for SNMPv3.

• Equipped for the mobile power monitoring solution using a Bluetooth

®

module (for either Google Android or

Apple iOS), along with Server Technology’s ST Eye mobile application.

• Branch current measurements on both Switched and Smart PRO2 products, and notification of fuse or

breaker failure.

• Several new levels of power monitoring for high-low warning-alarm thresholds and threshold hysteresis.

• If the master unit loses power, redundant power is provided to the master via the first linked unit, ensuring

uptime.

• On-board firmware file system to allow direct GUI downloads of system files, firmware version updates, and

MIB/OID tree files without using FTP.

• Intuitive and soft-mapped naming conventions used in both the PRO2 hardware and firmware to reflect the

system hierarchy of units, cords, lines, phases, over-current protectors (OCPs), branches, outlets, outlet

groups, and sensors.

Page 6

Switched PRO2 – User Guide

Introducing the PRO2 • 6

What’s the PRO1?

Like the PRO2, the PRO1 (Switched and Smart) is another new PDU design from Server Technology to provide the

same type of flexibility for power management, cost savings, and advanced data center solutions that the PRO2

delivers.

What’s Unique About the PRO1?

Server Technology’s PRO1 design allows for PRO2 functionality in a CDU1 form factor.

The PRO1 uses the Sentry4-MIB and the PRO2 firmware, version 8.0.x, allowing PRO1 products to offer the latest

features and functions of the PRO2 product family.

Equipment View of the PRO1 Unit

Feature Comparison: PRO1 vs. PRO2

The PRO1 is similar to the PRO2 in hardware architecture, object mapping, user interfaces (GUI and CLI), firmware

(version 8.0.x or later), and new Sentry4-MIB, but the PRO1 does not include the following PRO2 items:

• Branch Current Monitoring feature

• TRMS Current Input Monitoring (in some cases rather than PIPS)

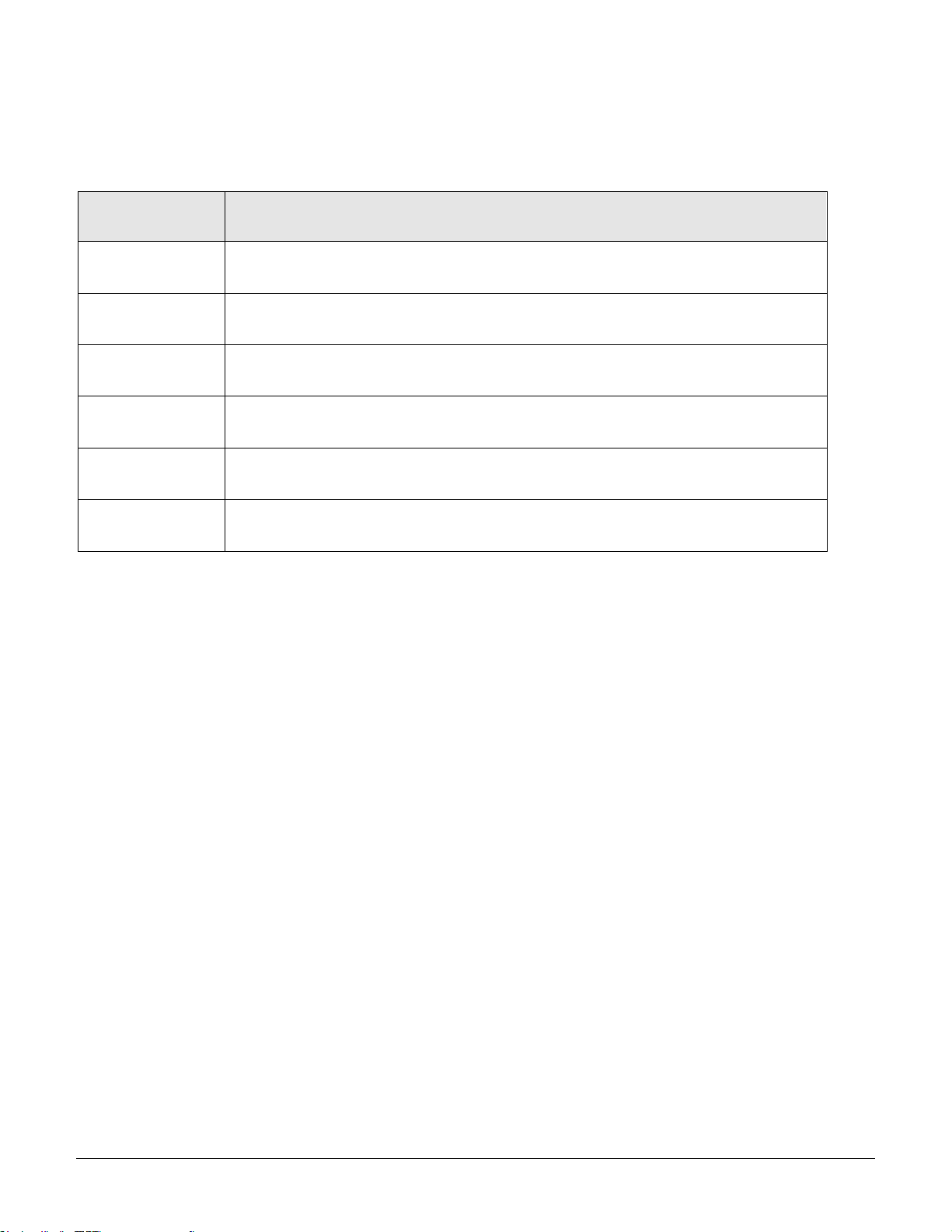

The following table shows a detailed benefit comparison:

Product

Benefits

PRO1

CDU with the NIM2/PRO2 network card:

• Faster processor and more memory

• Hot swap network card

• Network card swap with no re-programming (PCM)

• Features/functions can be added as needed

• Multi-linking (up to 4 units)

• Power from link unit keeps network up if power from master unit goes down

• Sentry4-MIB allows additional alarm warning and threshold levels

PRO2

PRO2 architecture with the NIM2 network card:

• PRO1 features, plus additional features

• PIPS standard

• Branch monitoring standard

• Locking data and low voltage cables

• Smart products with breaker/fuse branch circuit sensing

• All products 60 degrees Celsius rated

Page 7

Switched PRO2 – User Guide

Introducing the PRO2 • 7

About Your User Guide

This user guide was designed for data center personnel who monitor power, control outlet actions, and administer

equipment operations in the data center network using Server Technology’s firmware, version 8.0x or later, on the

PRO2 product family.

Your guide provides installation, connection, and mounting instructions for the PRO2 product in the equipment

cabinet and illustrates the PRO2’s key features in a hardware overview.

Also provided is task-based information for working with the firmware. Step-by-step instructions are presented for

daily operational tasks on the PRO2 when using the firmware Web Interface, including GUI screen samples for

each function. If CLI is preferred, a separate chapter provides detailed command syntax and usage for every

command that can be issued on the PRO2.

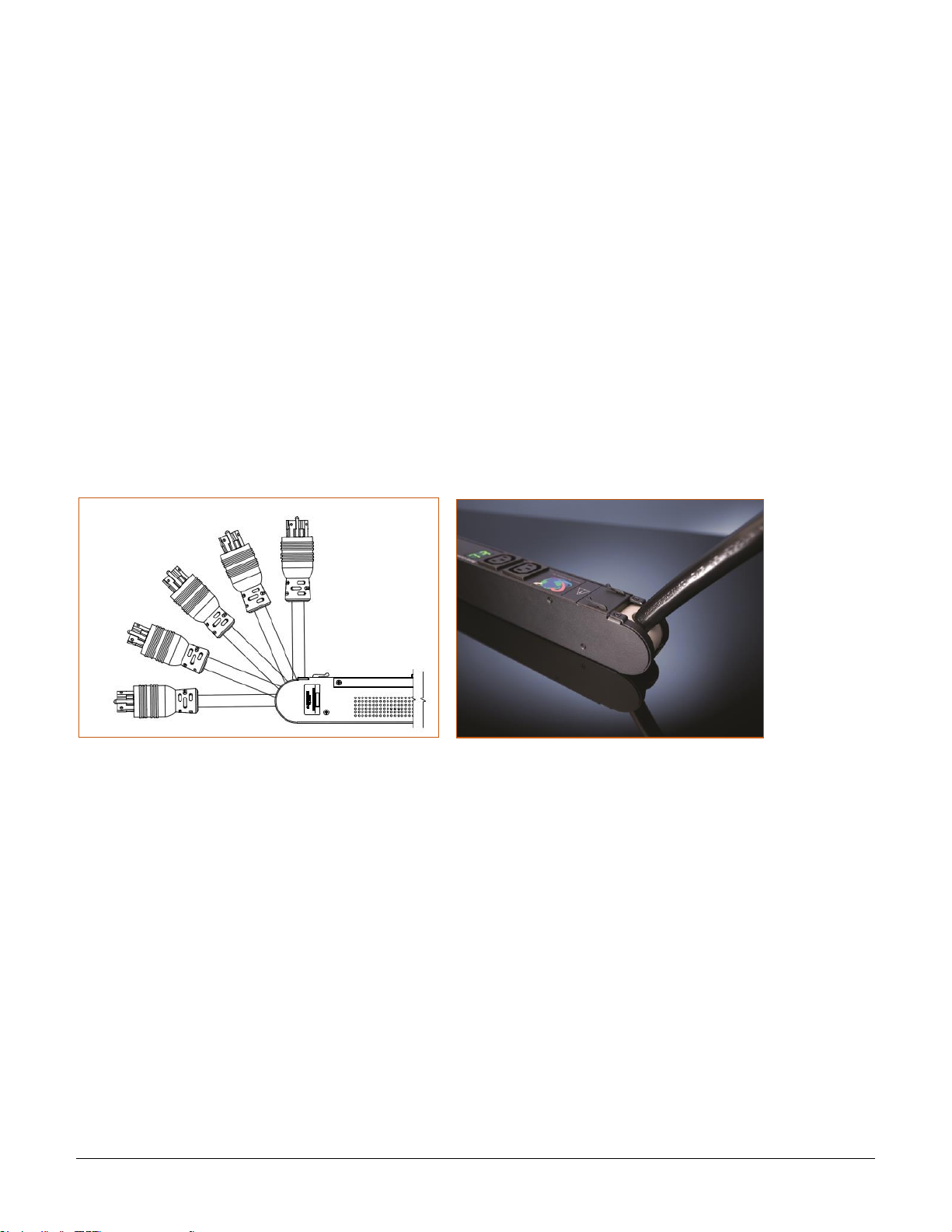

PDU Power Pivot

Server Technology’s PDU Power Pivot flexible infeed provides a simplified power cord routing to the PRO2 unit

with a design that eliminates bend radius issues.

As illustrated below, the PDU Power Pivot capability can deliver a solution for several types of PDU installations

and mountings, setting the correct cord angle for overhead power, offset overhead power, concrete floor, raised

floor, and intra-rack power.

PDU Power Pivot – Flexible Cord Design

Page 8

Switched PRO2 – User Guide

Introducing the PRO2 • 8

Star Linking Technology

Server Technology’s PRO2 introduces Star Linking technology that supports the optional linking of up to three

expansion (link) units per one PRO2 master unit, allowing a single IP address for multiple cabinets.

Note: The Star Linking feature is available only with PRO2 products.

The following illustrations show multi-linking between separate units and within the cabinet:

Multi-Linked PRO2 Units Multi-Linking View in the Equipment Cabinet

Redundant Power and Communication

The Star Linking arrangement is fault tolerant, with redundant power coming from the first link unit. The

arrangement also offers significant cost reduction as the link units do not require a network card.

Another significant advantage of Star Linking technology is that if power in the master unit is lost, communication

will continue with the other link units – a major improvement over a daisy chain linking configuration.

Outlet Grouping

The multi-linking arrangement allows outlet grouping across the master and three link units.

Cable Length

The maximum cable length allowed from link unit to master unit is 21-feet.

Multi-Linking Module

In the Star Linking arrangement, the first PRO2 link unit connects via the PRO2 link port. However, the second and

third link units in the multi-linking arrangement attach to an optional T-shaped module that connects to the

Bluetooth® port on the PRO2 master unit, while still allowing full functionality for Bluetooth® mobile power

monitoring.

Page 9

Switched PRO2 – User Guide

Introducing the PRO2 • 9

The module and its connection are illustrated as follows:

Multi-Linking Module Connection to Bluetooth® Module Port

Getting Started

The optional Star Linking feature is sold as a separate kit purchased from Server Technology. To use the feature,

contact your sales representative to order the PRO2 Multi-Linking Module Kit, part number KIT-PRO2LINK-01M.

The kit contains:

• 1 link module (labeled to show the 2nd and 3rd link unit)

• 2 linking cables, (21 ft.) 6.4 m

Unit Persistence

Unit Persistence is an internal PRO2 feature that works as follows:

If a link unit is connected to a master unit, and the link unit is disconnected (powered down or accidentally

disconnected), and the master unit is restarted, the link unit will be reported as “Not Found” after the restart

because the link unit is no longer physically connected to the master.

However, the association between the master/link units is retained to allow the continuation of alerts. If the

disconnected link unit is physically re-connected to the master, the “Not Found” status will return to “Normal” status.

To intentionally remove a link unit from connection with a master unit, the link unit must be purged using the Purge

function.

Unit persistence affects all connected PRO2 master/link units whether or not they are connected in a multi-

linking configuration.

Additional PRO2 Resources

For more information about the PRO2, including available product models and an introductory product video, see

Server Technology’s Uptime Solutions page:

http://www.servertech.com/solutions/uptime-solutions

Page 10

Switched PRO2 – User Guide

Introducing the PRO2 • 10

Contact Technical Support

Experience Server Technology's FREE Technical Support

Server Technology understands that there are often questions when installing and/or using a new product. Free Technical

Support is provided from 8 a.m. to 5 p.m. PST, Monday through Friday. After-hours service is provided to ensure your

requests are handled quickly no matter what time zone or country you are located in.

Server Technology, Inc.

1040 Sandhill Drive Tel: 1-800-835-1515 Web: www.servertech.com

Reno, Nevada 89521 USA Fax: 775-284-2065 Email: support@servertech.com

Page 11

Switched PRO2 – User Guide

Introducing the PRO2 • 11

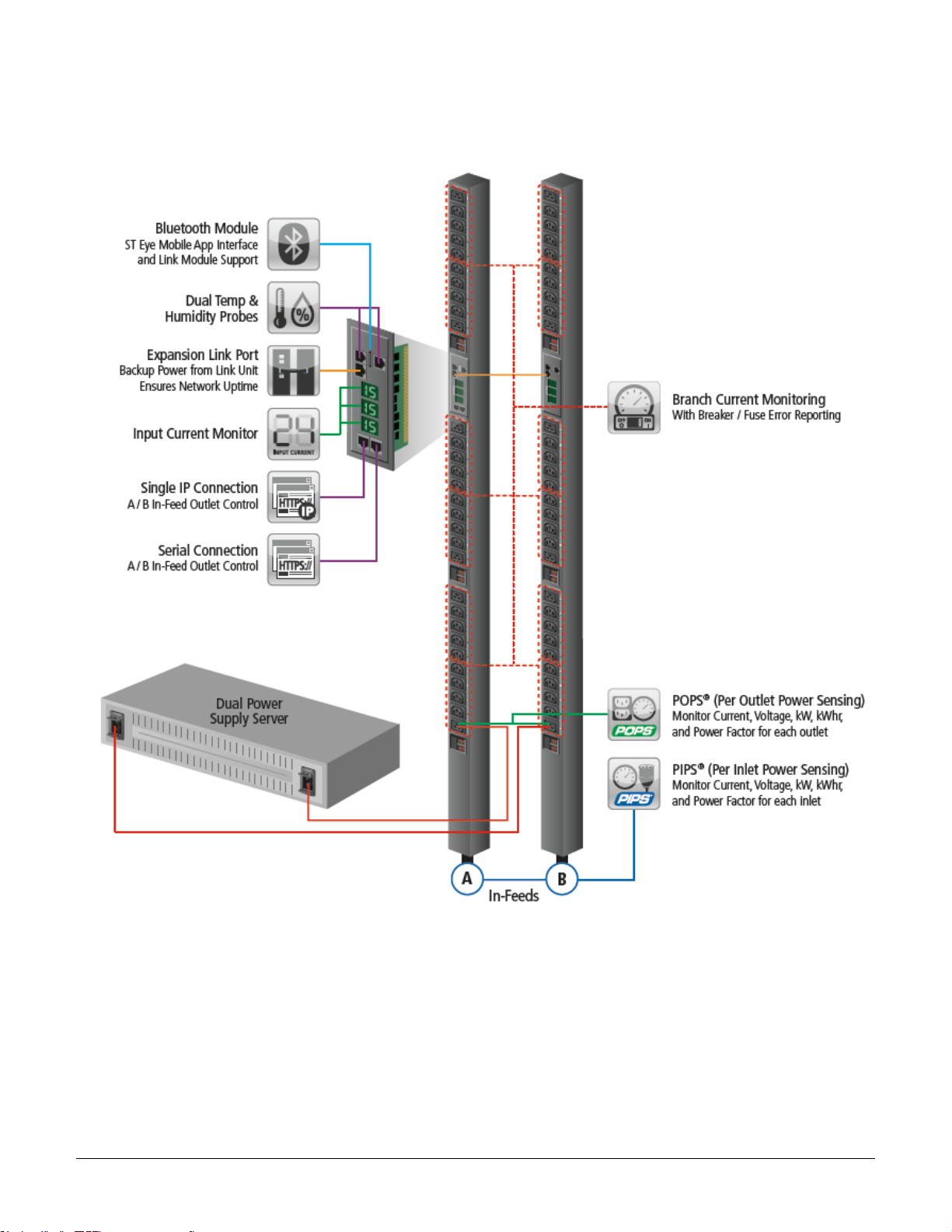

Equipment Overview

The following illustration highlights the key operational areas of the Switched PRO2 unit:

Switched PRO2 – Equipment Overview

Page 12

Switched PRO2 – User Guide

Installing the PRO2 • 12

Chapter 2: Installing the PRO2

Before installing your Switched PRO2 unit, look over the following lists to make sure you have all the items shipped

with the unit, as well as any other items needed for proper installation.

Standard Accessories

Mounting Hardware

• Vertical Models: Two mounting buttons with two M4 (10 mm) screws.

• Horizontal Models: Two removable L-brackets with four M4 screws (for 1U models),

or M5 screws (for 2U models).

Cables/Adapters

• For C2L, C2LG, C2X, C2XG, or SEV models – link cables (6P6C connectors).

• Link units are shipped with a 7-inch link cable and a 14-foot link cable.

Additional Items

• Units with IEC C20 power inlets: input power cords (ordered separately).

Optional Accessories

• Star-Link Module Kit (Part No. KIT-PRO2LINK-01M).

• Temperature/Humidity Sensors (Part No. EMTH-1-1).

• Environmental Monitor (Part No. EMCU-1-1B).

• Water Sensor (Part No. EMWS-1-1, used with EMCU-1-1B).

• Vertical mounting brackets; additional mounting options are available in the Accessories section of

www.servertech.com.

Additional Required Items

• Flathead and Phillip screwdrivers.

• Screws, washers, and nuts to attach the PRO2 unit to your equipment rack.

Page 13

Switched PRO2 – User Guide

Installing the PRO2 • 13

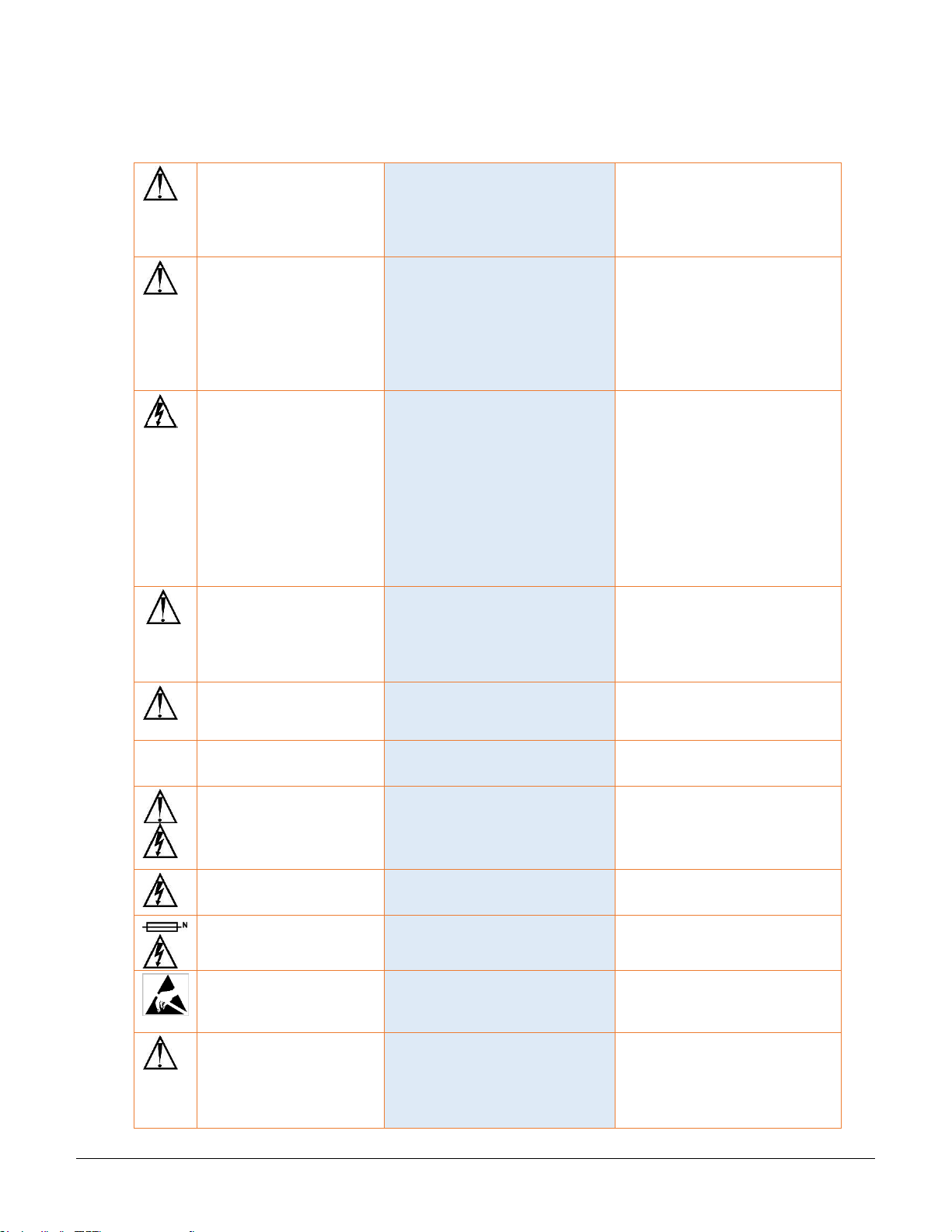

Safety Precautions

This section contains important safety and regulatory information that must be reviewed before installing and

using the Switched PRO2.

Only for installation and use in a

Restricted Access Location in

accordance with the following

installation and use instructions.

This equipment should only be

installed by trained personnel.

Destiné à l'installation et l'utilisation dans le

cadre de Restricted Access Location selon

les instructions d'installation et d'utilisation.

Cet équipement est uniquement destiné

à être installé par personnel qualifié.

Nur für Installation und Gebrauch in

eingeschränkten Betriebszonen gemäß der

folgenden Installations-und

Gebrauchsanweisungen.

Dieses Gerät ist nur für den Einbau

durch Personal vorgesehen.

This equipment is designed to be

installed on a dedicated circuit.

The power supply cord shall be a

minimum of 1.5m (4.9ft) and a

maximum of 4.5m (15ft). If using

an extension power cord, the total

length shall also be no more than

the maximum allowed. The plug is

considered the disconnect device

and must be easily accessible.

Cet équipement a été conçu pour être

installé que un circuit dédié. Le cordon

d’alimentation doit être d’au moins 1,5M et

un maximum de 4,5m. Si vous utilisez un

cordon de rallonge, la longueur totale est

également plus que le maximum autorise.

La prise est considérée comme un

dispositif de coupure et doit être facilement

accessible.

Die Geräte sind für eine Installation an

einer fest zugeordneten Leitung ausgelegt.

Die Stromzuleitung hat eine Mindestlänge

von 1,5m, und hochstens 4,5m. Sollten Sie

ein Verlangerrungsnetzkabel, der

Gesamtlange auch nicht mehr als die

maximal zulassige sein. Der Stecker dient

zur Trennung vom Netz und muss einfach

erreichbar sein.

The dedicated circuit must have

circuit breaker or fuse protection.

PDUs have been designed without

a master circuit breaker or fuse to

avoid becoming a single point of

failure. It is the customer’s

responsibility to provide adequate

protection for the dedicated power

circuit. Protection of capacity equal

to the current rating of the PDU

must be provided and must meet

all applicable codes and

regulations. In North America,

protection must have a 10,000A

interrupt capacity.

Le circuit spécialisé doit avoir un disjoncteur

ou une protection de fusible. PDUs ont été

conçus sans disjoncteur général ni fusible

pour éviter que cela devient un seul endroit

de panne. C’est la responsabilité du client

de fournir une protection adéquate pour le

circuit-alimentation spécialisé. Protection de

capacité équivalant à la puissance de

l'équipement, et respectant tous les codes

et normes applicables. Les disjoncteurs ou

fusibles destinés à l'installation en Amérique

du Nord doivent avoir une capacité

d'interruption de 10.000 A.

Der feste Stromkreis muss mit einem

Schutzschalter oder einem

Sicherungsschutz versehen sein. PDUs

verfügt über keinen Hauptschutzschalter

bzw. über keine Sicherung, damit kein

einzelner Fehlerpunkt entstehen kann. Der

Kunde ist dafür verantwortlich, den

Stromkreis sachgemäß zu schützen. Der

Kapazitätsschutz entspricht der aktuellen

Stromstärke der Geräte und muss alle

relevanten Codes und Bestimmungen

erfüllen. Für Installation in Nordamerika

müssen Ausschalter bzw. Sicherung über

10.000 A Unterbrechungskapazität

verfügen.

Models with unterminated power

cords: Input connector must be

installed by qualified service

personnel. Input connector rating

must meet all applicable codes and

regulations.

Modèles avec cordons d'alimentation non

terminées: Le connecteur d’entrée doit être

installé par un personnel qualifié. Entrée

cote de raccordement doit respecter tous

les codes et règlements électriques

applicables.

Modelle mit nicht abgeschlossenen

Netzkabel: Der Eingangsstecker darf nur

von qualifiziertem Wartungspersonal

installiert werden. Eingangsanschluss

Bewertung müssen alle geltenden und

verbindlichen Normen und Vorschriften

entsprechen.

Do not block venting holes when

installing this product. Allow for

maximum airflow at all times.

Ne bloquez pas les orifices d'aération lors

de l'installation de ce produit. Permettre une

circulation d'air maximale à tout moment.

Achten Sie darauf, dass keine

Belüftungslöcher bei der Installation dieses

Produkts. Damit für maximalen Luftstrom

zu allen Zeiten.

Installation Orientation: Vertical

units are designed to be installed

in vertical orientation.

Installation Orientation: Les unités vertical

sont conçues pour être installées dans une

orientation verticale.

Installationsausrichtung: Vertical Einheiten

sind zur vertikalen Installation vorgesehen.

Always disconnect the power

supply cord before servicing to

avoid electrical shock. For

products with two input power

cords, both must be disconnected

before servicing.

Toujours débrancher le cordon

d'alimentation avant de l'ouverture pour

éviter un choc électrique. Pour les produits

avec deux cordons d'alimentation d'entrée,

les deux doivent être déconnectés avant

l'entretien.

Trennen Sie das Netzkabel, bevor Sie

Wartungsarbeiten Öffnung einen

elektrischen Schlag zu vermeiden. Für

Produkte mit zwei Eingangsstromkabel,

sowohl, müssen vor der Wartung

abgeschaltet werden.

WARNING! High leakage current!

Earth connection is essential

before connecting supply!

ATTENTION! Haut fuite très possible! Une

connection de masse est essentielle avant

de connecter l’alimentation !

ACHTUNG! Hoher Ableitstrom! Ein

Erdungsanschluss ist vor dem Einschalten

der Stromzufuhr erforderlich!

WARNING! Cx-xxE-x units double

pole/neutral fusing

ATTENTION! Les unités Cx-xxE-x Double

Pôle/Fusible sur le Neutre

ACHTUNG!: Cx-xxE-x Zweipolige bzw.

Neutralleiter-Sicherung

ATTENTION! Observe precautions

for handling Electrostatic Sensitive

Devices.

Attention ! Respecter les mesures de

sécurité en manipulant des dispositifs

sensibles aux décharges électrostatiques.

Achtung! Vorsichtshinweise zur

Handhabung elektrostatisch empfindlicher

Geräte beachten.

Products rated for 240/415VAC

may be fitted with a plug that is

rated for a higher voltage. Caution

must be taken to assure that the

rating of the unit and the supply

voltage match.

Les produits prévus pour 240/415VAC peut

être équipé d'un bouchon qui est conçu

pour une tension plus élevée. Des

précautions doivent être prises pour assurer

que la cote de l’unité et la tension

d’alimentation correspond.

Produkte die für 240/415VAC zugelassen

sind können mit einem Stecker der für eine

höhere Spannung ausgestattet sein.

Vorsicht ist geboten, um sicherzustellen,

dass die erlaubten Betriebswerte des

Gerätes und der Versorgungsspannung

zueinander passen.

Page 14

Switched PRO2 – User Guide

Installing the PRO2 • 14

Input Power Cord Retention Options for PRO2s with IEC C20 Inlets

Determine which Detachable Input Cord was supplied with your PRO2 unit:

For the following Detachable Input Cords with the self-locking

IEC C19 feature, follow Procedure A below.

PTCORD-L1, PTCORD-L2, PTCORD-L3, PTCORD-L5, PTCORD-L6, or

PTCORD-L7.

For the following Detachable Input Cords, follow Procedure B below.

PTCORD-1, PTCORD-2, PTCORD-3, PTCORD-4, PTCORD-5, PTCORD-6,

or PTCORD-7.

Procedure A

If the PRO2 was supplied with a Detachable Input Power Cord with a self-locking IEC C19, install it directly

into the C20 inlet.

1. Verify the Retention Bracket Assembly (part number KIT-0016) is not installed.

a. If KIT-0016 is installed, remove the two screws attaching the bracket to the IEC 60320 C20 inlet

to the enclosure.

b. Remove the Retention Bracket Assembly.

c. Re-attach the two screws to the IEC C20 and securely tighten.

2. Push the C19 from the Detachable Input Cord firmly into the C20 inlet to ensure it is properly seated.

C20 Inlet Without Retention Bracket Assembly KIT-0016 Retention Bracket Assembly

Procedure B

If the PRO2 was supplied with a Detachable Input Power Cord without the self-locking C19 feature, install

with the Retention Bracket Assembly (part number KIT-0016), followed by the power cord.

1. Remove the two screws attaching the IEC 60320 C20 inlet to the enclosure.

2. Assemble and attach the Retention Bracket to the enclosure as shown

3. Connect the power cord. Ensure the C19 is fully seated against the C20 inlet. (It may be necessary

to loosen some of the Retention Bracket Assembly screws to allow the C19 plug to be properly

installed.)

4. Tighten the Retention Bracket Assembly to restrain the power cord.

Page 15

Switched PRO2 – User Guide

Installing the PRO2 • 15

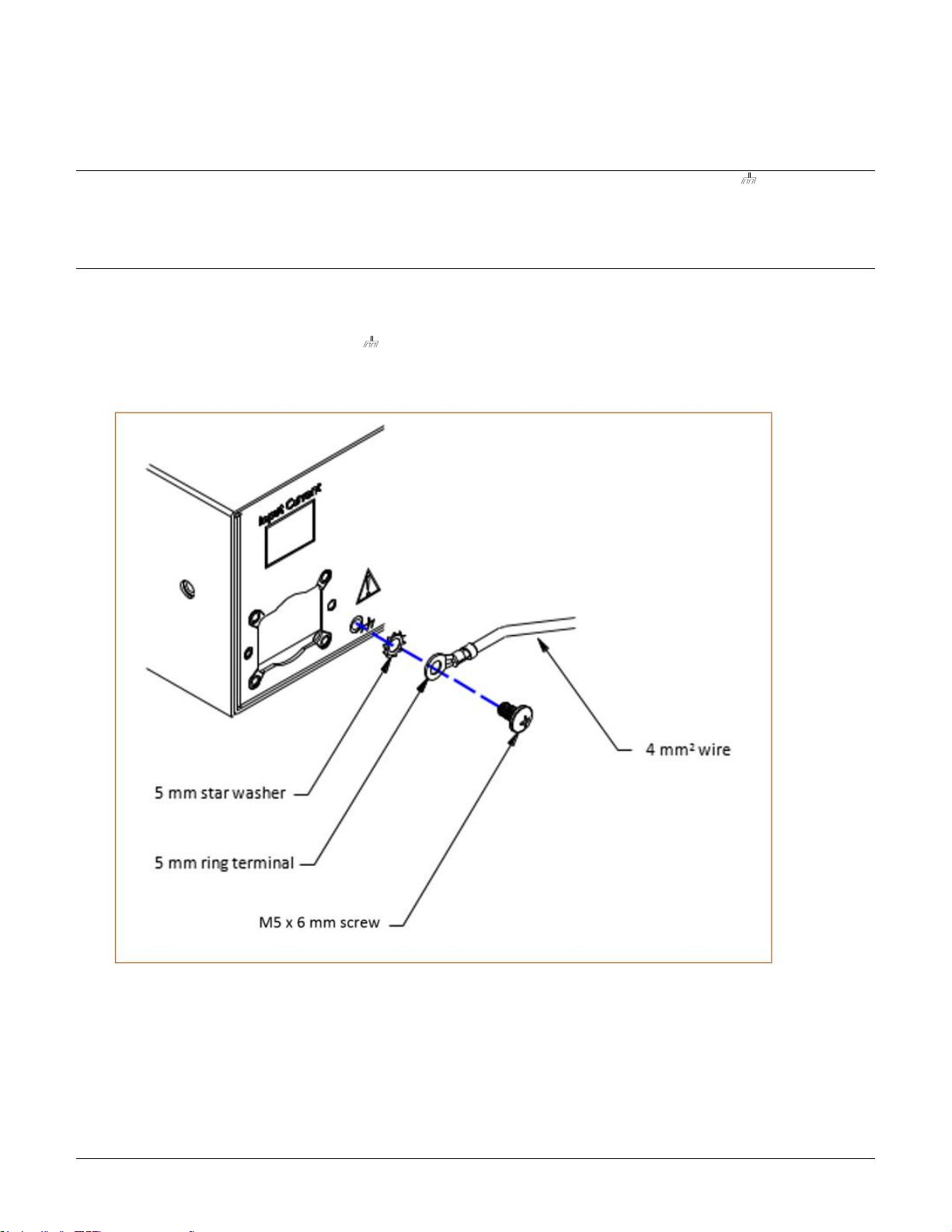

Attaching Safety Earth Ground Connection

Server Technology PDUs are supplied with an external safety ground connection to provide an alternate ground path for fault

currents, and to maintain the same ground reference between it and the equipment rack.

NOTE: The auxiliary external ground location may vary. Most PDUs will have it located near the power cord entry located near the symbol.

User-supplied materials:

• One 5 mm internal (or external) tooth star washer;

• One 4.0 mm

2

(10 AWG) wire with 5 mm ring terminal;

• One metric M5 x 6 mm coarse pitch screw.

Instructions:

1. Connect one end of the ground wire to the equipment cabinet or local ground.

2. Locate the PDU external ground near the symbol.

3. Connect the other end with a ring terminal and a M5 screw to the PDU external ground. To ensure proper grounding

to the chassis, use a star washer between the ring terminal and the PDU.

Page 16

Switched PRO2 – User Guide

Installing the PRO2 • 16

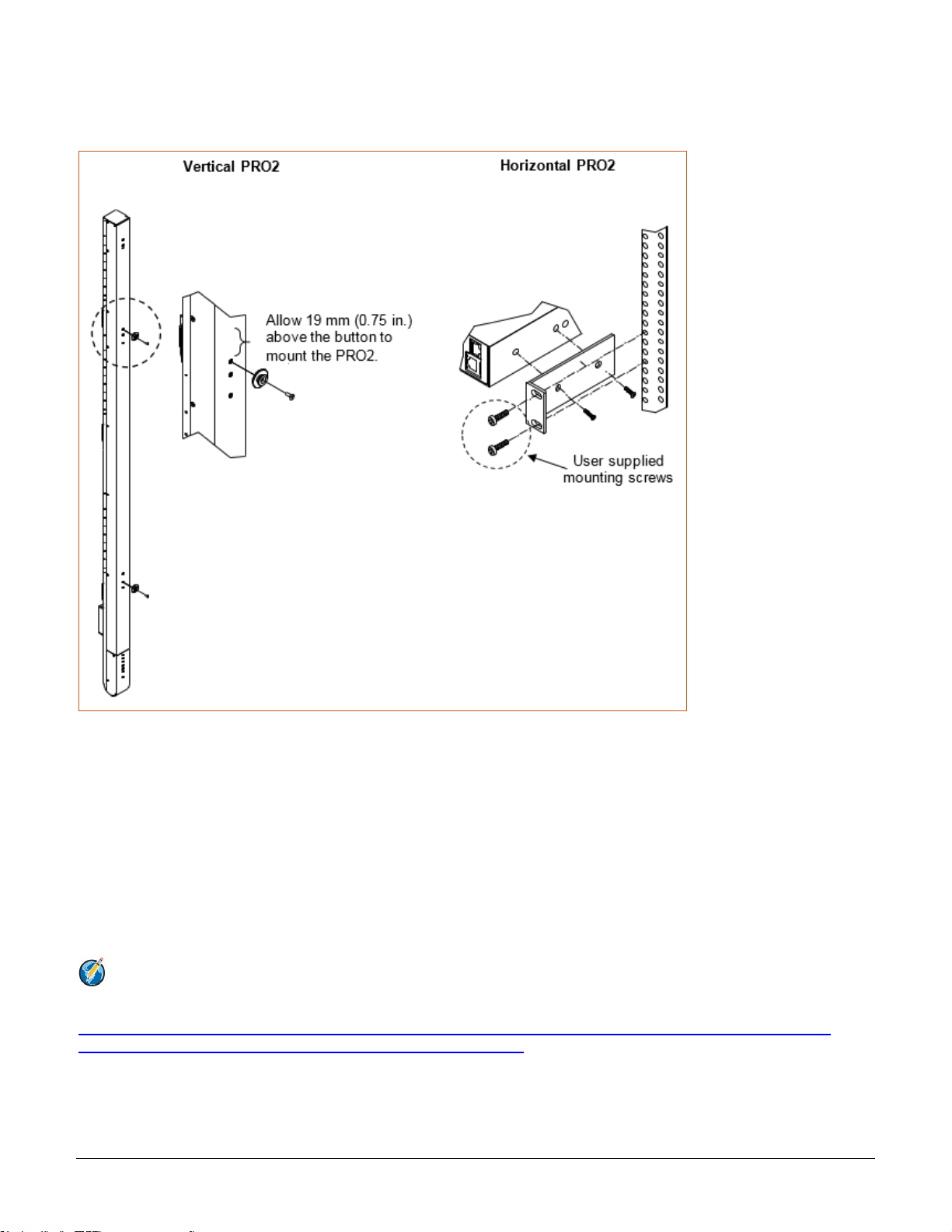

Mounting the PRO2 Unit

The following illustration shows how to mount the PRO2 unit in vertical or horizontal orientation:

Horizontal/Rack

1. Select the appropriate bracket mounting points for proper mounting depth within the rack.

2. Attach the L-brackets to these mounting points with two screws for each bracket.

3. Install the enclosure into your rack, using the slots in each bracket. The slots allow about 6 mm (0.25 inch)

of horizontal adaptability to align with the mounting holes of your rack.

Vertical

PRO2 units are supplied with button mounting kit(s). Distribute the buttons vertically and attach to the PRO2 as

appropriate for the cabinet. An additional 19 mm (0.75 inch) of clearance is required at the top of the PRO2 to allow

the button to mount into the keyholes.

Note: For more information about horizontal/vertical mounting options for the PRO2, see the Server

Technology PDU Mounting Bracket Catalog:

https://cdn10.servertech.com/assets/documents/documents/246/original/Mounting_Bracket_Catalog.2015-09-

25.pdf?1453767377#_ga=1.196494891.640622464.1488848222

Page 17

Switched PRO2 – User Guide

Installing the PRO2 • 17

Attaching the Link Unit

Connect the PRO2 link unit with the provided 6P6C crossover cable at the link port on the PRO2 unit. The overall

length of the crossover cable should not exceed 25 feet.

Connecting to the Power Source

On PRO2 units with a rating ≥ 24 A, the input power cord is attached to the base of the unit. On PRO2 units with a

total maximum output < 24 A, you may need to attach the power cord to the unit before connecting the unit to the

power source.

To attach a power cord to the unit:

1. Plug the female end of the power cord firmly into its connector on the PRO2.

2. If using the Retention Bracket Assembly (Part No. KIT-0016), use a screwdriver to tighten the two screws

on the retention bracket.

To connect to the power source:

1. Plug the male end of the power cord into the AC power source.

Connecting Devices

To avoid the possibility of noise due to arching:

1. Keep the on/off switch on the device in the off position until after it is plugged into the outlet.

2. Connect the devices to the PRO2 outlets.

Note: Server Technology recommends even distribution of attached devices across all available outlets to

avoid exceeding the outlet, branch, or phase limitations.

Always disconnect ALL power supply cords before opening to avoid electrical shock.

Afin d’éviter les chocs électriques, débranchez TOUTES les cables électrique avant d’ouvrir

Vor dem Offnen immer Netzleitung abziehen um elektrischen Schlag zu vermeiden.

Connecting the Sensors

The PRO2 is equipped with two mini RJ11 temperature/humidity ports for attachment of the temperature/humidity

sensors. Attach the mini RJ11 plug of the sensor(s) to the appropriate temperature/humidity port.

Connecting to the Unit

Connection can be made with a serial (RS232) port or with an Ethernet port, as described:

For the Serial (RS232) Port:

The PRO2 is equipped with an RJ45 serial RS-232 port – for attachment to a PC or networked terminal server –

using the supplied RJ45-to-RJ45 crossover cable and the RJ45-to-DB9F serial port adapter, as required.

For the Ethernet Port:

The PRO2 is equipped with an RJ45 10/100Base-T Ethernet port for attachment to an existing network. This

connection allows access to the PRO2 unit via Telnet or Web.

Page 18

Switched PRO2 – User Guide

Installing the PRO2 • 18

Network Defaults

The PRO2 is configured with the following network defaults to allow unit configuration out-of-the-box through either

Telnet or Web. However, note that when the PRO2 is installed on a DHCP-enabled network, the following network

defaults do not apply because the PRO2 ships with DHCP support enabled by default.

Network Defaults (for non-DHCP-enabled networks):

• IP Address: 192.168.1.254

• Subnet Mask: 255.255.255.0

• Gateway: 192.168.1.1

Reconfigure the Network Connection

A local PC network connection must be reconfigured as follows. For detailed instructions about this connection,

contact your system administrator. Note that a restart of the system may be required for the network reconfiguration

to take effect.

• IP Address: 192.168.1.x (where “x” is 2-253)

• Subnet Mask: 255.255.255.0

Page 19

Switched PRO2 – User Guide

Getting Started with the Firmware • 19

Chapter 3: Getting Started with the Firmware

This chapter introduces several key features of the firmware (version 8.0x or later) for the PRO2.

Note: Firmware, version 8.0, for the PRO2 product is not compatible with other Server Technology

Rack Power Distribution Unit products. There is no upgrade path from earlier PDI products to PRO2

products.

On-Board File System

The firmware Web Interface provides an embedded file system to give quick access to system configuration files,

as well as the on-board and downloadable Sentry4-MIB and OID Tree for the PRO2, eliminating website MIB/OID

downloads.

The page also allows GUI-based file uploads (without FTP) for system, configuration, and firmware versions.

However, all PRO2 configuration/system files, MIB, and OID Tree can also be accessed via FTP/SFTP.

Intuitive and Consistent Terminology

The design of the firmware includes intuitive and soft-mapped naming conventions between the interfaces (Web

and CLI) and the PRO2 product. For example, the firmware GUI areas (cords, lines, phases, over-current

protectors, branches, outlets, sensors, etc.) match the same areas designed in the PRO2 hardware architecture.

Outlet numbers are named 1-n sequentially and the outlet name is not tied to infeeds or branches. Input cords are

also simply named 1-n sequentially (like 1-24), no longer 1-n for each phase (like XY 1-8, YZ 1-8, ZX 1-8).

Also, firmware naming formats match the exact silkscreened names on the hardware unit.

Outlet Grouping

An outlet group is named group with a collection of PRO2 outlets assigned to the group. Outlet groups can be

granted access to selected outlets by the administrative user (via the Web interface or CLI), and outlet activity by

group can be monitored on a separate Web interface page for outlet group monitoring.

Setting Thresholds

When setting threshold values, the PRO2 firmware allows expanded alerting capabilities. Threshold values can be

set by the administrative-user for multiple low/high warning/alarm levels (and threshold hysteresis), as listed below

in the following PRO2 areas.

Every item shown in the following list – for which a threshold can be set – also has a corresponding Monitoring

page for viewing the item’s current threshold values and operational status.

• Branch current (low and high).

• Cord power (low and high), cord apparent power (low and high), cord power factor (low), 3-phase out-of-

balance (high).

• Line current (low and high).

• Outlet current (low and high), outlet power (low and high), outlet power factor (low).

• Phase voltage (low and high), phase power factor (low).

• Temperature sensor (low and high).

• Humidity sensor (low and high).

• Analog-to-Digital (ADC) sensor (low and high) – if an EMCU is connected to the PRO2 unit.

Page 20

Switched PRO2 – User Guide

Getting Started with the Firmware • 20

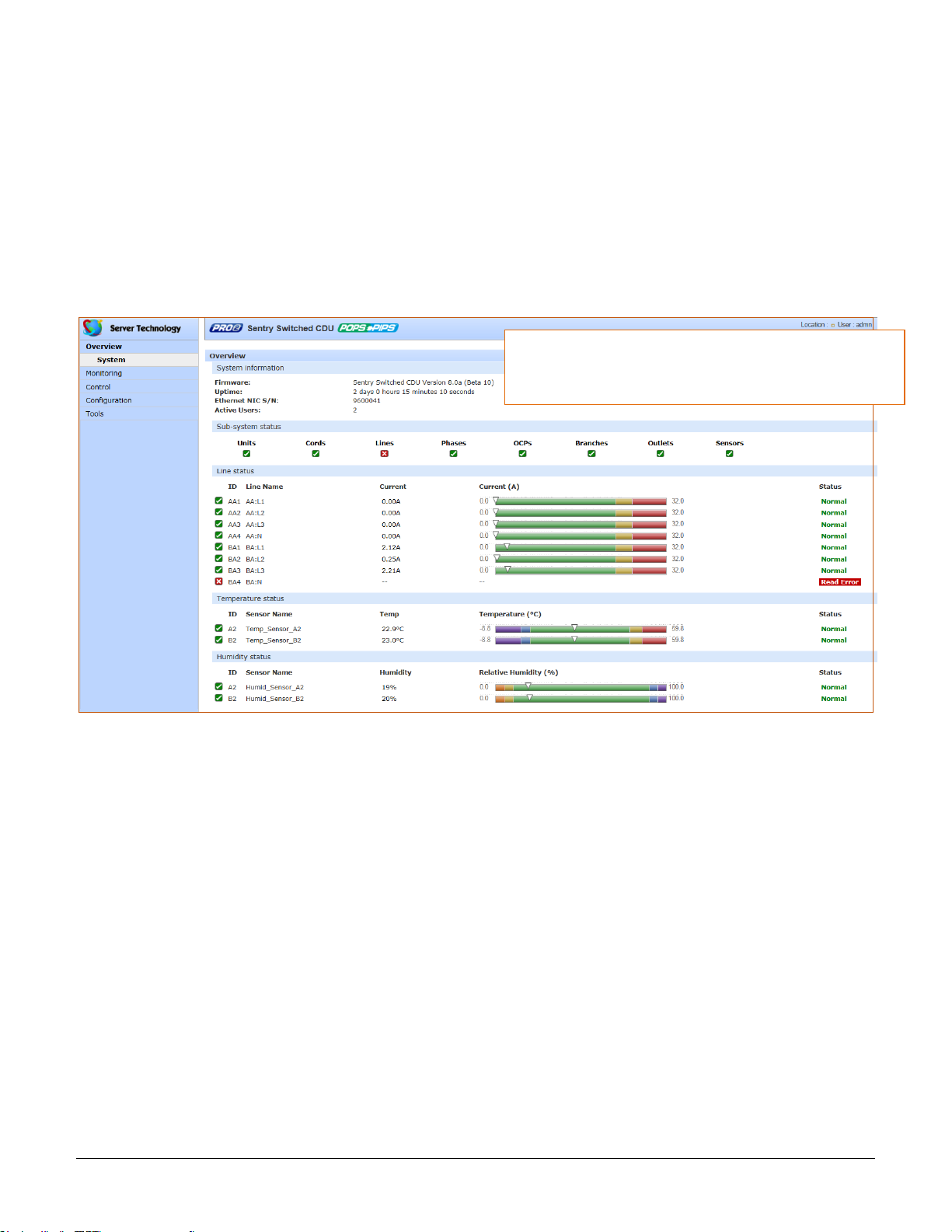

PRO2 Dashboard View

The firmware Overview > System page provides a fast and high-level view of the overall condition of the PRO2

unit. The sub-system status view shows the current operational state of individual PRO2 (units, cords, lines, etc.).

The color-coded status icon for each area is hot-linked to the corresponding monitoring page to show the operating

details behind the status, for example:

Page 21

Switched PRO2 – User Guide

Getting Started with the Firmware • 21

The User Interfaces

The Switched PRO2 offers two built-in user interfaces:

• Web interface (GUI) accessed via HTTP-enabled Ethernet connections.

• Command Line Interface (CLI) for serial and Telnet connections.

Both interfaces allow power monitoring of PIPS/POPS data points, temperature/humidity measurements,

system/network configuration, outlet control, ST Eye Bluetooth® connection, user account management, and

numerous other operations for the Switched PRO2.

Either interface can be used as preferred; most firmware operations can be performed on GUI screens or by CLI

commands on the command line. When using either interface, the availability of firmware functions for your user

login account depends on your current user access rights as granted by the system administrator.

Usernames and Passwords

The Switched PRO2 is shipped with one default administrative user account (username/password is admn/admn).

There is no “i” in the admn username or password.

Only an administrative user can manage user accounts, such as creating new user accounts, removing user

accounts, and changing user passwords.

The PRO2 supports a maximum of 112 defined user accounts with the following restrictions:

User Account

Length

Case-Sensitive

Spaces Allowed

Usernames

1-32 characters

No

No

Passwords

1-32 characters

Yes

Yes

Note: For security, Server Technology recommends first creating a new user account with administrative

rights, and then removing the default admn account.

Page 22

Switched PRO2 – User Guide

Getting Started with the Firmware • 22

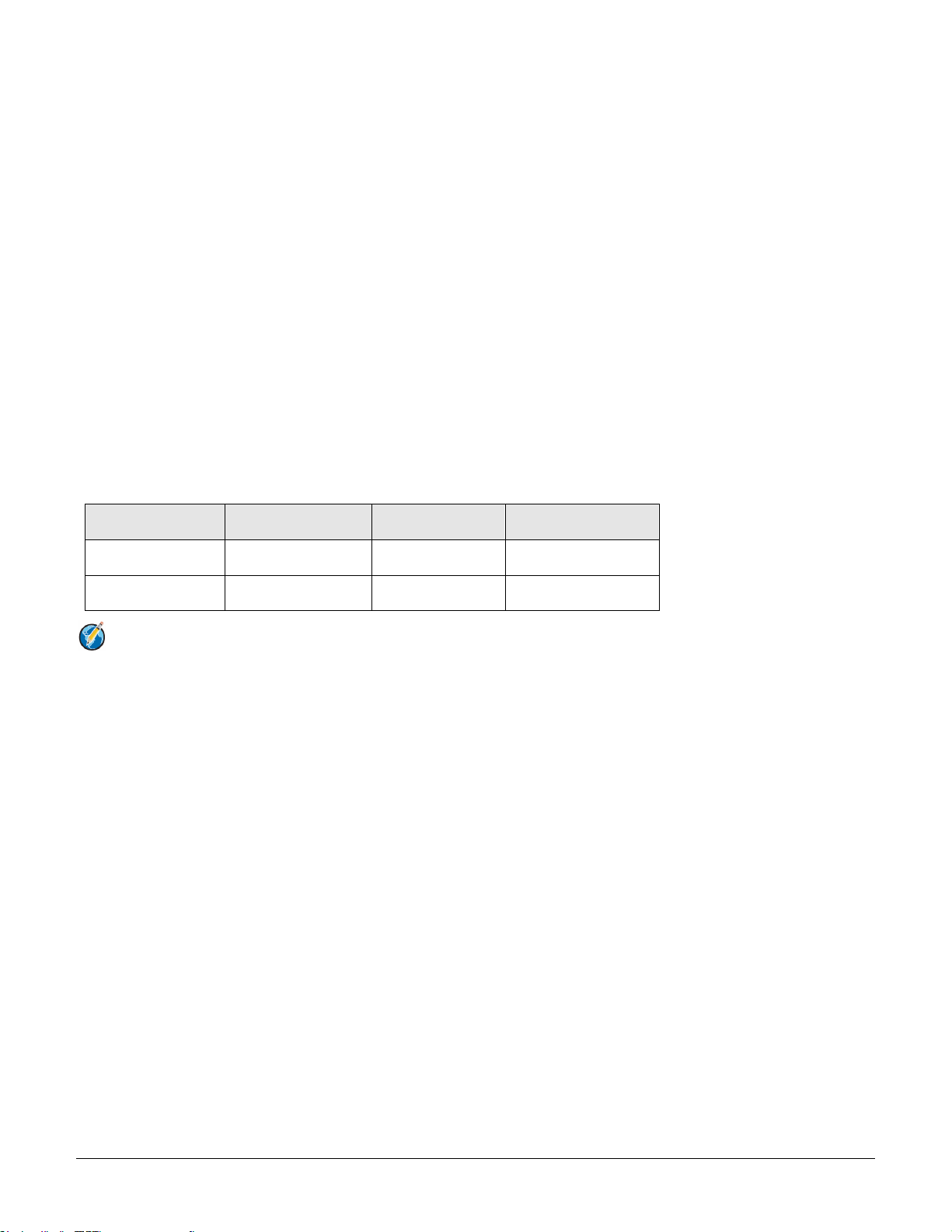

User Access Rights

The following table defines the user rights granted by the administrative user for access to PRO2 operations using

either the Web GUI or the Command Line interface (CLI). Only the options for which the user has access rights will

be available in the firmware for the user.

User Access Level

(highest to lowest)

Description

Administrator

Administrative user; full access for all configuration, user management, all outlet power control

actions (On, Off, Reboot), status, and serial/pass-thru ports.

Power User

Full access for all outlet power control actions (On, Off, Reboot), status, and serial/pass-thru

ports. Note: The Power User does not have access to user management.

User

Partial access for outlet power control actions (On, Off, Reboot), status, and pass-thru of

assigned outlets, outlet groups, and serial/pass-thru ports.

Reboot-Only User

Partial access for outlet power control actions (Reboot), status, and pass-thru of assigned

outlets, outlet groups, and serial/pass-thru ports.

On-Only User

Partial access for outlet power control actions (On), status, and pass-thru of assigned outlets,

outlet groups, and serial/pass-thru ports.

View-Only User

Partial access for status and pass-thru of assigned outlets, outlet groups, and serial/pass-thru

ports.

The administrative user can also grant administrative-level rights to other user accounts, allowing the PRO2 unit to

have more than one administrative user.

Administrative access rights cannot be removed from the default admn user account until an administrative user

grants administrative access rights to another user account.

To use administrative commands, the user must be granted administrative user access rights.

Page 23

Switched PRO2 – User Guide

Getting Started with the Firmware • 23

IPv4/IPv6 Support

Note: Throughout the Web and CLI firmware interfaces, both IPv4 and IPv6 formats are accepted

wherever a hostname or IP address is provided.

Server Technology uses IPv6 “dual stack” support in the firmware PRO2 product line. IPv6 has been designed to

succeed IPv4 as the dominant communications protocol for internet traffic, to avoid depletions of the IPv4 address

space, and to allow more IP address growth. Many devices already in use support IPv6.

IPv6 has several new operational methods:

• Static IPv6 Address: The IPv6 equivalent of Static IPv4.

• DHCPv6 Address: The IPv6 equivalent of a DHCP IPv4 address, also known as a “stateful” auto-

configuration of DHCPv6.

• IPv6 Stateless Auto-Configured Address – (RFC 4862): An automatically-generated unique link-local IPv6

address used for client based configurations. This address is always present in the Server Technology dual

stack and cannot be disabled.

• DHCPv6 Stateless Auto-Configured Address – (RFC 3736): A “stateless” Dynamic Host Configuration

Protocol (DHCP) service for IPv6 (DHCPv6). This address is used by nodes to obtain configuration

information, such as addresses of DNS recursive name servers that do not require the maintenance of any

dynamic state for individual clients.

Protocol Support for PRO2 Firmware

IPv6 and IPv4 Protocols:

The PRO2 firmware supports the following network IPv6 and IPv4 protocols:

• DNS Ping

• FTP (or SFTP) Server SNMPv1/2/3

• FTP (or SFTP) Updates SNTP

• HTTP or HTTPS

• SMTP

• Static IPv6 DHCPv6 (stateless and stateful)

• Syslog SNMPv1/2/3 Traps

• Telnet SSH

IPv4-Only Protocols:

The PRO2 firmware supports the following network IPv4-only protocols:

• Cisco EnergyWise

• LDAP

• Load Shedding *

• RADIUS *

• TACACS+

* = may work with IPv6 addresses, but not tested.

Page 24

Switched PRO2 – User Guide

Getting Started with the Firmware • 24

Network-Enabled Modes

Notes:

• For all network-enabled modes described below, the PRO2 will set an auto-configured IPv6 address, and if

IPv6 router announcements are active, a stateless DHCP IPv6 address will also be set. Further, in all

network-enabled modes, at least one IPv4 or one IPv6 address will be active.

• For maximum backward compatibility, the default network mode is “IPv4 only”.

Descriptions for the network-enabled modes:

• Network disabled – No IPv4 or IPv6 addresses available.

• IPv4 only, DHCP disabled (static IPv4) – If the IPv4 Static Address and Net Mask of the PRO2 are valid,

they will be set.

• IPv4 only, DHCP enabled (DHCP IPv4) – The PRO2 will try to resolve an IPv4 DHCP address. If a DHCP

address cannot be obtained after 90 seconds, the PRO2 can: (1) optionally fall back to its static IPv4

settings, or (2) indefinitely wait to acquire an address based on DHCP configuration settings. This setting

is the default.

• Dual IPv6/IPv4, DHCP disabled (static IPv6/IPv4) – If the IPv6 Static Address and prefix of the PRO2 are

valid, they will be set. Otherwise, the PRO2 will attempt to use DHCPv6 to obtain an IPv6 address. In

addition, if the IPv4 Static Address and Net Mask of the PRO2 are valid, they will be set.

• Dual IPv6/IPv4, DHCP enabled (DHCP IPv6/IPv4) – The PRO2 will try to resolve both its IPv6 and IPv4

addresses by DHCP. If both DHCP requests are answered, the primary DNS server of the PRO2 will

become the primary IPv6 DNS server, and the secondary DNS server of the PRO2 will become the

primary IPv4 DNS server. If only one of the DHCP requests is answered, the DNS servers of the PRO2 will

map to the primary and secondary DNS server from that request. If a DHCP address cannot be obtained

after 90 seconds, the PRO2 can: (1) optionally fall back to its static IPv4 and/or IPv6 settings, or (2)

indefinitely wait to acquire an address based on DHCP configuration settings.

Page 25

Switched PRO2 – User Guide

Getting Started with the Firmware • 25

Viewing Network Status

You can obtain the IPv6 network status through the firmware Web Interface or Command Line Interface (CLI). For

the CLI, use the show network command as follows:

Switched CDU: show network

Network Configuration

State: Static IPv4 Network: Dual IPv6/IPv4

Link: Up Negotiation: Auto

Speed: 100 Mbps Duplex: Full

MAC: 00-0A-9C-60-0029

AutoCfg IPv6: FE80::20A:9CFF:FE60:29/64

IPv4 Address: 10.1.2.65 Subnet Mask: 255.255.0.0

IPv4 Gateway: 10.1.1.1

DNS1: 10.1.5.133

DNS2: 10.1.5.134

Static IPv4/IPv6 Settings

IPv6 Address: ::/64

IPv6 Gateway: ::

IPv4 Address: 10.1.2.65 Subnet Mask: 255.255.0.0

IPv4 Gateway: 10.1.1.1

DNS1: 10.1.5.133

DNS2: 10.1.5.134

DHCP Settings

DHCP: disabled

FQDN: enabled [sentry-600029]

Boot Delay: disabled

Static Fallback: disabled

Network Services

FTP Server: enabled Port: 21

FTP Updates: disabled Port: 21

SSH: enabled Port: 22 Auth: Password, Kb-Int

Telnet: enabled Port: 23

HTTP: enabled Port: 80

HTTPS: enabled Port: 443 Installed Cert: Self Generated

User Cert: Disabled Stored Files: None

User Passphrase: (none)

SNMPv1/2: enabled Port: 161 TrapPort: 162

SNMPv3: disabled Port: 161 TrapPort: 162

SPM Access: enabled

Note: The fields IPv4 Address, IPv4 Subnet Mask, IPv4 Gateway, DNS1, and DNS2 are equivalent to existing

PRO2 IPv4 settings except that current network settings and static settings are displayed separately.

This allows you to view both static configuration settings and active network settings that can be obtained

using DHCP. The DNS addresses may be in IPv4 or IPv6 (based on RFC4291) format at this time.

Page 26

Switched PRO2 – User Guide

Using the Web Interface • 26

Chapter 4: Using the Web Interface

This chapter shows how to work with the firmware GUI (version 8.0x or later) for the PRO2.

Logging In

Logging into the Web interface directs the Web client to the configured IP address of the Switched unit.

To login by Web interface

In the firmware login window, provide a valid username and password, and click OK.

If you enter an invalid username or password, you will be prompted again.

You are given three attempts for a valid username/password combination, after which the session ends and a

protected page will be displayed

Note: The default firmware username/password is admn/admn. There is no “i” in admn.

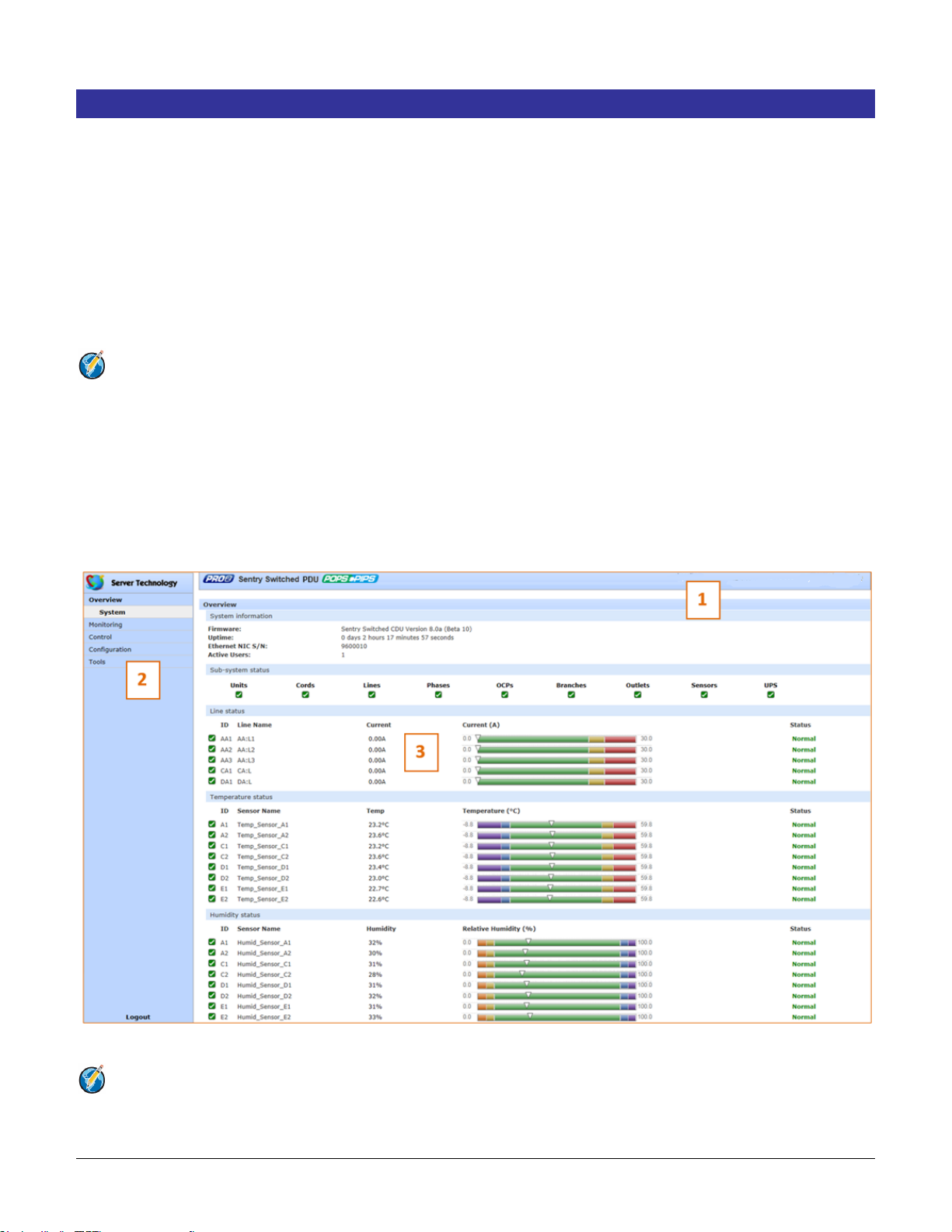

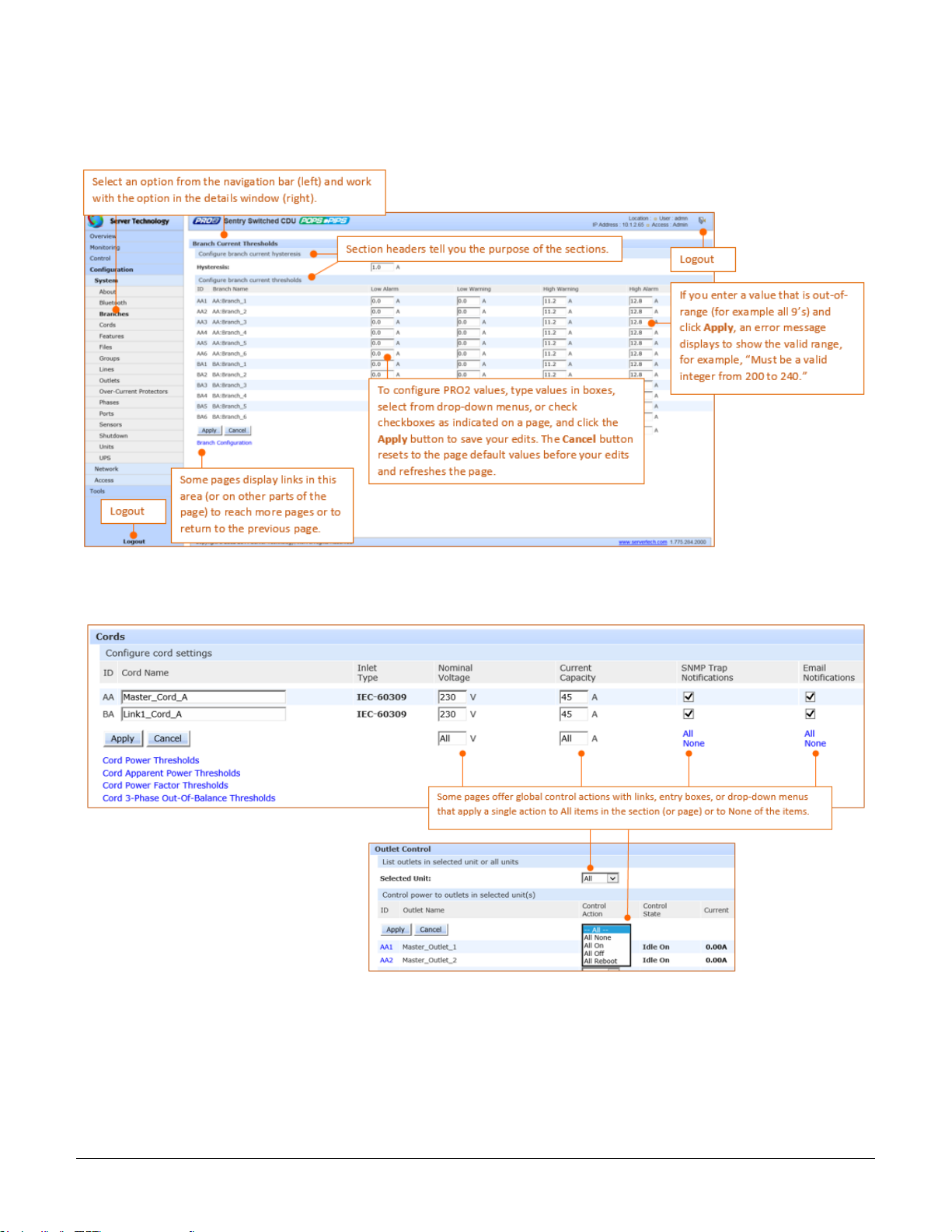

Quick Tour of the GUI

The web interface provides web-based access to the firmware for the Switched unit. The interface is designed with

three major screen sections shown in the following screen example:

1. System Header: Displays PRO2 description/location, IP address, and user/access level.

2. Navigation Bar: Provides access to PRO2 power monitoring, control actions, and configuration.

3. Details Window: Shows control/status information based on option selected in navigation bar.

Example of PRO2 Firmware Web Interface: Overview > System Page

Note: The optional blinking PRO2 location string (IP address) in the System Header may not work with all web

browsers.

Page 27

Switched PRO2 – User Guide

Using the Web Interface • 27

Working with the Pages

Using a configuration page:

Using the All or None global action:

Page 28

Switched PRO2 – User Guide

Using the Web Interface • 28

Summary of the GUI Options

Overview

The Overview > System option is the first stop for high-level and fast monitoring of major PRO2 operational areas.

The page displays a quick view of color-coded icons showing current status of the units, cords, branches, lines,

phases, sensors. Click an icon for the related monitoring page to view the metrics behind the status.

The System page also shows color-coded graphs for the operational status of line current and

temperature/humidity sensor readings.

General system information displays on the page to show firmware version in use, uptime data, Ethernet NIC serial

number, and current number of active users.

The System page dynamically updates status and threshold values with a full-screen refresh to reflect the latest

PRO2 details for instant assessment and response.

Monitoring

The Monitoring option provides viewing of dynamically updated metrics for the PRO2 operational areas that have

the highest power impact on the unit and the data center.

The design of the GUI monitoring pages follows the major areas in the hardware architecture of the PRO2,

providing a separate and detailed page for the overall status of units, cords, lines, OCPs, branches, outlets, groups,

and sensors.

Each system object for which a threshold can be configured – such as line current and phase voltage – has a

corresponding monitor page that displays up-to-the-minute power metrics.

Many metrics are presented on the pages in color-coded graphs for at-a-glance monitoring. A regular full-page

refresh dynamically updates theses details to reflect the current condition of the PRO2, providing the opportunity for

instant assessment and fast response to critical system issues.

Control

The Control option allows the issuing of control actions On, Off, and Reboot for all PRO2 individual outlets, global

outlets, and named outlet groups.

Outlet details are also available by individual outlet to provide the outlet’s general identification, socket type,

capacity, operational state, power factor, as well as color-coded graphs for current and power.

A PRO2 unit with Per Outlet Power Sensing (POPS) technology will also display values for current capacity used

and reactance.

Configuration

The Configuration option allows administrative access to all options for setting PRO2 values. The pages are

organized into three major areas of configuration:

• System (options for PRO2 hardware areas)

• Network (options for setting up network protocols)

• Access (options for local/remote user access and management)

Page 29

Switched PRO2 – User Guide

Using the Web Interface • 29

Network

The Network option provides network setup options for the protocols supported by PRO2: DHCP/IP, Email/SMTP,

FTP/SFTP, HTTP/HTTPS, LDAP, RADIUS, SNMP, SNTP, Syslog, TACACS+, and Telnet/SSH. The Network

option only allows the administrator to set up network protocol parameters. To configure how the PRO2 user uses

the network and system, see the Access option.

Access

The Access option determines how a PRO2 user works with the network and system by configuring the options

related to a user: authentication, privilege levels, user access to the unit, and additional functions for individual local

users and user groups. The Access option only allows the administrator to determine how the PRO2 user uses the

network and system. To set up network protocol parameters, use the Network option.

Tools

The Tools option is a collection of several utility options for miscellaneous system actions: changing user password,

pinging other network devices, viewing the system/debug log, and uploading new firmware versions. Also included

are several options for rebooting the PRO2, resetting the PRO2 to factory defaults, and restarting the PRO2 with

user preferences.

Page 30

Switched PRO2 – User Guide

Using the Web Interface • 30

Overview (Viewing the System Dashboard)

The System page of the Web interface is the first stop for high-level and fast monitoring of major PRO2 operational

areas. The page displays a quick view of color-coded icons showing current status of the units, cords, branches,

lines, phases, sensors. Click an icon for the related monitoring page to view the metrics behind the status.

The System page also shows color-coded graphs for the operational status of line current and

temperature/humidity sensor readings.

General system information displays on the page to firmware version in use, uptime data, Ethernet NIC serial

number, and current number of active users.

The System page dynamically updates status and threshold values with a full-screen refresh to reflect the latest

PRO2 details for instant assessment and response.

How to Read the Metrics

The color-coded status icons and graphs on the System page update dynamically (normal-green, warning-yellow,

critical-red) with the latest metrics of the unit, line status, and temperature/humidity sensor status.

About Auto-Scaling

The displayed graphs reflect the internal function of auto-scaling. This means that if the threshold range of values

changes for the graph, the graph will auto-scale to the appropriate range, allowing the graphs to still present

relevant and consistent information.

What To Look For

The dynamic performance of the System page is essential for monitoring new PRO2 installation or watching for

power distribution changes in hi-density environments. High-level status information on the System page gives the

chance to correct of an operating condition before it affects the entire device network.

System administrators and power users can also view the System graphs to quickly identify thermal and humidity

issues that might otherwise escalate to infrastructure repairs if left unchecked.

The sub-system icons across the page match the left-pane

Monitoring options. Click either the icon name or select a

monitoring option to display the related monitoring page.

Page 31

Switched PRO2 – User Guide

Using the Web Interface • 31

Overview > System Page Definitions

The System page uses the following fields and definitions:

Field

Description

ID

System-assigned internal name that cannot be changed.

Name

User-defined descriptive name for each line or temperature/humidity sensor.

Current, Temp,

Humidity

Current state of the reported input load (in amps), current temperature (temperature scale C

F, as configured), or current percent of relative humidity (%RH).

Low Limit

User-defined low limit of the load, temperature, or humidity graph. These values depend on

the sensor limitation and cannot be set by the user. For example, a 0ºC low limit would be

displayed as 0 for a temperature sensor graph in Celsius.

High Limit

Displays the high limit of the load, temperature, or humidity graph. For the

temperature/humidity sensors, these values depend on the physical sensor limits and cannot

be set by the user. For example, a 100ºC high limit would be displayed as 100 in the high limit

in a (Celsius) temperature sensor graph.

Sensor Graph and

Level Indicator

The horizontal sensor graph shows current operating conditions with color-coded icons,

described in the following table, Status Icons and Descriptions”. The level indicator

appears in the graph to indicate relative position of the current data value with respect to the

minimum (low limit) and maximum (high limit) values displayed at the left end and right end of

the graph.

Status Icons and Descriptions

The System page uses the following icons to report current operating conditions:

Icon

Status

Description

Reading

Unit is reading a new or restored sensor.

Normal

Normal operation.

Low/High Warning

Current value outside user-configured threshold range.

Low/High Alarm

Current value outside user-configured threshold range.

Lost

Connection has been lost to a sensor that was previously detected.

Read Error

Error polling data from the PRO2.

Page 32

Switched PRO2 – User Guide

Using the Web Interface • 32

Sensor Graph Color-Coding

The sensor graph colors change dynamically to communicate operating conditions:

For Line (Load) Status:

Green = Normal

Yellow = low warning/high warning (threshold configured by user)

Red = low alarm/high alarm (threshold configured by user)

Configure line current thresholds and threshold hysteresis at Configuration > System > Lines.

For Temperature Status:

Violet = coldest; low alarm (threshold configured by user)

Blue = cold; low warning (threshold configured by user)

Green = acceptable temperature range

Yellow – warm; high warning (threshold configured by user)

Red = hot; high alarm (threshold configured by user)

Configure low/high temperature thresholds and threshold hysteresis at Configuration > System > Sensors.

For Humidity Status:

Violet = wettest; high alarm (threshold configured by user)

Blue = wet; high warning (threshold configured by user)

Green = acceptable percentage of relative humidity

Yellow = dry; low warning (threshold configured by user)

Red = driest; low alarm (threshold configured by user)

Configure low/high temperature thresholds and hysteresis at Configuration > System > Sensors.

System Information

This section of the Summary page provides general information:

• Firmware: Current firmware version

• Uptime: Cumulative time the PRO2 has been up and running since the last unit restarted. Shows

continuous, real-time system updates with an approximate 5-second automatic refresh. A manual refresh is

not required.

• Ethernet NIC S/N: The serial number of the PRO2 derived from the Ethernet NIC.

• Active Users: Number of active user sessions accessing the firmware. These sessions include serial,

Telnet, SSH, and Web sessions. Also shows sessions that an unauthorized user may be attempting to

access the system. The number changes instantly as the number of active user sessions changes. A total

of 4 concurrent web user sessions are allowed (HTTPS or HTTPS).

Note: Depending on the web browser, multiple web accesses from the same machine are often

considered as one active user.

Page 33

Switched PRO2 – User Guide

Using the Web Interface • 33

Sub-System Status

This Sub-System section of the Summary page provides a quick status view of the current operational state of

major PRO2 areas (units, cords, branches, etc.) showing a color-coded status icon.

Also provided is a link from each of the sub-system areas to the related monitoring page:

Click the name of one of the PRO2 system areas to display

its corresponding Monitoring page.

View detailed operating status on the Monitoring page.

Page 34

Switched PRO2 – User Guide

Using the Web Interface • 34

Monitoring (Analyzing Metrics)

The Monitoring section of the Web interface provides viewing of dynamically updated metrics for the PRO2

operational areas that have the highest power impact on the unit and the data center.

The design of the GUI monitoring pages follows the major areas in the hardware architecture of the PRO2,

providing a separate and detailed page for the overall status of units, cords, lines, OCPs, branches, outlets, groups,

and sensors.

Each system object for which a threshold can be configured – such as line current and phase voltage – has a

corresponding monitor page that displays up-to-the-minute power metrics.

Many metrics are presented on the pages in color-coded graphs for at-a-glance monitoring. A regular full-page

refresh dynamically updates theses details to reflect the current condition of the PRO2, providing the opportunity for

instant assessment and fast response to critical system issues.

Monitoring > Units

The Units page is a high-level quick reference for the PRO2 units in the network, identifying the connected

master/link units (and any connected external monitoring devices), the current LED display orientation of the PRO2

units, and the overall current operational status of all units and devices.

What to look for:

The operating status of all units (master and link) should be Normal (green). The Status field reports the overall

health of the units and their connectivity, not an exceeded user-defined threshold. Depending on a yellow or red

status message, basic troubleshooting will be needed to determine the best solution for the affected unit.

Page 35

Switched PRO2 – User Guide

Using the Web Interface • 35

Monitoring > Cords

The Cords page displays cord hardware specifications, overall operational status of each cord, and individual

color-coded graphs and status for cord active power (W), cord apparent power (VA), power factor (if present), and

cord 3-phase out-of-balance level (%).

Note: The inlet type, frequency, power capacity, and energy rating of the cord were determined for the PRO2

product at factory assembly and cannot be user-edited.

What to look for:

The cord power graphs display a blinking warning (yellow) when the total input load exceeds the user-defined

threshold. If an overload occurs, a blinking error condition (red) is displayed. The unit continues to display yellow

and red states until the condition changes or the issue has been resolved.

The default input feed high load threshold is 80% of the input feed maximum load capacity.

Cord power thresholds are user-defined at Configuration > System > Cords.

Page 36

Switched PRO2 – User Guide

Using the Web Interface • 36

Monitoring > Lines

The Lines page shows overall line operational status, line load capacity, line state, and a color-coded graphic for

the current used by each line.

What to look for:

The line status and line current status should be Normal, and the line current should be operating within defined

thresholds.

The line current graph displays a blinking warning (yellow) when the total input load on an infeed exceeds the user-

defined threshold. If an overload occurs, a blinking error condition (red) is displayed. The unit continues to display

yellow and red states until the condition changes or the issue has been resolved.

The default input feed high load threshold is 80% of the input feed maximum load capacity.

The line current thresholds are user-defined at Configuration > System > Lines.

Page 37

Switched PRO2 – User Guide

Using the Web Interface • 37

Monitoring > Phases

The Phases page reports the current phase status, voltage, and power factor.

What to look for:

The phase status, voltage status, and phase power factor should be Normal, and the phase voltage and power

factor should be operating within defined thresholds.

The phase voltage graph displays a blinking warning (yellow) when the total input load on an infeed exceeds the

user-defined set threshold. If an overload occurs, a blinking error condition (red) is displayed.

The unit continues to display yellow and red states until the condition changes or the issue has been resolved. The

same color-coding applies to the phase power factor graph if the threshold is exceeded.

The default input feed high load threshold is 80% of the input feed maximum load capacity.

Phase voltage and power factor thresholds are user-defined at Configuration > System > Phases.

Page 38

Switched PRO2 – User Guide

Using the Web Interface • 38

Monitoring > Over-Current Protectors

The Over-Current Protectors (OCPs) page displays the current status, type, and current capacity (A) for any

OCPs connected to the PRO2 unit. If there are no OCPs on the unit, the OCP monitoring page will not be available.

What to look for:

The operating status of all OCPs listed should be Normal.

Page 39

Switched PRO2 – User Guide

Using the Web Interface • 39

Monitoring > Branches

The Branches page displays branch status that supports the standard Branch Current Monitoring feature of the

PRO2. Branch Current Monitoring allows the configuration of thresholds on the branch circuit to provide notification

before a breaker trips. Displayed on the page are branch current (A), percentage of current utilized, and threshold

status.

Note: The PRO2 allows the capability to load-shed based on branch current status.

What to look for:

Branch names are set internally on the PRO2 at factory assembly and cannot be changed. Branch operations

status should be Normal and branch current should be within defined thresholds. Branch threshold range values

are affected by changing the current capacity of an over-current protector (OCP).

The branch status and branch current status displays a blinking warning (yellow) and red (error condition) when a

branch exceeds the user-defined thresholds. The branch continues to display yellow and red states until the

condition changes or the issue has been resolved.

Branch current thresholds are user-defined at Configuration > System > Branches.

Page 40

Switched PRO2 – User Guide

Using the Web Interface • 40

Monitoring > Outlets

The Outlets page lists the outlets in the PRO2 unit with a quick overview of general outlet information, including

operational status based on user-configured thresholds for current, active power, and power factor.

Also displayed are the last user action (on, off, reboot) issued on the outlet (shown in the State column), and the

outlet’s last reported condition (shown in the Control State column).

The page allows a fast drill-down from the ID link for more operational data about a specific outlet in the list.

What to look for:

The operating status of all outlets should be Normal. If necessary, view operational details for an outlet. The ID and

socket type are determined at factory assembly and cannot be user-configured.

Each outlet has a unique number, and the numbering sequence of outlets is not associated with the PRO2’s branch

or phase number. For example, a 30-outlet PRO2 unit (either single-phase or 3-phase) unit will have outlet

numbers sequenced from 1 to 30.

The outlet status displays a blinking warning (yellow) and red (error condition) when an outlet exceeds the userdefined thresholds. The status continues to display yellow and red states until the condition changes or the issue

has been resolved.

A descriptive text outlet name can be configured at Configuration > System > Outlets.

Page 41

Switched PRO2 – User Guide

Using the Web Interface • 41

To view details for an outlet:

1. From the Control > Outlets page, click the ID link for any outlet in the list, such as AA2 in this example.

2. The AA2 Outlet Details page displays specific information about the selected outlet that includes capacity

and usage, along with status graphs for outlet current (A) and outlet power (W).

3. To return to the previous monitoring page, click the Outlet Monitor link.

Page 42

Switched PRO2 – User Guide

Using the Web Interface • 42

Monitoring > Groups

The Groups page shows the status of all outlets in a user-defined outlet group. An outlet group is named group

with a collection of PRO2 outlets assigned to the group.

The page also allows a fast drill-down by outlet ID for more details about the outlet.

What to look for:

The operating status of all outlets within a selected group should be Normal. If necessary, view operational details

for an outlet.

The outlet status for a group displays a blinking warning (yellow) and red (error condition) when an outlet exceeds

the user-defined thresholds. The status continues to display yellow and red states until the condition changes or the

issue has been resolved.

Creating an outlet group and assigning outlet access to the group is done at System > Configuration > Groups.

To view operational details for an outlet in an outlet group:

1. From the Groups page, select an outlet group from the drop down list.

Page 43

Switched PRO2 – User Guide

Using the Web Interface • 43

2. When you click an outlet ID link in the list, the details page for that outlet displays:

3. The AA14 Outlet Details page displays specific information about the selected outlet that includes capacity

and usage, along with status graphs for outlet current (A) and outlet power (W).

4. To return to the previous monitoring page, click the Group Monitor link.

Page 44

Switched PRO2 – User Guide

Using the Web Interface • 44

Monitoring > Sensors

The Sensors page provides a quick view of the operating status and color-coded graphic showing current

operating value of environmental sensors for temperature and humidity.

What to look for:

The operating status of all sensors should be Normal, and operating temperature or relative humidity should be

within defined thresholds.

Temperature Status

The Temperature graph displays a blinking warning or critical error whenever temperature exceeds low or high

threshold. The PRO2 continues to display the status until the condition changes or the issue has been resolved.

Temperature graph colors:

• Violet = coldest; low alarm (threshold configured by user)

• Blue = cold; low warning (threshold configured by user)

• Green = acceptable temperature range

• Yellow – warm; high warning (threshold configured by user)

• Red = hot; high alarm (threshold configured by user)

The default range of low/high temperature threshold values is -40 to 123(C°). Temperature threshold values are

user-defined at Configuration > System > Sensors.

Humidity Status

The Humidity graph displays a blinking warning or critical error whenever humidity exceeds low or high threshold.

The PRO2 continues to display the status until the condition changes or the issue has been resolved.

Humidity graph colors:

• Violet = wettest; high alarm (threshold configured by user)

• Blue = wet; high warning (threshold configured by user)

• Green = acceptable percentage of relative humidity

• Yellow = dry; low warning (threshold configured by user)

• Red = driest; low alarm (threshold configured by user)

The default range of low/high relative humidity threshold values is 0-100%RH. Humidity threshold values are userdefined at Configuration > System > Sensors.

Page 45

Switched PRO2 – User Guide

Using the Web Interface • 45

Temperature/Humidity Sensor Status

Status

Description

Found

The PRO2 found the sensor and connection is established.

Not Found

On a fresh reboot, the PRO2 does not find a sensor.

Lost The connection to a previously found sensor is now lost.

No Comm

Communication loss occurred due to a hardware issue (not loss of communication with the probes).1

1

The ENV part of the sensor supports two temperature/humidity (T/H) probes as part of the master unit, two T/H probes as part

of the link unit, and the optional EMCU-1-18 (which can support two T/H probes, four contact-closure monitoring points, and one

water sensor). The “No Comm” sensor status is not loss of communication with the probes themselves.

Page 46

Switched PRO2 – User Guide

Using the Web Interface • 46

Environmental Monitor (EMCU) Status

If an EMCU is connected to the PRO2, the Sensors pages will also include monitoring of water, contact closures,

and analog-to-digital (ADC) sensors.

What to look for:

The operating status of all sensors should be Normal and operating within defined thresholds. View the color-coded

graph showing current operating range within thresholds for the ADC.

Water and contact closure sensors can have either Normal or Alarm status – there are no other states or value

ranges.

The ADC sensors can be configured at Configuration > System > Sensors

Page 47

Switched PRO2 – User Guide

Using the Web Interface • 47

Monitoring > UPS

The UPS page identifies each UPS device connected to the PRO2 unit, displaying hostname/IP address and UPS

status.

What to look for:

Monitoring page will be blank if a UPS has not been connected to, and configured for, the PRO2. After connecting a

UPS to the unit, configure the UPS and the lines to be powered by the UPS at Configuration > System > UPS.

Page 48

Switched PRO2 – User Guide

Using the Web Interface • 48

Control (Managing Outlets)

The Control section of the Web interface allows the issuing of outlet control actions On, Off, and Reboot for

individual outlets in a master unit (or in all units), for all outlets globally in a master unit (or in all units), and for

named outlet groups.

Outlet details are also available by individual outlet to provide the outlet’s general identification, socket type,

capacity, operational state, power factor, as well as color-coded graphs for current and power.

A PRO2 unit with Per Outlet Power Sensing (POPS) technology will also display values for current capacity used

and reactance.

Control > Outlets

The Outlet Control page displays outlets assigned to the current user:

What to look for:

• Provides viewing of outlet current, power, power factor, current control state applied to the PRO2,

and status information.

• Includes an ID link for viewing detailed operational data about the outlet.