Page 1

ConserveWell

DROP-IN UNIT

MODEL: CW-DI

UNIT 87760

120V USA

UNIT 87770

120V USA

Programmable Timer

™

Thank You

...for purchasing our ConserveWell™

Drop-In Heated Utensil Holder. This unit holds

serving utensils above 140°F, keeping them

safe while saving water, energy and money.

SAVE WATER. SAVE MONEY.

Page 2

YOU MAY NEED:

Appropriate personnel and

tools to cut countertop hole(s)

SETUP

YOU WILL NEED:

Phillips-head Screwdriver

or

PRACTICE SAFETY. WASH ALL PARTS PROPERLY BEFORE USE.

See pages 8 & 9.

SELECT COUNTERTOP HOLE

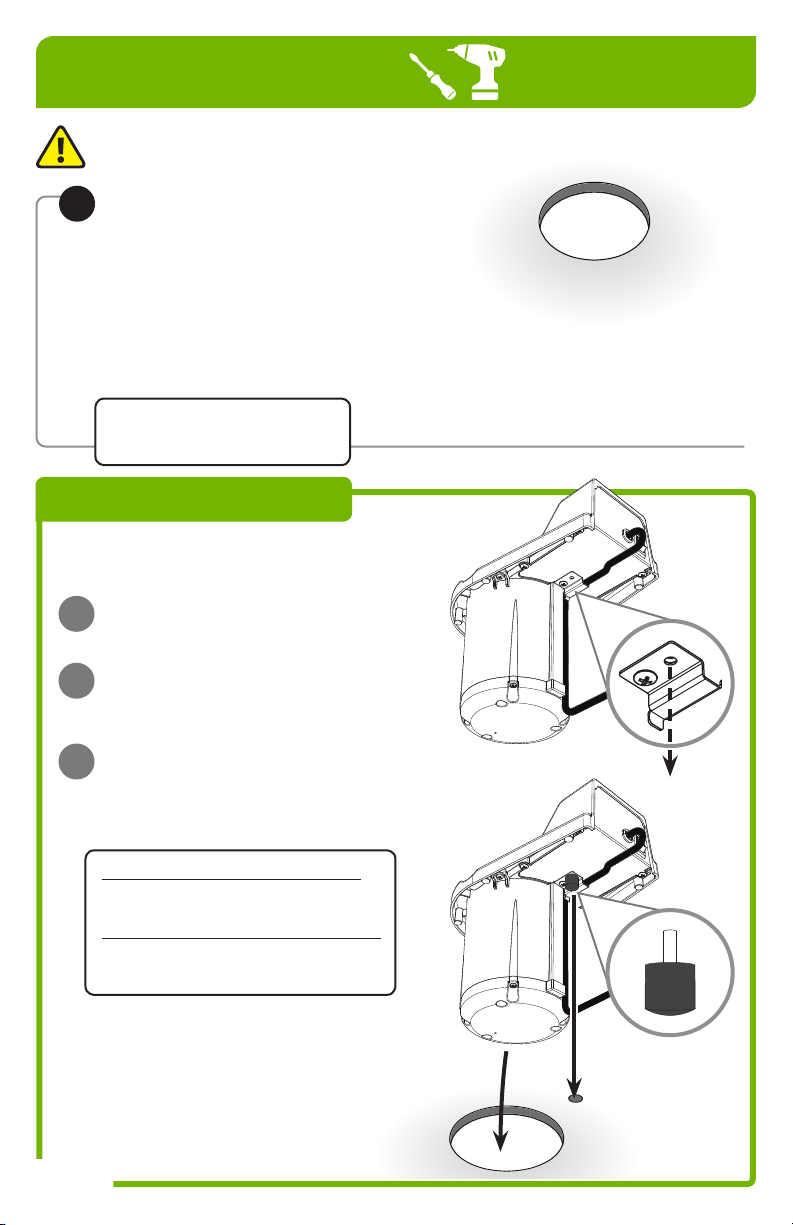

1

for unit to drop into.

Consider best placement for ease of use.

6" of clearance needed below countertop.

Ensure cord can reach power source.

EXISTING HOLE

Unit fits within countertop hole cutout

diameters 5.5"—6.5"

TIP: Unit is factory assembled to fit 6"

diameter hole. Skip steps 2 & 3 if

countertop hole is 6" wide.

OPTIONAL

ADD ANTI-ROTATIONAL FOOT

to prevent unit pivoting within countertop hole.

REMOVE OUTER SCREW

A

from cord cover.

INSERT ANTI-ROTATIONAL

B

FOOT

in place of removed screw.

DRILL FOOT HOLE IN

C

COUNTERTOP

Refer to cutout template for details.

Drill 3/4" diameter hole in countertop.

5.75"—6.5" diameter countertop holes:

Locate foot hole center 3.75"

from large countertop hole center.

5.5" up to 5.75" diameter countertop hole:

Locate foot hole center 3.5"

from large countertop hole center.

NEW HOLE

Use appropriate personnel and tools to

cut a 6" diameter hole.

See below and refer to cutout template for

details on an additional optional

anti-rotational hole.

Page 2

UNIT & ANTI-ROTATIONAL

FOOT WILL FIT INTO

CORRESPONDING

COUNTERTOP HOLES.

Page 3

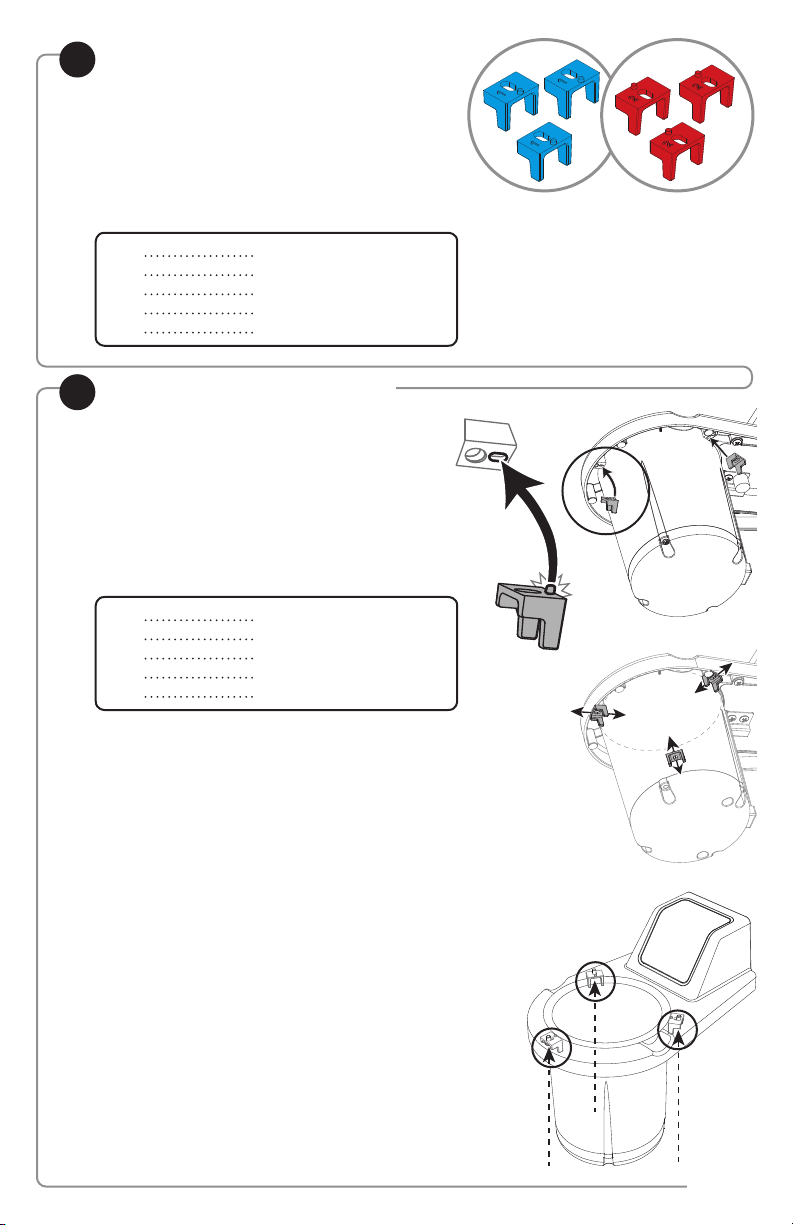

SELECT LOCATION BLOCK HARDWARE

2

to create proper fit within countertop hole.

Hole diameter determines which 3 location

blocks to use.

If size is between two listed dimensions,

refer to smaller diameter.

COUNTERTOP

HOLE DIAMETER

5.5"

5.75"

6"

6.25"

6.5"

ATTACH 3 LOCATION BLOCKS

3

to underside of rim.

Place each location block peg into slot in

underside of rim.

Slide location blocks either away from

or towards base.

Refer to chart below.

COUNTERTOP

HOLE DIAMETER

5.5"

5.75"

6"

6.25"

6.5"

LOCATION BLOCKS

No location blocks needed

BLUE, embossed with “1”

BLUE, embossed with “1”

RED, embossed with “2”

RED, embossed with “2”

LOCATION BLOCK FITTING

Remove all location blocks

BLUE, slide towards base

BLUE, slide away from base

RED, slide towards base

RED, slide away from base

Screw in each location block using 1 screw

and Phillips-head screwdriver.

Page 3

Page 4

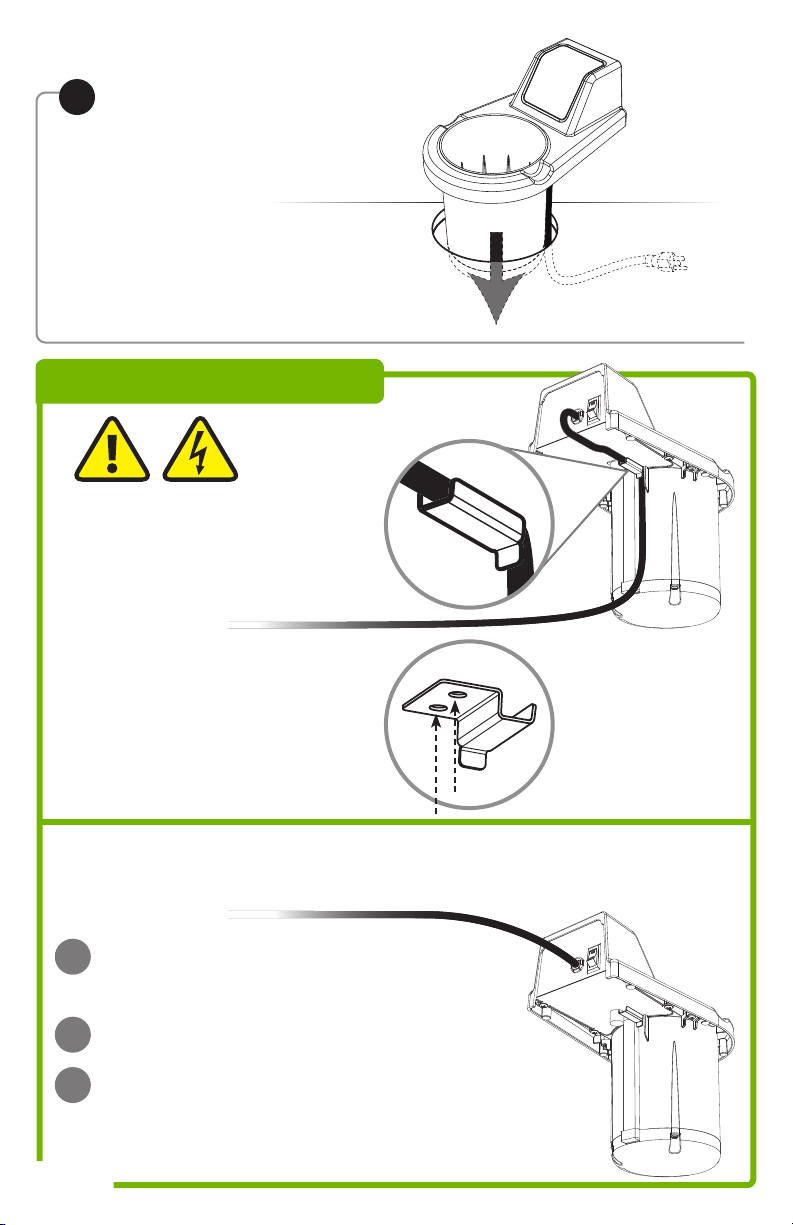

INSERT UNIT

4

and cord into countertop hole.

If outlet is above the countertop,

refer to CORD COVER instructions below.

CORD COVER

CAUTION-

PREVENT CORD DAMAGE

Secure cord within cord cover

when plug is used below counter.

USE CORD COVER WHEN

CORD IS PLUGGED IN BELOW

COUNTERTOP

Affix cord cover using 2 screws

and Phillips-head screwdriver.

A

B

C

Page 4

DO NOT USE CORD COVER

WHEN CORD IS PLUGGED IN

ABOVE COUNTERTOP

DETACH CORD COVER

Use Phillips-head screwdriver to remove

both screws.

RELEASE CORD

REATTACH CORD COVER

with both screws.

Secure onto unit in case of future need.

Page 5

INSERT WATER PAN

5

Fill 28 oz. of HOT water up to fill-line in pan.

Refer to water temperature charts below.

Insert pan of water into basin.

Pour water into pan only.

Never pour or spill water

directly into basin of unit.

NO

BE AWARE OF THE WATER TEMPERATURE

Help prevent bacteria growth. The FDA warns

that bacteria grow most rapidly in the range of

temperatures between 41°F—135°F. (5°C—57°C.)

YES

WATER HEATING TIMES

(When unit is not pre-heated)

INITIAL

TARGET TEMPERATURE

WATER

TEMP.

135°F 140°F 145°F

70°F 40 min. 45 min. 50 min.

110°F 25 min. 30 min. 40 min.

120°F 20 min. 20 min. 30 min.

130°F 15 min. 20 min. 25 min.

PLUG CORD INTO

6

POWER SOURCE

TURN UNIT ON

7

Press switch at back of unit.

PRESS RESET TO START

8

countdown cycle.

Timer is programmed

for 4 hour cycles.

WATER HEATING TIMES

(In pre-heated unit)

INITIAL

TARGET TEMPERATURE

WATER

TEMP.

135°F 140°F 145°F

70°F 30 min. 35 min. 40 min.

110°F 15 min. 20 min. 25 min.

120°F 5 min. 10 min. 15 min.

130°F 5 min. 5 min. 10 min.

Page 5

Page 6

WATER CHANGE-OUT

REMOVE & EMPTY PAN OF WATER

1

CAUTION- HOT

Unit, pan and water will be hot.

Take proper care while removing pan.

Carefully pour water down a drain.

REFILL & RETURN WATER PAN TO BASIN

2

Fill 28 oz. of new HOT water up to

fill-line in pan.

Insert pan of water into basin.

Never pour water

directly into basin of unit.

Pour water into pan only.

USING THE COUNTDOWN TIMER

Instructions for units with programmable timers.

PRESS RESET TO START COUNTDOWN CYCLE

1

Timer is factory programmed for 4 hour cycles.

When countdown timer ends:

Alarm will beep.

Display will indicate “END”

PRESS RESET TO STOP ALARM

2

To replace water BEFORE

3

4

Page 6

CHANGE OUT WATER

Complete “WATER CHANGE-OUT” steps listed above.

PRESS RESET BUTTON

to restart the countdown cycle.

countdown cycle ends,

follow steps 2—4.

Page 7

PROGRAMMING TIMER

Instructions for units with programmable timers.

SET COUNTDOWN CYCLE TIME

ENTER TIME PROGRAM MODE:

Simultaneously press and hold the

UP and RESET buttons for 10 seconds.

Red light indicates unit is in timer program mode.

SELECT DESIRED COUNTDOWN TIME:

Press the UP or DOWN buttons.

LOCK IN TIME SETTING AND EXIT

PROGRAM MODE:

Press and hold the RESET button for 3 seconds.

SET ALARM VOLUME

ENTER ALARM PROGRAM MODE:

Simultaneously press and hold the

DOWN and RESET buttons for 10 seconds.

10 SEC.

3 SEC.

10 SEC.

Beeping indicates unit is in alarm program mode.

SELECT ALARM VOLUME:

Press the UP or DOWN buttons. A beep

accompanies each level to indicate the volume

setting. Volume level is shown in display. Adjust

number to desired volume level.

LOCK IN VOLUME SETTING AND EXIT

PROGRAM MODE:

Press and hold the RESET button for 3 seconds.

UNIT TAKE-DOWN

CAUTION- HOT

Allow unit to cool first

or take proper care with hot surfaces.

PRESS SWITCH TO OFF

1

UNPLUG CORD

2

REMOVE PAN FROM BASIN

3

Pour water down a drain.

Clean pan. (See page 9.)

Dry pan fully with clean soft cloth.

VOLUME LEVELS

3- Highest volume

2- Average volume

1- Lowest volume

0- Silent (No audible alarm)

3 SEC.

Page 7

Page 8

SAFETY

WARNING-

ELECTRICAL SHOCK COULD OCCUR

This unit must be earthed or grounded.

This requires all three prongs (terminals)

on cord plug to be plugged into power source.

BE AWARE OF THE WATER TEMPERATURE

Help prevent bacteria growth. The FDA warns

that bacteria grow most rapidly in the range of

temperatures between 41°F—135°F. (5°C—57°C.)

NSF International listed.

This unit is not to be used for serving food.

Page 8

Page 9

CLEANING

WARNING-

ELECTRICAL SHOCK COULD OCCUR

YES!

Use dishwashing

soap and hot water

Pan is dishwasher safe.

• Electrical components of unit could

be damaged from water exposure or

any liquid.

• Never immerse unit into water or any liquid.

• Never use any water jet or pressure

sprayer on unit.

• Ensure unit is “OFF” and unplugged.

CAUTION- HOT

Allow unit to cool before cleaning.

CLEAN THE PAN

CLEAN

1

Wash water pan

with soap and hot water.

RINSE

2

fully with clear water.

SANITIZE

3

all parts according to local sanitization

requirements. All parts in contact with

food must be sanitized.

DRY

4

pan fully with a clean soft cloth.

CLEAN EXTERNAL

SURFACES

• Wipe daily with a clean damp cloth.

• Dry with a clean soft cloth.

• Glass and surface cleaners approved

for use in food contact areas may be used.

CARE OF STAINLESS STEEL

The water pan is constructed

of stainless steel.

If you notice corrosion beginning on any

stainless steel surface, you may need to change

the cleansing agent, sanitizing agent, or the

cleaning procedures you are using.

• A mildly abrasive nylon or brass brush may

be used to remove any stubborn deposits on

interior surfaces of unit.

• Fully rinsing and drying all parts can help

prevent corrosion. Elements and minerals in

tap water can accumulate on stainless steel

parts and create corrosion.

• Do not use abrasive, caustic or ammonia

based cleansers.

• Do not use products containing acids,

alkalines, chlorine, or salt. These agents can

corrode stainless steel.

• Do not use metal scrapers or cleaning pads

that could scratch surfaces.

Page 9

Page 10

WIRING DIAGRAM

87760

120V USA

1 2 3 476

A

B

C

8 5

Cord Assembly

1

120V

Black

A

White

B

Green

C

2 5

Bushing/Strain Relief

Rocker Switch

3 6

Wire Assembly, 18GA, Black, 4"

4 7

8

128C Pepi, Thermal Assembly, Cut-out

Wire Nut

100W Silicone Element

Wire Assembly, 18GA, Green, 14"

87770

120V USA

Programmable Timer

Cord Assembly

1

120V

Black

A

White

B

Green

C

2

Bushing/Strain Relief

Rocker Switch

3

Wire Assembly, 18GA, Black, 4"

4

128C Pepi, Thermal Assembly, Cut-out

5

Wire Nut

6

100W Silicone Element

7

Wire Assembly, 18GA, Green, 14"

8

Transformer Assembly

9

Timer Board

10

Page 10

1 2

A

B

C

RED

YELLOW

+

9

BLACK

WHITE

-

3 4 6

10

5

8

7

Page 11

TROUBLESHOOTING

UNIT DOES NOT HEAT? WATER NOT REACHING 140° F?

• Ensure cord is securely plugged in.

• Ensure power is available from source.

• Ensure unit is on.

UNIT OVERHEATING?

• Ensure water has not spilled or leaked

from pan into the basin.

CAUTION:

WATER IN BASIN MAY STEAM & BURN.

• Allow unit to cool. Pour out any water and

dry basin.

• Make sure to use HOT water in pan.

Refer to temperature charts on page 5.

• Damaged pan may not heat properly.

Inspect and replace pan if needed.

SERVER PRODUCTS

LIMITED WARRANTY

Server Products equipment is backed by a

two-year limited warranty against defects in

materials and workmanship.

For complete warranty information go to:

www.Server-Products.com

GENERAL SERVICE,

REPAIR OR RETURNS

Before sending any item to Server Products

for service, repair, or return, contact Server

Products customer service to request a Return

Authorization Number. Merchandise must be

sent to Server Products with this number. Service

is extremely prompt. Typically, units are repaired

and ship out within 48 hours of receipt.

Merchandise being returned for credit must be in

new and unused condition and not more than 90

days old and will be subject to a 20% restocking

charge. Electrical parts (thermostats, heating

elements, etc.) are not returnable.

Servicing Cord: Specific tools are required for

safe and proper power supply cord removal

and installation. If cord must be replaced, only

a representative of the OEM (original equipment

manufacturer) or a qualified technician may

replace cord. Cord must meet code designation

H05 RN-F requirements.

Page 11

Page 12

CONSERVEWELL™ DROP-IN

MODEL: CW-DI

PAN

87771

LOCATOR BLOCK HARDWARE

Two Sets Supplied:

#1 BLUE LOCATOR BLOCKS (QTY 3) 87785

#2 RED LOCATOR BLOCKS (QTY 3) 87786

CORD COVER

87795

ANTI-ROTATIONAL FOOT

81058

HELP or ORDERING REPLACEMENT PARTS

Server Products Inc.

3601 Pleasant Hill Road

Richfield, WI 53076 USA

262.628.5600 | 800.558.8722

SPSALES@SERVER-PRODUCTS.COM

Page 12

Please be prepared with your Series Number and

Description located on the back of the unit.

Individual Part Numbers listed above.

Manual #01925-RevA 090215

Loading...

Loading...