Page 1

REMOTE PUMPING SYSTEM

Stock #’s 85883, 85884, 85885, 85886

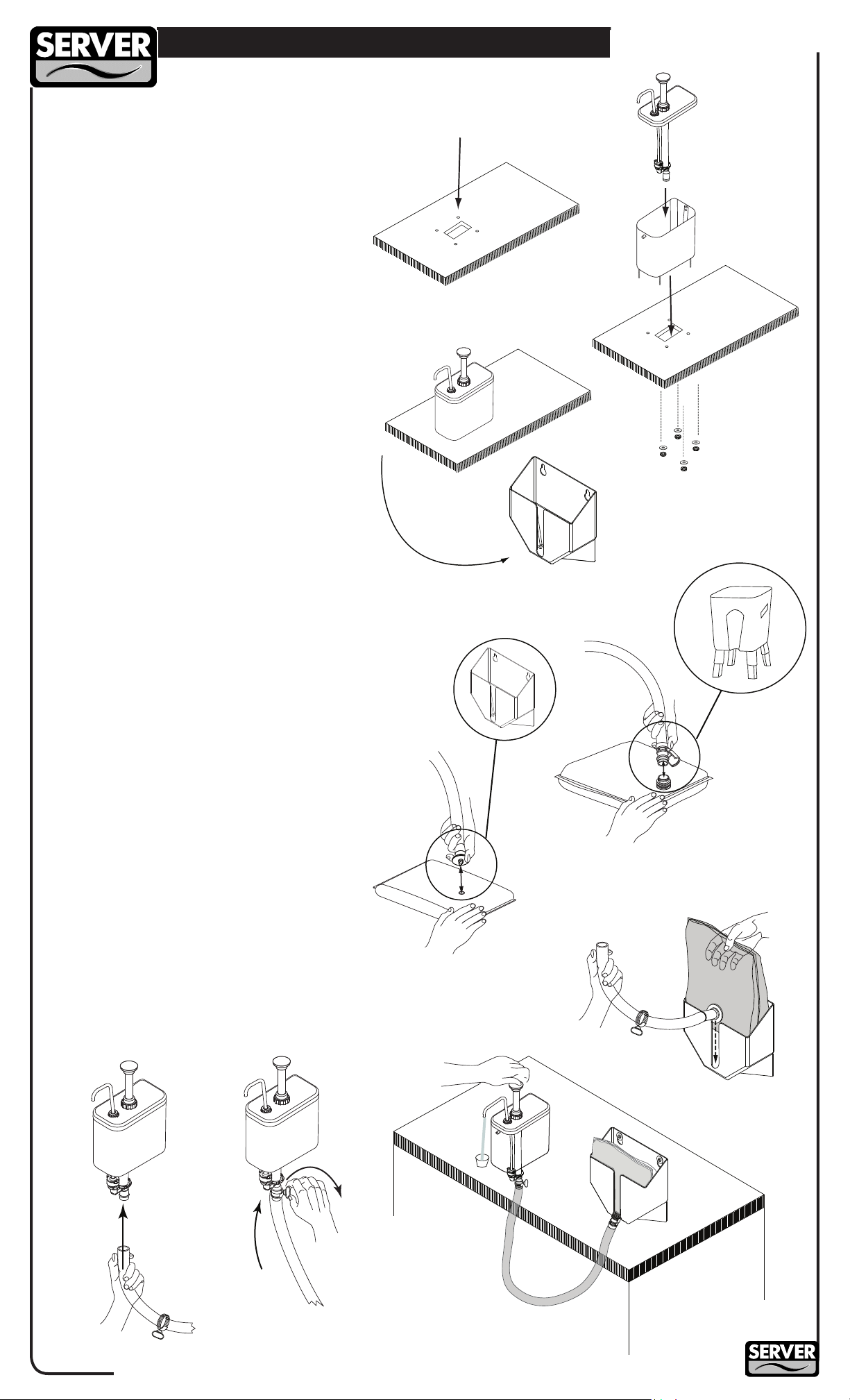

Unit installation

ALWAYS CLEAN UNIT THOROUGHLY BEFORE USE. See Cleaning and

Safety Guidelines. For assembly and cleaning of the pump see

included PUMP INSTRUCTION MANUAL.

The installation of this unit should be performed by a qualied

technician.

1 DETER M I N E W H E R E T H I S UNIT CAN B E S E C U R E LY

INSTALLED.

• Pump and pouch support can be installed on a cart or a

cabinet which can support the weight of the condiment

pouch and at a convenient height for operation of the

pump.

• Consider the length of hose and product pouch tment

needed to be attached to the pump, condiment pouch,

and pouch support. (Four different hose kits are

avaliable, see part list on opposite page.)

2 REFERING TO THE CUTOUT TEMPLATE included at the back of

the manual, drill holes for the mounting screws and cutout the

opening for the tower and pump assembly.

3 Secure the tower assembly to the countertop from underneath,

by threading a washer and then a nut to the four 2” threaded

studs supplied with the unit.

4 DROP PUMP ASSEMBLY ONTO PUMP TOWER, secure by centering

over front post and pressing in ex tabs at back of tower.

5 THE CRYOVAC POUCH SUPPORT CAN REMAIN FREE STANDING,

placed beneath the pump/tower assembly or hung on spools

included with the pouch support

THE VOLUME POUCH SUPPORT in designed to be freestanding

and placed under pump/tower assembly.

01883.REVA.030306

Series 05H

2

4

1

3

7

ConneCting Hose to ProdUCt PoUCH

6 Place condiment pouch on a counter top with pouch tment facing

upward.

NOTE: Hose can be connected or disconnected to pump when

installing product pouch.

7 See below for the hose with product pouch connector and product

support pouch that t your condiment pouch.

8 For CRYOVAC™ type product pouch install piercing connector end

of hose into condiment pouch.

9 For VOLUME type product pouch, install the hinged clip connector

to the product pouch tment.

J Lift and place condiment pouch in product pouch support with

pouch/hose connection seated in front slot.

NOTE: Make sure product pouch and hose tment assembly is seated

all the way to bottom of the pouch support slot and directed downward

for best evacuation of product.

K Reconnect hose to pump if it was removed.

ConneCting Hose & ProdUCt PoUCH to PUmP

L SLIDE END OF HOSE ONTO BODY VALVE CONNECTOR ON THE

END OF THE PUMP.

M Bring up Turn Key Clamp and rmly tighten to seal hose to Body

Valve Connector.

N FINAL ASSEMBLED VIEW. Depress head assembly to prime

pump and to Dispense Product.

5

7

Cryovac™ Hose Support Pouch

8

6

Volume Hose Support Pouch

9

6

Volume Hose Fitment & Pouch

J

K

Unit disassembly

O LOOSEN TURN KEY CLAMP and remove hose from pump.

P LIFT PROD UCT POUCH OUT OF S UPPORT. Remove pouch

connection.

Q REMOVE POUCH CONNECTION END OF HOSE FROM PRODUCT

POUCH.

M

L

Cryovac™ Hose Fitment & Pouch

N

Turn Key Clamp

800-558-8722 262-628-5600 spsales@server-products.com 7 262-628-5110

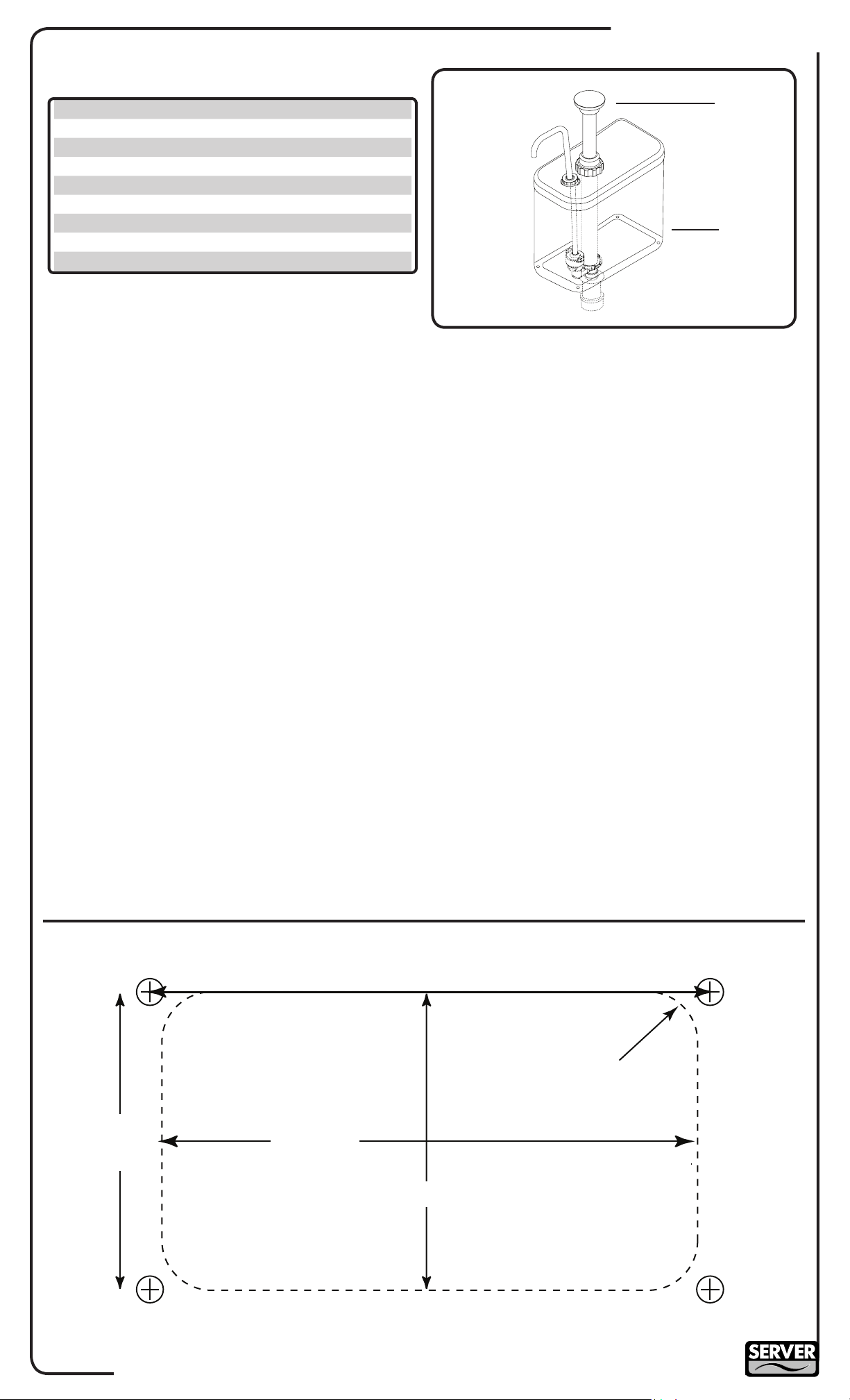

Page 2

Part # Model Description

01883.REVA.030306

85204 85883, 85884 POUCH SUPPORT, CRYOVAC*

85863 ALL TOWER ASSEMBLY, 5 1/2”

85865 ALL CONDIMENT PUMP REMOTE PUMPING

85866 85883 KIT, HOSE, 30” CRYOVAC

85868 85884 KIT, HOSE, 24” CRYOVAC

85867 85885 KIT, HOSE, 30” VOLUME

85869 85886 KIT, HOSE, 24” VOLUME

85895 85885, 85886 POUCH SUPPORT, VOLUME*

* SEE OPPOSITE PAGE

Unit Cleaning

NOTE: FOR PUMP DISASSEMBLY AND CLEANING see:

PUMP INSTRUCTION MANUAL.

CLEANING

Before rst use and after use daily, disassemble and clean unit. Stainless

steel parts can corrode. It is important to clean, rinse, sanitize, and dry these

parts daily and properly. Failure to comply with any of these instructions may

void unit warranty:

1 SEE UNIT DISASSEMBLY.

• Do not use any highly alkaline or acidic solvents, steel wool,

or other harsh abrasives to clean unit.

• Do not use abrasive cleansers, scrapers, steel pads, steel wool,

or other cleaning tools that can scratch surfaces.

• A general purpose, nonabrasive cleaner may be used on hard

to remove food deposits.

• A mildly abrasive nylon or brass brush may be used to remove

any food or mineral deposits on the unit.

• Abrasive cleansing agents can corrode stainless steel.

• Fully rinsing all parts can help prevent corrosion.

• A nontoxic glass cleaner may be used for cleaning any

stainless steel parts and the dome.

2 Wipe external surfaces of unit with a clean damp cloth daily. Dry with a

clean soft cloth.

3 CLEAN AND SANITIZE ALL SURFACES IN CONTACT WITH FOOD

PRODUCT. Hose can be rinsed free of residual condiment by running

water through it in a sink. Clean out any remaining food procuct with

the brushes supplied with unit.

4 REMOVE AND WASH pump, hose, ttings, in warm soapy water. Rinse

thoroughly and dry with a soft clean cloth.

Use supplied brushes to clean all conned areas.

5 Sanitize parts following your local sanitization requirements.

• ALL PARTS IN CONTACT WITH FOOD MUST BE SANITIZED.

• ALLOW PARTS TO FULLY AIR DRY AFTER SANITIZATION.

Various elements and minerals, such as chlorides in tap water, can

accumulate on stainless steel parts and create corrosion.

To prevent corrosion on any stainless steel parts, it is important

to fully air dry, as required after sanitization, or to fully dry with a

clean soft cloth regularly.

85865

85863

safety gUidelines

According to food and safety regulations, most foods must be stored and/or served

at certain temperatures or they could become hazardous. Check with your local

food and safety regulators for specic guidelines.

• Be aware of the product you are serving and the temperature the

product is required to maintain. Server Products, Inc. can not be

responsible for the serving of potentially hazardous product.

• NSF Internation al lists this pu mp as: “Not acceptab le for

dispensing potentially hazardous foods.”

serviCe

Contact your dealer or Server Products Inc. customer service department for the

following:

ORDERING REPLACEMENT PARTS

Be prepared to give this information:

1 Model Number

2 Series Number

3 Part Description

4 Part Number

You can nd the unit model number, series number, and other specic data stamped

on the bottom or back side of every unit.

General Service, Repair, or Returns

Before sending any item to Server Products for service, repair, or return, contact Server

Customer Service to request a Return Authorization Number. Merchandise must be sent

to Server with this number and will be subject to a 20% (percent) restocking charge.

Returned goods must be in new and unused condition and not more than 90 days old.

Electrical parts (thermostats, heating elements etc.) are not returnable.

Server Products maintains a fully staffed service department with highly skilled factory

trained personnel. Service is extremely prompt. Under normal circumstances, a repaired

unit is shipped out the day after it is received. Labor charges are reasonable.

Server Products Limited Warranty

All Server Products equipment is backed by a two-year limited warranty against defects

in materials and workmanship. For complete warranty information go to:

www.server-products.com

5.625 “

TO CENTER SCREW HOLES

.281 DIA SCREW HOLES

.500 “ R

3.00 “

5.375 “

3.00 “

DIM FOR OPENING

Cutout Template for Remote Pumping System

800-558-8722 262-628-5600 spsales@server-products.com 7 262-628-5110

Loading...

Loading...