Server Products 86070 Service Manual

Server Products Inc.

3601 Pleasant Hill Road

Richfi eld, WI 53076 USA

(262) 628-5600

℡

(800) 558-8722

℡

(262) 628-5110

spsales@server-products.com

01882-REVB-010407

www.server-products.com

CHILLER

CONDIMENT CHILLER CONDIMENT CHILLER-Cont. Euro. CONDIMENT CHILLER-Aust. CONDIMENT CHILLER-Ital. CONDIMENT CHILLER-Switz. CONDIMENT CHILLER-UK

(Series 06H) (Series 06H) (Series 06H) (Series 06H) (Series 06H) (Series 06H)

Stock No. 86070 Stock No. 86091 Stock No. 86092 Stock No. 86093 Stock No. 86094 Stock No. 86095

CONDIMENT CHILLER-Den.

(Series 06H)

Stock No. 86096

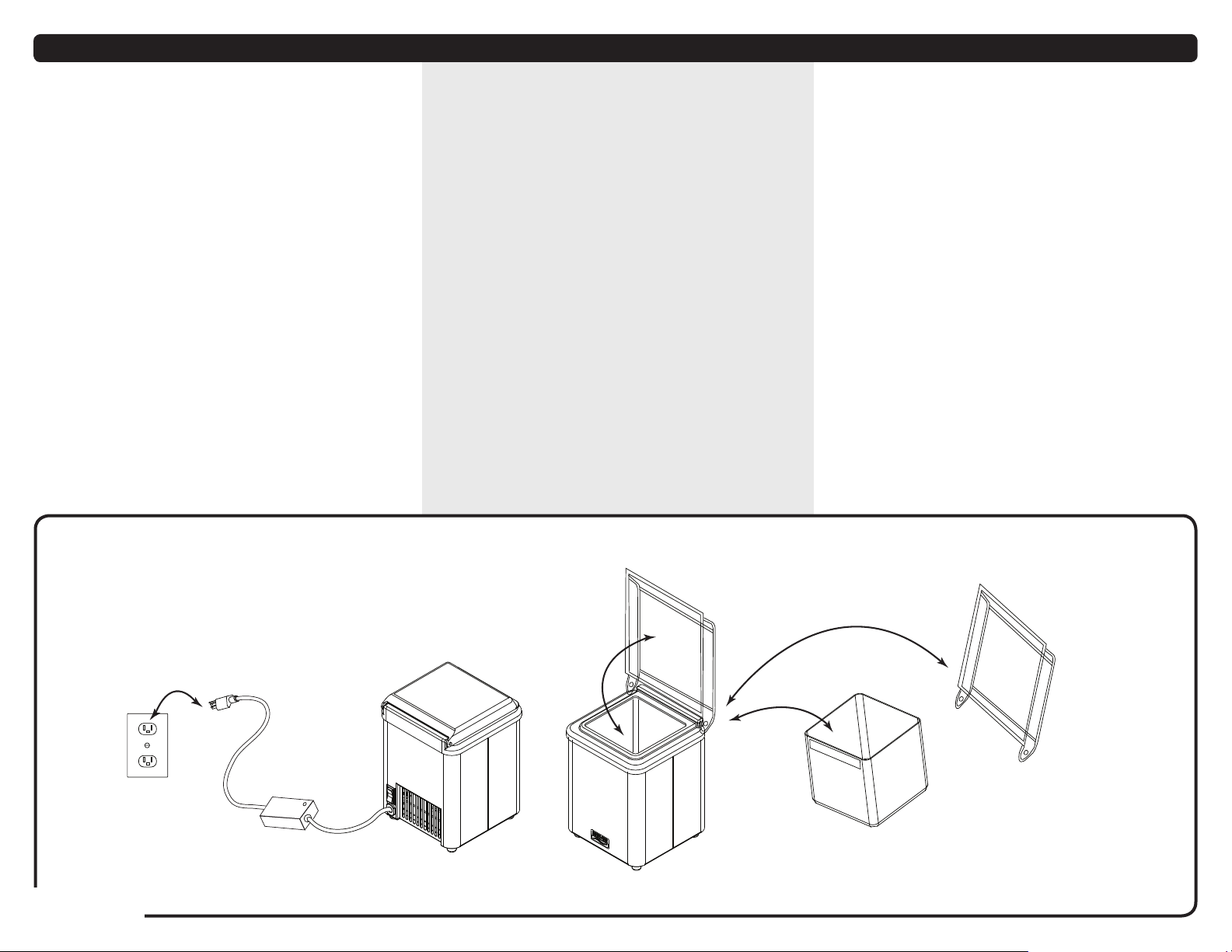

UNIT SET-UP

ALWAYS CLEAN UNIT THOROUGHLY BEFORE EACH USE.

See Unit Take-Down, Cleaning and Safety Guidelines.

Power unit up allowing it to pre-cool for 20 minutes.

Lift lid and fi ll with product vessel in place. Do not overfi ll.

Maximum capacity is two (2) quarts.

Close lid to maintain maxiumum cold temperature.

Temperature tape is located on front of product vessel. It is

recommended to keep unit running 24-7 to prevent

pre-cool period and improve performance.

UNIT TAKE-DOWN

DETACH POWER inlet cord from power pack.

LIFT UP LID, remove any remaining product. Product vessel

can be removed for cleaning.

CLEANING

Before fi rst use and after use daily, remove product vessel

to clean, and wipe down unit. Metal parts can corrode. It is

important to clean, rinse, sanitize, and dry these parts daily

and properly. Failure to comply with any of these instructions

may void unit warranty:

See Unit Take-Down.

MAKE SURE UNIT IS UNPLUGGED FROM POWER SUPPLY.

WARNING: NEVER IMMERSE BASE OR SHROUD OF UNIT INTO

WATER. NEVER USE ANY WATER JET OR PRESSURE SPRAYER ON

BASE OR SHROUD OF UNIT. Electrical shock could occur or

electrical components inside the unit base could be damaged

from water exposure.

WASH PRODUCT VESSEL AND LID WITH DISHWASHING

DETERGENT AND HOT WATER DAILY. (Lid can be removed

by gently pulling hinge tabs out and lifting off.)

Rinse thoroughly and dry with a clean soft cloth.

You may use a mildly abrasive nylon or brass brush

•

to remove any food or mineral deposits on the interior

of the vessel.

Do not use any highly alkaline or acidic solvents, steel

•

wool, or other harsh abrasives to clean vessel.

WIPE EXTERNAL SURFACES OF BASE OR SHROUD WITH A

CLEAN DAMP CLOTH DAILY. Dry with a clean soft cloth.You

may use a general purpose, nonabrasive cleaner on hard to

remove food deposits.

Do not use abrasive cleansers, scrapers, steel pads, steel wool, or

other cleaning tools that can scratch any polished surfaces.

A nontoxic glass cleaner may be used for cleaning any

•

stainless steel parts.

SANITIZE PARTS FOLLOWING YOUR LOCAL

SANITIZATION REQUIREMENTS.

All parts in contact with food must be sanitized.

ALLOW PARTS TO FULLY AIR DRY AFTER SANITIZATION.

Various elements and minerals, such as chlorides in tap water,

can accumulate on metal parts and create corrosion.

To prevent corrosion on metal parts, it is important to fully air dry,

as required after sanitization, or to fully dry with a clean soft cloth

regularly.

NOTE: If unit will not be used or powered up for an extended period

after cleaning, remove lid and vessel to allow unit to warm to room

temperature and air dry to prevent condensation from developing

between vessel and basin.

Unit can remain assembled if powered up and cooling after cleaning

and sanitizing.

2 1882

2 1882

Loading...

Loading...