Server Products 250 Service Manual

200 & 300 SERIES

CAUTION

Service and Installation Manual

Please read this manual completely before attempting to install or operate this equipment!

Notify carrier of damage! Inspect all components immediately. See page 2.

Drop In and Undercounter Products

IMPORTANT INFORMATION

READ BEFORE USE

PLEASE SAVE THESE INSTRUCTIONS!

Effective APRIL 2003

200 and 300 Series Service and Installation Manual

200 and 300 Series Service and Installation Manual

3

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

CONTENTS

RECEIVING & INSPECTING EQUIPMENT ................................. 2

SPECIFICATIONS........................................................................2

INSTALLATION .......................................................................... 3

SERIAL NUMBER INFORMATION

The serial number on all Model 225 and 227 units is located

on the tag affixed next to the temperature control, inside the

compressor stand at the bottom of the unit.

OPERATION................................................................................4

MAINTENANCE .......................................................................... 4

WIRING DIAGRAM .................................................................... 8

STANDARD LABOR GUIDELINES.............................................. 9

REPLACEMENT PARTS LIST..................................................5-8

STANDARD WARRANTY.....................................................10-11

PARTS DEPOTS ........................................................BACK PAGE

Always have the serial number of your unit available when calling for parts or service.

©2003 The Delfield Company. All rights reserved. Reproduction without

written permission is prohibited. “Delfield” is a registered trademarks of

The Delfield Company.

RECEIVING AND INSPECTING THE EQUIPMENT

Even though most equipment is shipped packaged, care

should be taken during unloading so the equipment is not

damaged while being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported to

the delivering carrier immediately.

2. If damaged, open and inspect the contents with the

carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notification should be made verbally

as well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10

days from receipt of the equipment.

5. Visually inspect the refrigeration package. Be sure lines

are secure and base is still intact.

6. Freight carriers can supply the necessary damage forms

upon request.

7. Retain all crating material until an inspection has been

made or waived.

SPECIFICATIONS

MODEL OVERALL CUTOUT CABINET DESIGN SYSTEM

NUMBER L D H SIZE CAPACITY H.P. AMP LOAD BTU CAP. BTU

DROP-IN ICE CREAM FREEZERS

N225

16.56” 27.87” 26.75” 26.37” x 15.37” 6 gal. 1/4 5.0 292 569

N227

30” 27.87” 26.75” 26.37” x 28.56” 12 gal. 1/4 5.0 473 661

DROP-IN ICE CREAM FREEZERS WITH LEXAN® LID

225L

16.56” 27.87” 26.75” 26.37” x 15.37” 6 gal. 1/4 5.0 292 569

227L

30” 27.87” 26.75” 26.37” x 28.56” 12 gal. 1/4 5.0 473 661

MODEL OVERALL CUTOUT ICE

NUMBER DESCRIPTION L D H SIZE CAPACITY

DROP-IN WATER STATIONS AND ICE STORAGE

203

ice chest 20.25” 20.25” 23.25” 19.25” x 19.25” 90 lbs.

204

water and ice station 24” 21” 23.5” 21” x 17.75” 45 lbs.

240

ice chest with cover 21” 17.5” 17” — 75 lbs.

248

water and ice station 31” 15” 22.5” 28” x 12.5” 45 lbs.

305

ice chest with cover 21.25” 15.25” 13” 17.75” x 13.25” 45 lbs.

307

glass filler 12” 12” 9.5” — —

UNDERCOUNTER SINKS, WATER STATIONS AND ICE STORAGE

242

UC sink & faucet 18” 13.5” 12.75” 17” x 12.5” —

250

UC sink, ice chest 46” 14.12” 22.75” 45” x 13” 45 lbs.

and water station

2

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

INSTALLATION

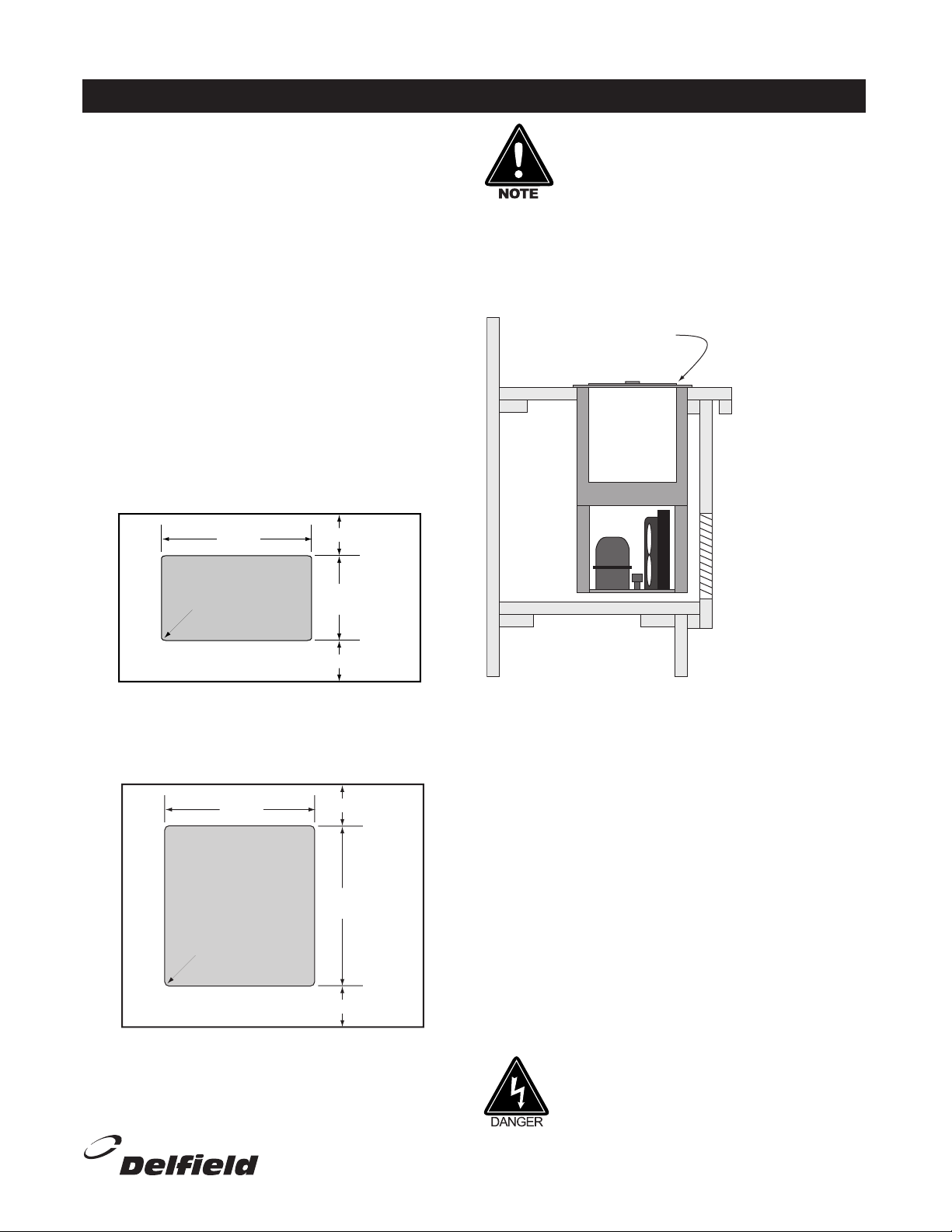

225 or 227 DROP-IN

TYPICAL

COUNTER

CABINET

LOUVER

13.00" x 24.37"

33.0cm x 61.9cm

LOUVER CUTOUT SIZE

11.50" x 23.00"

29.2cm x 58.4cm

(typical installation)

NOTE: A second cutout

(without louver) must

also be made to allow

proper air flow.

26.37"

67.0cm

28.56"

72.5cm

CUTOUT

.75"/1.9cm radius

1.00"/2.5cm (min.)

1.00"/2.5cm (min.)

COUNTERTOP

26.37"

67.0cm

15.37"

39.0cm

CUTOUT

.75"/1.9cm

radius

1.00"/2.5cm (min.)

1.00"/2.5cm (min.)

COUNTERTOP

200 and 300 Series Service and Installation Manual

Location

The refrigeration system has been factory tested

and should require no further adjustment during

installation.

For the most efficient refrigeration, be sure to provide

good air circulation inside and out.

Outside Cabinet: Be sure that the unit has access

to ample air. Avoid hot corners and locations near

stoves and ovens.

Counter Cutouts

For installation provide a cutout in the counter as

shown (see illustration 1 or 2). The counter must be

sturdy enough to hold the combined weight up to 300

lbs. of the drop-in and the product stored inside.

The louver provided must be installed

in front of the condensing unit’s finned

coil (see illustration 3). A second

cutout must be made at the rear or

end of the equipment to allow air flow

through the unit. No louver is provided

for the second cutout. Any restriction

to the proper air flow, total or partial,

will void the compressor warranty.

Illustration 1. Model 225 cutout dimensions

Illustration 2. Model 227 cutout dimensions

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Illustration 3. Models 225 & 227 louver installation

Electrical Connection

Refer to the amperage data on page 2, the serial tag,

your local code or the National Electrical Code to be

sure the unit is connected to the proper power source.

A protected circuit of the correct voltage and amperage

must be run for connection of the line cord.

If the unit does not operate after it is plugged in, check

the thermostat to see if it was inadvertently turned

OFF during installation.

The unit must be disconnected from

the power source whenever performing

service or maintenance functions.

3

200 and 300 Series Service and Installation Manual

200 and 300 Series Service and Installation Manual

5

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

OPERATION MODELS 225 AND 227

After installation, the unit will begin operating simply

by plugging it into the proper outlet. If the unit does

not operate after being plugged in, check to see if the

thermostat is in the OFF position.

MAINTENANCE MODELS 225 AND 227

In order to maintain proper refrigeration performance,

the condenser fins must be cleaned of dust, dirt, and

grease every three months. If conditions are such

that the condenser is totally blocked in three months,

the frequency of cleaning should be increased.

Clean the condenser with a vacuum cleaner or stiff

brush. If extremely dirty, a commercially available

condenser cleaner may be required.

Defrosting must be done manually after 3/8” of ice

accumulation.

The models 225 and 227 are designed to

hold ice cream or other frozen products at a

temperature range of 5°F to -5°F (-15°C to 21°C). The thermostat is located in the machine

compartment.

The lid should be cleaned regularly with a soft

cloth or sponge and solution of soap and water to

maintain their ability to seal properly.

MAINTENANCE - MODELS 203, 204, 240, 242, 248, 250, 305 & 307

The interior and exterior of these models may be

cleaned using soap and warm water. If this is not

sufcient, try ammonia and water or a non-abrasive

cleaner. Be sure to rinse thoroughly with clean water

after using ammonia or a cleaner. When cleaning the

exterior, always rub with the “grain” of the stainless

steel to avoid marring the nish.

Do not use an abrasive cleaner. Abrasive

cleaners will scratch the stainless steel

and plastic.

4

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Loading...

Loading...