Page 1

Syrup Server

MODEL: SY 1.5

85480 UNIT

1½ GALLON SERVER

MODEL: SY

84190 UNIT

3 GALLON SERVER

Thank You

...for purchasing this Syrup Server

to heat and neatly dispense sticky syrups

and sauces.

WARM & SERVE SYRUP—SIMPLY!

Page 2

PARTS

LID ASSEMBLY

for 1½ gallon unit: 85473

for 3 gallon unit: 84199

NUT

85488

FAUCET KIT

85487

(includes 85488 nut)

THERMOSTAT

90186

THERMOSTAT BRACKET

85479

THERMAL CUT-OUT

for 1½ gallon unit: 86218

for 3 gallon unit: 04627

RUBBER

WASHER

84217

KNOB

82023-000

HEATING ELEMENT

for 1½ gallon unit:

85484

for 3 gallon unit:

05256

MOUNTING

BRACKET

84198

SNAP-IN

ROCKER

SWITCH

04544

BUSHING,

STRAIN RELIEF

11201

THERMOSTAT LOCK

85485

Page 2

CORD

ASSEMBLY

11379

FOOT w/SCREW

81058

Page 3

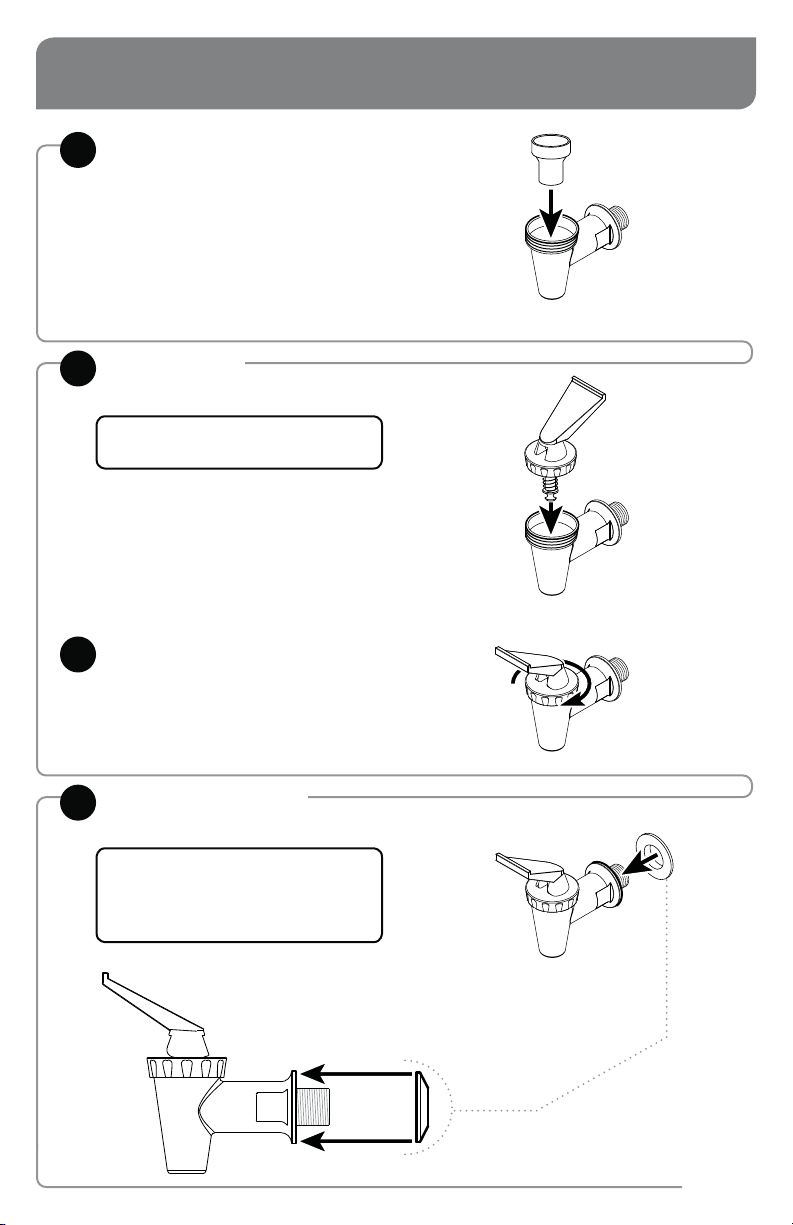

FAUCET ASSEMBLY

INSERT CUP SEAT

1

into faucet.

INSTALL TOP

2

onto faucet.

TIP: Lubricate threads with a small amount

of clean water.

WASH ALL PARTS PROPERLY

BEFORE EVERY USE.

See page 6.

ROTATE TOP CLOCKWISE

3

to secure.

INSTALL WASHER

4

onto threaded shank of faucet.

IMPORTANT:

• Flat side of washer must face faucet.

• Round side of washer must face away

from faucet.

Page 3

Page 4

UNIT SETUP

See page 4 for FAUCET ASSEMBLY

INSTALL FAUCET

1

into hole.

Attach nut to faucet from inside vessel.

YES

• Round side of washer seals inside hole.

• Tighten nut until snug.

NO

• Flat side of washer must not face hole.

• Do not over-tighten nut.

Overtightened nut will strip threads

and cause washer to leak.

Overtightened nut will flatten washer

and cause leak.

ADD PRODUCT & LID

2

WASH ALL PARTS PROPERLY

BEFORE EVERY USE.

See page 6.

3

4

Page 4

PLUG CORD into power source.

PRESS SWITCH to the “ON” position.

To adjust TEMPERATURE SETTING,

see page 7.

Page 5

UNIT TAKE-DOWN

PRESS SWITCH to the “OFF” position.

1

UNPLUG CORD

2

CAUTION- HOT

Allow unit to cool before continuing or

use proper care with hot surfaces.

REMOVE LID

3

EMPTY ANY REMAINING

4

PRODUCT

from vessel.

REMOVE FAUCET

5

Unscrew nut from inside vessel.

DISASSEMBLE FAUCET

6

Take apart all four pieces.

IMPORTANT:

PREVENT DRIPPING

Disassemble and clean faucet daily.

Page 5

Page 6

SAFETY

WARNING-

ELECTRICAL SHOCK COULD OCCUR

This unit must be earthed or grounded.

This requires all three prongs (terminals) on cord

plug to be plugged into power source.

CLEANING

WARNING-

ELECTRICAL SHOCK COULD OCCUR

• Electrical components of unit could be

damaged from water exposure or any liquid.

• Never immerse unit into water or any liquid.

• Never use any water jet or pressure sprayer

on unit.

• Ensure unit is “OFF” and unplugged.

CAUTION- HOT

Allow unit to cool before cleaning.

CLEAN EXTERNAL SURFACES

• Wipe daily with a clean damp cloth.

• Dry with a clean soft cloth.

• Glass and surface cleaners approved for use

in food contact areas may be used.

According to food and safety regulations, most

foods must be stored and/or served at certain

temperatures or they could become hazardous.

Check with local food and safety regulators for

specific guidelines.

Be aware of the product you are serving and the

temperature the product is required to maintain.

Server Products, Inc. can not be responsible for

the serving of potentially hazardous product.

CLEAN

1

After disassembling, thoroughly clean all

washable parts with soap and hot water.

RINSE fully with clear water.

2

SANITIZE

3

all parts according to local sanitization

requirements. All parts in contact with

food must be sanitized.

4

DRY

Air dry faucet parts fully.

Dry stainless steel with clean, soft cloth.

CARE OF STAINLESS STEEL

This syrup server is constructed

of stainless steel— one of the

best materials for food serving

and storage.

If you notice corrosion beginning on any stainless

steel surface, you may need to change the

cleansing agent, sanitizing agent, or the cleaning

procedures you are using.

Page 6

• A mildly abrasive nylon or brass brush may

be used to remove any stubborn food or

mineral deposits on interior surfaces of unit.

• Fully rinsing and drying all parts can help

prevent corrosion. Elements and minerals in

tap water can accumulate on stainless steel

parts and create corrosion.

• Do not use abrasive, caustic or ammonia

based cleansers.

• Do not use products containing acids,

alkalines, chlorine, or salt. These agents can

corrode stainless steel.

• Do not use metal scrapers or cleaning pads

that could scratch surfaces.

Page 7

WIRING

1 2 3

BLACK

WHITE

GREEN

7

UNITS 85480 & 84190 | 120V | USA

1

4

2

Cord Assembly

1

Snap-In Rocker Switch

2

Thermal Cut-Out

3

Thermostat

4

Wire Assembly

5

Heating Element

6

Bushing, Strain Relief

7

TEMPERATURE SETTING

Thermostat is preset at 140 ºF

Temperature setting is adjustable in 20 ºF

increments from 80 ºF—180 ºF.*

To change setting:

ADJUST THERMOSTAT LOCK

Vessel must be empty.

Set unit upside down.

REMOVE SCREW from lock.

1

6

5

ROTATE LOCK to desired temperature.

2

SECURE THERMOSTAT LOCK

3

with screw to set temperature.

*Temperature is preset at 60 ºC.

Setting is adjustable in 11 ºC

increments from 26.6 ºC—82.2 ºC.

Page 7

Page 8

TROUBLESHOOTING

UNIT DOES NOT HEAT?

• Ensure cord is securely plugged in.

• Ensure unit is on.

• Ensure thermostat lock is set correctly.

• Ensure power is available from source.

• Do not allow any of the electrical components

to get wet. Moisture may cause the unit to

trip breaker or GCFI. If moisture is suspected,

discontinue use. Allow unit to fully air dry.

SERVER PRODUCTS

LIMITED WARRANTY

Server Products equipment is backed by a

two-year limited warranty against defects in

materials and workmanship.

For complete warranty information go to:

www.Server-Products.com

FAUCET LEAKS?

• Fully disassemble and clean faucet daily.

Ensure that washer is installed with flat side

•

towards faucet.

YES

• Round side of washer

seals inside hole.

• Tighten nut until snug.

NO

• Flat side of washer must

not face hole.

• Do not over-tighten nut.

Overtightened nut will strip

threads and cause washer

to leak.

Overtightened nut will flatten

washer and cause leak.

GENERAL SERVICE,

REPAIR OR RETURNS

Before sending any item to Server Products for service,

repair, or return, contact Server Products customer

service to request a Return Authorization Number.

Merchandise must be sent to Server Products with this

number. Service is extremely prompt. Typically, units

are repaired and ship out within 48 hours of receipt.

Merchandise being returned for credit must be in new

and unused condition and not more than 90 days

old and will be subject to a 20% restocking charge.

Electrical parts (thermostats, heating elements, etc.)

are not returnable.

Servicing Cord: Specific tools are required for safe

and proper power supply cord removal and installation.

If cord must be replaced, only a representative of the

OEM (original equipment manufacturer) or a qualified

technician may replace cord. Cord must meet code

designation H05 RN-F requirements.

NEED HELP?

Server Products Inc.

3601 Pleasant Hill Road

Richfield, WI 53076 USA

262.628.5600 | 800.558.8722

SPSALES@SERVER-PRODUCTS.COM

Page 8

Please be prepared with your Model, Part and

Series Numbers. This information and other

important data is located on the base of the unit.

Manual #01861-RevH 021919

Loading...

Loading...