Page 1

GE Fanuc Automation

Computer Numerical Control Products

DATA SERVER

Operator's Manual

B- 62694EN/03 April 1998

Page 2

Warnings and notices for

GFLE-003

this publication

Warning

In this manual we have tried as much as possible to describe all the various

matters. However, we cannot describe all the matters which must not be done,

or which cannot be done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this

manual should be regarded as “impossible”.

Notice

This document is based on information available at the time of its publication. While efforts have

been made to be accurate, the information contained herein does not purport to cover all details or

variations in hardware or software, nor to provide every contingency in connection with

installation, operation, or maintenance. Features may be described herein which are not present in

all hardware and software systems. GE Fanuc Automation assumes no obligation of notice to

holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory with

respect to, and assumes no responsibility for accuracy, completeness, sufficiency, or usefulness of

the information contained herein. No warranties of merchantability or fitness for purpose shall

apply.

The following are Registered Trademarks of GE Fanuc Automation

CIMPLICITY® Genius®

The following are Trademarks of GE Fanuc Automation

Alarm Master

CIMSTAR

Field Control

Genet

Helpmate

LogicMaster

Modelmaster

PowerMotion

ProLoop

PROMACRO

Series Five

Series 90

Series One

Series Six

Series Three

VuMaster

Workmaster

© Copyright 1998 FANUC Ltd.

Authorized Reproduction GE Fanuc Automation Europe S.A.

All Rights Reserved

No part of this manual may be reproduced in any form.

All specifications and designs are subject to change without notice.

Page 3

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export from Japan may be subject to an export license by the

government of Japan.

Further, re-export to another country may be subject to the license of the government of

the country from where the product is re-exported. Furthermore, the product may also be

controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by ® or ™ in the main body.

Page 4

Page 5

B62694EN/03

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

This section describes the safety precautions relating to the use of CNC units, to

ensure safe operation of machines fitted with FANUC CNC units.

section carefully before attempting to use any function described in this manual.

Users should also read the relevant descriptions in the Operator’s Manual to

become fully familiar with the functions to be used.

Contents

Read this

1. WARNING, CAUTION, AND NOTE

2. GENERAL WARNINGS AND NOTES.

.............................

........................... s_3

s_2

s-l

Page 6

SAFETY PRECAUTIONS

1 WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and

preventing damage to the machine. Precautions are classified into

Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the

Warning, Caution, and Note thoroughly before attempting to use the

machine.

WARNING

Applied when there is a danger of the user being injured or

when there is a damage of both the user being injured and

the equipment being damaged if the approved procedure is

not observed.

B-62694ENlOQ

CAUTION

Applied when there is a danger of the equipment being

damaged, if the approved procedure is not observed.

NOTE

The Note is used to indicate supplementary information

other than Warning and Caution.

s-2

Page 7

B62694EN103

SAFETY PRECAUTIONS

2

GENERAL WARNINGS AND NOTES

WARNING

1. Before operating the machine, thoroughly check the

entered data.

Operating the machine with incorrect data may result in the

machine behaving unexpectedly, possibly causing damage

to the workpiece and/or machine itself, or injury to the user.

2. Never attempt to perform a production run, such as

actually machining a workpiece, without first checking the

operation of the machine.

a production run, ensure that the program command

values, offsets, current position, external signals, and other

settings are suitable for the operation to be performed.

Also check that the machine operates correctly by

performing a trial run using, for example, the single block,

feedrate override, or machine lock function or by operating

the machine with neither a tool nor workpiece mounted.

3. Ensure that the specified feedrate is appropriate for the

intended operation.

a maximum allowable feedrate.

feedrate varies with the intended operation.

manual provided with the machine to determine the

maximum allowable feedrate.

than the correct speed, it may behave unexpectedly,

possibly causing damage to the workpiece and/or machine

itself, or injury to the user.

4. When using a tool compensation function, thoroughly

check the direction and amount of compensation.

Operating the machine with incorrectly specified data may

result in the machine behaving unexpectedly, possibly

causing damage to the workpiece and/or machine itself, or

injury to the user.

5. The parameters for the CNC and PMC are factory-set.

Usually, there is not need to change them. When,

however, there is not alternative other than to change a

parameter, ensure that you fully understand the function of

the parameter before making any change.

Failure to set a parameter correctly may result in the

machine behaving unexpectedly, possibly causing damage

to the workpiece and/or machine itself, or injury to the user.

Before starting the machine for

Generally, for each machine, there is

But, the appropriate

Refer to the

If a machine is run at other

s-3

Page 8

SAFETY PRECAUTIONS B62694FNl03

WARNING

6.

Immediately after switching on the power, do not touch any

of the keys on the MDI panel until the position display or

alarm screen appears on the CNC unit.

Some of the keys on the MDI panel are dedicated to

maintenance or other special operations.

Pressing any of

these keys may cause the machine to behave

unexpectedly.

7.

The operator’s manual supplied with a CNC unit provide an

overall description of the machine’s functions, including

any optional functions.

will vary from one machine model to another.

Note that the optional functions

Therefore,

some functions described in the manuals may not actually

be available for a particular model.

Check the

specification of the machine if in doubt.

8.

Some machine operations and screen functions may

have been implemented at the request of the machinetool builder. When using such functions, refer to the

manual supplied by the machine-tool builder for details of

their use and any related cautions.

NOTE

1. Command programs, parameters, and variables are stored

in nonvolatile memory in the CNC unit. Usually, they are

retained even if the power is turned off. Such data may

be deleted inadvertently, however, or it may prove

necessary to delete all data from nonvolatile memory as

part of error recovery.

To guard against the occurrence of the above, and assure

quick restoration of deleted data, backup all vital data, and

keep the backup copy in a safe place.

s-4

Page 9

P-@‘-4FN/O3

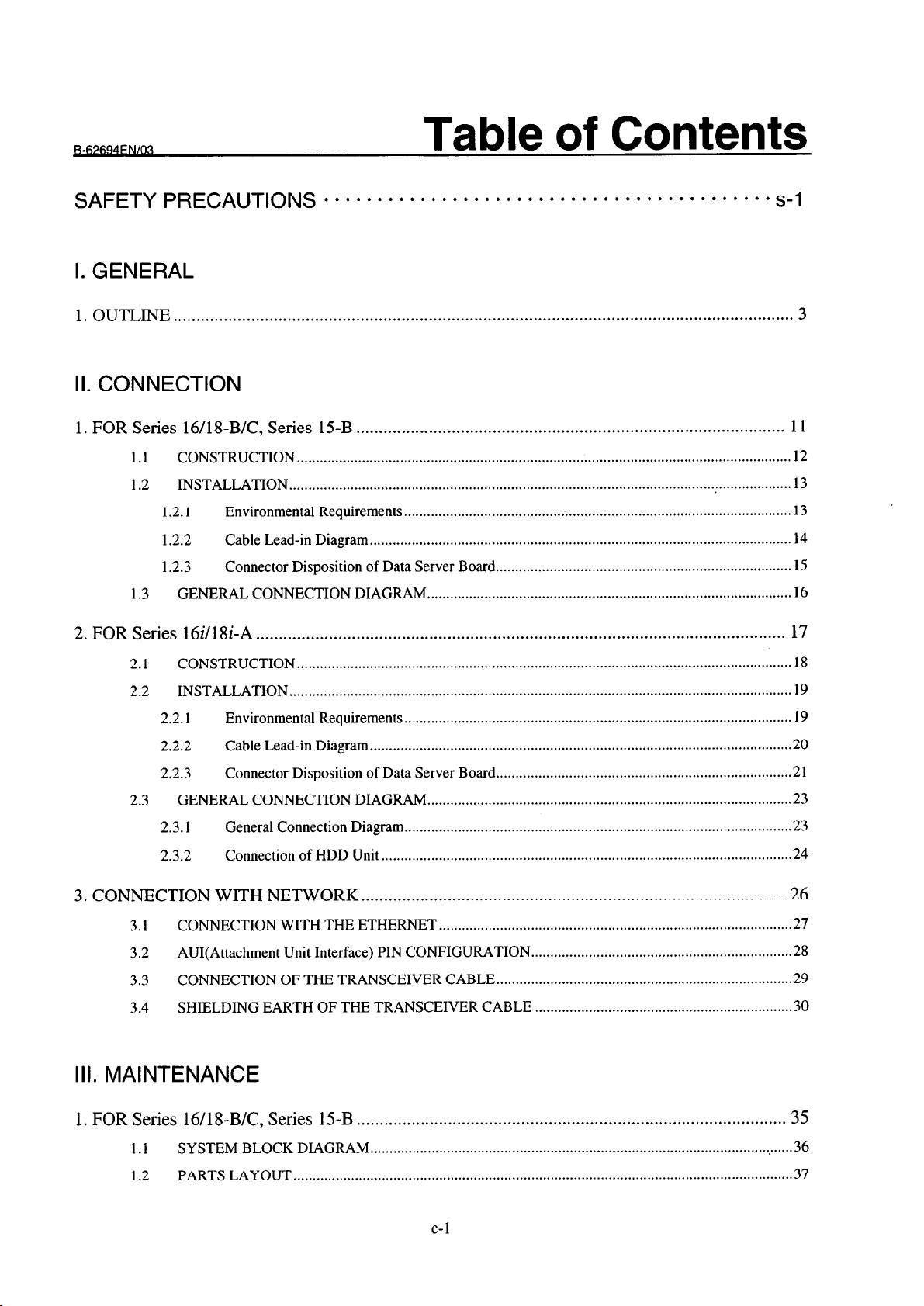

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . s-1

Table of Contents

I. GENERAL

1. OUTLINE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ................

II. CONNECTION

1. FOR Series 16/18-B/C, Series 15-B

CONSTRUCTION

1.1

1.2 INSTALLATION..

1.2.1

1.2.2

1.2.3

GENERAL CONNECTION DIAGRAM

1.3

Environmental Requirements

Cable Lead-in Diagram

Connector Disposition of Data Server Board

2. FOR Series 16i/l8i-A

2.1

2.2

2.3

CONSTRUCTION

INSTALLATION

2.2.1

2.2.2

2.2.3

GENERAL CONNECTION DIAGRAM

2.3.1

2.3.2

Environmental Requirements

Cable Lead-in Diagram..

Connector Disposition of Data Server Board

General Connection Diagram

Connection of HDD Unit

.................................................................................................................................

............................................................................................................. . ..................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.................................................................................................................................

...................................................................................................................................

3

.............................................................................................. 11

12

.13

.....................................................................................................

..............................................................................................................

.............................................................................

...............................................................................................

13

14

15

16

17

18

19

.....................................................................................................

...........................................................................................................

.............................................................................

...............................................................................................

.....................................................................................................

...........................................................................................................

19

.20

21

23

23

24

3. CONNECTION WITH NETWORK

3.1 CONNECTION WITH THE ETHERNET

3.2

3.3

3.4

AUI(Attachment Unit Interface) PIN CONFIGURATION..

CONNECTION OF THE TRANSCEIVER CABLE

SHIELDING EARTH OF THE TRANSCEIVER CABLE

.............................................................................................

............................................................................................

.................................................................

.............................................................................

...................................................................

III. MAINTENANCE

1. FOR Series 16/l 8-B/C, Series 15-B ..............................................................................................

SYSTEM BLOCK DIAGRAM ..... ..........................................................................................................

1.1

PARTS LAYOUT.. ................................................................................................................................

1.2

c-l

26

27

.28

29

30

.

35

36

.

37

Page 10

TABLE OF CONTENTS

B-62694EN/OIj

1.3 LIGHTING OF LEDS AND MEANING

1.4

HOW TO EXCHANGE A FUSE

2. FOR Series 16i/l%-A

2.1 SYSTEM BLOCK DIAGRAM

2.2

2.3

PARTS

LIGHTING OF LED AND MEANING

2.3.1

2.3.2 In Case of Latter Edition than 02B

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .......... 43

In Case of Edition 01 A

IV. OPERATION

1. FOR Series 16/18-B/C, Series

1.1

OUTLINE ..............................................................................................................................................

1.1.1

1.2

1.2.1 Description of Each Data

Notice when You

SETTING SCREEN ...............................................................................................................................

.............................................................................................

..........................................................................................................

.38

.40

41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1.6i/18i-A.. ..................................................................................... 53

54

Use for the First Time

..........................................................................................................

..................................................................................

.55

56

.58

1.2.2

1.2.3 How to Input Small Letters

1.2.4 How to Set a Host Directory

1.2.5 How to Save Modified

1.3 NC PROGRAM MANAGEMENT FUNCTION

1.3.1 Displaying the Table of NC Programs

1.3.2 Searching a NC

1.3.3 Deleting NC Programs ...............................................................................................................

1.3.4 Getting a NC Program

1.3.5 Putting a NC Program

1.3.6 List-Getting NC

1.3.7

1.3.8

1.3.9 A Format of List-File

1.3.10

1.4

CALLING

1.5

REGISTERING A NC PROGRAM

1.6 OUTPUTTING A NC PROGRAM

How to Input Data..

List-Putting NC

List-Deleting NC

A Format of NC

A SUBPROGRAM WITH Ml 98

...................................................................................................................

........................................................................................................

Data

Program

Programs

Programs..

Program..

...........................................................................................................

..............................................................................................................

...............................................................................................................

........................................................................................................

.......................................................................................................

Programs..

................................................................................................................

........................................................................................................

.....................................................................................................

......................................................................................................

..................................................................................

......................................................................................

.....................................................................................................

.......................................................................................

......................................................................................................

......................................................................................................

.60

62

.63

.65

.66

.67

.71

72

.74

.76

.79

.82

.85

.87

.88

.89

.91

.92

1.7 DNC OPERATION ................................................................................................................................

1.8

MAINTENANCE

OF

THE

BUILT-IN HARD

c-2

DISK

..........................................................................

93

.94

Page 11

Page 12

Page 13

Page 14

1

About this manual SAFETY PRECAUTIONS

OUTLINE

This manual consists of the following parts:

Notes for reading this manual is described.

I. GENERAL

Chapter organization, applicable models, and related

manuals are described.

II. CONNECTION

The method of connecting each device and notes for

connection are described.

Ill. MAINTENANCE

The drawing number of the Data Server, meaning of the

LEDs, and the error messages are described.

IV. OPERATION

How to operate the Data Server functions are described.

APPENDIX

The error messages and technical terms, etc. are described.

-3-

Page 15

1. OUTLINE

GENERAL

B-62694ENl03

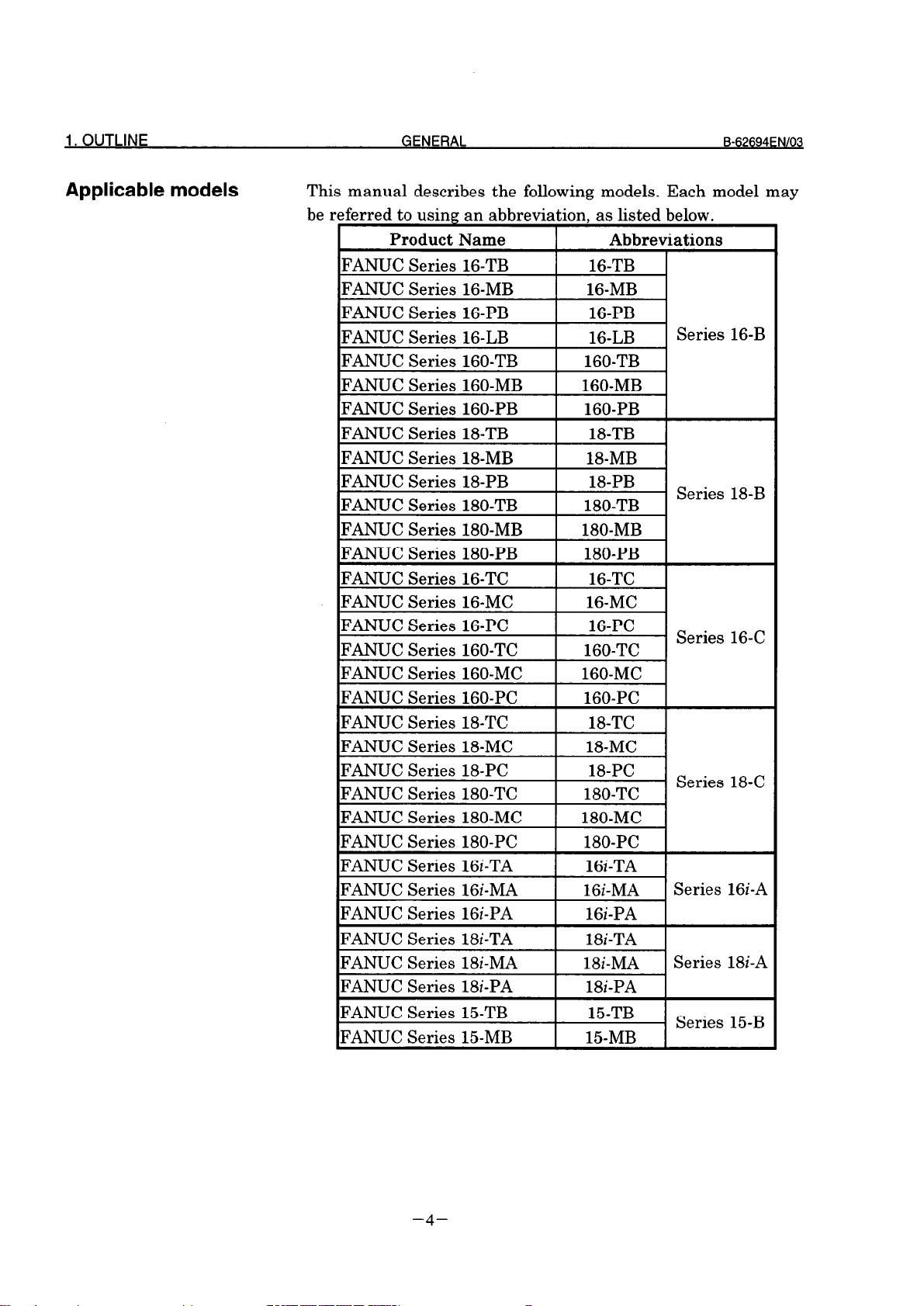

Applicable models

This manual describes the following models. Each model may

be referred to using an abbreviation. as listed below.

I

IFANUC Series 16-TB

FANUC Series 16-MB

FANUC Series 16-PB

FANUC Series 16-LB

IFANUC Series 160-TB 1 160-TB 1

IFANUC Series 160-MB 1 160-MB 1

IFANUC Series 160-PB I 160-PB I

FANUC Series 18TB

FANUC Series l&MB

FANUC Series 18PB

FANUC Series 180-TB

FANUC Series 16-PC

FANUC Series 160-TC

Product Name

!

Abbreviations

16-TB

16-MB

16-PB

16-LB

18-TB

H-MB

18-PB

180-TB

16-PC

160-TC

Series 16-B

I

Series 18-B

Series 16-C

FANUC Series 18-PC

FANUC Series 180-TC

FANUC Series 180-MC

FANUC Series 180-PC

FANUC Series 16i-TA

FANUC Series 16i-MA

FANUC Series 16i-PA

IFANUC Series 18i-TA

IFANUC Series 18i-MA

IFANUC Series 18i-PA

FANUC Series 15TB

FANUC Series l&MB

-4-

18-PC

180-TC

180-MC

180-PC

16i-TA

1 Gi-MA

16i-PA

I 18i-TA I

Series 18-C

Series 16i-A

I 18i-MA I Series 18i-A

I 18i-PA I

15-TB

l&MB

Series 15-B

Page 16

Page 17

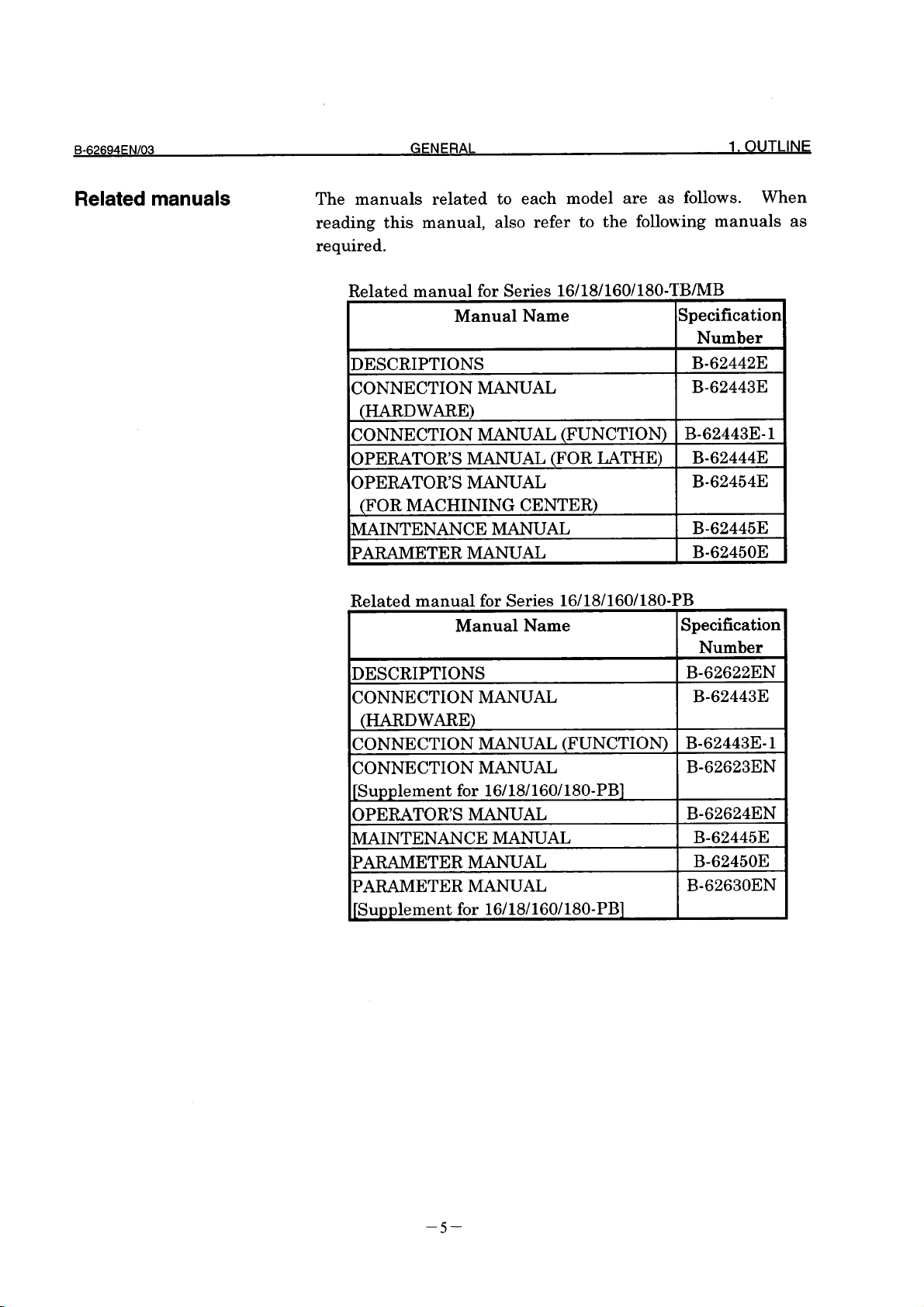

1. OUTLINE GENERAL

Related manual for Series 16-LB

Manual Name Specification

IDESCRIPTIONS

CONNECTION MANUAL

(HARDWARE)

ICONNECTION MANUAL (FUNCTION) 1 B-62443c i 1

CONNECTION MANUAL

JSupplement for 16-LB]

OPERATOR’S MANUAL

MAINTENANCE MANUAL

PARAMETER MANUAL

PARAMETER MANUAL

JSupplement for 16-LB]

Related manual for Series 16/18/160/180-TCYMC

Manual Name

DESCRIPTIONS

CONNECTION MANUAL

(HARDWARE)

CONNECTION MANUAL (FUNCTION) B-62753EN-1

OPERATOR’S MANUAL (FOR LATHE) B-62754EN

OPERATOR’S MANUAL

(FOR MACHINING CENTER)

MAINTENANCE MANUAL B-62755EN

IPARAMETER wu~L 1 B-62760EN 1

B-62694ENIOQ

Number

1 B-62442E 1

B-62443E

-.

B-62593EN

B-62594EN

B62595EN

B-62450E

B-62600EN

Specification

Number

B-62752EN

B-62753EN

B-62764EN

Related manual for Series 16/18/160/180-PC

Manual Name Specification

Number

DESCRIPTIONS B-62772EN

CONNECTION MANUAL B-62753EN

(HARDWARE)

CONNECTION MANUAL (FUNCTION) B-62753EN-1

CONNECTION MANUAL

B-62773EN

JSupplement for 16/18/160/180-PC]

OPERATOR’S MANUAL

B-62774EN

MAINTENANCE MANUAL B-62755EN

PARAMETER MANUAL

B-62760EN

PARAMETER MANUAL B-62780EN

[Supplement for 16/18/160/180-PC]

-6-

Page 18

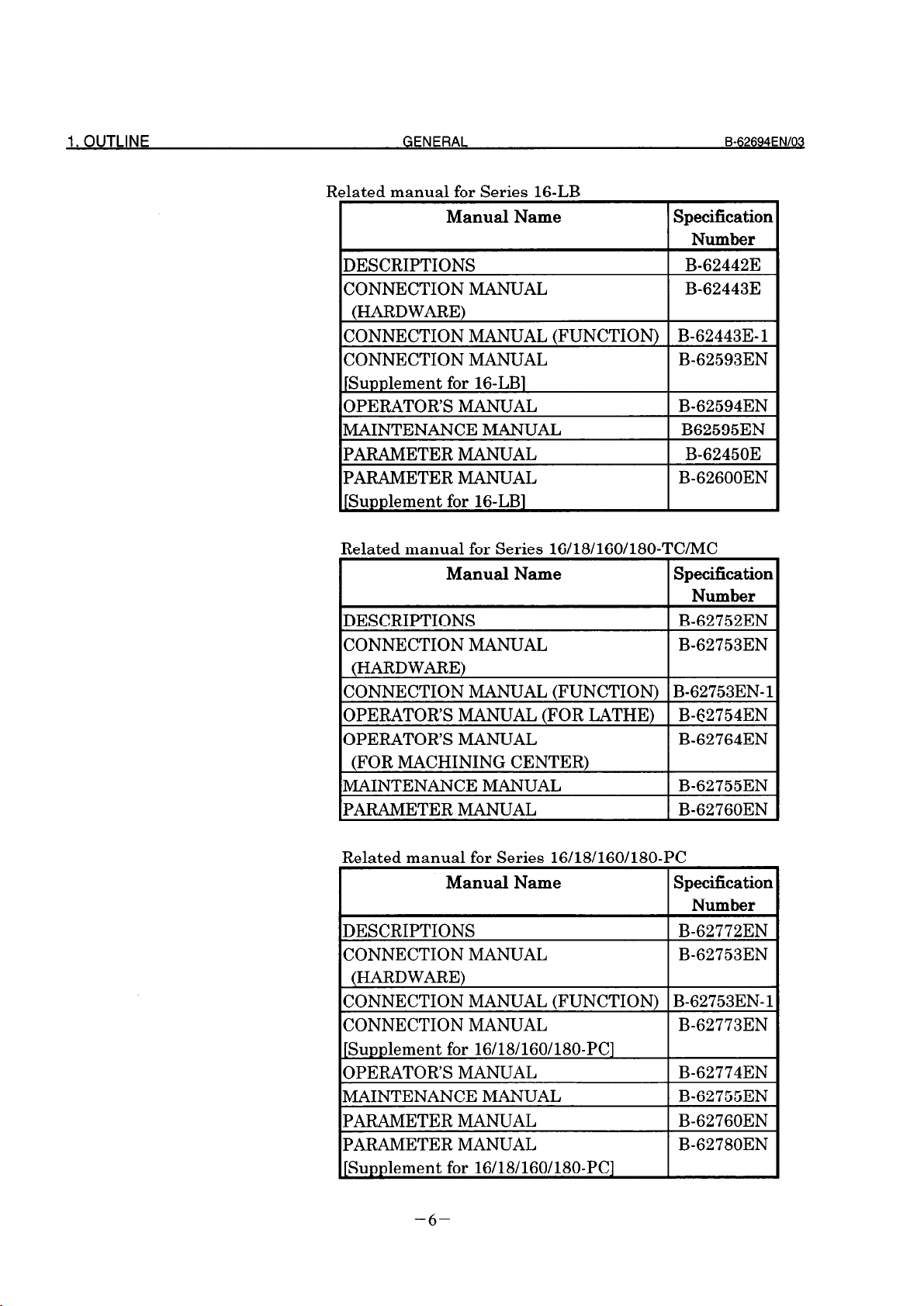

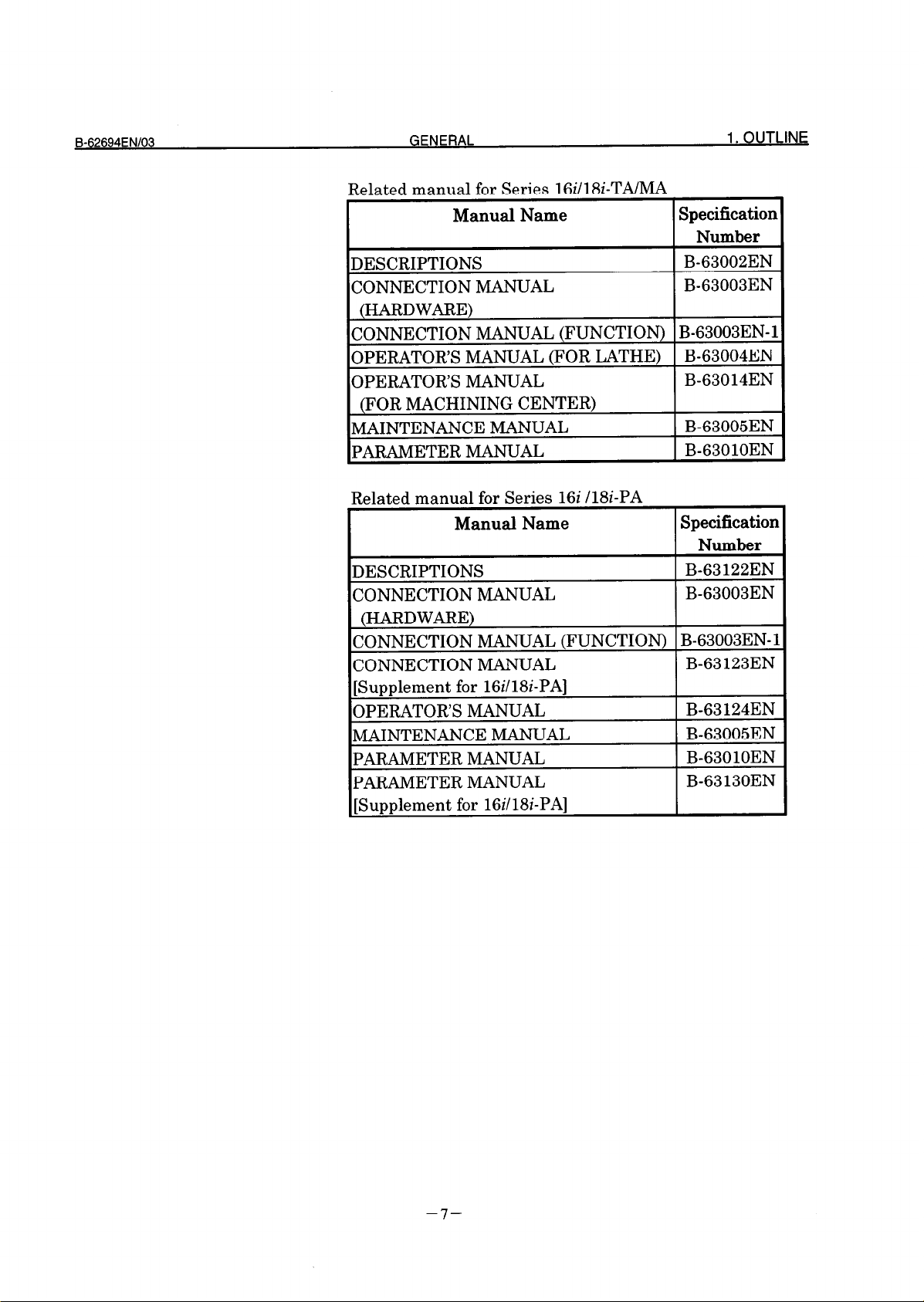

Related manual for Series 16iIl8i-TAIMA

Manual Name

Specification

Number

DESCRIPTIONS

CONNECTION MANUAL

B-63002EN

B-63003EN

(HARDWARE)

CONNECTION MANUAL (FUNCTION) B-63003EN-1

OPERATOR’S MANUAL (FOR LATHE)

OPERATOR’S MANUAL

B-63004EN

B-63014EN

(FOR MACHINING CENTER)

MAINTENANCE MANUAL

~PARAMETER h4mum

B-63005EN

B-63010EN

Related manual for Series 16i /l&-PA

Manual Name

Specification

Number

DESCRIPTIONS

CONNECTION MANUAL

B-63 122EN

B-63003EN

(HARDWARE)

CONNECTION MANUAL (FUNCTION) B-63003EN-1

CONNECTION MANUAL

B-63 123EN

[Supplement for 16i/lSi-PA]

OPERATOR’S MANUAL

MAINTENANCE MANUAL

PARAMETER MANUAL

PARAMETER MANUAL

B-63 124EN

B-63005EN

B-63010EN

B-63 130EN

[Supplement for 16i/18i-PA]

-7-

Page 19

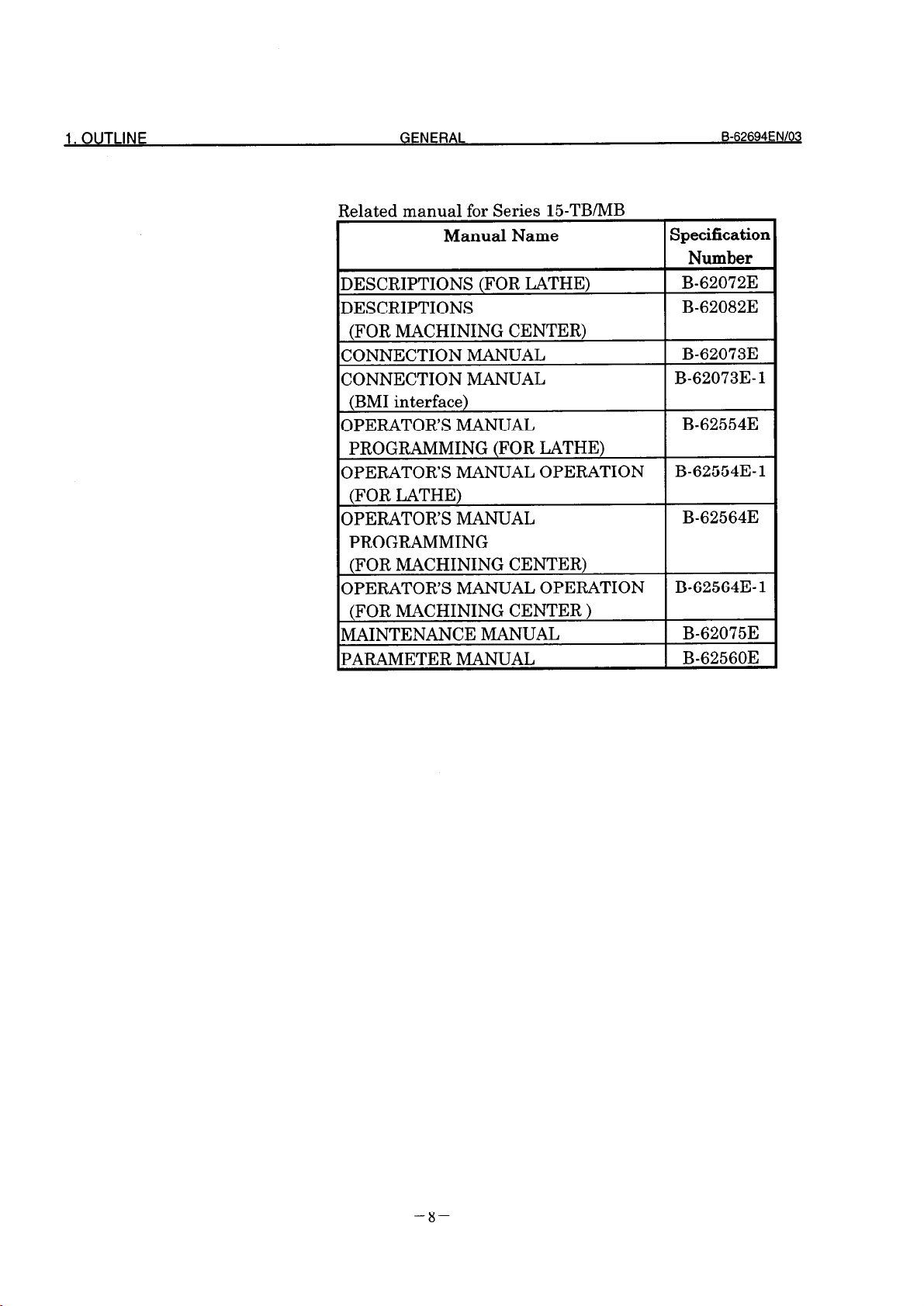

1. OUTLINE

GENERAL

Related manual for Series l&TB/MB

Manual Name

DESCRIPTIONS (FOR LATHE)

DESCRIPTIONS

(FOR MACHINING CENTER)

CONNECTION MANUAL

CONNECTION MANUAL

(BMI interface)

OPERATOR’S MANUAL

PROGRAMMING (FOR LATHE)

OPERATOR’S MANUAL OPERATION

(FOR LATHE)

OPERATOR’S MANUAL

PROGRAMMING

(FOR MACHINING CENTER)

OPERATOR’S MANUAL OPERATION

(FOR MACHINING CENTER )

MAINTENANCE MANUAL

PARAMETER MANUAL

B-62694ENlOQ

Specification

Number

B-62072E

B-62082E

B-62073E

B-62073E- 1

B-62554E

B-62554E-1

B-62564E

B-62564E- 1

B-62075E

B-62560E

-8-

Page 20

Page 21

1 FOR Series 16/18-B/C, Series 15-B

The information for connection of the Data Server interface

for Series 16/18-B/C and Series 15-B is described in this

chapter.

-ll-

Page 22

1. FOR Series 16/l 8-B/C.Series 15-B

CONNECTION

B-62694ENIO;i

II .

CONSTRUCTION

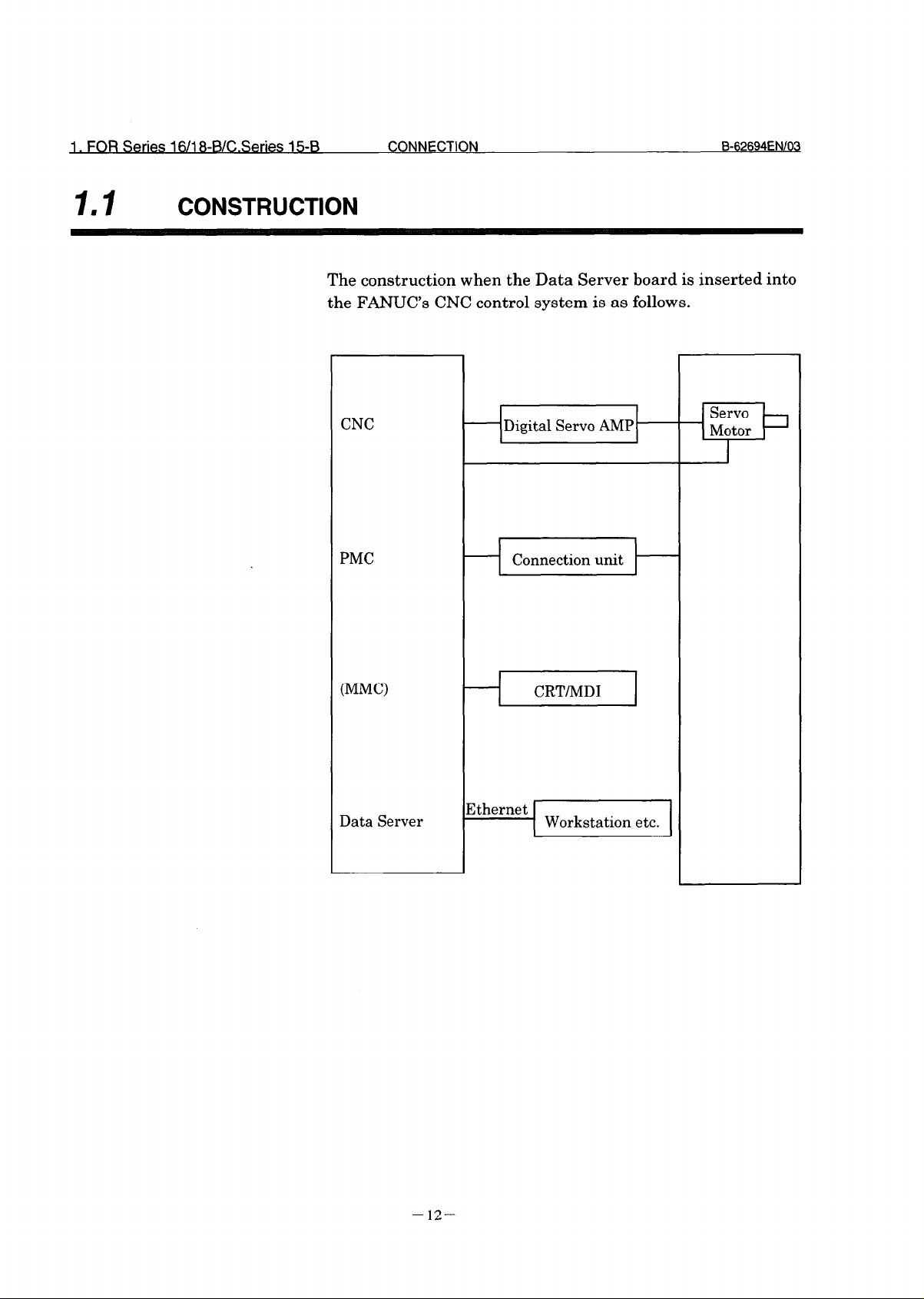

The construction when the Data Server board is inserted into

the FANUC’s CNC control system is as follows.

CNC

PMC

ADigital Servo AMP)

Connection unit

-I

I-

(MM0

Data Server

+ CRT/MD1 1

Xhernet

Workstation etc.

- 12-

Page 23

B-62694EN/03

CONNECTION

INSTALLATION

1.2. I Environmental Requirements

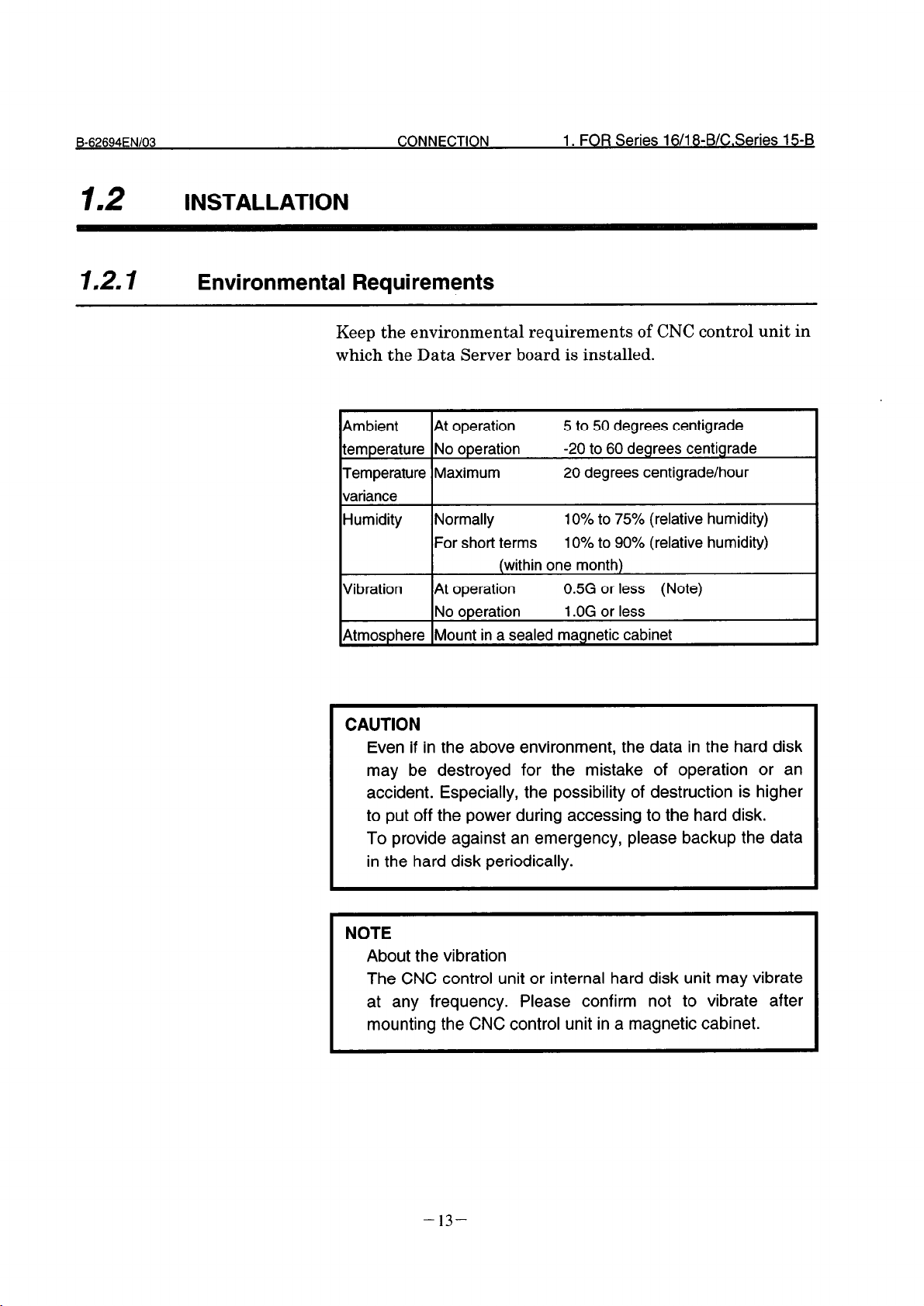

Keep the environmental requirements of CNC control unit in

which the Data Server board is installed.

1. FOR Series 16/l 8-B/C.Series 15-B

Ambient

temperature No operation

Temperature Maximum

variance

Humidity Normally

Vibration At operation

Atmosphere Mount in a sealed magnetic cabinet

At operation

For short terms

(within one month)

No operation 1 .OG or less

5 to 50 degrees centigrade

-20 to 60 degrees centigrade

20 degrees centigrade/hour

10% to 75% (relative humidity)

10% to 90% (relative humidity)

0.5G or less (Note)

CAUTION

Even if in the above environment, the data in the hard disk

may be destroyed for the mistake of operation or an

accident. Especially, the possibility of destruction is higher

to put off the power during accessing to the hard disk.

To provide against an emergency, please backup the data

in the hard disk periodically.

NOTE

About the vibration

The CNC control unit or internal hard disk unit may vibrate

at any frequency. Please confirm not to vibrate after

mounting the CNC control unit in a magnetic cabinet.

- 13-

Page 24

1. FOR Series 16/l 8-B/C.Series 15-B

CONNECTION B62694ENlOCj

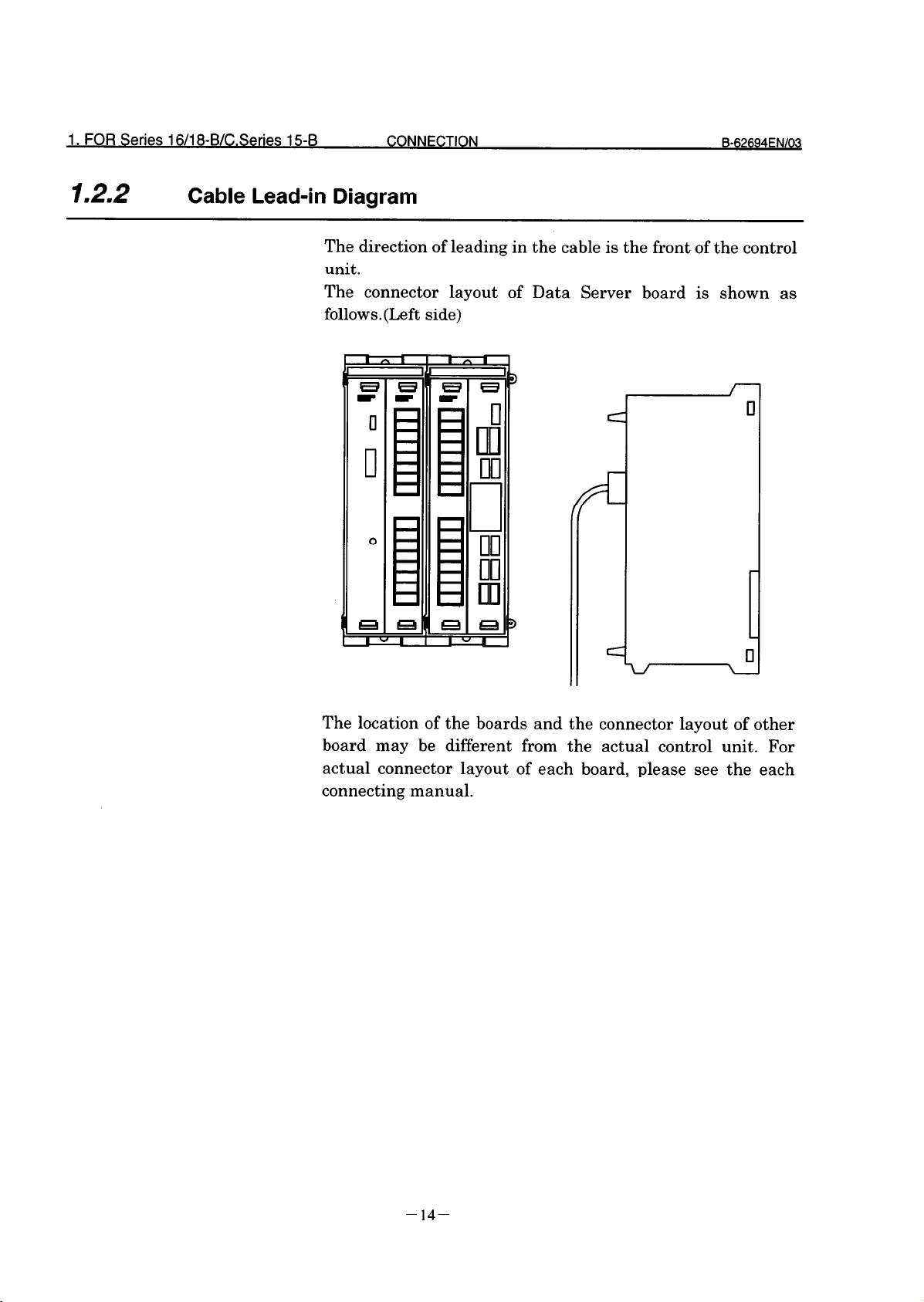

1.2.2 Cable Lead-in Diagram

The direction of leading in the cable is the front of the control

unit.

The connector layout of Data Server board is shown as

follows. (Left side)

The location of the boards and the connector layout of other

board may be different from the actual control unit. For

actual connector layout of each board, please see the each

connecting manual.

- 14-

Page 25

_&62694ENl

CONNECTION 1. FOR Series 8 Se 03 16/l -B/C

ries 15-B

1.2.3

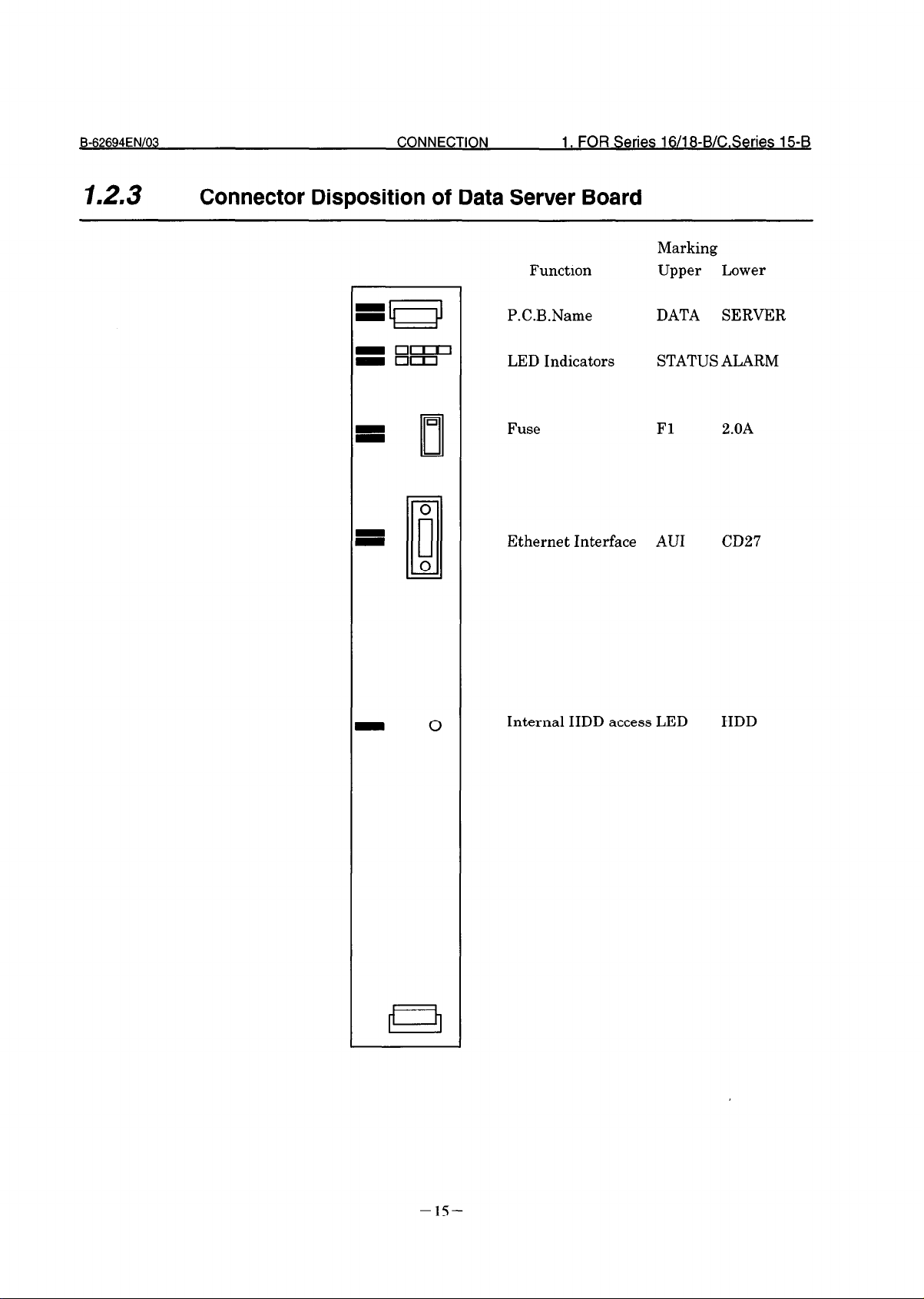

Connector Disposition of Data Server Board

Function

P.C.B.Name

LED Indicators

Fuse Fl 2.OA

Ethernet Interface AU1

Marking

Upper Lower

DATA SERVER

STATUS ALARM

CD27

Internal HDD access LED HDD

- 15-

Page 26

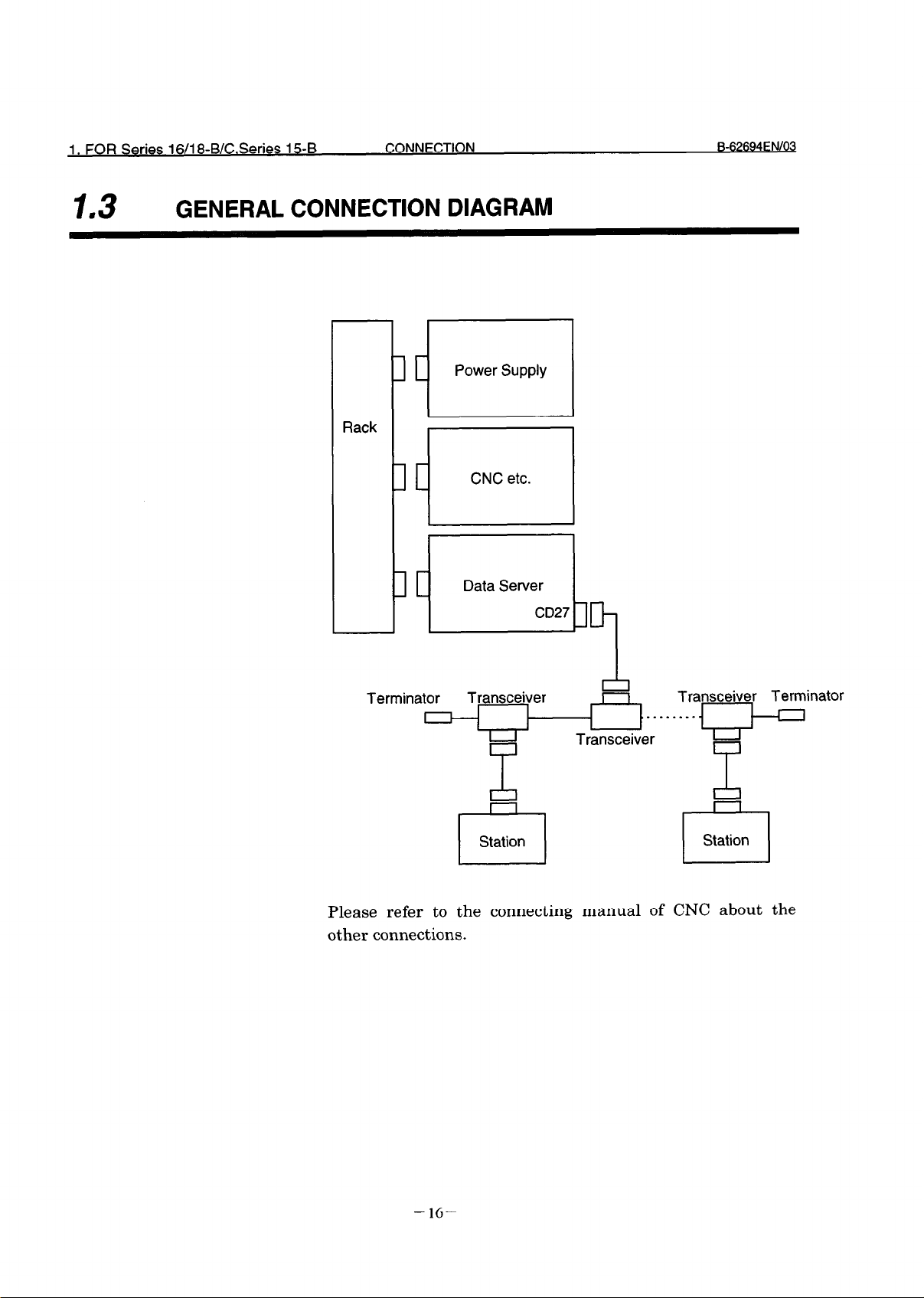

1. FOR Series 16/l 8-B/C.Series 15-B

CONNECTION

13 .

GENERAL CONNECTION DIAGRAM

Power Supply

1

Rack

CNC etc.

li

Terminator

Please refer to the connecting manual of CNC about the

other connections.

Transceiver

- 16-

Page 27

Eb62694ENl03 CONNECTION

2. FOR Series 16i/l8i-A

2

FOR Series 16dl8i-A

The information for connection of the Data Server Interface

board for Series 16i/18i-A is described in this chapter.

- 17-

Page 28

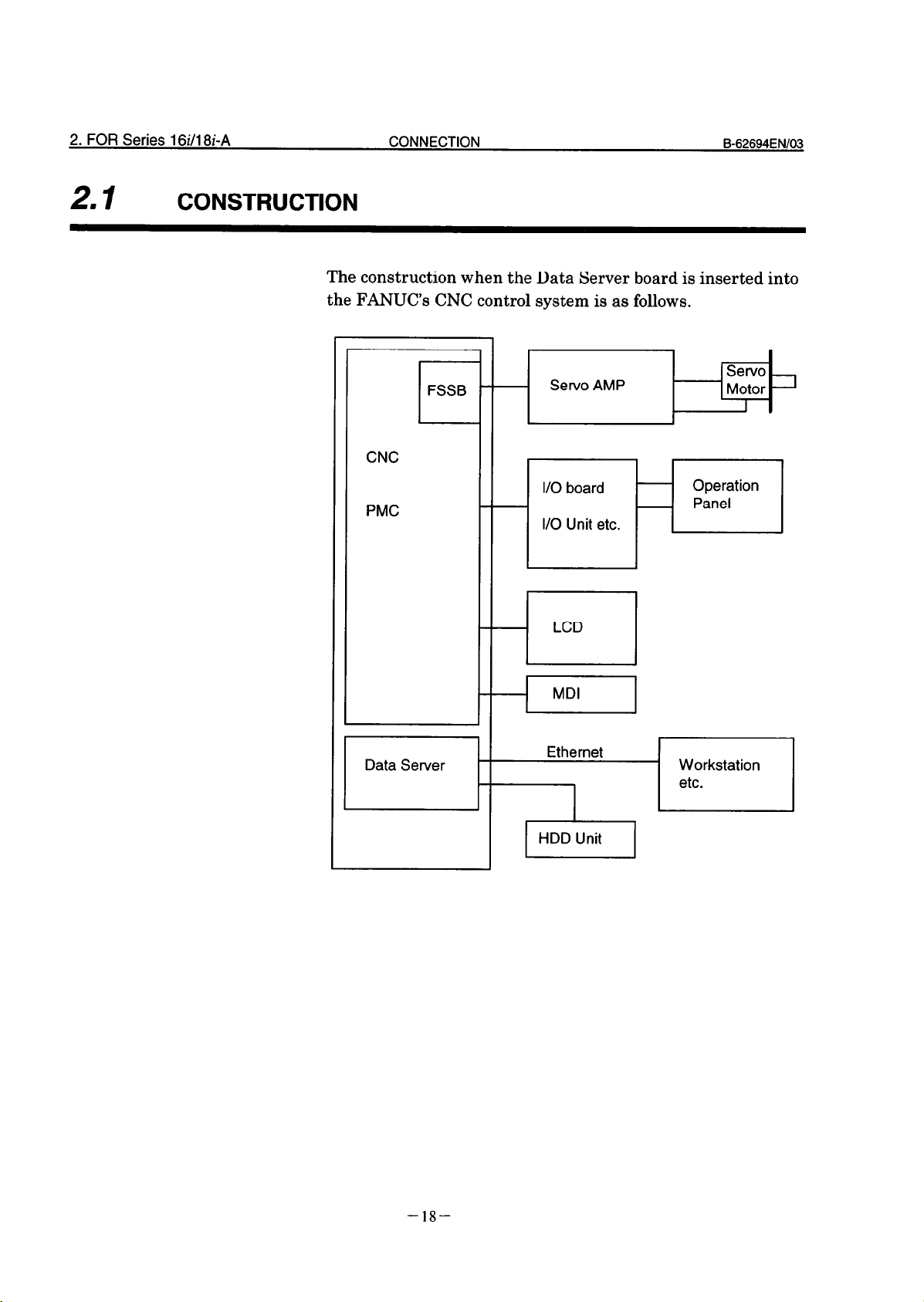

2. FOR Series 16i/l8i-A CONNECTION B-62694ENl03

.

21

CONSTRUCTION

The construction when the Data Server board is inserted into

the FANUC’s CNC control system is as follows.

FSSB

r

CNC

PMC

Data Server

- Servo AMP

LCD

--I

-1 Workstation

MDI

I

Servo

Allotor 1

-18-

HDD Unit

I

I

Page 29

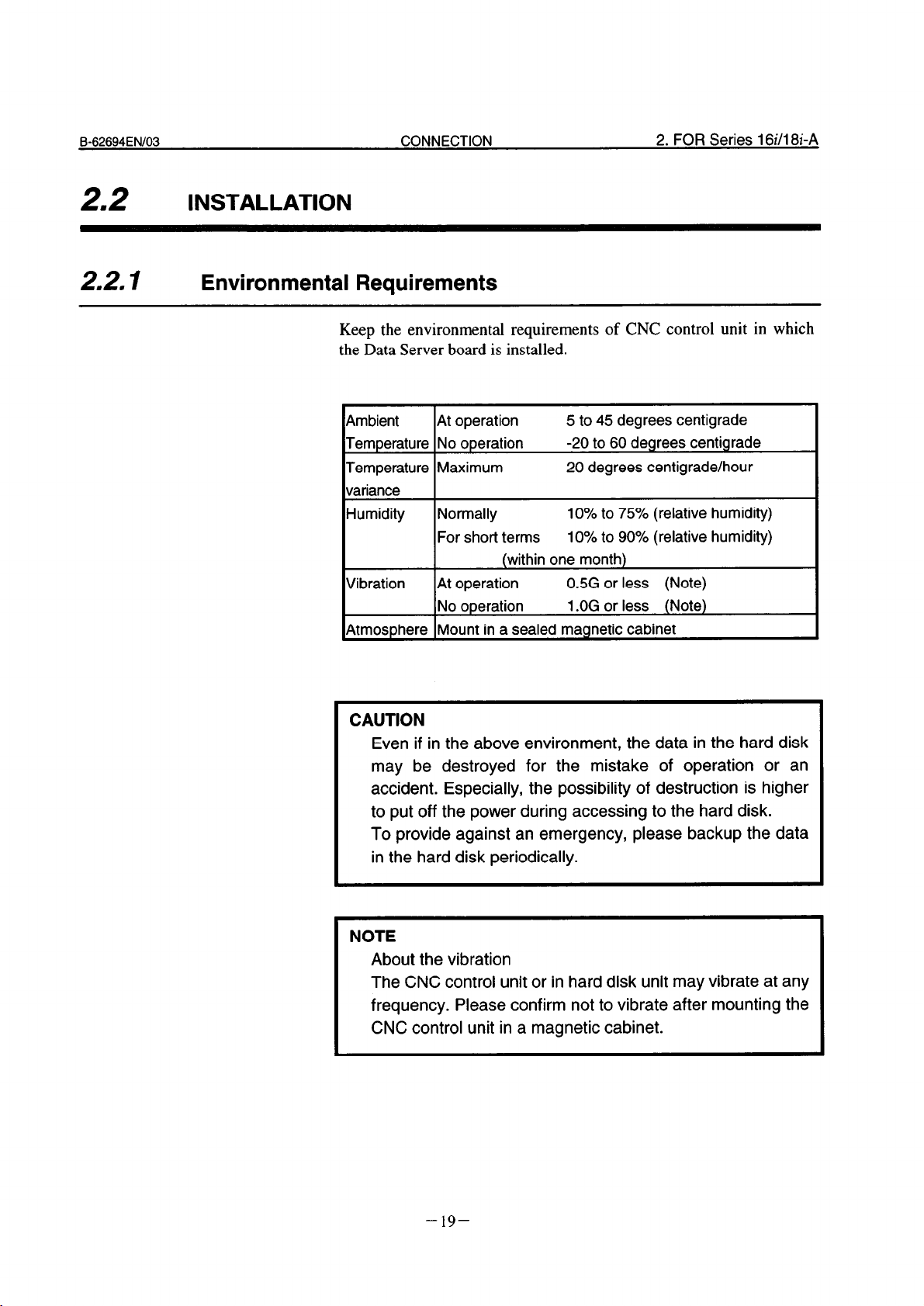

B-62694ENl03 CONNECTION

22 . INSTALLATION

2.2. I Environmental Requirements

Keep the environmental requirements of CNC control unit in which

the Data Server board is installed.

2. FOR Series 16i/18i-A

Ambient At operation

Temperature No operation

Temperature Maximum

variance

Humidity Normally

For short terms

(within one month)

Vibration

Atmosphere Mount in a sealed magnetic cabinet

At operation

No operation

5 to 45 degrees centigrade

-20 to 60 degrees centigrade

20 degrees centigrade/hour

10% to 75% (relative humidity)

10% to 90% (relative humidity)

0.5G or less (Note)

1 .OG or less (Note)

CAUTION

Even if in the above environment, the data in the hard disk

may be destroyed for the mistake of operation or an

accident. Especially, the possibility of destruction is higher

to put off the power during accessing to the hard disk.

To provide against an emergency, please backup the data

in the hard disk periodically.

NOTE

About the vibration

The CNC control unit or in hard disk unit may vibrate at any

frequency. Please confirm not to vibrate after mounting the

CNC control unit in a magnetic cabinet.

-19-

Page 30

2. FOR Series 16i/18i-A

CONNECTION

B-62694EN103

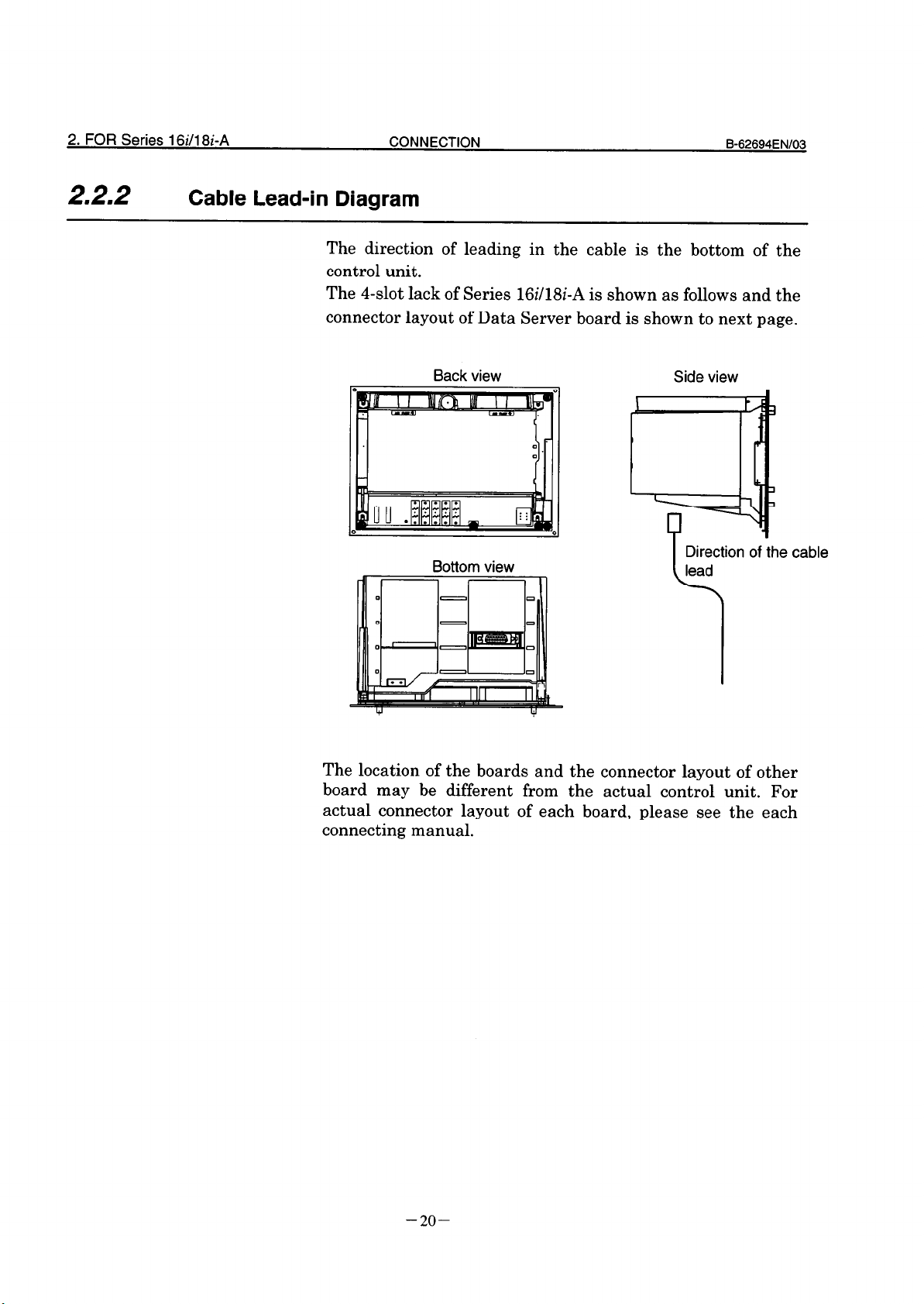

2.2.2

Cable Lead-in Diagram

The direction of leading in the cable is the bottom of the

control unit.

The 4-slot lack of Series 16i/lSi-A is shown as follows and the

connector layout of Data Server board is shown to next page.

Bottom view

Direction of the cable

lead

c

The location of the boards and the connector layout of other

board may be different from the actual control unit. For

actual connector layout of each board, please see the each

connecting manual.

-2o-

Page 31

B-62694ENl03

CONNECTION

2. FOR Series 16i/l8i-A

2.2.3

Connector Disposition of Data Server Board

Total edition OlA only

0 0

0

-

0

Communication LSI

0

-

0

Oil

osc

c

CPU

7

-

CUSTOM

LSI

AU1

CD27

STATUS 1

STATUS 2

STATUS 3

STATUS 4

Parity Alarm

CPU HALT

HDD Access

CUSTOM

LSI

IDD Interface

:NHl

JNA

-21-

Page 32

2. FOR Series 16i/l8i-A

CONNECTION

Total Edition 02B or newer

. I

, , ;__________.:

. I .

I

. 4

* *

. .

. .

I .

. *

. * .

. * .

* * .

. I 8

, , . . . .._.______ *

1

-.___-

p

i Communi- i

i cation LSI i

---.-_.__._

: osc i - 1

’ . _ . . _ . _ . _ _ ,

(....._.___.__..._

I

B-62694EN103

AU1

CD27

CPU HALT

STATUS 4

STATUS 3

STATUS 2

STATUS 1

Parity Alarm

, @l-r

CPU

CUSTOM

LSI

n

I

I

/

CUSTOM

LSI

-

01

HDD Access

HDD Interface

CNHl

Terminal

TM1

-22-

Page 33

Page 34

2. FOR Series 16i/18i-A

CONNECTION

B-62694ENl03

2.3.2

Connection of HDD Unit

The board of total edition 02B or newer must be assemble the

plate which is to prevent slipping out of the hard disk

connector.

To connect or disconnect the hard disk cable, this plate also

need to be connected or disconnected.

(The board of total edition OlA has no terminal to assemble

the plate.)

1) Connection of the cable

2) Assemble of the plate

-

Plat

Terminal

I

LoJ

3) Fix the plate using the screw

To disconnect the hard disk cable, do the reveres way of the

above order.

CAUTION

Before connect or disconnect the cable to Data Server

board, cut the power supply of CNC unit and confirm that

the power is off.

-24-

Page 35

B-62694ENl03

CONNECTION

2. FOR Series 16i/l8i-A

HDD Unit is mounted on the back side of MD1 unit.

The

length of the HDD flat cable is 370mm.

In the case of mounting the MD1 unit apart from control unit,

the hard disk unit is not be able to be connected. So,

considering the cable length of hard disk unit, mount the

MD1 unit as follows.

1 MD1 Unit (Horizontal) 1

Mounting example of MD1 Unit

0

MD1 Unit (Vertical)

-25-

Page 36

3. CONNRXION WI-W NFTWORK

CONNFCTION

B-6%94FNIQ

3

CONNECTION WITH NETWORK

In this chapter, we describe the information about the

connection to the Ethernet.

CAUTION

Before connect or disconnect the cable to Data Server

board, cut the power supply of CNC unit and confirm that

the power is off.

NOTE

Please inquire of each maker about the construction of

network or the condition of using the equipment except the

Data Server (transceiver and cable etc.) . To construct the

network, it is necessary not to be influenced by the noise.

Separate the network line electrically from the noise source

as power line and motor etc..

of each equipment must be done. And the high impedance

to the ground makes the obstacle of communication.

Please test and confirm the communication before working

the machine in earnest.

The network trouble which is case of the equipment except

the Data Server is not guaranteed by FANUC.

And the ground treatment

-26-

Page 37

. CONNECTION WITH THE ETHERNET

31

MAU (Media Attachment Unit : Transceiver)

Coaxial cable

\

Transceiver cable

Te<minator

I I

AL

C

I

I

MAU

StaGn

Items Marks

Maximum segment length a 500m

Length

transceiver

Length of transceiver cable C Maximum 50m

Node number per segment n Maximum 100

MAU : TDK : CIU-1000 Ethernet Transceiver or equivalent

Set for IEEE802.3 standard. (Include the hart-beat function)

NOTE

1. The transceiver must be connected to

Server using the transceiver cable. The

should be shielded. (Refer 3.4 )

2. The SQE TEST function (Hart-beat

transceiver must be set. There are some transceivers that

the setting switch or jumper are inside the transceiver.

I

between the b On the marking at intervals of

(Transceiver)

Conditions

2.5m

the AUI of Data

transceiver cable

function) of the

-27-

Page 38

3. CONNFCTION WITH NFTWORK

.

32

AUI (Attachment Unit Interface) PIN CONFIGURATION

CONNFCTION

CD27 D-sub 15pin

Fb67694FNlCQ

-28-

Page 39

Page 40

3. CONNFCTI~N W-W bE!-WOW

. SHIELDING EARTH OF THE TRANSCEIVER CABLE

34

The transceiver cable should be clamped by the method as

shown below. This cable clamp treatment is not only for cable

support but also for shield-treatment. As it is very important

for stable operation of the system, perform this treatment.

Peel out the sheath partially as shown in the following figure

and expose the shield. Push and clamp by the plate metal

fittings for clamp at the part.

CONNWTION B-67694FNlOa

Ground plate

Cable

Metal fittings for clamp

Peel of cable ’

Transceiver cable

Hitachi-densen LTD Transceiver cable or equivalent

-3o-

Page 41

8-@‘694FN/O3

CONNFCTION

3. CONNECTION WITH NFTWORY

, Ground plate

Example for shield treatment of transceiver cable

Prepare ground plate like the following figure.

Mount screw hole

Ground terminal

Clamp metal hole

(grounded)

Ground plate

For the ground plate, use a metal plate of 2mm or thicker,

which surface is plated with nickel.

-31-

Page 42

3. CONNFCTlON WITH NETWORK

hGroun;_

CONNFCTION

t-t,

Fi m

I

1 20mm 4 i /

Ground plate holes

Max 55mm

B-67Fi94FNIOC$

Cable clump outer diagram

Order specification for cable clump

AOZB-0083-K301 ( 5 pieces )

-32-

17mm

Page 43

Page 44

EO/N36929-9

33NVN31NIVW

g-9 1 =!-JaS 38-8 l/9 1 =!JaS tlOJ- 1

9-a =!a ‘3/a=8c/9c sa!Js kiOA

-SE-

Page 45

11 .

SYSTEM BLOCK DIAGRAM

A

Power Supply Unit

CNC Main CPU Board

Other Option Board

I I I I I

1 ROM 1-w-j HDD 1

I ,

CPU

IH

-

-

-

Name

Data Server Board

Custom

LSI

LAN

Controller

I -

DRAM

Ko

SRAM

Data Server P.C.B.

Specification

A16B-2202-0630

DViRV

Note

lOBASE

1

CNl

HDD Unit

Fuse

-36-

A02B-0207-CO50

A02B-0207-CO5 1

A02B-0207-CO53

AO8R-0048-K 10 1

85MB

256MB

810MB

2.OA

Page 46

B-62694EN/03

MAINTENANCE

1 .FOR Series 16/l 8-B/C. Series 15-B

12 .

PARTS LAYOUT

Specification : A02B-02 13- JO0 1

Printed

letters

DATA

SERVER

0

0

0

0

STATUS

ALARM

Fl

2.OA

AUI

CD27

LED c

0

0

+12vo

[

=

=

0

II

Back Plane Connector HDD

c

HDD

0

-37-

Page 47

1 .FOR Series 16/l 8-B/C. Series 15-B

MAINTENANCE

B-62694ENl03

.

13

LIGHTING OF LEDS AND MEANING

In the Data Server board for Series 16/18-B/C and Series 15

B, there are four green LEDs for “STATUS”, three red LEDs

for “ALARM” and one green LED for “HDD”.

In the following explanation, status of LED is expressed as

follows.

q : Turn off

n : Turn on

IATA

SERVER

El

STATUS &&&A

PILARM 000

The indication of LEDs when turning on the power

‘ower off

nitial state of power injection

5 1 STATUS q ltlHW

0 : Don’t care

State of Data Server Board

Main memory test

Ethernet RAM test

9 1 STATUS q IOCID

I

10 1 STATUS n mWl

Under checking Initialization of s stem area

Hardware

FANUC BUS Interrupt test 1

FANUC BUS Interrupt test 2

FANUC BUS Interrupt test 3

FANUC BUS Interrupt test 4

Initialization of

interrupt

When the Data Server Software runs normally, the status of

LEDs becomes the state of 14.

-38-

Page 48

B-62694ENl03

MAINTENANCE

1 .FOR Series 16/l 8-B/C. Series 15-B

The indication of LEDs(STATUS) when an error occurs

LEDs of “STATUS’ repeat the pattern of “LONG” and

“SHORT”. The pattern of “LONG” is indicated long and the

pattern of “Sl

[ORT” is indicated short.

LEDs (

LONG

No.

1234

q llJcl~

1

x--pi

cnmm

8

I

9 I IJclmm

clclmm

12

(Note) When

STATUS)

SHORT

1234

q ICIKI Defect of main memory

Check the Data Server P.C.B.

Kill Defect of Ethernet RAM

Check the Data Server P.C.B.

lXw0 Defect of Common RAM

ICheck the Data Server P.C.B.

0000 Unexpected interrupt to the CPU

occurred.

0000 Unexpected interrupt to the CPU

occurred.

0000 Unexpected interrupt to the CPU

occurred.

~000 The system error occurred in the Dat

Server software.

¤~~~ Bus error of FANUC BUS occurred.

Check the Data Server P.C.B.

q B00 Parity error of main memory occurred.

n KICI Parity error of Ethernet RAM occurred.

q ICIKI Parity error of Common RAM occurred.

n 0Kl Refresh toward the main memory wa

interrupted beyond the fixed conditio

time.

,hese errors occur, please contact FANUC.

State of Data Server board

(Note)

(Note)

(Note)

(Note)

The indication of LEDs(ALARM) whc

LEDs

ALARM

ALARM

1 ALARM

-39-

47 an error occurs

123 State of Data Server board

HO0 Parity error of main memory, Ethernet

RAM or Common RAM occurred, or refresh

toward the main memory was interrupted

beyond the fixed condition time. Identify

the defect and exchange by referring tc

“STATUS” LED from No.9 to No. 12.

OWO The fuse is broken. Exchange the fuse.

0Om CPU is in HALT state or SHUTDOWN

state. Check the Data Server P.C.B.

Page 49

1 .FOR Series 160 8-B/C. Series 15-B

MAINTENANCE B-62694EN/03

14 .

HOW TO EXCHANGE A FUSE

(1)Check a fuse on the front panel of the Data Server P.C.B.

and confirm whether it is broken.

There is a little window in the fuse and a white marker

appears there at the time of the breakage.

(2)Remove the cause of the fuse cutting.

(3)After the broken fuse is pulled out, insert the new fuse of

the same specification.

- Fuse

Fuse Specification :

A08B-004%KlOl

Capacity : 2.OA

Use : For Ethernet power

-4o-

Page 50

B62694EN/03

MAINTENANCE 2.FOR Series 16i/l8i-A

2

FOR Series 16i/l8i-A

In this section, the maintenance information about Series

16i/18i-A is described.

-4l-

Page 51

2.FOR Series 16dl8i-A MAINTENANCE

SYSTEM BLOCK DIAGRAM

CNC Main CPU Board

B-62694EN/03

4

Other Option Board

Ethernet _

CPU

Custom -

LSI

CJ

Cl

Data Server P.C.B.

AUI

1

CD27

HDD

CNHl

I

Name Specification Note

Data Server Board AZOB-8100-0160

Sub Board A20B-2002-0590 latter edition than 02B

HDD Unit A02B-0236-C252

Note)

In case of latter edition than 02B, the DC/DC

converter is loaded on the sub board.

-42-

810MB

Page 52

B-62694EN/03

MAINTENANCE

2.FOR Series 16i/l8i-A

22 .

PARTS LAYOUT

Parts Layout (Only 0 1A edition)

ommunicati n

Controller

cl

0 0

0

Custom

LSI

c

I

1

c

AUI

CD27

STATUS 1

STATUS 2

STATUS 3

STATUS 4

Parity Alarm

CPU HALT

HDD Access

-43-

u-

HDD Interface

CNHl

JNA

E

Page 53

2.FOR Series 16i/l8i-A

MAINTENANCE

Parts Layout (Latter edition than 02B)

B-62694ENl03

7

J

Interface Board : AZOB-2002-0590

Custom c

LSI

AUI

CD27

CPU HALT

STATUS 4

STATUS 3

STATUS 2

STATUS 1

Parity Alarm

HDD Access

Custom

LSI

0

7

1

HDD Interface

CNHl

Terminal

0

c

TM1

JNA

E

-44-

Page 54

B-62694ENl03

MAINTENANCE

2.FOR Series 16i/l8i-A

.

23

LIGHTING OF LED AND MEANING

In the Data Server Board for Series 16i/18i-A, there are four

green

one green LED for “HDD”. But, LEDs’ position is different by

the edition of the Data Server board.

The LEDs’ position is displayed for each edition.

In the following explanation, status of LED is expressed as

follows.

LEDs for “STATUS”, two red LEDs for “ALARM” and

0 : Turn off

n : Turn on

0 : Don’t care

-45-

Page 55

2.FOR Series 16i/l8i-A

MAINTENANCE

2.3. I In Case of Edition 01 A

B-62694EN103

The indication of LEDs when turning on the power

LEDs

No.

1

STATUS 0000 Power off

2 STATUS WmmH Initial state of power injection

3 1 STATUS n m=Cl

4 1 STATUS WHO1

5 1 STATUS HKl0

6 1 STATUS WClHm Under checking

7 1 STATUS WClmU

8 1 STATUS KlClW

9 1 STATUS HClCllJ

10 1 STATUS q lmmH

11 STATUS IJ~MCI

I

12 STATUS q IKI~ Boot up Initialization of BIOS

13 STATUS q lKl0 Data Server Loading software to

14 STATUS 000~ Boot up completely

When the Data Server Software runs normally, the status of

LEDs becomes the state of 14.

4321

Hardware

software

State of Data Server Board

I

Main memory test

Ethernet RAM test

Common RAM test

Initialization of system area

FANUC BUS Interrupt test 1

FANUC BUS Interrupt test 2

FANUC BUS Interrupt test 3

FANUC BUS Interrupt test 4

Initialization of

controller

memory

interrupt

main

-46-

Page 56

B-62694ENl03

MAINTENANCE

The indication of LEDs(STATUS) when an error occurs

LEDs of “STATUS” repeat the pattern of “LONG” and

“SHORT”. The pattern of “LONG” is indicated long and the

pattern of “SHORT” is indicated short.

LEDs (STATUS)

LONG SHORT

IO.

4321 4321

KICKI q lKI0 Defect of main memory

1

Check the Data Server P.C.B.

WI00 q l~Cl~ Defect of Ethernet RAM

2

Check the Data Server P.C.B.

KICKI q WKl Defect of Common RAM

3

Check the Data Server P.C.B.

KICI~ 0000 Unexpected interrupt to the CPU

4

occurred.

WXCl 0000 Unexpected interrupt to the CPU

5

occurred.

WElam 0000 Unexpected interrupt to the CPU

6

occurred.

WBKI q ICICI~ The system error occurred in the Dat,

7

Server software.

n m00 q 00m BUS error of FANUC BUS occurred.

8

Check the Data Server P.C.B.

n KICI q IOKI Parity error of main memory occurred.

9

mm00 q CImm Parity error of Ethernet RAM occurred.

10

mm00 q I~CICI Parity error of Common RAM occurred.

11

State of Data Server board

2.FOR Series 16i/l8i-A

(Note)

(Note)

(Note)

(Note)

The indication of LEDs(ALARM) when an error occurs

.

Lighting LED

Parity Alarm

State of Data Server board

n Parity error of main memory, Ethernet

RAM or Common RAM occurred. Identify

the defect and exchange it by referring to

“STATUS” LED from No.9 to No.11.

CPU HALT

n CPU is in HALT state or SHUTDOWN

state. Check the Data Server P.C.B.

-47-

Page 57

2.FOR Series 16i/l8i-A

MAINTENANCE

B-62694ENl03

2.3.2’

In Case of Latter Edition than 02B

Note) The Sub Board is displayed by a dotted line.

The indication of LEDs when turning on the power

LEDs 1234

No.

1

STATUS 0000 Power off

2

STATUS WmHm Initial state of power injection

STATUS ElmHW

3

STATUS HnmH

4

STATUS 00~~

5

STATUS HKIH

6

STATUS IJKlH

7

STATUS n 00m

8

STATUS q KIIJ~

9

STATUS n mKl

10

STATUS q lWWl

ii

12

13

14

When the Data Server Software runs normally, the status of

LEDs becomes the state of 14.

Under checking

Hardware

State of Data Server Board

I

Main memory test

Ethernet R4M test

Common BAM test

Initialization of system area

FANUC BUS Interrupt test 1

FANUC BUS Interrupt test 2

FANUC BUS Interrupt test 3

FANUC BUS Interrupt test 4

Initialization of

interru

-48-

Page 58

&62694EN/03

MAINTENANCE

The indication of LEDs(STATUS) when an error occurs

LEDs of “STATUS” repeat the pattern of “LONG” and

“SHORT”. The pattern of “LONG” is indicated long and the

pattern of “SHORT” is indicated short.

2.FOR Series 16i/l8i-A

.-.

1234 1234

q ICIO~ q IIJ~CI Defect of main memory

1

State of Data Server board

e system

error occurre

C BUS occurred.

(Note) When these errors occur, please contact FANUC.

The indication of LEDs(ALARM) when an error occurs

No.

Lighting LED State of Data Server board

1

Parity Alarm

n Parity error of main memory, Ethernet

RAM or Common RAM occurred. Identify

the defect and exchange it by referring to

“STATUS” LED from No.9 to No. 11.

2

CPU HALT

n CPU is in HALT state or SHUTDOWN

state. Check the Data Server P.C.B.

-49-

Page 59

Page 60

1

FOR Series 16/l 8-B/C, Series 16ill8i-A

The operation of Data Server for Series 16/18-B/C and Series

16i/18i-A is described in this chapter.

-53-

Page 61

1 .FOR Series 16/l 8-B/C, Series 16ill8i-A OPERATION

B-62694EN103

11 I

OUTLINE

By using this function, the following items can be achieved.

(l)Drive high-speed machining operation by calling the

subprogram from a built-in hard disk on the Data Server

board (described as “HDD” below).

(2)Input a NC program in the Host Computer into the HDD

by using FTP.

Output a NC program in the HDD into the Host Computer

by using FTP.

(3)Input a NC program in the HDD into the memory of the

CNC.

Output a NC program in the memory of the CNC into the

HDD.

(4)Delete NC programs and display the table of NC programs

in the HDD.

NOTE

There is the software option “PROGRAM NUMBER 08-

DIGIT” in the Series 16/18-C and Series 16i/l8i-A, but the

Data Server function doesn’t support this feature.

So, the Data Server function and the software option

“PROGRAM NUMBER 08-DIGIT” are not used at the

same time.

-54-

Page 62

B62694ENl03

OPERATION

1 .FOR Series 16/l 8-B/C. Series 16i/l8i-A

1.1. I

Notice when You Use for the First Time

WARNING

1 If you use this function for the first time, you must initiate

the HDD according to “1.8.2 Formatting the Built-in Hard

disk” and input the setting data according to “1.2 SETTING

SCREEN”. And turn off and then turn on the power of the

CNC.

If you use this function before you operate these, we don’t

guarantee that this function operates normally.

2 About FTP on the Ethernet, when you use this function for

the first time, please set Ethernet addresses carefully and

check this function on your environment according to your

network administrator’s advice.

If you set wrong Ethernet addresses, it may make a heavy

effect on your network.

CAUTION

1 If you turn off the power during reading the data from the

HDD or writing to the HDD, it may make the registered file

in the HDD broken.

So, you must not turn off the power during executing the

Data Server functions.

2 Be sure to take the backup of the data in the HDD against

an emergency.

-55-

Page 63

1 .FOR Series 16/l 8-B/C, Series 16i/l8i-A OPERATION

I SETTING SCREEN

12

By using this screen, you can set the data to transfer a NC program

between the HDD and the Host Computer with FTP.

You must set the data shown as the section “1.2.1 Description of Each

Data” before you use the Data Server functions.

Procedure

(l)Press SySTm the function key.

(1

(2)When the softkey [DS-SET] isn’t displayed, press the continuous

menu key several times.

@Press the softkey [DS-SET]. The following screen is displayed.

When the data are already registered, their contents are displayed.

(4)Input the data by using the MD1 keys and the softkeys.

DATA SERVER SETTING-l 00001 NO0010

(HOST-COMPUTER)

IP ADDRESS

I I

USER NAME

I

I

I

I

+

1

l I

----_--------------------------

PASSWORD

-------------------------------

HOST DIRECTORY

________---_--------------------

--------------------------------

--------------------------------

B-62694ENl03

Change two screens

by using the page

1 &I *** STOP *** Lo;-::5

[STRING][ LOCK ][ INPUT ] [ CHECK I[ SET ]

IP ADDRESS

b

MASK ADDRESS

---------------

---------------

1 ;DI *** STOP *** “z:;,;;;G

[STRING][ LOCK I[ INPUT 1 [ CHECK ][ SET 1

-56-

Page 64

Page 65

1 .FOR Series 16/l 8-B/C, Series 16i/l8i-A

OPERATION

B-62694EN103

1.2. I

Description of Each Data

.) Setting data of the Host Computer

(a

(DATA SERVER SETTING- 1)

IPADDRESS IP address of the Host Computer’s Ethernel

USER NAME User name of the Host Computer

PASSWORD Password for the above “USER NAME”

HOST

DIRECTORY to communicate with the Data Server

You can input small letters in these items.

Please see the section “1.2.3 How to Input Small Letters”.

(b) Setting data of the Data Server

(DATA SERVER SETTING-2)

board

( Ex. : “192.168.0.1” )

( Max. 31 letters )

This password must be set.

( Max. 31 letters )

Working directory of the Host Computer in order

( Max. 127 letters )

MAC MAC address of the Data Server board

ADDRESS You must input the 12 alphanumerical let1

printed as the “ADR” at the seal on the D

Server board.

( Ex. : “080019ABCDEF”’ )

IP ADDRESS IP address of the Data Server board

( Ex. : “192.168.0.2” )

MASK Netmask for the network

ADDRESS ( Ex. : “255.255.255.0” )

CAUTION

1 If you change the above “(b) Setting data of the Data

Server” data, you must turn off the power of the CNC once.

2 You must input the 12 alphanumerical letters printed as the

“ADR” at the seal on the Data Server board into the MAC

address.

If you set the wrong address into the MAC address, it may

make a heavy obstacle on your network.

-58-

Page 66

B-62694EN103

OPERATION

1 .FOR Series 16/l 8-B/C, Series 16i/l8i-A

The meanings of each address are as follows:

MAC ADDRESS

: It means the address that identifies

each machine connected by Ethernet in

the MAC layer.

It must be unique in the network.

IP ADDRESS

: It means the address that identifies

each machine connected by Ethernet in

the Network layer.

It must be unique in the network.

MASK ADDRESS : It means a bit typed value which takes

out the part of the network address

from the IP address.

Refer to “APPENDIX C. ETHERNET TECHNICAL

TERMS” in detail.

-59-

Page 67

1 .FOR Series 16/l 8-B/C, Series 16i/l8i-A

OPERATION

B-62694ENl03

1.2.2

Procedure

How to Input Data

In this section, how to input data is explained.

(1)Move the cursor to an item that you wiII input.

(2)Input the data by using the MD1 keys.

(s)Press the softkey [INPUT].

In this screen, the MD1 key

Ex.) In case of setting “192.168.0.1” into the IP ADDRESS

item

(1) Move the cursor and put the cursor on the IP

INWT can’t be used.

I:

ADDRESS item.

DATA SERVER SETTING-l

(HOST-COMPUTER)

IP ADDRESS

USER NAME

>

MD1

1 [STRING] [ LOCK I [ INPUT I[ CHECK I [ SET 11

*** STOP

00001 NO0010

***

12:34:56

I

(2) Input the data “192.168.0.1” by using the MD1 keys.

DATA SERVER SETTING-l

(HOST-COMPUTER)

IP ADDRESS

USER NAME

> 192.168.0.1

MD1

[STRING] [ LOCK ][ INPUT I[ CHECK ][ SET ]

*** STOP **k

00001 NO0010

12:34:56

(3)Press the softkey [INPUT].

DATA SERVER SETTING-l

(HOST-COMPUTER)

IP ADDRESS

USER NAME

MD1

[STRING][ LOCK I[ INPUT ][ CHECK ][ SET ]

I

*** STOP *k*

00001 NO0010

12:34:56

-6O-

Page 68

B-62694ENl03

OPERATION

1 .FOR Series 16/l &B/C, Series 16i/l8i-A

NOTE

The above setting data of Data Server are different from

other NC parameters. They are saved in the HDD.

Therefore you must save the setting data after inputting or

changing these data.

Please refer to the section “1.2.5 How to Save Modified

Data”.

-61-

Page 69

1 .FOR Series 16/l 8-B/C, Series 16Ul8i-A OPERATION

B-62694EN103

1.2.3

Procedure

How to Input Small Letters

When you input the setting data for the Host Computer, you

can input small letters.

How to input small letters is described as follows.

(1)Press the softkey [ LOCK ] before inputting small letters.

Confirm the “LOCK : ON” on the right and low of the

screen.

(z)Then the inputted letter from the MD1 keys is changed to a

small letter.

(3)To cancel this mode, press the softkey [ LOCK ] again or

set the data by using the softkey [INPUT].

Confirm the “LOCK : OFF” on the right and low of the

screen.

-62-

Page 70

B-62694ENi03 OPERATION

1 .FOR Series 16/l 8-B/C, Series 16i/l8i-A

1.2.4

Procedure

How to Set a Host Directory

The data in the HOST DIRECTORY can be specified with

maximum 127 letters. But the data can be inputted with

maximum 32 letters once, so that you can’t specify the data

completely once, In this case, refer to the following.

Ex.) In case that you specify “/DATASERVER/NCPROGRAM

/LINEOO1/GROUP0002”

(1)Move the cursor and put it on the “HOST DIRECTORY”.

HOST DIRECTORY

-8

>

MD1

[STRING] [ LOCK I [ INPUT I [ CHECK I [ SET I

--------------------------------

--------------------------------

--------_--____-____------------

*k* STOP k**

LOCK : OFF

12:34:56

(z)Press the softkey [STRING], so that the cursor

and the

softkeys are changed as follows.

HOST DIRECTORY

~-------------------------------

--------------------------------

-------------------------------LOCK : OFF

>

MD1

[ EXIT I[ LOCK ][INSERT][DELETE][ INPUT ]

*** STOP k**

12:34:56

(@Input “/DATASERVER/NCPROGRAM/LINEOO1/GR” from

the MD1 keys and press the softkey [INPUT].

HOST DIRECORY

/DATASERVER/NCPROGWiM/LINEOOl/GR

~---------------------_---------

--------------------------------

-63-

Page 71

1 .FOR Series 16/l 8-B/C, Series 16i/l8i-A

(UAfterward, input the remained string “OUPOO02” from the

@After inputting the above data, if you insert

OPERATION

B62694ENl03

MD1 keys and press the softkey [INPUT].

HOST DIRECTORY

/DATASERVER/NCPROGRAM/LINEOOl/GR

o”po()o2(1------------------------

-------------------------------_

[ Reference ]

You may divide this string into two strings

“/DATASERVER/NCPROGRAM” and “/LINE00 l/GRO

UPOO02” and input these strings. In this case, the

result is the same as the above.

“/FACTORYOOlO” between

“NCPROGRAM”

and

“/LINEOOl” (“/DATASERVER/NCPROGRAM/FACTORYOO

lO/LINE001/GROUP0002”), move the cursor to “f before

“LINEOOl”, input “/FACTORYOOlO” from the MD1 keys

and press the softkey [INSERT].

HOST DIRECTORY

/DATASERVER/NCPROGRAM/FACTORYOOl

O@.JNE001/GROUP0002-------------

--------------------------------

(6)If you delete a letter, move the cursor to the letter that you

want to delete. And press the softkey [DELETE].

(7)If you overwrite letters, move the cursor to the letter that

you want to overwrite. Input new string from the MD1 keys

and press the softkey [INPUT].

(@If you end to input the data then press the softkey [ EXIT 1.

The cursor and the softkeys are returned to the status like

0).

NOTE

If you will input the letter that can’t be inputted from the

MDI keys, please refer to the section “1.12

PARAMETERS”.

-64-

Page 72

B-62694EN/03

OPERATION

1 .FOR Series 16/l 8-B/C. Series 16ill8i-A

1.2.5

Procedure

How to Save Modified Data

The setting data of the Data Server are different from other

CNC parameters. They are saved in the HDD. Therefore you

must save the setting data by the following operation after

inputting or changing these data.

If you only set the data on the screen and don’t save them,

then the Ethernet communication is not effected.

And if you change the CNC’s screen without saving modified

data, then modified data are lost. So, if you display the

setting screen again, then the old data are displayed.

(1)Press the softkey [ SET ] after you finish inputting all data.

(z)The blinking ‘SETTING” is displayed on the right and low

of the screen when saving modified data.

[Reference]

If the item is changed, then the name of the item is

blinking. And if you operate the above, then it becomes

normal display.

CAUTION

1 When the data are saved, the form of data is checked. If

there is a mistake in the data, the error message is

displayed and no part of the data is saved into the HDD.

In this case, “SETTING ERROR” message is displayed on

the left and low of the screen. Confirm the problem by

referring to the section “1 .l 1 ERROR MESSAGE”, then set

the correct data.

2 In case of changing the setting data for Host Computer

(DATA SERVER SETTING-l), these saved data are

available without turning off the power. But in case of

changing the setting data for Data Server (DATA SERVER

SETTING-2), these saved data are not available before

turning off the power.

3 The setting screen consists of two screens, but the setting

data are saved together. Therefore, you must save these

data after setting all data in two screens.

If you save the data after setting data only in one screen,

the error occurs by the reason of 1.

If you don’t save the data, the setting data aren’t available.

4

-65-

Page 73

1 .FOR Series 16/l 8-B/C, Series 16i/l8i-A OPERATION

B-62694ENl03

.

13

NC PROGRAM MANAGEMENT FUNCTION

By using Data Server function, the following items can be

achieved.

(1)Displaying the table of NC programs

Display the table of NC programs in the HDD in

alphanumerical order.

(2)Searching a NC program

Search a NC program in the HDD and display it.

(3)Deleting NC programs

Delete NC programs from the HDD

(4)Getting a NC program

Get a NC program from the Host Computer with GET

command of FTP

@Putting a NC program

Put a NC program into the Host Computer with PUT

command of FTP

(G)List-Getting NC programs

Get NC programs that are appointed in the List-File

from the Host Computer with GET command of FTP

(7)ListPutting NC programs

Put NC programs that are appointed in the List-File into

the Host Computer with PUT command of FTP

(@List-Deleting NC programs

Delete NC programs that are appointed in the List-File

from the HDD

CAUTION

1 Two or more items of the above can’t be operated at the

same time.

2 When you are operating “Calling a subprogram with Ml 98”

or “DNC Operation” on the buffer mode ( See “1 .lO

BUFFER MODE” ), you can’t operate the above functions.

And if you are operating neither “Calling a subprogram with

M198” nor “DNC Operation” on the buffer mode, you can

operate the above functions. But in case that you create a

new file into the HDD by operating “Getting a NC

program” ,etc., the remainder of the HDD is decreased by

this new file. In this case, you may not operate on the

buffer mode because of the shortage of the HDD’s

remainder. Therefore, in case of using the Data Server on

the buffer mode, you must not use “Getting a NC

program” ,etc.

-66-

Page 74

B-62694EN/03

OPERATION

1 .FOR Series 16/l 8-B/C, Series 16i/l8i-A

1.3. I

Procedure

Displaying the Table of NC Programs

You can display the table of NC programs in the HDD.

(1)Press

(z)When the softkey [DS-DIR] isn’t displayed, press the

continuous menu key several times.

(s)Press the softkey [DS-DIR], then the following screen is

displayed.

(4)Scroll the previous or next screen by pressing the page key.

(5)Change the contents of the screen by pressing the softkey

[CHANGE].

The screens imaged for 9 inch CRT and for 14 inch CRT are

shown as follows.

In this manual, 9 inch CRT is used for the example screens.

PROG the function key.

r:

-67-

Page 75

1 .FOR Series 16/l 8-B/C, Series 16i/l8i-A OPERATION

DATA SERVER HD DIRECTORY 00001 NO0010

I

REGISTERED PROGRAMS

FREE DISK AREA

FILE NAME COMMENT

00001

00002

00003 (SHAFT XSFOOl

01000 (GEAR XGROOl

02000 (GEAR XGR002 -

Change these screens

by pressing the softkey

[CHANGE].

I

I-

DATA SERVER HD DIRECTORY 00001 NO0010

REGISTERED PROGRAMS : 123

FREE DISK AREA : 45678901

FILE NAME SIZE

00001 12345678 94-01-11 09:lO

00002 1234 93-12-30 11:ll

00003 54321 94-03-21 15:39

01000 876543 94-02-21 20:47

02000 3456 94-04-01 23:59

03000 1357 93-01-15 00:03

03200 975318 94-01-01 19:32

03300 98765 94-02-14 12:oo

(SHAFT XSFOOl

(SHAFT XSFOOl

B-62694ENl03

123

: 45678901

PROGRAM001 )

SUBPROGRAMOl)

SUBPROGRAM02)

)

MAIN PROGRAM)

DATE

MD1

[ GET ][ PUT ][DELETE][SEARCH][CHANGE]

I

The screen imaged for 9 inch CRT

-68-

*k* STOP *kk

12:34:56

Page 76

B-62694ENl03 OPERATION

1 .FOR Series 16/l 8-B/C, Series 16ill8i-A

DATA SERVER HD DIRECTORY

FILE NAME

00001

00002

00003

010~0

02000

03000

03200

03300

03309

03411

03478

04012

04509

04567

05015

(SHAFT XSFOOl

(SHAFT XSFOOl

(SHAFT XSFOOl

(GEAR XGROOl

(GEAR XGR002 (BOLT XBTOOOl - TEST PROGRAM

(GEAR XGR 002 - SUBPROGRAM

(SHAFT XSF012 SAMPLE

(1234567890123456789012345678901234567890123456789012345678901234)

(ABCDEFGHIJKLMNOPQRSTWWXYZABCDEFGHIJKLMNYZABCDEFGHIJKL)

(ABCDEFGHIJKLMNOPQRSTUVWXYZl23456789OABCDEFGHIJKL~OPQRST~XYZl2)

(1234567890ABCDEFGHIJKLMNOPQRSTUVWXYZl23456789OABCDEFGHIJKL~OPQR)

(TEST PROGRAM

(SAMPLE PROGRAM

(

COMMENT

PROGRAM001

SUBPROGRAM01

SUBPROGRAM02

MAIN PROGRAM

00001 NO0010

REGISTERED PROGRAMS : 123

FREE DISK AREA : 45678901

94-01-14

MD1

23:45

DELETE SEARCH CHANGE +

)

1

1

1

1

1

1

1

1

1

)

12:34:56

DATA SERVER HD DIRECTORY

FILE NAME

00001

00002

00003

01000

02000

03000

03200

03300

03309

03411

03478

04012

04509

04567

05015

SHAFT XSFOOl PROGRAM001

SHAFT XSFOOl SUBPROGRAM01

SHAFT XSFOOl SUBPROGRAM02

GEAR XGROOl

GEAR XGR002 - MAIN PROGRAM

BOLT XBTOOOl - TEST PROGRAM 94- ) 1,357

GEAR XGR 002 - SUBPROGRAM

SHAFT XSF012 SAMPLE

12345678901234567890123456789012) 543,210

ABCDEFGHIJKLMNOPQRSTUVWXYZABCDEF) 468,024

ABCDEFGHIJKLMNOPQRSTWWXYZl23456) 2,134,657

1234567890ABCDEFGHIJKLMNOPQRSTUV) 4,892,182

TEST PROGRAM

SAMPLE PROGRAM

(

COMMENT SIZE

00001 NO0010

REGISTERED PROGRAMS : 123

FREE DISK AREA

1

1

1

1

1

)

)

1

1

1

MD1

12,345,678 94-01-11 09:lO

1,234

54,321

876,543

3,456

975,318

98,765

38,262

89,267

3,289

DELETE SEARCH CHANGE +

: 45,678,901

93-12-30 11:ll

94-03-21 15:39

94-02-21 20:47

94-04-01 23:59

93-01-15 00:03

94-01-01 19:32

94-02-14 12:oo

93-10-27 08:20

94-02-10 15:47

94-04-04 12:58

94-03-14 19:25

94-01-06 18:45

94-05-02 11:43

94-04-11 09:51

DATE

12:34:56

The screen imaged for 14 inch CRT

Change the above screens by pressing the softkey [CHANGE].

-69-

Page 77

1 .FOR Series 16/l 8-B/C, Series 16i/l8i-A

OPERATION

Each item means as follows,

REGISTERED

: number of registered NC programs in

PROGRAMS the HDD

FREE DISK

: free disk space in the HDD (unit : byte)

AREA

FILE NAME

COMMENT

: NC program name

: comment in a NC program

SIZE : size of a NC program

DATE

: registered date of a NC program

B-62694ENl03

(unit : byte)

-7o-

Page 78

B-62694EN/03

OPERATION

1.3.2 Searching a NC Program

When the table of NC programs in the HDD is displayed, you

can display the specified file at the top of the screen.

Procedure

(1)Input an O-number of the NC program that you will

search.

(z)Press the softkey [SEARCH].

(@Display the table of NC programs so that the top is the

specified NC program.

(4)The blinking “SEARCH” is displayed on the right and low

of the screen when searching.

CAUTION

If the specified NC program doesn’t exist in the HDD, the

next NC program in alphanumerical order is displayed at

the top of the screen.

1 .FOR Series 16/l 8-B/C, Series 16i/l8i-A

-71-

Page 79

1 .FOR Series 16/l 8-B/C, Series 16i/l8i-A

OPERATION B62694EN/03

1.3.3

Procedure

Deleting NC Programs

You can delete NC programs from the HDD.

(1)Display the “DATA SERVER HD DIRECTORY screen.

DATA SERVER HD DIRECTORY 00001 NO0010

FILE NAME COMMENT

00001

z-

03200

03300

>

MD1

[ GET I[ PUT 1 [DELETE][SEARCH][CHANGE]

(z)Press the softkey [DELETE].

DATA SERVER HD DIRECTORY 00001 NO0010

REGISTERED PROGRAMS

FREE DISK AREA

(SHAFT XSFOOl

(GEAR XGR 002 - SUBPROGRAM )

(SHAFT XSF012 SAMPLE

*** STOP kk*

123

: 45678901

PROGRAM001 )

.-

1

12:34:56

123

)

12~34~56

FILE NAME

00001

03200

03300

>

MD1

[

REGISTERED PROGRAMS :

FREE

DISK AREA : 45678901

COMMENT

(SHAFT XSFOOl PROGRAM001 )

(GEAR XGR 002 - SUBPROGRAM )

(SHAFT XSF012 SAMPLE

**k STOP k*k

1 [

I[ CAN I[ STOP I[ EXEC ]

(3)Input an O-number of the NC program that you will delete.

(4)Press the softkey [ EXEC 1.

(@The blinking “DELETE” is displayed on the right and low

of the screen when deleting.

[Reference]

In case of deleting NC programs, you can use the wild card

“*” in an O-number.

Example :

(1) In case of deleting all NC programs in the HDD, you

will specify “O*” as an O-number.

(2) In case of deleting NC programs from 00100 to

00199, you will specify “OOl*” as an O-number.

In case that you specify “012*0”, ignore letters latter than

-72-

Page 80

B-62694EN103

OPERATION

1 .FOR Series 16/l 8-B/C. Series 16i/l8i-A

the “*“,

so that “OlZ*O” is equal to “012*“. In both cases,

delete NC programs from 01200 to 01299.

In case that you use the wild card in an O-number, after

pressing the softkey [ EXEC 1, the message “FILE

DELETE?” is displayed on the left and low of the screen.

And the files are deleted by pressing the softkey [ EXEC ]

again. In order to cancel to delete files, press the softkey

[CM].

In case of deleting NC programs by using the wild card,

you can stop deleting NC programs by pressing the softkey

[ STOP 1. However, you can’t recover the files that are

deleted before stopping.

NOTE

When you delete the file by specifying one NC program,

you must specify O-number exactly. For example, when

specifying O-number of NC program as 1, usually you can

specify “Ol”, but you must specify “00001” in this function.

-73-

Page 81

1 .FOR Series 16/l 8-B/C, Series 16i/l8i-A OPERATION B62694ENl03

1.3.4

Procedure

Getting a NC Program

You can get a NC program from the Host Computer with

“GET” command of FTP, and register it into the HDD.

(1)Display the “DATA SERVER HD DIRECTORY” screen.

DATA SERVER HD DIRECTORY 00001 NO0010

FILE NAME COMMENT

00001

03200

03300 (SHAFT XSF012

>

MD1

1 [ GET ] [ PUT ] [DELETE] [SEARCH] [CHANGE] 1

(z)Press the softkey [ GET 1.

DATA SERVER HD DIRECTORY 00001 NO0010

REGISTERED PROGRAMS : 123

FREE DISK AREA

(SHAFT XSFOOl

(GEAR XGR 002

k*+r STOP k**

: 45678901

PROGRAM001 )

- SUBPROGRAM )

SAMPLE

12:34:56

)

REGISTERED PROGRAMS

FREE DISK AREA

FILE NAME COMMENT

00001

03200

03300

>

MD1

[ 1 [

(SHAFT XSFOOl

(GEAR XGR 002 - SUBPROGRAM )

(SHAFT XSF012 SAMPLE

*** STOP *kk

I [ CAN I [ STOP ][ EXEC ]

(3)Input an O-number of the

register into the HDD and a

Computer.

[ FORMAT ]

O****,@@@@

0

**** : an O-number of the NC program that you

will register into the HDD

**** is the integer of four digits)

(

@@a@: a file name stored in the Host Computer

123

: 45678901

PROGRAM001 )

)

12:34:56

NC program that you will

file name stored in the Host

-74-

Page 82

B-62694ENl03

OPERATION

1 .FOR Series 16/l 8-B/C, Series 16i/l8i-A

NOTE

You must use “,” between O**** and Q Q Q Q.

You must specify O****

that is not registered in the HDD.

If you specify the registered O-number, an error occurs.

You can omit “@@I@ a”. In this case, Q 8 Q @ is equal to

0 ****. It is available in case that a file name in the Host

Computer is named by O-number.

And in this case, omit ‘I,” between O**** and 6 Q Q @ too.

You can use small letters at 8 Q @ Q.

Input a letter from A to Z after pressing the softkey

[ LOCK 1. This softkey [ LOCK ] is available till pressing this

softkey [ LOCK ] again.

In case that the file name stored in the Host Computer

includes a letter that can’t be inputted from the MDI keys,

you can specify the substitutional letter for only one letter.

Refer to the section “1.12 PARAMETERS”.

(4)Press the softkey [ EXEC 1.

(5)The blinking “GET” is displayed on the right and low of the

screen when getting a NC program.

[Example]

In case that you register “TEST.PRG” in the Host

(1)

Computer as the name of “00001” into the HDD, please

input “OOOOl,TEST.PRG”.

In case that you register “00002” in the Host Computer

(2)

as the name of “00002” into the HDD, please input

“00002,00002” or only “00002”.

NOTE

1 In case of transferring a large NC program, you are careful

because you can’t stop “GET” function.

2 If an error occurs in this function, “GET ERROR” is

displayed on the left and low of the screen.

Confirm the problem by referring to the section “1.11

ERROR MESSAGE”. About error messages, refer to the

section “APPENDIX A. TABLE OF ERROR MESSAGES”.

-75-

Page 83

1 .FOR Series 16/l 8-B/C, Series 16i/l8i-A

OPERATION

1.3.5 Putting a NC Program

You can put a NC program in the HDD to the Host Computer

with “PUT” command of FTP.

Procedure

(1)Display the “DATA SERVER HD DIRECTORY” screen.

DATA SERVER HD DIRECTORY 00001 NO0010

B-62694EN/O3

REGISTERED PROGRAMS :

FREE DISK AREA

FILE NAME

00001

03200

03300 (SHAFT XSF012 SAMPLE

>

MD1

[ GET I[ PUT ][DELETE][SEARCH][CHANGE]

(SHAFT XSFOOl PROGRAM001 )

(GEAR XGR 002 - SUBPROGRAM )

kkk STOP k**

(z)Press the softkey [ PUT 1.

DATA SERVER HD DIRECTORY 00001 NO0010

REGISTERED PROGRAMS :

FREE DISK AREA

FILE NAME COMMENT