Page 1

MODEL:

CSP

01694-REVC_081315_ENGLISH

EZ-CREAM

3/8 OUNCE, CHICK-FIL-A

120V

Series 14I

94152

TM

Page 2

SAFETY GUIDELINES WHEN

USING THIS UNIT:

C EWarning- Electrical shock could occur:

• This unit must be earthed or grounded.

• This requires all three prongs (terminals) on

cord plug to be plugged into power source.

According to food and safety regulations, most foods

must be stored and/or served at certain temperatures

or they could become hazardous. Check with local food

and safety regulators for specic guidelines.

Be aware of the product you are serving and the

temperature the product is required to maintain.

Server Products, Inc. can not be responsible for

the serving of potentially hazardous product.

NSF International listed.

(National Sanitation Foundation)

Stainless steel is one of the best materials for food

serving and storage, but there are many products which

can corrode it. If you notice corrosion beginning on

any stainless steel surface, you may need to change

the cleansing agent, sanitizing agent, or the cleaning

procedures you are using.

• Products containing: acids, alkalines, chlorine,

or salt can corrode stainless steel.

Do not place plastic lid, plastic cover, plastic

top or plastic chiller block insulation assembly

under, in, or near to high heat, as this can melt

the plastic.

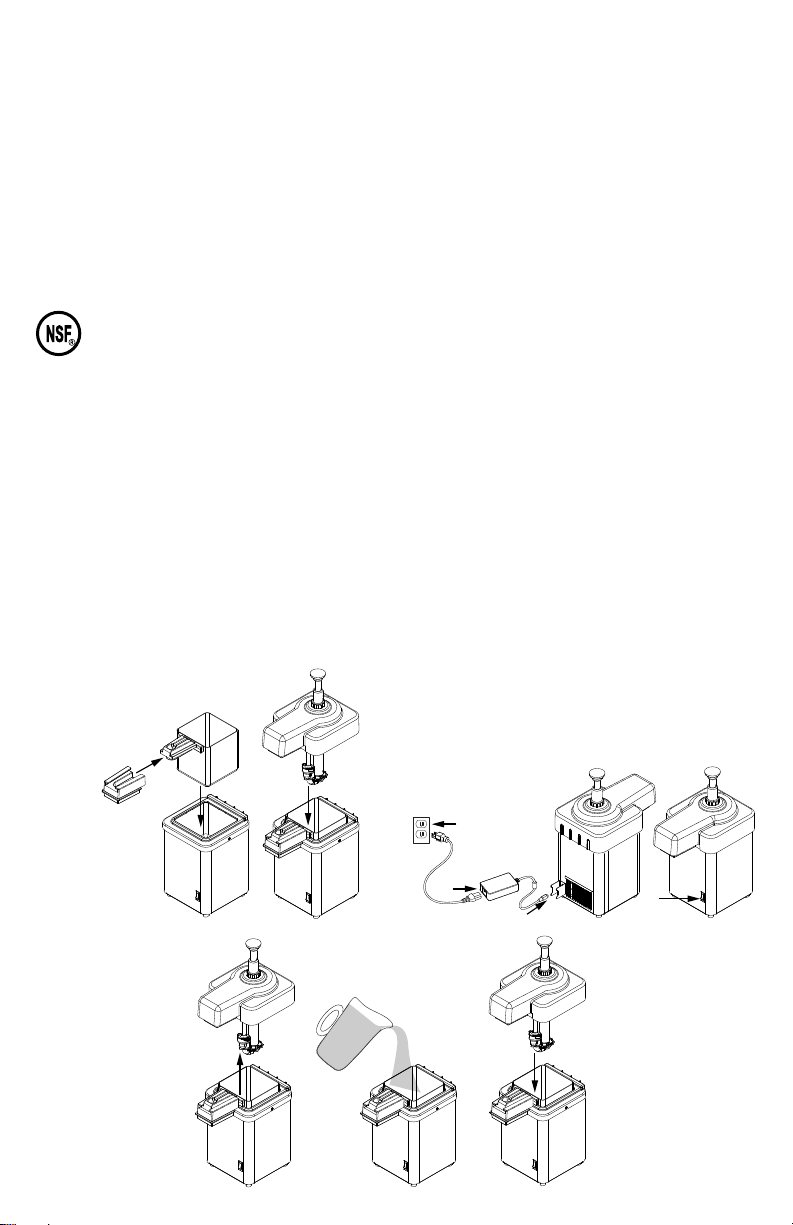

UNIT SET-UP

UNIT SET-UP

ALWAYS CLEAN UNIT THOROUGHLY BEFORE EACH

USE. SEE UNIT TAKE-DOWN, SAFETY GUIDELINES, AND

UNIT CLEANING. SEE SEPARATE PUMP MANUAL FOR

PUMP INSTRUCTIONS.

1 INSTALL CHILLER BLOCK COVER ONTO FOOD

PRODUCT VESSEL.

2 INSTALL FOOD PRODUCT VESSEL INTO BASIN OF

UNIT TO PRE-COOL.

3 INSTALL PUMP TO MAINTAIN MAXIMUM COLD

TEMPERATURE.

• Temperature can be monitored by viewing

temperature strip located on side of product

vessel.

• For best unit cooling and performance, always

keep unit on continuously all day and all night,

every day and every night, to prevent pre-cool

period. Unit should remain on, as a refrigerator.

Server Products Inc. claims no responsibility

for actual serving temperature of product. It is

the responsibility of the user to ensure that any

product is held and served at a safe temperature.

4 PLUG CORD INTO POWER SOURCE.

• Verify that cord is securely plugged into the unit,

the power supply (adaptor), and the power source

(outlet).

5 PRESS SWITCH TO THE “ON” POSITION.

• Allow unit to pre-cool for 60 minutes.

6 REMOVE PUMP.

7 POUR FOOD PRODUCT INTO FOOD PRODUCT

VESSEL.

• Food product must always be inside food product

vessel.

• Never place food product directly into unit basin

without a food product vessel.

• Food product vessel maximum capacity is

two (2) quarts.

• DO NOT OVER FILL.

8 INSTALL PUMP.

Page 3

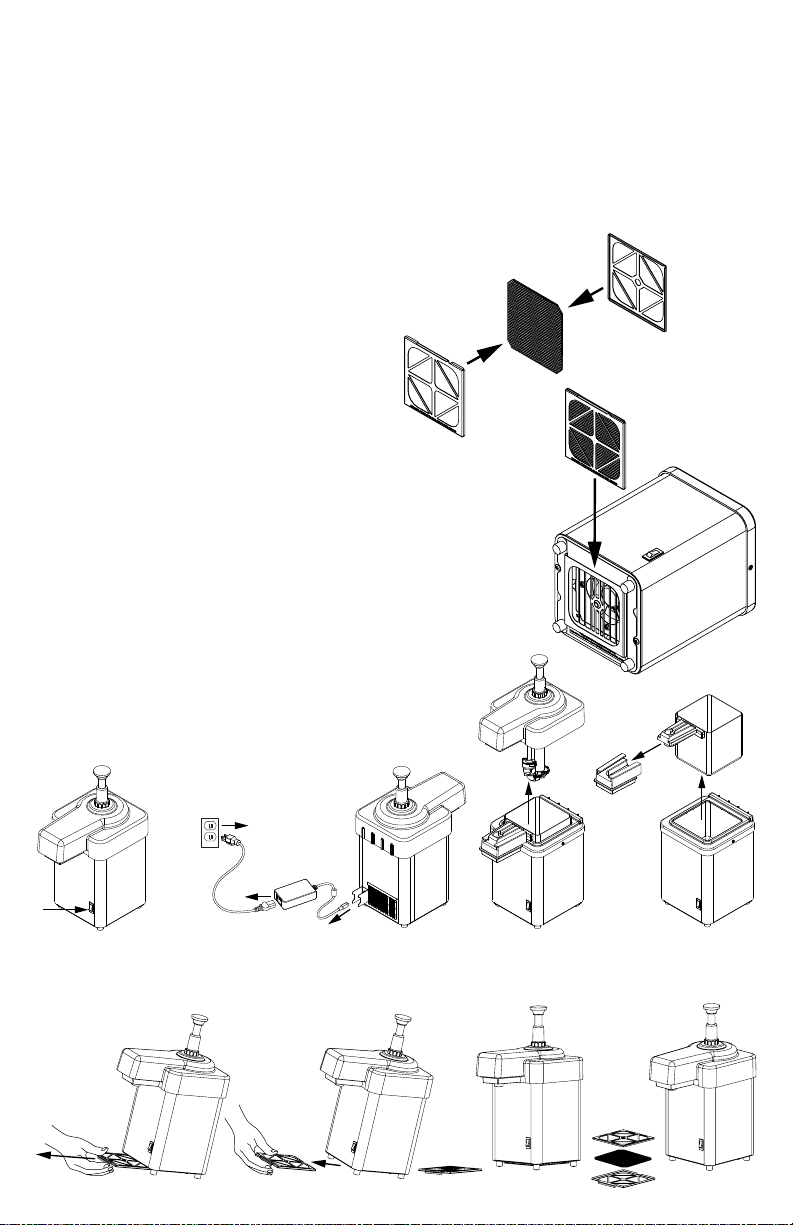

UNIT TAKE-DOWN

1 PRESS SWITCH TO “OFF” POSITION.

2 UNPLUG CORD.

3 REMOVE PUMP.

4 REMOVE PRODUCT VESSEL.

SEE SEPARATE PUMP MANUAL FOR PUMP

INSTRUCTIONS.

CHANGING OR CLEANING

FILTER

FOR BEST UNIT COOLING AND PERFORMANCE,

CHANGE OR CLEAN FILTER AT A MINIMUM OF ONCE

PER MONTH.

1 SEE UNIT TAKE DOWN.

2 ENSURE UNIT IS “OFF” AND UNPLUGGED.

3 REMOVE FILTER DRAWER FROM UNDERSIDE OF

UNIT BY SLIDING OUT OF DRAWER SLOTS.

4 REMOVE DRAWER COVER FROM DRAWER.

5 REMOVE FILTER AND CLEAN OR REPLACE.

• Server Products Inc. Pack of 5 Replacement lters:

86067

• Filter can be cleaned with hot water and

dishwashing detergent. Fully rinse.

6 IF NECESSARY, WIPE DOWN FAN COVER AND

SURROUNDING AREA ON UNDERSIDE OF UNIT

WITH CLOTH DAMPENED WITH DISHWASHING

LIQUID OR MILD SANITIZING DETERGENT.

C EWarning- Electrical shock could occur:

• Be sure to wring out any excess water from

cloth before wiping near fan of unit.

• Dripping water into unit can cause electrical

damage to unit.

7 INSTALL NEW OR CLEANED FILTER INTO FILTER

DRAWER.

8 INSTALL DRAWER COVER OVER FILTER AND INTO

FILTER DRAWER.

9 INSTALL FILTER DRAWER INTO UNDERSIDE OF

UNIT BY SLIDING INTO DRAWER SLOTS.

INSTALL NEW OR CLEANED

FILTER

UNIT TAKE-DOWN

CHANGING OR CLEANING FILTER

Page 4

PUMP DISASSEMBLY

BEFORE FIRST USE AND AFTER USE DAILY,

DISASSEMBLE AND CLEAN PUMP.

1 PUMP OUT ALL (IF ANY) REMAINING FOOD

PRODUCT FROM INSIDE PUMP BODY.

2 WASH AND RINSE OFF OUTSIDE OF PUMP BODY.

3 FLUSH AND RINSE ALL INSIDE AND OUTSIDE

SURFACES OF PUMP THOROUGHLY WITH HOT

WATER.

• Place lower end of pump into container of

hot water and operate pump until all (if any)

remaining product is expelled and only hot water

ows from discharge tube. Then remove pump

from container of water to disassemble.

• Use a container to collect small parts of pump to

prevent any loss.

4 REMOVE PLUNGER ASSEMBLY AND LID FROM

PUMP BODY BY TURNING LOCKING COLLAR AND

DISCHARGE TUBE NUT COUNTERCLOCKWISE.

5 REMOVE CYLINDER AND DISCHARGE TUBE FROM

VALVE BODY BY ROTATING COUNTERCLOCKWISE

TO RELEASE FROM SLOTS IN VALVE BODY.

6 REMOVE O-RING FROM VALVE BODY.

7 REMOVE SMALL O-RING FROM DISCHARGE TUBE.

• Be careful not to damage o-ring when prying it off

of discharge tube.

8 REMOVE KNOB FROM PLUNGER ASSEMBLY BY

ROTATING COUNTERCLOCKWISE.

• Firmly hold head tube towards piston head while

unscrewing knob. Pressure on spring will release

and push knob off rapidly.

9 REMOVE LOCKING COLLAR FROM HEAD TUBE.

• Remove gaging collar(s), if used, from head tube

by sliding them off.

J REMOVE HEAD INSERT FROM INSIDE HEAD TUBE.

K REMOVE SPRING FROM PISTON.

L REMOVE WASHER FROM PISTON.

M REMOVE SEAL ASSEMBLY FROM PISTON HEAD.

• Be careful not to damage seal when prying it off

of piston head.

N REMOVE O-RING FROM INSIDE SEAL

• Be careful not to damage o-ring when prying it

out of seal.

IMPORTANT PUMP AREAS TO CLEAN:

CLEAN ALL SIDES OF STAINLESS STEEL BALLS

CLEAN VALVE BODY PASSAGEWAY

CLEAN VALVE BODY OPENINGS

FERRULE CAP DISASSEMBLY

REMOVE FERRULE CAP FROM DISCHARGE TUBE BY

a

ROTATING FERRULE CAP COUNTER CLOCKWISE.

b REMOVE CONE WASHER FROM INSIDE FERRULE

CAP.

Do not use any sharp tools for disassembly,

this can damage parts.

a

a

b

Page 5

PUMP CLEANING

BEFORE FIRST USE AND AFTER USE DAILY OR

REGULARLY, DISASSEMBLE AND CLEAN PARTS.

FOR SAFE AND PROPER CARE, AND TO PREVENT

CORROSION, OF PARTS, IT IS IMPORTANT TO

CLEAN, RINSE, SANITIZE, AND DRY PARTS DAILY OR

REGULARLY. FAILURE TO COMPLY WITH ANY OF THESE

INSTRUCTIONS MAY VOID UNIT WARRANTY.

1 SEE PUMP DISASSEMBLY.

2 WASH ALL PARTS WITH DISHWASHING

DETERGENT AND HOT WATER.

• Wash small parts in a pan or other container

to prevent part loss.

• Scrub with supplied brushes to clean

all conned areas. Maintain a clean and

efcient pump by using the brushes

supplied with pump to prevent product

build up inside pump.

• IMPORTANT PUMP AREAS TO CLEAN:

Clean inside cylinder thoroughly with

brush 82049. Clean inside discharge tube

and valve body thoroughly with brush

82526/82824.

• Do not use scrapers, steel pads, steel wool, or

other cleaning tools that can scratch surfaces.

• Do not use abrasive cleansers.

• Do not use caustic cleansers.

• Do not use cleansing agents with high

concentrations of acid, alkaline or chlorine.

• Do not use ammonia based cleansers.

• A nontoxic glass cleaner may be used for cleaning

any stainless steel parts.

3 FULLY RINSE ALL PARTS THOROUGHLY WITH

CLEAR WATER.

• Fully rinsing all parts can help prevent corrosion.

4 DRY ALL STAINLESS STEEL PARTS WITH A CLEAN

SOFT CLOTH.

• Various elements and minerals, such as chlorides

in tap water, can accumulate on stainless steel

parts and create corrosion.

• To prevent corrosion on any stainless steel parts,

it is important to fully dry with a clean soft cloth

regularly.

5 SANITIZE PARTS FOLLOWING YOUR LOCAL

SANITIZATION REQUIREMENTS.

ALL PARTS IN CONTACT WITH FOOD MUST BE

SANITIZED.

• Allow parts to fully air dry after sanitization.

• Dishwasher safe.

Page 6

Cone Washer

a

Ferrule Cap

FERRULE CAP ASSEMBLY

INSTALL CONE WASHER INTO FERRULE CAP.

a

b INSTALL FERRULE CAP, WITH CONE WASHER

INSIDE, ONTO DISCHARGE TUBE THREADING.

c ROTATE FERRULE CAP CLOCKWISE TO SECURE TO

THREADS OF DISCHARGE TUBE.

Do not use any sharp tools for assembly,

this can damage parts.

FERRULE CAP ASSEMBLY

a

b

c

a

UNIT TROUBLESHOOTING

POSSIBLE PROBLEM:

Unit does not cool.

•

POSSIBLE SOLUTIONS:

•

Ensure cord is securely plugged in.

Verify that cord is securely plugged into the unit,

the power supply (adaptor), and the power source

(electrical outlet).

• Ensure power is available from source.

• Ensure unit is on.

• Ensure fan is on/running.

• Ensure lter is clean or replace if necessary.

b

PUMP TROUBLESHOOTING

PROBLEMS WITH PUMP OPERATION AND/OR FLOW:

• Clean pump.

PORTION CONTROL IS NOT CONSISTENT.

• Inspect gaging collar for any damage and/

or proper installation.

PUMP PLUNGER DOES NOT RETURN TO TOP OF

STROKE AFTER DISPENSING PRODUCT.

• Inspect spring for any damage; bent or

broken. Replace spring if necessary.

PUMP DRIPS.

• Clean discharge tube with supplied cleaning

brushes.

Page 7

PUMP ASSEMBLY

BEFORE FIRST USE AND AFTER USE DAILY,

DISASSEMBLE AND CLEAN PUMP.

ASSEMBLE PLUNGER:

1 INSTALL SEAL O-RING INSIDE SEAL.

• Apply food equipment lubricant on seal o-ring.

2 INSTALL SEAL ASSEMBLY ONTO PISTON HEAD.

• Apply food equipment lubricant inside seal assembly.

3 INSTALL WASHER ONTO THREADED END OF PISTON.

4 INSTALL SPRING ONTO THREADED END OF PISTON.

5 INSTALL HEAD INSERT INSIDE HEAD TUBE.

• Beveled edge of head insert should be facing inside

of head tube.

6 INSTALL GAGING COLLAR(S), IF NEEDED, AND

LOCKING COLLAR ONTO HEAD TUBE BY SLIDING

THEM ON.

• Position locking collar with threading inside locking

collar facing gaging collar(s) and/or head tube ared

end.

7 INSTALL HEAD TUBE ASSEMBLY ONTO PISTON

ASSEMBLY.

8 INSTALL KNOB ONTO PLUNGER ASSEMBLY AND

ROTATE CLOCKWISE TO SECURE ONTO THREADED

END OF PISTON.

• Firmly hold head tube towards piston head,

compressing spring, while screwing knob on.

INSTALL O-RINGS AND ASSEMBLE PUMP BODY:

9 INSTALL SMALL O-RING ONTO DISCHARGE TUBE.

• Apply food equipment lubricant on o-ring.

• Be careful not to damage o-ring while installing

and/or rolling onto discharge tube.

J INSTALL O-RING INTO VALVE BODY.

• Apply food equipment lubricant on o-ring.

K INSTALL CYLINDER ONTO VALVE BODY.

• Rotate cylinder clockwise and press down rmly to

secure into slots on valve body.

L INSTALL DISCHARGE TUBE ONTO VALVE BODY.

• Rotate discharge tube clockwise and press down

rmly to secure into slots on valve body.

INSTALL LID ONTO PUMP BODY AND SECURE

WITH LOCKING COLLAR:

M INSTALL LID ONTO DISCHARGE TUBE AND

CYLINDER ASSEMBLY(PUMP BODY).

• Install hole on lid onto cylinder threading.

N INSTALL PLUNGER INTO CYLINDER AND SECURE

PLUNGER TO CYLINDER BY ROTATING LOCKING

COLLAR CLOCKWISE.

Page 8

UNIT CLEANING

BEFORE FIRST USE AND AFTER USE DAILY OR

REGULARLY, DISASSEMBLE AND CLEAN PARTS.

FOR SAFE AND PROPER CARE, AND TO PREVENT

CORROSION, OF PARTS, IT IS IMPORTANT TO

CLEAN, RINSE, SANITIZE, AND DRY PARTS DAILY OR

REGULARLY. FAILURE TO COMPLY WITH ANY OF THESE

INSTRUCTIONS MAY VOID UNIT WARRANTY.

1 SEE UNIT TAKE DOWN, PUMP DISASSEMBLY, AND

PUMP CLEANING.

2 ENSURE UNIT IS “OFF” AND UNPLUGGED.

C EWarning- Electrical shock could occur:

• Electrical components of unit could be

damaged from water exposure or any liquid.

• Never immerse unit into water or any liquid.

• Never use any water jet or pressure sprayer

on unit.

3 WASH PRODUCT VESSEL AND PUMP WITH

DISHWASHING DETERGENT AND HOT WATER.

RINSE THOROUGHLY AND DRY WITH A CLEAN SOFT

CLOTH.

• A general purpose, nonabrasive cleaner may be

used on hard to remove food deposits.

• A mildly abrasive NYLON or brass brush may be

used to remove any stubborn food or mineral

deposits on interior surfaces of unit.

• Do not use abrasive cleansers, scrapers,

steel pads, steel wool, or other cleaning tools

that can scratch surfaces.

• Do not use cleansing agents with high

concentrations of acid, alkaline or chlorine.

These agents can corrode stainless steel.

• Fully rinsing all parts can help prevent corrosion.

• Various elements and minerals, such as chlorides

in tap water, can accumulate on stainless steel

parts and create corrosion.

• To prevent corrosion on any stainless steel parts,

it is important to fully dry with a clean soft cloth

regularly.

4 WIPE EXTERNAL SURFACES OF UNIT WITH A CLEAN

DAMP CLOTH. DRY WITH A CLEAN SOFT CLOTH.

• A nontoxic glass cleaner may be used for cleaning

any stainless steel parts.

5 SANITIZE ALL PARTS FOLLOWING LOCAL

SANITIZATION REQUIREMENTS. ALL PARTS IN

CONTACT WITH FOOD MUST BE SANITIZED.

• Allow parts to fully air dry after sanitization.

• Fully air drying all parts will prevent condensation

from developing between food vessel and unit

basin.

Plastic Lid, Plastic Cover, Plastic Top and

Plastic Chiller Block Insulation Assembly:

• Not dishwasher safe.

• Hand Wash Only.

• Do not place plastic lid, plastic cover, plastic top or

plastic chiller block insulation assembly under, in, or

near to high heat, as this can melt the plastic.

GENERAL SERVICE, REPAIR,

OR RETURNS

Before sending any item to Server Products for service,

repair, or return, contact Server Products customer

service to request a Return Authorization Number.

Merchandise must be sent to Server Products with this

number.

Server Products maintains a fully staffed service department with highly skilled factory trained personnel.

Service is extremely prompt. Under normal circumstances, a repaired unit is shipped out the day after it is

received. Labor charges are reasonable.

SERVICE

Contact your dealer or Server Products Inc.

customer service department for the following:

ORDERING REPLACEMENT PARTS

Be prepared to give this information:

• MODEL Letters/Name/Numbers

• Part Numbers- P/N

• Series Numbers/Letters

• Part Description

This information and other important data is stamped

on the lid or cylinder of pumps or on the bottom or

back side of every unit.

SERVER PRODUCTS

LIMITED WARRANTY

All Server Products equipment is backed by a

two-year limited Warranty against defects in materials

and workmanship. For complete Warranty information

go to: www.server-products.com

Server Products Inc.

3601 Pleasant Hill Road

Richfield, WI 53076 USA

262.628.5600

800.558.8722

262.628.5110

spsales@server-products.com

www.server-products.com

Loading...

Loading...