Page 1

01804-REVB�080414�ENGLISH

MODEL:

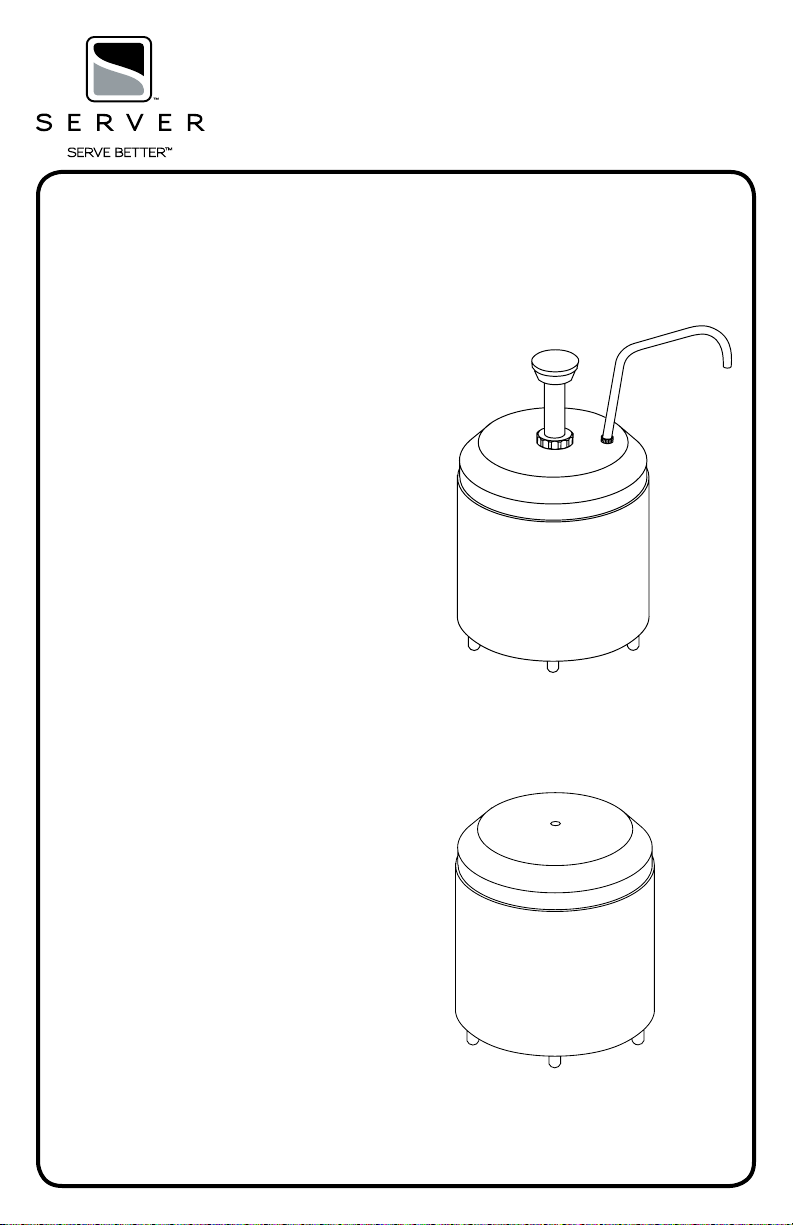

CSM CREAM SERVER, MANUAL

Series 93I

94000

MMS CONDIMENT SERVER,

MANUAL MAYONNAISE

Series 93I

94070

CSM CREAM SERVER, MANUAL

W/(1)94055

Series 93I

94111

CSM CREAM SERVER, MANUAL

W/(1)94055 & (1)94056

Series 93I

94113

ECH ESPRESSO CREAM HOLDER

Series 94L

94090

Page 2

SAFETY GUIDELINES

According to food and safety regulations, most foods

must be stored and/or served at certain temperatures

or they could become hazardous. Check with local food

and safety regulators for specic guidelines.

Be aware of the product you are serving and the

temperature the product is required to maintain.

Server Products, Inc. can not be responsible for

the serving of potentially hazardous product.

Server Products Inc. claims no responsibility

for actual serving temperature of product. It is

the responsibility of the user to ensure that any

product is held and served at a safe temperature.

Stainless steel is one of the best materials for food

serving and storage, but there are many products which

can corrode it. If you notice corrosion beginning on

any stainless steel surface, you may need to change

the cleansing agent, sanitizing agent, or the cleaning

procedures you are using.

• Products containing: acids, alkalines, chlorine,

or salt can corrode stainless steel.

• Sauerkraut and Au Jus sauces corrode stainless

steel. Server Products, Inc. regrets that we can

not honor Warranty claims on stainless steel parts

that have been affected by sauerkraut

or Aus Jus.

Insulated Units

• Do not place ice packs or crushed ice into

non-insulated units, they are not designed to hold

water and will leak.

• Do not expose insulated shroud or base of unit to

a dishwasher or temperatures over 150°F,

this will damage the insulation.

Eutectic Ice Packs and HOLDCOLD jars

• Do not expose ice packs or HOLDCOLD jars to

a dishwasher or any extreme heat, this could

cause leakage or explosion of the ice packs or

HOLDCOLD jars. The operating temperature range

for the eutectic ice packs or HOLDCOLD jars is

between -40°F and 175°F.

UNIT SET-UP

ALWAYS CLEAN UNIT AND PUMP THOROUGHLY

BEFORE EACH USE. SEE UNIT TAKE-DOWN,

SAFETY GUIDELINES AND CLEANING. SEE SEPARATE

PUMP MANUAL FOR PUMP INSTRUCTIONS.

1 PRE-FREEZE EUTECTIC ICE PACK(S) OR

HOLDCOLD JAR(S).

• Each eutectic ice pack must be allowed to

freeze for about 12 hours (or overnight) prior

to use.

• Each HOLDCOLD jar must be allowed to freeze

upside down for about 8 hours (or overnight)

prior to use.

• HOLDCOLD jars can be used to replace ice

packs and stainless steel jars or standard #10

cans. A HOLDCOLD jar has 2.75 Quart capacity.

2 INSERT ONE EUTECTIC ICE PACK OR ONE

HOLDCOLD JAR INTO SHROUD OR BASE.

KEEP OTHER ICE PACK OR HOLDCOLD JAR IN

FREEZER TO BE READY FOR FUTURE USE.

3 IF USING EUTECTIC ICE PACKS, INSTALL

STAINLESS STEEL JAR INTO SHROUD OR BASE

AFTER ICE PACK IS INSTALLED.

4 INSTALL LID OR PUMP.

5 MONITOR TEMPERATURE OF PRODUCT,

AS NEEDED, AND MAINTAIN A PRODUCT

TEMPERATURE OF 40ºF OR BELOW TO PREVENT

PRODUCT FROM BECOMING HAZARDOUS.

• Remove eutectic ice pack or HOLDCOLD jar

from shroud or base when product temperature

rises above 40ºF and replace with other frozen

ice pack or HOLDCOLD jar which has been in

freezer storage for the minimum hours required

for pre-freeze.

• A eutectic ice pack can keep product at 40ºF

or below for up to 4 hours when placed into

an insulated shroud or base and lled with

refrigerated product.

• A HOLDCOLD jar can keep product at 40ºF

or below for up to 12 hours when placed into

an insulated shroud or base and lled with

refrigerated product.

UNIT TAKE-DOWN

1 REMOVE LID OR PUMP.

2 REMOVE STAINLESS STEEL JAR OR HOLDCOLD JAR

FROM SHROUD OR BASE.

3 IF USED, REMOVE EUTECTIC ICE PACK FROM

SHROUD OR BASE.

4 RE-FREEZE EUTECTIC ICE PACK(S) OR

HOLDCOLD JAR(S).

• Each eutectic ice pack must be allowed to

freeze for about 12 hours (or overnight) prior

to use.

• Each HOLDCOLD jar must be allowed to freeze

upside down for about 8 hours (or overnight)

prior to use.

Page 3

UNIT SET-UP

UNIT TAKE-DOWN

Page 4

UNIT CLEANING

BEFORE FIRST USE AND AFTER USE DAILY OR

REGULARLY, DISASSEMBLE AND CLEAN PARTS.

FOR SAFE AND PROPER CARE, AND TO PREVENT

CORROSION, OF PARTS, IT IS IMPORTANT TO

CLEAN, RINSE, SANITIZE, AND DRY PARTS DAILY OR

REGULARLY. FAILURE TO COMPLY WITH ANY OF THESE

INSTRUCTIONS MAY VOID UNIT WARRANTY.

SEE SEPARATE PUMP MANUAL FOR PUMP

INSTRUCTIONS.

1 SEE UNIT TAKE DOWN.

2 WASH CLEAN ALL PARTS WITH DISHWASHING

DETERGENT AND HOT WATER.

• Do not use scrapers, steel pads, steel wool, or

other cleaning tools that can scratch surfaces.

• Mildly abrasive NYLON or brass brush may be

used to remove any stubborn food or mineral

deposits on interior surfaces of unit.

• Do not use abrasive cleansers.

• Do not use caustic cleansers.

• Do not use cleansing agents with high

concentrations of acid, alkaline or chlorine.

• Do not use ammonia based cleansers.

3 FULLY RINSE ALL WASHED PARTS THOROUGHLY

WITH CLEAR WATER.

• To prevent corrosion on parts, it is important to

thoroughly and fully rinse washed parts.

4 WIPE CLEAN EXTERNAL SURFACES OF UNIT WITH

A CLEAN DAMP CLOTH.

• Nontoxic glass cleaner may be used to clean

stainless steel parts.

5 DRY ALL PARTS WITH A CLEAN SOFT CLOTH.

• Various elements and minerals, such as chlorides

in tap water, can accumulate on stainless steel

parts and create corrosion.

• To prevent corrosion on stainless steel parts, it is

important to thoroughly and fully dry with a clean

soft cloth regularly.

6 SANITIZE ALL PARTS FOLLOWING LOCAL

SANITIZATION REQUIREMENTS. ALL PARTS IN

CONTACT WITH FOOD MUST BE SANITIZED.

• Allow parts to fully air dry after sanitization.

• Fully air drying all parts will prevent condensation

from developing between food vessel and unit

basin.

GENERAL SERVICE, REPAIR,

OR RETURNS

Before sending any item to Server Products for service,

repair, or return, contact Server Products customer

service to request a Return Authorization Number.

Merchandise must be sent to Server Products with this

number.

Merchandise being returned for credit must be in new

and unused condition and not more than 90 days old

and will be subject to a 20% (percent) restocking

charge. Electrical parts (thermostats, heating elements,

etc.) are not returnable.

Server Products maintains a fully staffed service

department with highly skilled factory trained personnel.

Service is extremely prompt. Under normal

circumstances, a repaired unit is shipped out the day

after it is received. Labor charges are reasonable.

SERVICE

Contact your dealer or Server Products Inc.

customer service department for the following:

ORDERING REPLACEMENT PARTS

Be prepared to give this information:

• Model Letters/Name/Numbers

• Part Numbers- P/N

• Series Numbers/Letters

• Part Description

This information and other important data is stamped

on the lid or cylinder of pumps or on the bottom or

back side of every unit.

SERVER PRODUCTS

LIMITED WARRANTY

All Server Products equipment is backed by a

two-year limited warranty against defects in materials

and workmanship. For complete warranty information

go to: www.server-products.com

Server Products Inc.

3601 Pleasant Hill Road

Richfield, WI 53076 USA

262.628.5600

800.558.8722

262.628.5110

spsales@server-products.com

www.server-products.com

Loading...

Loading...