Server 87690 Owner’s Manual

MODEL:

01955-REVA�080414�ENGLISH

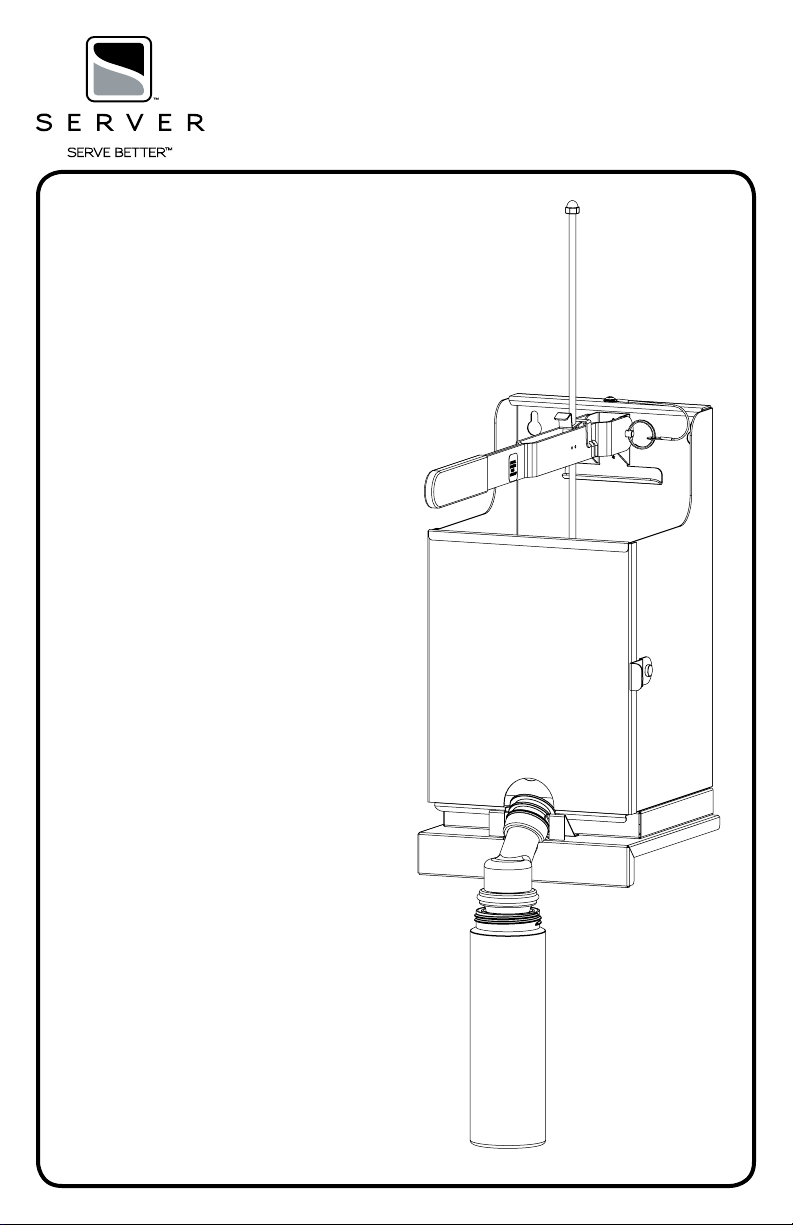

FSF

FAST FILL,

SQUEEZE BOTTLE

FILLING STATION,

CRYOVAC™ FITMENT 16MM

1.5 GALLON

Series 13E

87690

SAFETY GUIDELINES WHEN

USING THIS UNIT:

According to food and safety regulations, most foods

must be stored and/or served at certain temperatures

or they could become hazardous. Check with local food

and safety regulators for specic guidelines.

Be aware of the product you are serving and the

temperature the product is required to maintain.

Server Products, Inc. can not be responsible for

the serving of potentially hazardous product.

Stainless steel is one of the best materials for food

serving and storage, but there are many products which

can corrode it. If you notice corrosion beginning on

any stainless steel surface, you may need to change

the cleansing agent, sanitizing agent, or the cleaning

procedures you are using.

• Products containing: acids, alkalines, chlorine,

or salt can corrode stainless steel.

INSTALLATION OPTIONS

This unit can be set onto a countertop or mounted onto

a wall. There are four mounting holes available on back

side of unit.

UNIT SET-UP

ALWAYS CLEAN UNIT THOROUGHLY BEFORE EACH USE

AND AFTER USE DAILY.

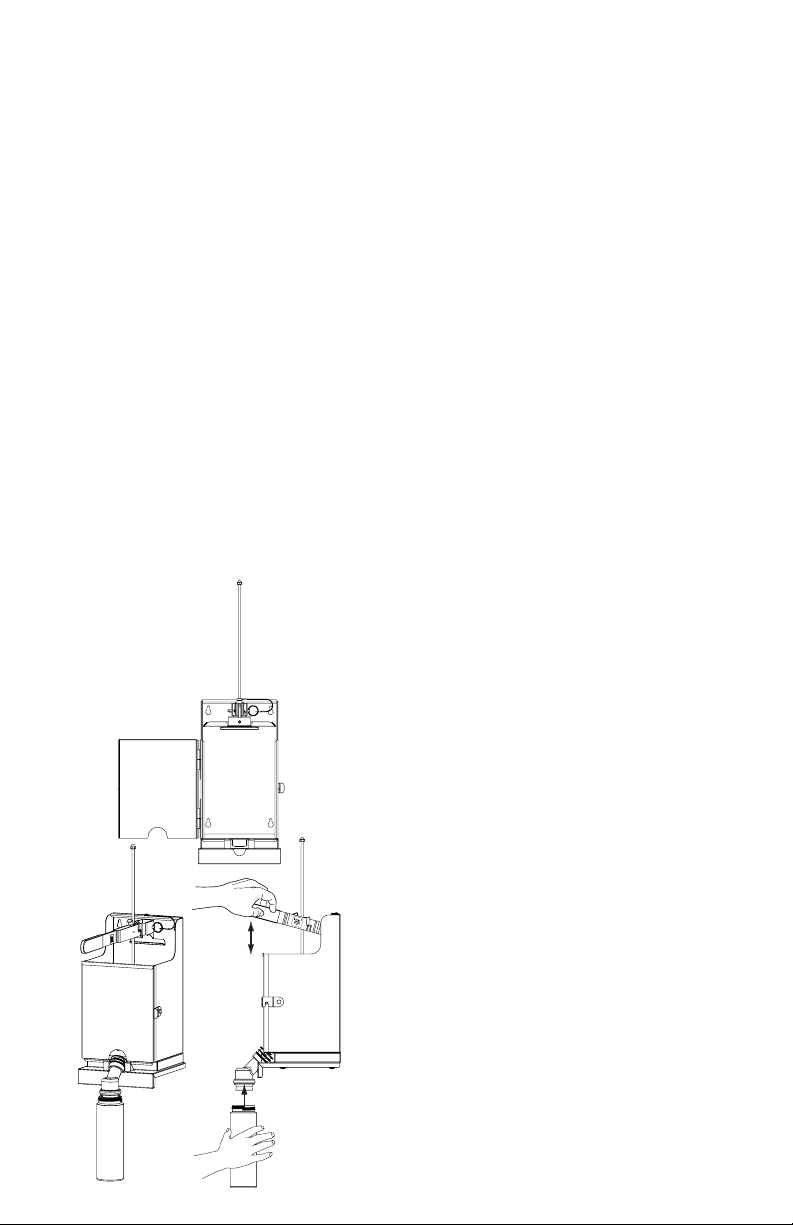

1 POSITION PLUNGER UP ONTO PLUNGER REST TO

INSTALL PRODUCT POUCH.

• Open unit door by lifting latch.

• Lift up handle and plunger assembly by depressing

handle lever release and lifting handle into

horizontal position to allow plunger rod to move

up freely.

• Tip plunger front up enough to position plunger

back up onto plunger rest on back wall of unit.

2 INSTALL VALVE BODY AND CONNECTOR ASSEMBLY

ONTO PRODUCT POUCH.

• Ensure valve nut is installed onto valve body

with threading facing out.

• Install connector into valve body and secure

with valve nut threading.

• Place product pouch on a counter top

with circular pouch tment facing upward.

• Position valve body and connector assembly

directly over center of circular pouch tment.

• Press valve body and connector assembly down to

pierce through lm in circular pouch tment. Valve

body and connector assembly will “snap” securely

onto tment.

• Valve body and connector assembly is fully

engaged into pouch tment when surface of

circular pouch tment is ush with connector.

• Prime valve body by applying light pressure on

end of product pouch while holding valve body like

a cup, so that product does not spill out. Continue

to press on product pouch until valve body is full

of product.

• Install silicone valve onto valve body. Push silicone

valve down around edges of valve body until

silicone valve “snaps” securely into groove on edge

of valve body.

3 INSTALL POUCH, WITH ATTACHED VALVE BODY,

INTO UNIT.

• Align connector grooves onto unit valve body

holder.

• Connector groove which is closest to threaded cap

on valve body is the groove which must align and

slide into holder.

4 RELEASE PLUNGER FROM PLUNGER REST ON BACK

WALL OF UNIT.

• Close unit door and secure latch.

• Tip plunger front up enough to release plunger

back up off of plunger rest on back wall of unit.

• Set plunger into position resting on

product pouch.

UNIT OPERATION

PLACE BOTTLE TO FILL DIRECTLY UNDER VALVE BODY.

PUSH PLUNGER LEVER DOWN TO DISPENSE PRODUCT

FROM POUCH INTO BOTTLE.

Loading...

Loading...