Page 1

New Carbon’s

Batter Serving Center

MODEL:

BSC

87319

Thank You

...for purchasing this Batter Serving Center.

Easily dispense batter from a convenient vessel.

DISPENSE BETTER— SERVE BETTER

Page 2

SAFETY

According to food and safety regulations, most foods

must be stored and/or served at certain temperatures

or they could become hazardous. Check with local

food and safety regulators for specific guidelines.

Be aware of the product you are serving and the

temperature the product is required to maintain.

Server Products, Inc. cannot be responsible for the

serving of potentially hazardous product.

CLEANING

CLEAN

1

After disassembling, thoroughly clean all

washable parts with soap and hot water.

RINSE fully with clear water.

2

SANITIZE

3

all parts according to local sanitization

requirements. All parts in contact with

food must be sanitized.

4

AIR DRY all parts fully.

5

CLEAN EXTERNAL SURFACES

• Wipe daily with a clean damp cloth.

• Dry with a clean soft cloth.

• Glass and surface cleaners approved for

use in food contact areas may be used.

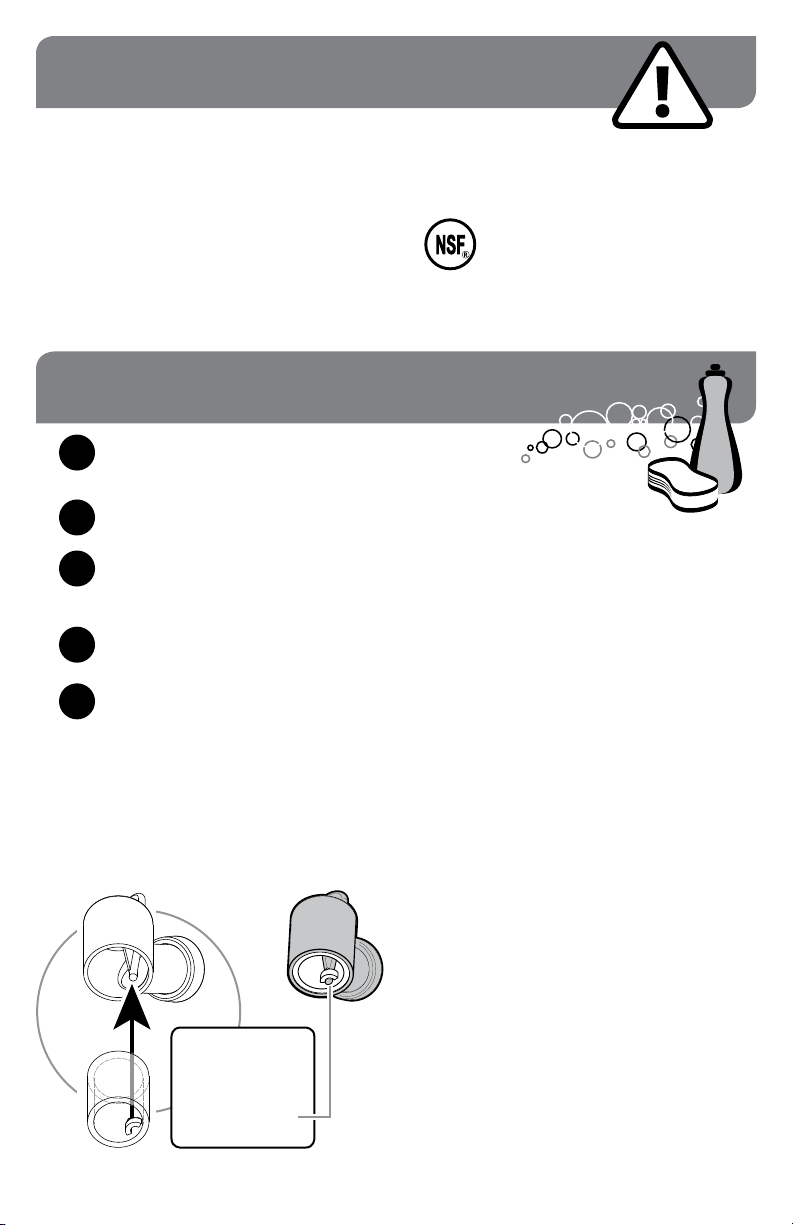

AFTER CLEANING VALVE:

TIP: To reinstall valve

into faucet, lubricate

with clean water.

Ensure valve loop

wraps around lever

inside faucet.

IMPORTANT

Clean, rinse, sanitize, and dry parts daily or regularly

to comply with local sanitization requirements.

NSF International listed.

YES!

Use dishwashing

soap and hot water

CARE OF STAINLESS STEEL

• If you notice corrosion beginning on any stainless

steel surface, you may need to change the

cleansing agent, sanitizing agent, or the cleaning

procedures you are using.

• A mildly abrasive nylon or brass brush may be

used to remove any stubborn deposits.

• Fully rinsing and drying all parts can help prevent

corrosion. Elements and minerals in tap water

can accumulate on stainless steel parts and

create corrosion.

• Do not use abrasive, caustic or ammonia

based cleansers.

• Do not use products containing acids, alkalines,

chlorine, or salt. These agents can corrode

stainless steel.

• Do not use metal scrapers or cleaning pads that

could scratch surfaces.

Page 2

Page 3

SETUP

WASH ALL PARTS

PROPERLY BEFORE USE.

ATTACH FAUCET TO VESSEL

1

• Insert faucet neck into vessel spout.

• Screw faucet connector to vessel.

PLACE VESSEL ONTO BASE

2

POSITION DRIP TRAY

3

UNDER BASE

TAKE-DOWN

REMOVE DRIP TRAY

1

REMOVE VESSEL & ANY

2

REMAINING FOOD PRODUCT

See page 2.

DISASSEMBLE FAUCET

3

• Unscrew and remove faucet from

food vessel.

• Remove valve from faucet:

Pinch valve and gently pull it out for cleaning.

TROUBLESHOOTING

UNIT DISPENSES LITTLE OR NO PRODUCT?

FAUCET DRIPS?

• Ensure faucet connector is threaded

correctly to create tight seal.

• Ensure there is enough product

remaining to dispense.

• Ensure lever inside faucet

is placed correctly within valve loop.

• Check valve for defects.

Replace if necessary.

Page 3

Page 4

PARTS

87319

BATTER SERVING CENTER

FAUCET

FOOT w/SCREW (4)

HOUSING BASE

PROTECTIVE CAPS (4)

FOOT w/SCREW (4)

SERVER PRODUCTS

LIMITED WARRANTY

87337

81169

86337

81058

LID

87338

VESSEL

87327

RUBBER TRIM, 10-3/4

87333

PROTECTIVE CAPS (4)

87339

RUBBER TRIM, 1-3/4 (2)

87332

DRIP TRAY COVER

87328

DRIP TRAY

87329

GENERAL SERVICE,

REPAIR OR RETURNS

Before sending any item to Server Products

for service, repair, or return, contact Server

Products customer service to request a Return

Authorization Number. Merchandise must be

sent to Server Products with this number. Service

Server Products equipment is backed by a

two-year limited warranty against defects in

materials and workmanship.

For complete warranty information go to:

www.Server-Products.com

is extremely prompt. Typically, units are repaired

and ship out within 48 hours of receipt.

Merchandise being returned for credit must be in

new and unused condition and not more than 90

days old and will be subject to a 20% restocking

charge.

NEED HELP WITH REPLACEMENT PARTS?

New Carbon Co., Inc.

4101 William Richardson Dr.

South Bend, IN 46628

574.247.2270

Page 4

Please be prepared with your Series Number and

Description located on the back of unit base.

Individual Part Numbers listed above.

Manual #01733-RevB 090616

Loading...

Loading...