Page 1

IntelliServ™

1/3-Size Pan Warmer

MODEL: IS-1/3

120V USA

86090

120V USA

86254 (custom)

120V Canada

86481

100V Japan

86479

230V

Continental Europe

86338

230V Australia

86339

230V United Kingdom

86341

230V Brazil

86478

Thank You

...for purchasing our IntelliServ™ warmer. Its

digital temperature control ensures accurate holding

of toppings and sauces from the first serving to the last.

DON'T COMPROMISE YOUR MENU—INTELLISERV™!

Page 2

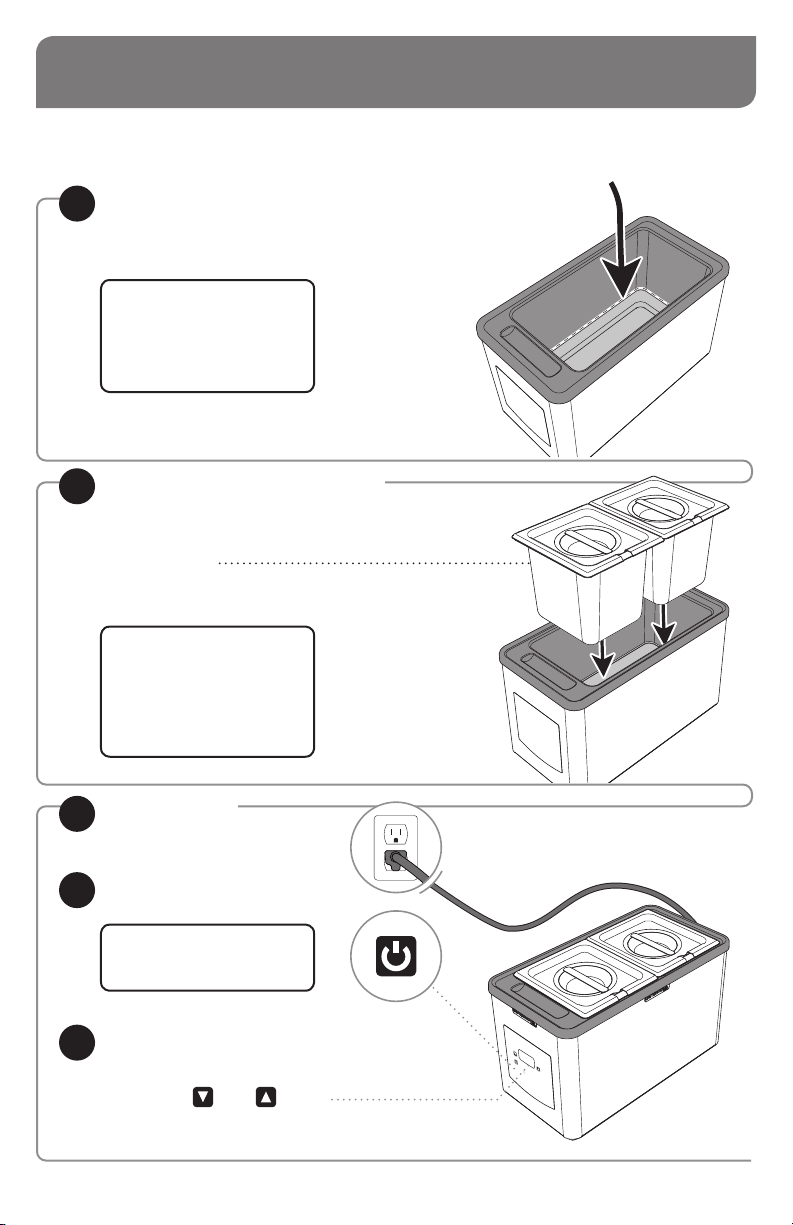

UNIT SET-UP

WASH ALL PARTS PROPERLY BEFORE EVERY USE. See page 5.

FILL UNIT BASIN WITH WATER

1

• Fill 1 liter of water up to

fill-line-ridge inside basin.

TIP: Check water levels

throughout the holding period

to ensure even heating.

Filtered water is recommended

to deter corrosion.

PUT PAN(S) INTO BASIN

2

• Product being served must always

be inside pan(s).

Never place food directly

into basin of unit.

TIP: Food pan(s) not included–

modular design lets you

choose pan(s), pump(s) or

high-temp squeeze bottles for

your food application.

See page 11.

3

4

5

Page 2

PLUG CORD

into power source.

PRESS POWER BUTTON

to turn unit on.

UNITS WITH 230 VOLTS

also have a power switch.

Press to ON position.

SET THERMOSTAT

to recommended

serving temperature.

• Press Down

to set temperature.

• See page 6 for control function details.

or Up buttons

Page 3

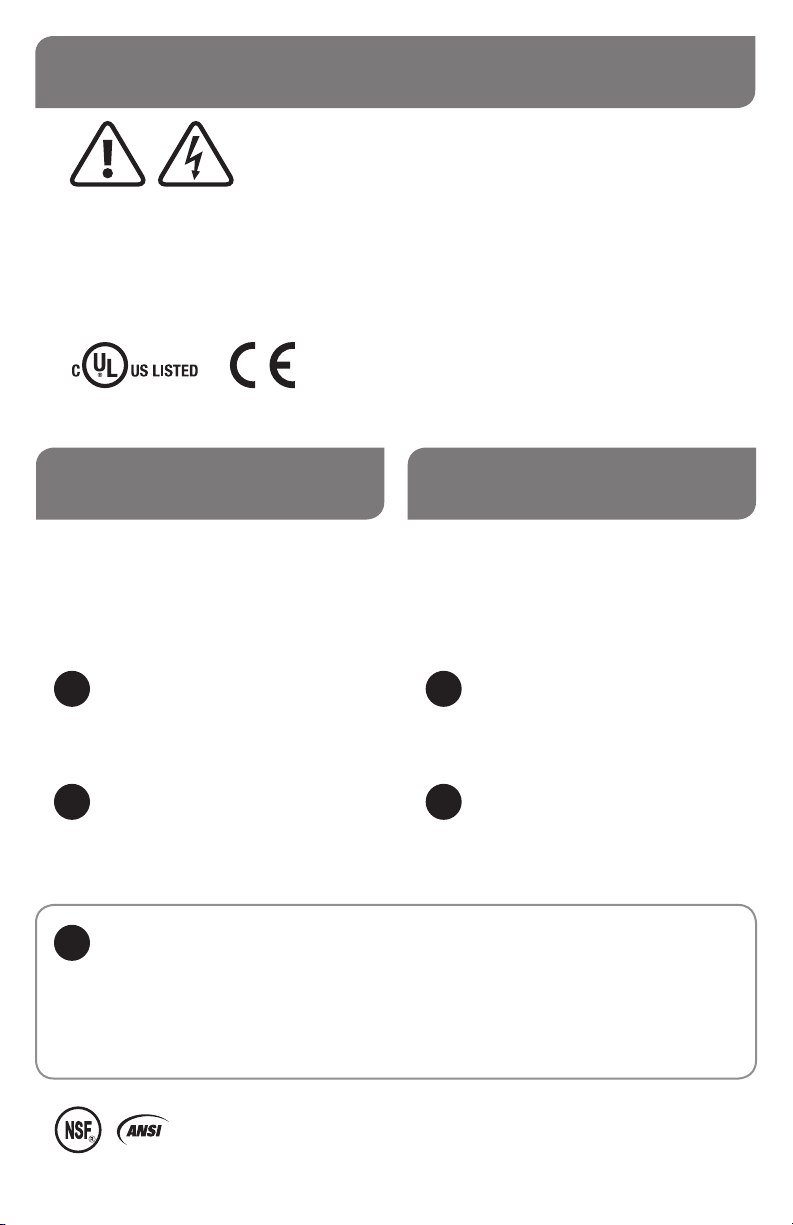

SAFETY

According to food and safety regulations, most

foods must be stored and/or served at certain

temperatures or they could become hazardous.

Check with local food and safety regulators for

WARNING-

ELECTRICAL SHOCK COULD OCCUR

This unit must be earthed or grounded.

This requires all three prongs (terminals) on cord

plug to be plugged into power source.

RETHERMALIZATION HOT FOOD HOLDING

specific guidelines.

Be aware of the product you are serving and the

temperature the product is required to maintain.

Server Products, Inc. can not be responsible for

the serving of potentially hazardous product.

Rethermalization of food products is achieved by

this appliance when it elevates the food product

temperature from a refrigerated 40°F (4°C) to a

safe serving temperature of 165°F (74°C) within a

period of 2 hours.

PRE-HEAT UNIT

1 1

for at least 5 minutes

• Correct amount of water in basin.

• Lid(s) closed.

• Temperature set at maximum setting.

ADD FOOD PRODUCT

2 2

• Put food into pans.

• Do not overfill.

MAINTAIN SAFE

3

HOT FOOD HOLDING

•

After food reaches safe serving temperature

of 165°F (74°C), maintain product

temperature at or above 150°F (66°C).

• Adjust controller if needed to avoid

overheating food.

with:

NSF International and ANSI (American National Standards Institute) list this unit as a

“Rethermalization and Hot Food Holding unit (Standard 4).”

Hot Food Holding is achieved with this appliance

when it maintains a food product temperature at or

above 150°F (66°C), in all locations throughout the

product, for a minimum of 2 hours, even if any lid,

cover, or pump is removed. The lid, cover, or pump is

recommended to help maintain product temperature.

PRE-HEAT UNIT

for at least 5 minutes

• Correct amount of water in basin.

• Lid(s) closed.

• Temperature set at maximum setting.

with:

ADD FOOD PRODUCT

• Put food which has already been

preheated to 150°F (66°C) into pans.

• Do not overfill.

MONITOR FOOD CLOSELY FOR FOOD SAFETY.

The United States Public Health Service

recommends that hot food be held at a minimum

of 140°F (60°C) to help prevent bacteria growth.

COLD FOOD IS NOT TO BE ADDED TO THE

UNIT FOR RETHERMALIZATION WHILE HOT

FOOD IS BEING HELD.

Page 3

Page 4

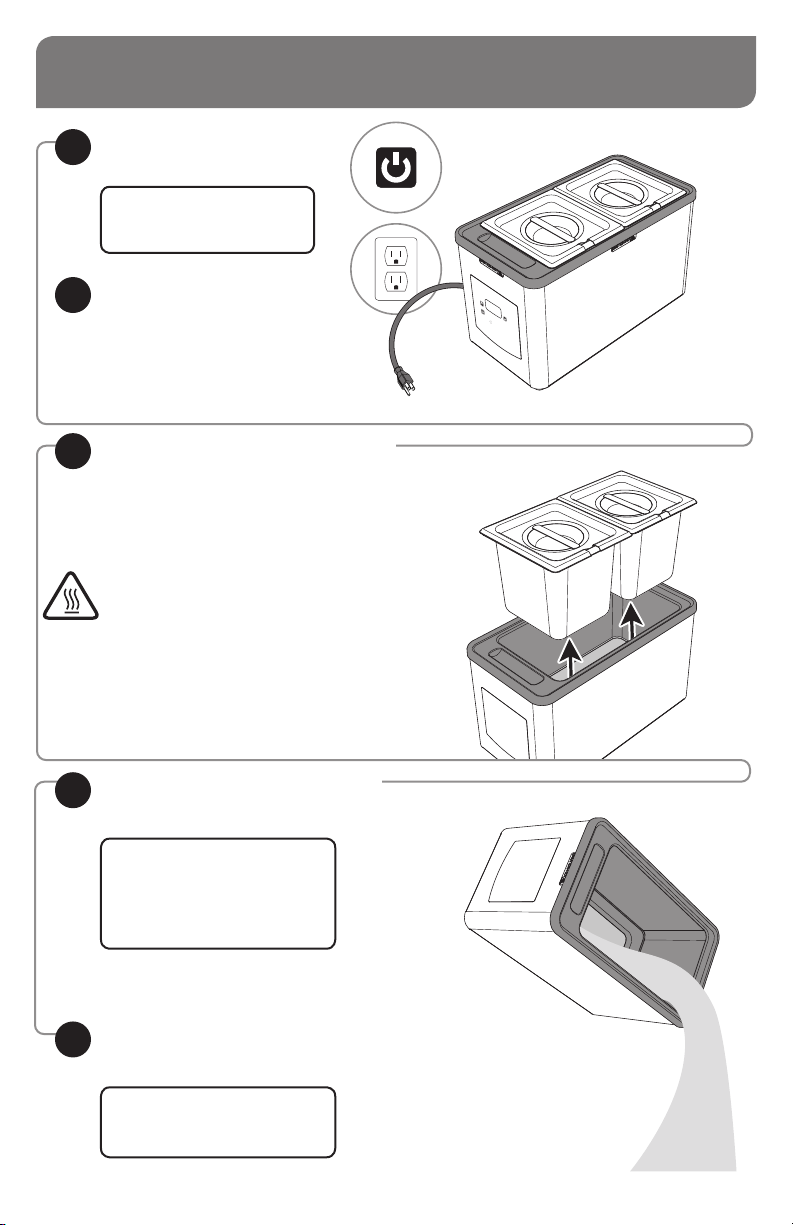

UNIT TAKE-DOWN

PRESS POWER BUTTON

1

to turn unit off.

UNITS WITH 230 VOLTS

also have a power switch.

Press to OFF position.

UNPLUG CORD

2

REMOVE PAN(S) FROM BASIN

3

CAUTION- HOT

Allow unit to cool before continuing.

4

5

Page 4

EMPTY WATER FROM BASIN

after each use.

TIP: Remember to empty the

water each day rather than add—

This will greatly extend the life

of your warmer.

DRY

thoroughly with a soft dry cloth.

Proper drying after each use helps

maintain the aluminum heat plate

and the stainless steel.

Page 5

CLEANING

WARNING-

ELECTRICAL SHOCK COULD OCCUR

• Electrical components of unit could be

damaged from water exposure or any liquid.

• Never immerse unit into water or any liquid.

• Never use any water jet or pressure sprayer

on unit.

• Ensure unit is “OFF” and unplugged.

CAUTION- HOT

Allow unit to cool before cleaning.

REMOVE LIME SCALE

RECOMMENDED ONCE A MONTH OR AS NEEDED:

Use a non-corrosive lime scale remover to eliminate

mineral buildup on the interior of the basin.

This will greatly extend the life of your warmer.

CLEAN

1

• Before first use and after use daily,

disassemble and clean unit.

• Ensure unit is “OFF” and unplugged.

• Wash with dishwashing soap and hot water.

RINSE fully with clear water.

2

SANITIZE all parts according to local

3

sanitization requirements. All parts in contact

with food must be sanitized.

DRY all parts fully with a clean soft cloth.

4

CLEAN EXTERNAL SURFACES

5

• Wipe daily with a clean damp cloth.

• Dry with a clean soft cloth.

• Glass and surface cleaners approved for use

in food contact areas may be used.

CARE OF STAINLESS STEEL

This warmer is constructed of

stainless steel— one of the best

materials for food serving and

storage.

If you notice corrosion beginning on

any stainless steel surface, you may need to

change the cleansing agent, sanitizing agent, or

the cleaning procedures you are using.

• A mildly abrasive nylon or brass brush may

be used to remove any stubborn food or

mineral deposits on interior surfaces of unit.

• Fully rinsing and drying all parts can help

prevent corrosion. Elements and minerals in

tap water can accumulate on stainless steel

parts and create corrosion.

• Do not use abrasive, caustic or ammonia

based cleansers.

• Do not use products containing acids,

alkalines, chlorine, or salt. These agents can

corrode stainless steel.

• Do not use metal scrapers or cleaning pads

that could scratch surfaces.

Page 5

Page 6

CONTROL FUNCTIONS

DISPLAY MESSAGES

COL = COOL

Heating element is off and cooling down to set

temperature.

PRE = HEAT

Heating element is on and warming up to set

temperature.

ERR = ERROR

Control board is not functioning. Repair is required.

(Please see page 12 for repairs.)

DOWN & UP BUTTONS

Press and hold the Down or Up

buttons to cycle through temperature range.

TEMPERATURE RANGES

For most units: 100°F (37°C)—220°F (104°C)

For unit 86254: 135°F (57°C)—220°F (104°C)

Temperature differential between cool and heat

is 10° F (5.5°C) of set temperature.

Display will switch between control functions

and set temperature until unit stabilizes.

POWER BUTTON

On/Off

HEATING INDICATOR

Light indicates heating element is active.

CELSIUS INDICATOR

Light indicates temperature display mode is °C.

No light indicates temperature display mode is °F.

TO SET DISPLAY °F OR °C

• Turn unit off.

• Press and hold Down button,

then simultaneously press and hold

Power button for 30 seconds.

• Celsius indicator will activate to display °C

or deactivate to display °F.

Page 6

Page 7

WIRING UNITS 86090, 86254, 86481 (120V)

A B C

1

2

3

4

T1L2T2NT3

CHASSIS GROUND

10

PROBE

11

H/L1T6LOAD

8

9

5

Cord Assembly

120V USA

1

2

3

4

5

White

A

Black

B

Green

C

Bushing/Strain Relief

Wire Nut

19" White Wire Assembly

6" White Wire Assembly

7

6

500W Heating Element

6

6" Black Wire Assembly

7

Thermal Cutout

8

Thermistor Assembly

9

Temperature Controller

10

3/4 Hole Shorty Bushing

11

Page 7

Page 8

WIRING UNIT 86479 (100V JAPAN)

A B C

1

12

2

3

L2L1L2

L1

CHASSIS GROUND

CHASSIS GROUND

11

4

10

5

PROBE

9

T1L2T2NT3

H/L1T6LOAD

8

6

7

Page 8

Cord Assembly

100V JAPAN

1

Blue

A

Brown

B

Yellow/Green

C

Bushing/Strain Relief

2

Thermal Cutout

3

4" White Wire Assembly

4

6" Black Wire Assembly

5

6" White Wire Assembly

6

500W Heating Element

7

6" Black Wire Assembly

8

3/4 Hole Shorty Bushing

9

Thermistor Assembly

10

Temperature Controller

11

5" Green Wire Assembly

12

Page 9

WIRING

UNITS 86338, 86339, 86341 (CONTINENTAL. EURO, AU, UK)

A B C

4

5

6

7

8

1

2

3

1 4

2 5

L2

L1L2L1

9

T1L2T2NT3

15

CHASSIS GROUND

CHASSIS GROUND

14

13

PROBE

12

H/L1T6LOAD

11

10

Cord Assembly

1

230V

Blue

A

Brown

B

Yellow/Green

C

Bushing/Strain Relief

2

Thermal Cutout

3

8" White Wire Assembly

4

8" Black Wire Assembly

5

Rocker Switch

6

6" White Wire Assembly

7

6" Black Wire Assembly

8

6" White Wire Assembly

9

10

500W Heating Element

11

6" Black Wire Assembly

12

3/4 Hole Shorty Bushing

13

Thermistor Assembly

Temperature Controller

14

5" Green Wire Assembly

15

Page 9

Page 10

WIRING UNIT 86478 (230V BRAZIL)

A B C

3

4

5

1

2

1 4

2 5

12

CHASSIS GROUND

CHASSIS GROUND

11

10

PROBE

9

T1L2T2NT3

H/L1T6LOAD

8

6

7

Page 10

Cord Assembly

1

230V BRAZIL

Blue

A

Brown

B

Yellow/Green

C

Bushing/Strain Relief

2

Rocker Switch

3

6" White Wire Assembly

4

6" Black Wire Assembly

5

6" White Wire Assembly

6

500W Heating Element

7

6" Black Wire Assembly

8

3/4 Hole Shorty Bushing

9

10

Thermistor Assembly

11

Temperature Controller

12

5" Green Wire Assembly

Page 11

ACCESSORY ITEMS

Customize your IntelliServ™

warmer with pans, pumps, ladles

or squeeze bottles for topping,

finishing or platescaping.

PAR T

NUMBER

Stainless Steel FP-1/6 Pump, 86312

1 oz (30 mL)

Magnetic Sign- Fudge 86788

Magnetic Sign- Caramel 86789

1/6-Size Squeeze Bottle Holder 87530

w/(3) 16 oz Bottles

1/3-Size, 6" (150mm) Deep Pan, 90083

6 qt (5.7 L)

1/6-Size, 6" (150mm) Deep Pan, 90089

2¾ qt (2.6 L)

1/6-Size Pan Lift-off Lid 90094

Stainless Steel 6" Ladle, 87213

1 oz (30 mL)

Page 11

Page 12

TROUBLESHOOTING

UNIT DOES NOT HEAT?

• Ensure cord is securely plugged in.

• Ensure power is available from source.

• Ensure unit is on.

• Ensure thermostat is set correctly.

that the correct amount of water is in basin.

• Ensure

UNIT TRIPS THE BREAKER?

(GROUND FAULT INTERRUPTER)

• Never expose electrical components to water

or liquid. This may result in damage.

Unit may not function.

If electrical components have gotten wet:

• Turn off unit and unplug.

• Allow unit to dry completely.

SERVER PRODUCTS

LIMITED WARRANTY

Server Products equipment is backed by a

two-year limited warranty against defects in

materials and workmanship.

For complete warranty information go to:

www.Server-Products.com

NEED HELP?

Server Products Inc.

3601 Pleasant Hill Road

Richfield, WI 53076 USA

262.628.5600 | 800.558.8722

SPSALES@SERVER-PRODUCTS.COM

GENERAL SERVICE,

REPAIR OR RETURNS

Before sending any item to Server Products for service,

repair, or return, contact Server Products customer

service to request a Return Authorization Number.

Merchandise must be sent to Server Products with this

number. Service is extremely prompt. Typically, units

are repaired and ship out within 48 hours.

Merchandise being returned for credit must be in new

and unused condition and not more than 90 days

old and will be subject to a 20% restocking charge.

Electrical parts (thermostats, heating elements, etc.)

are not returnable.

Servicing Cord: Specific tools are required for safe

and proper power supply cord removal and installation.

If cord must be replaced, only a representative of the

OEM (original equipment manufacturer) or a qualified

technician may replace cord. Cord must meet code

designation H05 RN-F requirements.

Please be prepared with your Model, Part and

Series Numbers. This information and other

important data is located on the base of the unit.

Page 12

Manual #01908-RevD 050517

Loading...

Loading...