Page 1

MODEL:

01670-REVC_061615

CCP

CONDIMENT CHILLER WITH PUMP,

BURGER KING

120V

Series 14I

86342

Page 2

SAFETY GUIDELINES WHEN

USING THIS UNIT:

C EWarning- Electrical shock could occur:

• This unit must be earthed or grounded.

• This requires all three prongs (terminals) on

cord plug to be plugged into power source.

According to food and safety regulations, most foods

must be stored and/or served at certain temperatures

or they could become hazardous. Check with local food

and safety regulators for specic guidelines.

Be aware of the product you are serving and the

temperature the product is required to maintain.

Server Products, Inc. can not be responsible for

the serving of potentially hazardous product.

Stainless steel is one of the best materials for food

serving and storage, but there are many products which

can corrode it. If you notice corrosion beginning on

any stainless steel surface, you may need to change

the cleansing agent, sanitizing agent, or the cleaning

procedures you are using.

• Products containing: acids, alkalines, chlorine, or

salt can corrode stainless steel.

• Sauerkraut and Au Jus sauces corrode stainless

steel. Server Products, Inc. regrets that we can

not honor Warranty claims on stainless steel parts

that have been affected by sauerkraut or Au Jus.

SAFETY GUIDELINES WHEN

CLEANING THIS UNIT:

Ensure unit is “OFF” and unplugged.

C EWarning- Electrical shock could occur:

• Electrical components of unit could be

damaged from water exposure or any liquid.

• Never immerse unit into water or any liquid.

• Never use any water jet or pressure sprayer

on unit.

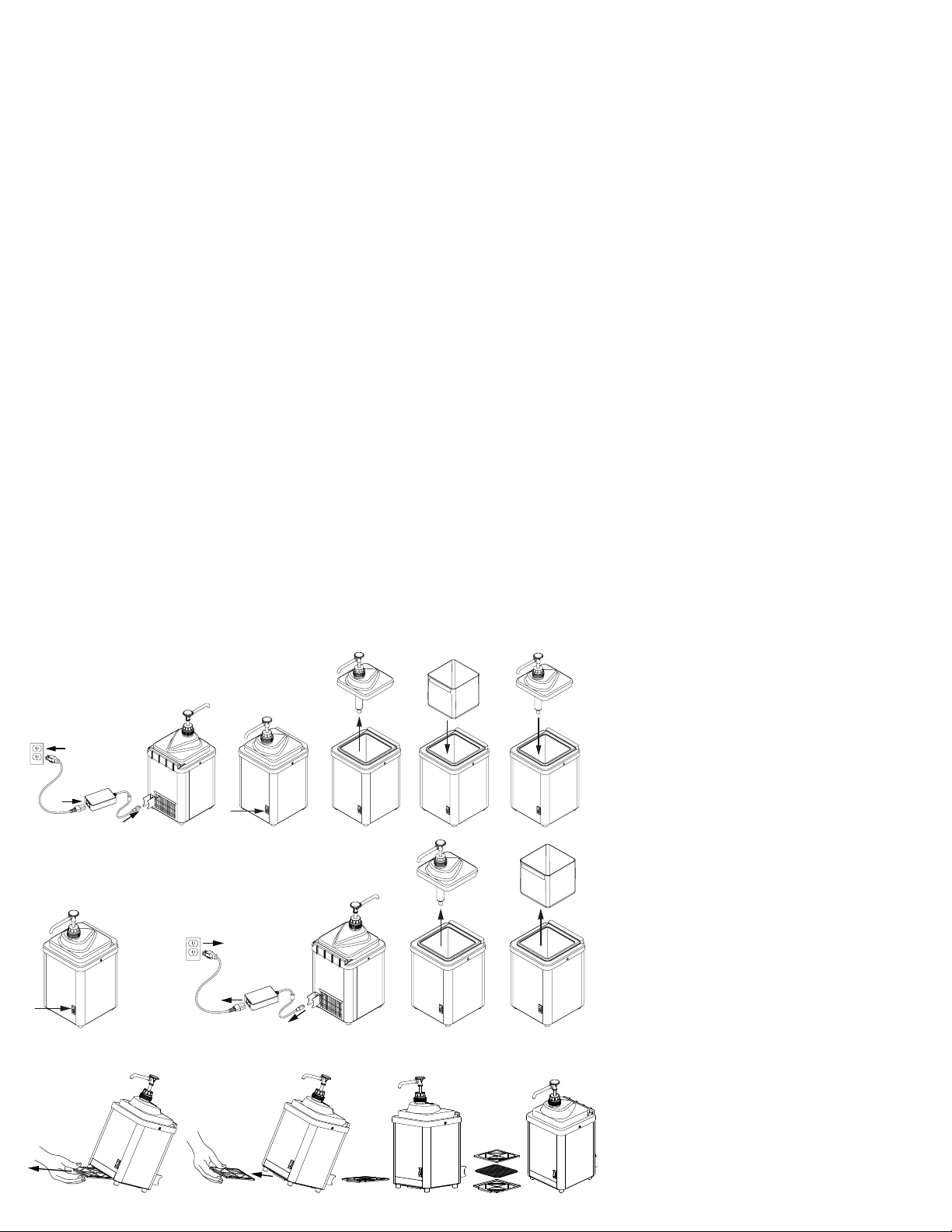

UNIT SET-UP

UNIT SET-UP

ALWAYS CLEAN UNIT THOROUGHLY BEFORE EACH USE.

SEE UNIT TAKE-DOWN, PUMP DISASSEMBLY, PUMP

CLEANING, PUMP ASSEMBLY, SAFETY GUIDELINES, AND

UNIT CLEANING.

1 PLUG CORD INTO POWER SOURCE.

• Verify that cord is securely plugged into unit,

power supply (adaptor), and power source (outlet).

2 PRESS SWITCH TO “ON” POSITION.

• Allow unit to pre-cool for 20 minutes.

3 REMOVE PUMP.

4 INSERT PRODUCT VESSEL INTO BASIN OF UNIT.

FOOD PRODUCT MUST ALWAYS BE INSIDE

PRODUCT VESSEL. NEVER PLACE FOOD PRODUCT

DIRECTLY INTO UNIT BASIN WITHOUT A VESSEL.

• Food product vessel maximum capacity is

two (2) quarts.

• DO NOT OVER FILL.

5 INSTALL PUMP TO MAINTAIN MAXIMUM COLD

TEMPERATURE.

• Temperature can be monitored by viewing

temperature strip located on front of product

vessel.

• For best unit cooling and performance, always

keep unit on continuously all day and all night,

every day and every night, to prevent pre-cool

period. Unit should remain on, as a refrigerator.

Server Products Inc. claims no responsibility

for actual serving temperature of product. It is

the responsibility of the user to ensure that any

product is held and served at a safe temperature.

UNIT TAKE-DOWN

1 PRESS SWITCH TO “OFF” POSITION.

2 UNPLUG CORD.

3 REMOVE PUMP.

4 REMOVE PRODUCT VESSEL.

UNIT CLEANING

BEFORE FIRST USE AND AFTER USE DAILY OR

REGULARLY, DISASSEMBLE AND CLEAN PARTS.

FOR SAFE AND PROPER CARE, AND TO PREVENT

CORROSION, OF PARTS, IT IS IMPORTANT TO

CLEAN, RINSE, SANITIZE, AND DRY PARTS DAILY OR

REGULARLY. FAILURE TO COMPLY WITH ANY OF THESE

INSTRUCTIONS MAY VOID UNIT WARRANTY.

1 SEE UNIT TAKE DOWN.

2 ENSURE UNIT IS “OFF” AND UNPLUGGED.

C EWarning- Electrical shock could occur:

• Electrical components of unit could be

damaged from water exposure or any liquid.

• Never immerse unit into water or any liquid.

• Never use any water jet or pressure sprayer

on unit.

3 WASH CLEAN ALL WASHABLE PARTS WITH

DISHWASHING DETERGENT AND HOT WATER.

• Do not use scrapers, steel pads, steel wool, or

other cleaning tools that can scratch surfaces.

• Mildly abrasive NYLON or brass brush may be

used to remove any stubborn food or mineral

deposits on interior surfaces of unit.

• Do not use abrasive cleansers.

• Do not use caustic cleansers.

• Do not use cleansing agents with high

concentrations of acid, alkaline or chlorine.

• Do not use ammonia based cleansers.

4 FULLY RINSE ALL WASHED PARTS THOROUGHLY

WITH CLEAR WATER.

• To prevent corrosion on parts, it is important to

thoroughly and fully rinse washed parts.

5 WIPE CLEAN EXTERNAL SURFACES OF UNIT WITH

A CLEAN DAMP CLOTH.

• Nontoxic glass cleaner may be used to clean

stainless steel parts.

6 DRY ALL PARTS WITH A CLEAN SOFT CLOTH.

• Various elements and minerals, such as chlorides

in tap water, can accumulate on stainless steel

parts and create corrosion.

• To prevent corrosion on stainless steel parts, it is

important to thoroughly and fully dry with a clean

soft cloth regularly.

7 SANITIZE ALL PARTS FOLLOWING LOCAL

SANITIZATION REQUIREMENTS. ALL PARTS IN

CONTACT WITH FOOD MUST BE SANITIZED.

• Allow parts to fully air dry after sanitization.

UNIT TAKE-DOWN

CHANGING OR CLEANING FILTER

CHANGING OR CLEANING

FILTER

FOR BEST UNIT COOLING AND PERFORMANCE,

CHANGE OR CLEAN FILTER AT A MINIMUM OF ONCE

PER MONTH.

1 SEE UNIT TAKE DOWN.

2 ENSURE UNIT IS “OFF” AND UNPLUGGED.

3 REMOVE FILTER DRAWER FROM UNDERSIDE OF

UNIT BY SLIDING OUT OF DRAWER SLOTS.

4 REMOVE DRAWER COVER FROM DRAWER.

5 REMOVE FILTER AND CLEAN OR REPLACE.

• Server Products Inc. Pack of 5 Replacement

lters: 86067

• Filter can be cleaned with hot water and

dishwashing detergent. Fully rinse.

6 IF NECESSARY, WIPE DOWN FAN COVER AND

SURROUNDING AREA ON UNDERSIDE OF UNIT

WITH CLOTH DAMPENED WITH DISHWASHING

LIQUID OR MILD SANITIZING DETERGENT.

C EWarning- Electrical shock could occur:

• Be sure to wring out any excess water from

cloth before wiping near fan of unit.

• Dripping water into unit can cause electrical

damage to unit.

Page 3

PUMP DISASSEMBLY

BEFORE FIRST USE AND AFTER USE DAILY,

DISASSEMBLE AND CLEAN PUMP.

1 REMOVE PUMP FROM UNIT.

2 SUBMERGE, FLUSH, RINSE, AND SANITIZE PUMP

THOROUGHLY USING THREE COMPARTMENT SINK.

OPERATE PUMP A MINIMUM OF 8 TIMES IN EACH

SINK.

• Submerge pump into wash sink. Then place

lower end of pump into wash sink and operate

pump, to PUMP CLEANING solution through

pump, at least 8 times, until all (if any)

remaining product is expelled and only the

wash water ows through.

• Submerge pump into rinse sink. Then place

lower end of pump into rinse sink and operate

pump, at least 8 times, to fully rinse inside of

pump.

• Submerge pump into sanitizer sink. Then place

lower end of pump into sanitizer sink and

operate pump, at least 8 times, to fully sanitize

inside of pump.

• After submerging, ushing, rinsing, and

sanitizing pump, remove pump from sink to

disassemble pump.

• Use a container to collect small parts of pump

to prevent any loss.

3 LOOSEN PLASTIC CAP SECURING PUMP TO LID

AND REMOVE PUMP FROM LID.

4 LOOSEN LOCKING COLLAR AND REMOVE

CYLINDER ASSEMBLY FROM HEAD ASSEMBLY.

5 REMOVE SPRING FROM CYLINDER ASSEMBLY.

6 REMOVE PINCH VALVE FROM HEAD ASSEMBLY

• Pinch and gently turn to pull valve out.

7 REMOVE SEAL FROM HEAD ASSEMBLY BY

PRESSING DOWN AND OFF WITH THUMB.

• Do not use a sharp tool to remove seal, this

may damage seal.

• If seal is damaged, product will leak past seal.

8 REMOVE GAGING COLLAR FROM HEAD ASSEMBLY.

PUMP ASSEMBLY

ALWAYS CLEAN PUMP THOROUGHLY BEFORE EACH

USE AND AFTER USE DAILY. SEE UNIT TAKE-DOWN,

PUMP DISASSEMBLY, AND PUMP CLEANING.

1 INSTALL SEAL SECURELY ONTO HEAD ASSEMBLY

PISTON.

• Align seal so that ared edge is facing down

towards bottom of piston. If seal is installed

incorrectly, product will leak past seal.

2 APPLY A SMALL AMOUNT OF FOOD EQUIPMENT

LUBRICANT INSIDE BOTTOM OF HEAD ASSEMBLY

PISTON. THEN INSTALL PINCH VALVE INTO

BOTTOM END OF HEAD ASSEMBLY PISTON.

• Rotate pinch valve inside head assembly

piston to spread lubricant evenly inside end

of head assembly piston. Then position pinch

valve securely into a sealed position on end of

head assembly piston.

3 INSTALL GAGING COLLAR ONTO SIDE OF HEAD

ASSEMBLY PISTON.

4 INSTALL SPRING INTO CYLINDER.

5 INSTALL CAP BY SECURELY SNAPPING IT ONTO

CYLINDER, PAST THREADING.

6 INSTALL LID BY SLIDING LID UP FROM BOTTOM

OF CYLINDER TO ALIGN WITH CAP. SECURE PUMP

TO LID BY TIGHTENING CAP TO LID THREADING.

7 APPLY A SMALL AMOUNT OF FOOD EQUIPMENT

LUBRICANT INSIDE TOP OF CYLINDER AND TO

OUTSIDE SURFACE OF SEAL.

8 INSTALL HEAD ASSEMBLY PISTON INTO

CYLINDER.

9 SLIDE LOCKING COLLAR DOWN ONTO CYLINDER

THREADING AND TIGHTEN TO SECURE HEAD

ASSEMBLY TO CYLINDER.

J PREPARE PUMP FOR USE.

• Install pump onto unit and product vessel.

Operate pump several times until only product,

without air bubbles, is delivered with each

stroke of pump.

PUMP ASSEMBLY

3

2

1

5

4

6

8

9

PUMP CLEANING

BEFORE FIRST USE AND AFTER USE DAILY OR

REGULARLY, DISASSEMBLE AND CLEAN PARTS.

FOR SAFE AND PROPER CARE, AND TO PREVENT

CORROSION, OF PARTS, IT IS IMPORTANT TO

CLEAN, RINSE, SANITIZE, AND DRY PARTS DAILY OR

REGULARLY. FAILURE TO COMPLY WITH ANY OF THESE

INSTRUCTIONS MAY VOID UNIT WARRANTY.

1 SEE PUMP DISASSEMBLY.

2 WASH CLEAN ALL PARTS WITH DISHWASHING

DETERGENT AND HOT WATER.

• Do not use scrapers, steel pads, steel wool, or

other cleaning tools that can scratch surfaces.

• Mildly abrasive NYLON or brass brush may be

used to remove any stubborn food or mineral

deposits on interior surfaces of unit.

• Do not use abrasive cleansers.

• Do not use caustic cleansers.

• Do not use cleansing agents with high

concentrations of acid, alkaline or chlorine.

• Do not use ammonia based cleansers.

3 FULLY RINSE ALL WASHED PARTS THOROUGHLY

WITH CLEAR WATER.

• To prevent corrosion on parts, it is important to

thoroughly and fully rinse washed parts.

4 DRY ALL PARTS WITH A CLEAN SOFT CLOTH.

• Various elements and minerals, such as chlorides

in tap water, can accumulate on stainless steel

parts and create corrosion.

• To prevent corrosion on stainless steel parts, it is

important to thoroughly and fully dry with a clean

soft cloth regularly.

5 SANITIZE ALL PARTS FOLLOWING LOCAL

SANITIZATION REQUIREMENTS. ALL PARTS IN

CONTACT WITH FOOD MUST BE SANITIZED.

• Allow parts to fully air dry after sanitization.

7

7

Page 4

TROUBLESHOOTING FOR

PUMP

Pump dispenses little or no product:

• Ensure pinch valve is properly installed

into bottom of head assembly.

• Ensure ball is snapped in place down

inside cylinder.

• Product may be too stiff or contain a solid

that will not pass through pinch valve.

Product oozes out around locking collar:

• Ensure seal is securely installed onto head

assembly piston. Ensure ared edge of

seal is facing down towards bottom of piston.

Pump head assembly does not return to top of

stroke after dispensing product:

• Inspect spring for any damage. If bent or

broken, spring may cause permanent damage

to cylinder. Replace spring if necessary.

Pump drips:

• Clean head assembly discharge tube with

manufacturer’s supplied smaller bristled

brush.

• Ensure product is not being heated by any

external source(s) causing product to expand

and drip from pump.

Portion control is not consistent:

• Inspect gaging collar for any damage, verify

that it is the correct one, and is installed

properly onto head assembly piston.

• Inspect pinch valve for any damage. Replace

if necessary.

• Ensure ball is snapped in place down inside

cylinder.

Problems with pump operation and/or ow:

• Replace seal if necessary.

• Replace cylinder assembly if necessary.

• Clean pump.

SAFETY GUIDELINES

According to food and safety regulations, most foods must

be stored and/or served at certain temperatures or they

could become hazardous. Check with local food and safety

regulators for specic guidelines.

Be aware of the product you are serving and the

temperature the product is required to maintain.

Server Products, Inc. can not be responsible for the

serving of potentially hazardous product.

NSF International

(National Sanitation Foundation)

lists this pump as: “Not acceptable for

dispensing potentially hazardous foods.”

Stainless steel is one of the best materials for food

serving and storage, but there are many products which

can corrode it. If you notice corrosion beginning on

any stainless steel surface, you may need to change

the cleansing agent, sanitizing agent, or the cleaning

procedures you are using.

• Products containing: acids, alkalines, chlorine,

or salt can corrode stainless steel.

• Sauerkraut and Au Jus sauces corrode stainless steel.

Server Products, Inc. regrets that we can not honor

Warranty claims on stainless steel parts that have

been affected by sauerkraut

or Aus Jus.

SERVER PRODUCTS

LIMITED WARRANTY

All Server Products equipment is backed by a two-year

limited Warranty against defects in materials and

workmanship. For complete Warranty information go to:

www.server-products.com

SCOPE OF Warranty:

Server Products Inc. (“Server Products”) warrants that,

for a period of two (2) years from the date of purchase

(the “Warranty Period”), the equipment manufactured by

it will be free from defects in workmanship and materials

provided the equipment is used in the manner and in the

environment for which they were manufactured.

DISCLAIMERS AND LIMITATIONS:

Other than as set forth above, Server Products specically

disclaims all express and implied warranties, including but

not limited to, warranties of merchantability and/or tness

for a particular purpose or use.

This Warranty does not extend to repairs or alterations

undertaken without the prior written consent of

Server Products or for goods that are misused, abused

or neglected or if the goods are not properly stored,

maintained, installed or operated.

Server Products shall not be liable for incidental, special,

indirect, exemplary, punitive or consequential damages

resulting from the use of the good or arising out of any

breach of this Warranty; including but not limited to

damage to property or loss of prots or revenue.

CLAIMS ADMINISTRATION:

All Warranty claims must be made by calling our customer

service department for a return authorization during the

Warranty Period and any alleged defective unit must

be returned to Server Products factory, freight prepaid.

Upon receipt of any defective unit, Server Products, at its

option, may either: (i) replace any equipment proved to

be defective, (ii) remedy or repair such defect or

(iii) refund the purchase price of the defective equipment

in the form of a credit applicable to future purchases.

Server Products obligation and Buyer’s sole remedy will

be limited to these options. In the case of units or parts

purchased by Server Products from a third-party supplier:

Server Products’ obligation and Buyer’s sole remedy

against Server Products or Server Products’s suppliers shall

not exceed the settlement which Server Products is able to

obtain from its supplier.

TROUBLESHOOTING FOR

CHILLER

Unit does not cool:

• Ensure cord is securely plugged in. Verify that

cord is securely plugged into the unit, the

power supply (adaptor), and the power source

(electrical outlet).

• Ensure power is available from source.

• Ensure unit is on.

• Ensure fan is on/running.

• Ensure lter is clean or replace if necessary.

GENERAL SERVICE, REPAIR, OR

RETURNS

Before sending any item to Server Products for service,

repair, or return, contact Server Products customer service

to request a Return Authorization Number.

Merchandise must be sent to Server Products with this

number.

Merchandise being returned for credit must be in new and

unused condition and not more than 90 days old and will

be subject to a 20% (percent) restocking charge.

Electrical parts (thermostats, heating elements etc.)

are not returnable.

Server Products maintains a fully staffed service

department with highly skilled factory trained personnel.

Service is extremely prompt. Under normal circumstances,

a repaired unit is shipped out the day after it is received.

Labor charges are reasonable.

SERVICE

Contact dealer or Server Products Inc.

customer service department for the following:

ORDERING REPLACEMENT PARTS

Be prepared to give this information:

• MODEL Letters/Name/Numbers

• Part Numbers- P/N

• Series Numbers/Letters

• Part Description

This information and other important data is stamped on

the lid or cylinder of pumps or on the bottom or back side

of every unit.

Server Products Inc.

3601 Pleasant Hill Road

Richfield, WI 53076 USA

262.628.5600

800.558.8722

262.628.5110

spsales@server-products.com

www.server-products.com

Page 5

PART

40179

82049

82526

86343

94135

88349

86343

DESCRIPTIONQTY

1

LUBRICANT, FOOD EQUIPMENT

1

BRUSH, 11", 1¼” DIAMETER

1

BRUSH, 21"

1

BASE ONLY COND CHILLER, BK

1

POWER INLET GUIDE

POWER SUPPLY, 5", 5A, 4 PIN CONN180068

FOOT, W/SCREW481058

FAN, CHILLER186007

SWITCH, LIGHTED ROCKER, 12V 186032

BOTTOM ASSEMBLY186049

FILTER (PACK OF 5)186067

KIT, VESSEL/THERMOMETER, CHILLER 186144

MODULE, BASIN ASSEMBLY, 3.35V186419

HOUSING ASSEMBLY 186472

THERMOMETER, STRIP186873

TOP, WO/HINGE HOLES186938

DRAWER, FILTER GUARD194154

SCREEN, FILTER GUARD194153

DRAWER COVER, FILTER GUARD194155

SHROUD, FILTER GUARD194156

CORD, 18GA W/CONNECTOR186584

BP-1, 38MM, BK - 5/16 OZ, 10" DEEP188349

LID, CHILLER, BP, BLACK-PLASTIC 186255

SPRING ASSEMBLY, BP-1188166

HEAD ASSEMBLY BP-1, 5/16 FL OZ-BK188347

SEAL ASSEMBLY: INCLUDES

183003

O-RING AND SEAL

VALVE, PINCH, BP-1188202

COLLAR, GAGING-5/16 OZ, CREAM188344

CYLINDER ASSY BP-1, SILVER, 7 11/16188348

BALL, 1/2" DIA, SS106022

CAP, PLASTIC, 38MM, 1.156 HOLE, BLK188016

94155

86067

94154

86144

86938

86472

86032

86419

81058(4)

Server Products, Inc.

3601 Pleasant Hill Road (PO Box 98)

Richfield, WI 53076 USA

www.server-products.com

Model Name

Model Number

Series

14I

86342 FINAL UNIT, 86343 BASE, 88349 PUMP

CHILLER W/PUMP, 5/16 OZ-BK

94135

86584

88349

80068

86007

86049

94153

94156

88347

88166

88348

86255

06022

88344

83003

88202

88016

Direct 262.628.5600

Toll Free 800.558.8722

Fax 262.628.5110

spsales@server-products.com

6/9/15

40179

82049

82526

A

Loading...

Loading...