Page 1

EZ-Topper™

Tall, Single

MODEL: EZT-S

WITH SPOUT HEATER:

85790 COMPLETE

85850 WARMER BASE

WITHOUT SPOUT HEATER:

85860 COMPLETE

85707 WARMER BASE

Used with

48 fl. oz pouches

with 16mm

center fitments.

Thank You

...for your purchase. This pouched topping

warmer virtually eliminates product degradation

and waste, so you can reduce food costs while

delivering a superior product.

SIMPLIFY TOPPING MANAGEMENT—GO POUCHED

Page 2

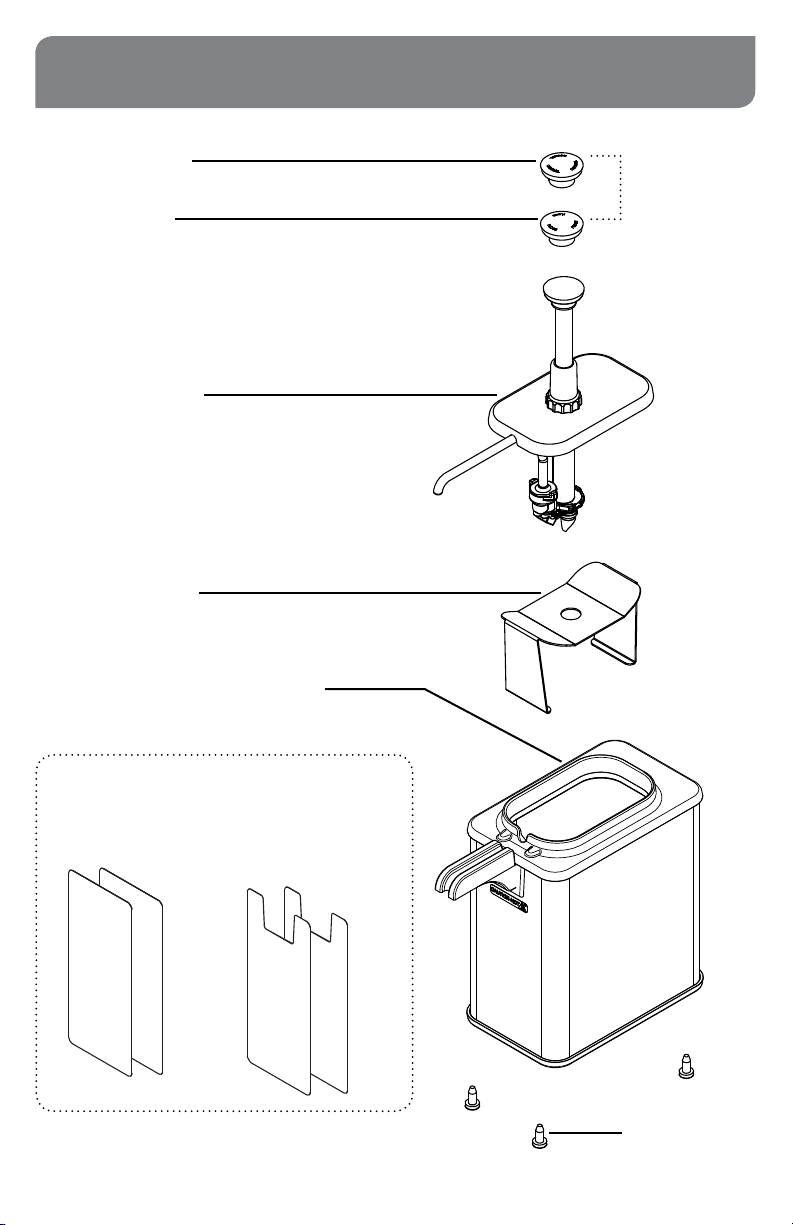

PARTS

CARAMEL KNOB

82023-024

FUDGE KNOB

82023-015

EZ-TOPPER PUMP

85820

POUCH SUPPORT

85819

WARMER BASE

WITH SPOUT HEATER 85850 (SHOWN)

WITHOUT SPOUT HEATER 85707

OPTIONAL:

USE KNOBS TO

QUICKLY IDENTIFY

PUMP CONTENTS

Units 85860 & 85707

include

MAGNETIC DECAL SET

84971

Page 2

Units 85790 & 85850

include

MAGNETIC DECAL SET

84972

FOOT

07429

Page 3

SAFETY

According to food and safety regulations, most

foods must be stored and/or served at certain

temperatures or they could become hazardous.

Check with local food and safety regulators for

WARNING-

ELECTRICAL SHOCK COULD OCCUR

This unit must be earthed or grounded.

This requires all three prongs (terminals) on cord

plug to be plugged into power source.

specific guidelines.

Be aware of the product you are serving and the

temperature the product is required to maintain.

Server Products, Inc. can not be responsible for

the serving of potentially hazardous product.

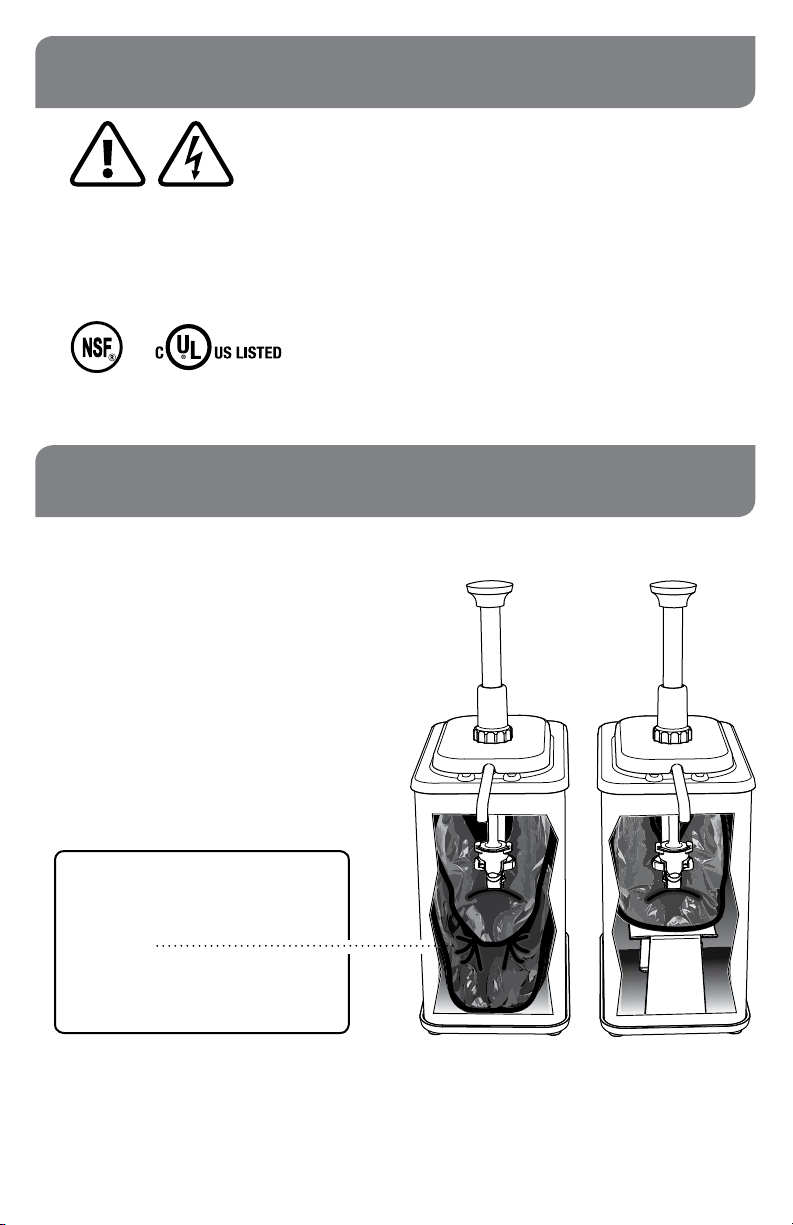

PRE-HEATING PRODUCT POUCHES

• Install pump with pouch.

(See UNIT SETUP, pg. 4.)

• Adjust thermostat to food manufacturer's

recommended serving temperature.

Make change-outs a cinch.

Place a reserve pouch in the bottom

of the base.

When the primary pouch is emptied,

the reserve pouch is pre-heated

and ready for use.

Cutaway views show:

Reserve Pouch

in base bottom

Pouch Support

in base bottom

Page 3

Page 4

WASH ALL PARTS PROPERLY

UNIT SETUP

BEFORE EVERY USE.

SEE SEPARATE PUMP MANUAL FOR PUMP SETUP.

See page 6.

INSERT INTO BASE: POUCH SUPPORT RESERVE POUCH

1

IMPORTANT: A pouch

support or reserve pouch

gives the primary pouch the

proper elevation to dispense

all product and heat evenly.

ATTACH PUMP

2

OR

TO PRIMARY POUCH

• Place pouch on countertop with

pouch fitment circle facing upward.

• Position pump connector directly

over center of pouch fitment.

• Press pump connector down to

pierce through film in pouch fitment.

INSTALL PUMP WITH

3

SNAP

Pump is fully engaged when

top surface of pouch fitment

touches pump connector rim.

POUCH INTO BASE

4

5

6

Page 4

PLUG CORD into power source.

PRESS SWITCH to the “ON” position.

SET THERMOSTAT KNOB

to food manufacturer's recommended

serving temperature.

• Dial indicator uses increments of 5º F.

• Thermostat maximum is 210º F/99º C.

Page 5

UNIT TAKE-DOWN

PRESS SWITCH to the “OFF” position.

1

UNPLUG CORD

2

CAUTION- HOT

Allow unit to cool before continuing or

use proper care with hot surfaces.

REMOVE PUMP

3

WITH POUCH

REMOVE POUCH SUPPORT

4

OR RESERVE POUCH

DETACH POUCH

5

from bottom of pump.

FLUSH AND RINSE PUMP

6

Thoroughly rinse all inside and outside

surfaces of pump with hot water.

DISASSEMBLE AND CLEAN PUMP.

7

SEE SEPARATE PUMP MANUAL FOR PUMP CLEANING.

Page 5

Page 6

CLEANING

SEE SEPARATE PUMP MANUAL

FOR PUMP INSTRUCTIONS.

WARNING-

ELECTRICAL SHOCK COULD OCCUR

• Electrical components of unit could be

damaged from water exposure or any liquid.

• Never immerse unit into water or any liquid.

• Never use any water jet or pressure sprayer

on unit.

• Ensure unit is “OFF” and unplugged.

CAUTION- HOT

Allow unit to cool before cleaning.

CLEAN EXTERNAL SURFACES

• Wipe daily with a clean damp cloth.

• Dry with a clean soft cloth.

• Glass and surface cleaners approved for use

in food contact areas may be used.

CARE OF STAINLESS STEEL

This warmer and accessories are

constructed of stainless steel—

one of the best materials for food

serving and storage.

If you notice corrosion beginning on any stainless

steel surface, you may need to change the

cleansing agent, sanitizing agent, or the cleaning

procedures you are using.

Page 6

• A mildly abrasive nylon or brass brush may

be used to remove any stubborn food or

mineral deposits on interior surfaces of unit.

• Fully rinsing and drying all parts can help

prevent corrosion. Elements and minerals in

tap water can accumulate on stainless steel

parts and create corrosion.

• Do not use abrasive, caustic or ammonia

based cleansers.

• Do not use products containing acids,

alkalines, chlorine, or salt. These agents can

corrode stainless steel.

• Do not use metal scrapers or cleaning pads

that could scratch surfaces.

Page 7

WIRING

UNITS 85850, 85707 | 120V | USA

TOP

(USING

10068

SCREW)

GROUND

STANDOFF

PIN VESSEL

ASSEMBLY

GROUND

STUD

CONTROL

PANEL

2

1

7

GREEN

WHITE

2

1

BLACK

3

4

2

6

5

1

Cord Assembly

1

Bushing/Strain Relief

2

Snap-In Rocker Switch

3

6" Wire Assembly, Black

4

Thermostat

5

Heating Element

6

15" Wire Assembly, Green

7

Page 7

Page 8

TROUBLESHOOTING

UNIT DOES NOT HEAT?

• Ensure cord is securely plugged in.

• Ensure unit is on.

• Ensure thermostat knob is set correctly.

• Ensure power is available from source.

• Do not allow any of the electrical components

to get wet. Moisture may cause the unit to

trip breaker or GCFI. If moisture is suspected,

discontinue use. Allow unit to fully air dry.

SERVER PRODUCTS

LIMITED WARRANTY

Server Products equipment is backed by a

two-year limited warranty against defects in

materials and workmanship.

For complete warranty information go to:

www.Server-Products.com

POUCH DOES NOT EVACUATE

ALL PRODUCT?

• Ensure

that the pouch is properly connected

with pump.

• Ensure that the pouch being dispensed is raised

to proper height. Always use either a pouch

support or a reserve pouch beneath

primary pouch.

GENERAL SERVICE,

REPAIR OR RETURNS

Before sending any item to Server Products for service,

repair, or return, contact Server Products customer

service to request a Return Authorization Number.

Merchandise must be sent to Server Products with this

number. Service is extremely prompt. Typically, units

are repaired and ship out within 48 hours of receipt.

Merchandise being returned for credit must be in new

and unused condition and not more than 90 days

old and will be subject to a 20% restocking charge.

Electrical parts (thermostats, heating elements, etc.)

are not returnable.

Servicing Cord: Specific tools are required for safe

and proper power supply cord removal and installation.

If cord must be replaced, only a representative of the

OEM (original equipment manufacturer) or a qualified

technician may replace cord. Cord must meet code

designation H05 RN-F requirements.

NEED HELP?

Server Products Inc.

3601 Pleasant Hill Road

Richfield, WI 53076 USA

262.628.5600 | 800.558.8722

SPSALES@SERVER-PRODUCTS.COM

Page 8

Please be prepared with your Model, Part and

Series Numbers. This information and other

important data is located on the lid and/or base

of the unit.

Manual #01744-RevC 020717

Loading...

Loading...