Page 1

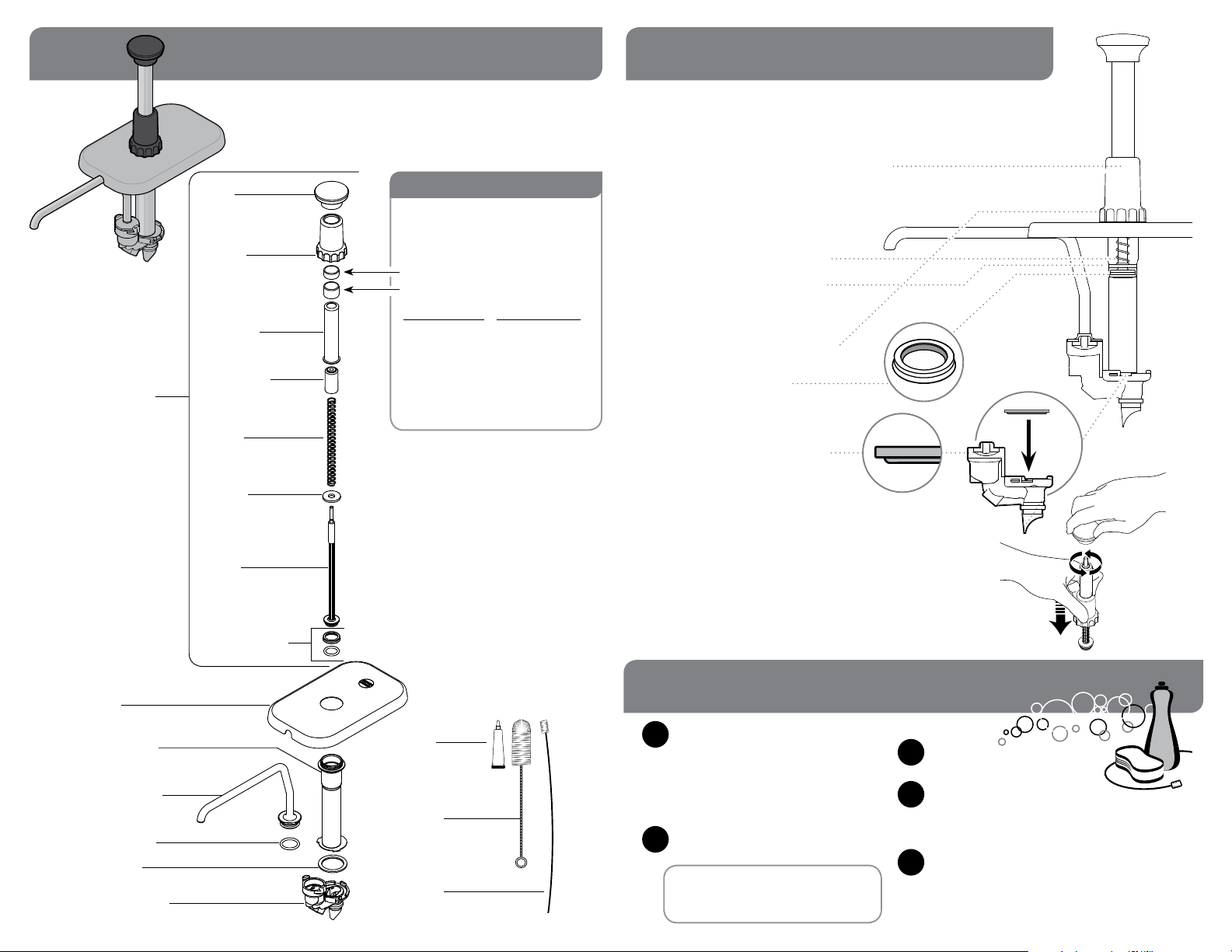

PLUNGER

ASSEMBLY

PARTS for PUMP 85820

KNOB

82023-000

LOCKING

COLLAR

83412

HEAD TUBE

82017

HEAD INSERT

82018

SPRING

82016

PORTION CONTROL

PUMP DELIVERS 1 FL OZ PORTIONS

To reduce portion, add

GAGING COLLAR(S)

83529 SM COLLAR: 1/8 fl oz reduction

82022 LG COLLAR: 1/4 fl oz reduction

COLLAR(S) USED PORTION RESULT

None 1 fl oz

1 Sm

3/4 fl oz

1 Lg

1 Lg + 1 Sm

2 Lg

1/2 fl oz

2 Lg + 1 Sm

1/4 fl oz

3 Lg

3 Lg + 1 Sm

7/8 fl oz

5/8 fl oz

3/8 fl oz

1/8 fl oz

TROUBLESHOOTING

PROBLEMS WITH FLOW OR PORTIONS?

• Clean pump.

• Food product may be too thick or contain

a solid that will not pass thr

• If used: Ensure gaging collar(s) are undamaged

and properly installed on head tube.

PLUNGER DOESN’T RETURN

TO TOP AFTER DISPENSING?

• Ensure that the spring is functional.

Replace broken spring if necessary.

• Ensure that the washer is installed

between the spring and piston head.

FOOD PRODUCT OOZES OUT

AROUND LOCKING COLLAR?

• Ensure seal is properly installed on piston.

TIP: Seal has a slight taper.

Install with flat side towards

top, flared side down.

LEAKS NEAR THE VALVE BODY?

• Ensure gasket is properly installed.

Flat side of gasket should face up.

ough pump.

LID

85829

CYLINDER

82362

DISCHARGE

TUBE

85827

O-RING, 1"

05127

GASKET

88554

VALVE BODY

82635

WASHER

82015

PISTON

82013

SEAL ASSEMBLY

83003

FOOD

EQUIPMENT

LUBRICANT

40179

BRUSH

82049

BRUSH

82526

PUMP DRIPS?

• Clean discharge tube with supplied brush.

• Inspect all o-rings. Replace if damaged.

•

oduct may be too thin.

Food pr

Visit www.Server-Products.com for more tips.

CAN’T FIND THREADS FOR KNOB?

• Look inside the cylinder.

If the knob is unscr

Press the collar down to expose the threads.

ewed, piston threads retract into the plunger.

CLEANING

FLUSH & RINSE

1

all pump surfaces with hot water.

Place lower end of pump into container

of hot water and operate pump until all

remaining product is expelled and only

hot water is discharged.

DISASSEMBLE & CLEAN

2

all washable parts with soap and hot water.

USE SUPPLIED BRUSH

to thoroughly clean inside discharge

tube and any confined areas.

Use dishwashing soap, hot water and nylon brush.

Pump is dishwasher safe.

RINSE

3

fully with clean water.

SANITIZE

4

all parts according to local sanitization

requirements. All parts in contact with food

must be sanitized.

AIR DRY

5

all parts fully.

Page 2

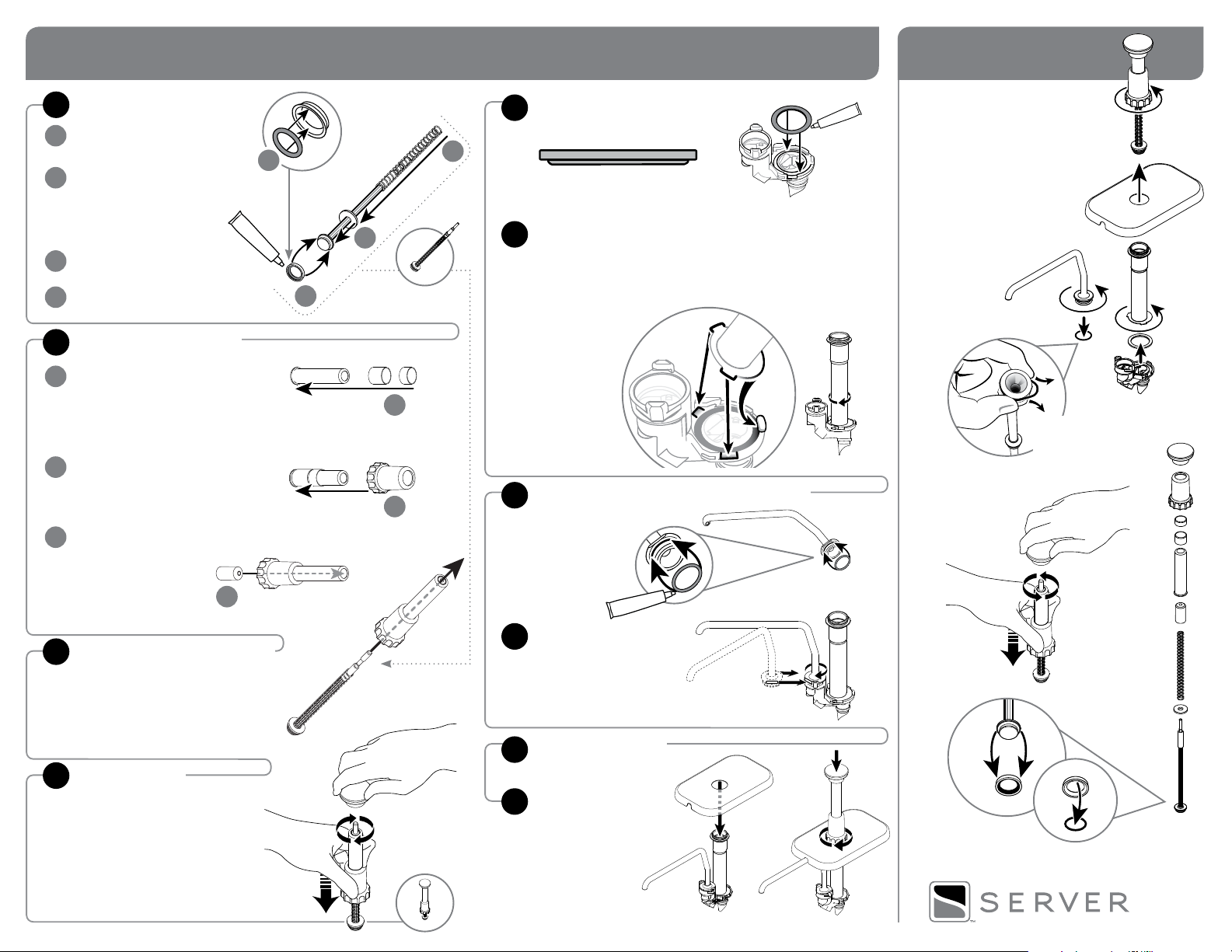

ASSEMBLY

DISASSEMBLY

PREPARE PISTON

1

INSTALL SMALL O-RING

A

into seal.

INSTALL SEAL

B

onto piston head. Apply food equipment

lubricant to outside of seal.

TIP: Flared end of seal should

face away from piston head.

SLIDE WASHER onto piston.

C

SLIDE SPRING onto piston

D

PREPARE HEAD TUBE

2

OPTIONAL:

A

ADD GAGING COLLAR(S)

to reduce portion size

SLIDE LOCKING COLLAR ON

B

SLIDE HEAD INSERT

C

(beveled edge first)

into head tube.

TIP: The end

with smaller hole

should go in first.

INSTALL GASKET

5

into valve body. Apply food equipment

lubricant on gasket.

A

C

B

SET ASIDE

FOR STEP 3

A

B

D

TIP: Flat side of gasket

should face up.

INSTALL CYLINDER

6

onto valve body.

TILT wide edge of cylinder under

nub on rim of valve body.

FIT TABS on cylinder into

corresponding notches

in valve body.

PRESS DOWN

firmly and

ROTATE

cylinder

clockwise

to secure

into slots.

INSTALL O-RING

7

onto discharge tube.

Apply food equipment

lubricant on o-ring.

PINCH & PULL

to remove o-ring

C

INSERT PISTON ASSEMBLY

3

into head tube assembly.

INSTALL KNOB

4

Press head tube down to compress

spring and expose piston threads.

Rotate knob clockwise to secure.

INSTALL

8

DISCHARGE TUBE

onto valve body. Rotate

discharge tube clockwise

and press down firmly to

secure into slots on valve body.

INSTALL LID

9

INSTALL PLUNGER

10

ASSEMBLY

Loading...

Loading...