Page 1

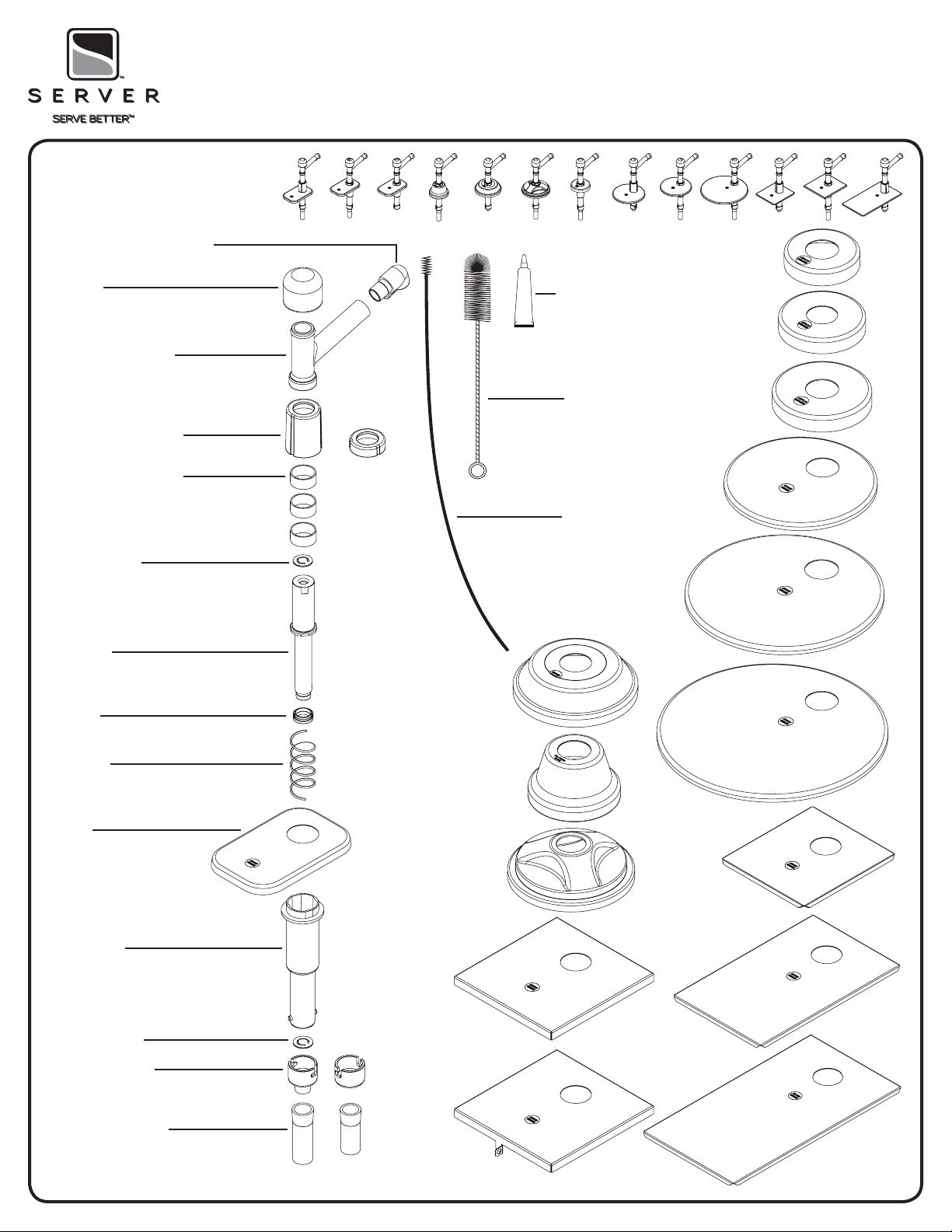

SOLUTIONTM PUMP PARTS

DISCHARGE FITTINGS

01570-REVI_050712_ENGLISH

TM

SOLUTION

Go to server-products.com for translations and for each pump parts breakdowns

PARTS INCLUDED VARY DEPENDING ON PUMP

PUMPS INSTRUCTION MANUAL

KNOB

DISCHARGE TUBE

LOCKING COLLARS

GAGING COLLARS

(Portion Control) Each collar

added reduces portion served

by .25 oz

BALL VALVE

PISTON

SEAL

FOOD EQUIPMENT

LUBRICANT 40179

1

BRUSH 82049 (1

/

BRUSH 82526 (21”)

” D)

4

SPRING

LIDS

CYLINDER

BALL VALVE

CONNECTORS

SUCTION TUBES

Page 2

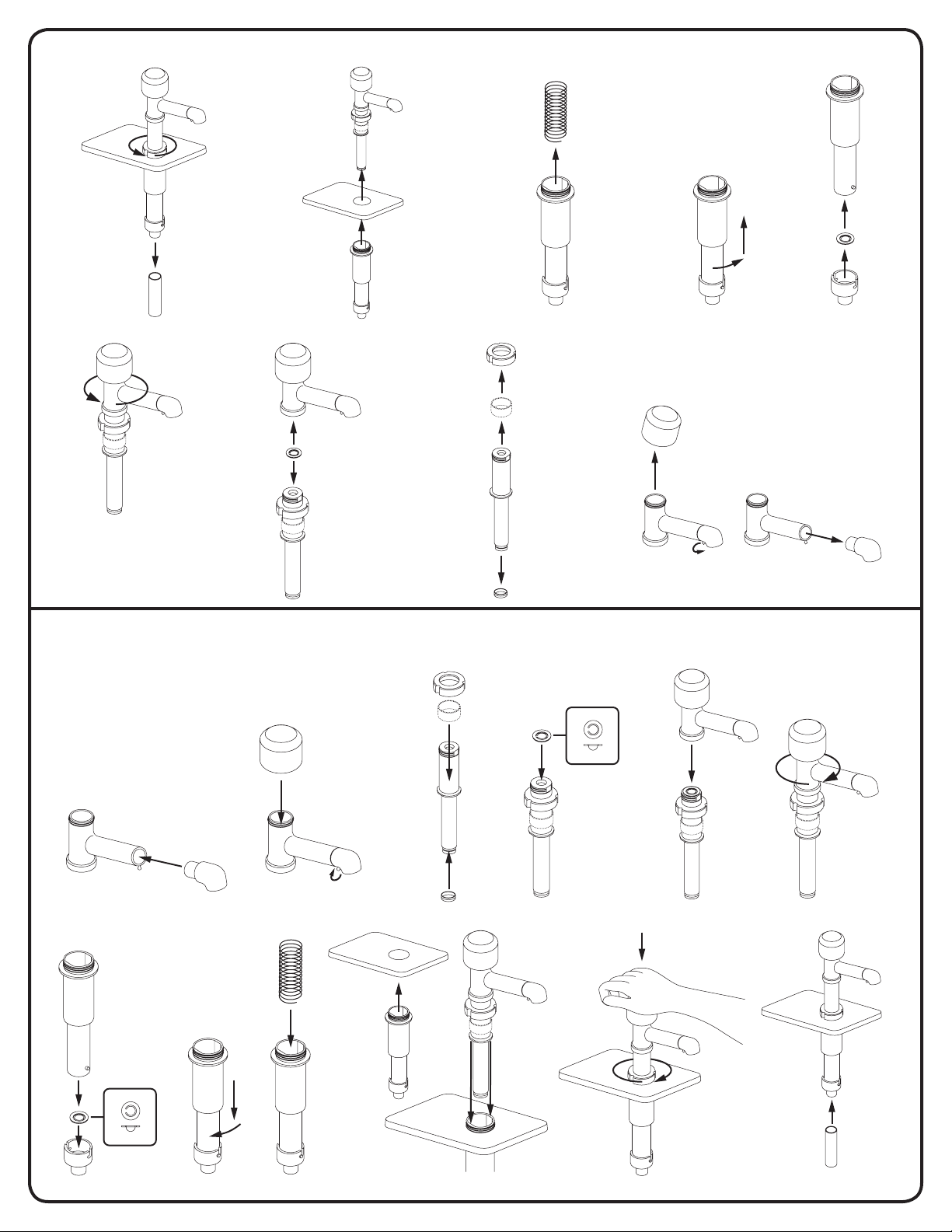

PUMP DISASSEMBLY

8

4

9

4

5

6

7

J

L

M

PUMP ASSEMBLY

1

9

2

1

J

4

M

K

6

5

6

3

L

7

8

K

M

Page 3

PUMP DISASSEMBLY

BEFORE FIRST USE AND AFTER USE DAILY, DISASSEMBLE

AND CLEAN PUMP.

1 PUMP OUT ALL (IF ANY) REMAINING FOOD PRODUCT

FROM INSIDE PUMP BODY.

2 WASH AND RINSE OFF OUTSIDE OF PUMP BODY.

3 FLUSH OUT AND RINSE THROUGH INSIDE OF PUMP.

• Place lower end of pump into container full of

water and operate pump until all (if any) remaining

product is expelled and only warm water ows from

discharge tube. Then remove pump from container

of water to disassemble.

• Use a container to collect small parts of pump to

prevent any loss.

4 REMOVE PLUNGER ASSEMBLY AND LID FROM

PUMP BODY BY TURNING LOCKING COLLAR

COUNTERCLOCKWISE.

5 REMOVE SPRING FROM PUMP BODY.

6 REMOVE CYLINDER FROM CONNECTOR. PUSH

CYLINDER INTO CONNECTOR TO COMPRESS

BALL VALVE WHILE ROTATING CYLINDER

COUNTERCLOCKWISE. ROTATE CYLINDER TO

RELEASE PINS FROM SLOTS ON CONNECTOR.

7 REMOVE BALL VALVE FROM INSIDE CONNECTOR.

8 REMOVE DISCHARGE TUBE BODY FROM

PISTON BY ROTATING DISCHARGE TUBE BODY

COUNTERCLOCKWISE.

• Be prepared for ball valve to fall loose when

removing discharge tube body from piston.

9 REMOVE BALL VALVE FROM PISTON, IF REMAINING

ON END OF PISTON.

J REMOVE LOCKING COLLAR AND GAGING COLLAR(S),

IF USED, FROM PISTON BY SLIDING THEM OFF.

K REMOVE SEAL FROM END OF PISTON BY ROTATING

AND PULLING OFF OF LIP ON PISTON.

L REMOVE KNOB FROM DISCHARGE TUBE BODY BY

PULLING KNOB AT AN ANGLE UNTIL KNOB FLANGES

RELEASE FROM LIP ON DISCHARGE TUBE BOD

M REMOVE DISCHARGE FITTING FROM DISCHARGE

TUBE BY RELEASING FITTING LOOP AND PULLING

FITTING AWAY FROM DISCHARGE TUBE.

• DO NOT USE FITTING LOOP ON DISCHARGE

FITTING AS A PULL.

y.

PUMP CLEANING

BEFORE FIRST USE AND AFTER USE DAILY, DISASSEMBLE

AND CLEAN PUMP.

STAINLESS STEEL PARTS CAN CORRODE.

IT IS IMPORTANT TO CLEAN, RINSE, SANITIZE, AND DRY

THESE PARTS DAILY AND PROPERLY.

FAILURE TO COMPLY WITH ANY OF THESE

INSTRUCTIONS MAY VOID UNIT WARRANTY.

1 SEE PUMP DISASSEMBLY.

2 WASH AND SCRUB ALL PARTS WITH DISHWASHING

DETERGENT AND HOT WATER DAILY.

• Wash small parts in a pan or other container

to prevent part loss.

• Use supplied brushes to clean all conned

areas. Maintain a clean and efcient pump

by using the brushes supplied with pump to

prevent product build up inside pump.

• Do not use abrasive cleansers, scrapers, steel pads,

steel wool, or other cleaning tools that can scratch

surfaces.

• A general purpose, nonabrasive cleaner may be

used on hard to remove food deposits.

• Do not use cleansing agents with high

concentrations of acid, alkaline or chlorine.

These agents can corrode stainless steel.

Do not use ammonia to clean pump parts.

•

Ammonia can damage plastic parts.

• A nontoxic glass cleaner may be used for cleaning

any stainless steel parts.

3 FULLY RINSE ALL PARTS THOROUGHLY WITH CLEAR

WATER.

• Fully rinsing all parts can help prevent corrosion.

4 DRY ALL STAINLESS STEEL PARTS WITH A CLEAN

SOFT CLOTH.

• Various elements and minerals, such as chlorides in

tap water, can accumulate on stainless steel parts

and create corrosion.

• To prevent corrosion on any stainless steel parts,

it is important to fully dry with a clean soft cloth

regularly.

5 SANITIZE PARTS FOLLOWING YOUR LOCAL

SANITIZATION REQUIREMENTS.

ALL PARTS IN CONTACT WITH FOOD MUST BE

SANITIZED.

• Allow parts to fully air dry after sanitization.

• Dishwasher safe.

PUMP ASSEMBLY

BEFORE FIRST USE AND AFTER USE DAILY, DISASSEMBLE

AND CLEAN PUMP.

1 INSTALL DISCHARGE FITTING INTO DISCHARGE

TUBE. SECURE DISCHARGE FITTING TO TUBE BY

HOOKING FITTING LOOP AROUND PROJECTION ON

END OF DISCHARGE TUBE.

2 INSTALL KNOB ONTO TOP OF DISCHARGE TUBE BODY

BY PUSHING TOGETHER UNTIL KNOB SNAPS ONTO

LIP OF DISCHARGE TUBE BODY.

3 INSTALL SEAL ONTO BOTTOM OF PISTON. SEAL IS

SECURE WHEN IT SNAPS ONTO LIP AROUND BOTTOM

OF PISTON.

4 INSTALL GAGING COLLAR(S), IF NEEDED, AND

LOCKING COLLAR ONTO THREADED END OF PISTON

BY SLIDING THEM ON. POSITION LOCKING COLLAR

WITH THREADING INSIDE LOCKING COLLAR FACING

SEAL AT BOTTOM OF PISTON.

5 INSTALL ONE OF THE BALL VALVES WITH BALL SIDE

SEATED DOWN INTO OPENING IN TOP OF PISTON.

6 INSTALL BOTTOM OF DISCHARGE TUBE BODY ONTO

THREADED TOP OF PISTON WITH BALL VALVE IN

POSITION RESTING ON TOP OF PISTON. ROTATE

DISCHARGE TUBE BODY CLOCKWISE UNTIL SECURE

WITH PUMP TUBE ASSEMBLY.

7 INSTALL THE OTHER BALL VALVE WITH THE BALL

SIDE SEATED DOWN INTO OPENING INSIDE

CONNECTOR.

8 INSTALL BOTTOM END OF PUMP BODY, WITH PINS,

INTO CONNECTOR WITH BALL VALVE IN POSITION

RESTING INSIDE CONNECTOR. COMPRESS BALL

VALVE SLIGHTLY AND ROTATE PUMP BODY INTO

CONNECTOR UNTIL PINS SECURE INTO SLOTS IN

CONNECTOR.

9 INSTALL SPRING INTO PUMP BODY.

J INSTALL LID ONTO PUMP BODY BY ALIGNING LARGE

HOLE IN LID TO REST ON THREADED LIP OF PUMP

BODY ASSEMBLY.

K INSTALL PLUNGER ASSEMBLY INTO PUMP BODY

ASSEMBLY. COMPRESS PUMP AND ROTATE UNTIL

FLATS ON PISTON ALIGN INTO POSITION WITH

FLATS INSIDE CYLINDER.

L WHILE COMPRESSING PUMP, ROTATE LOCKING

COLLAR CLOCKWISE TO SECURE ONTO THREADING

OF CYLINDER.

M IF SUCTION TUBE IS INCLUDED, INSTALL ONTO

BOTTOM OF CONNECTOR. THE SUCTION TUBE MAY

BE CUT WITH SCISSORS TO THE NEEDED LENGTH.

Page 4

PORTION CONTROL

After cleaning pump and during pump assembly, determine

amount of product to be dispensed with each full stroke of

pump. Gaging collars are included with pump to allow for

changing of portion control.

1 INSTALL DESIRED NUMBER OF GAGING COLLARS

ONTO THREADED TOP OF PUMP TUBE TO SET

PORTION CONTROL.

• Each gaging collar added reduces portion per pump

stroke by .25 ounces.

Portion desired

per pump

stroke

1 Ounce 0 A

3/4 Ounce 1 B

1/2 Ounce 2 C

1/4 Ounce 3 D

2 COMPLETELY ASSEMBLE PUMP.

SEE PUMP ASSEMBLY.

3 TEST PORTION CONTROL.

• Put pump in product container and operate pump

several times until only product without air bubbles

is delivered with each stroke of pump.

• Then measure amount of product being delivered

through discharge tube with each stroke of pump to

assure portion control is satisfactory.

A B C D

Number of

Gaging Collars

Needed

Illustration

SAFETY GUIDELINES WHEN

USING THIS PUMP:

According to food and safety regulations, most foods must

be stored and/or served at certain temperatures or they

could become hazardous. Check with your local food and

safety regulators for specic guidelines.

Be aware of the product you are serving and the

temperature the product is required to maintain.

Server Products, Inc. can not be responsible for the

serving of potentially hazardous product.

Stainless steel is one of the best materials for food

serving and storage, but there are many products which

can corrode it. If you notice corrosion beginning on

any stainless steel surface, you may need to change

the cleansing agent, sanitizing agent, or the cleaning

procedures you are using.

• Products containing: acids, alkalines, chlorine,

or salt can corrode stainless steel.

• Sauerkraut and Au Jus sauces corrode stainless

steel. Server Products, Inc. regrets that we can not

honor warranty claims on stainless steel parts that

have been affected by sauerkraut

or Aus Jus.

SERVER PRODUCTS

LIMITED WARRANTY

All Server Products equipment is backed by a

two-year limited warranty against defects in materials and

workmanship. For complete warranty information go to:

www.server-products.com

SCOPE OF WARRANTY

Server Products Inc. (“Server Products”) warrants that,

for a period of two (2) years from the date of purchase

(the “Warranty Period”), the equipment manufactured by

it will be free from defects in workmanship and materials

provided the equipment is used in the manner and in the

environment for which they were manufactured.

DISCLAIMERS AND LIMITATIONS

Other than as set forth above, Server Products specically

disclaims all express and implied warranties, including but

not limited to, warranties of merchantability and/or tness

for a particular purpose or use.

This warranty does not extend to repairs or alterations

undertaken without the prior written consent of Server

Products or for goods that are misused, abused or neglected or if the goods are not properly stored, maintained,

installed or operated.

Server Products shall not be liable for incidental, special,

indirect, exemplary, punitive or consequential damages

resulting from the use of the good or arising out of any

breach of this warranty; including but not limited to dam-

age to property or loss of prots or revenue.

CLAIMS ADMINISTRATION

All warranty claims must be made by calling our customer

service department for a return authorization during the

Warranty Period and any alleged defective unit must be

returned to Server Products factory, freight prepaid.

Upon receipt of any defective unit, Server Products, at its

option, may either: (i) replace any equipment proved to be

defective, (ii) remedy or repair such defect or (iii) refund

the purchase price of the defective equipment in the form

of a credit applicable to future purchases. Server Products

obligation and Buyer’s sole remedy will be limited to these

options. In the case of units or parts purchased by Server

Products from a third-party supplier: Server Products’ obligation and Buyer’s sole remedy against Server Products or

Server Products’s suppliers shall not exceed the settlement

which Server Products is able to obtain from its supplier.

TROUBLESHOOTING

PROBLEMS WITH PUMP OPERATION AND/OR FLOW:

• Clean pump.

• Replace cylinder if necessary.

PUMP DISPENSES LITTLE OR NO PRODUCT.

• Product may be too stiff or contain a solid

that will not pass through pump.

• Install correct discharge tting for product

being pumped.

PRODUCT OOZES OUT AROUND LOCKING COLLAR.

• Be sure to compress pump and spring while

aligning ats on piston with ats inside

cylinder during assembly. Tighten locking

collar with pump compressed.

PORTION CONTROL IS NOT CONSISTENT.

• Inspect gaging collar for any damage and/or

proper installation.

PUMP PLUNGER DOES NOT RETURN TO TOP OF STROKE

AFTER DISPENSING PRODUCT.

• Inspect spring for any damage. If bent or

broken, spring may cause permanent damage

to cylinder. Replace spring if necessary.

PUMP DRIPS.

• Clean discharge tube and discharge tting

with supplied cleaning brushes.

• Ensure product is not being heated by any

external source(s) causing product to expand

and drip from pump.

CHECK BALL VALVES AND SEAL FOR ANY DAMAGE.

REPLACE BALL VALVES AND SEAL IF NECESSARY.

• Make sure ball valves are installed correctly.

Balls must be facing downward with at of

valve facing upward.

GENERAL SERVICE, REPAIR, OR

RETURNS

Before sending any item to Server Products for service, repair, or return, contact Server Products customer service to

request a Return Authorization Number. Merchandise

must be sent to Server Products with this number.

Merchandise being returned for credit must be in new

and unused condition and not more than 90 days old and

will be subject to a 20% (percent) restocking charge.

Electrical parts (thermostats, heating elements etc.) are

not returnable.

Server Products maintains a fully staffed service department with highly skilled factory trained personnel. Service

is extremely prompt. Under normal circumstances, a repaired unit is shipped out the day after it is received. Labor

charges are reasonable.

SERVICE

Contact your dealer or Server Products Inc.

customer service department for the following:

ORDERING REPLACEMENT PARTS

Be prepared to give this information:

• Model Letters/Name/Numbers

• Part Numbers- P/N

• Series Numbers/Letters

• Part Description

This information and other important data is stamped on

the lid or cylinder of pumps or on the bottom or back side

of every unit.

Server Products Inc.

3601 Pleasant Hill Road

Richfield, WI 53076 USA

262.628.5600

800.558.8722

262.628.5110

spsales@server-products.com

www.server-products.com

Loading...

Loading...