Page 1

MODEL:

01747-REVA�080414�ENGLISH

ECD

EXTREMETM

COUNTERTOP DISPENSER

CARLS JR.

Series 13G

07555

Page 2

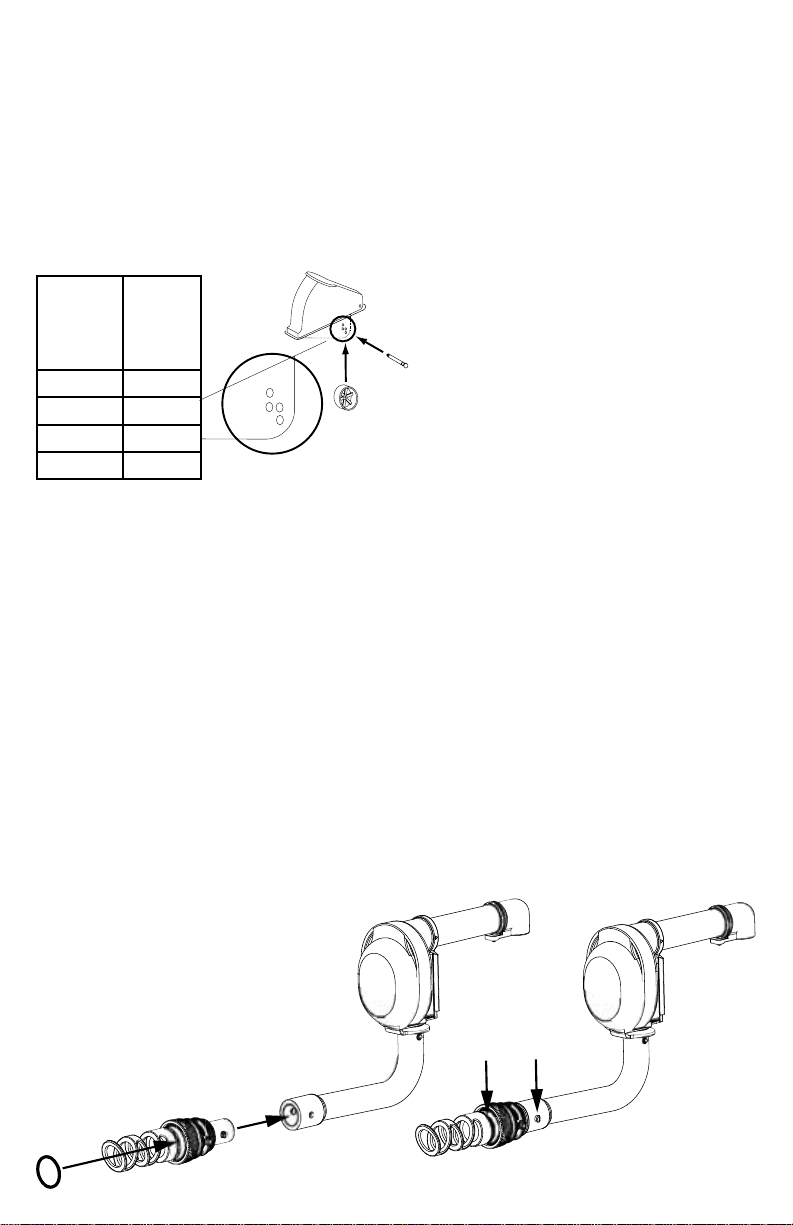

PORTION CONTROL

Portion control is the amount of product which will

dispense from the pump with each full push of the lever.

The roller, which is attached to the bottom of the lever,

can be adjusted to allow for specic portion control.

How to Set Portion Control

1 OPEN UNIT LID.

2 REMOVE ROLLER FROM LEVER BY PULLING

HINGE PIN OUT.

3 DETERMINE WHICH PIVOT HOLES IN LEVER WILL

BE USED TO HOLD ROLLER FOR PORTION DESIRED

PER FULL PUSH OF LEVER.

Portion

Desired

(per full

push of

lever)

1 Ounce

3/4 Ounce

1/2 Ounce

1/4 Ounce

Adjust

roller to

pivot on

hole as

shown

A

B

C

D

D

B

C

A

4 ALIGN CENTER OF ROLLER WITH SELECTED

PIVOT HOLES.

5 INSTALL HINGE PIN THROUGH PIVOT HOLES AND

CENTER OF ROLLER. PUSH HINGE PIN THROUGH

UNTIL IT SECURELY SNAPS INTO PLACE.

6 CLOSE UNIT LID.

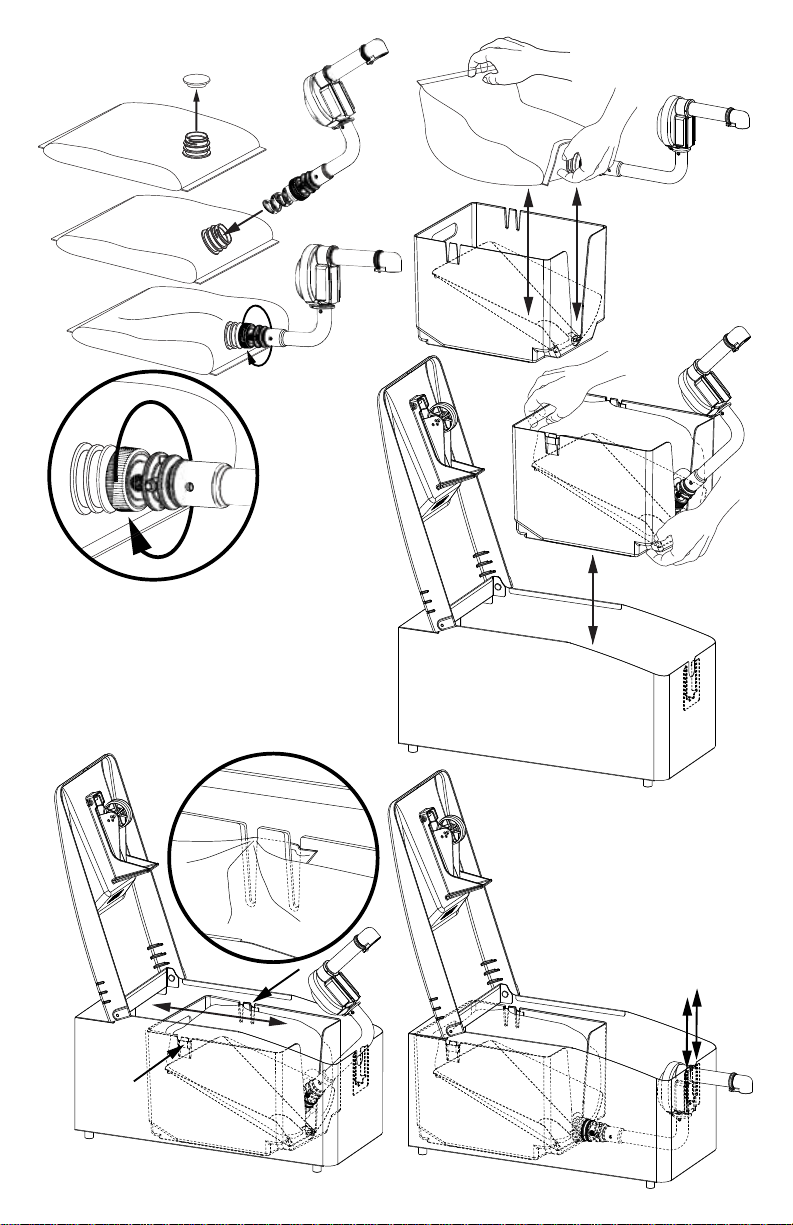

UNIT TAKE-DOWN

1 OPEN LID.

2 REMOVE PRODUCT POUCH WITH PUMP ATTACHED.

3 DISCONNECT PUMP FROM PRODUCT POUCH.

• Rotate connector locking collar counterclockwise

to release from product pouch.

• Remove connector from inside

pump exible tube.

• Do not discard connector.

4 CLEAN PUMP. SEE PUMP CLEANING.

DISASSEMBLE PUMP. SEE PUMP DISASSEMBLY.

UNIT SET-UP

ALWAYS CLEAN UNIT THOROUGHLY BEFORE FIRST USE.

SEE SAFETY GUIDELINES, UNIT TAKE-DOWN, PUMP

DISASSEMBLY, CLEANING, AND PUMP ASSEMBLY.

1 SET PORTION CONTROL.

2 ASSEMBLE PUMP. SEE PUMP ASSEMBLY.

3 INSTALL CONNECTOR INTO PUMP FLEXIBLE TUBE.

• Secure pins on connector into holes on tube.

4 INSTALL O-RING ONTO GROOVE ON CONNECTOR.

• Also ensure that connector locking collar is in

position between anges of connector and will

not slide off.

5 INSTALL CONNECTOR, WITH PUMP ATTACHED,

INTO PRODUCT POUCH FITMENT.

• Place product pouch on a counter top with

circular pouch tment facing upward.

• Remove cap from product pouch tment.

• For easier removal of protective cap,

contact food product vendor for optional

available tool.

• Install connector into product pouch tment.

• Secure connector onto product pouch tment by

rotating connector locking collar clockwise.

6 INSTALL PRODUCT POUCH, WITH PUMP ATTACHED,

INTO POUCH SUPPORT.

7 INSTALL POUCH SUPPORT, WITH PRODUCT POUCH

INSIDE, WITH PUMP ATTACHED, INTO UNIT.

8 FOLD SMALL AMOUNTS OF TWO BACK CORNERS

OF PRODUCT POUCH TO WRAP AROUND POUCH

CORNER HOLDERS ON SIDE WALLS OF POUCH

SUPPORT.

• This will hold pouch for best product evacuation.

9 SLIDE POUCH SUPPORT TOWARDS BACK OF UNIT

TO INSTALL PUMP HOUSING GROOVES INTO

RETAINING SLOTS ON INSIDE FRONT WALL OF

UNIT TO SECURE PUMP INTO ALIGNED POSITION.

J CLOSE LID.

Page 3

Page 4

PUMP DISASSEMBLY

1 REMOVE O-RING FROM CONNECTOR.

• Carefully pry o-ring off with ngers.

Do not use a tool or any sharp object to remove

o-ring, this will damage the o-ring.

2 REMOVE CONNECTOR FROM

FLEXIBLE PLASTIC TUBE.

• Rotate and pull connector away from

exible plastic tube.

3 REMOVE FLEXIBLE PLASTIC TUBE FROM

BOTTOM OF PUMP HOUSING.

• Rotate and pull exible plastic tube away from pump

housing.

4 REMOVE PUMP DOME FROM PUMP HOUSING.

• Unhook loop from bottom of dome to release

dome from bottom tube of pump housing.

5 REMOVE PINCH VALVE FROM INSIDE PUMP

HOUSING.

6 REMOVE DISCHARGE TUBE FITTING FROM END OF

DISCHARGE TUBE.

• Unhook loop from bottom of discharge tube tting

to release from pin on discharge tube.

• Rotate and pull discharge tube tting away from

discharge tube.

PUMP ASSEMBLY

ALWAYS CLEAN PUMP THOROUGHLY BEFORE EACH USE.

SEE UNIT TAKE-DOWN, PUMP DISASSEMBLY, PUMP

ASSEMBLY, SAFETY GUIDELINES, AND CLEANING.

1 INSERT PINCH VALVE INTO PUMP HOUSING

DISCHARGE TUBE.

2 INSTALL DOME ONTO PUMP BODY.

• Align valve ap inside dome to be on top of

opening between pump body and pump body

discharge tube.

• Place loop onto pump housing tube to secure

dome.

3 INSTALL FLEXIBLE TUBE ONTO PUMP BODY

SHORT EXTENSION TUBE.

• Use small amount of water as lubricant when

installing exible tube.

• Rotate exible tube onto pump body short

extension tube until projections on pump body

short extension tube align with holes in

exible tube.

• Rotate and position exible tube with connector

on opposite end to be pointing away from pump

body discharge tube.

4 INSTALL CONNECTOR ONTO FLEXIBLE TUBE.

• Use small amount of water as lubricant when

installing connector.

• Rotate connector into exible tube until

projections on connector align and fall into holes

in exible tube.

Page 5

PUMP CLEANING

BEFORE FIRST USE AND AFTER USE DAILY OR

REGULARLY, DISASSEMBLE AND CLEAN PARTS.

FOR SAFE AND PROPER CARE, AND TO PREVENT

CORROSION, OF PARTS, IT IS IMPORTANT TO

CLEAN, RINSE, SANITIZE, AND DRY PARTS DAILY OR

REGULARLY. FAILURE TO COMPLY WITH ANY OF THESE

INSTRUCTIONS MAY VOID UNIT WARRANTY.

1 SEE UNIT TAKE DOWN

2 FLUSH AND RINSE ALL INSIDE AND OUTSIDE

SURFACES OF PUMP THOROUGHLY WITH HOT

WATER.

• Place lower end of pump into container of

hot water and operate pump until all (if any)

remaining product is expelled and only hot water

ows from discharge tube. Then remove pump

from container of water to disassemble.

3 DISASSEMBLE PUMP. SEE PUMP DISASSEMBLY.

4 WASH CLEAN ALL PARTS WITH DISHWASHING

DETERGENT AND HOT WATER.

• Clean all conned areas with any supplied

brush(es).

• Do not use scrapers, steel pads, steel wool, or

other cleaning tools that can scratch surfaces.

• Mildly abrasive NYLON or brass brush may be

used to remove any stubborn food or mineral

deposits on interior surfaces of unit.

• Do not use abrasive cleansers.

• Do not use caustic cleansers.

• Do not use cleansing agents with high

concentrations of acid, alkaline or chlorine.

• Do not use ammonia based cleansers.

5 FULLY RINSE ALL WASHED PARTS THOROUGHLY

WITH CLEAR WATER.

• To prevent corrosion on parts, it is important to

thoroughly and fully rinse washed parts.

6 SANITIZE ALL PARTS FOLLOWING LOCAL

SANITIZATION REQUIREMENTS. ALL PARTS IN

CONTACT WITH FOOD MUST BE SANITIZED.

• Allow parts to fully air dry after sanitization.

• Dishwasher safe.

CLEANING UNIT

BEFORE FIRST USE AND AFTER USE DAILY,

DISASSEMBLE AND CLEAN UNIT.

STAINLESS STEEL PARTS CAN CORRODE.

IT IS IMPORTANT TO CLEAN, RINSE, SANITIZE, AND

DRY THESE PARTS DAILY AND PROPERLY.

FAILURE TO COMPLY WITH ANY OF THESE

INSTRUCTIONS MAY VOID UNIT WARRANTY.

SEE PUMP DISASSEMBLY AND PUMP CLEANING FOR

PUMP INSTRUCTIONS.

1 SEE UNIT TAKE DOWN.

2 WASH CLEAN ALL PARTS WITH DISHWASHING

DETERGENT AND HOT WATER.

• Do not use scrapers, steel pads, steel wool, or

other cleaning tools that can scratch surfaces.

• Mildly abrasive NYLON or brass brush may be

used to remove any stubborn food or mineral

deposits on interior surfaces of unit.

• Do not use abrasive cleansers.

• Do not use caustic cleansers.

• Do not use cleansing agents with high

concentrations of acid, alkaline or chlorine.

• Do not use ammonia based cleansers.

3 FULLY RINSE ALL WASHED PARTS THOROUGHLY

WITH CLEAR WATER.

• To prevent corrosion on parts, it is important to

thoroughly and fully rinse washed parts.

4 WIPE CLEAN EXTERNAL SURFACES OF UNIT WITH

A CLEAN DAMP CLOTH.

• Nontoxic glass cleaner may be used to clean

stainless steel parts.

5 DRY ALL PARTS WITH A CLEAN SOFT CLOTH.

• Various elements and minerals, such as chlorides

in tap water, can accumulate on stainless steel

parts and create corrosion.

• To prevent corrosion on stainless steel parts, it is

important to thoroughly and fully dry with a clean

soft cloth regularly.

6 SANITIZE ALL PARTS FOLLOWING LOCAL

SANITIZATION REQUIREMENTS. ALL PARTS IN

CONTACT WITH FOOD MUST BE SANITIZED.

• Allow parts to fully air dry after sanitization.

Page 6

PARTS LIST

Part # Qty. Description

07014

07056

07161

07383

07388

07823

07813

07507

07814

07818

07517

07796

07798

07811

07812

07821

81058

81105

82049

85248

86337

LEVER

1

ROLLER

1

PIN, HINGE

1

DOME, PUMP

1

PUMP HOUSING ASSEMBLY

1

LID

1

SPRING, TORSION

1

CONNECTOR, ANTI-CHOKE OFF

1

PLATE, EVACUATION

1

HOUSING, OUTER ASSEMBLY

1

CAP, PLASTIC 38MM

1

FITTING, DISCHARGE

1

VALVE, PINCH

1

SUPPORT, POUCH

1

HOSE, RIGHT ANGLE

1

PUMP ASSEMBLY

1

FOOT W/SCREW

4

PIN, COTTERLESS HINGE

1

BRUSH, 1

1

O-RING

1

CAP, PROTECTIVE

4

1

/

4

” D

EXTREMETM PUMP

07821

07517

85248

07507

07383

07798

07388

07796

07812

Page 7

ECD

07555

07014

81105

07161

07056

07823

07814

07813

07821

82049

07811

86337 (4)

07818

81058 (4)

Page 8

UNIT TROUBLESHOOTING

Possible Problems:

• Pump dispenses little or no product.

• Portion control is not consistent.

Possible Solutions:

• Clean pump.

• Ensure product pouch is not empty.

• Ensure product pouch and torsion spring are

installed correctly.

• Ensure roller is properly installed on lever.

• Ensure ap inside pump dome and ap on pinch

valve are properly positioned when assembling

pump.

• Ensure pump is installed into retaining slot on

inside front wall of unit.

SAFETY GUIDELINES

According to food and safety regulations, most foods

must be stored and/or served at certain temperatures

or they could become hazardous. Check with local food

and safety regulators for specic guidelines.

Be aware of the product you are serving and the

temperature the product is required to maintain.

Server Products, Inc. can not be responsible for

the serving of potentially hazardous product.

Server Products Inc. claims no responsibility for

actual serving temperature of product. It is the

responsibility of the user to ensure that any

product is held and served at a safe temperature.

GENERAL SERVICE, REPAIR,

OR RETURNS

Before sending any item to Server Products for service,

repair, or return, contact Server Products customer

service to request a Return Authorization Number.

Merchandise must be sent to Server Products with this

number.

Merchandise being returned for credit must be in new

and unused condition and not more than 90 days old

and will be subject to a 20% (percent) restocking

charge. Electrical parts (thermostats, heating elements,

etc.) are not returnable.

Server Products maintains a fully staffed service

department with highly skilled factory trained personnel.

Service is extremely prompt. Under normal

circumstances, a repaired unit is shipped out the day

after it is received. Labor charges are reasonable.

SERVICE

Contact your dealer or Server Products Inc.

customer service department for the following:

ORDERING REPLACEMENT PARTS

Be prepared to give this information:

• Model Letters/Name/Numbers

• Part Numbers- P/N

• Series Numbers/Letters

• Part Description

This information and other important data is stamped

on the lid or cylinder of pumps or on the bottom or

back side of every unit.

SERVER PRODUCTS

LIMITED WARRANTY

All Server Products equipment is backed by a

two-year limited warranty against defects in materials

and workmanship. For complete warranty information

go to: www.server-products.com

NSF International

(National Sanitation Foundation)

lists this pump as: “Not acceptable for

dispensing potentially hazardous foods.”

Stainless steel is one of the best materials for food

serving and storage, but there are many products which

can corrode it. If you notice corrosion beginning on

any stainless steel surface, you may need to change

the cleansing agent, sanitizing agent, or the cleaning

procedures you are using.

• Products containing: acids, alkalines, chlorine,

or salt can corrode stainless steel.

• Sauerkraut and Au Jus sauces corrode stainless

steel. Server Products, Inc. regrets that we can

not honor Warranty claims on stainless steel parts

that have been affected by sauerkraut

or Aus Jus.

Plastic Lid, Plastic Cover, Plastic Top or

Plastic Organizer Pan

• Not dishwasher safe.

• Hand Wash Only.

• Do not place plastic lid, plastic cover, plastic top

or plastic organizer pan under, in, or near to high

heat, as this can melt the plastic.

Server Products Inc.

3601 Pleasant Hill Road

Richfield, WI 53076 USA

262.628.5600

800.558.8722

262.628.5110

spsales@server-products.com

www.server-products.com

Loading...

Loading...