Page 1

Extreme

™

Countertop Dispenser

MODEL: ECD

07500

07543 (CUSTOM)

Used with pouches up to

3 gallons with 38mm

threaded connector.

Thank You

...for purchasing our Extreme™ Countertop

Dispenser. This portion controlled, high-volume unit

is sealed and sanitary, achieves excellent evacuation

and has only a few parts for easy clean-up.

SIMPLIFY CONDIMENT MANAGEMENT— GO POUCHED

Page 2

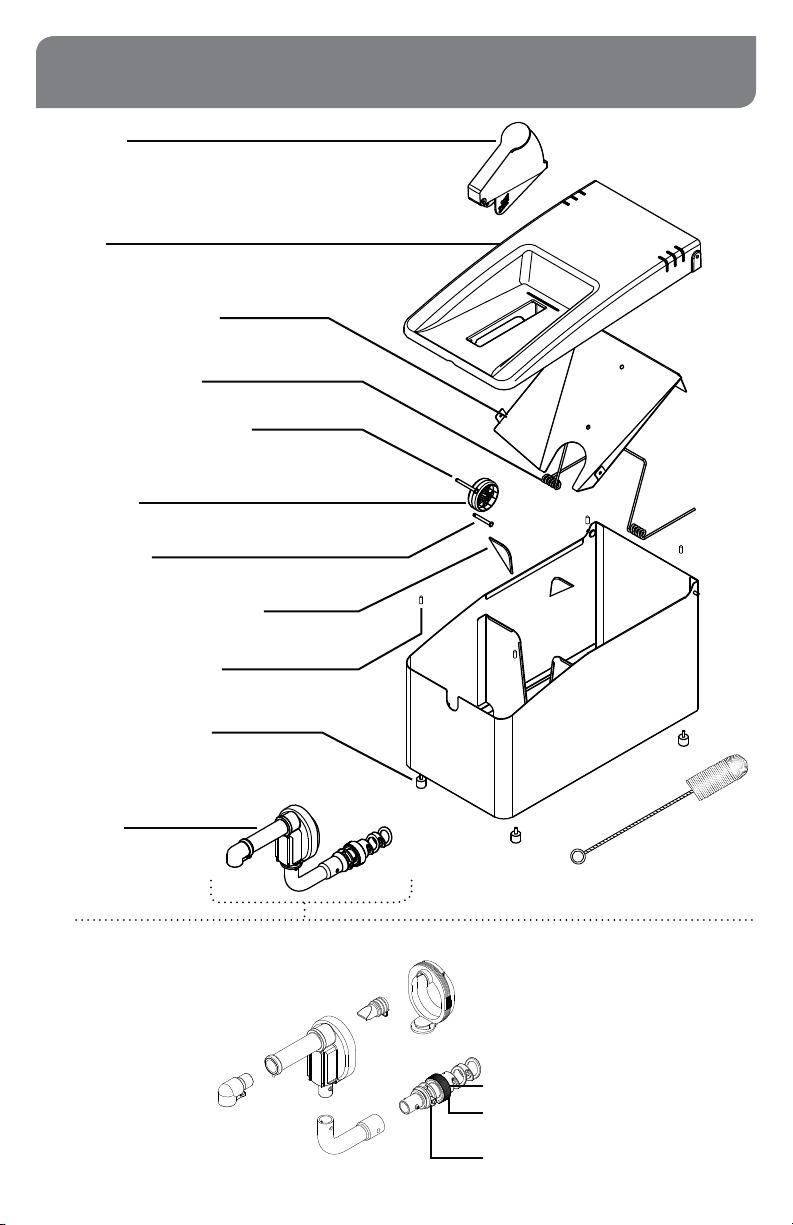

EXTREME™ DISPENSER PARTS

LEVER

07014

LID

07501

EVACUATION PLATE

07508

TORSION SPRING

07505

COTTERLESS HINGE PIN

81105

ROLLER

07056

HINGE PIN

07161

PROTECTIVE CORNERS (2)

07644

PROTECTIVE CAP (4)

86337

FOOT W/SCREW (4)

81058

PUMP

07518

PUMP PARTS

Page 2

DISCHARGE

FITTING

07796

PUMP

HOUSING

07388

HOSE

07502

PINCH

VALVE

07798

11" BRUSH

82049

DOME

07383

O-RING, 1-3/16"

85248

CAP

07517

CONNECTOR, ANTI-CHOKE

07507

Page 3

SAFETY

According to food and safety regulations, most

foods must be stored and/or served at certain

temperatures or they could become hazardous.

Check with local food and safety regulators for

specific guidelines. Server Products, Inc. cannot be

responsible for the serving of potentially hazardous

product.

IMPORTANT

Clean, rinse, sanitize, and dry parts daily or regularly

to comply with local sanitization requirements.

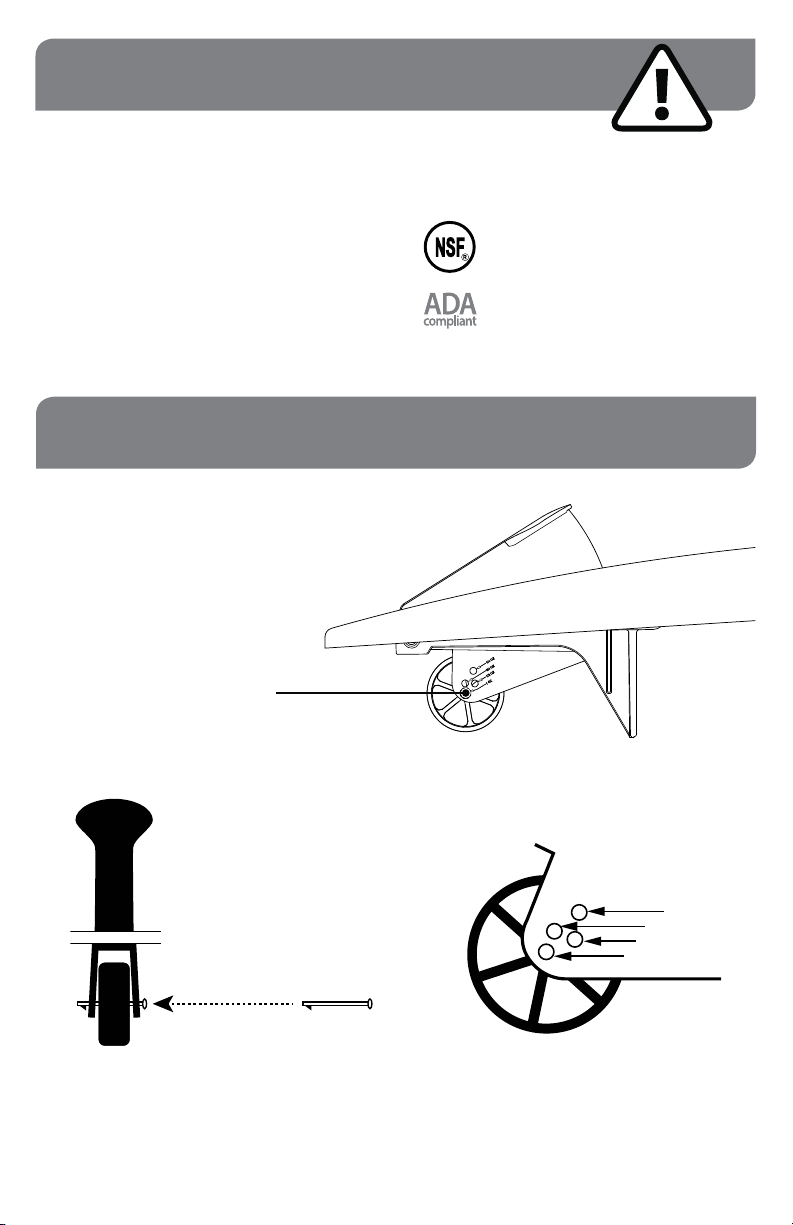

PORTION CONTROL

MAXIMUM PORTION IS

1 OZ PER PUSH

Adjustable in 1/4 oz increments

Hinge pin attaches roller to lever.

(Controls portion dispensed.)

NSF International lists this pump as:

“Not acceptable for dispensing potentially

hazardous foods.”

Install hinge pin through center

roller hole and desired portion

hole on lever.

Pin snaps into place.

1/4 OZ

3/4 OZ

1/2 OZ

1 OZ

Page 3

Page 4

PUMP ASSEMBLY

INSERT PINCH VALVE

1

into pump housing.

TIP: Squeeze the pinch valve

open before installation to

ensure it isn’t stuck shut.

INSTALL DOME

2

Press dome into

housing fully.

Ensure valve flap

covers bottom

opening.

INSTALL TUBE

3

Lubricate with a small amount of clean water.

Rotate and position until both pegs on

housing fit into holes on tube.

WASH ALL PARTS

PROPERLY BEFORE USE.

Wrap loop

around lower

opening to

secure dome.

See page 7.

4

5

Page 4

INSERT CONNECTOR

Lubricate connector with a small amount of clean water.

Rotate and position until both pegs on connector

fit into holes on tube.

INSERT DISCHARGE FITTING

into pump housing discharge tube.

Place loop of fitting around peg

on end of discharge tube to secure.

Page 5

UNIT SETUP

PREPARE POUCH

1

• Place condiment pouch on flat surface

with circular pouch fitment facing upward.

• Remove pouch cap.

ATTACH POUCH TO PUMP

2

• Insert pump connector into pouch fitment.

• Rotate locking collar clockwise to secure.

TIP: Make pump priming even easier.

Push condiment toward connector and

squeeze pump dome several times until

product is visible in pump.

INSTALL PUMP & POUCH INTO UNIT

3

• Place pouch in rear compartment of unit.

• Slide pouch connector grooves into unit

divider channel.

• Insert pump into slots inside front of unit.

WASH ALL PARTS

PROPERLY BEFORE USE.

See page 7.

SECURE POUCH

4

• Fold two back corners of pouch

over side walls.

• Close lid to secure pouch corners

for best product evacuation.

PRIME PUMP

5

Press lever several times until you see

product in discharge tube.

Page 5

Page 6

TAKE-DOWN & DISASSEMBLY

OPEN LID

1

REMOVE PUMP & POUCH

2

DETACH PUMP FROM POUCH

3

Rotate locking collar to release pouch.

IMPORTANT: Only throw away empty pouch.

Keep the pump connector.

FLUSH & RINSE PUMP

4

Place lower end of pump into container of

hot water. Pump until all remaining product

is expelled and only water flows from

discharge tube.

5

Page 6

DISASSEMBLE PUMP

Page 7

CLEANING

PUMP CLEANING

FLUSH & RINSE

1

all pump surfaces with hot water.

Place lower end of pump into container

of hot water and operate pump until all

remaining product is expelled and only hot

water is discharged.

YES!

Use dishwashing

soap, hot water

and nylon brush

DISASSEMBLE & CLEAN

2

all washable parts with soap and hot water.

Use brush to clean any confined areas.

RINSE

3

fully with clear water.

SANITIZE

4

all parts according to local sanitization

requirements. All parts in contact with food

must be sanitized.

AIR DRY

5

all parts fully.

UNIT CLEANING

• Pump is dishwasher safe

• Do not use abrasive, caustic or ammonia

based cleansers.

• Do not use cleansing agents with high

concentrations of acid, alkaline or chlorine.

• Do not use metal scrapers or cleaning

pads that could scratch surfaces.

PLASTIC LID:

Handwash Only

• External surfaces may be wiped clean with

a clean damp cloth.

• Glass and surface cleaners approved for

use in food contact areas may be used.

• Do not use abrasive, caustic or ammonia

based cleansers.

• Do not use metal scrapers or cleaning

pads that could scratch surfaces.

CARE OF STAINLESS STEEL

This unit is constructed

with stainless steel— one of

the best materials for food

serving and storage.

If you notice corrosion beginning on

any stainless steel surface, you may need

to change the cleansing agent, sanitizing

agent, or the cleaning procedures you

are using.

• A mildly abrasive nylon or brass brush may

be used to remove any stubborn food or

mineral deposits on interior surfaces of unit.

• Fully rinsing and drying all parts can help

prevent corrosion. Elements and minerals in

tap water can accumulate on stainless steel

parts and create corrosion.

• Do not use products containing acids,

alkalines, chlorine, or salt. These agents can

corrode stainless steel.

Page 7

Page 8

TROUBLESHOOTING

DIFFICULT TO ATTACH PARTS?

• Wet parts with clean water to help fit.

PRODUCT DOESN’T PUMP?

• Ensure pinch valve is inserted in housing.

• Ensure connector is snapped fully in place to

TIP: Squeeze the pinch valve

open before installation to

ensure it isn’t stuck shut.

fitment in pouch.

• Ensure pump is properly attached to pouch.

• Clean pump thoroughly.

• Ensure pump is properly installed into retaining

slots inside front wall of shroud.

DOME POPS OFF?

• Clean thoroughly. Food residue could prevent

a tight seal between dome and housing.

• Ensure dome edges are flush with housing.

SERVER PRODUCTS

LIMITED WARRANTY

Server Products equipment is backed by a

two-year limited warranty against defects in

materials and workmanship.

For complete warranty information go to:

www.Server-Products.com

NEED HELP?

Server Products Inc.

3601 Pleasant Hill Road

Richfield, WI 53076 USA

262.628.5600 | 800.558.8722

SPSALES@SERVER-PRODUCTS.COM

GENERAL SERVICE,

REPAIR OR RETURNS

Before sending any item to Server Products

for service, repair, or return, contact Server

Products customer service to request a Return

Authorization Number. Merchandise must be

sent to Server Products with this number. Service

is extremely prompt. Typically, units are repaired

and ship out within 48 hours of receipt.

Merchandise being returned for credit must be in

new and unused condition and not more than 90

days old and will be subject to a 20% restocking

charge.

Please be prepared with your Model, Part,

Series Number and Description.

This information is located on the base of the unit.

Individual Part Numbers listed on page 2.

Page 8

Manual #01725-RevH 062117

Loading...

Loading...