Serma EVA4201, EVA4301 User Manual

Documentation

EVA4201/4301 – User Guide

Evaluation Board for

80W

Power Factor Corrected (PFC) Supply

Featured Products: PE4201/PE4301

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 2 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

Table of Contents

1.

Revision History ....................................................................................................................... 2

2.

Safety Instructions .................................................................................................................... 3

3.

Introduction .............................................................................................................................. 3

3.1

Features ................................................................................................................................... 3

3.2

IC`s General Description .......................................................................................................... 3

4

How to design an application ................................................................................................... 4

4.1

Given board specification ......................................................................................................... 4

4.2

Calculating the Current ............................................................................................................ 4

4.3

Inductor .................................................................................................................................... 6

4.4

Current Sense Resistor ............................................................................................................ 7

4.5

Error Amplifier Compensations .............................................................................................. 10

4.6

Self Biasing ............................................................................................................................. 11

4.7

EMI and Driver SlewRate ....................................................................................................... 12

4.8

Start-Up Bypass Rectifier ....................................................................................................... 12

5

Description ............................................................................................................................. 13

5.1

Evaluation Board Specifications ............................................................................................. 14

5.2

Wire bridges ........................................................................................................................... 14

5.3

Schematic .............................................................................................................................. 15

5.4

Component Placement........................................................................................................... 16

5.5

Board Picture and Layout ...................................................................................................... 17

5.6

Bill of Material ......................................................................................................................... 18

6

Operating ............................................................................................................................... 19

6.1

Caution ................................................................................................................................... 19

6.2

Load ....................................................................................................................................... 19

6.3

AC-Input ................................................................................................................................. 19

6.4

Power-up Sequence ............................................................................................................... 19

7.

List of Abbreviations ............................................................................................................... 20

8.

Notes ...................................................................................................................................... 21

9.

Contact Addresses ................................................................................................................. 22

1. Revision History

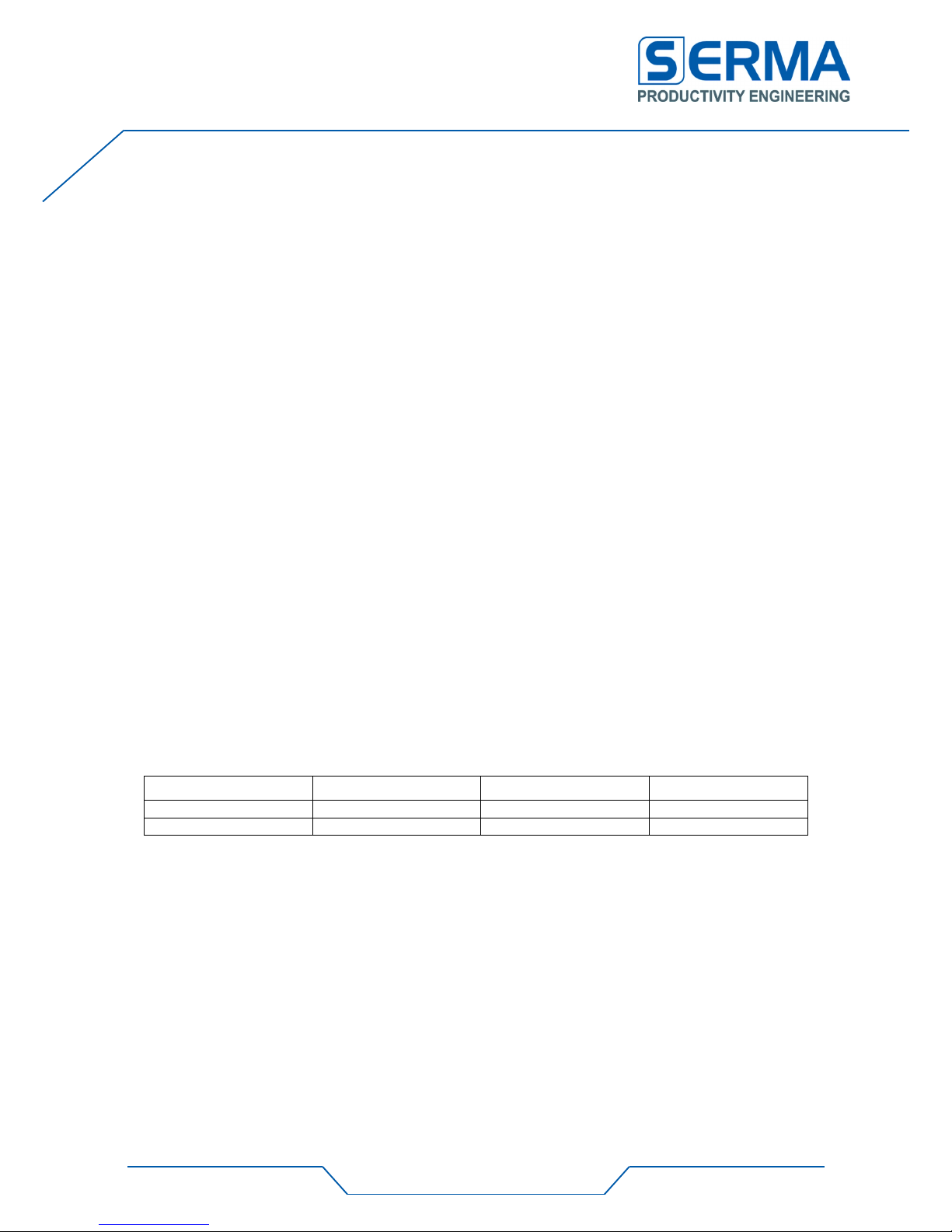

Version Date Changes Page

Initial Version V1.0 12/2008

V1.1 04/2013 Formula (2) 4

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 3 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

2. Safety Instructions

Please take caution - the board operates at 405V DC and is directly plugged into the power

network. Operating this Board requires an isolated transformer!

The EVA4201/4301 was designed to help understand and evaluate the features of two Power Factor

Correction IC`s. Used external devices are standard components chosen for safe operation and do not

represent a completely fine-tuned OEM application. The BOM (bill of material) for a final application may

look slightly different.

The board can also be used with PEs high precision PFC ICs, the PE4202 and the PE4302.

3. Introduction

3.1 Features

The board is designed to support applications of our two PFC-IC’s PE4201 and PE4301

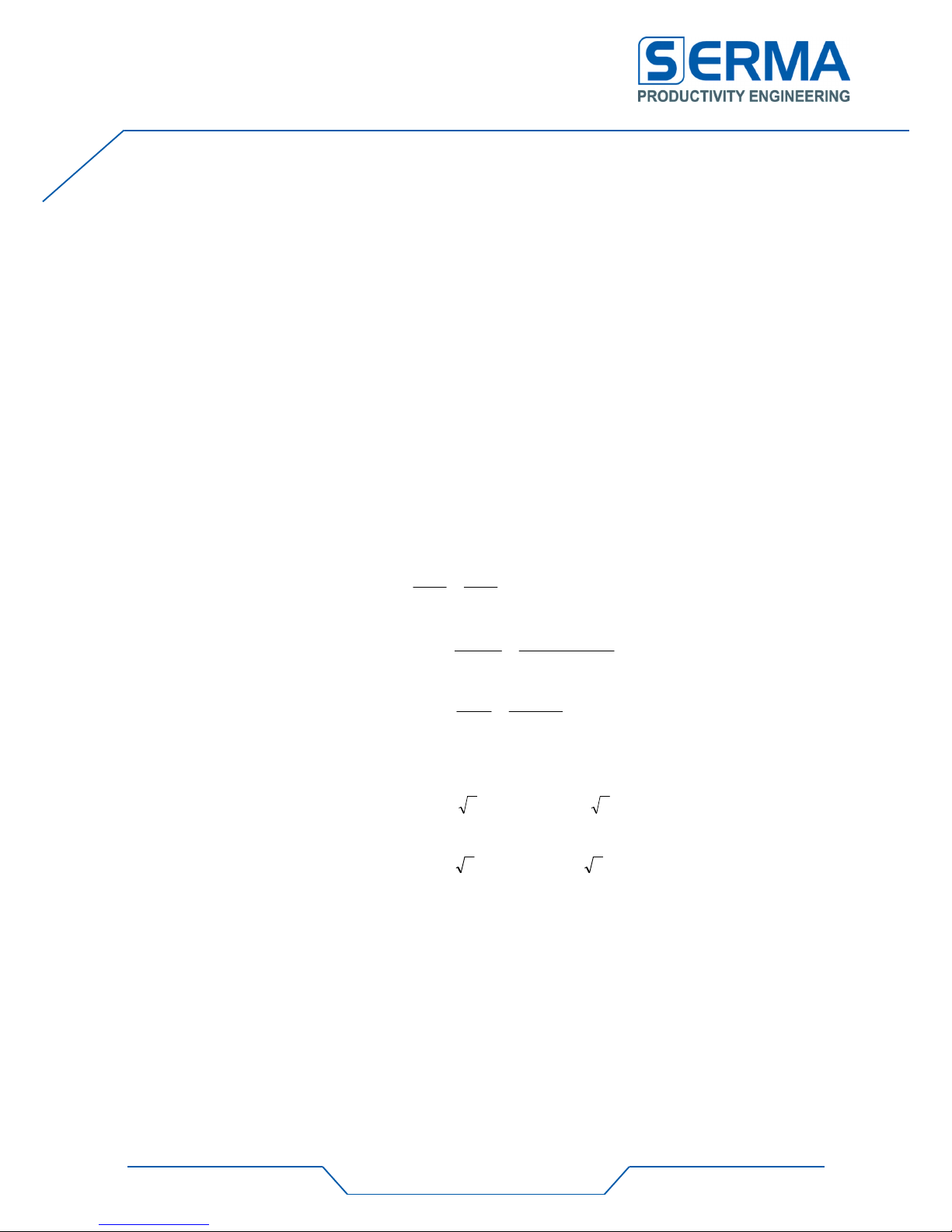

PE4201 PE4301

- Low Total Harmonic Distortion (THD) - Wide Range Input

- Low StartUp Current (<5µA) - Low Total Harmonic Distortion (THD)

- Low Operating Current (<450µA) - Low Operating Current (<550µA)

- Disable Function (<170µA) - Disable Function (<100µA)

- Under-Voltage Lockout with >8V Hysteresis - Under-Voltage Lockout with >8V Hysteresis

- Over voltage and Over current protection with - Over voltage protection, Peak current

separate Reference protection and Open loop protection with

- Reduced operating Frequency at low Output separate Reference

Power - low Peak current protection threshold

- High Efficiency at high and low Output Power - Operating Frequency between 40 kHz and

- Internal Clamping Resistor at G 250 kHz dependent upon load

- fast Driver turn ‘off’ - High Efficiency at high and low Output Power

- very fast Driver ‘off’ at over current sense - Internal Clamping Resistor at Driver

- Driver load up to 5nF - Soft start

- fast Driver Switch ‘off’

Application with PE4201/PE4301

• Active power factor correction

• Switch mode power supplies

3.2 IC`s General Description

The PE4201 and PE4301 are wide input range controller ICs for active power factor correction

converters. Both ICs provide many protection functions, such over voltage protection, open loop

protection, supply under voltage lockout, output under voltage protection and peak current limit

protection. These protection functions are working with separate reference.

The PE4201 operates in the CRM with voltage mode PWM control and in DCM under light load

condition. The maximum switching frequency is clamped with an internal delay circuit. Compensations

for voltage loop are external.

The PE4301 IC operates in the CCM with average current control. The switching frequency depends upon

load. At high output load the frequency is low and with low load the frequency is high. The Compensation

for voltage loop and soft start is external.

For more information refer to the datasheets.

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 4 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

4 How to design an application

4.1 Given board specification

PE4201/PE4301

The board setup in the original state has the following specification parameters. The following chapters

show, what has to be changed to design an active PFC supply towards different parameters. Please

take caution when calculating. Wrong device parameter calculation can damage the Evaluation board or

other devices.

AC Line Input voltage 85 VAC ... 265 VAC

AC Line Frequency 47 ... 63Hz

Switching Frequency 40 ... 250 kHz

Output voltage 340 -405V DC (adjustable)

Output Load max 80W

Over Voltage Threshold 416V DC

4.2 Calculating the Current

PE4201

The input power:

86,96W=

92%

80W

=

η

out

P

=

in

P (1)

The input current:

A0,52=

110V

0,66*86,96W

=

AC

V

in

P

=

ACin_LL

I

D∗

(2)

A=

265V

86,96W

=

AC

V

in

P

=

ACin_HL

I

0,33

(3)

D… Duty Cycle at 110V

The peak current:

A=0,52A22=

ACin_LL

I22=

pk_LL

I

1,48

∗∗∗∗

(4)

A0,93=A33,022=

ACin_HL

I22=

pk_HL

I ∗∗∗∗

(5)

This peak current affects the component selection on the current sense resistor, Power-MOSFET, diode

and inductor.

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 5 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

0,11A0,40A20,220,2

ACin_LLLL

==I=∆I ∗∗∗∗

0,093A0,33A20,220,2

ACin_HLHL

==I=∆I ∗∗∗∗

,61A0

2

0,22

A40,02

2

2

LL

ACin_LLpk_LL

=+=

∆I

+I=I ∗∗

,51A0

2

0,22

A33,02

2

2

LL

ACin_HLpk_HL

=+=

∆I

+I=I ∗∗

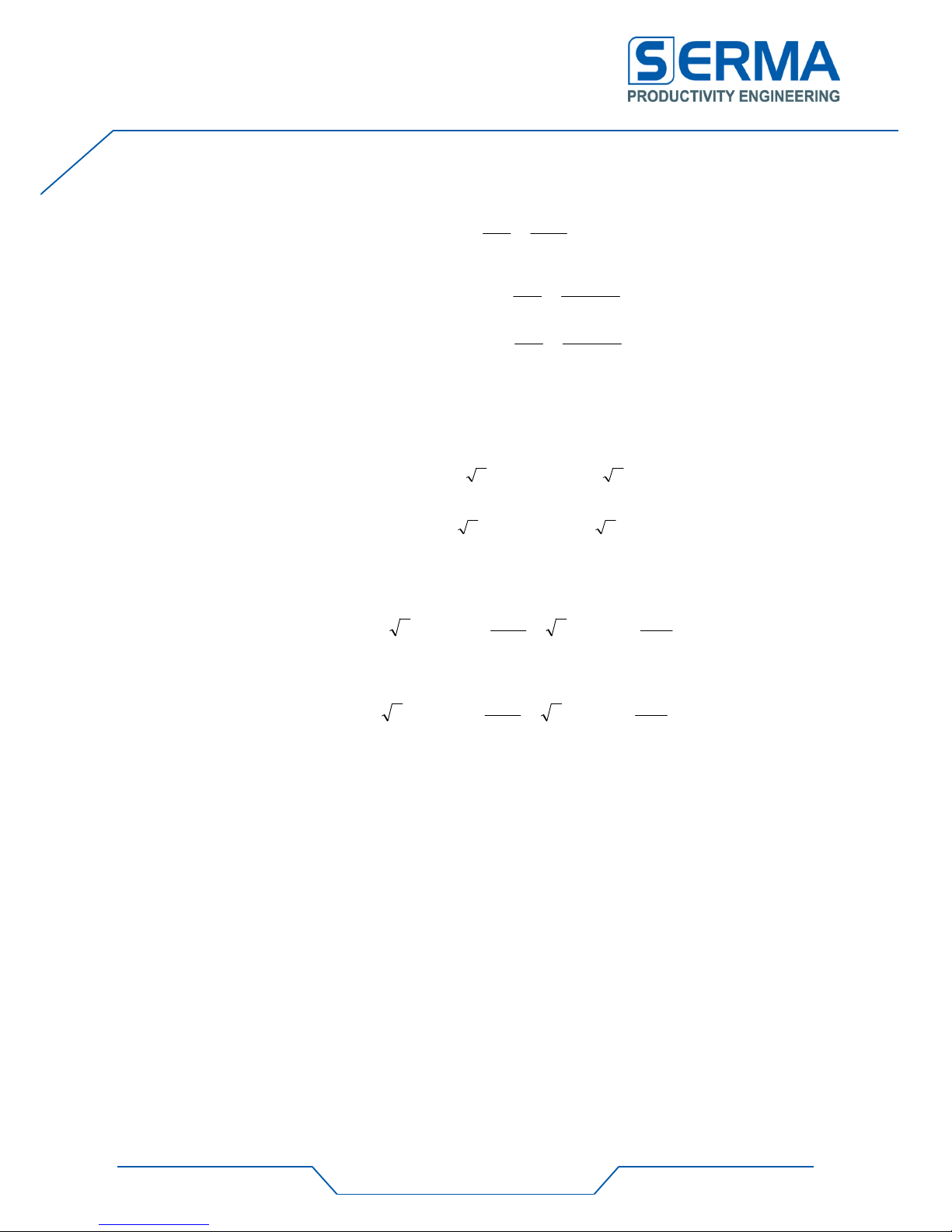

PE4301

The input power:

86,96W

92%

80W

out

in

==

η

P

=P

(6)

The input current:

0,40A

110V

86,96W

AC

in

ACin_LL

==

V

P

=I

(7)

0,33A

265V

86,96W

AC

in

ACin_HL

==

V

P

=I

(8)

The ripple current ∆I is set to 20%

(9)

(10)

The peak current:

(11)

(12)

This peak current affects the component selection on the current sense resistor, MOSFET,

diode and inductor.

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 6 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

out

inout

V

VV=D−

0,615V

405

110V2405V

LL

==D

∗−

0,074V

405

265V2405V

HL

==D

∗−

4.3 Inductor

PE4201

For CRM operation, the maximum 'on' time and the maximum 'off' time control the lowest frequency.

The minimum CRM inductance L

(CRM)

at low and high line input voltage can be calculated as follows:

f

1

pk

I

in

V

out

V

in

V

out

V

=

(CRM)

L ∗∗

−

(13)

µH=

40kHz

1

1,48A

V2

405V

V2405V

=

(CRM)

L

1623

110110

∗

∗

∗

∗−

(14)

µH=

40kHz

1

0,93A

265V2

405V

265V2405V

=

(CRM)

L

754

∗

∗

∗

∗−

(15)

For high line voltage and high output power the inductor has to have a nominal inductance of 400µH.

The switching frequency at low line voltage can be calculated according to equation (16):

(CRM)

L

1

pk

I

in

V

out

V

in

V

out

V

=f ∗∗

−

(16)

39,9kHz=

1623µH

1

1,48A

110V2

405V

110V2405V

=f ∗

∗

∗

∗−

(17)

PE4301

For CCM operation, the maximum 'on' time and the maximum 'off' time control are the lowest

frequencies. The minimum CCM inductance L

(CCM)

at low and high line input voltage can be calculated

as follows:

Duty Cycle

(18)

(19)

(20)

CCM Inductor

ISO 9001 / ISO 14001 01/06/2016 © Productivity Engineering GmbH

Page 7 of 22

EVA4204/4301

User Guide

Evaluation Board for 80W PFC Supply

∆If

DV

=L

∗

∗∗

in

CCM

2

(21)

µH21425

A11,040kHz

0,615110V2

CCM_LL

==L

∗

∗∗

(22)

µH7536

0,093A40kHz

0,074265V2

CCM_HL

==L

∗

∗∗

(23)

For high line voltage and high output power the inductor set to 8000µH.

The switching frequency at low line voltage obtains as:

∆IL

DV

=f

∗

∗∗

CCM

in

2

(24)

kHz6,109

A11,08000µH

0,62110V2

==f

∗

∗∗

(25)

4.4 Current Sense Resistor

PE4201

The current sense resistor provides the threshold voltage for the over-current protection function. The

maximum inductor peak current is set to 1,48 A.

0,15

Ω

=

1,48A

0,22V

=

OCP

I

SHPCP

V

=

s

R

(26)

R

sense

=0,15 Ω

PE4301

1,55

Ω

=

0,61A

0,95V

=

OCP

I

CSPCP

V

=

s

R

(27)

R

sense

=1,55 Ω

For higher/lower output power the resistor RS has to be reduced/increased and the inductor has to be

re-calculated.

Loading...

Loading...