Serengeti-IR B2245897 User Manual

COMBUSTION RESEARCH CORPORATION

FOR YOUR SAFTEY

If you smell gas:

1. Open windows

2. DO NOT try to light any appliance

3. DO NOT use electrical switches

4. DO NOT use any telephone in your

building

5. Leave the Building

6. Immediately call your local gas

supplier after leaving the building.

Follow gas supplier’s instructions.

7. If you cannot reach your gas

supplier, call the fire department.

Heaters for Residential Garages and

Gas fired, Low Intensity Infrared

Light Industrial / Commercial

Applications

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

Some objects will catch fire or explode

when placed near this heater.

Failure to follow these instructions can

result in death, injury or property

damage.

WARNING

Fire Hazard

Installation, Operation, Maintenance

and Parts Manual

Read and understand these installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

Only trained, qualified gas installation and service personnel may

install or service this equipment.

A gas-fired appliance could expose you to substances in fuel or fuel

combustion, which has been determined by the State of California to

cause cancer, birth defects, or other reproductive harm. Contact

factory for further information.

WARNING

Installer

Please take time to read and understand these

instructions prior to any installation. Installer must

give a copy of this manual to the owner

Owner

Keep this manual in a safe place in order to provide

your serviceman with the necessary information.

Combustion Research Corp.

2516 Leach Rd.

Rochester Hills, MI 48309-3555

Telephone: 248.852.3611

Fax: 248.852.9165

www.combustionresearch.com

TM

TM

Issue Date: 7-18-05 Revision Date: 9/16/2016 Rev. 7 Bulletin SE050718

Omega II® Installation, Operation & Service

FIRE OR EXPLOSION HAZARD

Can cause death, severe injury and/or property damage.

WARNING

!

1. Read this manual carefully before installing or servicing

this equipment. Improper installation, service or

maintenance can cause death, injury and/or property

damage.

2. Check clearances given on the outside of each burner to

make sure the product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. All service must be performe d only by a trained service

technician or representative

5. After installation is complete, check system operation as

provided in these instructions.

Combustibles: Failure to maintain the specified minimum

clearances to combustibles could result in a serious fire

hazard. Do not locate flammable or combustible materials

within this distance. Signs must be posted near thermostat

and in storage areas to specify maximum stacking h eight to

maintain required clearances to combustibles. Do not locate

in hazardous atmospheres containing flammable vapors or

combustible dust.

United States: Installations in public garages or airplane

hangars are permitted when in accordance with NFPA-88

(latest edition) and NFPA-409 (latest edition) Codes.

Canada: Installation in public garages and airplane hangars

is permitted when in accordance with CAN/CGA B.149.1 &

CAN/CGA B149.2.

Vehicles: Minimum clearances must be maintained from

vehicles parked, below the heater. Ensure that adequate

clearance is maintained where vehicles are in operation or

being serviced.

Gas Connection: There is an expansion of the r adiant pipe

With each firing cycle, and this will cause the burner to move

with respect to the gas line. This can cause a gas leak

resulting in an unsafe condition if the gas connection in not

made strictly in accordance with page 12 of these

instructions.

Ignition: This appliance does not have a pilot. It is equipped

with an ignition device, which automatically lights the burner .

Do not try to light the burner by hand.

Mechanical Hazard - Vacuum Exhauster: High speed

rotating vacuum exhauster impeller/wheel can c ause severe

injury. Do not operate the vacuum exhauster without

impeller. Loose clothing can be drawn into unguard ed inlet

and entangle with impeller wheel. Keep hands and fingers

away from inlet and outlet. Install exhaust duct with "bird

screen" or approved vent cap on vacuum exhauster outlet.

Mechanical Hazard - Suspension: Use appropriate

suspension hardware, beam clamps (rod or perforated

strap) and turnbuckles at predetermined locations. The

weight and normal movement of the heating system may

cause support failure if the following minimum suspension

requirements are not met: Distance between combination

hangers must be 10-ft. (3 M) or less; chain size must be 3/0

minimum or equivalent.

NOTICE CAUTION

Failure to follow these instructions can cause personal inju ry

or property damage:

Caution must be used when running the system near

combustible materials such as wood, paper, rubber, etc.

Consideration should be given to partitions, storage racks,

hoists, building construction, etc. Page 14 & 15 outlines

minimum acceptable clearances to combustibles.

If the building has a slight negative pressure or

contaminants are present in the air, an outside combustio n

air supply to the heaters is strongly recommended.

Do not use in an atmosphere containing halogenated

hydrocarbons or other corrosive chemicals. Some

compounds in the air can be drawn into the equ ipment and

can cause an accelerated rate of corrosion of some p arts of

the radiant heat exchanger. The use of such chemical

compounds in or near the enclosure should be avoided

where a longer life of the burner, tubing and other parts is

desirable.

Combustion Research Corporation

!

Failure to follow these instructions can cause damage to the

system components:

DO NOT high-pressure test the gas piping with the burners

connected. Failure to follow this procedure will exceed the

pressure rating of burner gas controls and this will require

complete replacement of these parts.

DO NOT operate a blower with an unrestricted inlet. An

unrestricted airflow will overload the motor, which can cause

burnout or failure.

This heater is designed for heating nonresidential indoor

spaces. These instructions, the layout drawing, local code s

and ordinances, and applicable standards that a pply to gas

piping, electrical wiring, venting, etc. must be thoroughly

understood before proceeding with the installation.

Serengeti-IR™ Installation, Operation & Service

INSTALLER

PLEASE TAKE TIME TO READ AND UNDERSTAND THESE INSTRUCTIONS PRIOR TO ANY

INSTALLATION. Contact your representative or the factory if you have any questions

OWNER

Retain this manual in a safe place to provide your serviceman with information if the situation arises.

TABLE OF CONTENTS

Heater Safety & Burner Label Locations 1 & 2

Warning Symbols 3

Standards, Certifications & Codes 3 & 4

Installer Qualifications & Responsibility 4

Assembly – Tube & Reflectors 5 & 6

Suspension Methods 7

Combustion Tube Installation 8

Reflector Mounting 8

Customizing System 8

Seismic Restraint Suspension 9

Burner Connection & Installation 10

Gas Line Installation 11

Flexible Gas Connector Installation 12

Technical Data 13

System Dimensions 14

Clearance To Combustibles 15 & 16

Side Shield Installation 17

Combustion Air Supply 18 & 19

Venting 20 -22

Electrical Information 23

Burner Internal Wiring Schematic 24

Thermostat Wiring 25

System Startup 26 & 27

Sequence Of Operation 27

Maintenance & Service 27 – 31

Trouble Shooting Flow Chart 32 & 33

Burner Parts List 34 & 35

Accessories & Optional Equipment 36 – 38

Warranty Statement and Terms &d Conditions 39 & 40

Sample Clearance To Combustible Warning Sign 43

Serengeti-IR™ heating systems DO NOT qualify for use in explosion proof installations.

Heaters SHALL NOT be used in living/sleeping areas.

©2016 COMBUSTION RESEARCH CORPORATION, INC.

All rights reserved. No part of this work covered by the copyrights hereon in may be reproduced or copied in any form or by any means -

graphic, electronic, or mechanical, including photocopying, recording, taping, or information storage and retrieval systems - without written

permission of COMBUSTION RESEARCH CORPORATION, Inc.

PAGE(S)

Combustion Research Corporation

Omega II® Installation, Operation & Service

This Page Intentionally Left Blank

Combustion Research Corporation

Serengeti-IR

™

Installation, Operation & Service

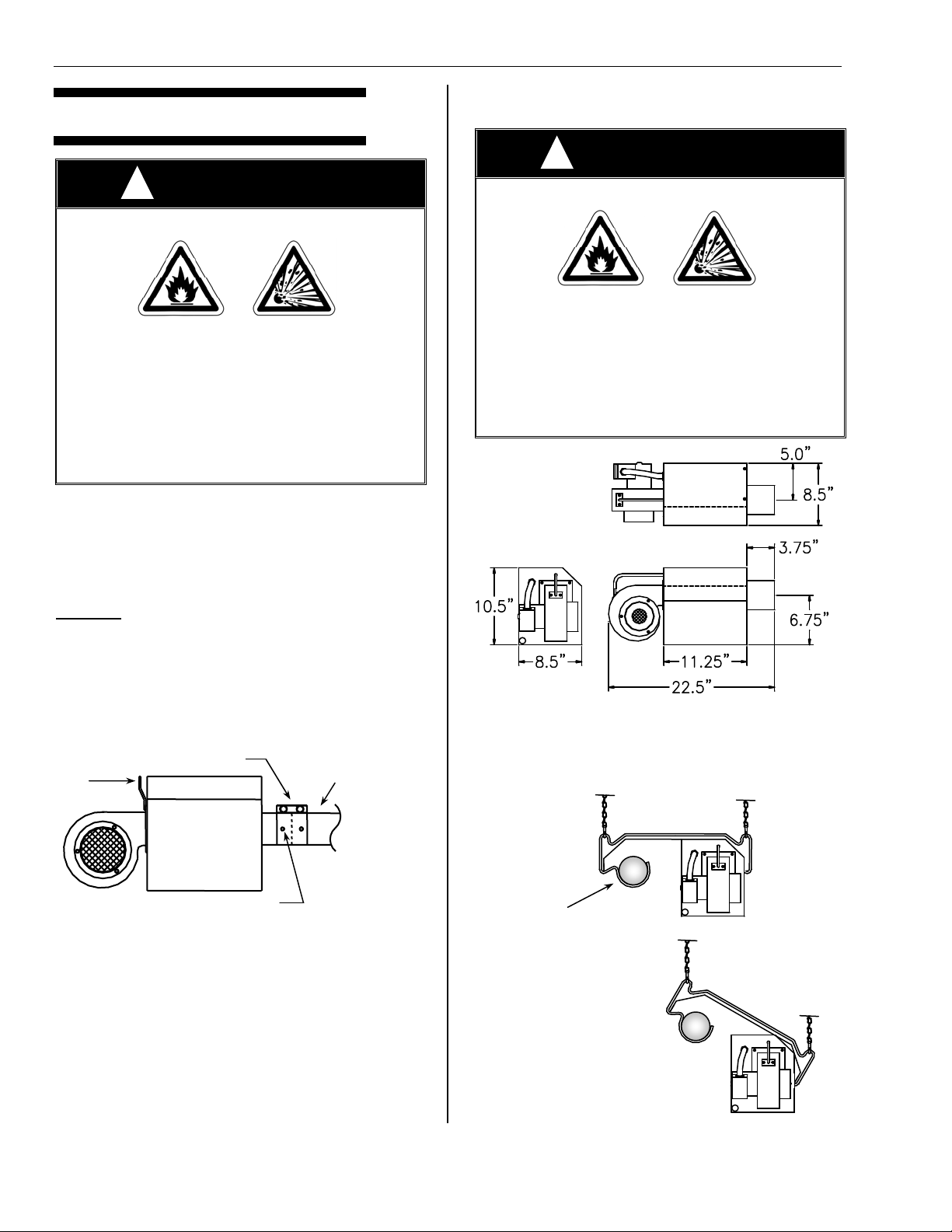

HEATER SAFETY

Please take time to familiarize yourself

this manual as your safety is important

is important to us. This symbol is used

throughout this manual to notify you of

possible fire, electrical, burn hazards or

other safety issues. Pay special

attention when reading this manual and

follow the warnings.

Read this manual carefully before installation, operation or

service of this equipment.

Protective gear (including safety glasses) is to be worn

during installation, set up and service. Sheet metal

components, including the aluminum reflectors and field cut

radiant tubes used on this system as well as various

venting components have sharp edges. The use of gloves

will also help in reducing dirt and oils to the surface of the

reflectors.

If additional Installation, Operation and Service Manuals are

needed, contact your Combustion Research Corporation

independent representative or Combustion Research

Corporation. The IOM’s can also be found at

www.combustionresearch.com.

In order to help prevent personal injury and damage to the

heater components, at least two persons will be required for

installation.

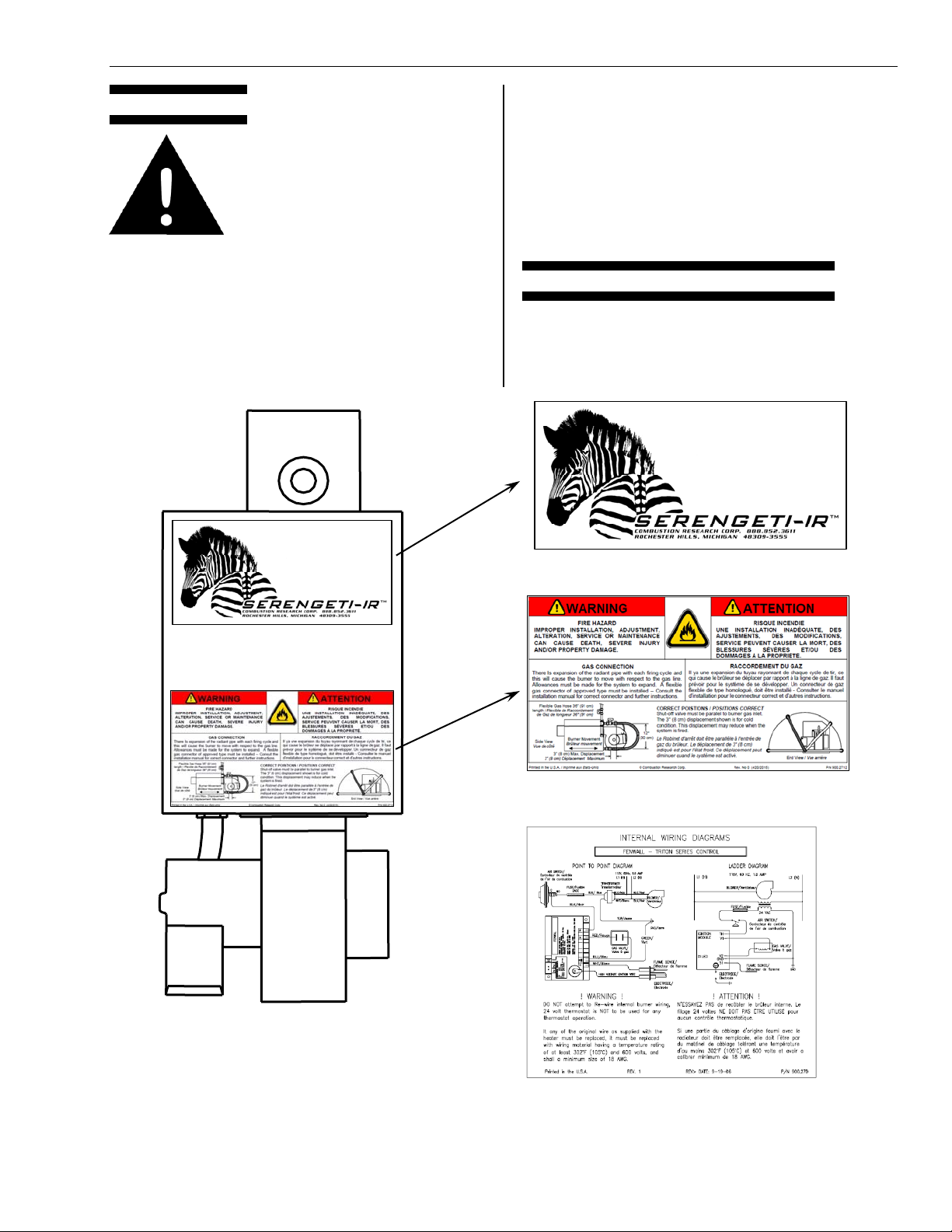

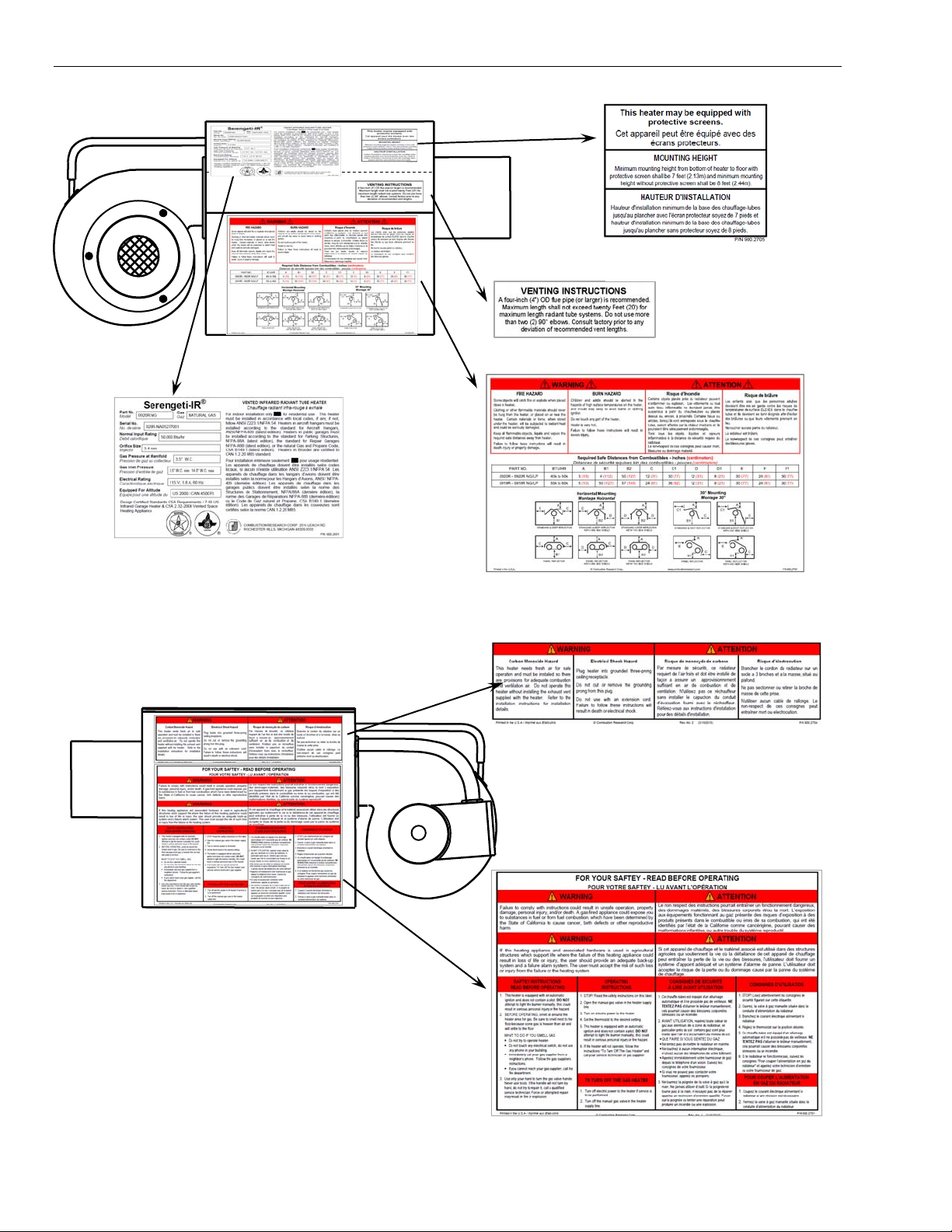

SAFETY LABELS AND THEIR LOCATION

Product safety signs or labels should be replaced by the

end user or servicing contractor when they are no longer

legible or have been damaged. Please contact Combustion

Research Corp. or your Combustion Research Corp.

independent representative to obtain signs or labels.

Logo Label

P/N 900.2706

Gas Connector Label

P/N 900.2712

Bottom Panel

Wiring Schematic located inside Bottom Panel

P/N 900.27D

Combustion Research Corporation Page 1

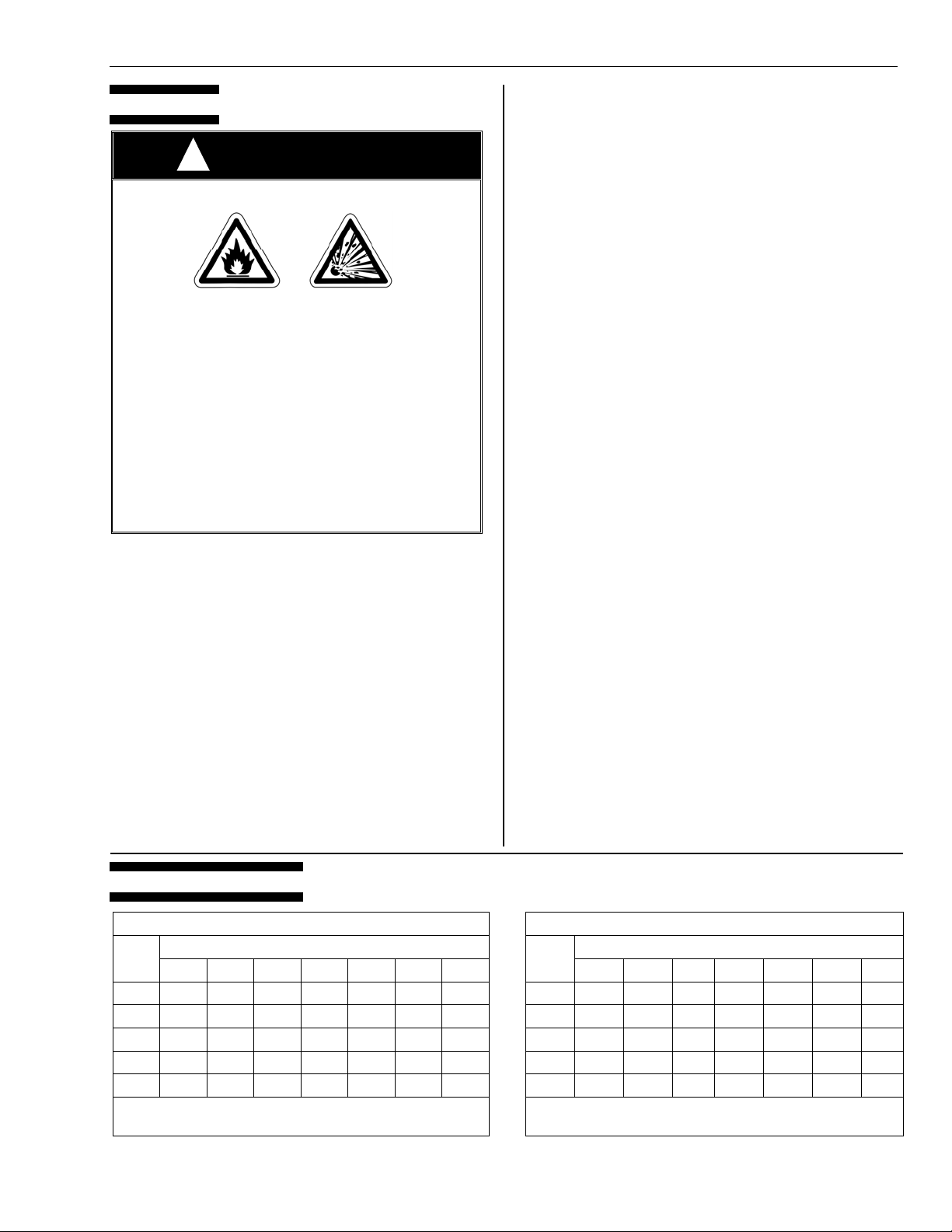

Serengeti-IR™ Installation, Operation & Service

Mounting Height Information Label

P/N 900.2705

Side Panel

Venting Instructions Label

Rating Plate Label

P/N 900.2601

Clearance to Combustibles Label

P/N 900.2702

Warning Label

P/N 900.2704

Side Panel

Operating Instructions Label

P/N 900.2701

Page 2 Combustion Research Corporation

Serengeti-IR™ Installation, Operation & Service

WARNING SYMBOLS

!

WARNING

Warning indicates a potentially hazardous situation which,

if not avoided, could result in death or injury.

CAUTION

!

Caution indicates a potentially hazardous situation which, if

not avoided, could result in minor or moderate injury.

NOTICE

Notice indicates a potentially hazardous situation which, if

not avoided, could result in property damage.

CHECKING SHIPMENT

Upon receipt of shipment, check shipment against Bill of

Lading for shortages. Also check for external damage to

cartons or tube bundles. Shortages and/or external

damage to cartons or tubes must be noted on the Bill of

Lading in the presence of delivery trucker. The delivery

trucker should acknowledge any shortages or damage by

initialing this "noted" Bill of Lading.

Claims for damaged material, or shortages that were not

evident upon receipt of shipment must be reported to

carrier and Combustion Research Corporation Sales

Representatives within 72 hours.

Before starting to assemble the heater, make sure

that all optional and accessory items are accounted

for and are available for assembly. It is also

important to verify that the correct gas burner is

supplied for the gas service, i.e., natural gas burner

for natural gas supply.

IMPORTANT

TESTED UNDER STANDARDS

AMERICAN STANDARDS – Z83.20-(current standard)

Z21.86-(current standard)

CSA Requirement 7-89

CANADIAN STANDARDS – CSA 2.34-(current standard)

CSA 2.32-(current standard)

GAS FIRED BROODERS - CAN 1-2.20-M85

BUILDING CODES

In the absence of local codes, the installation must conform

to the latest edition of:

United States: National Fuel Gas Code, ANSI Z223.1

(NFPA 54).

Canada: CAN/CGA B149.1 and .2, Canadian Electrical

Code C22.1

AIRCRAFT HANGERS

Heaters for use in aircraft hangers must be installed in

accordance with;

United States: Refer to Standard for Aircraft Hangars,

ANSI/NFPA 409 (latest edition).

In Canada: Refer to Standard CAN/CGA B149.1 and

B149.2 and applicable Standards for Aircraft Hangars.

Basic guidelines are as follows:

1. Suspended heaters in aircraft storage or service areas

shall be installed at least ten feet (10') above the upper

surface of wings or engine enclosures of the highest aircraft

which may be housed in the hanger. This should be

measured from the bottom of the heater to the wing or

engine enclosure; whichever is highest from the floor.

2. In other sections of aircraft hangers, such as shops or

offices communicating with airplane storage or servicing

area, heaters shall be installed in accordance with their

listings and mounted not less than eight feet (8') above the

floor.

3. Heaters installed in aircraft hangers shall be located so

as not to be subject to injury by aircraft, cranes, moveable

scaffolding or other objects. Provisions shall be made to

ensure accessibility to suspended heaters for recurrent

maintenance purposes.

!

WARNING

IMPROPER INSTALLATION

CAN CAUSE DEATH, SEVERE

INJURY AND/OR PROPERTY

DAMAGE.

Read and understand these installation, operating and

maintenance instructions thoroughly before installing or

servicing this equipment. Only trained, qualified gas

installation and service personnel may install or serv ice

this equipment.

These instructions, the layout drawing, local codes and

ordinances, and applicable standards such as apply to gas

piping and electrical wiring must be thoroughly understood

before proceeding with the installation.

PUBLIC GARAGES

Heaters for use in public garages must be installed in

accordance with:

United States: Standard for Parking Structures NFPA 88A

(latest edition) or the Code for Motor Fuel Dispensing

Facilities and Repair Garages NFPA 30A (latest edition).

Canada: Refer to CAN/CGA B149.1 and B149.2:

Installation Codes for Gas Burning Appliances and

applicable Standards for Public Garages.:

Basic guidelines are as follows:

1. Heaters shall be installed in accordance with their listings

and not be mounted less than eight feet (8') above the floor.

Minimum clearances to combustibles must be maintained

from vehicles parked below the heater.

2. When installed over hoists, clearance to combustible

material must be maintained from upper most point of the

Combustion Research Corporation Page 3

hoist, or provided as insulating or reflective barrier on the

hoist (consult representative or factory for guidance).

Serengeti-IR™ Installation, Operation & Service

maximum stacking height so as to maintain the

required clearance to combustibles.

ELECTRICAL GROUNDING

The burner and blower unit must be electrically grounded in

accordance with the following codes:

United States: Refer to National Electrical Code

ANSI/NFPA 70 (latest edition). Wiring must conform to the

latest edition of National Electrical Code

™

™

,

, local ordinances,

and any special diagrams furnished.

Canada: Refer to Canadian Electrical Code CSA C22.1

Part 1 (latest edition).

GAS INPUT LINES

The method of pipe sizing must conform to the U.S.

National Standards: ANSI Z223.1 (current standard)

National Fuel Gas Code or CAN 1-B149.1 Installation

Code, and should be installed in accordance with all

National and Local Codes and ordinances.

CLEARANCES AND ACCESSIBILITY

Inlet air assemblies are to be installed with the air opening

pointing toward the ground to protect against rain and

snow. Inlet is provided with a bird screen. Adequate

clearance must be provided around the inlet air assembly

opening to provide an unobstructed entry for the

combustion air. The air should be taken from outside the

building. Clearances must be sufficient to provide

accessibility for servicing. The air inlets must be a

minimum of six feet (6') from the exhaust port.

HAZARDOUS LOCATIONS

Where there is the possibility of exposure to combustible

airborne materials or vapor, consult the local Fire Marshal,

the fire insurance carrier, or other authorities for approval of

the proposed installation. Serengeti-IR™ heating systems

DO NOT qualify for use in explosion proof installations.

INSTALLER QUALIFICATIONS

Only firms or individuals qualified to perform work in

accordance with the applicable specifications should be

engaged to install a Serengeti-IR™ system. Consult local

Building Inspectors, Fire Marshals, or the local applicable

Combustion Research Corporation representative for

guidance.

INSTALLER RESPONSIBILITY

Serengeti-IR™ systems are installed on the basis of

information given in a layout drawing. Together with these

instructions and the cited codes and regulations comprise

the information needed to complete the installation. The

installer must furnish all needed material that is not

furnished as standard Serengeti-IR

his responsibility to see that such material, as well as the

installation methods he uses result in a job that is workman

like and in keeping with all applicable codes.

In storage areas where stacking of materials may

occur, the installer must provide signs that specify the

™

equipment, and it is

GENERAL CONSIDERATIONS

Combustion Research Corporation Factory

Representatives are experienced in the application of this

equipment and can be called on for suggestions about

installation which can give the owner of the building a more

satisfactory and economical installation.

When installing the Serengeti-IR

advantage of the building upper structure, beams, Joists,

purloins etc. from which to suspend the system. Mount

units at minimum height for ease of installation and

maintenance but of specified height to fully utilize the

building.

The general lay out of the Serengeti-IR

has been established by the engineering drawing. The

Serengeti-IR

™

heaters are used to heat building structures

as well as localized areas that would include doors, loading

docks and isolated workstations throughout the building.

The location of the Serengeti-IR

that the area is covered uniformly, in that the heat is

positioned on the perimeter or to each side of the area to

be heated, rather than directly overhead. This will give a

better comfort condition for workers who would be in these

areas. Consult with your representative or the factory for

additional guidance in designing the optimum layout for

your project.

™

Serengeti-IR

is a suspended system, which requires that

consideration be given to the factors that determine its

stability, flexibility, safety, and satisfactory operation.

Before installation, the contractor should inspect the

building along with the owner (or engineer) responsible for

the building to check on the use of the building. Inspection

of the building including the use of floor space for storage

and height of materials stored in the building must be noted

so that there are no problems with clearances to

combustibles. Particular care should be taken over doors

and high objects such as busses, trucks, cranes, car lifts,

etc. Whenever possible use side wall penetrations for

combustion air inlets to burners and exhaust venting.

DO -

Maintain specified clearances to combustibles, and

to heat sensitive material, equipment, and

workstations.

Provide approved heat radiation shielding or

barriers if needed. Refer to the National Fuel Gas

Code for guidance.

Provide access for general servicing; provide easy

access for complete removal of burner and blower.

Familiarize yourself with local and national codes.

Develop a planned installation procedure, which will

conserve material and labor on the job. Check to

see that all material and equipment is on the job

before starting installation. Be sure to

accommodate thermal expansion of the hot tube.

Use the gas connector ONLY as shown in the

instructions.

Provide end clearance so tubing won't expand and

touch a wall or a structural member.

™

system, take maximum

™

heating system

™

heaters should be such

Page 4 Combustion Research Corporation

Serengeti-IR™ Installation, Operation & Service

A

A

R

SSEMBLY: TUBE & REFLECTO

STRAIGHT & "U" TUBE ASSEMBLY

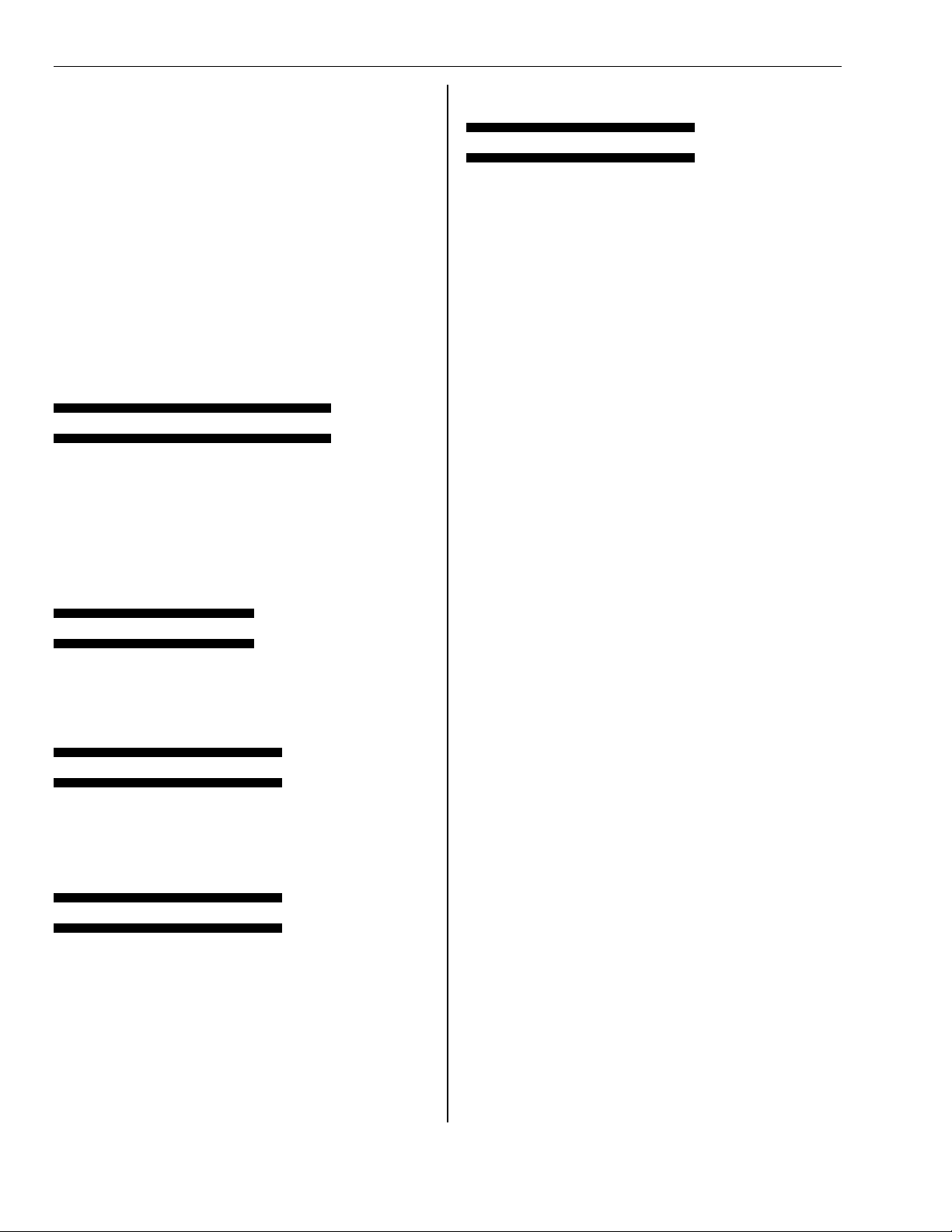

CAUTION

!

CUT HAZARD - SHARP EDGES.

Wear protective gloves when installing and handling

and cutting radiant tubes. Failure to follow these

instructions will result in personal injury.

1. Remove the Reflector(s), tubes and hanger from the

shipping carton. Inspect for shortages and damages as

well as correct gas service for burners.

2. Assemble the tubes as illustrated making sure to apply

sealer to the couplers before sliding the tubes together.

INSTALL COMBUSTION TUBE WITH WELD SEAM

ON BOTTOM AND MAKE SURE THAT THE TUBE

WITH THE INTERNAL TURBULATORS IS

ASSEMBLED IN TUBES AS SHOWN IN ILLSTRATED

ON PAGES 4 & 5.

Burner Tube End View

Weld Seam

Position

pply sealer sparingly to inside

edge of radiant tube, spread

with dowel or plastic tube.

Placement of screws @

approximately 120°

3. Next secure joints with the self drilling and taping

screws provided (use three per joint).

4. Next install hangers supports by sliding them into place

and position them as illustrated. REFER TO PAGES 4

& 5 FOR PROPER LOCATION. NOTE: Do not vary the

location of the hangers anymore than +/- 4" from the

recommendations.

5. IMPORTANT: Slide the reflectors into place (inside

hangers) and overlap them approximately 1" to 2"

and secure no more than two together with sheet

metal screws. A reflector expansion joint (unsecured

reflectors) at every other overlap is required for

expansion and contraction of the system

Bottom of Tube

STRAIGHT TUBE SYSTEMS

“U” TUBE SYSTEMS

NOTE: The assembled tubing and reflector assembly

may be too long to conveniently install in one piece,

therefor it is recommended that the assembly be

raised into position in two pieces. Apply sealer and

secure the final joint when in position.

Combustion Research Corporation Page 5

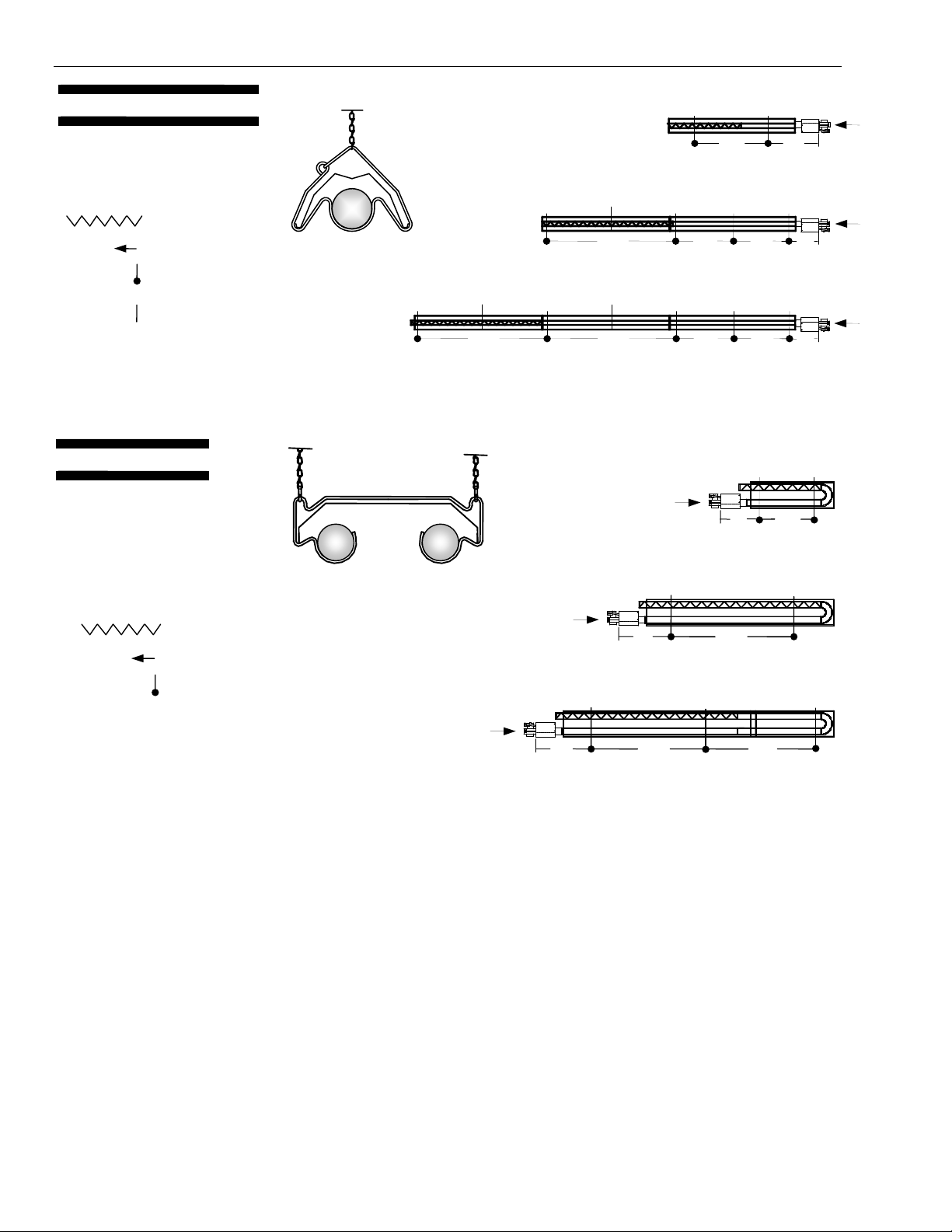

ASSEMBLY: TUBE & REFLECTOR

STRAIGHT TUBE SYSTEM

Serengeti-IR™ Installation, Operation & Service

NOTE: Install Reflector inside

hanger as shown

10’ SYSTEM

66”

40”

- TURBULATOR

- BURNER END

- HANGER

S

- INTERMEDIATE SUPPORT

“U” TUBE SYSTEM

- TURBULATOR

- BURNER END

- HANGER

S

S

118”

S

20’ SYSTEM

55”55”118”

30’ SYSTEM

55”55” 118”

21”

21”

5’ “U”

10’ TUBE LENGTH

21”

Note:

Install Reflector inside

hanger as shown.

40”

20’ TUBE LENGTH

66”

30’ TUBE LENGTH

44”

10’ “U”

15’ “U”

40”

66”

66”

Page 6 Combustion Research Corporation

Serengeti-IR™ Installation, Operation & Service

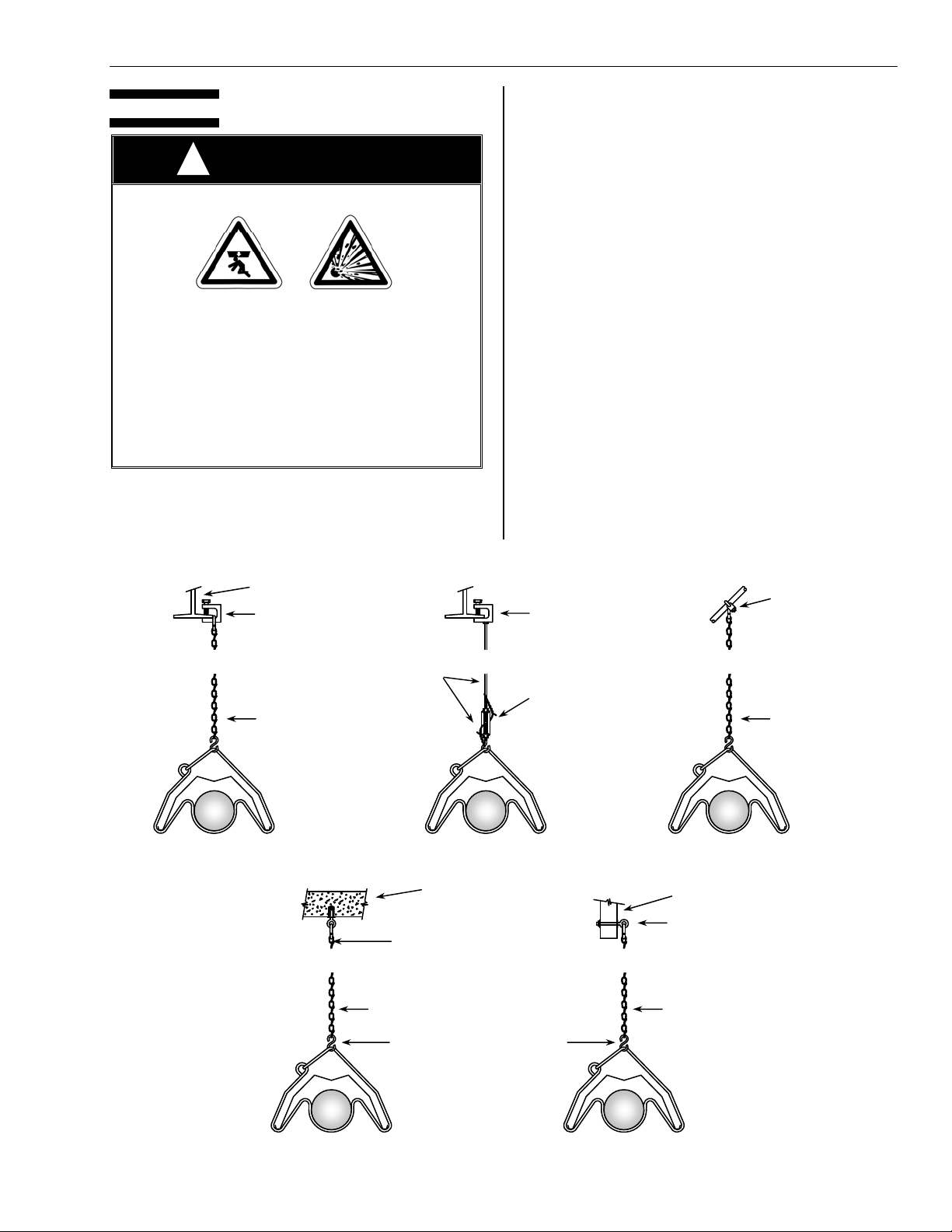

A

SUSPENSION

!

WARNING

COLLAPSE, FIRE AND EXPLOSION HAZARD

Improper suspension of the tube heater may result in

collapse and being crushed. Always suspend from a

permanent and secure part of the building structure

that can evenly support the total force and weight of

entire the heating system.

Failure to maintain minimum clearance to

combustibles may result in fire and/or explosion,

property damage, serious injury or death. Always

maintain minimum clearances and post clearance

signs where needed.

Combustion Research Corporation recommends that

Serengeti-IR

Chain and “S” hooks are supplied as an option. DO NOT

STRETCH OR INSTALL CHAIN OTHER THAN IN A

™

systems are hung by means of chain.

SSEMBLY: SUSPENSION

VERTICAL FASHION WHEN INITIALLY INSTALLED

(BURNER NOT FIRING).

If chain is not supplied by Combustion Research Corp.,

furnish a chain with a minimum 90 lb. workload (trade size

#3 or larger). A minimum of 12" (30 cm) of hanging chain

is recommended. This allows for system expansion and

contraction, reducing the likelihood of reflector and radiant

tube warping and/or expansion noise.

CAUTION: Infrared tube systems expand and contract

upon each call for heat. System expansion of up to 4” can

be expected.

Provisions must be made to limit lateral movement when

systems are installed in site conditions where open doors

may create a wind condition – see page 8 for guidelines.

Radiant tubes DO NOT require sloping.

For fine adjustment turnbuckles may be used.

NOTES:

SECURE TURNBUCKLES SO THAT THEY WILL NOT

UNWIND OR UN-SCREW.

CRIMP "S" HOOKS CLOSED BEFORE LEAVING JOB.

REFLECTORS ARE NOT TO BE INSTALLED ON TOP OF

COMBINATION HANGERS.

Beam

Beam Clamp

and Turn Buckle

Chain

Threaded Rod

Suitable Expansion

Anchor

Chain

Concrete

Beam

Beam Clamp

Secure turnbuckle

with JAM nuts or wire

to prevent unwinding

Eye Bolt Screw

with Washer and

Locknut

Chain

Bar Clamp

Chain

Wood Beam

All ”S” Hooks MUST Be

Manually Closed By

Installer

Combustion Research Corporation Page 7

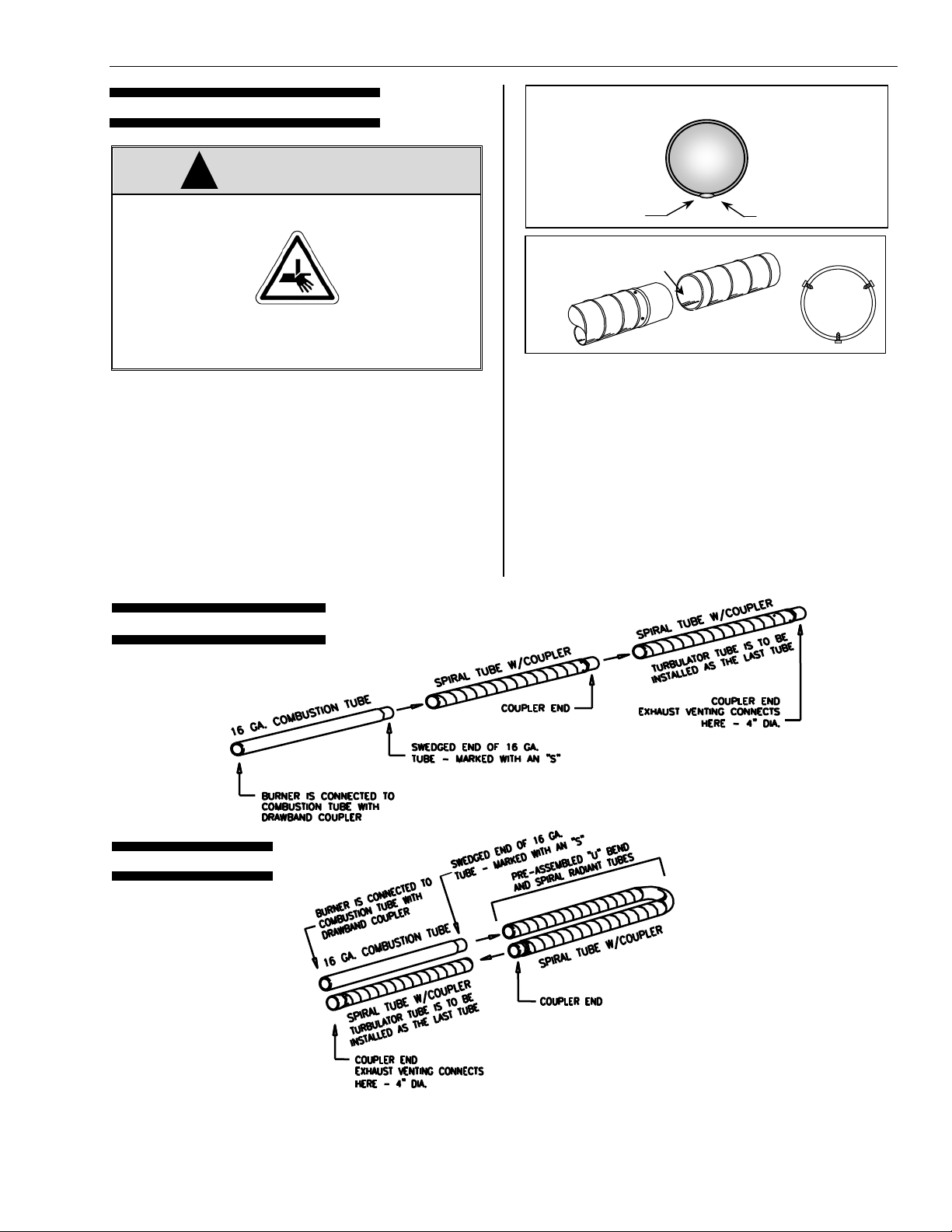

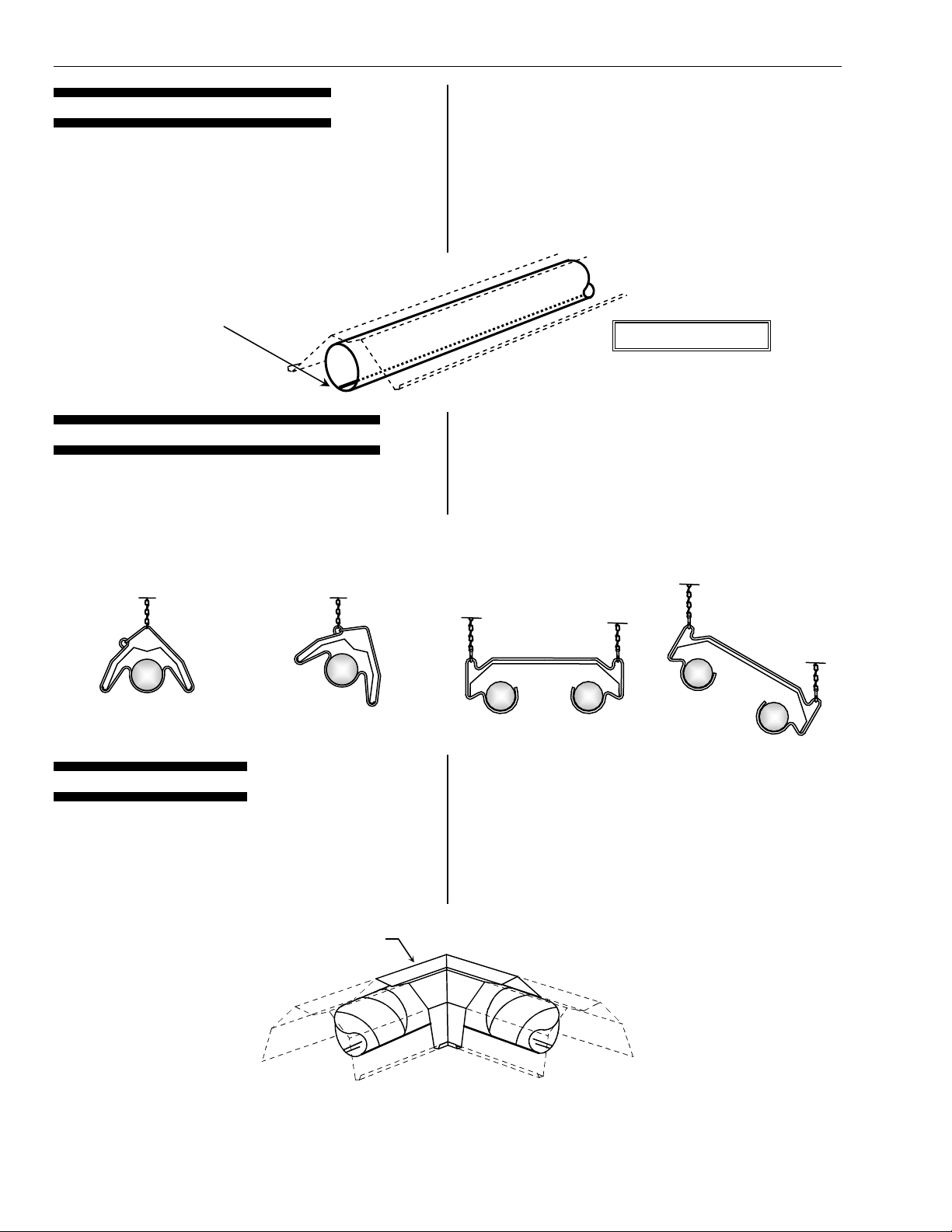

ASSEMBLY: INSTALLATION GUIDELINES

COMBUSTION TUBE INSTALLATION

The first section or radiant tube downstream of the

burner is a heavy wall 16 Ga. heat-treated

aluminized steel tube. This tube is referred to as the

combustion tube. One end of this tube is swaged to

fit inside the next spiral radiant tube. The end that is

un-swaged is coupled to the burner assembly – see

Install Combustion Tube

with Weld Seam On Bottom

Serengeti-IR™ Installation, Operation & Service

page 9. It is necessary that the weld seam on this

combustion tube be positioned so that it is on the

bottom when installed.

This applies for both straight tube and “U” tube

systems. When the systems are mounted on a 30°

angle the weld seam should always be on the

bottom.

! IMPORTANT !

TUBE & REFLECTOR HANGING METHODS

The Serengeti-IR™ system reflectors can be suspended

horizontally or at a 30° angle. The combination hanger is

designed so that the reflector angle will be horizontal when

suspended from the top loop or at a 30° angle when

Horizontal Mounting With

“Combination” Hanger

30° Mounting With

“Combination” Hanger

CUSTOMIZING SYSTEMS

A maximum of two 90° or four 45° elbows may be installed

after THE SECOND tube. The tube couplers that have

been factory installed will have to be removed to

accommodate the installation of any elbows. Any

additional elbows, radiant tube and reflector is optional

equipment.

Reflector Elbow

suspended from the offset loop – see the illustration

below.

The panel hangers may also be suspended horizontally or

at a 30° angle – see illustration below

Horizontal Mounting With

“Panel” Hanger

30° Mounting With “Panel”

Hanger

DO NOT INSTALL OR JAM TURBULATORS IN

ELBOWS OR "U" BENDS. CONSULT YOUR

REPRESENTATIVE OR THE FACTORY FOR PROPER

INSTALLATION & GUIDANCE.

Secure To Connecting Reflector

With Sheet Metal Screws

Page 8 Combustion Research Corporation

Serengeti-IR™ Installation, Operation & Service

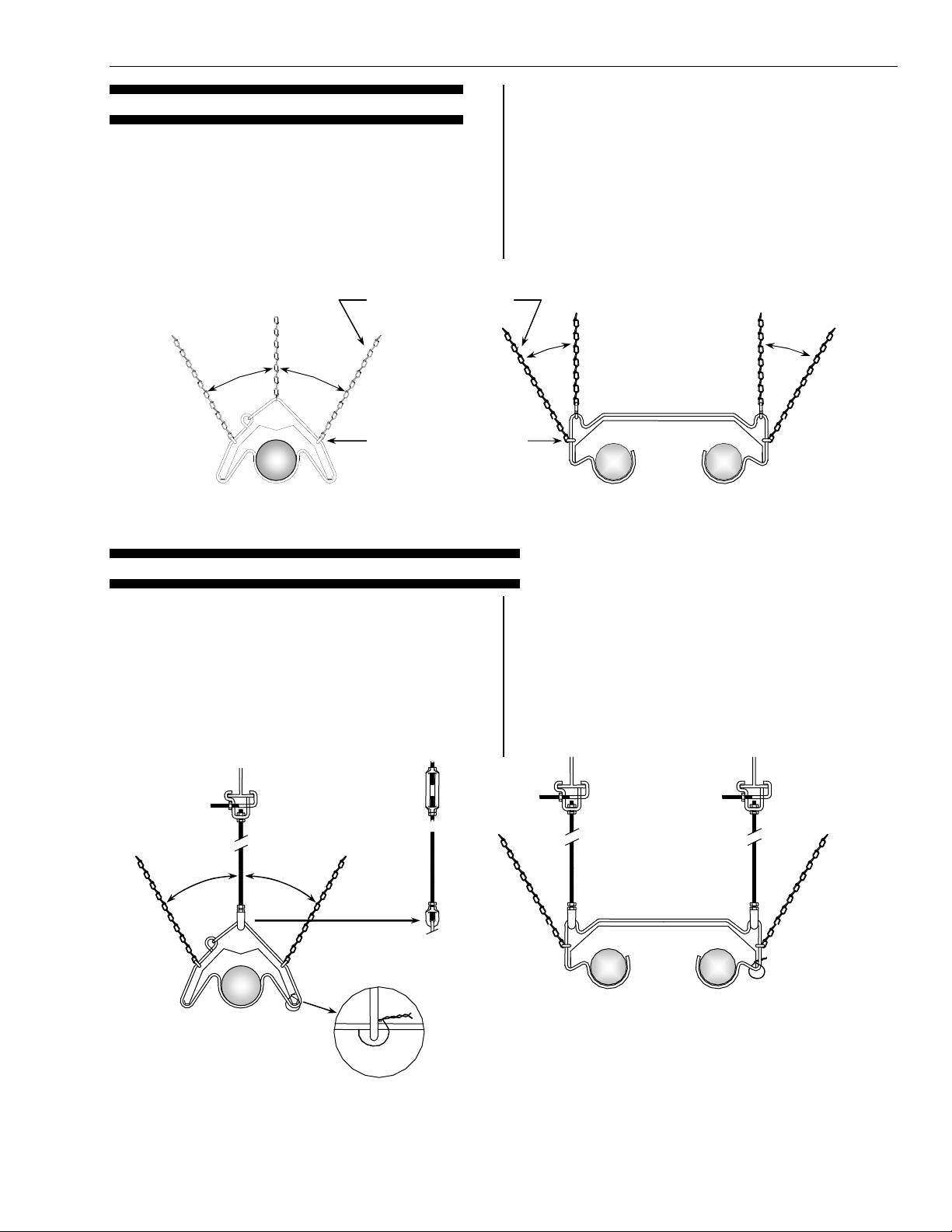

SEISMIC RESTRAINT SUSPENSION METHODS

For standard seismic restraint such as earthquake

prone areas, install seismic restraint chain or cable

as shown below. If high winds can be encountered

in the building, such as found in airplane hangers

where opposing doors are simultaneously open, or

system is installed near or below the door opening,

additional support of the radiant tube and reflector

Seismic Restraints

Use chain or min. 1/8”

aircraft cable

30° Min.

45° Max.

30° Min.

45° Max.

Install the cable clamp

approximately 3” from the

edge of the reflector.

Clamp tight to prevent

chains or cables from

sliding on hanger

SUSPENSION: SEISMIC RESTRIANT

network will be required. See the “Seismic

Suspension For High Wind Applications” below for

details. If there are any questions regarding what

method is best suited for your application consult

your sales representative or contact the factory. If

the system is a straight system (no elbows or tee's),

apply an anti sway chain or wire rope which is

parallel to the radiant tube at approximately the

middle of the run.

30° Min.

45° Max.

30° Min.

45° Max.

SEISMIC RESTRAINT FOR HIGH WIND APPLICATIONS

In high wind conditions it is recommended that

seismic restraints and reflector retention wire be

installed. See details below for recommended

installation of seismic restraint and anti sway

retention chains (wire rope). The vertical threaded

rod shall be attached and suspend the reflector

hangers at intervals of eight to ten feet (8' - 10'). At

least one vertical threaded rod shall be placed at

every elbow and/or tee connection. The threaded

30° MIN.

°

30° MIN.

°

rod is used to prevent the system from lifting during

high wind conditions, the chain or wire rope will keep

the system from swaying from side to side. When

connecting threaded rod to "Z" purlin use beam

clamp or drill a hole through "Z" purlin and secure

with two 3/8" nuts and a lock washer. If the system

is a straight system (no elbows or tee's), apply an

anti sway chain or wire rope which is parallel to the

radiant tube at approximately the middle of the run.

Punch or drill a small hole (approximately 1/8”) in the reflector near the

reflector hanger. Insert an appropriate length of 14 Ga. galvanized

wire through this hole and encircle the combination hanger. Maintain

a loose loop around the hanger, this will allow for expansion of the

system. Twist the ends of the wire together and trim as required. This

retention wire may be installed on either sides, or edges of the

reflector for severe wind conditions.

Combustion Research Corporation Page 9

ASSEMBLY: BURNER CONNECTION

CONNECTING BURNER ASSEMBLY TO

RADIANT TUBE/REFLECTOR ASSEMBLY

!

WARNING

FIRE OR EXPLOSION HAZARD

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE DEATH, SEVERE INJURY

AND/OR PROPERTY DAMAGE.

There Is expansion of the radiant pipe with each firing

cycle and this will cause the burner to move with

respect to the gas line. This can cause an unsafe

condition if the gas pipe connection is not done in strict

accordance to the instructions.

Serengeti-IR™ Installation, Operation & Service

Angle Iron, Uni-strut, etc. and then suspend the chain so

that it hangs vertically.

!

WARNING

FIRE OR EXPLOSION HAZARD

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE DEATH, SEVERE INJURY

AND/OR PROPERTY DAMAGE.

To insure proper burner performance the burner head

assembly MUST be mounted vertically even when tube

and reflector assembly is angle mounted. Failure to do

so may result in erratic pressure switch operation.

1. Remove the burner assembly from its shipping carton

and using the same type of chain, hang the burner so that

it butts up to the 16 Ga. tube of the tubing and reflector

assembly, and connect the two with the draw band coupler

provided. IMPORTANT NOTE - THE WELD SEAM OF

THE 16GA. TUBE MUST BE POSITIONED SO THAT IT

IS ON THE BOTTOM. Position bolting assembly on the

TOP SIDE of the tube assembly as shown. After

tightening the coupler, check to make sure the burner is

lined up squarely - reposition as may be required, and retighten the drawband clamp. Secure with 2 sheet metal

screws. See illustration below. Install reflector end cap at

the burner end of the reflector. Fasten to reflector with

sheet metal screws.

Drawband Coupler

Mount Bolt Assembly

Suspension

Point

2. Connect the thermostat, gas and electrical supplies and

hook up the exhaust flue and combustion air supply as it

outlined in this manual.

3. The system is now ready to be fired. Refer to the

START UP section of this manual.

NOTES: Heater must be independently supported and not

rely on the gas or electrical line for any of its support.

If there is not a convenient point for suspending the

hanging chain above the heater DO NOT try to "stretch"

the span by having severe angles on the chain. Rather

build a bridge between the existing building structure using

On Top Of Tube

Secure With Sheet

Metal Screws

Install Reflector End

Cap On This Side

Of Drawband

Coupler

NOTE: On “U” tube systems, install exhaust end of radiant

tube on motor side of burner assembly. This will allow

easy access to burner controls and is necessary for proper

burner operation for un-vented systems.

Install exhaust on

motor side of burner

assembly

Reflector Mounted at

30° angle. Keep burner

assembly vertical

Page 10 Combustion Research Corporation

Serengeti-IR™ Installation, Operation & Service

GAS SUPPLY

!

WARNING

FIRE OR EXPLOSION HAZARD

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE DEATH, SEVERE INJURY

AND/OR PROPERTY DAMAGE.

Follow these warnings exactly.

1. Disconnect power supply before wiring to prevent

electrical shock or equipment damage.

2. To avoid dang erous accumulation of fuel gas, turn

off gas supply at the appliance service valve befor e

starting installation, and perform Gas Leak Test

after completion of installation.

3. Always install sediment trap in gas supply line to

prevent contamination of gas control.

Meter and service must be large enough to handle all the

burners being installed plus any other connected load.

When gas piping is not included in the layout drawing, the

local gas supplier will usually help in planning the gas

piping.

Supp ort all gas piping with suitable suspension

materials and in accordance with local codes

Use wrought iron or wrought steel pipe and malleable

iron fittings. All pipe and fittings should be new and

free from defects. Ream the pipe ends and tubing

ends to remove obstructions and burs.

Use LP-gas resistant joint compound on all threads.

Apply only to male end of piping.

Check all piping, fittings and connections for leaks before

placing heating equipment into service. Use only soap and

water solution for checking for gas leaks, NEVER use and

open flame.

GAS LINE INSTALLATION

In industrial installations where the natural gas pressure at

the meter is available at higher pressure than the standard

7" TO 14" W.C., it may be possible to cut down on gas

piping costs (when local codes and the Fire Marshal

approve) by running high pressure gas lines inside the

building or on the outside of the building. In no case should

the pressure exceed 10% of the service supply pressure.

When using a high pressure gas distribution system each

heating zone should be equipped with a pounds to inches

service regulator with soft seat, positive 100% lock-up.

Allowing high gas pressure on the downstream side of the

regulator will damage the control valve in the gas train. The

outlet pressure of the service regulators should be set at 7"

W.C. for natural gas and 11" W.C. for LP gases/propane

gases. If it is not practical to regulate in "zones", each

burner may be equipped with its own regulator.

To meet the requirements of 100% positive lock-up and

internal relief vent must be piped to the outside of the

building. It is recommended that an intermediate service

regulator, such as a Maxitrol 325 Series or approved equal

be used.

The typical discharge pressure on the down stream side of

the gas meter furnished by the gas company is usually 5

P.S.I.G. while the discharge pressure of the regulator on

the propane tank is usually set at 15 P.S.I.G.

Proper sizing of low and high pressure piping distribution

systems for natural gas should be made in accordance

with the National Fuel Gas Code, ANSI Z223.1 (current

standard) NFPA No. 54. Consult the supplier of the

propane tank and vaporizing system for the sizing of the

piping system for LP gas pipe work.

When leak testing the gas piping system, the Serengeti-

™

burners must be isolated from the gas piping system.

IR

High-pressure compressed air used in the leak test will

damage the control valve in the burner gas train, which will

result in unsafe operation of the burner(s). For proper and

safe test procedures, observe the provisions of Part #4, of

the National Fuel Gas Code, ANSI Z223.1 (current

standard) - Inspection, Testing and Purging or refer to

equivalent local. In Canadian see gas code CAN/CGAB149.1- M91.

NOTE: It is important that the entire system, up to the

burner gas connection, be checked for leaks, prior to start

up.

GAS PIPE SIZING CHART

NATURAL GAS

Pipe

Size

1-¼” 848 600 517 427 380 310 268 1-¼” 2205 1039 834 724 630 511 439

1-½” 1316 931 801 661 588 480 416 1-½” 3307 1559 1275 1086 976 787 665

20’ 40’ 60’ 80’ 100’ 150’ 200’

½” 120 82 66 57 50 40 35 ½” 275 129 103 89 78 63 54

¾” 250 170 138 118 103 84 72 ¾” 567 267 217 185 162 132 112

1” 465 320 260 220 195 160 135 1” 1071 504 409 346 307 252 209

½” W.C. P.D. WITH 7.0” SUPPLY PRESSURE

Total Length of Pipe (feet) Pipe

PIPE CAPACITY - MBTU/HR

Size

20’ 40’ 60’ 80’ 100’ 150’ 200’

½” W.C. P.D. WITH 11.0” SUPPLY PRESSURE

LP / PROPANE GAS

Total Length of Pipe (feet)

PIPE CAPACITY - MBTU/HR

Combustion Research Corporation Page 11

Loading...

Loading...