Page 1

Sequans Module VZM20Q

SEQUANS Communications

15-55, Boulevard Charles de Gaulle

92700 Colombes, France

Phone. +33.1.70.72.16.00

Fax. +33.1.70.72.16.09

www.sequans.com

contact@sequans.com

Module

Integration

Guide

Page 2

Legal Notices

Copyright© 2016, SEQUANS Communications

All information contained herein and disclosed by this document is

confidential and the proprietary property of SEQUANS Communications,

and all rights therein are expressly reserved. Acceptance of this material

signifies agreement by the recipient that the information contained in this

document is confidential and that it will be used solely for the purposes set

forth herein. Acceptance of this material signifies agreement by the recipient

that it will not be used, reproduced in whole or in part, disclosed, distributed,

or conveyed to others in any manner or by any means – graphic, electronic, or

mechanical, including photocopying, recording, taping, or information

storage and retrieval systems – without the express written permission of

SEQUANS Communications.

Preface

All Sequans’ logos and trademarks are the property of SEQUANS

Communications. Unauthorized usage is strictly prohibited without the

express written permission of SEQUANS Communications. All other

company and product names may be trademarks or registered trademarks of

their respective owners. Products and services of SEQUANS

Communications, and those of its licensees may be protected by one or more

pending or issued U.S. or foreign patents.

Because of continuing developments and improvements in design,

manufacturing, and deployment, material in this document is subject to

change without notification and does not represent any commitment or

obligation on the part of SEQUANS Communications. SEQUANS

Communications shall have no liability for any error or damages resulting

from the use of this document.

MODULE INTEGRATION GUIDE PROPRIETARY i

SEQUANS Communications

Page 3

Document Revision History

Revision Date Product Application

01 November 2016 First edition of the VZM20Q Module Integration Guide.

ii PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 4

Purpose and Scope

This Application note is intended to help customers who want to deviate from

the Sequans’ Reference Designs to successfully integrate and test their

product based on module.

It presents Integration Guidelines for:

• All VZM20Q Interface Requirements

• Tips and “how-to”s for troubleshooting

Development of the Hardware should follow a process that ensures the

solution will be optimum and it is the purpose / goal of this document to reach

this. For this to occur it is recommended that these processes are followed in

order. This document is delivered as three sections:

About this Guide

1. System Overview

2. Hardware and software design guidelines

3. Bring-up verification and test

Caution: It is highly recommended that Sequans support teams are

involved during all processes to ensure the very best can be

achieved for the alternative design.

Who Should Read this Document

This Application Note is for hardware designers of user applications based on

Sequans VZM20Q Module.

Important: Reference design source files are based on the application PADS®

from Mentor Graphics® (www.mentor.com). Customers using

the other CAD applications can use schematics translators and

viewers, such as Elgris® (www.elgris.com). Such translators may

save time and prevent mistakes during manual PADs conversion.

MODULE INTEGRATION GUIDE PROPRIETARY iii

SEQUANS Communications

Page 5

Reference Documentation

1. DV Tool User Guide

2. Sequans Hardware Platform User Guide

3. mTools Reference Manual

4. Nimbelink™ Evaluation Kit User Manual

See http://nimbelink.com/

Changes in this Document

This is the first edition of the document.

iv PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 6

Documentation Conventions

This section illustrates the conventions that are used in this document.

General Conventions

Note Important information requiring the user’s attention.

A condition or circumstance that may cause damage to the equipment or loss of

data.

Caution

A condition or circumstance that may cause personal injury.

War ning

Italics Italic font style denotes

• emphasis of an important word;

• first use of a new term;

• title of a document.

Screen Name Sans serif, bold font denotes

• on-screen name of a window, dialog box or field;

• keys on a keyboard;

• labels printed on the equipment.

Software Conventions

Code Regular Courier font denotes code or text displayed on-screen.

Code Bold Courier font denotes commands and parameters that you enter exactly as

shown. Multiple parameters are grouped in brackets [ ]. If you are to choose only

one among grouped parameters, the choices are separated with a pipe: [parm1 |

parm2 | parm3] If there is no pipe separator, you must enter each parameter:

[parm1 parm2 parm3]

Code Italic Courier font denotes parameters that require you to enter a value or

variable. Multiple parameters are grouped in brackets [ ]. If you are to choose

only one among grouped parameters, the choices are separated with a pipe:

[parm1 | parm2 | parm3] If there is no pipe separator, you must enter a value for

each parameter: [parm1 parm2 parm3]

MODULE INTEGRATION GUIDE PROPRIETARY v

SEQUANS Communications

Page 7

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Legal Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .i

Document Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

About this Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Purpose and Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Who Should Read this Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Reference Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Changes in this Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Documentation Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 System Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Recommended Design Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.1 Design Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.2 Schematics Review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.3 PCB Placement and Layout Review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.4 Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.5 Functional Validation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.6 Manufacturing Recommended Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2

Manufacturing Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Manufacturing Process Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Module Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 3

Hardware Integration Recommendations . . . . . . . . . . . . . . . . . . . 6

3.1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1.1 Synthesis of the Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1.2 Power Supply Circuit Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.3 Module Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 SIM Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2.1 Interface Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2.2 Other Hardware Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2.3 Software-Configurable Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Host Communications Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Proprietary vi

SEQUANS Communications

Page 8

Table of Contents

3.3.1 Introduction to UART Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3.2 General Notes on UART Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3.3 UART0 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3.4 UART1 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.5 UART2 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 RF Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4.1 RF Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4.2 Circuit Diagram Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4.3 Test Points and Measurement Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4.4 Antennas and RF Design Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5 Reset and Environmental Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.6 GPIO Control Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.6.1 Interface Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.6.2 Software Configurable Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Chapter 4

PCB Layout Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1 Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2 Trace Characteristic Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.1 Digital Traces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.2 Power Supply Traces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.3 RF Traces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.4 Controlled Impedance Traces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.5 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 5

Bring-Up and Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2 Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3 Functional Verification without Assembled Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.3.1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.3.2 RF Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.4 Functional Verification with Assembled Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.4.1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.4.2 Confirm Module Power-Up Operation (UART1) . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.4.3 GPIOs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.4.4 SIM Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.5 LTE RF Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.5.1 Test Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.5.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.5.3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Appendix A

Hardware Test Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . 37

A.1 RF Interfaces Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Proprietary vii

SEQUANS Communications

Page 9

Table of Contents

A.1.1 LTE RF Test Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Appendix B

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

viii Proprietary M

SEQUANS Communications

ODULE INTEGRATION GUIDE

Page 10

Introduction

,K^dW>d&KZD

sDϮϬY

Z&

ŽĂdž

/&dž

Zydy

sd

sϭͺW

sϮͺW

sdϭ

Z^dE

DKh>ͺKE

:d '

^/D

hZdϭ;KƉƚŝŽŶĂůͿ

DŽĚĞŵ/ŶƚĞƌĨĂĐĞ;hZdϬͿ

'W/K

ϯsϬ

ĞďƵŐ;hZdϮͿ

;ĞďƵŐDĂŶƵĨĂĐƚƵƌŝŶŐĐŽŶƐŽůĞͿ

1

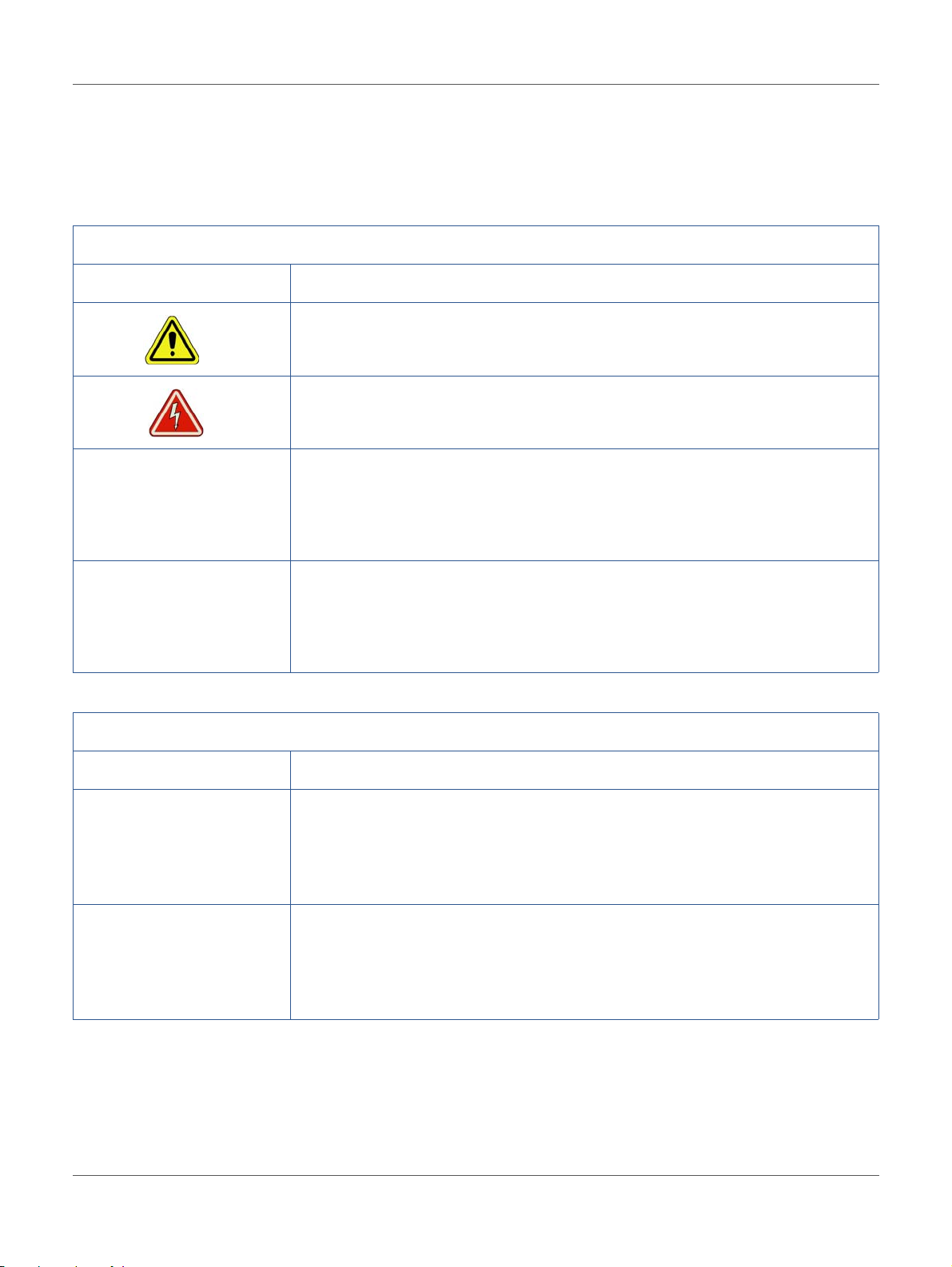

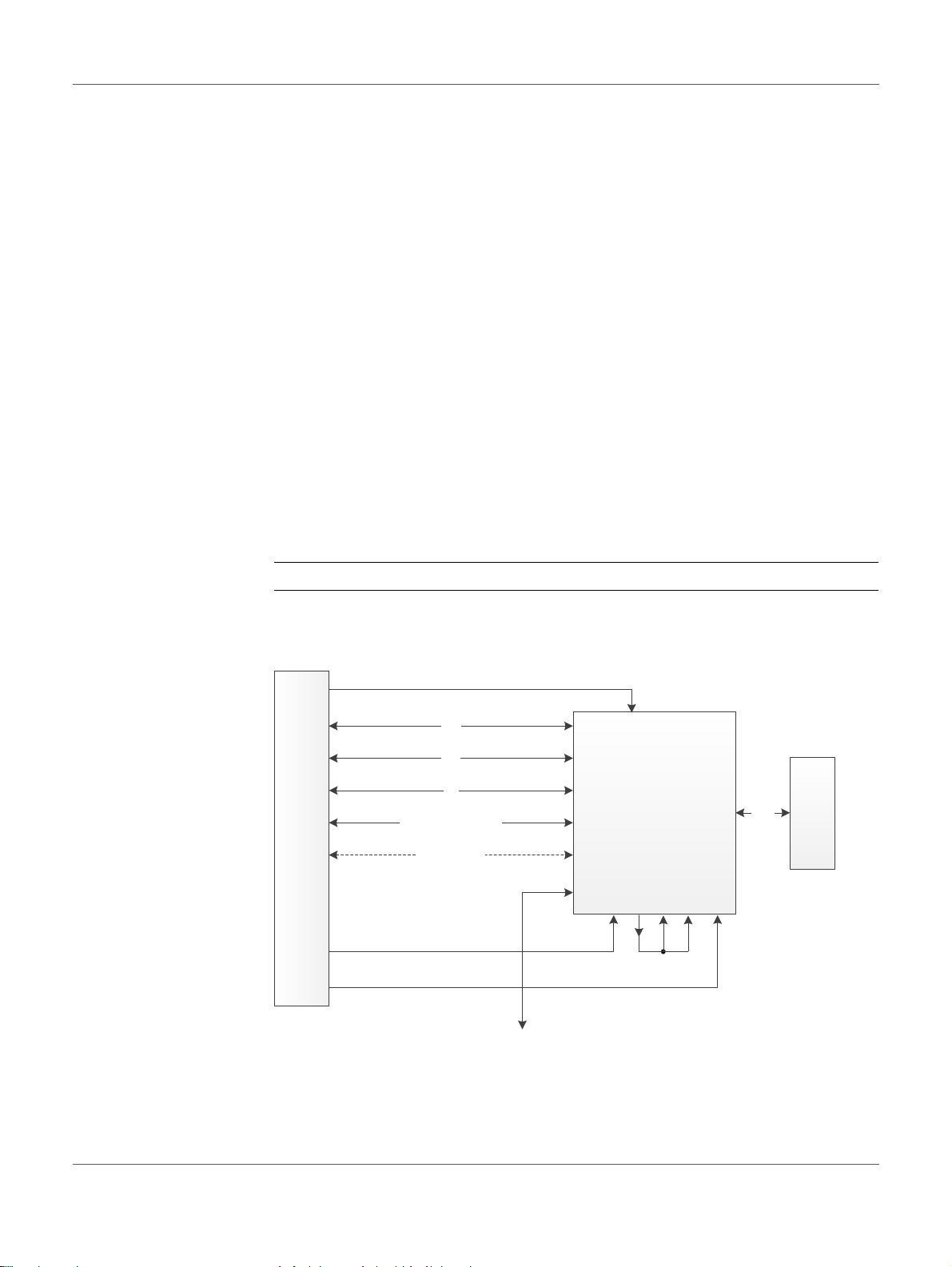

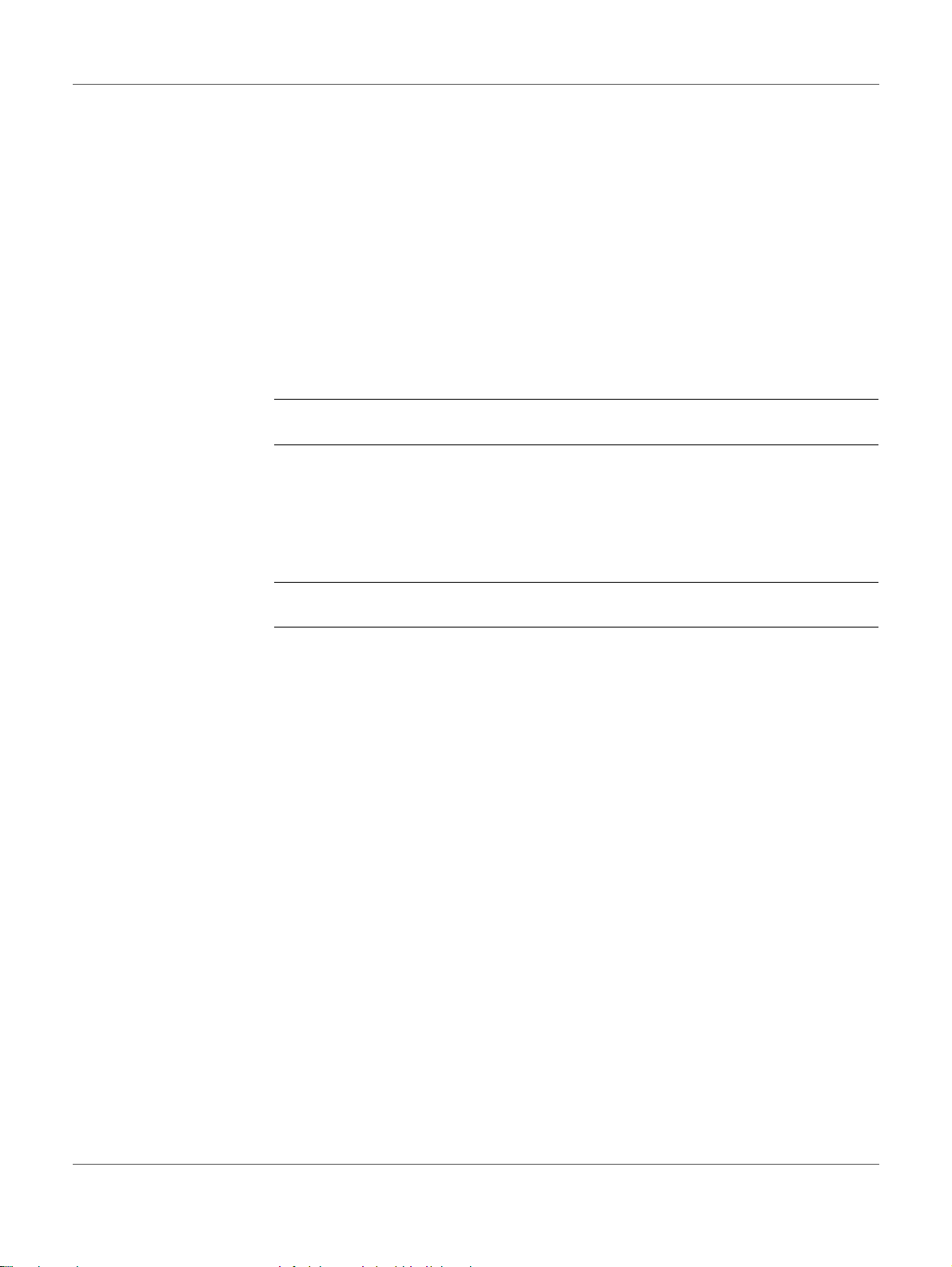

1.1 System Architecture

Figure 1-1 provides an overview of the Host to VZM20Q interfacing

relationship. The various interfaces are explained in detail later in this

document.

It provides summary details of:

• Digital interfaces between the VZM20Q and the host platform

• Power supply requirement (V

Note: V

It does not show the VZM20Q local terminations.

range is 3.1 V to 4.5 V.

BAT1

bat

).

MODULE INTEGRATION GUIDE PROPRIETARY 1

Figure 1-1: VZM20Q-Based System Architecture

SEQUANS Communications

Page 11

INTRODUCTION

SYSTEM ARCHITECTURE

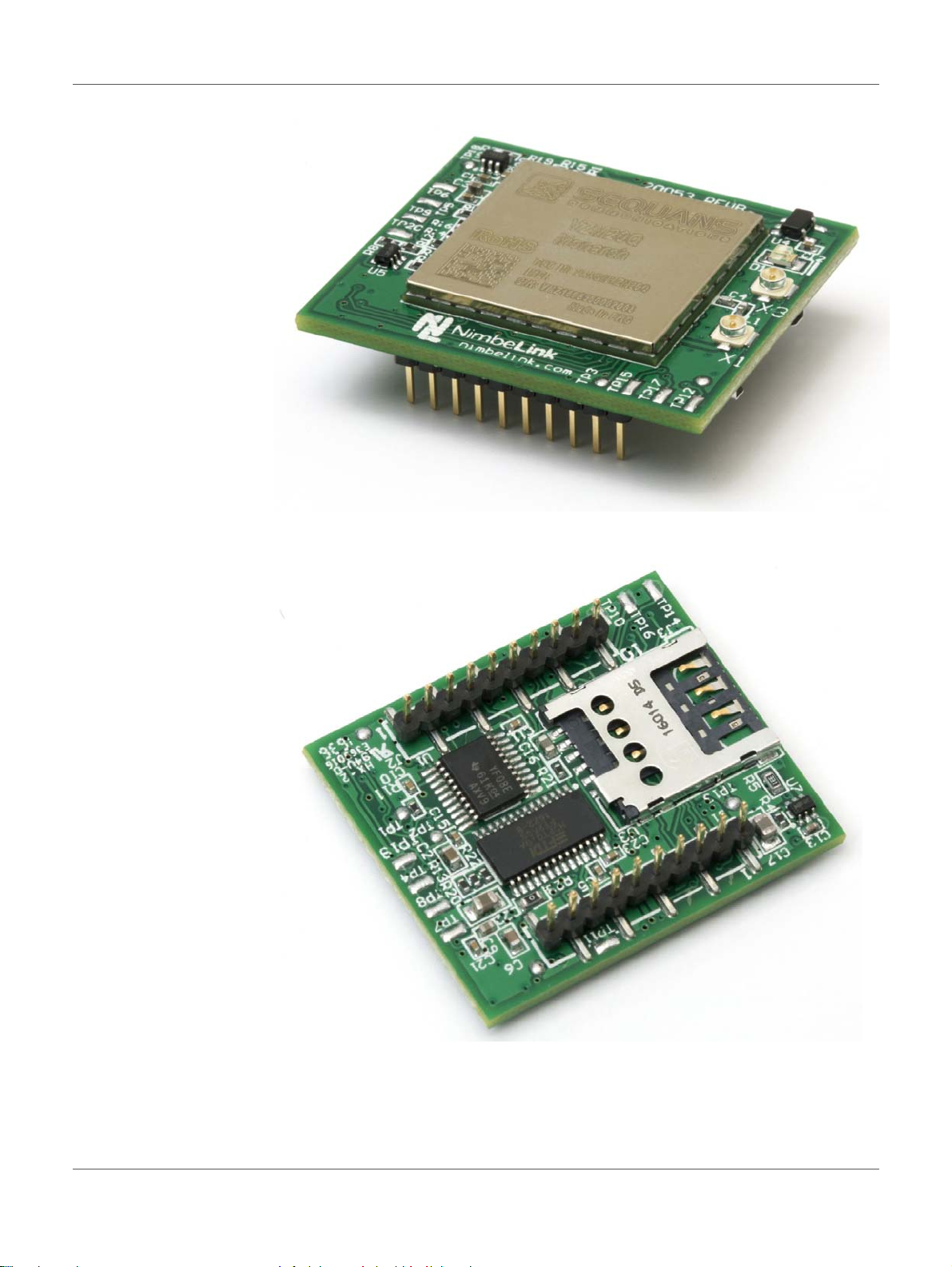

Figure 1-2: VZM20Q Mounted on Skywire™ 4G LTE CAT M1 Embedded

Modem

Figure 1-3: Skywire™ 4G LTE CAT M1 Embedded Modem - Bottom View

2 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 12

Note: The hardware design package of VZM20Q reference design is

available from your Sequans local contact.

1.2 Recommended Design Flow

To ensure that the customer benefits from the details of this document we

recommend to carefully take the following information into account during

the design process.

1.2.1 Design Modifications

Compared to Nimbelink™ reference design, only the following modifications

to the BOM are allowed to designers:

INTRODUCTION

RECOMMENDED DESIGN FLOW

• SIM connector

•Level shifter on UARTs

• Circuitry on RESETN

Note: Any GNSS/GPS function is out of scope of VZM20Q Reference

Design.

Consultancy with Sequans is highly recommended to verify these alternate

preferences.

1.2.2 Schematics Review

Ensuring that the circuit design by analysis will be compliant with the

Sequans’ chipset. It is recommended that the review of the design includes

Sequans’ technical support team.

1.2.3 PCB Placement and Layout Review

To ensure the PCB layout is compliant, it is recommended that the review of

this CAD activity includes Sequans at several iterative steps such as

component placement, RF and digital routing, final layout levels etc. This

might avoid later rework.

MODULE INTEGRATION GUIDE PROPRIETARY 3

SEQUANS Communications

Page 13

INTRODUCTION

RECOMMENDED DESIGN FLOW

1.2.4 Optimization

When the design returns from the manufacture, it might occur that

improvements have to be made to the circuits. It is also recommended to

communicate such results to Sequans who can help to verify the

implementation.

1.2.5 Functional Validation

The test of the design performance should be done in thorough detail. This

will ensure the compliance with the test standard as the final design will be

subjected to a formal qualification. It is the designer’s responsibility to meet

this goal. Sharing the results with Sequans will help identify any particular

problem that could be fixed at an early stage to ensure strong confidence of

qualification. This should be done for all the tests that involve Sequans

chipsets.

Hardware Test Preparation on page 37 provides you with the hardware setup

required to proceed with test phases.

1.2.6 Manufacturing Recommended Process

Manufacturing Process on page 5 provides information on the process

required to achieve the manufacturing of your product.

4 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 14

Manufacturing Process

2

2.1 Manufacturing Process Overview

Note: The contents of this section will be provided in a future revision

of the document.

2.2 Module Upgrade

Note: The contents of this section will be provided in a future revision

of the document.

MODULE INTEGRATION GUIDE PROPRIETARY 5

SEQUANS Communications

Page 15

Hardware Integration Recommendations

3

This chapter provides the information necessary to understand the various

interface requirements to interconnect with the VZM20Q, associated

software-configurable items for the respective interface and, more generally,

good practices for board design when considering the various interface types.

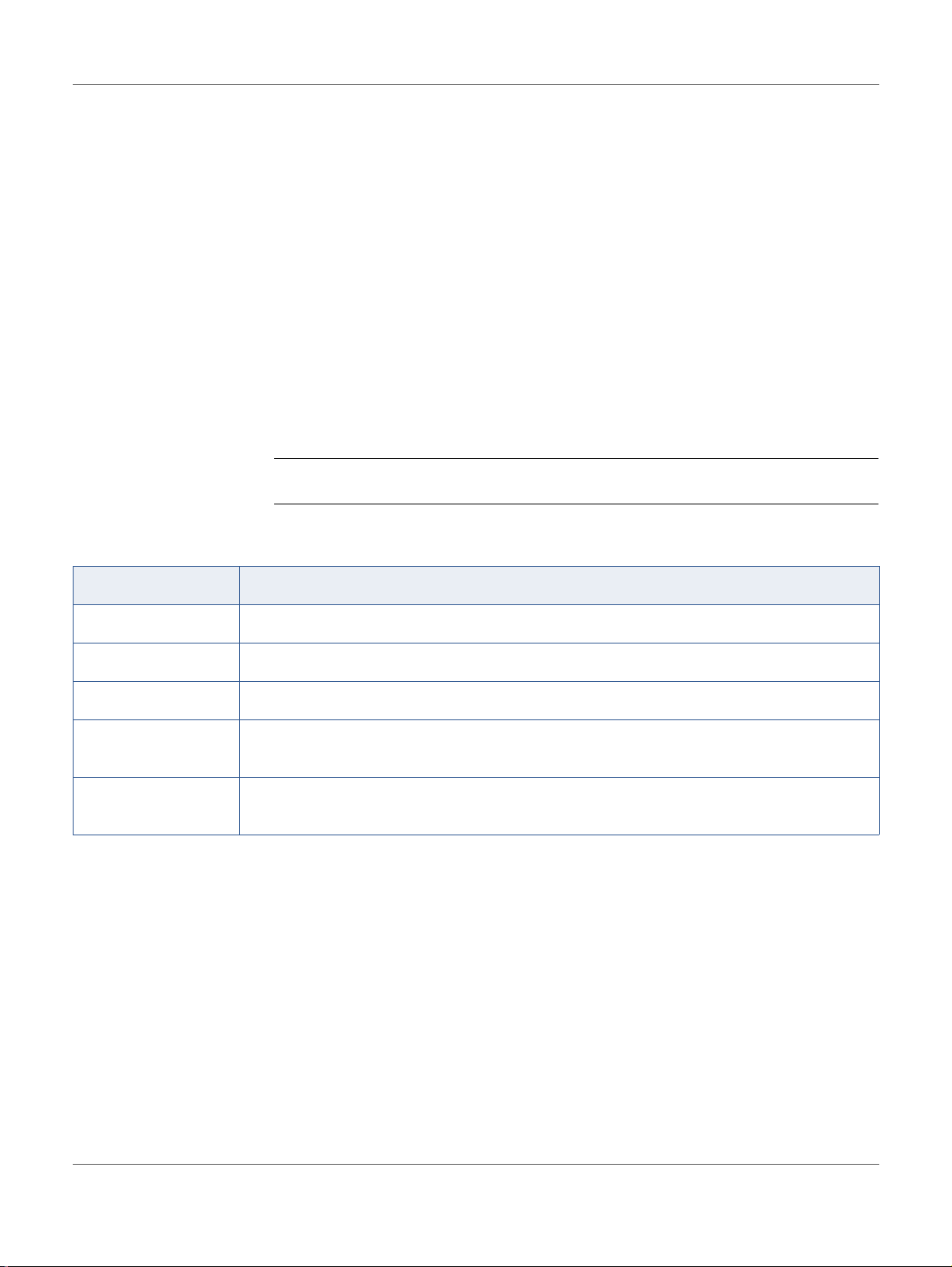

Table 3-1 describes the requirements for trace characteristics.

Important: Different signals require different special needs. Please consider

carefully the interfacing requirement of each relevant connection.

Table 3-1: Requirements Overview: Trace Characteristics

Trace Characteristics Description

Digital Generic digital trace if reasonable high impedance

Supply Broader trace routing based on the power needs of the load

50 Ohm Conventionally used for RF routing. Track must be retained to this impedance

Quiet Intention is to keep away from digital signals and as short as possible, possibly burying

the signal

Ground Shortest VZM20Q Ground to Host Ground possible, best possible lowest impedance

path

MODULE INTEGRATION GUIDE PROPRIETARY 6

SEQUANS Communications

Page 16

HARDWARE INTEGRATION RECOMMENDATIONS

3.1 Power Supply

3.1.1 Synthesis of the Power Supplies

Table 3-2 and Table 3- 3 provide a synthesis of the power supplies and their

characteristics. Please see typical voltage values in VZM20Q Datasheet.

Note: Each output reference voltage (pads 3, 9, 11) can be either running

or powered off depending on the internal software configuration.

They should not be used to power external IC or parts that require

permanent supply.

Table 3-2: Power Supply Signals

POWER SUPPLY

Pin

Pin Name

1V8 3 Supply Out Reference voltage. See the note above.

3V0 9,11 Supply Out To be only connected to VCC1_PA and VCC2_PA. These pads

GNSS_VCC1 100 Supply In Reserved. Do not connect.

GNSS_VCC2 101 Supply Out Reserved. Do not connect.

GNSS_VCC3 102 Supply In Reserved. Do not connect.

VBAT1 107, 108 Supply In Voltage used for qualification is 3.8 V, range 3.1 V to 4.5 V

VCC1_PA 97 Supply In To be connected to 3V0

VCC2_PA 98, 99 Supply In To be connected to 3V0

Number

Trace

Style

Direction Notes

should not be used for any other usage. See the note above.

Table 3-3: Power Supply Digital Enable Signals

Typical

Pin

Pin Name

POWER_EN 106 Digital In 1V8

MODULE INTEGRATION GUIDE PROPRIETARY 7

Number

Tra ce

Style

SEQUANS Communications

Direction

Voltage

Ref

Notes

Page 17

HARDWARE INTEGRATION RECOMMENDATIONS

SIM INTERFACE

3.1.2 Power Supply Circuit Example

3.1.2.1 Test Points and Measurement Access

Test point access is recommended on all supply nets so that the supply

voltages can be measured.

3.1.2.2 Special Layout Considerations

PLease refer to Section 4.2.2 Power Supply Traces on page 24.

3.1.3 Module Operating Mode

Note: The contents of this section will be provided in a future revision

of the document.

3.2 SIM Interface

3.2.1 Interface Description

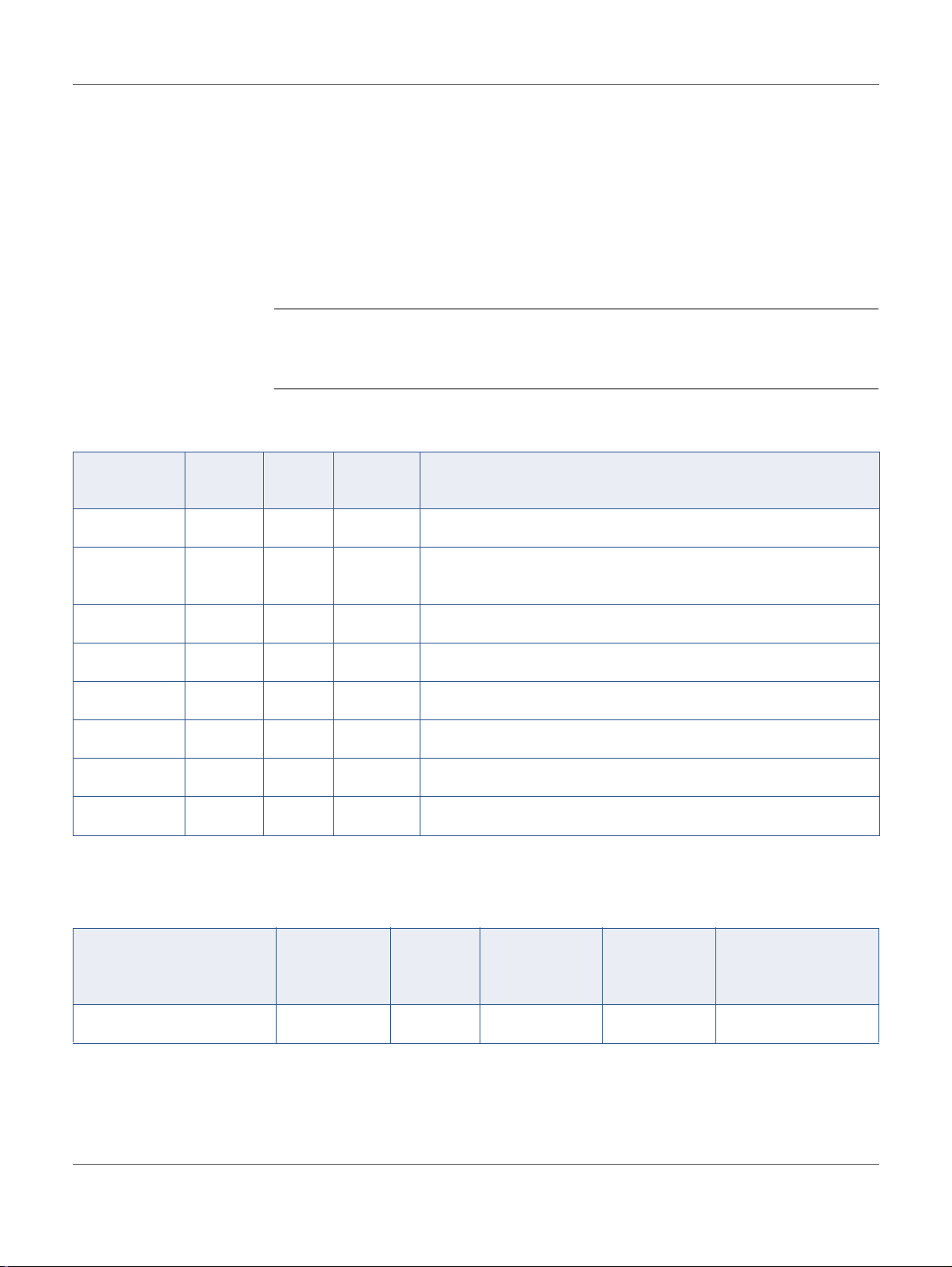

Table 3-4 lists the VZM20Q pins related to the SIM interface.

Table 3-4: SIM Interface Signals

Pin

Pin Name

SIM_CLK 14 Digital Output from Module SIM_VCC

SIM_DETECT

SIM_IO 17 Digital Input or Output to/from Module SIM_VCC

SIM_RESETN 12 Digital Output from Module SIM_VCC

SIM_VCC 18 Digital Output from Module 1V8 or 3V0

1

Number

16 Digital Input to Module 1V8

Trace Style Direction

Electrical

Characteristics

1. SIM_DETECT=1 signals that a card is present. SIM_DETECT=0 signals that no card is present.

8 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 18

HARDWARE INTEGRATION RECOMMENDATIONS

3.2.2 Other Hardware Considerations

• When considering the placement of the SIM connector and Monarch SIM

interface, try to keep the distance between them as small as possible. This

is to avoid supply trace inductance buildup which could cause unexpected

SIM VCC supply drops under specific SIM control situations. If it is

unavoidable, then be sure to add 4.7µF decoupling capacitor at the SIM

connector itself to act as a charge reserve in help in such situations.

• Please ensure that a good ground return exists between the SIM card and

the VZM20Q.

• If the application requires the support of the hot insertion or removal of

SIM card, then the SIM card handler must include a removal/insertion pad

detector in order to allow the software to process the event immediately.

• The software support of the “hot removal” feature is not currently available. Please contact your Sequans’ representative for details.

3.2.3 Software-Configurable Options

HOST COMMUNICATIONS SIGNALS

Note: The content of this section will be provided in a future revision of

the document.

3.3 Host Communications Signals

3.3.1 Introduction to UART Interfaces

The communication between the VZM20Q and the host platform is supported

as follows by 3 UART interfaces.

• UART0 is dedicated to Host-Modem interface

• UART1 is an optional additional Host-Modem interface. It is reserved for

future use.

• UART2 is reserved for debug usage and Sequans’ manufacturing and hardware qualification tools such as DMTool or DVTool.

The following sections detail those interfaces.

MODULE INTEGRATION GUIDE PROPRIETARY 9

SEQUANS Communications

Page 19

HARDWARE INTEGRATION RECOMMENDATIONS

sDϮdžY

ƉƉůŝĐĂƚŝŽŶ

dyϬϭϮ dy

ZyϬϭϮ Zy

Zd^ϬϭϮ Zd^

d^ϬϭϮ d^

><ϬϭϮ ><

dZϬ dZ

^ZϬ ^Z

Ϭ

Z/E'Ϭ Z/E'

HOST COMMUNICATIONS SIGNALS

3.3.2 General Notes on UART Connections

VZM20Q uses the DCE-DTE convention for UART lines.

The TXD output from the device at one end of the link connects to the RXD

input at the other end of the link and vice versa. Figure 3-1 represents the

typical implementation for the UART connection (including hardware flow

control in case of high-speed UART).

TXD and RXD signals are mandatory for all interfaces. The other signals are

optional. Only UART0 interface supports all data transfer signals.

The DCE (Data Communication Equipment) device will communicate with

the customer application (DTE) using the following signals:

• Port TXD on Application sends data to the VZM20Q's TXD signal line.

• Port RXD on Application receives data from the VZM20Q's RXD signal

line.

Figure 3-1: UART0, UART1, UART2 Connection Implementation

10 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 20

3.3.3 UART0 Interface

3.3.3.1 Interface Description

Important:

• See the Section 3.3.2 General Notes on UART Connections on

page 10 for usage of UART0.

• If not used, the UART0 signals should be connected to test

points.

Table 3-4 lists the VZM20Q pins related to the UART0 interface.

Table 3-5: UART Interface Signals

HARDWARE INTEGRATION RECOMMENDATIONS

HOST COMMUNICATIONS SIGNALS

Pin

Pin Name

RXD0 79 Digital Out 1.8 V UART0 RXD

TXD0 77 Digital In 1.8 V UART0 TXD

RTS0 75 Digital In 1.8 V UART0 RTS

CTS0 76 Digital Out 1.8 V UART0 CTS

GPIO19/CLK0 7 Digital In/Out 1.8 V UART0 CLK optional signal multiplexed

GPIO41/DTR0 84 Digital In 1.8 V UART0 DTR optional signal multiplexed

GPIO39/DSR0 85 Digital Out 1.8 V UART0 DSR optional signal multiplexed

GPIO24/DCD0 88 Digital Out 1.8 V UART0 DCD optional signal multiplexed

GPIO25/RING0 89 Digital Out 1.8 V UART0 RING optional signal multiplexed

Number

Trace

Style

Direction

Electrical

Characteristics

Notes

with GPIO19. Default setting is GPIO.

with GPIO41. Default setting is GPIO.

with GPIO39. Default setting is GPIO.

with GPIO24. Default setting is GPIO.

with GPIO25. Default setting is GPIO.

MODULE INTEGRATION GUIDE PROPRIETARY 11

SEQUANS Communications

Page 21

HARDWARE INTEGRATION RECOMMENDATIONS

HOST COMMUNICATIONS SIGNALS

3.3.3.2 Default Configuration

The default software configuration of UART0 is AT Commands mode.

The serial link settings are as follows:

• Baud rate: 921600

• Data: 8 bits

•Parity: None

• Stop : 1 bit

• Flow control: Hardware (RTS/CTS)

3.3.4 UART1 Interface

3.3.4.1 Interface Description

Important:

• See the Section 3.3.2 General Notes on UART Connections on

page 10 for usage of UART1.

• If not used, the UART1 signals should be connected to test

points.

Table 3-6 lists the VZM20Q pins related to the UART1 interface.

Table 3-6: UART1 Interface Signals

Pin

Pin Name

GPIO15/RXD1 80 Digital Out 1.8 V UART1 RXD optional signal multiplexed

GPIO14/TXD1 78 Digital In 1.8 V UART1 TXD optional signal multiplexed

GPIO16/RTS1 83 Digital In 1.8 V UART1 RTS optional signal multiplexed

GPIO17/CTS1 81 Digital Out 1.8 V UART1 CTS optional signal multiplexed

Number

Trace

Style

Direction

Electrical

Characteristics

Notes

with GPIO15. Default setting is RXD1.

with GPIO14. Default setting is TXD1.

with GPIO16. Default setting is GPIO.

with GPIO17. Default setting is GPIO.

GPIO38/CLK1 82 Digital In/Out 1.8 V UART1 CLK optional signal multiplexed

with GPIO38. Default setting is GPIO.

12 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 22

3.3.4.2 Default Configuration

The default software configuration of UART1 is console mode. Boot traces are

sent on this interface as shown on Section 5.4.2 Confirm Module Power-Up

Operation (UART1) on page 32.

The serial link settings are as follows:

• Baud rate: 115200

• Data: 8 bits

•Parity: None

• Stop : 1 bit

•Flow control: None

3.3.5 UART2 Interface

HARDWARE INTEGRATION RECOMMENDATIONS

HOST COMMUNICATIONS SIGNALS

3.3.5.1 Interface Description

Important:

• See the Section 3.3.2 General Notes on UART Connections on

page 10 for usage of UART2.

• If not used, the UART2 signals should be connected to test

points.

Table 3-7 lists the VZM20Q pins related to the UART2 interface.

Table 3-7: UART2 Interface Signals

Pin

Pin Name

RXD2 56 Digital Out 1.8 V UART2 RXD.

TXD2 58 Digital In 1.8 V UART2 TXD

GPIO28/RTS2 10 Digital In 1.8 V UART2 RTS optional signal multiplexed

Number

Trace

Style

Direction

Electrical

Characteristics

Notes

with GPIO28. Default setting is RTS.

GPIO27/CTS2 8 Digital Out 1.8 V UART2 CTS optional signal multiplexed

with GPIO27. Default setting is CTS.

GPIO26/CLK2 91 Digital In/Out 1.8 V UART2 CLK optional signal multiplexed

with GPIO26. Default setting is GPIO

MODULE INTEGRATION GUIDE PROPRIETARY 13

SEQUANS Communications

Page 23

HARDWARE INTEGRATION RECOMMENDATIONS

HOST COMMUNICATIONS SIGNALS

3.3.5.2 Default Configuration

UART2 default software configuration allows firmware upload when the

device is configured in FFH mode, then it switchs in debug mode (enabling

DVTool, DMTool).

The serial link settings are as follows:

• Baud rate: 921600

• Data: 8 bits

•Parity: None

• Stop : 1 bit

• Flow control: Hardware (RTS/CTS)

14 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 24

3.4 RF Interface

3.4.1 RF Signals

3.4.1.1 RF Interface Signals

Table 3-8: RF Interface Signals

HARDWARE INTEGRATION RECOMMENDATIONS

RF INTERFACE

Pin

Name

LTE_ANT0 54 RF In/Out RF LTE antenna. Special RF routing conditions

GNSS_ANT1 44 Reserved Reserved. Do not connect.

Pin

Number

Tra ce

Style

Direction

Electrical

Characteristics

Notes

3.4.1.2 RF Control Signals

Table 3-9: RF Control Signals

Pin

Name

RFDATA12 39 Digital In/Out Reserved.

RFDATA16 40 Digital In/Out Reserved.

RFDATA17 41 Digital In/Out Reserved.

Pin

Number

Tra ce

Style

Direction

Electrical

Characteristics

Notes

MODULE INTEGRATION GUIDE PROPRIETARY 15

SEQUANS Communications

Page 25

HARDWARE INTEGRATION RECOMMENDATIONS

RF INTERFACE

3.4.2 Circuit Diagram Example

Important: Figure 3-4 should be strictly followed as a topology reference. It is

recommended not to deviate from this circuit from your application. More information is provided in this document on the layout

constraint which are too very important to abide by.

The RF inter-connect called P1 is for example purposes only. Depending on

the antenna, interfacing system will dictate the RF inter-connect.

Figure 3-2: RF Typical Circuit

LTE_ANT0 is the primary (main) antenna pin and carries TX and RX signals.

Connect 50 Ohm transmission lines from this pins to the 50 Ohm Primary

Antenna/Antenna-connector.

Figure 3-2 shows, included in the connection between ANT and the antenna

connectors, T-type network for matching.

See Section 3.4.4 Antennas and RF Design Considerations on page 17 for more

detail on connecting to these pins and for information on the T-type matching

network and ESD protection.

16 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 26

HARDWARE INTEGRATION RECOMMENDATIONS

3.4.3 Test Points and Measurement Access

50 Ohm termination points, for example P1 in Figure 3-2, are needed for

Engineering and Production teams for the validation of the RF performance.

The potential need to optimize the Pi-type matching network in the antenna

path means that access to the IOs of this matching network is needed, so that a

coaxial cable (usually 1.25mm diameter semi-rigid) can be manually attached

for precision impedance measurements. Critically, a sufficient area of GND

metal on the top layer adjacent to these matching networks and

well-grounded to the transmission line reference GND is needed to permit

robust physical attachment of the coaxial cable and with short GND

connection. This area of GND metal does not need any resist removal as this

can be removed manually where needed.

Please refer to Section 3.4.4 Antennas and RF Design Considerations on page 17 for more detail on managing RF Trace Design.

RF INTERFACE

3.4.4 Antennas and RF Design Considerations

Antennas require special interfacing for optimum RX and TX Performance.

3.4.4.1 T-Type Matching

A 3-component T-type matching network is recommended to be fitted. The

purpose of the T-type matching network is to transform the impedance of the

RF-path that extends beyond to 50 Ohm if needed. The 3 components in this

matching network should be as close together as possible to minimise the

interconnecting track lengths.

By default the component pads should be for a 0201-size capacitor which can

be a No Fit by default. There should be a short low-impedance connection

connecting the GND node of this component.

The series matching element should be connected at the junction where first

shunt component and by default a 0 Ohm 0201-size resistor should be fitted

but if matching is needed the pads needs to be able to take 0201-size inductor;

The final shunt matching element should be connected from the node where

the series matching component ends to the signal ground connection. By

default the component pads should be for a 0201-size capacitor which can be a

No Fit by default. There should be a short low-impedance connection

connecting the GND node of this component to the GND node of the first

shunt component. There should be a short low-impedance connection

connecting the GND node of this component to the GND reference of the

50 Ohm transmission line that continues beyond to the

Antenna/Antenna-connector.

MODULE INTEGRATION GUIDE PROPRIETARY 17

SEQUANS Communications

Page 27

HARDWARE INTEGRATION RECOMMENDATIONS

RF INTERFACE

3.4.4.2 ESD Protection

ESD protection is a discretionary requirement and only required if necessary,

for higher ESD specifications than those provided by the VZM20Q.

It is recommended to select an ESD device with very low capacitance and

small size (0201) to prevent further RF matching compensation.

3.4.4.3 Standard Impedance Transmission Lines

There are 2 possible methods to design 50 Ohm transmission lines:

1. With the RF track on the outer metal layer both micro-strip and coplanar

types can be implemented.

2. With the RF track on an inner metal layer embedded micro-strip and

strip-line topologies can be used.

Irrespective of which one is selected the following guidelines are

recommended:

• Design the transmission line tracks appropriately wide to minimise the RF

insertion loss between the Antenna/Antenna-connector and VZM20Q. The

maximum insertion loss of the conducted path should be < 0.5dB

• Transmission lines EM fields will couple to adjacent metal layers.

For microstrip implementation, make sure that a minimum of twice the

spacing exists between transmission-line and associated GND. This clearance to adjacent metal layers will ensure that the designed transmission

line impedance is not impacted.

For co-planar design, the spacing helps to define the controlled impedance.

Take special care to make the calculations correctly.

Whether these are microstrip or co-planar designed transmission lines,

make sure that the adjacent metal GND areas are connected to the GND

reference plane using periodic via connections, as to effectively terminate

these leakage EM fields.

18 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 28

HARDWARE INTEGRATION RECOMMENDATIONS

RF INTERFACE

Figure 3-3: Transmission Line Implementation Examples

Figure 3-3 provides examples of both transmission line implementations,

specifically showing:

a) The clearance from the transmission line to adjacent metal on layer 1.

b) The periodic via connections connecting metal-1 layer through to the

reference GND layer for the transmission line.

• Avoid routing of noisy signal tracks adjacent to RF transmission lines to

minimize interference coupling into VZM20Q RF ports.

• The component pads for the SMD terminals of the matching components

used in the 3-component T-type matching circuit are effectively very short

transmission lines. To minimise the RF insertion loss caused by the discontinuity in width differences, the ideal width of the 50 Ohm track should be

as close as possible to the width of the component pads.

• If connectors are used in-line on antenna paths design the PCB interface

tracking and cut-out carefully to these connectors to keep the transmission

line impedance to 50 Ohm.

MODULE INTEGRATION GUIDE PROPRIETARY 19

SEQUANS Communications

Page 29

HARDWARE INTEGRATION RECOMMENDATIONS

RESET AND ENVIRONMENTAL SIGNALS

3.5 Reset and Environmental Signals

Table 3-1 0 lists the Reset and other environmental signals and the following

subsections describe their purpose and termination requirements.

Table 3-10: Non-Interfacing Signals

Pin

Pin Name

RESETN 47 Out 1V8

GPIO3/STATUS_LED 2 In/Out 1V8 - GPIO

RESERVED/FFF_FFH 5 In 1V8 Reserved pad: it must be PU & connected to a

ADC 57 In An external switch should be connected to the

WAKE0 104 In

WA KE 1 9 6 I n/ O ut

JTAG_TDO 48 Out JTAG interface, should be connected to a test

JTAG_TRSTN 49 In JTAG interface, should be connected to a test

Number

Direction

Electrical

Characteristics

Notes

- Optional STATUS_LED. Note that the LED

function is currently not available.

Test Point.

AuxADC pins to prevent current leakage in

low power modes.

point.

point.

JTAG_TMS 50 In JTAG interface, should be connected to a test

point.

JTAG_TDI 51 In JTAG interface, should be connected to a test

point.

JTAG_TCK 52 In JTAG interface, should be connected to a test

point.

20 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 30

HARDWARE INTEGRATION RECOMMENDATIONS

GPIO CONTROL INTERFACE

3.6 GPIO Control Interface

3.6.1 Interface Description

Several general purpose IOs are available:

Table 3-11: GPIOs Signals

Electrical

Pin Name Pin Number Direction

GPIO14/TXD1 78 In/Out 1V8 UART1 TXD (Input) alternate

GPIO15/RXD1 80 In/Out 1V8 UART1 RXD (Output) alternate

Characteristics

Notes

function to GPIO. See Section

UART1 Interface.

function to GPIO. See Section

UART1 Interface.

GPIO17/CTS1 81 In/Out 1V8 Optional UART1 CTS (Output)

alternate function to GPIO. See

Section UART1 Interface.

GPIO38/CLK1 82 In/Out 1V8 Optional UART1 CLK (I/O)

alternate function to GPIO. See

Section UART1 Interface.

GPIO16/RTS1 83 In/Out 1V8 Optional UART1 RTS (Input)

alternate function to GPIO. See

Section UART1 Interface.

GPIO41/DTR0 84 In/Out 1V8 Optional UART0 DTR (Input)

alternate function to GPIO. See

Section UART0 Interface.

GPIO39/DSR0 85 In/Out 1V8 Optional UART0 DSR (Output)

alternate function to GPIO. See

Section UART0 Interface.

GPIO24/DCD0 88 In/Out 1V8 Optional UART0 DCD (Output)

alternate function to GPIO. See

Section UART0 Interface.

GPIO25/RING0 89 In/Out 1V8 Optional UART0 RING (Output)

alternate function to GPIO. See

Section UART0 Interface.

MODULE INTEGRATION GUIDE PROPRIETARY 21

SEQUANS Communications

Page 31

HARDWARE INTEGRATION RECOMMENDATIONS

GPIO CONTROL INTERFACE

Table 3-11: GPIOs Signals (Continued)

Electrical

Pin Name Pin Number Direction

GPIO40/POWER_SHDN 90 In/Out 1V8 GPIO, emergency power shutdown

GPIO2/POWER_MON 6 In/Out 1V8 GPIO or Power monitor (Output) in

Characteristics

Notes

signal (Input) in option. In

emergency powershutdown mode,

1 kOhm PU needed, pin should be

forced low level to trigger

emergency shutdown procedure.

Note that this feature is currently

not available.

option.POWER_MON is high right

after POWER_ON, then remains

high until shutdown procedure is

completed. Module can be safely

electrically power off as soon as

POWER_MON goes low. Note that

this feature is currently not

available.

GPIO26/CLK2 91 In/Out 1V8 Optional UART2 CLK (I/O)

alternate function to GPIO. See

Section UART2 Interface.

GPIO21 95 In/Out 1V8

GPIO23 93 In/Out 1V8

GPIO29/32KHZ_CLK_OUT 103 In/Out 1V8 Optional 32 kHz (Output)

GPIO42/SAR_DETECT 105 In/Out 1V8 GPIO, SAR detection signal (Input,

active low) in option. In this SAR

detection mode, 1 kOhm PU

needed. Note that this feature is

currently not available.

3.6.2 Software Configurable Options

Note: The content of this section will be provided in a future revision of

the document.

22 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 32

PCB Layout Rules

4

This section provides general good practices in defining a PCB layout.

4.1 Placement

It is good to perform the placement of all the major components blocks before

routing any section of the PCB design. The considerations here are:

• VZM20Q module

•RF interface

Initial placement of these parts allows assessment of the PCB floor plan usage

and avoids any significant changes to final routed areas of the design if a

placement issue is found. This also provides an opportunity for Sequans to

review the placement.

The following information presents considerations when performing this

placement:

1. Keep them in a similar quadrant to interface they connect to.

2. Consider orientation to avoid crossing traces when routing

3. Keep them as close as possible to the VZM20Q module where possible.

Note: You can consider keeping 4mm from the perimeter of the module

for component placement to allow possible update of alternative

Sequans' module solution such as US130Q.

MODULE INTEGRATION GUIDE PROPRIETARY 23

SEQUANS Communications

Page 33

PCB LAYOUT RULES

TRACE CHARACTERISTIC DESIGN

4.2 Trace Characteristic Design

This section explains some standard design rules when considering different

types of signals involved (digital, power supply, RF).

4.2.1 Digital Traces

1. Careful and logical placement of digital signals are required to ensure separation of digital interference between each other and unrelated traces.

2. Consider the flow of ground currents during routing. Make sure that the

grounding surrounding the traces (from source to load) remains continuous, with no cut or breaks. This will avoid long convoluted ground return

currents which can create EMI-type problems.

3. Ensure the steps provided in Section Controlled Impedance Traces are

taken into account for digital traces requiring specific impedance.

4. For those with no impedance requirements, be practical with the trace

thickness. Keep them thin to avoid a buildup of capacitance, but make sure

they are suitable to manufacture.

5. If routing traces on alternate layers, avoid paralleling them and keep them

orthogonal. Good practice is to run traces on alternative layer from vertical

to horizontal and so forth. This avoid traces directly coupling.

6. Important recommendation related to SIM connector placement can be

found in Section 3.2.2 Other Hardware Considerations on page 9.

4.2.2 Power Supply Traces

1. Size the power supply traces appropriately for low impedance source. Pay

attention to the number of vias used when routing traces across multiple

layers. This is especially true for high current signals such as PA supply

voltage.

2. For each power supply output, the decoupling capacitors ground pad must

be connected to ground return of the power supply source.

3. Make sure that the digital traces remain well away from the power supply

traces.

4. Appropriate dimensioning of the width and length of each supply track

and the number of any interlayer connecting vias is needed to minimize the

resistive losses in each supply track.

24 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 34

4.2.3 RF Traces

1. Avoid burying these traces as much as possible, because it increases RF

losses compared with routing on the top.

2. Keep as short as possible to help reduce RF losses.

3. Design the impedance of the trace keeping in mind that the footprint of the

RF components should be of similar width. This help avoid impedance

discontinuities.

4. Ensure the steps provided in Section Controlled Impedance Traces are

taken into account when making the trace width.

4.2.4 Controlled Impedance Traces

• Calculation of traces width and spacing:

Use simple RF design tools to calculate the copper trace thicknesses based

upon:

PCB LAYOUT RULES

TRACE CHARACTERISTIC DESIGN

a) Thickness of the dielectric substrate that is used between the RF copper

trace and the ground plane

b) Spacing between the copper trace and the adjacent ground plane (on

the same layer)

c) Dielectric constant of the substrate material being used for manufac-

ture. It happens that the required trace width is impossible to manufacture. It must be reconsidered until feasible. In this case, consider

implementation of one of the following:

- Thicker substrate

- Moving the ground plane reference to the next layer down by

removing the ground plane under the transmission line of interest

• General good practice guidelines

a) Careful placement is required to keep RF traces short and kink-free.

b) Do not route RF traces on intermediate layers.

c) Ground planes beneath RF traces should be continuous.

d) The ground fill around RF traces should have sufficient clearance to

maintain the desired impedance.

• RF matching component footprints

Depending on the substrate thickness and the size of the components pads

used can deviate the desired transmission impedance from the wanted

(nominally 50 Ohm).

For RF devices, if any copper pad in relation to RF signals is significantly

larger than the transmission line width, then the ground reference could be

moved to the next layer down.

MODULE INTEGRATION GUIDE PROPRIETARY 25

SEQUANS Communications

Page 35

PCB LAYOUT RULES

TRACE CHARACTERISTIC DESIGN

4.2.5 Grounding

1. Stitch ground areas together with vias where flooded ground remains

unterminated.

2. Stitch ground areas together in general to keep common ground impedance the same across the region.

3. RF ground planes should be as large and continuous as possible and not be

cut into small islands. Check that strings of vias do not inadvertently create

slots in ground or power planes.

26 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 36

Bring-Up and Testing

5

5.1 Introduction

The purpose of this chapter is to describe what has to be done for board

bring-up, test and qualification.

The expectations at this stage of the product’s life are:

1. Consider any inconsistent and potentially hazardous manufacturing faults

to be eliminated.

2. Confirm that it is safe to proceed to further detailed calibration and

measurement steps.

3. Evaluate board performances.

5.2 Prerequisites

The following lists the necessary tools to perform all aspects of the Hardware

Qualification.

1. Device under test

a) Without VZM20Q assembled:

- to check RF extra loss between the VZM20Q RF ports and product RF

output

- to perform sanity check of connection with VZM20Q

- for debugging if necessary

b) With VZM20Q assembled: to do hardware qualification

2. External Host PC / Laptop for UART interface

Note: Detailed information will be provided in a future revision of

this document.

MODULE INTEGRATION GUIDE PROPRIETARY 27

SEQUANS Communications

Page 37

BRING-UP AND TESTING

FUNCTIONAL VERIFICATION WITHOUT ASSEMBLED MODULE

3. LTE RF test equipments Setup

a) Shielding box to avoid any RF performances results degradation due to

environment

b) RF components such as: cable, splitter, 50 Ohm loads corresponding to

the RF working band

4. Power supply with current measuring ability

5.3 Functional Verification without Assembled Module

Attention: If a fault is discovered, consider the impact of the issue observed

on all the manufactured samples.

The purpose of this section is to establish a sanity check of the board before

soldering the module, in order to avoid any damage due to a manufacturing

issue.

This test covers VBAT power supply.

5.3.1 Power Supply

5.3.1.1 Test Procedure

Figure 5-1 presents the equipment necessary to perform the next following

test steps and the required configuration for test.

Figure 5-1: Pre-Test Configuration (No Module on Board)

28 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 38

BRING-UP AND TESTING

dW

ϭsϴ

sDϮϬY

ϬZ

ϬZ

ϬZ

sϭͺW

sϮͺW

sdϭ

sd

dW

dW

dW

'E

ϬZ

ϯsϬ

FUNCTIONAL VERIFICATION WITHOUT ASSEMBLED MODULE

• Test voltage values

Test the DC nature of the voltage with an oscilloscope before connecting

the DUT. Once the DC source is confirmed, you can power the DUT and

measure accurately the test points voltage with a multimeter. At this stage,

only VBAT1 can be tested.

Check at each voltage test point, as illustrated on Figure 5-2, that the

voltage value corresponds to what is expected. The values must be in the

range specified in the VZM20Q Datasheet, section Electrical Operating Condi-

tions.

Figure 5-2: Measuring Voltage Value (VZM20Q)

5.3.1.2 Troubleshooting

• One power supply is incorrect

– If the voltage is zero for one or more supply outputs

- Check any resistor link to detect unexpected shunts or open circuits.

– If the voltage is incorrect for one of more supply outputs

- Check any resistor link to detect unexpected shunts or open circuits.

MODULE INTEGRATION GUIDE PROPRIETARY 29

SEQUANS Communications

Page 39

BRING-UP AND TESTING

FUNCTIONAL VERIFICATION WITHOUT ASSEMBLED MODULE

5.3.2 RF Path

5.3.2.1 Test Procedure

Important: Those tests should be run or supervised by engineers with RF

measurement preparation and test experience.

• RF path check

To avoid any issue on RF extra path (from the VZM20Q module antenna

output to the board antenna connector), the purpose of this part is to check

its integrity. It corresponds to losses between VZM20Q pin 54 and/or pin

44 and the antenna ports of the board.

Figure 5-3 provides an overview of the equipment configuration for this

test. The connection to the block RF is a connection to the VZM20Q pin 54,

using an RF soldered coaxial probe and RF cable connected to the SMA RF

connector.

Figure 5-3: RF Path Check Setup

a) Measure and record the insertion loss on LTE band 4 and LTE band 13

for the first antenna from pin 54 of the VZM20Q to LTE port antenna

b) By design, the extra RF path loss must be lower than 0.5 dB, to assume

having good RF performances.

5.3.2.2 Troubleshooting

• In case of unexpected RF losses

a) Ensure that the assembly of the coaxial connectors are correct :

- No dry joints.

- The right way round.

b) Ensure that the soldered SMA is not short circuit or open circuit

- Test with digital voltmeter.

c) Verify the RF equipment calibration, including coaxial cable used to

connect to the VZM20Q pin and RF cable

d) Verify that the RF matching is good

30 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 40

BRING-UP AND TESTING

FUNCTIONAL VERIFICATION WITH ASSEMBLED MODULE

5.4 Functional Verification with Assembled Module

Attention: If a fault is discovered, consider the impact of the issue observed

on all manufactured samples.

The purpose of this section is to validate the assembly process of the module.

This test covers:

1. VZM20Q pins and features:

a) Power supply

b) UART1 console output during power-up operation

c) SIM Interface

d) GPIOs

2. Nominal power consumption

3. VZM20Q boot

5.4.1 Power Supply

5.4.1.1 Procedure

1. Turn on the device under test in FFH mode.

2. Confirm voltages of the power supplies remain the same before VZM20Q

is assembled.

Caution: If, at this point, the voltages are incorrect, stop immediately

3. Confirm that the current is nominal from the internal power supply

Observe the current drawn and ensure it is in line with the expected one.

a) Expected VZM20Q current with no firmware loaded will be provided

in a future revision of this document.

to diagnose the cause of the issue.

MODULE INTEGRATION GUIDE PROPRIETARY 31

SEQUANS Communications

Page 41

BRING-UP AND TESTING

FUNCTIONAL VERIFICATION WITH ASSEMBLED MODULE

5.4.1.2 Troubleshooting

• Excessive current draw

Check all VZM20Q voltage supplies. Confirm that there is no VZM20Q

supply short circuits. Voltage should read according to the nominal

requirement.

• No current draw or current less than expected

a) Check the external power supply wiring

b) Check for dry joint between VZM20Q pin(s) and the power supply

source.

5.4.2 Confirm Module Power-Up Operation (UART1)

An example of the output on UART1 console is provided below (boot in FFH

mode):

[0000000000] RBGerbil 11.5@26553 '5.0.0.0 [26553]'

[0000000004] Reset cause 'EXT'(real 'EXT' ) (bootWDG :

'0') [rawRst '0x00000001']

[0000000011] regConfig 0xEF317ABF@1

[0000000014] Running sector 0x1C040000

[0000000018] boot: Current flash, timeout 10000, proto thp

[0000000023] FFH forced.

[0000000025] boot: Switched to uart1, timeout 60000, proto

at

[0000000031] uart: using uart1 with baudrate 921600

[0000000035] [AT] Info: Forcing baudrate to 115200 for AT

negociation

32 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 42

5.4.3 GPIOs

5.4.3.1 Procedure

This section helps to confirm a GPIO’s behavior.

Use the mTools command AT+SMGT.

The first 32-bits triplet of parameters is a bitmask to address the GPIO, the

second 32-bits triplet of parameters is the bitmask of the value to drive on the

GPIO, and the third 32-bits triplet provides the expected polarity setting for

the GPIO. Refer to mTools Reference Manual for more detail on this command.

The following command tests SQN3330_GPIO_22 (GPIO[22]) setting to 1,

active high. Value 22 is represented by bitmask 0x400000, coded as triplet

0,0,0x400000.

AT+SMGT=0,0,0x400000,0,0,0x400000,0,0,0

The following command tests SQN3330_GPIO_38 (GPIO[38]) setting to 1,

active low. Value 38 is represented by bitmask 0x4000000000, coded as

triplet 0,0x40,0.

AT+SMGT=0,0x40,0,0,0x40,0,0,0x40,0

BRING-UP AND TESTING

FUNCTIONAL VERIFICATION WITH ASSEMBLED MODULE

Test the expected behavior as needed by your implementation.

5.4.3.2 Troubleshooting

• Unexpected AT command error

Make sure that the version of Firmware used is the correct version.

• Unexpected GPIO behavior

– Ensure that there exists no short or open circuit between the test point

and the VZM20Q.

MODULE INTEGRATION GUIDE PROPRIETARY 33

SEQUANS Communications

Page 43

BRING-UP AND TESTING

FUNCTIONAL VERIFICATION WITH ASSEMBLED MODULE

5.4.4 SIM Communication

5.4.4.1 Procedure

Confirmation of SIM behavior:

Insert the following command to verify the SIM is working properly.

Send AT commands <AT+SMST?>, as described in mTools Reference Manual.

Response will display +SMST=<status>, where <status> can be:

OK: Test completed with a positive status.

NO SIM: No SIM card was detected.

NOK: Test completed and detected a problem.

5.4.4.2 Troubleshooting

• Unexpected AT command error

Make sure that the version of Firmware used is the correct version.

• Unexpected SIM behavior

– Check all the connections between the SIM housing and the VZM20Q

module are done according to Section 3.2 SIM Interface on page 8.

– Ensure that there exists no short or open circuit between the SIM

housing and the VZM20Q.

34 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 44

5.5 LTE RF Performance Test

sdŽŽů

,ŽƐƚƉƉůŝĐĂƚŝŽŶ

^ĞƋƵĂŶƐĚƌŝǀĞƌ

^ĞƌǀŝĐĞ

ŶĂůLJnjĞƌ

'ĞŶĞƌĂƚŽƌ

^ƉůŝƚƚĞƌ

hd

^ĞƋƵĂŶƐ

DŽĚƵůĞ

hZdϮ

The purpose of this part is to check LTE RF performances of module in

non-signaling mode. This test allows validation of TX and RX path using

mTools firmware. For this part, the board has to be used in FFH mode.

5.5.1 Test Configuration

The test configuration is as follows:

BRING-UP AND TESTING

LTE RF PERFORMANCE TEST

Figure 5-4: RF Performance Test Configuration

1. VZM20Q UART2 connection routed to an External PC/Laptop running:

a) VZM20Q mTools firmware (already validated with Sequans Reference

DUT)

b) Sequans DVTool (already validated with LTE RF test Equipment)

2. RF connection via coaxial cable to the coaxial test points of the VZM20Q

and LTE RF Test Equipment

3. The board is configured in FFH mode by configuring FFF_FFH level.

MODULE INTEGRATION GUIDE PROPRIETARY 35

SEQUANS Communications

Page 45

BRING-UP AND TESTING

LTE RF PERFORMANCE TEST

5.5.2 Procedure

1. Apply the power from the local Host to the VZM20Q.

2. Launch DVTool on UART2. Guidelines for using DVTool can be found in

document 4G-EZ DV Tool User Manual.

a) Ensure that the external RF losses from VZM20Q to MXA / MXG are

b) Perform the Rx and TX Screening

3. Change DV Tool configuration so as to perform Rx test in each band at

mid-frequency and mid input level (typically -60 dBm), and check the

usual criteria on RSRP and CINR for RX.

Notes:

• DVTool contains a board suite of RF test tools to help validate the RF

performance against the 3GPP test specification. It is highly recommended

that once the screening is validated a full DVTool test campaign is

performed for both RF bands. This should include releasing such results to

Sequans for qualification.

configured into DVTool

• Final product pre-conformance test at a reputable test facility to test standards TS 36.521-1 & 36.521-2 is further recommended in advance of final

conformance test requirements. Releasing results to Sequans for checking

is also highly recommended.

5.5.3 Troubleshooting

Note: The most frequent problems that can occur at this stage either can

be solved with recommendations deduced from other sections in

this document, or will be provided in a future edition of this document.

36 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 46

Hardware Test Preparation

A

A.1 RF Interfaces Preparation

A.1.1 LTE RF Test Preparation

Note: The list of the test equipment compatible with the tests is to be

found in Section 1.2 of 4G-EZ DV Tool User Manual.

To ensure that the RF test platform will provide the most reliable interface for

testing. The following setup is proposed when measuring RF characteristics of

the VZM20Q System.

The shield box cavity is configured as shown on Figure A-1:

• The DUT is connected to the computer by UART2.

• The DUT is also connected by one RF cable.

MODULE INTEGRATION GUIDE PROPRIETARY 37

SEQUANS Communications

Page 47

RF INTERFACES PREPARATION

Figure A-1: Shield Box Cavity View

Figure A-2 shows the required configuration for calibration and screening. It

consists of:

• 1 x ZN2PD2-50-S + power splitter if the signal analyzer and the signal

generator are two distinct equipments. R&S® CMW500 for instance allows

the use of a single bidirectional RF port and prevents the need of a power

splitter.

• 1 x RF cable to the MXA (if needed)

• 1 x RF cable to the MXG (if needed)

• 1 x RF cable to the DUT (in the shield box)

38 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Page 48

Figure A-2: Configuration for Calibration and Screening

RF INTERFACES PREPARATION

MODULE INTEGRATION GUIDE PROPRIETARY 39

SEQUANS Communications

Page 49

Abbreviations

B

AC Alternate Current

ACLR Adjacent Channel Leakage Ratio

LTE_ANT0 Antenna 0 for LTE

AT Command Modem-type commands prefixed with AT characters

ATR Answer To Reset ( S I M )

BOM Bill Of Material

cDRX Connected Discontinuous Reception

CLI Command Line Interface

CMOS Complementary Metal Oxide Semiconductor

COM Communication

CPU Central Processing Unit

CS Chip Select

dB decibel

DC Direct Current

DL Downlink

DRX Discontinuous Reception

DUT Device Under Test

DVM Digital Voltmeter

DV Tool Diagnostic and Validation Tool

EEPROM Electricaly Erasable Programable Read-Only Memory

MODULE INTEGRATION GUIDE PROPRIETARY 40

SEQUANS Communications

Page 50

EM Electromagnetic

EMI Electromagnetic interference

FFF Firmware From Flash module boot mode

FFH Firmware From Host module boot mode

FS File System

FW Firmware

GND Ground

GNSS Global Navigation Satellite System, such as GPS, GLONASS, IRNSS,

BeiDou-2tf, or GALILEO.

GPIO General Purpose Input/Output

GPS Global Positioning System (see GNSS)

HW Hardware

IC Integrated Circuit

IMEI International Mobile Equipment Identity

IT Interrupt

LNA Low-Noise Amplifier

LTE

Long-Term Evolution. See also

www.3gpp.org/.

MAC Medium Access Control protocol layer

MII Medim Independant Interface

MIO Multiple Input/Output

MXA Signal Analyzer

MXG Signal Generator

NIE Sequans’ internal format for data representation

OBB Opaque Binary Blob file format

PA Power amplifier

PC Personal Computer

PCB Printed Circuit Board

MODULE INTEGRATION GUIDE PROPRIETARY 41

SEQUANS Communications

Page 51

PMIC Power Management Integrated Circuit

PPS Protocol and Parameters Selection (SIM)

PS Power Supply

PS-P Power supply state. See section Operating Modes.

PS-PA Power supply state. See section Operating Modes.

PSI Platform Specification Interface

R Short notation for Ohm

RF Radio Frequency

RFIC Radio Frequency Integrated Circuit

RX Reception

S/N Serial Number

SIM Subscriber Identity Module

SMA RF connector type

SMD Storage Module Device

SPI Serial Peripheral Interface

SW Software

TX Transmission or Emission

UART Universal Asynchronous Receiver Transmitter

UE User Equipment

UL Uplink

USB Universal Serial Bus

USIM Universal SIM.

WP Write Protect

42 PROPRIETARY MODULE INTEGRATION GUIDE

SEQUANS Communications

Loading...

Loading...