Seppi MIDIPIERRE, MULTIFORST, MIDISOIL dt, MIDIPIERRE dt, MAXISOIL Operating And Maintenance Manual

...

1

DEUTSCHESPAÑOL ITALIANO ENGLISHFRANCIS

OPERATING AND MAINTENANCE MANUAL

STONE CRUSHERS & FORESTRY TILLERS

MIDIPIERRE, MIDIPIERRE dt, MIDISOIL dt, MULTIFORST, STARSOIL, SUPERSOIL, MAXISOIL

ENGLISH

MIDIPIERRE

STARSOIL SUPERSOIL MAXISOIL

MIDIPIERRE dt MIDISOIL dt MULTIFORST

2

Overall view

hood opening cylinders

hood

compacting roller or

grader blade

(optionals)

gearbox

3-point linkage

PTO shafts or

extensions

skids

gearboxes

or belts

3

DEUTSCHESPAÑOL ITALIANO ENGLISHFRANCIS

TABLE OF CONTENTS

Machine identification data

AttachmentsIntroduction

Congratulations on your choice! For over 75 years the

goal of SEPPI M. S.p.A. has been to guarantee high

quality products which will have a long working life,

and manufacture them to meet customers' requirements.

In manufacturing its machines, SEPPI M. S.p.A.

uses the best materials and technology. However, to

make the most of the designers’ best efforts to make

functional, reliable machines with valid safety devices,

you must read carefully the instructions in this user’s

manual and in the safety instructions (an integral part

of the manual). When the machine is treated and kept

with care, it limits all types of problems and saves you

time and money.

In case this information is insufficient, our staff and

your dealer will always be available for any further

clarification.

PLEASE CAREFULLY READ THE PRESENT MANUAL, THE USER'S MANUAL OF THE PTO SHAFT AND

RULES FOR THE USE OF

SHAFT CONES.

THE PRESENT MANUAL MUST BE KEPT TOGETHER

WITH THE USER'S MANUAL OF THE PTO SHAFT AND

THE RULES FOR THE USE OF SHAFT CONES.

- EC declaration of conformity

- Use and maintenance manual of PTO shaft

(if supplied upon request)

- Rules for the use of shaft cones

- Spare parts list

- Technical commercial documentation

This manual contains all functional, technical characteristics and performance features for the machine

regarding it’s “intended – expected use”. It also contains all operating and maintenance instructions. This

manual has been written for:

- operators responsible for transport and handling

- operators using the machine

- maintenance personnel.

A person must be responsible for keeping the documentation provided with the machine in a suitable

place so that it is always in good condition and available for consultation.

If this manual is lost or deteriorated, request a

replacement copy from the manufacturer; always indicate the serial number (indicated in the manual) when

making your request.

NOTE: the manufacturer must be promptly notified of

any changes to the site of destination and/or ownership or location of the machine

.

1. PRELIMINARY INFORMATION

1.1 Symbols: meaning and use 4

1.2 Collaboration with the user 4

1.3 Compliance with standards 4

1.4 Manufacturer's responsibility and warranty 4

2. SAFETY AND ACCIDENT PREVENTION

2.1 Operator qualification 5

2.2

Introduction to safety at work

5

2.3 Safety rules and residual risks 5

2.4 Stickers and safety labelling 9

3. TECHNICAL INFORMATION

3.1 Intended use 10

3.2 Models 10

3.3 Safety devices 11

3.4 Technical data

4. HANDLING AND COMMISSIONING

4.1 Handling, lifting and unloading 12

4.2 Commissioning 12

4.3 Adjustments 15

5. OPERATION AND USE

5.1 Checks prior to work 16

5.2 Tractor selection 16

5.3 Starting the cooling system 17

5.4 Start-up and processing 17

5.5 Safety distances 18

6. MAINTENANCE

6.1 Belt tension check and adjustment 18

6.2 Lubrication 19

6.3 Oil leaks 20

6.4 Safety devices and information 20

6.5 Replacing tools 20

6.6 Replacing anti-wear frame 22

6.7 Checking screws 22

6.8 Troubleshooting 22

6.9 Disabling 23

7 SPARE PARTS 23

8 CONTROL REGISTER 23

9 DISMANTLING, SCRAPPING AND WASTE

DISPOSAL

23

“CE” marking: affixed to machine structure

To fill out upon delivery of the machine:

Manufacturer: SEPPI M. S.p.A.

Zona Artigianale 1

39052 CALDARO (BZ) –

ITALY

Manual code: Stone crusher Rev 2 of

1.09.2014

Machine:

Model:

Serial number:

Year of manufacture:

4

1. PRELIMINARY INFORMATION

This manual introduces to the use of the following

models of stone crushers: MIDIPIERRE, MIDIPIERRE dt, MIDISOIL dt, MULTIFORST, STARSOIL,

SUPERSOIL, MAXISOIL.

The list is not binding as it can also be used for

other models (given the type of machine, operating modes and adjustments are almost identical).

Models with a different type of adjustment are

noted separately. The models are listed according

to their size (or power required to be driven).

It also contains all the essential

instructions for safety and adjustments,

maintenance and troubleshooting.

Directive 2006/42/EC

EN ISO 12100 Safety of machinery

- Basic concepts, general principles for design

- Technical principles and specifications

EN ISO 4413 Safety of machinery

- Hydraulic fluid power. General rules and safety

requirements for systems and their components

EN ISO 4254-1 Agricultural, forestry, landscaping and garden machinery

- Common safety requirements

- Part 1: agricultural self-propelled, mounted,

semi-mounted and trailed machines

EN ISO 4254-5 Agricultural machinery

- Power-driven soil-working machines

- Safety

Danger

Indicates a danger with the

risk of injury, even serious.

Failure to comply with the

instructions marked with this

symbol can lead to a situation

of serious danger for the

safety of the operator and/or

of exposed persons!

Strictly abide by that indi-

cated!

Caution

Represents a warning to pay

attention to possible deterioration of the machine or to

another personal object of

the operator.

Important warning to which

you must pay the utmost

attention!

Warning

Indicates a warning regard-

ing key functions or

useful information.

The warranty does not apply in case of any type

of direct or indirect breakage or accidents to

the appliance and/or objects and/or persons not

attributable to defects already present when

placed on the market and which were not easily

recognisable by the user.

In this manual, some symbols are used to draw

the reader’s attention and to emphasise some

particularly important aspects.

The manual reflects the state of the art at the

moment the machine was placed on the market.

If the manufacturer deems it timely to send the

user an addition to the manual, this document

must be kept on hand with the manual.

Contact the manufacturer for further information

and also if you have any suggestions for improvement which could help make the present manual

better meet user's needs.

If the first owner transfers the machine, he

should inform the manufacturer about the address of the new owner so that

he can receive notifications and/or essential

updates.

1.1 Symbols: meaning and use

1.2 Collaboration with the user

1.3 Compliance with standards

1.4 Manufacturer's responsibility and warranty

The machine was designed and built in compliance with the safety-related standards of industrial machinery in force when placed on the market.

In particular, the following legislative stand-

The customer is the holder of rights according to applicable national legislation governing the sale of goods.

This warranty does not place these rights in jeopardy

should they be more extensive than that indicated here.

ards and harmonised standards were taken into

account:

5

DEUTSCHESPAÑOL ITALIANO ENGLISHFRANCIS

2. SAFETY AND ACCIDENT PREVENTION

The warranty never covers maintenance service

expenses unless foreseen in the contract (scheduled assistance, good operation warranty, etc.).

- Improper operations. For example:

failure to comply with all the indications contained in this manual. This category includes

problems caused by negligence or errors by the

operator (such as using the machine contrary

to national laws, inadequate maintenance, use

by untrained personnel, failure to comply with

instructions, especially those in the "Safety"

chapter or marked with the "DANGER" symbol,

etc.);

using the machine despite having noticed evident

defects.

- Treatment of unsuitable materials (due to size

and/or type).

- Transport and/or handling.

- Environmental or climatic conditions. For example rain, lightning, freezing, contamination.

- Corrosion and standard wear (which objects such

as hammers, belts, paint, etc. are subject to)

- Modifications or adjustments not specifically

allowed in the manual or without written consent

of the manufacturer.

- Use of non-original spare parts or accessories or

not authorised by the manufacturer.

- use of the machine contrary to national laws;

- failure to comply with the instructions;

- unauthorised changes to the machine;

- use of the machine by untrained or

unfit personnel (see point 2.1);

- Use of different types of spare parts (with different features)

Also remember that, regardless of whether or not

a problem occurs, the warranty becomes null and

void in case of:

Therefore damage caused by the following is not included:

Do not use the appliance before having read or illustrated

the instruction manual. The

attachments are an integral

part of the manual.

2.1 Operator qualification

This appliance was designed to be used by a maximum of one professional operator on the tractor,

guaranteeing the following requirements:

The person in charge of delivery to the end

customer must watch over the tractor hitching

process.

Thereby he must have read the manual before

entrusting the customer with the machine and

understand its contents, also relating to laws of

the country of use, and taking on full responsibility for the operation.

- be older then 18 years of age and in good physical and mental health;

- have a sufficient level of general and technical

knowledge to understand the contents of this

manual, to correctly interpret diagrams and

pictograms and to perform the allowed maintenance;

- know this manual and its attachments, especially

regarding safety information;

- know the main technological, hygienic and

accident prevention standards and, if foreseen

by law, periodically attend training courses on

specific risks;

- know the risks and what to do in case of emergencies, where to find the personal protective

equipment and how to use it correctly;

- be sensitive to safety-related issues, promptly

reporting any failures.

2.2 Introduction to safety at work

2.3 Safety rules and residual risks

Safety was the primary objective

when designing the machine; nonetheless operators' carelessness can invalidate the efforts of the

designers.

The machine was designed and built with the

intention of eliminating as many risks as possible

for the user.

However, considering the variability of the situations as well as foreseeable misuse, there are

residual risks which cannot be eliminated, either

for functional purposes or because they do not

depend directly on the machine.

Information on residual risks is aimed at guaranteeing that the user take the protective measures

which, for example, can include adopting safe

work procedures, restricting tasks to trained and

authorised operators, etc.

We shall describe some of these risks, highlighting some, and not necessarily all, important recommendations for each one: further recommendations (or these) are included in other chapters,

either general or related to a specific operation.

Thereby SEPPI M. S.p.A. will not be held liable in

case of:

6

Always - reduce speed or interrupt work whenever gripping to the ground is reduced (strong slope, presence of mud, snow, etc.). Pay the utmost attention when changing direction on slopes or slippery ground.

Always - be extremely cautious when the work area is not completely visible (inspect the area before working). Only work with natural light and good visibility.

Always - check that the weight which the tractor can lift is compatible with that of the equipment. Conduct tests to check the driving stability of the tractor. With the

machine connected and lifted from the ground at least 20% of the weight of the tractor must rest on the front axle or, for machines mounted at the side, 10% on each

wheel on the side opposite the stone crusher.

Always - before detaching machine from the tractor, engage the parking brake and make sure the tool is stable.

Always - make sure that passages on roads, through gates, etc. are sufficiently wide so that the tractor with the applied tool can pass.

1)

Risk of losing adherence (with the possibility of the tractor rolling over)

To reduce the likelihood of risk to a minimum, strictly follow these instructions:

Never - abandon the tractor's driver seat and approach the machine before the blade holder rotor is stopped and the tractor stopped in safe conditions. Caution! The

rotor can continue to rotate for 5 minutes after the PTO has stopped due to inertia.

Never - work with the protections of the transmissions not intact or not in perfect working order. Immediately restore all protections and safety devices when damaged

or worn (stone guards, PTO shaft protection, etc.).

Always - prevent third parties from approaching the machine while running or when the tractor is moving.

Always - disengage the PTO and stop the engine, removing the key from the dashboard before performing any adjustment or maintenance.

3)

Risk of conveying due to pulleys, belts or chains

To reduce the likelihood of risk to a minimum, strictly follow these instructions:

Never - abandon the tractor's driver seat and approach the machine before the blade holder rotor is stopped and the tractor stopped in safe conditions. Caution! The

rotor can continue to rotate for 5 minutes after the PTO has stopped due to inertia.

Always - prevent third parties from approaching the machine while running or when the tractor is moving.

Always - disengage the PTO and stop the engine, removing the key from the dashboard before performing any adjustment or maintenance.

Always - check that the PTO shaft is mounted correctly (safety pin in its seat); appropriate protections on PTO shaft, tool side and tractor side; free wheel device mount-

ed on the tool side (see PTO shaft safety manual).

2)

Risk of conveying due to rotary shafts

To reduce the likelihood of risk to a minimum, strictly follow these instructions:

Never - transit or stop in front of machines in motion and/or with rotor running.

Always - disengage the PTO, close the hood, stop the engine, and remove the key from the dashboard before performing any adjustment or maintenance.

4)

Risk of crushing or shearing limbs between moving parts

To reduce the likelihood of risk to a minimum, strictly follow these instructions:

7

DEUTSCHESPAÑOL ITALIANO ENGLISHFRANCIS

Never - use the machine to mulch pieces of metal (iron wire, etc.) or non-vegetal material (risk of injury, pollution, intoxication, etc.) or work against unknown obstacles

without first having inspected the area to identify their nature.

Never - start the machine with the 3-point linkage lifted and the machine beyond 10 cm above the ground.

Never - keep the PTO engaged during transport or transfer.

Never - work with the protections of the transmissions not intact or not in perfect working order.

Never - work without suitable personal protective equipment: gloves, protective goggles, work suits and, if necessary, mask for the respiratory tract.

Never - abandon the tractor's driver seat and approach the machine before the blade holder rotor is stopped and the tractor stopped in safe conditions. Caution! The

rotor can continue to rotate for 5 minutes after the PTO has stopped due to inertia.

Always - inspect the ground and remove foreign material before working (steel and metal cables, other dangerous materials such as glass, powders and liquids in

containers, etc.)

Always - prevent third parties from approaching the machine while running or when the tractor is moving. The operator must always guarantee a safety distance even

towards houses, roads or animals.

Always - on roads or in public areas, use the danger/work in progress signs foreseen by standards in force, placing them at a sufficient distance from the machine.

5)

Risk of injury due to ejection of objects

To reduce the likelihood of risk to a minimum, strictly follow these instructions:

Never - work underneath the lifted machine without adequate safety supports.

Never - transit or pass or stop in front of machines in motion and/or with rotor running.

Never - use the machine to fell trees without mounting a guard frame, available as an option, as the trees could fall on the tractor.

Never - allow children to play near the tool.

Always - on roads or in public areas, use the danger/work in progress signs foreseen by standards in force, placing them at a sufficient distance from the machine.

Always - make sure there are no persons or obstacles before making manoeuvres.

7)

Risk of impact, crushing or falling

To reduce the likelihood of risk to a minimum, strictly follow these instructions:

Never - work without suitable personal protective equipment: gloves, protective goggles, work suit.

Never - check for oil leaks with bare hands, but always use a sheet of paper.

Never - disconnect quick or fixed couplings of pressurised pipes before having switched the tractor off and discharged the pipes by activating the tractor distributors

with the engine off and the appliance on the ground.

6)

Risk of injury by pressurised fluids

To reduce the likelihood of risk to a minimum, strictly follow these instructions:

8

Never - use the machine without knowing its technical features and without supervision by qualified personnel.

Never - use the machine with the tractor's PTO speed different than that recommended and/or indicated on the machine.

Never - work beyond the PTO shaft limit angles indicated by the manufacturer of the PTO shaft (see PTO shaft manual).

Never - continue working despite foreign material stuck on the blade holder rotor (such as iron wire, nylon, twine, etc.).

Never - use the machine to mulch pieces of metal (iron wire, etc.) or non-vegetal material (risk of injury, pollution, intoxication, etc.) or work against unknown obstacles

without first having inspected the area to identify their nature.

Never - switch off the engine of the tractor without first having disengaged the PTO.

Never - use the machine with the rotor off-balance. Always restore damaged or lost tools to immediately eliminate dangerous vibrations.

Never - use different types of spare parts as they might not have the required features.

Never - leave the machine outdoors subject to the elements.

Never - use the machine to fell trees without mounting a guard frame, available as an option, as the trees could fall on the tractor.

Always - approach the material to be mulched slowly without causing blows.

Always - check fixing of all parts frequently.

Always - check the state of wear and maintenance. If there are breakage or faults, repair immediately.

Always - adjust the machine appropriately to the type of work in conformity with the manual.

Always - use tractors compliant with the occupational safety regulations and the highway code.

Always - disengage the tractor's PTO in case of imminent danger.

Always - inspect vibrations coming from the tool (ask advice from your nearest dealer).

8)

Risk of breaking the machine with possible danger for persons

To reduce the likelihood of risk to a minimum, strictly follow these instructions:

Never - pour or drip liquids on the ground (oil, etc.).

Never - release parts of the machine into the environment. Hand the material over to authorised companies.

Always - pay attention that hydraulic oil does not penetrate skin. Should this occur, immediately contact a doctor.

Always - when working on uncultivated and potentially contaminated land, use tractors with a cab fit with air filters and with unbreakable guard screens installed.

9)

Risk of pollution or intoxication

To reduce the likelihood of risk to a minimum, strictly follow these instructions:

Never - work without hearing protections as the sound pressure level at the operator's seat can be greater than 85 dB depending on the tractor used.

Always – assess the real personal exposure value together with a technician.

10)

Risk of deafness

To reduce the likelihood of risk to a minimum, strictly follow these instructions:

9

DEUTSCHESPAÑOL ITALIANO ENGLISHFRANCIS

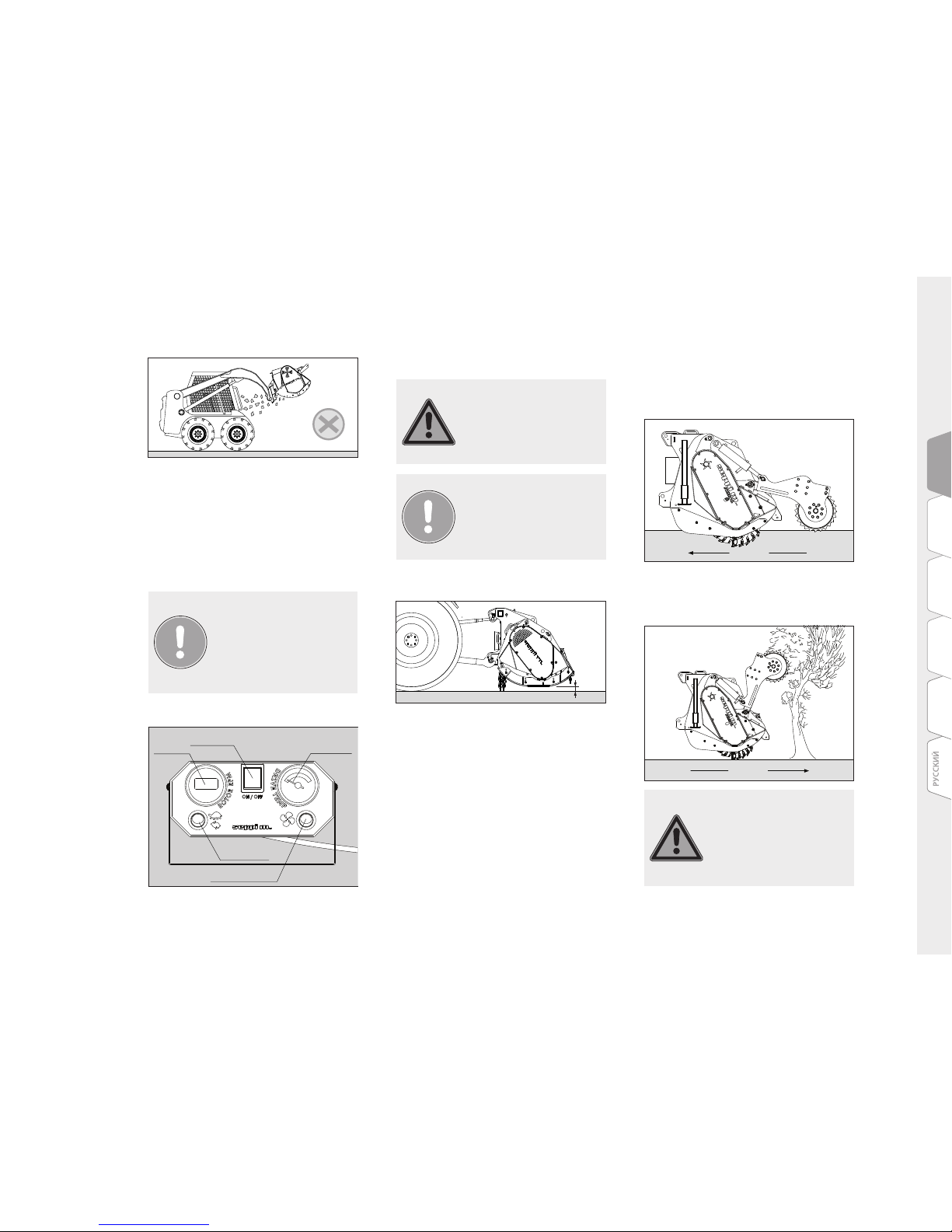

Risk of injury due to ejection

of objects. Keep a safety

distance from the machine.

Applied to the frame, well

visible from a distance.

2.4 Stickers and safety labelling

The safety pictograms used on the machine comply with the standard ISO 11684 (“Tractors

and machinery for agriculture and forestry,

powered lawn and garden equipment - General

principles for safety signs and hazard pictorials”).

All the indications provided must be respected

completely to prevent risky situations from turning

into danger, causing

severe injuries to the operator and/or damage to

the surrounding environment (persons, objects

and pets).

Therefore the stickers applied to the machine

regarding Pericolo (Danger), Attenzione (Caution), Nota (Warning), must be replaced immediately if damaged or detached.

Read the use and mainte-

nance manual.

Applied to the casing.

Risk of conveying due to

rotary shafts.

Do not approach rotary parts

of the machine.

Applied to PTO shaft linkage

area.

Risk of crushing, shearing.

Do not stop underneath the

machine or suspended parts

of it.

Applied to the casing, espe-

cially on the hood.

Risk of injury by pressurised

fluids. Do not approach

hydraulic pipelines when

pressurised.

Applied to the frame.

Risk of impact.

Forbidden to stand in danger

zone unprotected, even in

case of maintenance.

Applied to PTO shaft linkage

area.

Forbidden to intervene on

moving parts.

Forbidden to remove pro-

tections.

Applied to the frame.

Risk of conveying due to

pulleys, belts or chains. Do

not approach rotary parts

of the machine before they

have stopped.

Applied to pulley protection

Identification of lifting

points.

Applied close to these

points.

10

3. TECHNICAL INFORMATION

3.1 Intended use

These machines are suitable to crush various sizes of stones, to till the soil in presence of stumps

and to mulch different sizes of shrubs and trees,

in relation

to the power available for driving

the machines and to their constructive

features (see 3.2).

The machines are hitched to a tractor or

operating machine and driven by the PTO,

by means of the PTO shaft or hydraulic

circuit.

To perform this job, the operator must be

prepared and trained and the tractor must be

hooded to protect the frame and cab. All the

structural parts of the drive

machine must be reinforced and adapted to

forestry work which requires sturdy protections

suited to protect the operator.

The tractor driver must therefore check that:

- the driver's cab has safety guaranteed regarding

rolling over and falling objects (FOPS/ROPS);

- the windows are safety windows and/or protected

by protective meshes;

- inlet air is filtered;

- the presence on site is signalled by luminous

signs.

The following are prohibited:

- use by personnel not specialised in agricultural

work and informed by reading the manual;

- use the machine for other reasons than that

intended;

- modify any functional/performance feature;

- modify or remove safety devices and/or protections

3.2 Models

MIDIPIERRE

The smallest of the stone crushers can work with

power outputs from 80 to 130 HP. Depending on

conditions, it can till soil up to 12 cm deep and

crush stones as big as ø 15-20 cm. It can be

equipped with swinging hammers or fixed knives.

It is not suitable to mulch shrubs and trees.

MIDIPIERRE dt

This model of the stone crusher with dual transmission is suitable to work with power outputs

from 100 to 180 HP. Depending on conditions, it

can till soil up to 12 cm deep and crush stones as

big as ø 15-20 cm. It can be equipped with swinging hammers or fixed knives. It is not suitable to

mulch shrubs and trees. With the grader blade, it

is especially used for maintenance of gravel roads.

Mandatory to use PPE.

Applied to the casing

Wear safety shoes

Wear gloves

Wear suitable clothing

Protect hearing

Speed of PTO shaft.

Applied to

PTO shaft linkage area.

11

DEUTSCHESPAÑOL ITALIANO ENGLISHFRANCIS

MIDISOIL dt

The forestry tiller and stone crusher with gear

transmission is suitable for a maximum power

output from 100 to 170 HP. It crushes stones as

big as ø 25 cm, mulches wood up to ø 25 cm and,

thanks to the optional ADAMTM alignment system,

it can till soil as deep as 25 cm.

STARSOIL

The forestry tiller and stone crusher with gear

transmission is suitable for a maximum power

output from 150 to 260 HP. It crushes stones as

big as ø 30 cm, mulches wood up to ø 40 cm and,

thanks to the optional ADAM

TM

alignment system,

it can till soil as deep as 40 cm. A series of optionals make it suitable for all types of jobs.

MAXISOIL

The most powerful of the forestry tillers and stone

crushers can work with power outputs from 300 to

450 HP. It crushes stones as big as ø 50 cm, wood

up to ø 50 cm and reaches a depth of 35 cm. Like

other similar machines, it can be equipped with a

compacting roller.

SUPERSOIL

A forestry tiller and stone crusher suitable for

power outputs from 250 to 390 HP and to till soil in

extremely difficult conditions. It crushes stones as

big as ø 40 cm, wood up to ø 50 cm and tills soil as

deep as 30 cm. Thanks to the anti-wear frame and

the hood with the mulching grille, it can reach fine

granulometry.

MULTIFORST

The forestry mulcher, the forestry tiller and the

multi-purpose stone crusher with dual transmission is suitable to work with power outputs up

from 140 to 180 HP. With PTO at 1000 rpm, it can

mulch wood as large as ø 25 cm. With PTO at 540

rpm, it can crush stones as big as ø 15- 20 cm and

till soil as deep as 25 cm. The compacting roller

(optional) is designed to compact the earth after

being tilled, to level the machine and to keep trees

away from the tractor when being felled.

As specified in the maintenance chapter, the

efficiency of all the safety devices must be verified

periodically.

3.3 Safety devices

These machines have a series of devices and

safety set-ups to reduce the possibility of accidents to a minimum. These include the following:

- openable metal shields to avoid contact with

transmission parts;

- check valve against falling objects;

- Rows of chains against the projection of material.

3.4 Technical data

The technical data are provided in the technical

commercial documentation.

12

horizontal plane

4. HANDLING AND COMMISSIONING

Lift the machine using only the specific hooks

indicated.

NEVER lift the machine from the rotor!

1) Set the machine on a flat plane with a stable

bottom.

5) If applicable, fix the side outriggers of the tractor

4) Adjust the third point so that, when the

machine is flat, the PTO

is parallel to the inlet shaft of the mulcher.

It is not recommended

to use the third hydraulic point

without the ADAM™

alignment system

4.1 Handling, lifting and unloading

4.2.2 Application of the machine with

ADAM™ system

4.2 Commissioning

4.2.1 Applying machine to

tractor's 3-point linkage

2) Connect the hubs of the bottom lifting arms to

the bottom lifting pins (A)

3) Connect the joint of the third point to the pin of

the third point (B)

B

A

90°

PTO //

inlet shaft //

If the machine has the ADAM™ alignment

system, it can be connected as described in the

previous paragraph. Then you must:

1) Check that the tractor side support is suitable

to the tractor in use. The tractor side support

must be mounted so that the position of the

joint pin is at the same height as the PTO

and in the middle between the PTO and

gearbox inlet shaft.

L

joint pin

PTO

inlet shaft

PTO - Pin axis

L/2

13

DEUTSCHESPAÑOL ITALIANO ENGLISHFRANCIS

clamping lever

The tractor side support depends on the tractor itself.

In case the ADAM™ support is

not compatible with your tractor, please contact your SEPPI

M. dealer.

2) Connect the gearbox by means of the

telescopic arm to the tractor side support,

acting on the clamping lever.

3) When raising and lowering the machine, the

gearbox must follow the movement as in the

following graph.

Check the movement limits of the

machine, trying the lowest positions and the highest positions

with all the possible positions of

the third hydraulic point.

The ADAM™ lever mechanism

must never reach the limit

switch, slip off or collide with

parts of the frame

A

A > 100 mm

It is recommended to use the original SEPPI M.

PTO shaft for each model. It is not required to

use PTO shafts with clutch or torque limiter if not

expressly indicated.

1) Adjust the length of the PTO shaft as needed,

first by measuring all possible lengths and then

moving the bottom lift and the hydraulic third

point (if applicable).

4.2.3 Applying the PTO shaft

A

B

A

A>10 cm

A<10 cm

B<1 cm

The PTO shaft must always

sufficiently overlap all positions and never be flush!

L max / min

2) Check that the PTO shaft works properly:

a. WITHOUT alignment system or WITH EVA align-

ment system

If the PTO shaft becomes too

short, it is recommended to

mount the ADAM™ system.

= >max15˚

= >max15˚

B

A

14

Function Hydraulic

hood

Compacting

roller or

grader blade

MIDIPIERRE 6-10 l/min /

MIDIPIERRE dt 6-10 l/min 6 -10 /min

2 -3 l/min

MIDISOIL dt 6-10 l/min 6-10 l/min

MULTIFORST 10-14 l/min 25 -35 l/min

STARSOIL 10-14 l/min 25 -35 l/min

SUPERSOIL 10-14 l/min 25 -35 l/min

MAXISOIL 10-14 l/min 70 -95 l/min

Voltage 12V

Fuse 16A

If they do not work in the

described positions, the PTO

shaft and all the transmission

components wear prematurely.

The product warranty becomes

null and void.

Read the PTO shaft

manual!

2) Check movements of the hydraulic functions and

if necessary adjust at the following flow rates:

b. WITH ADAM™ alignment system

1) Connect a pair of hydraulic pipes marked with

the same colour to the tractor inlets by means of

quick couplings.

4.2.4 Connection of hydraulic quick couplings

for auxiliary functions

same colour

=

=

≠

If the tractor does not have a suitable socket,

connect the wires to another electricity source

according to the following indications.

On some models, the cooling system of the

transmission is electric.

4.2.5 Connection of electrical sockets

Position the control panel in the cab and fix it

properly.

Connect the three-pole electrical power connector to the tractor's socket.

not connected

15

DEUTSCHESPAÑOL ITALIANO ENGLISHFRANCIS

Only work with the hood open

when absolutely necessary!

The grader blade has the following functions:

1) Compacting the soil

2) Evenly distributing the material

3) Levelling the soil

- Lift the grader blade when transporting the

machine.

- Lower the blade during use.

- Push the blade down to increase compacting

pressure (indicated on the pressure gauge).

- Adjust inclination of the blade to move material

to the right or left.

- When the machine is parked, the grader blade

must rest on the ground.

4.3.5 Adjusting grader blade

Brown +12V

Blue GND

1) Check the features of the hydraulic motors and

valve blocks in the attached guide, if the machine

is supplied with them.

2) Follow the installation and commissioning instructions in the attached guide.

4.2.6 Connecting a hydraulically driven

machine

Connecting wires:

If the machine is equipped with one or more support stands, they must be closed during work.

1) Open the hood to expose the rotor, to fell trees

and to reduce power output

2) Close the hood to improve the degree of mulching

4.2.7 Support stand

4.3.2 Adjusting hydraulic hood

1) See points 4.2.1

4.3 Adjustments

4.3.1 Adjusting 3-point-linkage

manually or hydraulic

If the machine has support skids or adjustable

conveying skids, proceed as follows:

1) Lift the skids to bring the rotor close to the

ground

2) Lower the skids to move the rotor away from the

ground

The roller has the following functions:

1) Levelling the machine

2) Compacting the soil

3) Guard frame to push trees and shrubs

4.3.3 Adjusting support skids

4.3.4 Adjusting compacting roller

Some models are supplied with

non-adjustable anti-wear skids

as standard.

BAR PSI

BAR PSI

16

If the machine has hydropneumatic suspension

(nitrogen accumulator) for the compacting roller

or grader blade, it can be activated or deactivated

by acting on the valve mounted on the line.

- Close the valve to deactivate the suspension.

- Open the valve to activate the suspension.

4.3.6 Adjusting hydropneumatic suspension

of roller or blade

ON OFF

Bring the anvil close to the rotor to improve

mulching or move it away to reduce the power

output.

Adjust the anvil as follows:

1) loosen the screws fastening the anvil,

2) adjust the distance of the anvil with the adjust

-

ment screws on the frame,

3) check the distance of the anvil from the rotor,

4) tighten the screws blocking the anvil.

1) Presence and integrity of all stickers indicated

in chapter 2

2) Integrity of front protection (row of chains)

3) Conditions of PTO protection (tractor - tool)

4) Conditions of PTO shaft protection

4.3.7 Adjusting anvil

5.1 Checks prior to work

5.2 Tractor selection:

5. OPERATION AND USE

The operator must know the

features of the machine and be

capable of using it properly.

The operator must prohibit

anyone from approaching and

using it. It must never be left

unattended while running or

be climbed on.

Do not work in positions where

the mulcher rotor can cast

objects towards the cab or other parts of the tractor causing

damage or personal injury.

5) Are the protections on the tractor intact and

operational?

6) Are the pins for the three-point linkage

blocked?

7)

Integrity of the belt protections

8)

Integrity of protections around tools

9)

Integrity of safety valves

10) Check tractor stability with possible weighing

of the train.

Tractors can be used with the following features:

- super-reduced gears or continuously variable

transmission with minimum speed no higher

than 0.3 km/h

- Forestry tyres

- Cab safe according to ROPS/FOPS standard

5.2.1 Farming or forestry tractors

Tractors can be used with the following features:

- Hydraulic system capable of driving a stone

crusher according to specifications in the technical

commercial documentation.

- Cab safe according to ROPS/FOPS standard

5.2.2 Tractor with hydrostatic drive, earth

moving equipment

1

1

3

2

17

DEUTSCHESPAÑOL ITALIANO ENGLISHFRANCIS

Before starting to work with

the stone crusher, inspect its

designated work area.

- Lift the machine a few cm so that the rotor does

not touch the ground

- Take care to correctly angle the PTO shaft according to the indications in chapter 4.2.3

- Start the tractor PTO at moderate speed,

selecting the speed prescribed for the mulcher

(540 or 1000 rpm). In case of hydraulically driven

machine, feed the pump/s.

- Increase engine speed to gradually reach the

nominal rpm (540 or 1000 rpm)

- Lower the machine to the desired depth by acting

on the tractor lift or on the position of the compacting roller.

- Advance by pulling the machine (normally in

forward gear) to till the soil and to crush the

- Turn off the main switch when work is over to

avoid discharging the battery.

- Connect the system following the instructions in

point 4.2.5.

- Turn on the main switch. The switch lights up.

- Turn on the fan switch. The switch lights up.

- Check operation of the thermometer and of the

fan.

5.3 Starting cooling system:

If the transmission temperature exceeds 90°, stop the

machine and check the cooling

system. Never work without

the cooling system and temperature sensor running!

The performance capacity of

the machine must NEVER be

exceeded.

5.4 Start-up and processing

min 5 cm

stones or, for forestry work, feed the crusher

with material to be mulched.

- Close the hood to improve mulching.

- Advance by pushing the machine (normally in reverse) to fell the trees. Open the hood and adjust

the compacting roller (4.3.2 and 4.3.4)

main power switch

rev counter

radiator on-off

switch

high-low speed

change

radiator oil

temperature

indicator

Never fell trees more than

twice as high as the forestry

tiller or stone crusher (with

or without compacting roller).

They could fall on the operator.

movement

movement

18

- In both cases, choose the minimum forward

speed possible and increase if necessary.

- Stop or slow down when the tractor is exces

-

sively stressed to avoid stalling the rotor.

tree height limit

machine height

A

2xA

6.1.1 Setting the cogbelts

The precise alignment of the cogbelt pulleys is

very important to guarantee long life.

To align them:

-

Bring the belt to the desired tension, as described above, without tightening the screws

-

Only tighten the screws at the side

The operator is responsible

of making sure no persons or

objects are in the machine's

range of action!

5.5 Safety distances

The following safety distances must be respected for all forestry tillers/stone crushers

30 m 30 m

15m15m

All maintenance on the machine must be carried out with

the tool on the ground and the

tractor stopped, removing the

keys from the dashboard.

Interventions must be carried

out in safe conditions, using

appropriate tools and personal

protective equipment.

6. MAINTENANCE

To check the belt tension, use

a belt tension gauge to detect

belt frequency. A digital guitar

tuner which shows the frequency can also be used instead of

a belt tension gauge. (Smartphone)

To adjust the tension of traditional belts, proceed

as follows:

- unscrew the fixing screws and nuts of the belt

protection,

- after having opened the protection, loosen the

screws and nuts securing the extension to the

frame, without removing them,

- stretch the tie rod to reach the correct belt

tension,

- tighten the screws and nuts loosened in point 2,

- close the belt protections

All the operations not described in this manual can

only be carried out by qualified

and specifically specialised

personnel.

There are three types of lateral transmission:

V-belts, cogbelts and parallel axis gearboxes.

To adjust tension, strike the middle of the belt

with an object and measure the frequency with a

measuring instrument.

Check belt tension every 50 hours, as indicated in

the diagram below.

6.1. Belt tension check and adjustment

Model Frequency (from – to)

MIDIPIERRE 41-46 Hz

MIDIPIERRE dt 36-40 Hz

MIDISOIL dt -

MULTIFORST 35-45 Hz

STARSOIL -

SUPERSOIL 35-45 Hz

MAXISOIL 27-30 Hz

19

DEUTSCHESPAÑOL ITALIANO ENGLISHFRANCIS

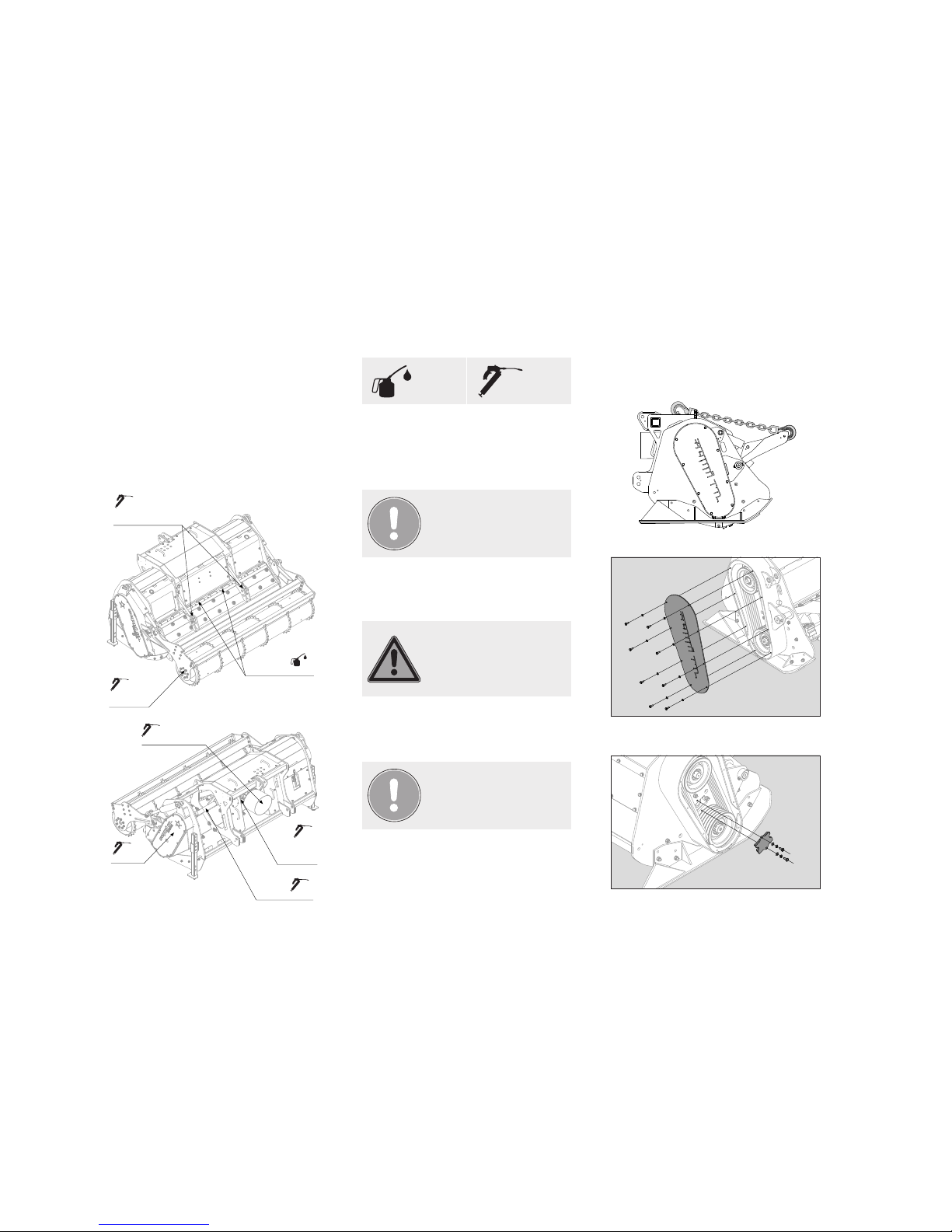

6.2 Lubrication

6.2.2 Changing oil

Before starting lubrication, clean all the lubrication points with a rag.

Use grease pumps with clean nozzles to avoid

introducing impurities into the lubrication

points.

After the first 50 hours, and then every 500

hours, it is necessary to change the gearbox oil.

Respect the following levels:

- Gearbox

During a test start, always

remain a safety distance away

of at least 2 m and NEVER turn

the adjustment screws while

the machine is running. Wait

for it to come to a full stop

before resuming maintenance.

6) Repeat the points above until the pulleys are

perfectly aligned

7) The pulleys are perfectly aligned when the belt

remains in the middle of the pulley

6.2.1 Recommended lubricant

Model Component Oil

MIDIPIERRE

MIDIPIERRE dt

MULTIFORST

Gearbox

SYNTHETIC

GEAR OIL ISO

220

(DIN 51502)

SUPERSOIL

MAXISOIL

Gearbox

SYNTHETIC

GEAR OIL ISO

320

(DIN 51502)

All models Extensions SYNTHETIC

GEAR OIL

ISO 220 (DIN

51502)

MIDISOIL dt

STARSOIL

Parallel gear

transmission

SYNTHETIC

GEAR OIL

ISO 150 (DIN

51502)

3)

Act on the tie rod to change angling of the

extension

4) Tighten the remaining screws to fix the exten

-

sion

5) Visually check alignment by starting the

machine briefly without belt protections and

without load

- Extensions

- gear transmission

3

1

5

2

Breather filler cap

Breather cap

and drain plug

Breather filler cap

Drain plugs

Oil level

Breather filler

cap

Drain plug

Oil level

Oil level

20

The cooling circuit guarantees correct lubrication

and ideal temperatures for the gearboxes. Always

check that the cooling system works properly.

The filters must be changed every time oil is

changed.

6.2.3 Cooling system

(MIDISOIL dt, STARSOIL)

6.2.4 Lubrication plan

Oil Grease

PTO shaft

40 h

Gearbox

rotation

40 h

PTO shaft

40 h

Rotor

8 h

40 h

hood bushes

Hood opening

cylinders joints

40 h

roller

bearing

8 h

6.5.1 Replacing swinging hammers

To remove and replace the swinging hammers,

proceed as follows:

2) open the belt protection cover

3)

disassemble the closures, installed at the sides of the

machine, to be able to pull out the hammer support bars

If damaged or worn, restore

them immediately, as well as

safety stickers if damaged or

missing.

6.3 Oil leaks

6.5 Replacing tools

6.4 Safety devices and information

If any machine component leaks oil, the oil

must be recovered and worn components

restored.

Use original Seppi components for proper

operation of the rotor.

Check the chains, rubbers, guards of the PTO

shaft, etc. every 8 hours

Oil leakage on the ground

causes pollution!

Using non-original spare parts

makes the rotor warranty null

and void.

1) lift the rear hood with the hydraulic controls

and secure it mechanically

against accidental closures

21

DEUTSCHESPAÑOL ITALIANO ENGLISHFRANCIS

7) block the stop screws of the previously removed bars

8) reinstall the closures and belt protections

9) lower the hood

4) remove the stop screws of the bars

OPT 214 OPT 228, 141

5) using a round bar with a diameter 5 mm less

than that of the hammer support bar, pull them

off by hitting one of the two ends. If the bars are

warped, they must be cut in pieces.

6) re-insert the bars in the rotor, inserting the

new hammers one by one

If only one hammer needs to be

replaced (e.g. broken), it is advisable to use hammers already

worn, with a shape and weight

similar to those mounted.

6.5.2 Replacing fixed knives

To remove and replace the fixed knives, proceed

as follows:

1) remove the fixing screw from the knife

2) remove the knife from its seat

3) replace the knife, screw, nut and tapered wash

-

er (if present)

4) tighten the screw at the following torques:

Rotor Screw Tightening torque

OPT 214 M16 350 NM (258 lb ft)

OPT 228, 141 M16 350 NM (258 lb ft)

After about one hour of work,

check that the new hammer is

tightened properly.

Assembling OPT 214

350 NM

(258 lb ft)

Assembling OPT 228

350 NM

(258 lb ft)

6.6 Replacing anti-wear frame

The anti-wear frame must be checked after

each day of work. Change it when worn to avoid

wearing the main frame.

6.7 Checking screws

Frequently inspect the machine, making sure

that all components are properly fastened and

that all screws and nuts are well-clamped.

Before starting particularly heavy duty work,

check the maintenance status.

6.8 Troubleshooting

The following are the main, reasonably foreseeable, malfunctioning conditions in relation

to the individual operational functions of the

machine.

(> see next page)

22

FAULT/ANOMALY POSSIBLE CAUSES REMEDIES

Abnormal vibrations - unbalancing of tool support rotor

- counterweight lost

- breakage of one or more tools

- re-balance the rotor

- replace tools

Low quality

cutting/mulching

- the rotor does not reach the intended speed

- machine adjustment not compliant with instructions

- too high forward speed

- tools worn

- check belt tension

- check PTO rpm

- adjust the hood or roller and reduce forward speed

- replace the tools

Excessive power absorption - hood or roller not adjusted properly

- too much material and too little tractor power

- adjust the machine according to the instructions

- find a compromise between power and forward speed

Frequent breakage of bearings - frame bent with excessive axial loads

- lubrication missing

- sealing systems broken

- repair frame

- lubricate

- replace sealing rings, etc.

The PTO turns and the rotor

stays still

- gearbox broken

- belts broken

- clutch burnt

- replace or repair the gearbox

- replace the belts

- replace the clutch

Rotor blocked - foreign body stuck

- lubrication missing

- gears or bearings in gearbox broken

- rotor bearings worn or broken

- turn the rotor the opposite direction using suitable tools

- lubricate

- replace the gears or bearings

- replace bearings and gaskets

The tools break, the bars are cut - presence of stones

- rotor speed too low or too high

- insufficient power

- remove, avoid this type of material

- increase or lower the nominal speed

- reduce the work load

Labyrinths and sealing rings

broken

- excessive lubrication

- fatigue

- lubrication missing

- replace sealing rings and lubricate correctly

Premature wear of belts or disk

clutches

- low PTO rotation speed

- machine starts above material to be mulched

- the rotor is not able to start and the belts slip

- insufficient belt tension

- adjust rotation speed as foreseen in user manual

- bring machine to proper speed before cutting

- check whether rotor is blocked

- tension the belts according to the instructions

Before depositing the machine at the end of the season, the frame

must be cleaned both inside and outside, removing all mulching

residue.

It must be dried, lubricated and/or greased.

Do not store it in moist areas or subject to the elements.

6.9 Disabling - Stopping the machine at the end of work

23

DEUTSCHESPAÑOL ITALIANO ENGLISHFRANCIS

To replace a component not

commonly used, only use original SEPPI M. spare parts.

Using non-original parts could

damage and endanger proper

operation of the machine.

Therefore the warranty loses

its validity and the manufacturer will not be held liable

thereof.

7. SPARE PARTS

The spare parts can be consulted in the attached

Spare Parts List.

Do not release parts or

fluids of the machine into the

environment and dispose of

them by means of specialised

companies.

9. DISMANTLING, SCRAPPING AND

WASTE DISPOSAL

It is necessary to separate the different types of

materials in order to send them to specific separate waste collection facilities.

As far as metals are concerned, recycling requires

dividing them into steel and other metals or

alloys.

Pay particular attention to electrical products,

plastic or rubber materials, which must be disposed of separately in compliance with standards

in force.

8. CONTROL REGISTER

To testify the correctness of all the inspections

and maintenance performed on the machine, as

described in this publication, it is recommended

to fill in a control register and to keep it updated

during the whole life of the machine, entering

dates, objects undergoing inspections/maintenance and overall hours of use. The maintenance

technician appointed by the customer is in charge

of filling in this register in all its parts

The register complies with that required by the

laws of most Countries, and must contain:

- inspection (even visual) interventions and

routine maintenance, included in the "Main

tenance" chapter or which are necessary to

maintain the machine in good conditions and

efficiency for its safety, regardless of who

performs them;

- extraordinary inspections and maintenance (in

cluding repairs and changes carried out by the

manufacturer), in order to keep the machine in

good conditions whenever exceptional events

occur;

- all activities regarding the life and use of the

machine.

Loading...

Loading...