Page 1

Dok.-Nr.: D10029.EN Rev.: 11 Page 1 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Operating Manual

Water separator / Fuel pre-filter SWK-2000

Page 2

Dok.-Nr.: D10029.EN Rev.: 11 Page 2 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Table of contents

General information...................................................................................................... 4 1

1.1 Disclaimer ............................................................................................................................................ 4

1.2 Symbols used ...................................................................................................................................... 4

1.3 Safety instructions............................................................................................................................... 4

1.4 Intended use ....................................................................................................................................... 5

Introduction .................................................................................................................. 6 2

2.1 Why Separ ........................................................................................................................................... 6

2.2 Function of the SWK-2000 .................................................................................................................. 6

2.3 Fields of application of the filter ......................................................................................................... 7

2.4 Tests and Certificates .......................................................................................................................... 8

Delivery ........................................................................................................................ 9 3

3.1 Scope of delivery ................................................................................................................................. 9

3.2 Unpacking............................................................................................................................................ 9

3.3 Storage ................................................................................................................................................ 9

Technical description .................................................................................................. 10 4

4.1 General arrangement drawing .......................................................................................................... 10

4.2 Dimensions and weights ................................................................................................................... 12

4.3 Characteristics ................................................................................................................................... 12

4.4 Available options ............................................................................................................................... 13

4.5 Materials used ................................................................................................................................... 14

4.6 Electrical data .................................................................................................................................... 14

4.7 Mechanical connections ................................................................................................................... 14

4.8 Temperature ranges .......................................................................................................................... 14

Filter combinations ..................................................................................................... 14 5

5.1 Switch-over system ........................................................................................................................... 15

5.2 Double-unit system ........................................................................................................................... 17

Options ....................................................................................................................... 18 6

6.1 Filter heating ..................................................................................................................................... 18

6.1.1 Heating system SWK-2000/5/50, /10 and /18 .................................................................................. 18

6.1.2 Fuel pre heating system SWK-2000/40/MH or MHS ........................................................................ 19

6.2 Water in fuel sensor (WIF) ................................................................................................................ 21

6.3 Differential pressure switch .............................................................................................................. 21

6.4 Relative pressure switch ................................................................................................................... 21

6.5 Vacuum gauge ................................................................................................................................... 22

6.6 Bowl................................................................................................................................................... 22

Page 3

Dok.-Nr.: D10029.EN Rev.: 11 Page 3 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Assembly .................................................................................................................... 23 7

7.1 Selection of mounting position ......................................................................................................... 23

7.2 Filter installation ............................................................................................................................... 23

7.3 Electrical connection ......................................................................................................................... 24

7.4 Disassembly ....................................................................................................................................... 24

Commissioning............................................................................................................ 25 8

Maintenance ............................................................................................................... 26 9

9.1 Tightening torques ............................................................................................................................ 26

9.2 Drainage of water ............................................................................................................................. 26

9.3 Back-flushing process ........................................................................................................................ 27

9.4 Element replacement ........................................................................................................................ 27

9.5 Cleaning ............................................................................................................................................. 28

Repair ......................................................................................................................... 28 10

Accessories ................................................................................................................. 29 11

Disposal ...................................................................................................................... 30 12

Annex B: Specific drawings .......................................................................................... 30 13

Page 4

Dok.-Nr.: D10029.EN Rev.: 11 Page 4 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

General information 1

1.1 Disclaimer

The preparation of this document was made as carefully as possible. However, errors can not be

excluded. Therefore, we do not take over any liability for errors or deficits in this document, nor for

any consequential damages which may arise there from.

We reserve the right to make technical changes to this document or the product described herein

without notice.

1.2 Symbols used

The following symbols are used in this document to visually emphasize important information and

warnings:

Note

Note on special tips and other helpful or important information.

Attention

Disregarding these instructions may damage the fuel filter or the mashine where the

filter is mounted.

Disposal

Note on special measures for protection of the environment / surroundings and

disposal of the system or parts of the system.

1.3 Safety instructions

Wear goggles

Wear

protective

gloves

Ventilate the

work area

Refrain from

smoking

No open fire

No food in the

work area

Works on the system have to be performed by trained personal only and in compliance with the

applicable work safety regulations. Generally operate on a cut-off, voltage-free system.

Page 5

Dok.-Nr.: D10029.EN Rev.: 11 Page 5 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

The filter may be under pressure. Therefore never open a filter in operation, otherwise fuel may leak

into the environment and the engine draws air, which can cause damage to the engine.

When using duplex or switchable filters, the lever position indicates which filter is in operation. At

this moment the other filter is isolated from the fuel circuit, but still could contain fuel.

Filters with fuel pre heating systems may only be placed in operation when completely filled with

fuel and primed of air.

The electrical current for the heater must never be turned on without grounding and activated

associated control system.

Remove spilled fuel immediately and dispose them in accordance with the applicable statutory

provisions (s. cha. 12).

1.4 Intended use

The filter is intended for the filtration of diesel fuels and mineral oils with a dynamic viscosity < 10

mPas, flash point > 55 °C and boiling point > 160 °C and is designed for operation in between fuel

tank and fuel lift pump (suction side). The filter should never be installed on the pressure side,

behind the fuel pump.

Page 6

Dok.-Nr.: D10029.EN Rev.: 11 Page 6 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Introduction 2

2.1 Why Separ

In 1992, the generation SWK-2000 water separators / fuel filter was developed by the company W.

Lösing Filtertechnik e. K. as an effective system for the separation of water and dirt particles which

are contained in the fuel. Both water and dirt can lead to high wear and tear on engines as well as

the injection systems and result in expensive, intensive repairs and equipment down time.

SWK-2000 offers:

Smallest and most compact design

High separation efficiency

Low flow resistance

Long life filter element

Easy installation

Simple maintenance

Different flow rates

Minimal maintenance effort

Enviroment friendly

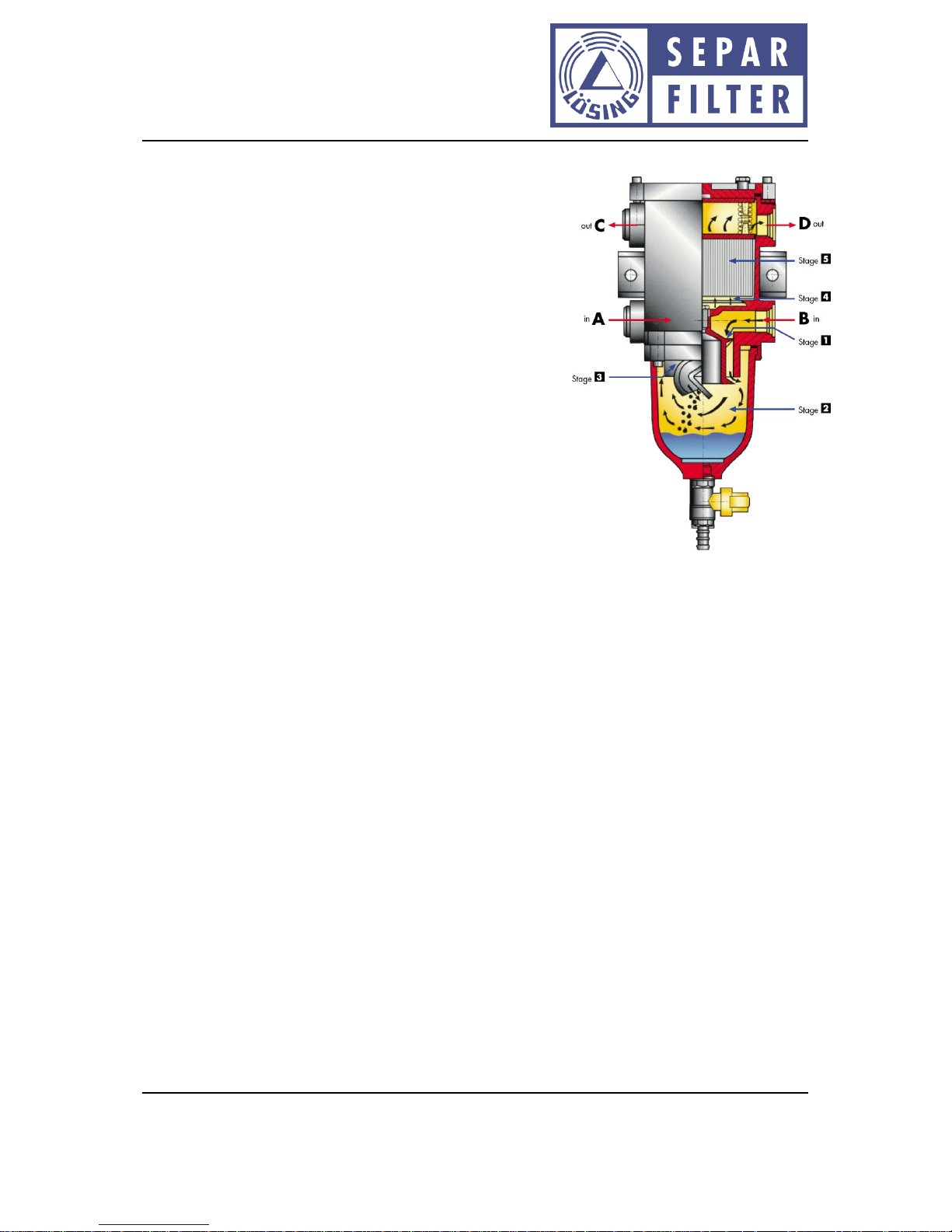

2.2 Function of the SWK-2000

The separation and purification process using a special patented system that is used throughout all

of the different sizes, which stick out through most compact design in relation to the effective flow

rate.

Generally, the SWK-2000 is installed on the vacuum side of the fuel system, i. e. between fuel tank

and fuel pump.

The fuel enters the filter through one of the two inlet parts, the unused port must be sealed off with

the attached plug.

Stage 1

From the inlet port, fuel flows into the filter and passes an interior vane system whereby the fuel is

moved in an intensive circular motion.

Stage 2

The centrifugal gravity, resulting from the circular motion, forces the fuel to the outer wall of the

bowl. The heavier water droplets and heavier particles collect on the wall of the bowl and settle due

to natural gravity to the bottom of the bowl.

Page 7

Dok.-Nr.: D10029.EN Rev.: 11 Page 7 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Stage 3

In the further flow the fuel passes the outer vane system. By

the different length of the vanes and the twofold change in the

fuel flow direction, smaller water droplets and fine dirt

particles settle on the vanes, where they agglomerate and than

decline, caused by gravity, down to the bottom of the bowl.

Already at this point the major portion of any contaminates in

the fuel have been separated.

Stage 4

Below the filter element, on the so-called dome, the flow

cross-section is considerably increased, whereby a slow-down

of the fuel occurs. This also allows smallest water droplets and

dirt particles to settle. Through the previous pre-separation,

the majority of the contamination (water and dirt) settles in

the bowl and prolongs significantly the lifetime of the filter

element.

Stage 5

The remaining suspended contamination in the fuel, finest water droplets and smallest particulates

are filtered by a replaceable filter element which is produced from a special cellulose paper or

stainless steel mesh elements.

The clean fuel leaves the filter through one of the outlet ports (the port not required should be

sealed off with the plug attached) and continues through thefuel system.

2.3 Fields of application of the filter

Vehicle industry – trucks, busses, crane trucks, municipal vehicles, etc.

Construction machinery, agricultural machinery, forklifts, compressors, etc.

Ship propulsion motors, auxialliary units

Stationary engines and generators, welding and pumping units

Mining machinery, rail vehicles

Page 8

Dok.-Nr.: D10029.EN Rev.: 11 Page 8 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

There are also versions available for special applications.

Specifically for marine or prime power application duplex or switchable filters are offered. Thereby a

filter can always be serviced, while the other filter is under flow without engine shut down.

For engines burning biodiesel appropriate versions are available.

For winter operation the SWK-2000 filter is available with pre-heating systems.

For hot environments there are custom high-temperature variants available.

2.4 Tests and Certificates

The SWK-2000 has various approvals and certificates. Copies can be provided on request. Below is a

list of organizations that have carried out these tests.

Rheinisch-Westfälischer TÜV

KBA - Kraftfahrt-Bundesamt Flensburg

German Technical Department for Army Ship and Marine Weapons

GL - Germanischer Lloyd Type Approval Certificate

Bureau Veritas Type Approval Certificate

RINA

ABS – American Board of Shipping

LR – Lloyds Registry London

Gost Standard

Fire Resistance Test by MPA – Material Prüfungsamt NRW

Page 9

Dok.-Nr.: D10029.EN Rev.: 11 Page 9 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Delivery 3

3.1 Scope of delivery

Check if you have the following accessories:

3.2 Unpacking

Before opening check the delivery for outer damage.Report any damage to carrier.

DISPOSAL

Please follow the environmental guidelines and laws of your country. Make sure the

the packaging material is disposed according to applicable regulations.

3.3 Storage

The filter and its accessories must be kept dry and in compliance with the maximum permitted

temperature ranges (s. chap. 5.8).

During a long storage period you should close all openings on the filter in order to protect the

interior and the filter element from unnecessary pollution. All filters out of the factory have all ports

sealed with plastic plugs.

Filter assembly

(s. chap. 4.1)

Operating instruction

Filter element

(already installed)

specific drawings

(upon request)

2 plugss

Page 10

Dok.-Nr.: D10029.EN Rev.: 11 Page 10 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Technical description 4

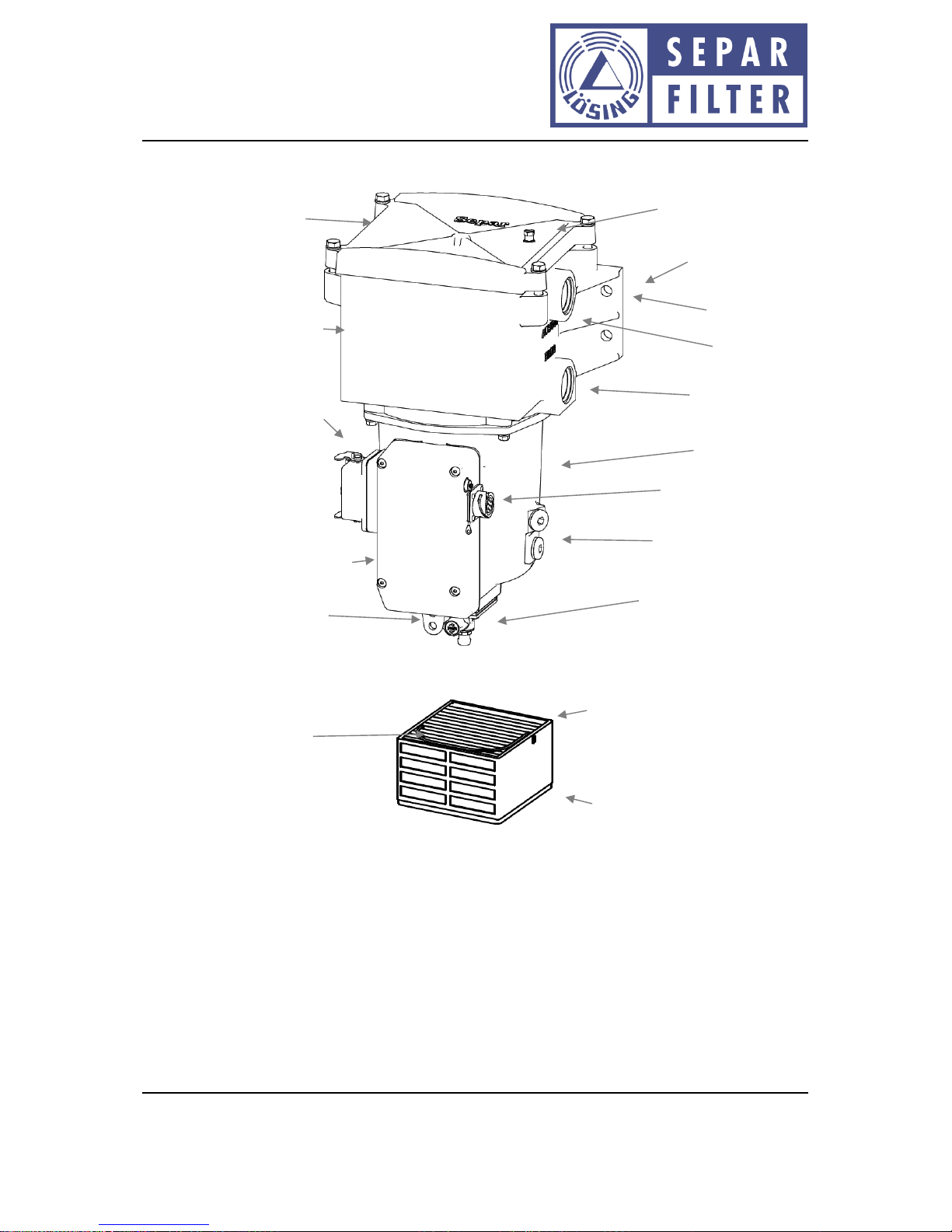

4.1 General arrangement drawing

Using the example of the SWK-2000/10:

FilterLid

Filter housing

Bleed screw

Mounting bracket

Mounting hole

Fuel inlet

(similar to the right filter side)

Fuel outlet

(similar to the right filter side)

bowl

Thread for water in fuel sensor

(on the right side)

Drain valve

Socket for heater control

Page 11

Dok.-Nr.: D10029.EN Rev.: 11 Page 11 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Using the example of the SWK-2000/40/M/H:

Example of a filter element:

The filter shown here may differ from your purchased filter. The actual appearance and arrangement

of the components depends on the configuration of the filter you have chosen.

Filter lid

Filter housing

Bleed screw

Mounting

Mounting hole

Fuel inlet

(similar to the left filter side)

Fuel outlet

(similar to the left filter side)

Bowl

2 sealed ports for water in fuel sensors

Drain valve

Heating electronics

(optional)

Connector for

heater

Socket for heatercontrol. Note to be

connected before heater plug

Grounding point

top

bottom

Handle

as replacement aid

Page 12

Dok.-Nr.: D10029.EN Rev.: 11 Page 12 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

4.2 Dimensions and weights

SWK-

2000/5

SWK-

2000/5/50

SWK-

2000/10

SWK-

2000/18

SWK-

2000/40

SWK-

2000/130

Width

140 mm

/WSA:

210 mm

140 mm

150 mm

/WSA:

220 mm

210 mm

290 mm

420 mm

Hight

275 mm

310 mm

340 mm

410 mm

470 mm

720 mm

Depth

90 mm

90 mm

110 mm

165 mm

250 mm

370 mm

Weight

< 2,5 kg

< 2,7 kg

< 3 kg

< 8 kg

< 15 kg

< 55 kg

Mountig holes

2 x Ø 9 mm

2 x Ø 9 mm

2 x Ø 9 mm

4 x Ø 9 mm

4 x Ø 12 mm

8 x Ø 15 mm

The dimensions of filter combinations may differ (see Chapter 5)

4.3 Characteristics

SWK-

2000/5

SWK-

2000/5/50

SWK-

2000/10

SWK-

2000/18

SWK-

2000/40

SWK-

2000/130

Flow performance

5 l/min

5 l/min

10 l/min

18 l/min

40 l/min

130 l/min

Complete interior

volume

450 ± 30 ml

700 ± 35 ml

1200 ± 50ml

3100 ± 90ml

7000 ± 200

ml

40 ± 1 l

Water-holding

capacity

120 ± 10 ml

120 ± 10 ml

240 ± 20 ml

500 ± 30 ml

1500 ± 50

ml

8,5 ± 0,5 l

Alarm on water

quantity

80 ± 10 ml

80 ± 10 ml

140 ± 20 ml

300 ± 30 ml

1250 ± 50

ml

7 ± 0,5 l

Water-holding capicity

with heater

-

100 ± 10 ml

200 ± 20 ml

450 ± 30 ml

1100 ± 50

ml

-

Alarm on water

quantity (with heater)

-

70 ± 10 ml

140 ± 20 ml

300 ± 30 ml

1) 350 ± 50

ml

2) 950 ± 50

ml

-

Max. allowable

pressure

15 bar

15 bar

12 bar

7 bar

4 bar

2 bar

Water separation

> 99 % des freien Wassers1

Available filter units

10 µm (coated cellulose paper)

30 µm (coated cellulose paper)

30 µm (stainless steel mesh)

60 µm (stainless steel mesh)

The characteristics of filter combinations may differ (see Chapter 5)

1

The water separation was detected at W. Lösing Filterproduction GmbH based on the DIN 4020 and the

ISO-TS 16332.

Page 13

Dok.-Nr.: D10029.EN Rev.: 11 Page 13 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

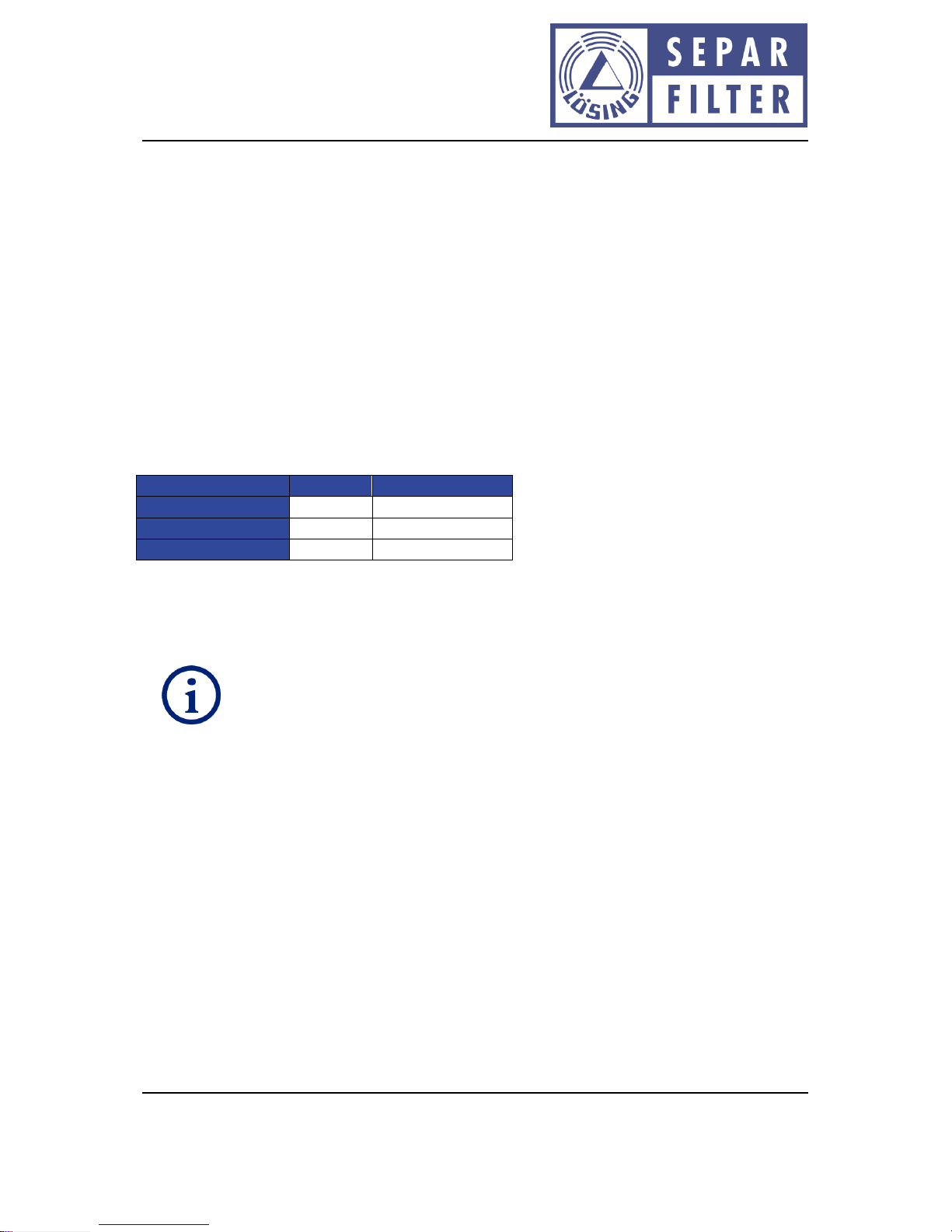

Pressure drop2

4.4 Available options

SWK-2000/5

SWK-2000/10

SWK-2000/18

SWK-2000/40

SWK-2000/130

heating

x3 x x x -

Water sensor

x x x x x

Relative

pressure switch

x x x x X

Differential

pressure switch

x x x x x

Clogging

indicator

x x x x x

Transp. bowl

x x x - -

Metal bowl x x x x

X

Heavy-Duty

design

x

Not applicable because only Heavy-Dutiy version available.

2

All pressure losses were measured with diesel according to EN590 at 20 °C ± 2 °C fuel and ambient

temperature.

3

Only in connection with option /50

Pressure drop of SWK-2000/5

Flow rate [l/min]

Flow rate [l/min]

Pressure drop of SWK-2000/10

Flow rate [l/min]

Pressure drop of SWK-2000/18

Flow rate [l/min]

Pressure drop of SWK-2000/40

Page 14

Dok.-Nr.: D10029.EN Rev.: 11 Page 14 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

4.5 Materials used

Filter cover, filter housing

Aluminium

Bowl

Aluminium or transparent PA

Drain valve

Brass, PBT

Gaskets

TPE and/or HNBR

Bleed screw

Steel

Outboard screws

Stainless steel A2

4.6 Electrical data

Electrical components are installed only in conjunction with a filter heater, water in fuel sensor

and/or pressure switch. The electrical data on these options please refer to chaptures 6.1 and 6.2.

Filter sizes for which the above options are available please refer to chapture 4.4.

4.7 Mechanical connections

SWK-2000/5

SWK-2000/10

SWK-2000/18

SWK-2000/40

SWK-2000/130

Fuel inlet

M16x1,5

M22x1,5

M26x1,5

M33x2

G2“

Fuel outlet

M16x1,5

M22x1,5

M26x1,5

M33x2

G2“

Recommended

minimum-diameter

performance

8 mm

12 mm

20 mm

26 mm

40 mm

The dimensions of filter combinations may differ (see Chapter 5)

Adapter for the fuel inlet and fuel outlet can be obtained as an accessory through the W. Lösing

Filtertechnik e. K..

4.8 Temperature ranges

Filters are designed to operate in temperature range of -40 °C to 80 °C.

On the filter with fuel pre heating system, selected thermal fuses are installed. Fuses will be

irrevocably destroyed when ignoring the stated temperature limit.

Filter combinations 5

In some areas of application it may be necessary to combine two structurally identical filters with

one another. Currently, two different combination options are offered.

Page 15

Dok.-Nr.: D10029.EN Rev.: 11 Page 15 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

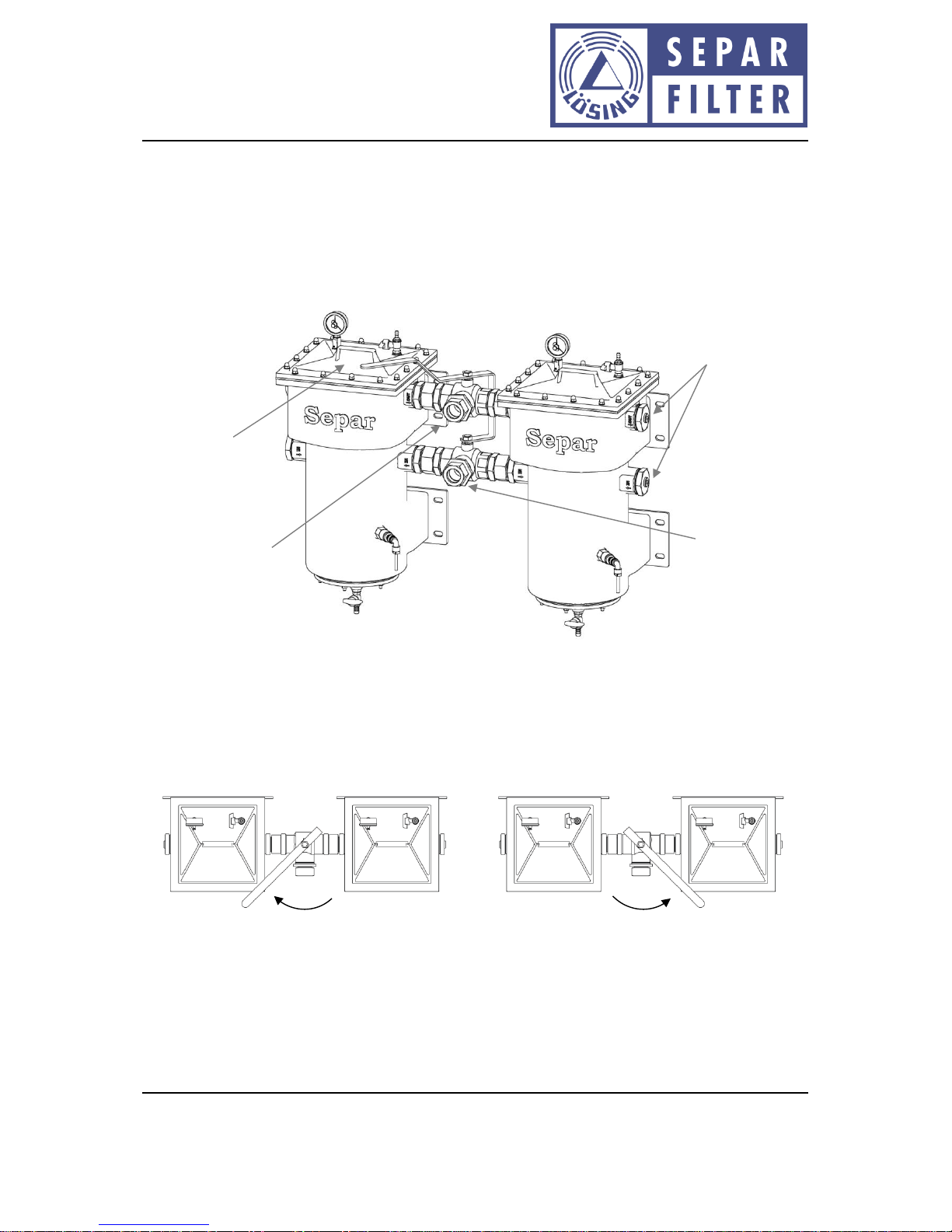

5.1 Switch-over system

A switch-over system (marked in the product key through the addition /U) is a redundant Separ filter

structure. The redundant system ensures uninterrupted operation of the filter system (e.g. during

maintenance work on the filter).

Example of a switch-over system4:

Both filters have a common fuel inlet and a common fuel outlet. Using the switch-over lever, the

filter through which the fuel should pass can be changed. The other respective filter is now no longer

part of the fuel circulation and can be emptied and opened for maintenance purposes (see Chapter

9). Operation of the switch-over system in other lever positions to those shown in the following

diagram is not permitted (move the lever only to the right or to the left as far as it will go)!

Left filter is active

Right filter is active

4

Example includes special options

The standard

inlets and

outlets remain

closed

Fuel inlet

Fuel outlet

Switch-over lever

Page 16

Dok.-Nr.: D10029.EN Rev.: 11 Page 16 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Deviations to Chapter 4.2 Dimensions and weights

SWK-

2000/5/U

SWK-

2000/5/50/U

SWK-

2000/10/U

SWK-

2000/18/U

SWK-

2000/40/U

SWK-

2000/130/U

Width [mm]

440

440

460

630

800

1,100

Height [mm]

300

340

380

450

530

860

Depth [mm]

160

160

200

230

280

430

Weight [kg]

< 8

< 8

< 10

< 20

< 40

< 120

Fixing holes

[mm]

2x slotted

holes (18x9)

Distance

apart: 416

2x slotted

holes (18x9)

Distance

apart: 416

4x slotted

holes (18x9)

Distance

apart: 435x85

4x slotted

holes

(24x12)

Distance

apart:

590x80

4x slotted

holes

(24x12)

Distance

apart: 760x100

16x slotted

holes (27x15)

Distance

apart:

See drawings

All sizes and weights may vary according to the precise configuration of the filter assembly. The exact

dimensions should be taken from the specific drawing of your filter.

The performance characteristics from Chapter 4.3 retain their validity for each individual filter.

Deviations to Chapter 4.7 Mechanical connections

SWK-

2000/5/U

SWK-

2000/10/U

SWK-

2000/18/U

SWK-

2000/40/U

SWK-

2000/130/U

Fuel inlet and

outlet

Union nut with a cutting ring for a pipe with an external diameter of

G2“

12 mm

15 mm

22 mm

35 mm

Page 17

Dok.-Nr.: D10029.EN Rev.: 11 Page 17 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

5.2 Double-unit system

In the case of a double-unit system, two identical filters are installed parallel in the fuel circulation.

By parallelising the filter, the double-unit system is able to achieve twice the flow rate as that of a

single filter.

Example of a double-unit filter system4:

Deviations to Chapter 4.2 Dimensions and weights

SWK-2000/40/2

SWK-2000/130/2

Width [mm]

870

1.100

Height [mm]

480

860

Depth [mm]

240

370

Weight [kg]

< 35

< 120

Fixing holes [mm]

4x slotted

holes (24x12)

Distance apart: 835x100

16x slotted holes (27x15)

Distance apart:

See drawings

All sizes and weights may vary according to the precise configuration of the filter assembly. The

exact dimensions should be taken from the specific drawing of your filter.

4

Example includes special options

The standard

inlets and

outlets remain

closed

Fuel inlet

Fuel outlet

Page 18

Dok.-Nr.: D10029.EN Rev.: 11 Page 18 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Deviations to Chapter 4.3 Characteristics

SWK-2000/40/2

SWK-2000/130/2

Flow rate

80 l/min

260 l/min

Total interior volume

14 ± 0.2 l

80 ± 1 l

Water absorption capacity

3 ± 0.05 l

17 ± 0.5 l

Water volume alarm

2.5 ± 0.05 l

14 ± 0.5 l

Deviations to Chapter 4.7 Mechanical connections

SWK-2000/40/2

SWK-2000/130/2

Fuel inlet and

outlet

Union nut with a cutting ring for a pipe with an

external diameter of 42 mm

G3“

Options 6

Please refer to chapture 5.4 which options are available for your filter.

6.1 Filter heating

Different heating coils are used as a heating element in the different filter sizes. The heating of the

filter size SWK-2000/40 is treated separately in one of the following chaptures. Heating controls of

SWK 2000/40/MH are operating differently than models SWK 2000/5/50/H, SWK 2000/10/H and

SWK-2000/18/H.

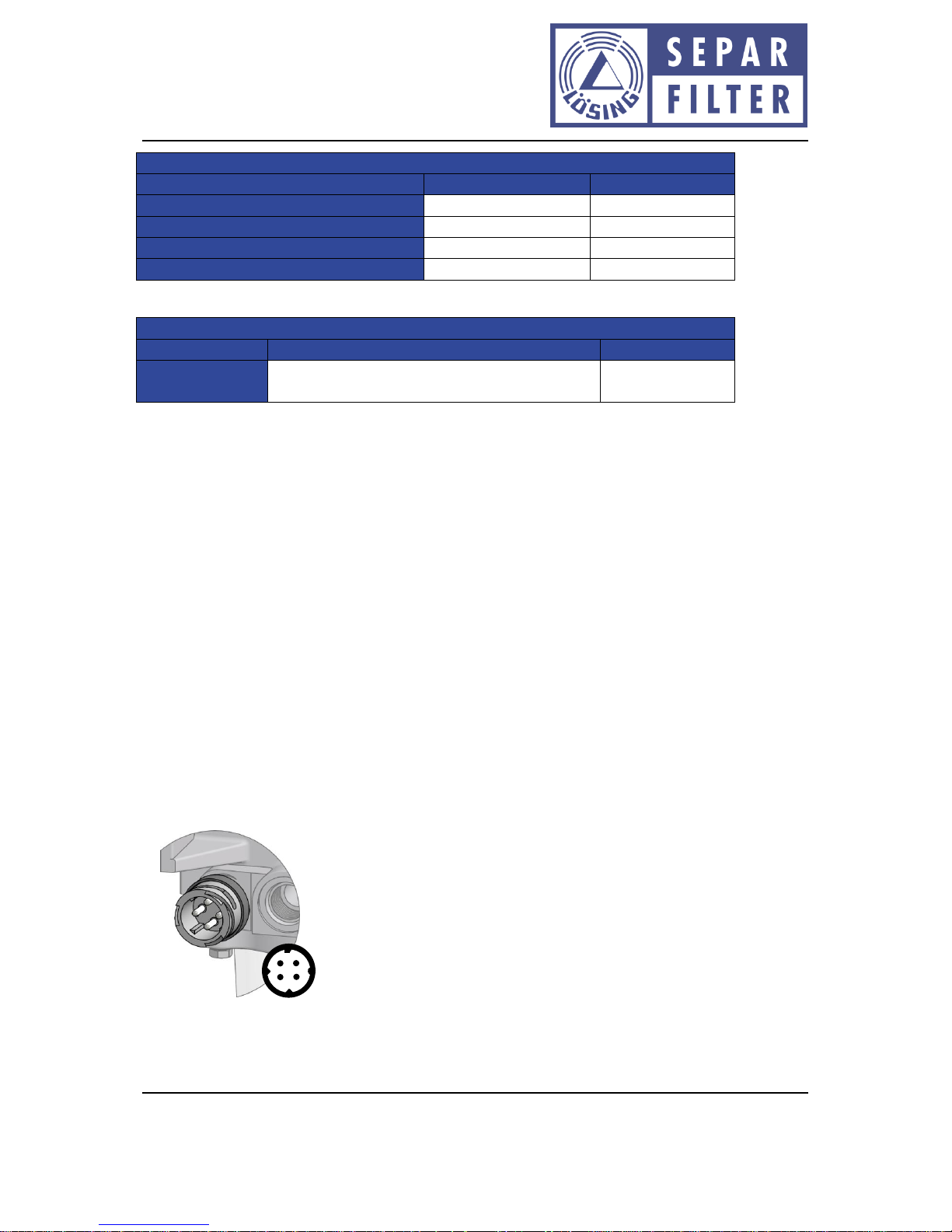

6.1.1 Heating system SWK-2000/5/50, /10 and /18

Types of fuel pre heating sytems

Operating voltage Heating power rating

12 VDC 250 W

24 VDC 300 W

24 VDC 450 W

Heating connection

Connectors

Pin 1

GND

Pin 2

Control terminal

Pin 3

GND (not used for all types)

Pin 4

VCC (has to be protected by electric fuse)

When fuel temperature is <5 °C, the control signal is connected to ground. At temperatures >10 °C,

the signal is interrupted.

4 2 1

3

Page 19

Dok.-Nr.: D10029.EN Rev.: 11 Page 19 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

External interconnection

6.1.2 Fuel pre heating system SWK-2000/40/MH or MHS

In the heated filter of the SWK-2000/40 series, a heating power of 1400 W is fed into the fuel. The

heating system is in a 230 V and a 440 VAC version available.

Attention

The heater voltage must always be switched to the filter via an external contactor

with sufficient breaking capacity. The heater voltage may only be switched on when

the contact between pins C and D (Hummel connector: 3 and 4) of the control

terminal is closed. In case of interruption between pins C and D (Hummel connector: 3

and 4) the heater voltage must be switched off immediately! Other switching states

can cause damage to the heating filter.

Control electronics

The control electronics are identical for all versions of the filters described here.

Operating voltage: 24 VDC

Maximum operating voltage: 36 VDC

Minimum operating voltage: 16 VDC

Power input: < 10 W

Types of heatin systems

Operating voltage: heater power rating

230 VAC (50 Hz/60 Hz): 1400 W

440 VAC (50 Hz/60 Hz): 1400 W

Voltage by ignition key

Battery voltage

relay (e. g.: Bosch 0 332 019 150) for 12 V

relay (e. g.: Bosch 0 332 019 203) for 24 V

Rotary switch with

indicator light

Page 20

Dok.-Nr.: D10029.EN Rev.: 11 Page 20 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Heating voltage connection

Connector: Harting

Pin 1

Heating voltage (see operating voltage from the heater)

Pin 3

Heating voltage (see operating voltage from the heater)

Pin 5

Protective conductor

Separate protective earth terminal

Old revision (stud M8)

New revision (lug with hole 8,5 mm)

Control connector (available with Cannon or Hummel connector)

Cannon:

Hummel:

Connector

Cannon

Connector

Hummel

Pin A

Pin 1

24 VDC (for control electronics)

Pin B

Pin 2

GND

Pin C

Pin 3

24 VDC (for external main contactor)

Pin D

Pin 4

Switching output for main contactor

Pin E

Pin 5

Connection to 6 (F) when error

Pin F

Pin 6

Medium changer connection (status)

Pin G

Pin 7

Connection to 6 (F) when heating OK

Pin 8

Not used

Pin 9

Not used

3

5 4 6

1

2

A C D B F G E

6 8 1 7 3

2

5

4

9

Page 21

Dok.-Nr.: D10029.EN Rev.: 11 Page 21 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Simplified diagram of the heating system

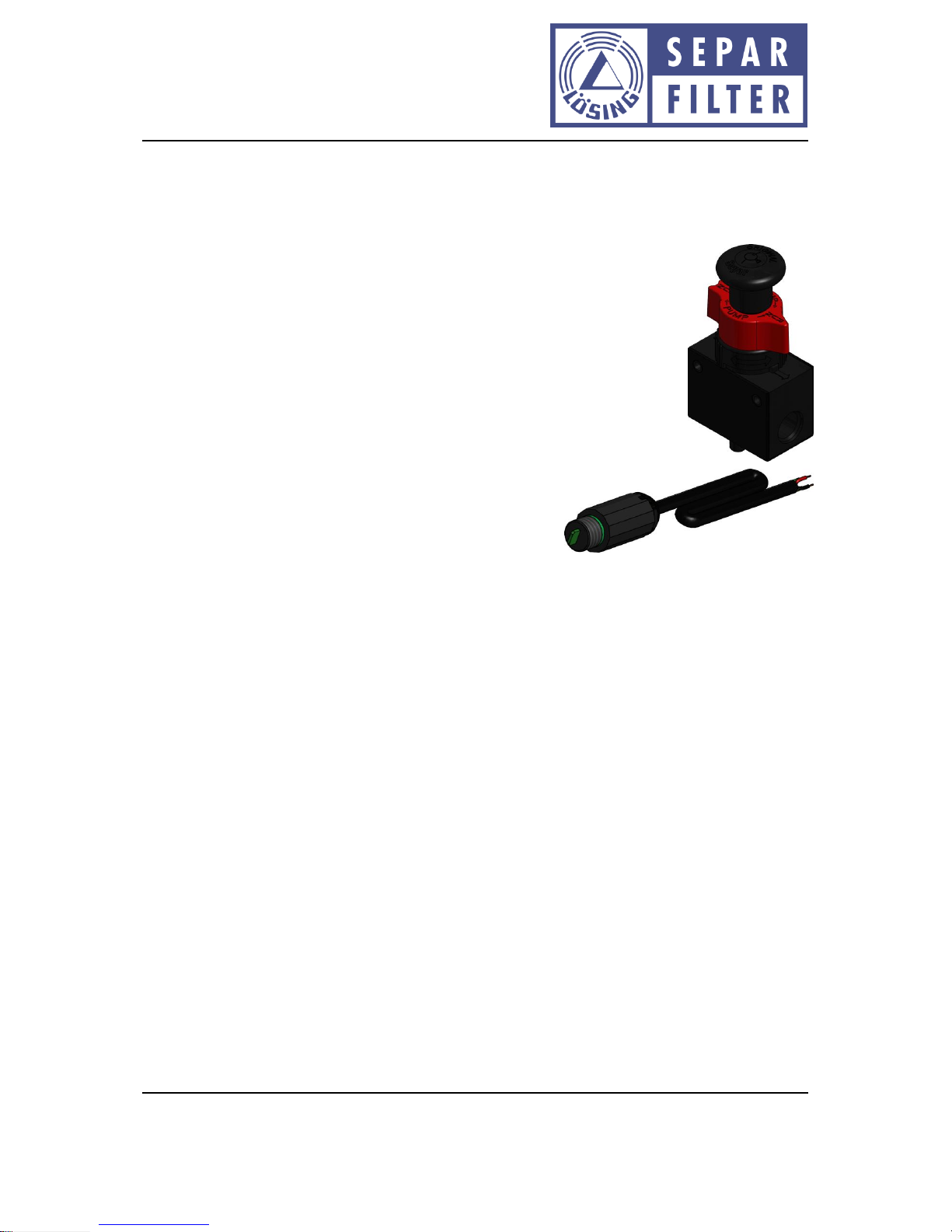

6.2 Water in fuel sensor (WIF)

Multiple WIF sensors are available either Bedia or SEPAR

designed.

All sensor parts of the SEPAR-series are potential free. The

detection of water is by capacitive measurement principle.

The exact thechnical specifications for water sensors can be found in a separate manual.

6.3 Differential pressure switch

The pressure switch is fitted in the fuel line at both the inlet and the outlet, and outputs an electrical

signal when the differential pressure produced by the filter exceeds a calibrated value. The pressure

switch is used as an indicator for a highly contaminated filter element.

6.4 Relative pressure switch

The relative pressure switch is fitted at the outlet port and outputs an electrical signal when the

vaccuum in the fuel line exceeds a calibrated value (measured against ambient air pressure). The

pressure switch is used as an indicator for highly contaminated filter elements.

The function of the relative pressure switch is the same as the differential pressure switch. But the

differential pressure switch is mounted at the inlet and the outlet port and can measure the

differential pressure between inlet and outlet.

Page 22

Dok.-Nr.: D10029.EN Rev.: 11 Page 22 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

6.5 Vacuum gauge

The vacuum gauge is mounted in the outlet line of the filter and measures negative pressure

(vacuum) downstream of the filter. You can use the vacuum gauge as a pollution indicator for the

filter element.

To use the gauge as pollution filter you have to install an unused filter element to the filter. Launch

the filter system and adjust the drag indicator to the preset value. We recommend to set a pressure

rise of 200 mbar as alarm value.

6.6 Bowl

Plastic bowls (PA) are standard for SWK 2000/5, SWK 2000/10

and 2000/18. Aluminium bowls are available for those models as

an option.

For models SWK 2000/40 and SWK 2000/130 only aluminium is

available.

The advantage of transparent plastic bowl is that you can

evaluate the water level and the degree of contamination of the

collecting area without sensors.

The metal bowl is for harsher requirements and is resistant to broader range of temperatures and

chemicals.

Page 23

Dok.-Nr.: D10029.EN Rev.: 11 Page 23 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

> 60 mm

Assembly 7

7.1 Selection of mounting position

The SWK-2000 should be installed in an easily accessible location in the suction line of the fuel

system between fuel tank and fuel pump. Any combination of inlet and outlet ports can be used.

NOTE

A shut off valve is always recommended in between the tank and the filter. If the

filter is postioned below the tank (position 2), there is always a slight pressure on the

fuel inlet of the filter, which can facilitate the priming of the filter.

NOTE

When the filter is positioned higher than the tank (position 1), we recommend the

hand priming pump of W. Lösing Filtertechnik e. K. (s. chap. 11) to be mounted in the

fuel line.

Please note that the filters have to be installed on an even surface..

When installing the filter sufficient space of at least 60 mm above the filter lid must be

allowed.

Below the filter sufficient space must be left to either place a suitable container for

draining bowl or to attach a hose directly to the drain valve to allow drainage of water

out of the filter.

7.2 Filter installation

Install the filter with the back against a sufficiently stable and flat surface. Depending on the filter

option the SWK-2000 offers two or four holes (s. chap. 4.1) for mounting the filter: The diameter of

the mounting holes can be found in the technical data (s. chap. 4.2).

Subsequently, the fuel ports are connected. There are ports for inlet and outleton either side of the

filter housing. Matching fittings and adapters are a neccessity please consult section 5.7 for port size.

Tank position 2

Tank position 1

Shut-off

valve

SWK-2000

Fuel feed

pump

Injection

system

Engine

Page 24

Dok.-Nr.: D10029.EN Rev.: 11 Page 24 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Ensure in the design of the fuel lines that the radii of the curve segments are greater than 5-times

pipe diameter in order to keep flow turbulence to a minimum.

7.3 Electrical connection

In its standard version, the SWK-2000 requires no electrical connections. Only when options with

electrical connections are selected, such as filter heater, water sensor and pressure switch, the filter

must be wired. For details see the appropriate subsections chapture 6.

7.4 Disassembly

Turn off the engine.

Set a suitable container under the drain valve.

Close shut off valves from tank. Open the bleed screw on the filter lid and then the drain valve. Let

the filter run empty.

Remove the inlet and outlet pipes from the filter. Make sure that any still existing fuel can also flow

into the provided container, to avoid pollution of the environment. Fuel leaking into the

environment should be collected directly by an absorbent rag.

Loosen the screws on the rear panel and remove the filter carefully.

Dispose of the filter and the fuel and the materials needed (e. g. rag) in accordance with chapture 12.

Page 25

Dok.-Nr.: D10029.EN Rev.: 11 Page 25 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Commissioning 8

After the filter has been installed in accordance with chapture 7, it can be put in operation.

1. Make sure that a filter element is inserted in the filter and check if all the openings of the

filter are sealed.

2. Rotate the drain valve several times to ensure that no contamination blocks closing of the

drain. Make sure that the drain valve is engaged in "closed" position.

3. Lay rags out to hold small amounts of fuel.

4. Open, if available, the shut off valve before the filter.

5. Loosen the bleed screw cautiously about 1-2 turns. Never turn the screw all the way out!

6. For priming of the fuel system use fuel priming pump.

7. Once the first small amounts of fuel come out of the bleed screw, tighten the screw again

(observe the tightening torque, see chapture 9.1).

8. Turn hand priming pump in flow position

9. Start the engine.

Page 26

Dok.-Nr.: D10029.EN Rev.: 11 Page 26 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Maintenance 9

For all maintenance works pay attention on providing suitable container under the SWK-2000 to

catch spilled fuel and for proper disposal (s. chap. 12).

Basically, the housing of the Separ filter is maintenance free. The maintenance is restricted to

removal of accumulated water in the bowl and to regular replacement of the filter element.

When screws of the filter are loosen and tightened again, please observe the tightening torques

(s. chap. 9.1).

9.1 Tightening torques

The tightening torques listed to be strictly observed. Lid and bowl retainer ring screws have to be

tightened in multipile turns and crosswise. Shown torques will result in no leakages of the filter and

avoid damages to the filter.

Bolted assembly

Height

Thigthening torque

Bleed screw

M6

4 Nm

Cover screws

M6 x 30

8 Nm

Bowl screws

M6 x 25

8 Nm

9.2 Drainage of water

If you find accumulated water at the bottom of the bowl, or the water sensor (optional) has

triggered an alarmwater has to be drained out of the bowl.

NOTE

You should, if water has collected in the bowl, not wait to long with the drainage, as

within a few days visible biomass might be foundat the interface between water and

diesel fuel. This defines itself as pollution to the bowl wall and can, if it dissolves,

reduce the service life of the filter element.

The following describes how the drainage must be performed. Make sure that during the operation

no fuel can escape into the environment. Collect the fuel and dispose it properly (s. chap. 12).

1. Shut down the engine.

2. Close, if available, the shut off valve before the filter. In case of switchable filters switch lever

to the other filter.

3. Open the bleed screw above the filter lod.

4. Open the drain valve. Water and dirt are flushed out of the bowl. Leave the drain valve open

as long until cleaned fuel leakes. Collect drained fluids in a container and dispose as per local

regulations.

5. Close the drain valve and the bleed screw (observe the tightening torque, s. chap. 9.1).

Page 27

Dok.-Nr.: D10029.EN Rev.: 11 Page 27 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

6. After the system has been primed, the engine can be restarted.

If the engine still shows power losses, replace the element.

9.3 Back-flushing process

If the filter element is clogged by dirt particles and currently there is no way to replace the element,

back-flushing can be used as an alternative. Hereby a part of the collected dirt again can be washed

out. Depending on the degree of contamination the performance of the filter element can be

restored.

1. Turn off the engine.

2. Open the bleed screw on the filter lid.

3. Place a container under the drain valve.

4. Open the drain valve by push or pull of the handle and turn it to a vertical position.

5. The clean fuel, which is located on the clean above the filter element, then flows back

through the filter element and cleans the element from water droplets and fine dirt.

6. Drain as much fuel from the filter so that the dirt is flushed out of the bowl.

7. Rotate the drain valve several times to ensure that no contamination blocks closing of

the drain. Make sure that the drain valve is engaged in "closed" position.

8. Close the drain valve.

9. Close the bleed screw.

10. Prime the fuel system.

11. The engine can be re-started again.

If the engine still continues to show power loss, repeat the process or replace the element (s. chap

9.4).

9.4 Element replacement

The filter element of the SWK-2000 should be changed if resistance exceeds engine manufacturer’s

specification, but at least once a year.

Replacement of the element:

1. Turn off the engine. In case of switchable filters switch lever to the other filter.

Page 28

Dok.-Nr.: D10029.EN Rev.: 11 Page 28 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

2. Close, if available, the shut off valve before the filter.

3. Open the bleed screw on the filter lid.

4. Open the drain valve. Water and dirt are flushed out of the bowl. Leave the drain valve open

as long until cleaned fuel leakes. Collectg liquids in a container and dispose according to the

local regulations

5. Rotate the drain valve several times to ensure that no contamination blocks closing of the

drain. Make sure that the drain valve is engaged in "closed" position.

6. Close the drain valve and the bleed screw (observe the tightening torque, s. chap. 9.1).

7. Loosen the screws on top of the filter lid in multiple turns and crosswise. Otherwise damage

may be caused to the lid and / or housing.

8. Take off the lid. Remove the spring casssette. Lift the filter element at the bracket located at

the element out of the filter. Dispose the filter element according to the requirements in

chapture 12.

9. Insert the new filter element. It is important to make sure that the sealing surface is the

bottom and the “Separ” logo represents the front.

10. Insert the spring cassette.

11. Replace if necessary the lid seal and hold the sealing surface of the filter housing and the lid

seal clean. If a new gasket is not on hand, make sure that the seal is free from particles and

slightly greased to ensure a perfect seal.

12. Put the lid back to its previous position and tighten the cover screws crosswise in multiple

turns (observe the tightening torque, s. chap. 9.1) to prevent damage and leaks.

13. After the system has been primed, the engine can be restarted (s. chap. 8).

9.5 Cleaning

Plastic bowl and gaskets shouldbe cleaned with diesel fuel only. Alcohol-containing detergents and

solvents can damage plastic bowl and gaskets severely.

Repair 10

Actual spareparts list can be obtained from Willibrord Lösing Filtertechnik e.K. or your distributor.

Please consider the recommendations/instructions given in chapter 7 for assembly and disassembly

of the filter. Repairs that go beyond the replacement of parts must be carried out by W. Lösing

Filtertechnik e. K. or an authorized company. W. Lösing Filtertechnik e. K. accepts no liability for any

damage caused by unauthorized persons or organizations.

Page 29

Dok.-Nr.: D10029.EN Rev.: 11 Page 29 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Accessories 11

A variety of accessories for the SEPAR filter can be obtained by Willibrord Lösing Filtertechnik or your

distributor:

The hand priming pump can also be installed in the fuel line and will ease the

priming process. It is recommended to use the hand priming pump when the

filter is situated higher than the fuel tank.

The water sensor is available as an option (s. chap.6.2) and as

a separate product. It triggers an alarm when the water level

rises in the bowl and water should be drained. As a digital

output signal are low-actice and high-active.

Page 30

Dok.-Nr.: D10029.EN Rev.: 11 Page 30 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Disposal 12

Drain and remove the filter according to the instructions in chapture 7.4.

Disused fuel filtersmight contain harmful residues. As thesespillfuel filters have to be disposed as per

the local regulations.

The previous rendered diesel-water-dirt mixture belongs to the waste oil containing waste. With

diesel fuel saturated absorbent, rags, etc. should be collected in non-combustible containers with

self-closing lid.

Dispose any waste according to local regulations.

Annex B: Specific drawings 13

Drawings for your personal filter configuration are compiled in a seperated document in case of

request.

Loading...

Loading...