Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

Specification

C9WT728

SSC

CUSTOMER

ApprovalApprovalDrawn

Rev. 03

Rev. 03

June 2009

June 2009

www.acriche.com

www.acriche.com

SSC-QP-7-07-24 (Rev.00)

Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

1. Description

2. Absolute Maximum Ratings

3. Electro-Optical Characteristics

4. Optical characteristics

5. Reliability Test

CONTENTS

6. Color & Binning

7. Bin Code Description

8. Outline Dimension

9. Reel Structure

10. Packing

11. Soldering

12. Precaution for use

13. Handling of Silicone Resin LEDs

Rev. 03

Rev. 03

June 2009

June 2009

www.acriche.com

www.acriche.com

SSC-QP-7-07-24 (Rev.00)

Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

C9WT728

1. Description

TOP VIEW LED is designed for

high current operation and

high flux output applications.

Furthermore, its thermal management characteristic

is better than other LED solutions by package SMD

design and good thermal emission material.

According to these advantages, it enables to apply

various lighting applications and design solution,

automotive lighting etc.

C9WT728

Features

• White & Warm colored

SMT package.

•High CRI PKG

• Pb-free Reflow Soldering

Application

• Suitable for all SMT

assembly methods ;

Suitable for all soldering

methods

• RoHS Compliant

•MSL LEVEL 2a

Applications

• Interior lighting

• General lighting

• Indoor and out door

displays

• Architectural / Decorative

lighting

Rev. 03

Rev. 03

June 2009

June 2009

www.acriche.com

www.acriche.com

SSC-QP-7-07-24 (Rev.00)

Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

2. Absolute maximum ratings

UnitValueSymbolParameter

Power Dissipation

Forward Current

Peak Forward Current

(Per die)

Reverse Voltage (per die)

Operating Temperature

Storage Temperature

*1 Care is to be taken that power dissipation does not exceed the absolute maximum rating of the product.

*2 IFM was measured at TW≤ 1msec of pulse width and D ≤ 1/10 of duty ratio.

FM

d

F

*2

R

opr

stg

mW324P

mA90I

mA100I

V5V

ºC-40 ~ +85T

ºC-40 ~ +100T

3. Electric & Optical characteristics

UnitMaxTypMinConditionSymbolParameter

Forward Voltage (per die)

Reverse Current (per die)

Luminance Intensity

*1

[4,700 ~ 7,000 K]

Luminance Intensity

*1

[2,600 ~ 4,700 K ]

V

F

I

R

I

V

I

V

IF=20mA

VR=5V

IF=60mA

IF=60mA

10--

V3.63.33.0

µA

cd-4.84.0

cd-4.54.0

Luminance Flux

[CIE X = 0.31, Y = 0.31]

Optical Efficiency

Viewing Angle

*2

Φ

V

Ŋ

elc

2

θ

½

RaColor Rendering Index

*1. The luminous intensity IV was measured at the peak of the spatial pattern which may not be aligned

with the mechanical axis of the LED package. Luminous Intensity Measurement allowance is ±10%

*2. 2θ½ is the off-axis where the luminous intensity is 1/2 of the peak intensity.

[Note] All measurements were made under the standardized environment of SSC.

IF=60mA

IF=60mA

IF=60mA

IF=60mA

95

www.

www.

lm/W-73-

deg-120-

June 2009

June 2009

acriche

acriche

SSC-QP-7-07-24 (Rev.00)

lm-14.5-

K7,0002,600CCTColor Temperature

Rev. 03

Rev. 03

.com

.com

Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

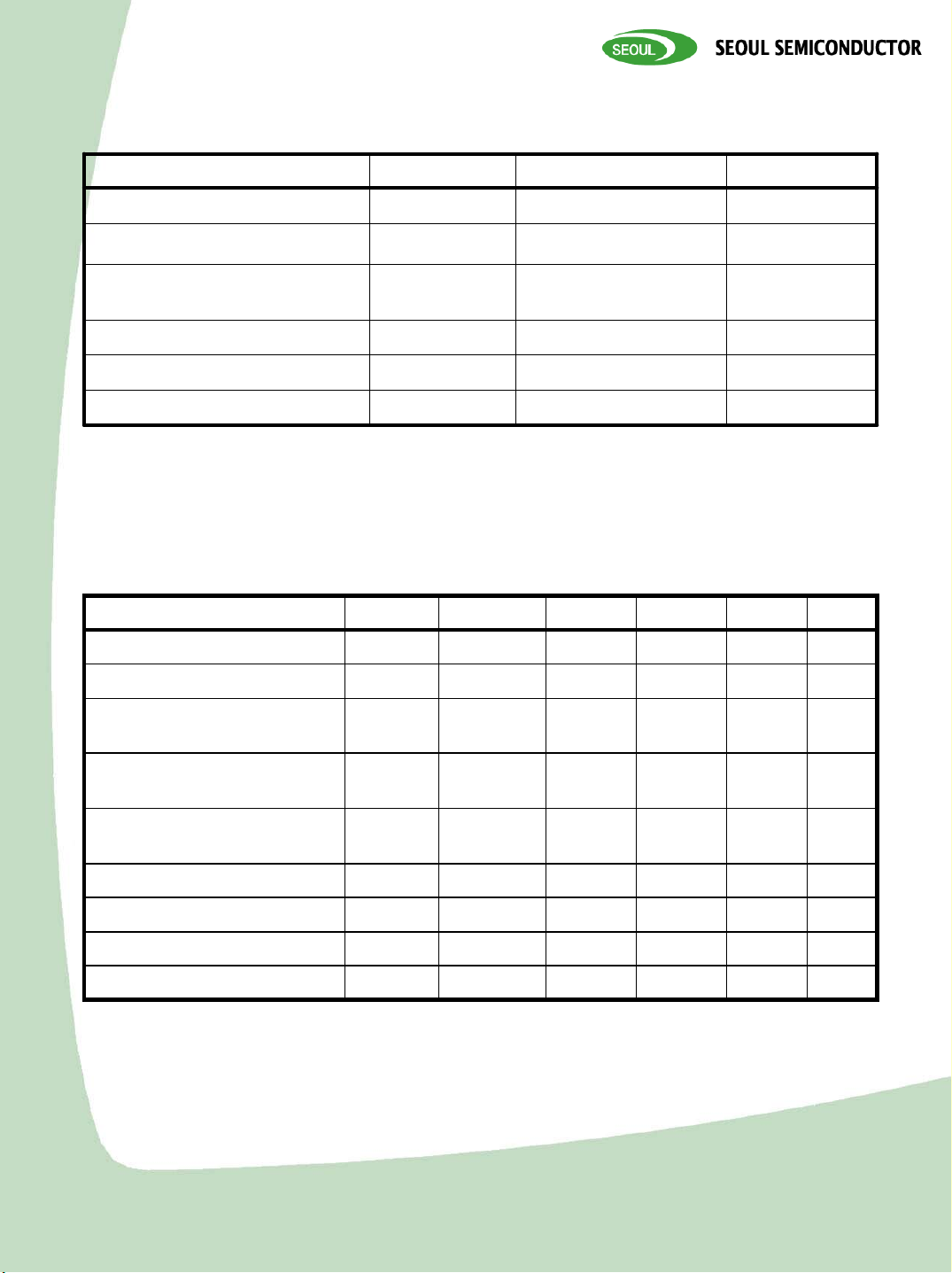

4. Optical characteristics

Forward Voltage

vs. Forward Current (Per die)

10

Forward Current [mA]

1

2.0 2.5 3.0 3.5 4.0

Forward Voltage[V]

Forward Current

vs. Relative Luminous Intensity

2.5

2.0

1.5

1.0

Relative luminouce Flux [lm]

0.5

0.0

0 50 100 150 200

Forward Current IF[mA]

Ambient Temperature

vs. Maximum Forward Current (per die)

35

30

25

[mA]

F

20

15

10

Forward Current I

5

0

-25 0 25 50 75 100

Ambient temperature Ta(OC)

-90

-60

Directivity

-30

0

30

60

90

Rev. 03

Rev. 03

June 2009

June 2009

www.

www.

acriche

acriche

.com

.com

SSC-QP-7-07-24 (Rev.00)

Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

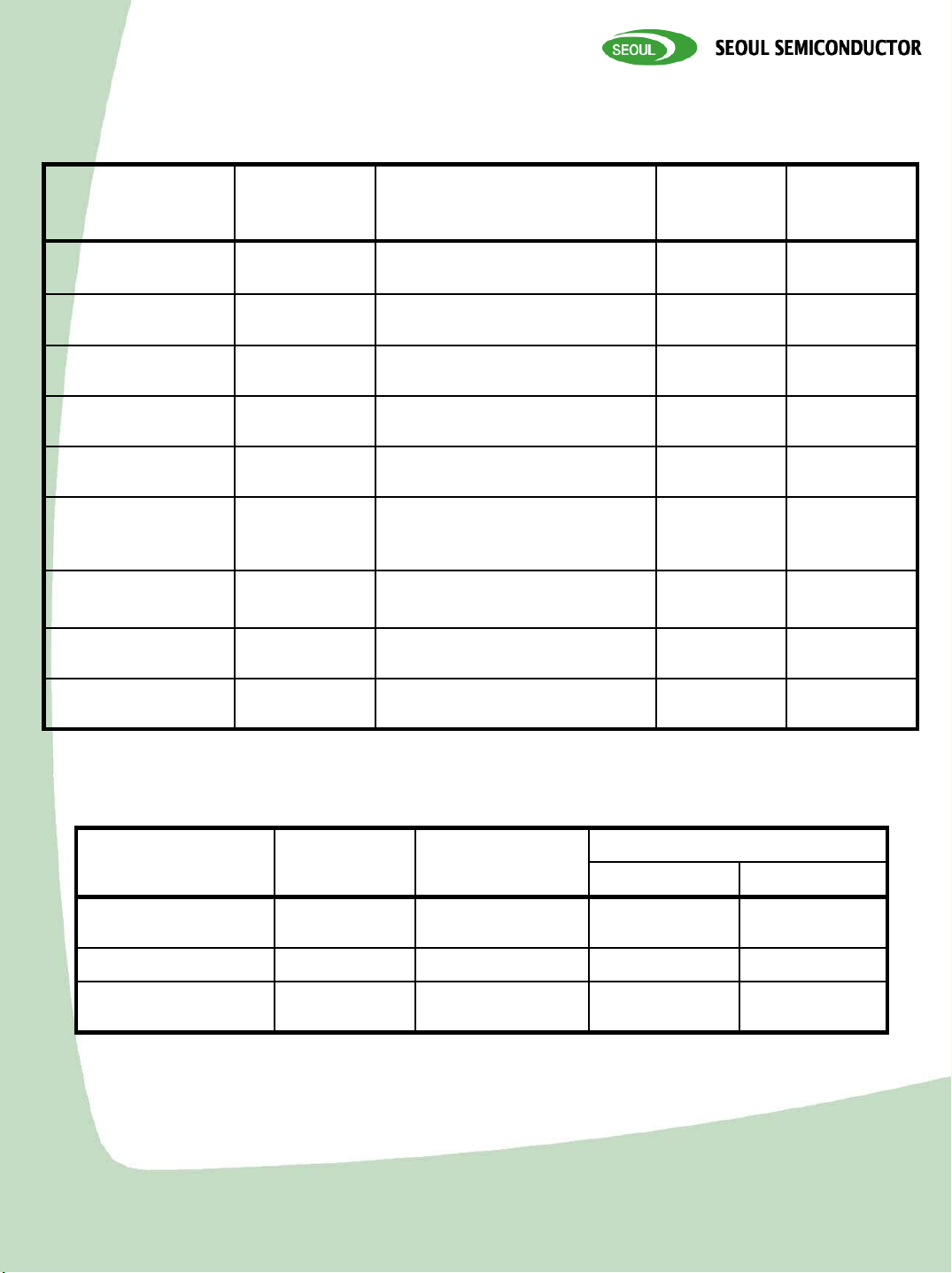

5. Reliability Test

Thermal Shock

High Temperature

Storage

High Temp. High

Humidity Storage

Low Temperature

Storage

Operating

Endurance Test

High Temperature

High Humidity Life

Test

High Temperature

Life Test

Low Temperature

Life Test

ESD(HBM)

EIAJ

ED-4701

EIAJ

ED-4701

EIAJ

ED-4701

EIAJ

ED-4701

Internal

Reference

Internal

Reference

Internal

Reference

Internal

Reference

MIL-STD-

883D

Test ConditionsReferenceItem

T

=-40oC(30min) ~

a

o

100

C(30min)

=100oC

a

=60oC, RH=90%

a

=-40oC

a

=25oC, IF=60mA

a

T

=60oC, RH=90%, IF=60mA

a

=85oC, IF=60mA

a

=-40oC, IF=60mA

a

Duration /

Cycle

1000

Cycle

500

Hours

Number

of

Damaged

0/22

0/221000 HoursT

0/221000 HoursT

0/221000 HoursT

0/221000 HoursT

0/22

0/221000 HoursT

0/221000 HoursT

0/223 Time1KV at 1.5kΩ; 100pF

□ CRITERIA FOR JUDGING THE DAMAGE

Forward Voltage

Reverse Current

Luminous Intensity

Note : *1 USL : Upper Standard Level

*2 LSL : Lower Standard Level

V

F

R

I

V

ConditionSymbolItem

I

=60mA

F

(20mA per die)

=5VI

R

I

=60mA

F

(20mA per die)

Criteria for Judgment

MAXMIN

*1

USL

USL

www.

www.

*1

acriche

acriche

LSL

*2

-

-V

× 0.5

SSC-QP-7-07-24 (Rev.00)

× 1.2

× 2.0

-

Rev. 03

Rev. 03

June 2009

June 2009

.com

.com

Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

6. Color & Binning

0.9

520

525

530

0.8

515

510

0.7

505

0.6

500

0.5

0.4

495

CIE (y)

0.3

490

535

540

545

550

555

560

565

570

575

580

585

590

595

600

610

620

630

830

0.2

0.1

485

480

475

470

460

0.0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

C I E (x)

Rev. 03

Rev. 03

June 2009

June 2009

www.

www.

SSC-QP-7-07-24 (Rev.00)

acriche

acriche

.com

.com

Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

6. Color & Binning

0.44

0.42

0.40

0.38

0.36

CIE Y

0.34

0.32

0.30

ENERGY STAR RANK

(7000K~2600K)

4700K

5000K

6500K

7000K

5600K

6000K

A2

A1

X

5300K

B2

B1

Y

C3

C1

C4

C2

Z

4200K

4500K

D1

D2

D3

D4

4000K

E1

E2

3700K

E3

E4

3500K

F1

F2

F3

F4

3200K

G2

3000K

G1

G4

2900K

G3

H2

2700K

H1

H4

2600K

H3

0.28

0.28 0.30 0.32 0.34 0.36 0.38 0.40 0.42 0.44 0.46 0.48

CIE X

www.

www.

SSC-QP-7-07-24 (Rev.00)

Rev. 03

Rev. 03

June 2009

June 2009

acriche

acriche

.com

.com

Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

6. Color & Binning

● COLOR RANK

<IF=60mA, Ta=25℃>

6000 ~ 5600 K7000 ~ 6500 K

5600 ~ 5300 K6500 ~ 6000 K

B2B1A2A1

CIE YCIE XCIE YCIE XCIE YCIE XCIE YCIE X

0.35390.32920.34620.32070.33930.31170.33040.3028

0.33060.32940.32430.32220.31870.31450.31130.3068

0.33690.33660.33060.32940.32610.32210.31870.3145

0.36160.33760.35390.32920.34810.32050.33930.3117

5000 ~ 4700 K5300 ~ 5000 K

C4C3C2C1

CIE YCIE XCIE YCIE XCIE YCIE XCIE YCIE X

0.35540.34510.36870.34630.3490.33710.36160.3376

0.34280.3440.35540.34510.33690.33660.3490.3371

0.34870.35150.3620.35330.34280.3440.35540.3451

0.3620.35330.3760.35510.35540.34510.36870.3463

5300 ~ 4700 K6000 ~ 5300 K7000 ~ 6000 K

ZYX

CIE YCIE XCIE YCIE XCIE YCIE X

0.31050.32340.2940.3104

0.33660.32430.32220.31130.3068

0.33690.33660.32610.3221

0.32580.33650.31050.3234

0.32580.3365

0.3369

0.34870.3515

0.340.35

● A~C, X~Z -> CCT 4700 ~ 7000 K

* Measurement Uncertainty of the Color Coordinates : ± 0.01

Rev. 03

Rev. 03

June 2009

June 2009

www.

www.

SSC-QP-7-07-24 (Rev.00)

acriche

acriche

.com

.com

Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

6. Color & Binning

● COLOR RANK

<IF=60mA, Ta=25℃>

4500 ~ 4200 K4700 ~ 4500 K

D4D3D2D1

CIE YCIE XCIE YCIE XCIE YCIE XCIE YCIE X

0.36590.36150.38040.36410.35970.35290.37360.3548

0.35210.3590.36590.36150.34650.35120.35970.3529

0.35780.3670.37220.37020.35210.3590.36590.3615

0.37220.37020.38740.37360.36590.36150.38040.3641

4000 ~ 3700 k4200 ~4000 K

E4E3E2E1

CIE YCIE XCIE YCIE XCIE YCIE XCIE YCIE X

0.37980.38250.39580.38690.37220.37020.38740.3736

0.36460.37830.37980.38250.35780.3670.37220.3702

0.37160.38980.38750.3950.36460.37830.37980.3825

0.38750.3950.40440.40060.37980.38250.39580.3869

3500 ~ 3200 K3700 ~ 3500 K

F4F3F2F1

CIE YCIE XCIE YCIE XCIE YCIE XCIE YCIE X

0.39160.4080.40890.41460.38480.39410.40150.3996

0.37510.40170.39160.4080.3690.38890.38480.3941

0.38140.41470.39840.42210.37510.40170.39160.408

0.39840.42210.41650.42990.39160.4080.40890.4146

3000 ~ 2900 k3200 ~3000 K

G4G3G2G1

CIE YCIE XCIE YCIE XCIE YCIE XCIE YCIE X

0.40280.43420.42120.4430.39840.42210.41650.4299

0.38530.42590.40280.43420.38140.41470.39840.4221

0.38930.43730.40710.44650.38530.42590.40280.4342

0.40710.44650.4260.45620.40280.43420.42120.443

2700 ~ 2600 K2900 ~ 2700 K

H4H3H2H1

CIE YCIE XCIE YCIE XCIE YCIE XCIE YCIE X

0.40990.45820.42890.46870.40710.44650.4260.4562

0.39190.44830.40990.45820.38930.43730.40710.4465

0.39440.45930.41260.470.39190.44830.40990.4582

0.41260.470.43190.48130.40990.45820.42890.4687

● D~H -> CCT 2600 ~ 4700 K

* Measurement Uncertainty of the Color Coordinates : ± 0.01

Rev. 03

Rev. 03

June 2009

June 2009

www.

www.

SSC-QP-7-07-24 (Rev.00)

acriche

acriche

.com

.com

Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

7. Bin Code Description

Bin Code

4,700

K ~ 7,000K

4,700

K ~ 7,000K

Forward Voltage [V]Color RankLuminous Intensity [mcd]

Z1A1M0

Luminous Intensity [mcd]

= 60mA

@ I

F

Max.Min.RANK

4,5004,000M0

5,0004,500M5

5,5005,000N0

6,0005,500N5

6,5006,000P0

Color Rank

= 60mA

@ I

F

Z

2,600

K ~ 4,700K

2,600

K ~ 4,700K

Color Rank

@ I

= 60mA

F

Average for Total

Forward Voltage [V]

A2A1

B2B1

C2C1

C4C3

YX

D2D1

D4D3

E2E1

E4E3

@ IF = 60mA

Max.Min.RANK

3.13.0Z1

3.23.1Z2

3.33.2Z3

3.453.3A1

3.63.45A2

F2F1

F4F3

G2G1

G4G3

H2H1

H4H3

Rev. 03

Rev. 03

June 2009

June 2009

www.

www.

SSC-QP-7-07-24 (Rev.00)

acriche

acriche

.com

.com

Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

8.Outline Dimension

Package Outlines

W1

Package

Marking

(Cathode)

Circuit Diagram

White Anode

6

5

6

1

W3W2

45

23

4

Right ViewFront View

R ecom m ended

Solder P ad

Rear View

( Tolerance: ±0.2, Unit: mm )

1

White Cathode

* MATERIALS

2

3

MATERIALSPARTS

Heat-Resistant PolymerPackage

Silicone ResinEncapsulating Resin

Ag Plating Copper AlloyElectrodes

Rev. 03

Rev. 03

June 2009

June 2009

www.

www.

SSC-QP-7-07-24 (Rev.00)

acriche

acriche

.com

.com

Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

9. Reel Structure

?

1

.

5

+

0

.

1

,

0

4±0.1

2±0.05

1.75±0.15.5±0.05

12.0±0.2

(4.75)

0.3-0.05

5.7±0.1

8±0.1

13

180

5.3

2

2.1±0.1

Package

Marking

15.4±1.0

13±0.3

60

22

( Tolerance: ±0.2, Unit: mm )

1)Quantity : 1,000pcs/Reel

2)Cumulative Tolerance : Cumulative Tolerance/10 pitches to be ±0.2mm

3)Adhesion Strength of Cover Tape : Adhesion strength to be 0.1-0.7N when the cover tape is

turned off from the carrier tape at the angle of 10 to the carrier tape

4)Package : P/N, Manufacturing data Code No. and quantity to be indicated on a damp proof

Package

Rev. 03

Rev. 03

June 2009

June 2009

www.

www.

acriche

acriche

SSC-QP-7-07-24 (Rev.00)

.com

.com

Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

10. Packing

Reel

QUANTITY : XXXX

LOT NUMBER : XXXXXXXXXX

PART NUMBER :

SEOUL SEMICONDUCTOR CO., LTD.

Aluminum Vinyl Bag

HUMIDITY INDICATOR

DESI PAK

QUANTITY : XXXX

LOT NUMBER : XXXXXXXXXX

PART NUMBER :

SEOUL SEMICONDUCTOR CO., LTD.

Outer Box Structure

Material : Paper(SW3B(B))

TYPE

7inch

SIDE

1

QUANTITY : XXXX

LOT NUMBER : XXXXXXXXXX

PART NUMBER :

SEOUL SEMICONDUCTOR CO., LTD.

SIZE (mm)

a

220245

245 220

c

b

102

142

TUV

Acriche

Semiconductor EcoLight

RoHS

a

c

MADE IN KOREA

1

b

Rev. 03

Rev. 03

June 2009

June 2009

www.

www.

acriche

acriche

.com

.com

SSC-QP-7-07-24 (Rev.00)

Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

11. Soldering

(1) Lead Solder

Lead Solder

(2) Lead-Free Solder

Lead Free Solder

Lead Solder

o

120~150℃Pre-heat

120 sec. Max.Pre-heat time

240℃ Max.Peak-Temperature

10 sec. Max.Soldering time Condition

150~200℃Pre-heat

120 sec. Max.Pre-heat time

260℃ Max.Peak-Temperature

10 sec. Max.Soldering time Condition

2.5~5 C / sec.

o

1~5 C / sec.

2.5~5 C / sec.

Pre-heating

120~150 C

120sec. Max.

Pre-heating

150~200 C

120sec. Max.

o

Lead-free Solder

o

1~5 C / sec.

o

60sec. Max.

Above 200 C

60sec. Max.

Above 220 C

o

o

240 C Max.

10 sec. Max.

o

o

260 C Max.

10 sec. Max.

(3) Hand Soldering conditions

Do not exceed 4 seconds at maximum 315ºC under soldering iron.

(4) The encapsulated material of the LEDs is silicone.

Precautions should be taken to avoid the strong pressure on the encapsulated part.

So when using the chip mounter,

the picking up nozzle that does not affect the silicone resign should be used.

[Note] In case that the soldered products are reused in soldering process, we don’t guarantee the products.

Rev. 03

Rev. 03

June 2009

June 2009

www.

www.

acriche

acriche

.com

.com

SSC-QP-7-07-24 (Rev.00)

Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

12. Precaution for use

1) Storage

In order to avoid the absorption of moisture, it is recommended to store in a dry box (or a desiccator)

with a desiccant. Otherwise, to store them in the following environment is recommended.

Temperature : 5ºC ~30ºC Humidity : maximum 65%RH

2) Attention after open.

LED is correspond to SMD, when LED be soldered dip, interfacial separation may affect the light

transmission efficiency, causing the light intensity to drop. Attention in followed;

a. After opened and mounted the soldering shall be quickly.

b. Keeping of a fraction

Temperature : 5 ~ 40ºC Humidity : less than 30%

3) In the case of more than 4 week passed after opening or change color of indicator on desiccant,

components shall be dried 10-12hr. at 60±5ºC.

4) Any mechanical force or any excess vibration shall not be accepted to apply during cooling process to

normal temperature after soldering.

5) Quick cooling shall be avoided.

6) Components shall not be mounted on warped direction of PCB.

7) Anti radioactive ray design is not considered for the products.

8) This device should not be used in any type of fluid such as water, oil, organic solvent etc.

When washing is required, IPA should be used.

9) When the LEDs are illuminating, operating current should be decided after considering the ambient

maximum temperature.

10) LEDs must be stored to maintain a clean atmosphere. If the LEDs are stored for 3 months or more

after being shipped from SSC, a sealed container with a nitrogen atmosphere should be used for storage.

11) The LEDs must be soldered within seven days after opening the moisture-proof packing.

12) Repack unused products with anti-moisture packing, fold to close any opening and then store

in a dry place.

13) The appearance and specifications of the product may be modified for improvement without notice.

Rev. 03

Rev. 03

June 2009

June 2009

www.

www.

acriche

acriche

.com

.com

SSC-QP-7-07-24 (Rev.00)

Technical Data Sheet

Z-Power LED X10490Z-Power LED X10490

13. Handling of Silicone Resin LEDs

1) During processing, mechanical stress on the surface should be minimized as much as possible.

Sharp objects of all types should not be used to pierce the sealing compound.

2) In general, LEDs should only be handled from the side. By the way, this also applies to LEDs

without a silicone sealant, since the surface can also become scratched.

3) When populating boards in SMT production, there are basically no restrictions regarding the form of the

pick and place nozzle, except that mechanical pressure on the surface of the resin must be prevented.

This is assured by choosing a pick and place nozzle which is larger than the LED’s reflector area.

4) Silicone differs from materials conventionally used for the manufacturing of LEDs. These conditions

must be considered during the handling of such devices. Compared to standard encapsulants, silicone is

generally softer, and the surface is more likely to attract dust.

As mentioned previously, the increased sensitivity to dust requires special care during processing.

In cases where a minimal level of dirt and dust particles cannot be guaranteed, a suitable cleaning solution

must be applied to the surface after the

soldering of components.

5) SSC suggests using isopropyl alcohol for cleaning. In case other solvents are used, it

must be assured that these solvents do not dissolve the package or resin.

Ultrasonic cleaning is not recommended. Ultrasonic cleaning may cause damage to the LED.

6) Please do not mold this product into another resin (epoxy, urethane, etc) and

do not handle this product with acid or sulfur material in sealed space.

Rev. 03

Rev. 03

June 2009

June 2009

www.

www.

SSC-QP-7-07-24 (Rev.00)

acriche

acriche

.com

.com

Loading...

Loading...