Seoul HY330 User Manual

YELLOW HIGH FLUX LED HY330

Technical Datasheet

This revolutionary package design allows the

lighting designer to reduce the number of

LEDs required and provide a more uniform

and unique illuminated appearance than with

other LED solutions.

This package LEDs are designed for high

current operation and high flux output

application. But the package’s design features

better thermal management characteristics

than other LED solutions. Because of these

advantages, this product have many

applications. Such as automotive tail, stop and

turn signal lamps, and electronic signs etc.

Features

• High flux output and high luminance

• Designed for high current operation

•Uniform color

• Low profile and low thermal resistance

• Packaged in tubes for use with

automatic insertion equipment

Application

• Automotive exterior lighting

• Electronic signs and signals

• Channel letter / lighting

• Decorative lighting

• Specialty Lighting

-1-

<070813> Rev. 1.5

서식번호 : QP-7-03-05 (Rev.00)

YELLOW HIGH FLUX LED HY330

Outline Dimensions

Unit : mm

CHAMFER 1.25 X 1.25

CATHODE

0.5

±

3 ± 0.2

0.5

±

2.5

1.4

ANODE

7.62 ± 0.5

0.4 ± 0.2

5.08 ± 0.3

7.62

5

.

0

°

1.4 MAX

4.4

0.5

±

1.5±0.2

7.5

0.76 ± 0.1

0.5

5.08 ± 0.2

Notes : Protruded epoxy is 1.4mm maximum.

-2-

<070813> Rev. 1.5

서식번호 : QP-7-03-05 (Rev.00)

YELLOW HIGH FLUX LED HY330

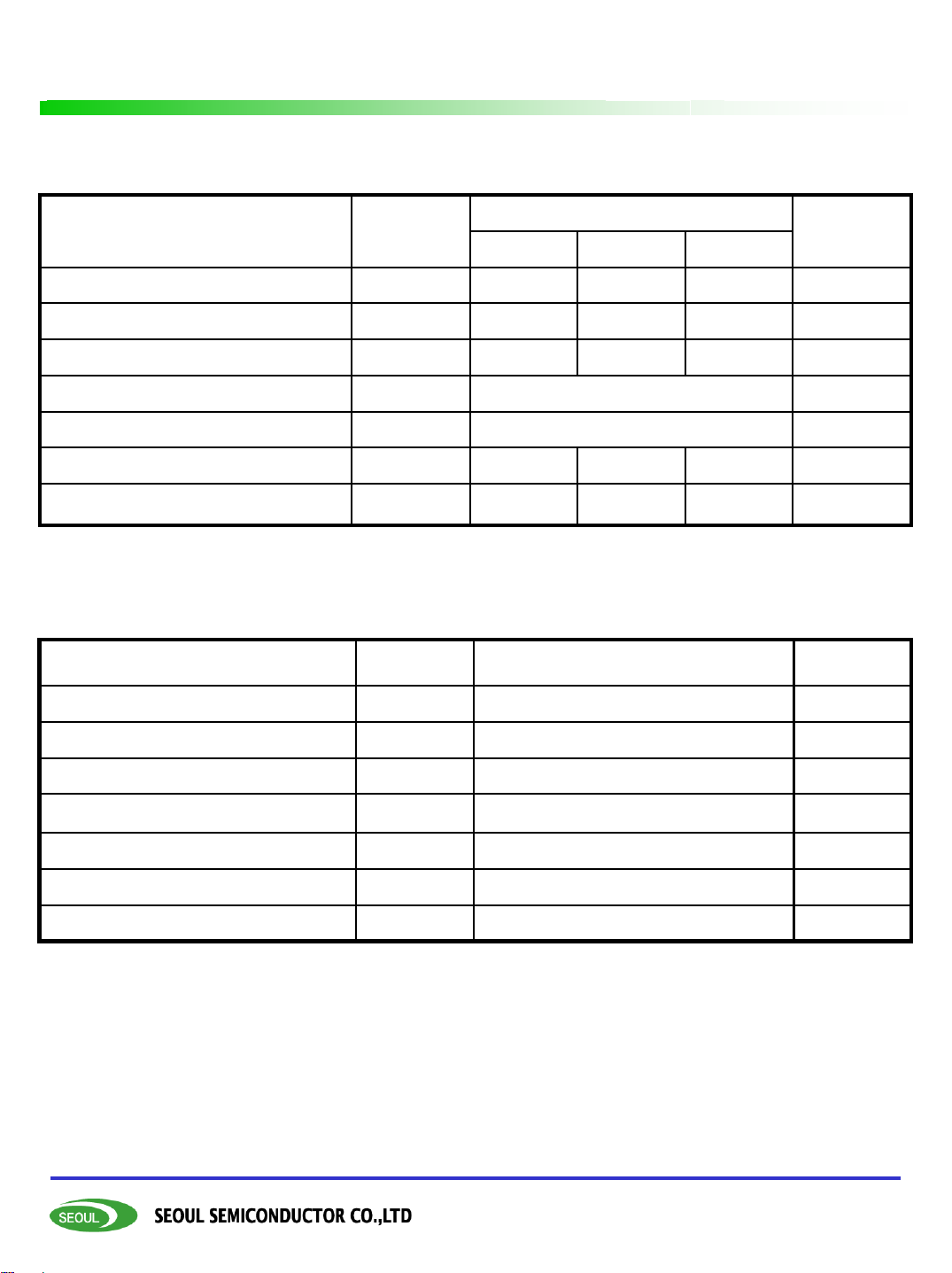

Electro-Optical Characteristics ( Ta = 25ºC, IF=70mA )

Value

SymbolItem

Max.Typ.Min.

Unit

Luminous Flux

Dominant Wavelength

Forward Voltage

[1]

[3]

[4]

View Angle

Thermal Resistance

Optical Efficiency

Reverse Current (at VR= 5V)

Ф

[2]

V

λ

d

F

2

θ

½

θ

J-A

ŋ

opt

R

Absolute Maximum Ratings ( T

DC Forward Current

Forward Peak Pulse Current

Reverse Voltage

FP

F

[5]

R

-I

= 25ºC )

a

-5.24.4

lm

600590 nm584

V3.42.62.4V

90 deg.

ºC /W220R

lm/W-22-

5-

µ

A

UnitValueSymbolItem

mA70I

mA100I

V5V

Power Dissipation

Operating Temperature

Storage Temperature

Solder Temperature

Notes :

[1] SSC maintains a tolerance of ±10% on flux and power measurements.

[2] ФV is the total luminous flux output as measured with an integrated sphere.

[3] Dominant wavelength is derived from the CIE 1931 Chromaticity diagram.

A tolerance of ±0.5nm for dominant wavelength

[4] A tolerance of ±0.05V on forward voltage measurements

[5] t ≤ 0.1ms, D = 1/10

[6] No closer than 1.5mm from the base of the stopper.

D

opr

stg

T

S

-3-

mW238P

ºC-40 ~ 100T

ºC-50 ~ 105T

[6]

ºC240ºC for 5second

<070813> Rev. 1.5

서식번호 : QP-7-03-05 (Rev.00)

YELLOW HIGH FLUX LED HY330

Reliability Tests

Thermal Shock

ESD

(Human Body Model)

= RT, IF= 70mALife Test

a

= -30ºC, IF= 70mALow Temperature Operating

a

= -50ºC (30min) ~ 105º (30min)

T

a

(Transfer time : 5sec, 1Cycle = 1hr)

= 105ºCHigh Temperature Storage

a

= -50ºCLow Temperature Storage

a

NoteConditionItem

1000hrsT

1000hrsTa= 85ºC, IF= 40mAHigh Temperature Operating

1000hrsT

100

cycles

1 timeTs= 235 ± 5ºC, t = 4 ± 1secResistance to soldering Heat

Failures

0/22

0/22

0/22

0/40

0/22

0/221 time1kV, 1.5kΩ ; 100pF

0/221000hrsT

0/221000hrsT

Temperature Humidity

Storage

Temperature Humidity

Operating

< Judging Criteria For Reliability Tests >

[1]

F

R

Ф

V

Notes :

[1] USL : Upper Standard Level

[2] LSL : Lower Standard Level.

USL

USL X 2.0I

LSL

[2]

X 0.7

X 1.2V

-4-

0/221000hrsTa= 85ºC, RH = 85%

0/22500hrsTa= 85ºC, RH = 85%, IF= 40mA

<070813> Rev. 1.5

서식번호 : QP-7-03-05 (Rev.00)

Loading...

Loading...