EVERYDAY PERFORMANCE

SWD8060

WASHER DRYER

SWD8060

User Manual

SENZ WASHING MACHINE.

SENZ VASKEMASKIN.

SENZ VASKEMASKIN.

SENZ VASKEMASKINE.

SENZ TVÄTTMASKIN.

Quick Guide

1

2

A

B

*

THANK YOU FOR PURCHASING A SENZ PRODUCT.

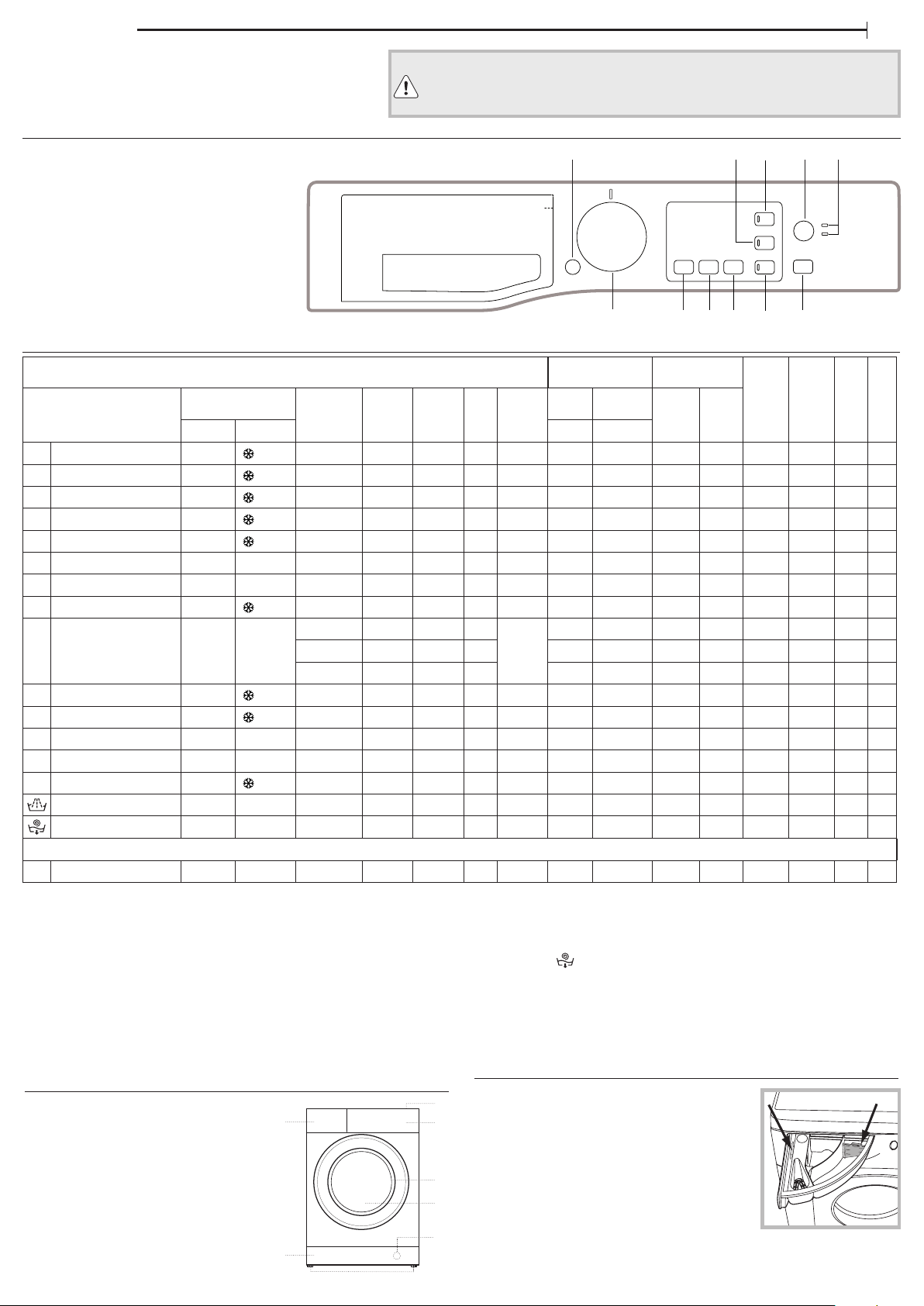

CONTROL PANEL

EN

Before using the appliance carefully read the Health and Safety guide.

Before using the appliences carefully read the Safety Instructions. Before using the machine,

it is imperative that the transport bolts are removed. For more detailed instructions on how

to remove them, see the Installation Guide (pag. 51-52)

1. ON/OFF button

2. DRYING ONLY button and indicator light

3. CHILD LOCK button and indicator light

4. CLEANING ACTION button

5. CLEANING ACTION indicator lights

6. START/PAUSE button and indicator light

7. DELAY START button and indicator light

8. DRYING button

9. SPIN button

10. TEMPERATURE button

11. WASH CYCLE SELECTOR KNOB

1

DISPLAY

11

10

2

9

8

4

3

7

6

WASH CYCLE TABLE

Maximum load 8 kg

Power input in o mode 0.5 W / in left-on mode 8 W

Wash cycle

Temperature

Setting Range 2 3

1 Anti-Stain Turbo 40 °C

2 Anti-Stain 40° 40 °C

3 Cotton (2) 40 °C

4 Synthetics (3) 40 °C

5 Rapid 30’ 30 °C

- 40 °C

- 40 °C

- 60 °C

- 60 °C

- 30 °C

Max.

spin speed

(rpm)

1200 4.5 **

1400 8.0 **

1400 8.0 3:55

1200 4.0 2:55

800 4.5 0:30 **** 4.5

Max.

load for

washing

(kg)

Duration

(h : m)

6 Mix Wash & Dry 40 °C 40 °C 800 3.5 **

7 Shirts Wash & Dry 40 °C 40 °C 1000 2.0 **

8 Wool 40 °C

- 40 °C

800 2.0 **

1351 8.0 3:30

9 Eco 40-60 (1) 40 °C 40°C

1351 4.0 2:45

1351 2,0 2:10

10 20°C 20 °C

11 White 60 °C

- 20 °C

- 90 °C

1400 8.0 1:50

1400 8.0 2:45

12 Anti Allergy 60°C 40 °C - 60 °C 1400 5.0 **

Max.

load for

drying

Drying

13 Steam Refresh – – – 2.0 ** – – – – – – – – – –

14 Ultradelicates 30 °C

Rinse&Spin – – 1400 8.0 **

Spin&Drain * – – 1400 8.0 **

- 30 °C

0 1.0 **

Required dosage Optional dosage

3 Eco Cotton (4) 60 °C 60 °C 1400 8.0 3:45

The cycle duration indicated on the display or instruction manual is an estimate based on

standard conditions. The actual duration may vary in relation to several factors, such as the

temperature and pressure of the incoming water, ambient temperature, amount of detergent,

load quantity and type, load balancing and any additional options selected.The values given

for programmes other than the Eco 40-60 programme are indicative only.

1) Eco 40-60 (Wash) - Test wash c ycle in compliance with EU Ecodesign r egulation

2019/2014. The most ecient programme in terms of energy and water consumption for

washing normally soiled cotton laundry.

Note: spin speed values shown on the display can slightly diers from the values stated in

the table.

Eco 40-60 (Dr ying) 2019/2014

“Drying” option level to

consumption for washing and drying normally soiled cotton laundry. (Cycle duration: full load

9h:55’ / half load 6h10’).

. To access “wash and dry” cycle select “Eco 40-60” wash programme and set

Test drying cycle in compliance with EU Ecodesign regulation

“A3”.

The most ecient programme in terms of energy and water

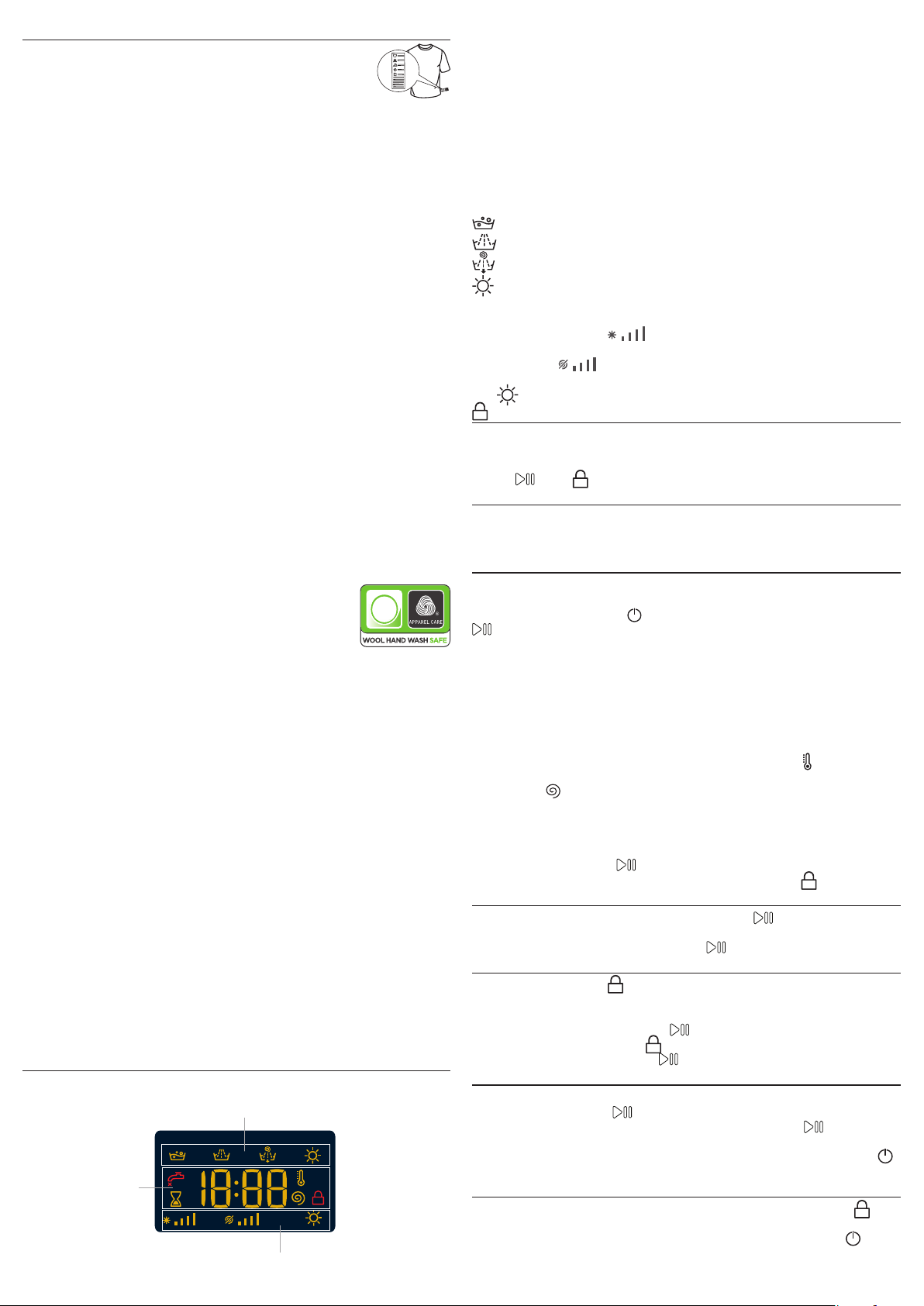

PRODUCT DESCRIPTION

1. Top

2. Detergent dispenser drawer

3. Control panel

4. Handle

5. Porthole door

6. Drain pump (behind the plinth)

7. Plinth (removable)

8. Adjustable feet (2)

2.

7.

8.

For all testing institutes:

2) Long cotton cycle: set programme 3 at temperature 40°C.

3) Long synthetics cycle: set cycle 4 at a temperature of 40°C.

4) Eco Cotton -

at a temperature of 60°C to access this cycles.

* By selecting the cycle and excluding the spin cycle, the washer-dryer will drain only.

** The duration of the wash cycles can be checked on the display.

*** After programme end and spinning with maximum selectable spin speed, in default

programme setting.

**** If a drying cycle is also programmed, the machine will run a “wash+dry” programme

lasting 45’ and a 1kg laundry load.

DETERGENT DISPENSER DRAWER

Compartment *:

1.

Do not insert detergent in this compartment.

Compartment 1: Washing detergent (powder

3.

or liquid)

If liquid detergent is used, the removable plastic

partition A (supplied) should be used for proper

dosage.

4.

If powder detergent is used, place the partition

5.

into slot B.

Compartment 2: Additives (fabric softeners, etc.)

The fabric softener must not exceed the “MAX” level.

6.

! Use powder detergent for white cotton garments, for pre-washing, and

for washing at temperatures over 60°C.

! Follow the instructions given on the detergent packaging.

(kg)

4.5

6.0

6.0

4.0

3.5

2.0

2.0

6.0

Detergents and

Additives

Wash

Fabric

softener

Recommended

detergent

Liquid

Powder

–

– – – – –

–

–

–

–

(***)

Energy

Residual

dampness %

consumption

– – – –

49 1.40 105 45

35 0.80 55 43

71 0.20 45 27

– – – –

– – – –

– – – –

53 0.77 54 33

53 0.65 52 36

53 0.45 37 33

6.0

6.0

5.0

1.0

6.0 –

–

49 0.16 90 22

49 0.90 90 55

– – – –

–

– – – –

– – – – – –

6.0 – – – – – – – –

6.0

Test wash cycle in compliance with regulations 1061/2010. Set “3” wash cycle

53 1.04 60 –

5

kWh

Total water lt

Laundry

temperature °C

WASH CYCLES

Follow the instructions on the symbols of the garment’s wash

care label. The value indicated in the symbol is the maximum

recommended temperature for washing the garment.

Anti-Stain Quick: This cycle is ideal for washing daily stains

in 60’. It is ideal for mixed fabrics and coloured garments.

If the drying option is selected, a drying cycle automatically activates at

the end of the wash cycle that resembles open-air drying, with the added

advantages of preserving garments from yellowing due to sunlight

exposure and preventing loss of whiteness caused by the possible

presence of dust in the air. Dryness level “A2” recommended.

Anti-Stain: This cycle is suitable to heavily-soiled garments with resistant

colours. It ensures a washing class that is higher than the standard class (A

class). When running the programme, do not mix garments of dierent

colours. We recommend the use of powder detergent. Pre-treatment with

special additives is recommended if there are obstinate stains.

If the drying option is selected, a drying cycle automatically activates at

the end of the wash cycle that resembles open-air drying, with the added

advantages of preserving garments from yellowing due to sunlight

exposure and preventing loss of whiteness caused by the possible

presence of dust in the air. Dryness level “A2” recommended.

Cotton: Suitable for washing towels, underwear, table cloths, etc. made of

resistant linen and cotton that are moderately to heavily soiled.

Synthetics: Specic for synthetic items. If the dirt is dicult to remove,

the temperature can be increased up to 60° and powder detergent can be

used too.

Fast 30’: For washing lightly soiled garments in a short time. Not suitable

for wool, silk and garments to be washed by hand.

Wash & Dry Mix: use programme 6 to wash and dry mixed garments

(cotton and synthetics). This cycle may be used to wash and dry loads of

up to 3.5 kg; we recommend the use of liquid detergent.

The use of the steam in this programme is optimised to reduce the

formation of creases on garments, making them easier to iron.

Shirts Wash & Dry: Use programme 7 to wash and dry shirts and T-shirts

in dierent fabrics and colours to ensure maximum care. This cycle may

be used to wash and dry loads of up to 2 kg. To achieve optimum results,

use liquid detergent and pre-treat cus, collars and stains. The use of the

steam in this programme is optimised to reduce the formation of creases

on garments, making them easier to iron.

Wool - Woolmark Apparel Care - Green:

The Wool wash cycle of this machine has been approved

by The Woolmark Company for the washing of wool

garments labelled as “hand wash” provided that the

products are washed according to the instructions on the

garment label and those issued by the manufacturer of

this washer-dryer (M1318). The Woolmark logo is a

Certication mark in many countries.

Eco 40-60: For washing normally soiled cotton garments declared to be

washable at 40 °C or 60 °C, together in the same cycle. This is the standard

cotton programme and the most ecient in terms of water and energy

consumption.

20°C: For washing lightly soiled cotton garments, at a temperature of 20 °C.

Whites: For heavily soiled whites and resistant colours.

Anti Allergy: Suitable for removing major allergens such as pollen, mites

and cat or dog hair.

Steam Refresh: For refreshing garments, neutralised unpleasant odours

and relaxing the bres by delivering steam into the drum. The garments

will be damp at the end of the cycle.

Ultra Delicates: For washing very delicate garments. It is advisable to

turn the garments inside out before washing them. For best results, use

liquid detergent on delicate garments.

We recommend turning the garments inside out before washing and

placing small items into the special bag for washing delicates. Use liquid

detergent on delicate garments for best results.

When selecting an exclusively time-based drying function, a drying cycle is

performed at the end of the wash cycle that is particularly delicate, thanks

to light handling and appropriate temperature control of the water jet.

The recommended durations are:

1 kg of synthetic garments --> 150 min

1 kg of synthetic and cotton garments --> 180 min

1 kg of cotton garments --> 180 min

The degree of dryness depends on the load and fabric composition.

Rinse: Designed for rinsing and spinning.

Spin + Pump out: Designed for spinning and draining the water.

Eco Cotton: For washing normally soiled cotton garments at 60°C.

DISPLAY

The display is useful when programming the washer-dryer and provides

plenty of information.

B

A

C

2

Section A displays the duration of the various available wash cycles and,

once the cycle starts, the time remaining to the latter’s end (the display

will show the maximum duration of the selected cycle which may

decrease after a few minutes, as the actual duration varies in relation to

the laundry load and the chosen settings); if the DELAY START option was

set, the display will show the time remaining to the start of the selected

wash cycle.

Moreover, pressing the relative button allows for visualising the maximum

values for the temperature, spin speed or type of drying relative to the

selected programme or the most recently selected ones, if compatible

with the selected programme.

The “washing phases” relative to the selected cycle and the “washing

phase” of the running cycle appear in section B:

Wash

Rinse

Spin/Drain

Drying

Section C displays – starting from the left – the icons corresponding to

“temperature”, “spin” and “delay star t”.

The “temperature” bars indicate the maximum temperature level

that can be selected for the chosen cycle.

The “spin” bars indicate the maximum spin speed that can be

selected for the chosen cycle.

The symbol lights up while the drying settings are being adjusted.

LOCKED DOOR INDICATOR

When lit, the symbol indicates that the door is locked. To prevent any

damage, wait until the symbol turns o before opening the door.

To open the door while a cycle is in progress, press the START/PAUSE

button ; if the symbol is o, the door can be opened.

FIRSTTIME USE

Once the appliance has been installed, and before it is used for the rst

time, run a wash cycle with detergent and no laundry, by setting the

“Auto-Clean” cycle.

DAILY USE

Prepare the laundry by following the suggestions appearing under the

“TIPS AND SUGGESTIONS” section.

- Press the ON/OFF button ; the indicator light relative to START/PAUSE

will ash slowly.

- Open the door. Load the laundry while making sure not to exceed the

maximum load quantity indicated in the wash cycle table.

- Pull out the detergent dispenser drawer and pour the detergent into the

relevant compartments, as described in the “DETERGENT DISPENSER

DRAWER” section.

- Close the door.

- The machine automatically displays the maximum temperature and spin

speed values for the selected cycle, or the most recently used settings if

they are compatible with the selected cycle. Pressing the button

gradually reduces the temperature down to the cold wash “OFF” setting.

Pressing the button gradually reduces the spin speed until it is

completely excluded (“OFF” setting). Pressing the buttons further restores

the maximum allowed values for the selected cycle.

- Select the desired wash cycle.

- Select the desired options.

- Press the START/PAUSE button to start the wash cycle; the relative

indicator light will light up steady and the door will lock ( symbol on).

PAUSING A CYCLE

To pause the wash cycle, press the START/PAUSE button again; the

indicator light will ash. To start the wash cycle from the point at which it

was interrupted, press the START/PAUSE button again.

OPENING THE DOOR, IF NECESSARY

Once a cycle starts, the symbol turns on to signal that the door cannot

be opened. While a wash cycle is running, the door remains locked. To

open the door while a cycle is under way, for example, to add or remove

garments, press the START/PAUSE button to pause the cycle; the

indicator light will ash. If the symbol is not lit, the door may be

opened. Press the START/PAUSE button again to continue the cycle.

CHANGING A RUNNING WASH CYCLE

To change a wash cycle while it is in progress, pause the washer-dryer

using the START/PAUSE button (the relative indicator light will ash),

then select the desired cycle and press the START/PAUSE button

again.

! To cancel a cycle that has already begun, press and hold the ON/OFF

button. The cycle will be stopped and the machine will switch o.

AT THE END OF THE WASH CYCLE

This will be indicated by the word “END” on the display; when the

symbol switches o, the door may be opened. Open the door, unload the

laundry and switch o the machine. If you do not press ON/OFF

button, the washing machine will switch o automatically after about a

10 minutes.

OPTIONS

- If the selected option is not compatible with the set wash cycle, the

indicator light will ash and the option will not be activated

Delay start

To set a delayed start for the selected cycle, press the corresponding

button repeatedly until the required delay period has been reached. To

remove the delayed start setting, press the button until the text “OFF”

appears on the display.

Temperature

Each wash cycle has a pre-dened temperature. To modify the

temperature, press the button. The value will appear on the display.

Spin

Each wash cycle has a pre-dened spin speed. To modify the spin speed,

press the button. The value will appear on the display.

Drying

The rst time the button is pressed, the machine will automatically

select the maximum drying cycle which is compatible with the selected

wash cycle. Subsequent presses will decrease the drying level and then

the drying time, until the cycle is excluded completely (“OFF”).

Drying may be set as follows:

A - Based on the desired laundry dryness level:

Iron “A1”: suitable for clothes which will need ironing afterwards. the

remaining dampness softens creases, making them easier to remove.

Hanger “A2”: ideal for clothes which do not need to be dried fully.

Cupboard “A3”: suitable for laundry which can be put back in a

cupboard without being ironed.

B - Based on a set time period: between 30 and 210 minutes.

If your laundry load to be washed and dried is much greater than the

maximum stated load, perform the wash cycle, and when the cycle is

complete, divide the garments into groups and put some of them back

in the drum. At this point, follow the instructions provided for a “Drying

only” cycle. Repeat this procedure for the remainder of the load. A

cooling-down period is always added to the end of each drying cycle.

Drying only

Press button to perform the drying-only cycle.

After selecting the desired cycle (compatible with the type of garments),

press button to exclude the washing phase and start the drying

phase at the maximum level for the selected cycle. The drying level or

time may be set and changed by pressing the drying button .

Cleaning Action

Option makes it possible to optimise washing based on the level of

soil in the fabrics and on desired wash cycle intensity.

For heavily-soiled garments press button until the “Intensive”

level is reached. This level ensures a high-performance wash due to a

larger quantity of water used in the initial phase of the cycle and due to

increased drum rotation. It is useful when removing the most stubborn

stains.

For lightly-soiled garments or a more delicate treatment of the fabrics,

press button until the “Delicate” level is reached. The cycle will

reduce drum rotation to ensure washing results that are perfect for

delicate garments.

CHILD LOCK

To activate the control panel lock, press and hold the button for

approximately 2 seconds. When the symbol is lit, the control panel is

locked (except for the ON/OFF button). This will prevent accidental

modications to wash cycles, especially when children are at home. To

deactivate the control panel lock, press and hold the button for

approximately 2 seconds.

TIPS AND SUGGESTIONS

Divide the laundry according to:

Type of fabric (cotton, mixed bres, synthetics, wool, garments to be

hand-washed). Colour (separate coloured garments from whites, wash

new coloured garments separately). Delicates (small garments – such as

nylon stockings – and items with hooks – such as bras: insert them in a

fabric bag).

Empty the pockets:

Objects such as coins or lighters can damage the washer-dryer and the

drum. Check all buttons.

Follow the dosage recommendation / additives

It optimizes the cleaning result, it avoids irritating residues of surplus

detergent in your laundry and it saves money by avoiding waste of

surplus detergent.

Use low temperature and longer duration

The most ecient programmes in terms of energy consumption are

generally those that perform at lower temperatures and longer duration.

Observe the load sizes

Load your washing machine up to the capacity indicated in the “Wash

Cycle Table” table to save water and energy.

Noise and remaining moisture content

They are inuenced by the spinning speed: the higher the spinning speed

in the spinning phase, the higher the noise and the lower the remaining

moisture content.

CARE AND MAINTENANCE

Before performing cleaning and maintenance, switch the washer-dryer o

and disconnect it from the mains power. Do not use ammable liquids to

clean the washer-dryer. Clean and maintain your washer-dryer periodically

(at least 4 times per year).

Cutting o the water and electricity supplies

Close the water tap after every wash. This will limit wear on the hydraulic

system inside the washer-dryer and help to prevent leaks.

Unplug the washer-dryer when cleaning it and during all maintenance

work.

Cleaning the washer-dryer

The outer parts and rubber components of the appliance can be cleaned

using a soft cloth soaked in lukewarm soapy water. Do not use solvents or

abrasives.

The washer-dryer has a “Auto-Clean” cycle for its internal parts; it must be

run without any load in the drum.

To optimise this cycle, it is possible to use either detergent (10% of the

quantity specied for lightly soiled garments) or special additives to clean

the washer-dryer. We recommend running a cleaning cycle every 40 wash

cycles.

To start the programme press button for 5 seconds.

The cycle will start automatically and will run for about 70 minutes. To

stop the cycle, press the START/PAUSE button.

Cleaning the detergent dispenser drawer

Remove the dispenser drawer by lifting and pulling it outwards. Wash it

under running water; this procedure should be eected regularly.

Caring for the door and drum

Always leave the porthole door ajar in order to prevent unpleasant

odours from forming.

Cleaning the pump

The washer-dryer is tted with a self-cleaning pump that does not require

any maintenance. Small items (such as coins or buttons) may sometimes

fall into the protective pre-chamber situated at the base of the pump.

! Make sure that the wash cycle has ended and unplug the appliance.

To access the pre-chamber:

1. remove the covering panel on the front side of the machine by

inserting a screwdriver in the centre and sides of the panel and using it as

a lever;

2. loosen the drainage pump cover by turning it anti-clockwise: it is

normal for some water to leak out;

3. clean the inside thoroughly;

4. screw the cover back on;

5. put the panel back in place, making sure the hooks slot in place before

pushing the panel onto the appliance.

Checking the water inlet hose

Check the water inlet hose at least once a year. If it is cracked or broken, it

must be replaced: during wash cycles, the high pressure of the water

could suddenly split the hose open.

! Never use hoses that have already been used.

ACCESSORIES

Contact our Technical Assistance Service to check whether the following

accessories are available for this washer-dryer model.

Stacking kit

With this accessory you can secure the tumble dryer to the upper part of

your washer-dryer to save space and facilitate loading and unloading of

the tumble dryer.

TRANSPORT AND HANDLING

Do not lift the washer-dryer by gripping it from the upper section.

Unplug the appliance and close the water tap. Check that the door and

detergent dispenser drawer are tightly closed. Detach the lling hose

from the water tap then detach the drain hose. Empty all the water

remaining in the hoses and secure the latter so that they do not get

damaged during transport. Apply the transport bolts back on. Repeat, in

reverse order, the transport bolt removal procedure described in the

“Installation instructions”.

3

DEMO MODE: to deactivate this function, switch the washer-dryer OFF. Than press and hold “Start/Pause” button, within 5 seconds press also

“ON/OFF” button and hold both buttons for 2 seconds.

TROUBLESHOOTING

Your washer-dryer could occasionally fail to work. Before contacting the Technical Assistance Service, make sure that the problem cannot be easily

solved using the following list.

Anomalies Possible causes / Solution

The washer-dryer does not

start.

The wash cycle does not start.

The washer-dryer does not ll

with water (“H2O” appears on

the display).

The washer-dryer

continuously loads and

unloads water.

The washer-dryer does not

drain or spin.

The washer-dryer vibrates a

lot during the spin cycle.

The washer-dryer leaks.

The appliance is not plugged into the socket fully, or not enough to make contact.

There is no power in the house.

The washer-dryer door is not closed properly.

The ON/OFF button has not been pressed.

The START/PAUSE button has not been pressed.

The water tap has not been opened.

A delay has been set for the start time.

The water inlet hose is not connected to the tap.

The hose is bent.

The water tap has not been opened.

There is no water supply in the house.

The pressure is too low.

The START/PAUSE button has not been pressed.

The drain hose is not tted between 65 and 100 cm from the oor.

The free end of the hose is immersed in water.

The wall drainage system is not tted with a breather pipe.

If the problem persists even after these checks, turn o the water tap, switch the appliance o and contact the

Technical Assistance Service. If the home is on one of the upper oors of a building, there may be problems relating

to back-siphonage, causing the washer-dryer to ll with water and drain continuously. Special anti-siphon valves

are available in shops and help to prevent this inconvenience.

The cycle does not include drainage: with certain cycles it must be started manually.

The drain hose is bent.

The drainage duct is clogged.

The drum was not unlocked correctly during installation.

The washer-dryer is not level.

The washer-dryer is tucked between furniture cabinets and the wall.

The water inlet hose is not screwed on properly.

The detergent dispenser drawer is obstructed.

The drain hose is not properly attached.

The START/PAUSE

indicator light ash rapidly

and an error code appears on

the display (e.g.: F-01, F-..).

There is too much foam.

The washer-dryer does not

dry.

Switch o the machine and unplug it, wait for approximately 1 minute and then switch it back on again.

If the problem persists, contact the Technical Assistance Service.

The detergent is not suitable for machine washing (it should display the text “for washer-dryers” or “hand and

machine wash”, or the like).

Too much detergent was used.

The appliance is not plugged into the socket, or not enough to make contact.

There has been a power failure.

The appliance door is not shut properly.

A Delay Timer has been set.

DRYING is in the OFF position.

4

CLEANING & MAINTENANCE

2

1

For any cleaning and maintenance, switch o and unplug the washing machine.

Do not use ammable uids to clean the washing machine.

CLEANING THE OUTSIDE OF THE WASHING MACHINE

Use a soft damp cloth to clean the outer parts of the washing

machine.

Do not use glass or general purpose cleaners, scouring

powder or similar to clean the control panel – these

substances might damage the printing.

CHECKING THE WATER SUPPLY HOSE

Check the inlet hose regularly for brittleness and cracks. If

damaged, replace it by a new hose available through our

After-Sales Service or your specialist dealer.

Depending on the hose type:

For water stop hoses: check the small safety valve inspection

window (see arrow). If it is red, the water stop function was

triggered, and the hose must be replaced by a new one.

For unscrewing this hose, press the release button (if

If the inlet hose has a transparent coating, periodically check

available) while unscrewing the hose.

if the colour intensies locally. If yes, the hose may have a leak

and should be replaced.

CLEANING THE MESH FILTERS IN THE WATER SUPPLY HOSE

1. Close water tap and unscrew the inlet hose.

1

2

2. Clean the mesh lter at the hose’s end carefully with a

ne brush.

3. Now unscrew the inlet hose on the back of the washing

machine by hand. Pull out the mesh lter from the valve

on the back of the washing machine with pliers and

carefully clean it.

4. Insert the mesh lter again. Connect the inlet hose to

water tap and washing machine again. Do not use a tool

to connect the inlet hose. Open the water tap and check

that all connections are tight.

5

CLEANING THE DETERGENT DISPENSER

1

2

Remove the dispenser by raising it and

pulling it out (see gure).

Wash it under running water; this

operation should be repeated frequently.

CLEANING THE WATER FILTER / DRAINING RESIDUAL WATER

Switch o and unplug the washing machine before cleaning the water lter or draining residual water. If you used a hot

wash programme, wait until the water has cooled down before draining any water.

Clean the water lter regularly, to avoid that the water cannot drain after the wash due to obstruction of the lter.

If the water cannot drain, the display indicates that the water lter may be clogged.

1. Remove the kick panel: Using a screwdriver, do that which

is shown in the following gure.

2. Container for the drained water:

Place a low and wide container under the water lter in

order to collect the residual water.

3. Drain the water:

Slowly turn the lter counter-clockwise until all the water

has come out. Allow the water to ow out without

removing the lter. Once the container is full, close the

water lter by turning it clockwise. Empty the container.

Repeat the procedure until all the water has been drained.

4. Remove lter: Lay a cotton cloth beneath the water lter,

which can absorb a small amount of rest water. Then

remove the water lter by turning it out anticlockwise.

5. Clean the water lter: remove residues in the lter and

clean it under running water.

6. Insert the water lter and reinstall the plinth: Reinsert the water

lter again by turning it in clockwise direction. Make sure to turn

it in as far as it goes; the lter handle must be in vertical position.

To test water tightness of the water lter, you can pour about 1

liter of water into the detergent dispenser. Then reinstall the

plinth.

2

1

6

TRANSPORT AND HANDLING

Never lift the washing machine by holding it at the worktop.

1. Pull out the mains plug, and close the water tap.

2. Make sure that door and detergent dispenser are properly

closed.

3. Disconnect the inlet hose from the water tap, and remove

the drain hose from your draining point. Remove all rest

water from the hoses, and x them so that they cannot get

damaged during transport.

AFTERSALES SERVICE

BEFORE CALLING THE AFTERSALES SERVICE

1. See if you can solve the problem by yourself with the help

of the suggestions given in the TROUBLESHOOTING

IF AFTER THE ABOVE CHECKS THE FAULT STILL

OCCURS, GET IN TOUCH WITH THE NEAREST

AFTERSALES SERVICE

To receive assistance, call the number shown in page 9 or

follow the instructions on the website.

When contacting our Client After sales service, always specify:

• a brief description of the fault;

• the type and exact model of the appliance;

xxxxxxxxxxxx

4. Ret the transport bolts. Follow the instructions for

removing the transport bolts in the “Installation Guide” in

reverse order.

Important: Do not transport the washing machine without

having xed the transport bolts.

2. Switch the appliance o and back on again to see if the

fault persists.

• the service number (number after the word Service on the

rating plate).

• your full address;

• your telephone number.

If any repairs are required, please contact an authorised aftersales service (to guarantee that original spare parts will be used

and repairs carried out correctly).

7

DISTRIBUTION LINE AND CUSTOMER SERVICE INFORMATION

imported and exclusively marketed by:

8

EN

SAFETY INSTRUCTIONS

Before using the appliance, read these safety instructions. Keep them nearby for future reference. These

instructions and the appliance itself provide important safety warnings, to be observed at all times.

The manufacturer declines any liability for failure to

observe these safety instructions, for inappropriate

use of the appliance or incorrect setting of controls.

Very young children (0-3 years) should be kept

away from the appliance. Young children

(3-8years) should be kept away from the

appliance unless continuously supervised.

Children from 8years old and above and persons

with reduced physical, sensory or mental

capabilities or lack of experience and knowledge

can use this appliance only if they are supervised

or have been given instructions on safe use and

understand the hazards involved. Children must

not play with the appliance. Cleaning and user

maintenance must not be carried out by children

without supervision. Never open the door forcibly

or use it as a step.

PERMITTED USE

CAUTION: The appliance is not intended to be

operated by means of an external switching

device, such as a timer, or separate remote

controlled system.

This appliance is intended to be used in

household and similar applications such as: sta

kitchen areas in shops, oces and other working

environments; farm houses; by clients in hotels,

motels, bed & breakfast and other residential

environments.

Do not load the machine above the maximum

capacity (kg of dry cloth) indicated in the

programme table.

This appliance is not for professional use. Do

not use the appliance outdoors.

Do not use any solvents (e.g. turpentine,

benzene), detergents containing solvents,

scouring powder, glass or general purpose

cleaners, or ammable uids; do not machine

wash fabrics that have been treated with solvents

or ammable liquids.

Do not dry unwashed items in the tumble

dr yer.

Items that have been soiled with substances

such as cooking oil, acetone, alcohol, petrol,

kerosene, spot removers, turpentine, waxes and

wax removers should be washed in hot water with

an extra amount of detergent before being dried

in the tumble dryer.

Items such as foam rubber (latex foam), shower

caps, waterproof textiles, rubber backed articles

and clothes or pillows tted with foam rubber

pads should not be dried in the tumble dryer.

Fabric softeners, or similar products, should be

IMPORTANT TO BE READ AND OBSERVE

used as specied by the fabric softener

instructions.

The nal part of a tumble dryer cycle occurs

without heat (cool down cycle) to ensure that the

items are left at a temperature that ensures that

the items will not be damaged.

Never stop a tumble dryer before the end of

the drying cycle unless all items are quickly

removed and spread out so that the heat is

dissipated.

During the drying phase, the door tends to get

quite hot.

Do not use the appliance to dry clothes that

have been washed with ammable solvents (e.g.

trichlorethylene).

Do not use the appliance to dry foam rubber or

similar elastomers.

Make sure that the water tap is turned on

during the drying cycles.

Remove all objects from pockets such as

lighters and matches.

INSTALLATION

The appliance must be handled and installed

by two or more persons- risk of injury. Use

protective gloves to unpack and install- risk of

cuts.

If you want to stack a dryer on top of your

washing machine, rst contact our After-Sales

Service or your specialist dealer to verify whether

this is possible. This is only possible if the dryer is

attached to the washing machine by means of

appropriate stacking kit available through our

After- Sales Service or your specialist dealer.

Move the appliance without lifting it by the

worktop or top lid.

Installation, including water supply (if any) and

electrical connections and repairs must be carried

out by a qualied technician. Do not repair or

replace any part of the appliance unless

specically stated in the user manual. Keep

children away from the installation site. After

unpacking the appliance, make sure that it has not

been damaged during transport. In the event of

problems, contact the dealer or your nearest

After-sales Service. Once installed, packaging

waste (plastic, styrofoam parts etc.) must be

stored out of reach of children- risk of suocation.

The appliance must be disconnected from the

power supply before any installation operationrisk of electric shock. During installation, make

sure the appliance does not damage the power

cable - risk of re or electric shock. Only activate

the appliance when the installation has been

completed.

9

Do not install your appliance where it may be

exposed to extreme conditions, such as: poor

ventilation, temperatures below 5 °C or above 35 °C.

When installing the appliance make sure that

the four feet are stable and resting on the oor,

adjusting them as required, and check that the

appliance is perfectly to level using a spirit level.

If the appliance is being installed on wood or

“oating” oors (certain parquet and laminate

materials), secure a 60x60x3cm (at least) sheet

of plywood to the oor then place the appliance

on top of this.

Connect the water inlet hose(s) to the water

supply in accordance with the regulations of your

local water company.

For cold ll only models: do not connect to the

hot water supply.

For models with hot ll: the hot water inlet

temperature must not exceed 60°C.

The washing machine is tted with transport

bolts to prevent any possible damage to the

interior during transport. Before using the

machine, it is imperative that the transport bolts

are removed. After their removal, cover the

openings with the 4 enclosed plastic caps.

After installation of the device, wait a few

hours before starting it so that it acclimates to the

environmental conditions of the room.

Make sure that the ventilation openings in the

base of your washing machine (if available on

your model) are not obstructed by a carpet or

other material.

Use only new hoses to connect the appliance

to the water supply. The old hose-sets should not

be reused.

The supply water pressure must be in the 0.1-1

MPa range.

Do not repair or replace any part of the

appliance unless specically stated in the user

manual. Use only authorized After-sales Service.

Self or non-professional repair may lead to

dangerous incident resulting in live or health

threatening and/or signicant property damage.

. The spare parts for the household machine

will be available for 10 years after placing the last

unit on the market as dictated by the European

Ecodesign regulation.

ELECTRICAL WARNINGS

It must be possible to disconnect the appliance

from the power supply by unplugging it if plug is

accessible, or by a multi-pole switch installed

upstream of the socket in accordance with the

wiring rules and the appliance must be earthed in

conformity with national electrical safety

standards.

Do not use extension leads, multiple sockets or

adapters. The electrical components must not be

accessible to the user after installation. Do not use

the appliance when you are wet or barefoot. Do

not operate this appliance if it has a damaged

power cable or plug, if it is not working properly,

or if it has been damaged or dropped.

If the supply cord is damaged, it must be

replaced with an identical one by the

manufacturer, its service agent or similarly

qualied persons in order to avoid a hazard- risk

of electric shock.

CLEANING AND MAINTENANCE

WARNING: Ensure that the appliance is

switched o and disconnected from the power

supply before performing any maintenance

operation; never use steam cleaning equipmentrisk of electric shock.

DISPOSAL OF PACKAGING MATERIALS

The packaging material is 100% recyclable and is marked with the

recycle symbol .

The various parts of the packaging must therefore be disposed of

responsibly and in full compliance with local authority regulations

governing waste disposal.

DISPOSAL OF HOUSEHOLD APPLIANCES

This appliance is manufactured with recyclable or reusable materials.

Dispose of it in accordance with local waste disposal regulations.

For further information on the treatment, recovery and recycling

of household electrical appliances, contact your local authority,

the collection service for household waste or the store where you

purchased the appliance. This appliance is marked in compliance

with European Directive 2012/19/EU, Waste Electrical and Electronic

Equipment (WEEE). By ensuring this product is disposed of correctly,

you will help prevent negative consequences for the environment and

human health.

The symbol on the product or on the accompanying documentation

indicates that it should not be treated as domestic waste but must be

taken to an appropriate collection center for the recycling of electrical

and electronic equipment.

10

Loading...

Loading...