CurveTrack

®

System

Installation Guide

Install Guide P/N : 0309-0218-00

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

SENTRYWAY

Les Carrés du Parc

10 rue des Rosiéristes

69410 Champagne au Mont d’Or

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 3 of 70

System Installation Guide

CurveTrack

®

System

Installation Guide

Installation Guide Revision Status :

Rev. Description of Change Date Approval

Sentryway - Les carrés du Parc - 10 rue des Rosiéristes - 69410 Champagne-au-Mont-d’Or

Phone : 06 64 78 59 57 - Website : www.sentryway.com

e CurveTrack® is a product of Sentryway, and is protected patents.

is document discloses information proprietary to Sentryway, and no intent to abandon such proprietary

information or to grant any rights to the recipient, is to be inferred from any transfer of this document. All

transfers of this document, except where express written consent has been granted, are made subject to the

conditions that the document not be reproduced, copied, or otherwise represented either in whole or in part,

and that no part of its contents or any embodiment thereof will be divulged or used in connection with any

matters other than for Sentryway

STATEMENT OF CONFIDENTIALITY

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 4 of 70

System Installation Guide

CAUTION

It is essential that safety precautions noted throughout this manual be followed

along with OSHA Safety Standards and local electrical codes at the installation

site. To prevent personal injury, use the safety equipment specied in the

Recommended Tool list elsewhere in this manual.

SENTRYWAY reserves the right to modify the contents of this manual at any

time. Sentryway shall not be held liable for errors contained herein or for incidental or consequential damages in connection with furnishing, performance,

or the use of material in this manual.

NOTICE TO USERS

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 5 of 70

System Installation Guide

Table of Contents

1. INTRODUCTION...............................................................................................................7

1.1 Explanation of Symbols.............................................................................................................................8

1.2 Technical Specications............................................................................................................................9

1.2.1 Physical Dimensions of the camera carriage..........................................................................................10

1.3 Units of measure.........................................................................................................................................10

1.4 General safety precautions.........................................................................................................................10

1.5 Responsibilities of the Installer.................................................................................................................11

2. IDENTIFICATION OF MAJOR

COMPONENTS...............................................................12

2.1 System Components...................................................................................................................................12

2.2 Rail Components........................................................................................................................................14

2.3 Carriage Components................................................................................................................................17

2.4 Power supply assembly (power end cap) Components..............................................................................18

3. SITE EVALUATION AND

PLANNING...............................................................................19

3.1 Overview.....................................................................................................................................................23

3.2 Setting Up A Schedule................................................................................................................................21

3.3 Planning Installation of the System Run...................................................................................................21

3.4 Material Inspection and Inventory............................................................................................................22

3.5 Material Storage.........................................................................................................................................22

3.6 Recommended Tool

List

.............................................................................................................................23

4. SUPPORT STRUCTURE INSTALLATION........................................................................24

4.1 General.......................................................................................................................................................24

4.2 Fastening Support Hardware to Bar

Joists—Perpendicular

.....................................................................24

4.3 Fastening Support Hardware to Bar

Joists—Parallel

................................................................................25

4.4 Fastening Support Hardware to Steel Beams—Perpendicular.................................................................26

4.5 Fastening Support Hardware to Steel

Beams—Parallel

............................................................................27

4.6 Fastening Support Hardware to C–Purlin

Beams—Perpendicular

..........................................................28

4.7 Fastening Support Hardware to C–Purlin Beams—Parallel....................................................................30

4.8 Fastening Support Hardware to Flush Concrete–Parallel and Perpendicular.........................................31

4.9 Fastening Support Hardware to Reinforced Concrete

Beams

..................................................................33

5. THREADED ROD INSTALLATION..................................................................................34

5.1 General.......................................................................................................................................................34

5.2 Cutting the readed Rod.........................................................................................................................34

5.3 Installing readed Rod in Channel for Parallel Runs............................................................................36

5.4 Installing Turnbuckles on readed Rods...............................................................................................38

6. RAIL SECTION

INSTALLATION.......................................................................................40

6.1 Rail Section Inspection..............................................................................................................................40

6.2 Rail Section Cleaning.................................................................................................................................40

6.3 Rail Section Preparation............................................................................................................................40

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 6 of 70

System Installation Guide

6.4 Connecting rail Sections to readed Rod Assemblies–Method 1..........................................................42

6.5 Connecting rail Sections to readed Rod Assemblies–Method 2..........................................................43

6.6 Alignment of System Run..........................................................................................................................43

6.7 Guy Wire Suspension.................................................................................................................................51

7. INSTALLATION OF COPPER CONDUCTORS............................................................53

7.1 General.......................................................................................................................................................53

7.2 Soldering copper conductors ....................................................................................................................54

7.3 Inserting conductors into plastic track.....................................................................................................58

8. INSTALLATION OF BUMPERS STOP BRACKETS

........................................................59

8.1 General.......................................................................................................................................................59

8.2 Installation.................................................................................................................................................59

9. INSTALLATION OF RF ADAPTER AND TERMINATOR BOARDS

............................60

9.1 RF Adapter PCB Installation....................................................................................................................60

9.2 Terminator Board Installation..................................................................................................................60

10. INSTALLATION OF LIMIT SWITCH ACTUATORS....................................................61

10.1 General....................................................................................................................................................61

10.2 Installing limit switch actuators.............................................................................................................61

11. SYSTEM CABLING WITH POWER END CAP ASSEMBLY.........................................66

12. INSTALLING THE CARRIAGE.....................................................................................63

12.1 Carriage inspection.................................................................................................................................63

12.2 Installing the carriage in the system run................................................................................................63

12.3 Inspecting the system run.......................................................................................................................64

13. SYSTEM INITIALIZATION AND POWERING UP.......................................................65

13.1 Power up / Initialization.........................................................................................................................65

13.2 Programming instructions....................................................................................................................65

14. WINDOWS.....................................................................................................................66

14.1 General description.................................................................................................................................66

14.2 Windows installation on straight rails...................................................................................................66

14.3 Windows installation on curved section of rail.....................................................................................68

15. FIELD REPLACEABLE PARTS LIST..............................................................................69

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 7 of 70

System Installation Guide

1. Introduction

Sentryway has designed and built this state-of-the-art Closed Circuit Television (CCTV) Traveling Camera

System using the nest materials and components available. e CurveTrack® consists of a CCTV camera, with

pan, tilt, and zoom capability, which moves along a rail on a carriage concealed from view within a transparent,

mirrored enclosure. e carriage is not tethered to any power or video cables. Because the camera moves on a

rail, line-of-sight and blind spot issues are eliminated and total coverage can be achieved using fewer cameras.

e CurveTrack® camera provides a continuous, high resolution, real-time, moving video picture while

remaining hidden. e system can be operated in automatic or manual modes. An on-site system operator can

easily tilt, pan, zoom, and focus the camera to monitor specic areas and follow activity.

Of primary importance is the fact that individual CurveTrack® systems can be accessed remotely via the

internet. is capability enables, for instance, corporate headquarter’s personnel to observe and monitor ongoing operations at multiple facilities in real time. Management can maintain total control over display, pricing,

and stocking of merchandise while ensuring compliance with all operational directives and procedures.

e instructions presented in this manual are intended for technicians and comprise the recommended

installation procedures for all components of the CurveTrack® system. Operating instructions for the system

are contained in a separate User’s Manual available from Sentryway

Quiet, long lasting, trouble – free operation of the CurveTrack® system is dependent upon proper installation of

all components. It is imperative that installation technicians read and understand this manual thoroughly before

beginning an installation. Installers must use good judgment when slight deviations from these instructions

are called for.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 8 of 70

System Installation Guide

1.1 Explanation of symbols

e Exclamation Mark is used as a general safety alert. Read and follow instructions carefully when

this symbol appears.

A Note is a specic fact or time– saving tip that, if not followed, could aect the performance of the associated

procedure.

A Caution is present when failure to properly perform a particular action or procedure could cause serious

equipment damage or cost considerable time to correct. Complying with a Caution can help to prevent serious

trouble.

A Danger statement is used to alert the user to the existence of the potential for serious bodily injury or death.

Information presented under the Danger symbol MUST BE ACTED UPON.

CAUTION

NOTE

DANGER

!

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 9 of 70

System Installation Guide

1.2 Technical specifications

Supplier’s name and address :

Model or Type :

Electrical rating :

Input 1 Power Chassis

Input 2 & 3 RF Modem & Video Demodulator

Atmospheric Specications

Operating

Temperature

Humidity

Atmospheric pressure

Storage

Temperature :

Humidity :

Atmospheric pressure :

Mode of operation :

Classication :

Type :

User accessible fuses :

External IEC Module

Output:

Protective Earth terminals :

CE Contact’s name and address :

CE Contact’s telephone number :

Sentryway - Les carrés du parc - 10 rue des Rosiéristes

69410 Champagne-au-Mont-d’Or

FRANCE

CurveTrack®

100-240VAC; 3A; 50-60Hz

100-240VAC; 0.33 - 0.19A; 50-60Hz

32 to 104 degrees F (0 to 40 degrees C)

L. T. 30 to 75% 10-90% non condensign

700HPa to 1060HPa

-10 to +60 degrees Centigrade

0 to 95%, condensation should not occur

500HPa to 1060HPa

Continuous

Class I

N/A

T3.15AH, 250V

No accessible outputs

Internal connections marked

No external connections

Supplied on request

Supplied on request

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 10 of 70

System Installation Guide

1.2.1 Physical dimensions of the camera carriage (see figure 1-1)

119 mm

575 mm

121 mm

194 mm

3.6 kg

Figure 1-1. CurveTrack® Camera Carriage

1.3 Units of measure

1.4 General Safety precautions

Dimensions and distances presented in this manual are expressed in metric units of measure.

If possible, avoid installing units in occupied buildings during regular business hours.

Installation area should be blocked o to keep bystanders safe from injury.

e track must be hung a minimum of 2.5 meters above the oor at its lowest point. e AC line providing power

to the Power Supply Assembly must be installed by a licensed electrician and must be in total conformance

with local electrical codes.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 11 of 70

System Installation Guide

CAUTION

Socket outlets shall be installed nea r the equipment and be

readily accessible to the mains plug connections.

Use protective clothing such as a hard hat, safety shoes and heavy leather gloves when doing overhead

construction or erection. Wear approved safety glasses at all times.

Make certain you are grounded before handling electronic circuit boards or their components to prevent static

electricity from damaging sensitive electronic parts.

Keypad controllers used with this system must contain SELV circuits and be UL, CSA, CE, or ETL certied to

UL1950.

Never allow an inexperienced or untrained person to operate the control devices or make adjustments to the

unit.

Aer ensuring that the rail installation is straight, level and plumb, verify that all hardware has been securely

fastened.

Comply with all local codes regarding the use of ladders, lis and scaolding.

1.5 Responsabilities of the installer

While installing the CurveTrack® system, it is important that the installer understands that he /she is installing

a one-of-a-kind system. Installation must follow the guidelines and instructions presented in this manual in

order for the system to operate reliably providing years of good service with low maintenance.

Since the stability and reliability of the carriage depends entirely upon the rail, it is important to make sure

that the rail is installed straight, level and plumb. All associated components must be installed according to the

specications described in this manual and all applicable Sentryway eld bulletins and Tech Tips. Shortcuts

taken during installation with the intention of saving time or money can actually result in lost time and

increased expense if personnel must subsequently return to make corrections.

Every successful installation is the result of good, thorough planning. It is important that the lead installer

research all aspects of the installation before starting the actual, physical installation. is research includes:

reviewing construction drawings and Sentryway documentation, verifying that all materials required are at

the site, determining the needs of the installation team, and thoroughly reviewing the installation site itself. It

is also impor- tant that the customer, and the electrical contractor (if any), are involved in this planning stage.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 12 of 70

System Installation Guide

2. Identification of major components

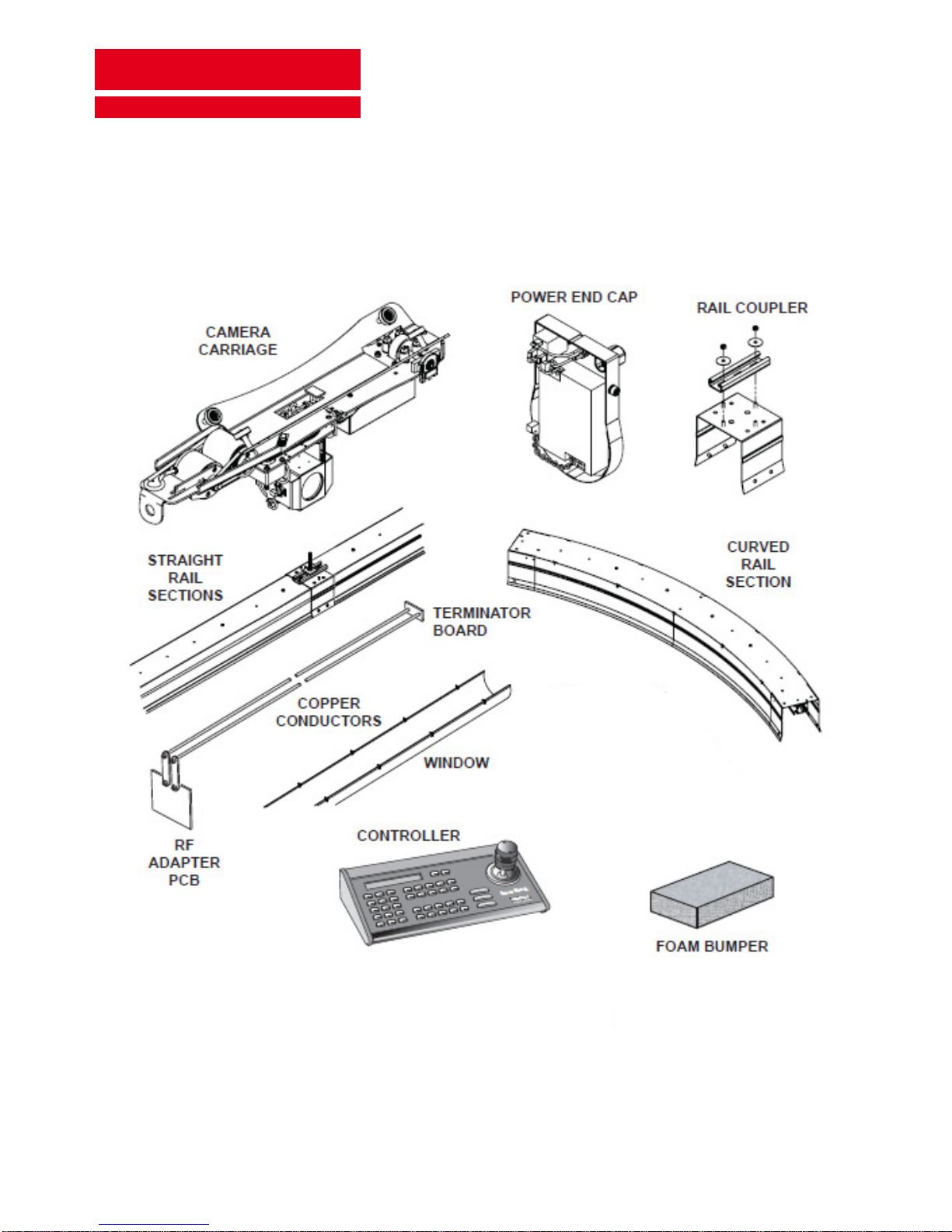

2.1 System components (see figure 2-1)

00010

Figure 2-1. Major System Components

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 13 of 70

System Installation Guide

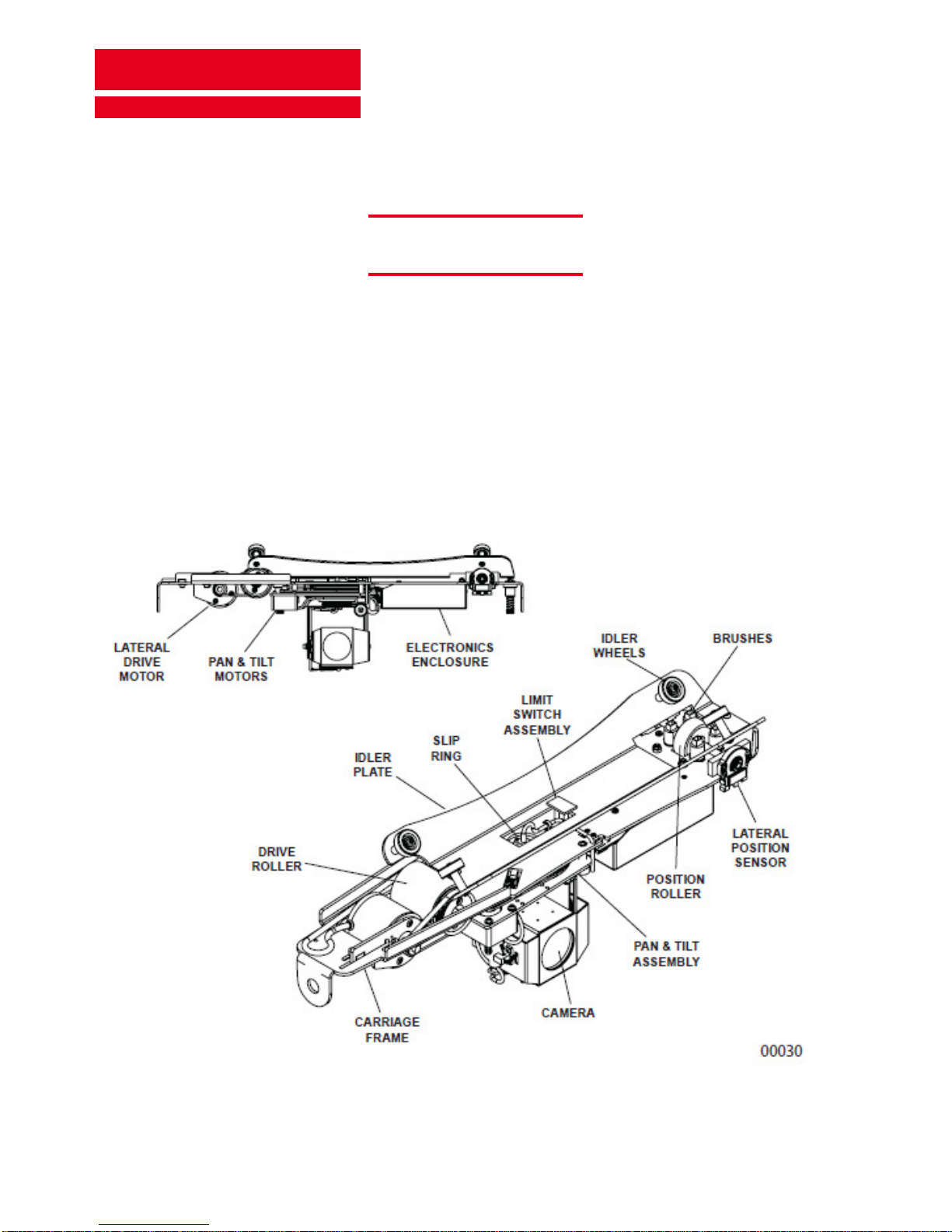

Carriage – e carriage is the wheeled assembly that travels the length of the system run. e carriage

provides mounting for the PTZ camera, control circuitry and the driving mechanism.

In manual mode, carriage movement and position are determined by the operator. In automatic mode,

the carriage “patrols” by continuously traversing the system run at a preset speed. A progammable tour

function makes it possible to have the cameras stopped and aimed at preset locations for specic lengths

of time, in any desired sequence, while patrolling.

Controller – e Controller is the device used by the operator of the system to send coded command

signals to the carriage.

Copper Conductors – Two lengths of copper tubing, pressed into the plastic track portions of the rail

sections, extend the length of the system run. ese conductors carry control, power, and video signals.

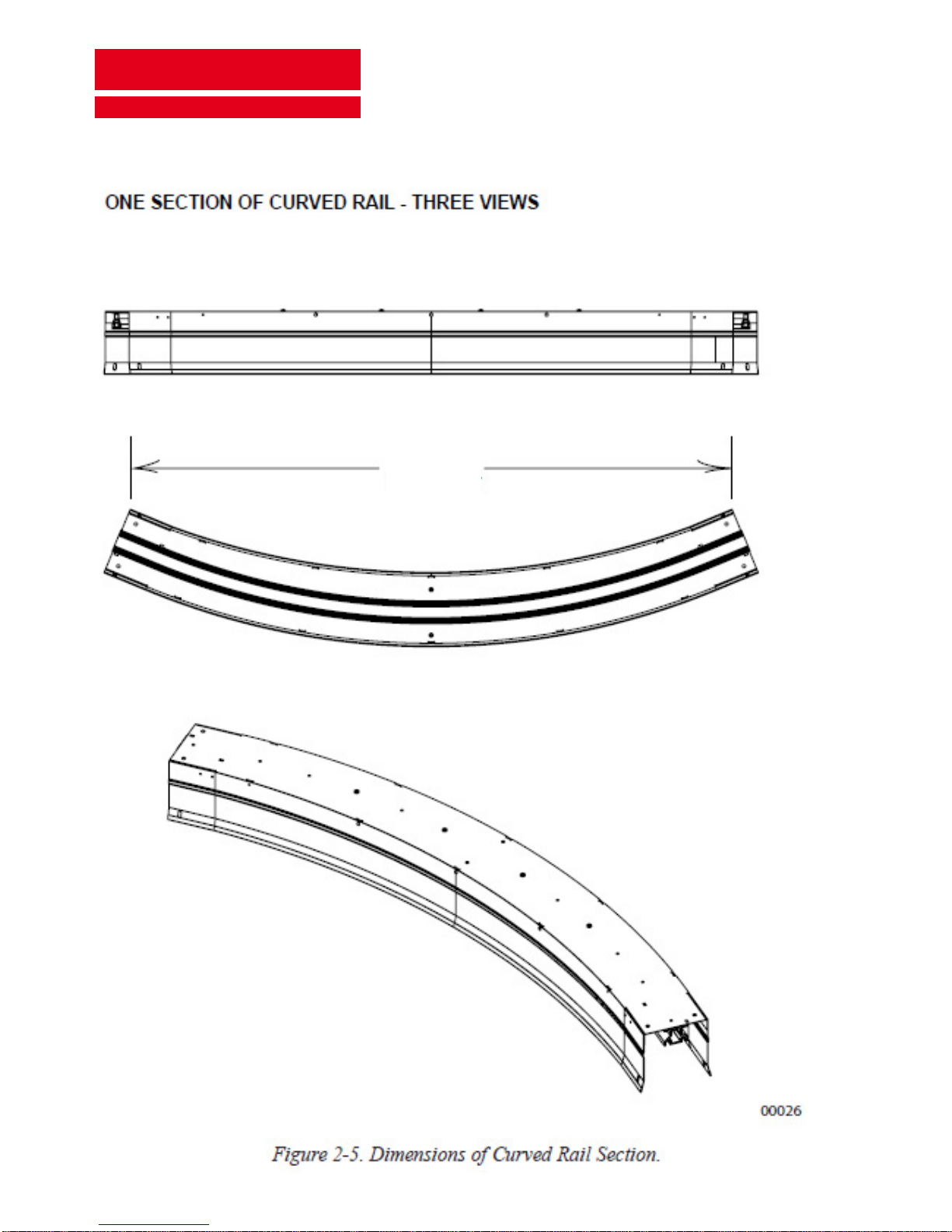

Rail Section – Each straight rail section is 2.5 meter long, three- sided, aluminum structure. Available

curved, 45-degree sections of rail can be combined to enable the system to be congured with 45, 90, or

180 degree bends and turns. Straight and curved rail sections are coupled together to form the system

run. All rail sections house the plastic track on which the camera carriage rolls. Continuous grooves in

the plastic track provide electrically isolated mounting for the copper conductors.

Rail Couplers – e rail couplers are shaped to snap over adjacent rail sections. readed studs on the

couplers engage holes pre-drilled in the rails. Nylon insert lock nuts secure the assembly together. e

short lengths of steel channel by which the rail is hung are secured to the top of each coupler.

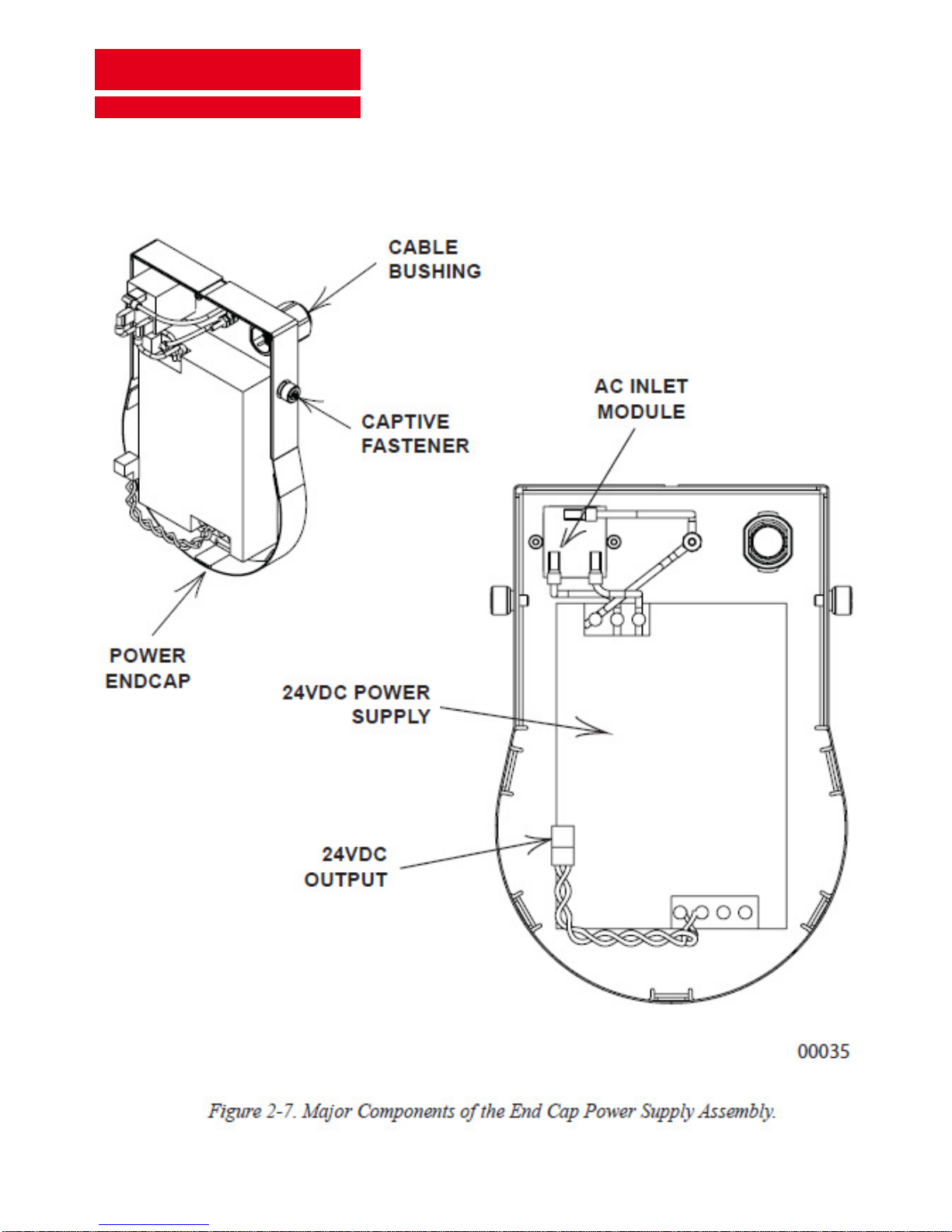

Power Supply Assembly (Power End Cap) – is enclosure connects to the power source and converts

(recties) AC to provide the necessary 24VDC power. e power supply is housed in the Power End Cap

at the service end of the system run. e power output cable from the power supply is plugged directly

into the RF Adapter PCB. A relay board is included to switch the DC output from a remote location.

RF Adapter Board – e RF Adapter board, located at the same end of the system run as the Power

Supply Assembly, acts as an interface and relays video, power, and control signals between the Power

Supply Assembly and Video Modem and the copper conductors.

System Run – e term system run refers to a single assembly of multiple rail sections joined together.

Only one camera carriage may operate within each system run, and each system run must be operated

from its own Power Supply Assembly. An installation site consists of one or more system runs.

Terminator Board – Provides electrical termination of the two copper conductors at the end of the system

run opposite the RF Adapter board.

Windows – e window material, delivered to the job site in rolls, is a plastic material with a mirror

nish. e windows are secured to the rail sections using small clips that pass through slots punched in

the window material and engage a rib on the edge of the rail housing.

Foam Bumper – A foam bumper is installed at each end of the system run to protect the carriage in the

event it strikes the end of the rail.

2.1.1

2.1.2

2.1.3

2.1.4

2.1.5

2.1.6

2.1.7

2.1.8

2.1.9

2.1.10

2.1.11

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 14 of 70

System Installation Guide

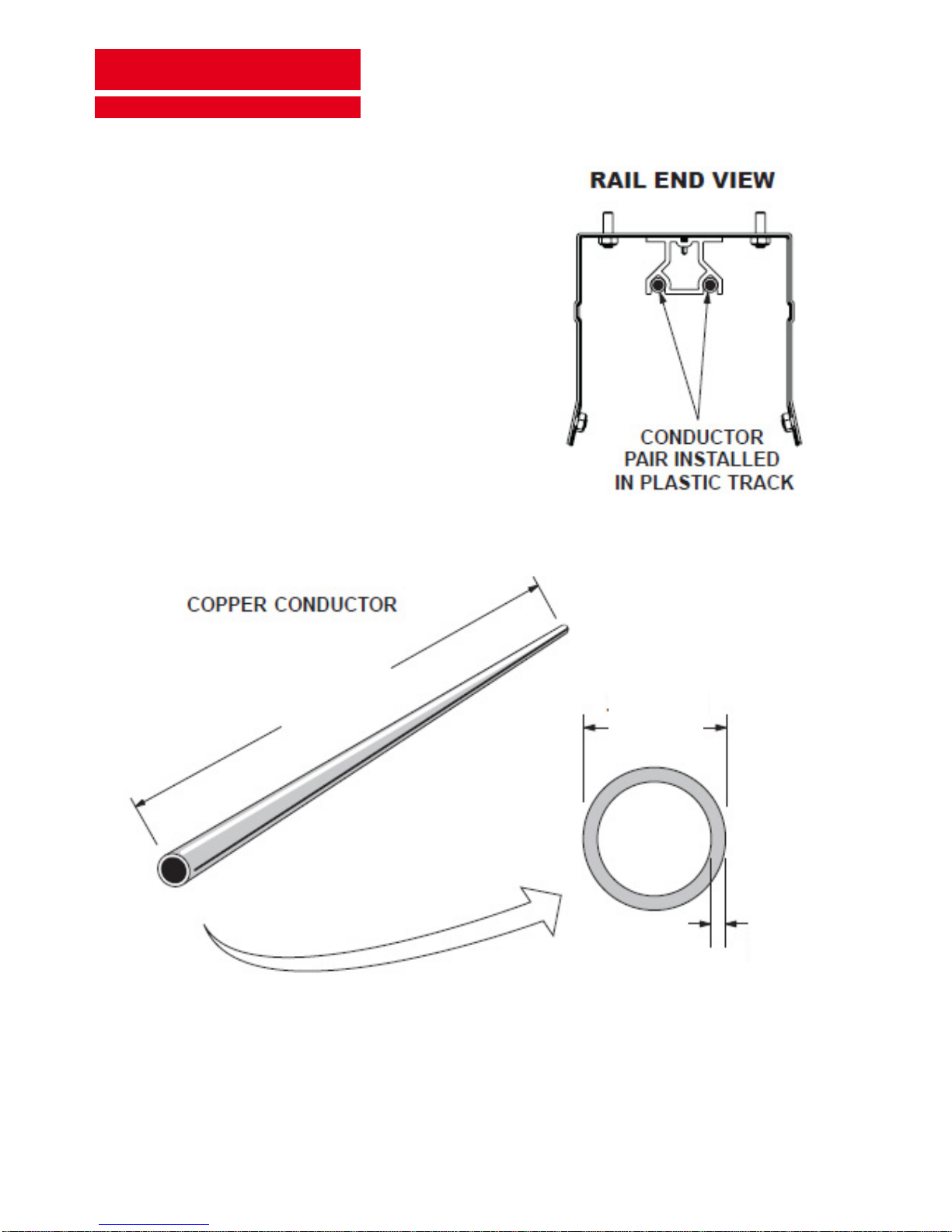

2.2 Rail components

WEIGHT: 1041 g

Weight specied is for each single 5 m section of copper

conductor. Remember that two such conductors, mounted

parallel to each other, as shown to the right, are pressed

into the plastic track and run the entire length of the rail.

e copper conductor tubes are 9.5mm OUTSIDE diameter by

5 meters long and have a wall thickness of 0.762mm.

00020

Figure 2-3. Copper Conductors.

5 m

0.762 mm

9.5 mm

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 15 of 70

System Installation Guide

2.5 m

165.5 mm

150 mm

255 mm

185 mm

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 16 of 70

System Installation Guide

1.35 m

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 17 of 70

System Installation Guide

2.3 Carriage components (See figure 2-6)

Any time you li the carriage, it must be supported with both hands. Li

the carriage by the frame and idler plate ONLY! Do not apply any liing

forces to the pan and tilt assembly or to the electronics enclosure.

Do not rest the carriage on the brushes, pan and tilt assembly, or slip ring.

If the carriage must be rested on a hard surface, lay it GENTLY on its side.

Alternatively, lean the carriage on end against the wall.

CAUTION

Figure 2-6. CurveTrack® Camera Carriage

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 18 of 70

System Installation Guide

2.4 Power supply assembly (Power End) components (See figure 2-7)

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 19 of 70

System Installation Guide

3. Site evaluation and planning

3.1 Overview

A good installation is always preceded by good preliminary planning. A comprehensive site survey and a set

of oor plans are valuable assets for system planning. It is essential to determine the location best suited for

the system run(s), and to identify the type of ceiling or roof structure from which it will be suspended, prior to

specifying the required mounting materials. Proper planning will ensure that you have an adequate supply of

mounting materials on hand, before starting the installation, to minimize delays.

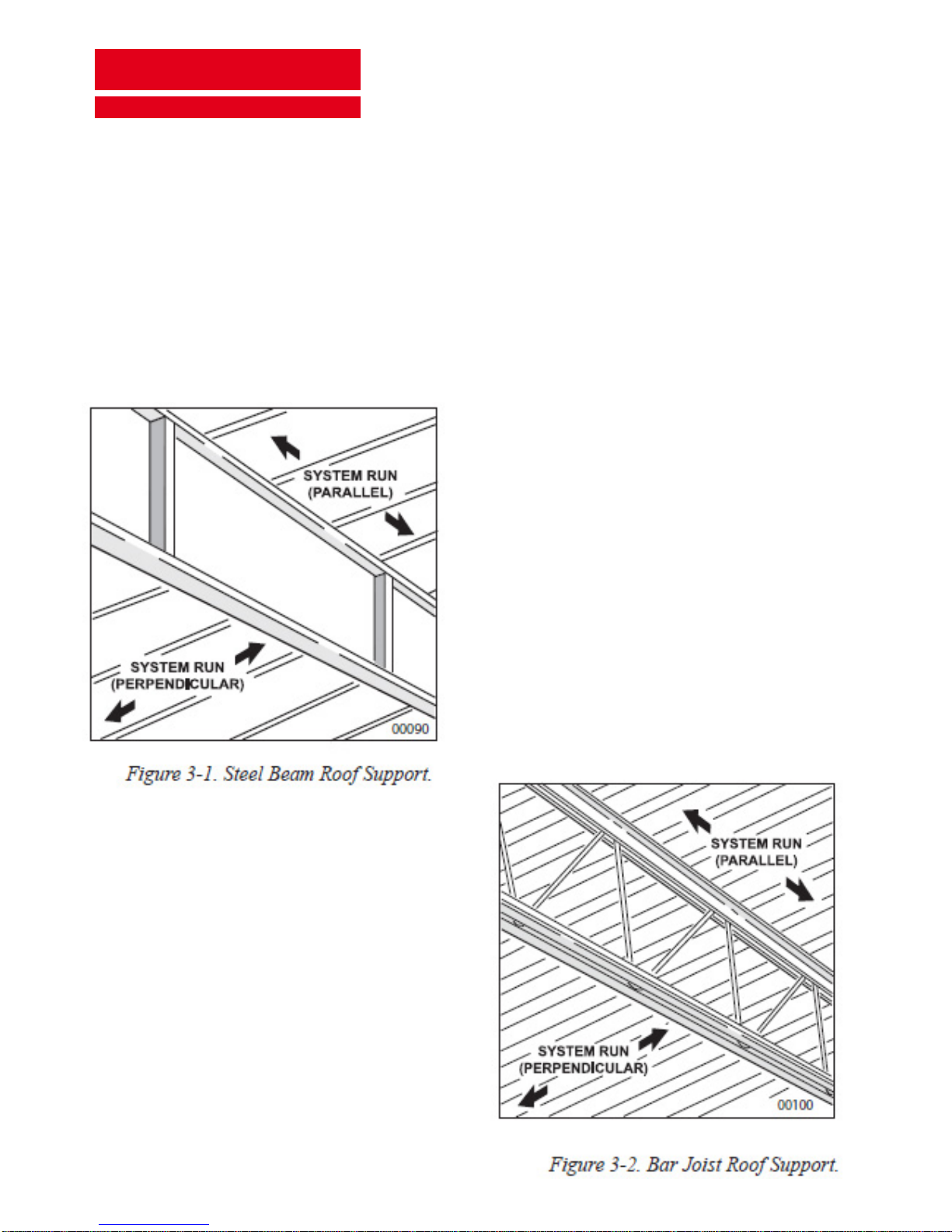

A system run can be installed either in parallel with, or perpendicular to, bar joists, steel beams, preformed

concrete beams, or C– Purlin beams. A at corrugated

steel roof is yet another possibility which will require its

own alternative method of installation.

e instructions in Sections 3 and 4 detail specic

installation methods suitable for the majority of roof and

ceiling types.

Figure 3-1 illustrates a typical steel beam type of roof

support structure. Since spacing between beams and

the distance between the beams and the oor can vary

greatly, close attention to these variables is important

when planning for sucient mounting material. Read the

following installation instructions rst before deciding

on the best mounting method and materials to use.

Figure 3-2 illustrates a typical bar joist type of roof

support structure. Mounting to this type of support will

not require drilling into the bar joist

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 20 of 70

System Installation Guide

Figure 3-3 illustrates a typical type of C – Purlin roof

support structure. Special clamps, which require no

drilling, are available from STC.

Figure 3-4 illustrates a typical reinforced concrete

type of roof support structure. is type of

construction will require drilling into the concrete

and the use of bolt anchors or the use of special

beam clamps. Installing into at concrete will

always require drilling and inserting bolt anchors.

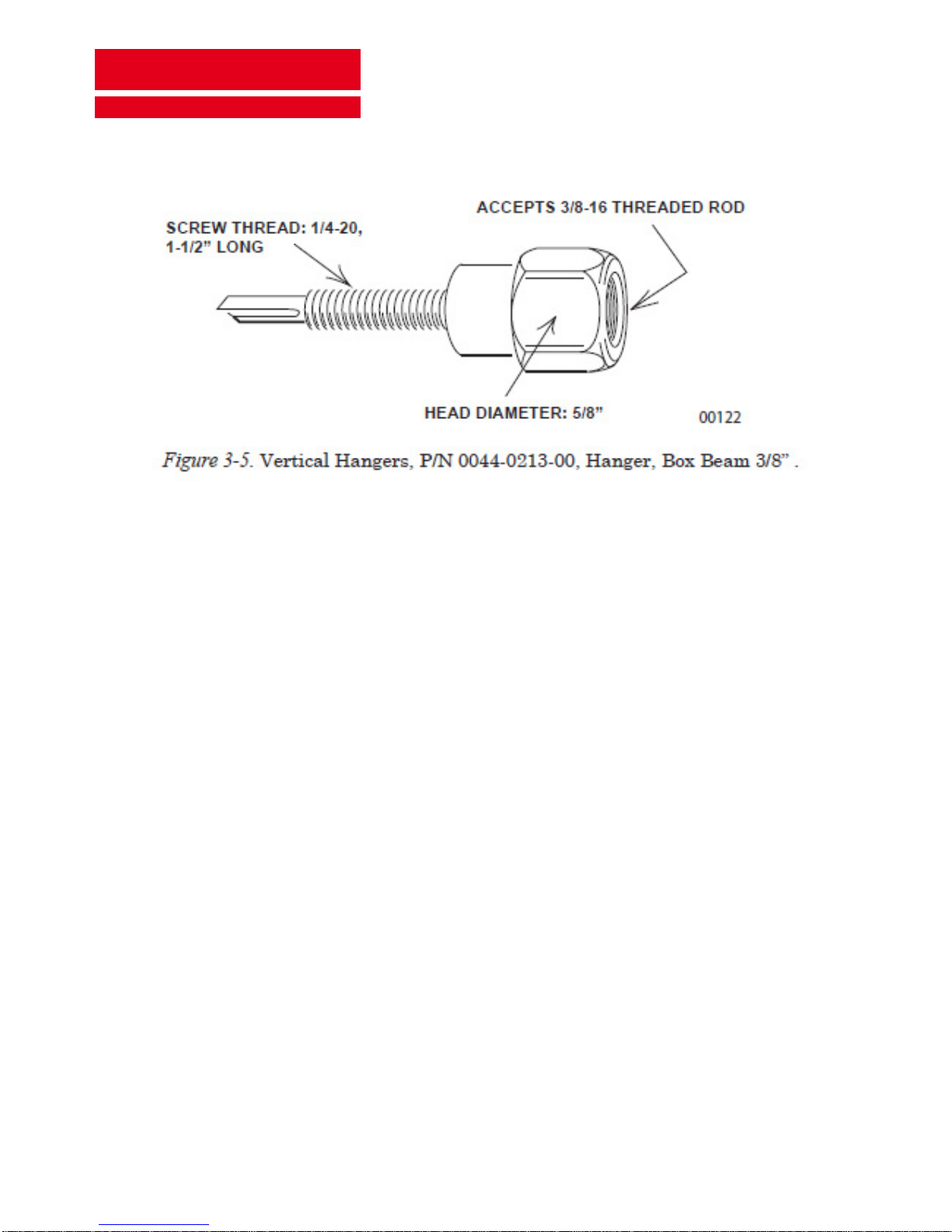

ere are some buildings, that have at corrugated steel roofs which may or may not have additional support

structures. If a steel roof has a thickness between 0.8 mm) and 4.76 mm, it is possible to use Vertical Hangers

(P/N 0044-0213-00, HANGER, BOX BEAM 3/8” ) to hang the rail. (See Figure 3-5.) is hanger has a 38 mm

long mounting sha and a M10 x1.5 female thread to accept the threaded rod end. One advantage to using

Vertical Hangers is that there are more options available when orienting the system run. If there is a support

structure to contend with, the run can be oriented in a parallel or perpendicular direction without regard to

the structure. Hangers can be installed wherever necessary. As with all installations, rst establish a centerline

for the system run.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 21 of 70

System Installation Guide

Locate two rod drops to align with the rst and last rail coupler mounting channel. Locate the remaining rod

drops along the centerline and placed no more than 5 meters (the length of two rail sections) apart. Drill a

mounting hole for each hanger. Hole diameter should equal the thickness of the steel, e.g., 0.8 mm diameter hole

for 20 gauge (.036”) steel, and 4.76 mm diameter hole for steel that is 3/16” thick (maximum). e remainder

of the hanging procedure is the same as it would be when dealing with any roof support structure.

Installation will progress smoothly if work can be scheduled for when there is little or no outside activity in

the work area. Reserve special equipment that may be needed, such as lis, scaolding, etc., well in advance.

Schedule a qualied electrician well in advance of when you anticipate needing his / her services.

Identify a straight, level, and unobstructed area for installing the entire system run. Refer to the engineering

drawings for your particular installation to determine the service end of the system run. e Power End Cap

(or Alternate Power Supply Assembly, as applicable) and the RF Adapter will need to be located at the service

end of the run. Carefully inspect the area above and near the proposed system run for physical obstructions

such as drop ceilings, lighting xtures, water pipes, electrical conduit, HVAC duct work, etc., which might

have to be relocated or would force another location for the system run.

3.2 Setting up a schedule

3.3 Planning installation of the system run

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 22 of 70

System Installation Guide

Establish a system height (distance from the oor to the system run) that allows adequate clearance from

obstructions and maximizes the desired viewing area. e rail must be hung a minimum of 2.5 meters above

the oor at its lowest point. Verify at least 0.3 meter of clearance, from the top of the rail section down, over

the entire proposed system run.

NOTE

Local codes may dictate dierent specic

distance requirements .

Power for the CurveTrack® systems should be controlled by dedicated circuit breakers. ere should be no

more than four CurveTrack® Power Supplies (i.e. four system runs) per circuit breaker.

Ensure that oor level obstructions to li equipment, ladders, etc. are

accounted for and can be worked around to maintain a safe environment for

installation workers and bystanders. Be especially aware of the potential hazard

of falling materials, tools and debris as well as potential trip hazards, including

power cords, in areas below the installation zone.

DANGER

All CurveTrack® equipment and installation materials that are at the site of the installation must be inspected

for damage. All Claims for losses, or damage to the system in transit, must be made with the carrier. Packing slip

documentation should be checked carefully against material received to ensure that everything that is needed

has arrived. It is suggested that before the actual construction begins, the installation team do a complete

inventory while the lead installer reviews the site. Any shortages in parts or materials must be reported as soon

as possible so that corrections can be made in a timely fashion.

Aer inspection, return all materials to their shipping containers to protect them until they are used. Designate

a specic storage area in a protected place to prevent accidental damage, especially to delicate electronic parts

and the easily – damaged windows.

3.4 Material inspection and inventory

3.5 Material storage

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 23 of 70

System Installation Guide

3.6 Recommended tool list

is list includes tools required to install the entire CurveTrack®™ system.

Safety Equipment

Safety Glasses

First Aid Kit

Hard Hats

Work Gloves

Hearing Protection

Cutting & Shaping Tools

Portable Band Saw

Power Drill

(with hammer capability)

Portable Drill Driver

Tubing Cutter/ Reamer

Utility Knife

Wire Strippers

CAT 5 Crimper/Stripper

Diagonal Cutters

File

Hammer

Measuring Devices

Surveyor’s Tape Measure

Multi – Meter

Tape Measure

String Line

Scratch Awl

I-beam level

120 cm Level

Torpedo Level

Plumb Bob

Fastening Tools

Straight Blade Screwdriver

Phillips Screwdriver

Tweaker Screwdriver

Crescent Wrench

Nut Drivers

Hex - Key Wrenches

Drive Ratchets

Socket wrenches

Combination wrenches

Drill Bits

One Set, High Speed

One Hole Saw, 22mm

Soldering Supplies

Propane or MAPP Torch

Solder

Flux

Emery Cloth

Torch Heads

Cleaning Supplies

Paper Towels

Clean, Lint– free Rags

Denatured Alcohol

Alkaline-based cleaner

(not Ammonia)

Non-abrasive Cleaning Pads

Miscellaneous

Drop Light

Flashlight

Duct Tape

Electrician’s Tape

Tool Pouch

Silicone Adhesive

One set of Two– Way Radios

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 24 of 70

System Installation Guide

4. Support structure installation

4.1 General

4.2 Fastening Support Hardware to Bar Joists - Perpendicular

readed rods (hangers) must be provided for attachment to the end couplers of both the rst and last rail

section in every system run. One threaded rod is to be located at least at every second rail section coupler.

When completed, there should never be a span of more than two rail sections between support rods.

Additional B-channel, installed spanning two rail couplers, may be added along the centerline of the rail to

provide mounting points for extra threaded rods, guy wires, etc. or to circumvent overhead obstructions.

Figure 4-1 illustrates a typical installation of the CurveTrack® rail to bar joist ceiling

construction using precut lengths of M10 threaded rod. See paragraph 3.3, Planning Installation of the System Run, to determine

hanging height, and paragraph 5.2, Cutting the readed Rod, before cutting the threaded rod.

Locate the approximate centerline of the system run and install a taut string line over the full

length of the system run. Install the string as high as possible making certain it remains clear of

all obstructions.

read a M10 x 1.5 hex nut (1, Fig.4-1), M10 spring lock washer (2, Fig. 4-1) and a square washer

(3, Fig. 4-1) onto one end of each threaded rod (4, Fig. 4-1) so that 100mm, plus the height of the

bar joist angle, is extending beyond the square washer.

Insert the end of the rod assembly between the bottom angles of the bar joist and fasten loosely

with a square washer (5, Fig. 4-1), lock washer (6, Fig. 4-1), and hex nut (7, Fig. 4-1). Do not

tighten until the associated track section is hung and aligned.

4.2.1

4.2.2

4.2.3

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 25 of 70

System Installation Guide

4.3 Fastening Support Hardware to Bar Joists - Parallel

When the installation requires the system run to be parallel to the bar joists, metal channel is used as a spanner

to bridge the bar joists at each mounting point of the system run as shown in Figure 4-2.

Lengths of channel should be cut 0.3 meter longer than the distance between the bar joists to allow for mounting

hardware.

Install the rst and the last channels on the system run. Determine the centerline of the system

run and mark it on each channel.

Place channels on bar joists every 4.8 meters so that there is one channel for each threaded rod

assembly and that each channel is placed at the same location, relative to the string

line (refer to paragraph 4.1).

Center channel (1, Fig. 4-2) over bar joist bottom angles with the open side of the channel facing

down. Slide M10 channel lock nuts (2, Fig. 4-2) into each end of the channel until they are

centered between joist angles.

Assemble M10 x 1.5 hex nuts (3, Fig. 4-2), M10 spring lock washers (4, Fig. 4-2)

and square washers (5, Fig. 4-2) onto two M10 x 1.5 x 150mm hex head cap screws (6, Fig 4-2).

Insert screw end between bar joist angles and thread into Twirl nuts. Do not tighten screws

securely until the rail section is hung and aligned.

4.3.1

4.3.2

4.3.3

4.3.4

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 26 of 70

System Installation Guide

4.4 Fastening Support Hardware to Steel Beams - Perpendicular

Figure 4-3 illustrates the use of Beam Clamps for attaching threaded rod to steel beam ceiling construction.

Locate the approximate center line of the system run. Insert a locking strap (1, Fig. 4-3) into

beam clamp (2, Fig. 4-3) and center the rst and last beam clamp on the centerline.

Install a taut string line the full length of the system run. Keep the string line in place for use as

a plumb line reference when aligning the system run.

Secure beam clamps to beam with square head, cone point set screws (3, Fig. 4-3) and M10 x 1.5

lock nuts (4, Fig. 4-3). Assemble two M10 x1.5 hex nuts (5, Fig. 4-3), one M10 spring lock washer

(6, Fig. 4-3) and a swivel (7, Fig. 4-3) on the end of the threaded rod (8, Fig. 4-3) as shown.

Insert plastic bushings (9, Fig. 4-3) into pivot holes on each side of the beam clamps. Position

swivels on threaded rod assemblies over the plastic bushings and secure with hex bolts (10, Fig.

4-3) and elastic lock nuts (11, Fig. 4-3). Tighten elastic lock nuts lightly so that rod assemblies

can swivel on beam clamps. When the

position of the clamps are nalized,

bend locking straps over the far

corner of the steel beams and tighten

set screws and locking nuts securely.

Observe that in the illustration, the

locking strap (1, Fig. 4-3) is shown

bent into the locking position.

4.4.1

4.4.2

4.4.3

4.4.4

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 27 of 70

System Installation Guide

4.5 Fastening Support Hardware to Steel Beams - Parallel

When the installation requires the system run to be parallel to the steel beams, channel is used as a spine to

bridge the beams at the mounting point for each rail section as shown in Figure 4-4. Lengths of channel should

be cut 0.3 meter longer than the outside distance between the beams to allow for mounting hardware.

Position each channel (1, Fig. 4-4) with open side down. Place U – bolts (2, Fig. 4-4) around

channel, facing up, and through beam clamps (3, Fig. 4-4) and M10 spring lock washers (4, Fig.

4-4). read M10 x 1.5 hex nuts (5, Fig. 4-4) loosely to each end. ese assemblies can be made

in the quantity needed for each system run before attaching to bottom of beams.

Raise and center channel assemblies in the desired locations on the beams, and slide lamps and

U–bolts rmly against the inside legs of the beams. Check to ensure that the distance between

channels coincides with the desired location of threaded rod hangers.Verify approximate

“squareness” of channels to the beams, and then tighten hex nuts securely.

4.5.1

4.5.2

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 28 of 70

System Installation Guide

4.6 Fastening Support Hardware to C–Purlin Beams - Perpendicular

Figure 4-5 illustrates the use of beam clamps for attaching threaded rod to C–Purlin beam

construction.

Mark the centerline of the system run on beams.

Insert locking straps (1, Fig. 4-5) into slots in each beam clamp (2, Fig. 4-5) and

then place

each beam clamp over the open lower edge of the beam.

4.6.1

4.6.2

Secure clamps to beams with square head cone point set screws (3, Fig. 4-5) and M10 x 1.5 hex

nuts (4, Fig. 4-5). Observe that, in the illustration, the locking strap (1, Fig. 4-5) is shown bent

into the locking position.

Assemble two M10 x 1.5 hex nuts (5, Fig. 4-5), one spring lock washer (6, Fig. 4-5) and a swivel

(7, Fig. 4-5) on one end of each pre-cut threaded rod (8, Fig. 4-5).

4.6.1

4.6.2

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 29 of 70

System Installation Guide

CAUTION

It is important to remember that, when mounting the support

structure to slanted ceilings, the ceiling pitch must be taken into

account when measuring and cutting lengths of threaded rod.

Insert plastic bushings (9, Fig. 4-5) into pivot holes on each side of beam clamps. Position

swivels of threaded rod assemblies over plastic bushings and secure with hex bolts (10, Fig.

4-5) and elastic lock nuts (11, Fig. 4-5). Tighten elastic lock nuts lightly so that rod assemblies

can swivel on beam clamps. When position of clamps is nalized, bend locking straps over the

back side of beams and tighten set screws and lock nuts securely.

Locate the approximate centerline of the system run and locate the rst and last beam clamp

on the centerline.

Install a taut string line the full length of the system run so that it is just o of the outside edge

of the clamp. Keep the string line in place for use as a plumb line reference when aligning the

system run.

4.6.5

4.6.6

4.6.7

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 30 of 70

System Installation Guide

4.7 Fastening Support Hardware to C–Purlin Beams - Parallel

When the installation requires the system run to be parallel to the C– Purlin beams, channel is used as a spine

to bridge the beams at each mounting point of a rail section as shown in Figure 4-6. Lengths of channel should

be cut 0.3 meter longer than the outside distance between beams to allow for mounting hardware.

Position each channel (1, Fig. 4-6) with the open side down. Place U–bolts (2,Fig. 4-6 ) around

channel facing up and through beam clamps (3, Fig. 4-6) (bent edges both facing the same

direction) and fasten with M10 spring lock washers (4, Fig. 4-6) and M10 x 1.5 hex nuts (5,

Fig. 4-6).

Raise and center channel assemblies at the desired position against beams. Hook bent edge

of beam clamps over open edge of C – Purlin beams. Check to ensure that distance between

channels coincides with the desired location of threaded rod hangers. Verify that the channels

are approximately square to the beams, and then tighten the hex nuts securely.

Install a taut string line, running the full length of the system run, 100mm to one side of

where the centerline of the rail sections will be located. Keep the string line in place to use as

a plumb line reference when aligning rail sections later.

4.7.1

4.7.2

4.7.3

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 31 of 70

System Installation Guide

4.8 Fastening Support Hardware to Flush Concrete - Parallel and

Perpendicular

Installing support structure to concrete presents both special considerations and limitations as well as some

advantages. An advantage of mounting in concrete is the unrestricted positioning of the locations for threaded

rod drops that allow the support structure to be positioned at the optimum location (see Figure 4-7). e

short, 355mm channel must be placed in accurate alignment on the system run centerline if you choose to

mount the channel parallel to the system rails. is provides signicant room for adjustment of the rod drops

to connect with the mounting points on the rail connectors.

ere is less height adjustment available than with some other types of construction due to the ush mounting

of the channel. Maximum height adjustment will be limited to 150mm in the turnbuckles, which must be used

with this type of construction.

Establish the location of the system run and, using a chalk or snap line, mark the centerline of

the run. Center the channel on a point where a rod drop will be located. Using the channel as

a template, mark, centerpunch, and drill additional holes centered in the slotted holes on each

end of the channel. Centerpunch and, using a carbide – tipped concrete bit, drill the two holes

in the concrete on the centerline.

Proceed to mark and drill sets of holes down the centerline at intervals that match the

desired location of threaded rod drops. Most threaded rod drops on straight sections of rail

will be 2.5 meters apart.

4.8.1

4.8.2

4.8.3

4.8.4

NOTE

e depth and diameter of the holes drilled will be determined by the

concrete anchors specied in the Bill Of Materials. Fastening hardware

can also vary, depending upon the installation.

Install concrete anchors (1, Fig. 4-7) in each drilled hole, and set them with a sharp hammer

blow.

Mount 355mm sections of channel (2, Fig. 4-7) to the concrete, using bolts (3, Fig. 4-7), spring

lock washers (4, Fig. 4-7) and fender washers (5, Fig. 4-7) through the end and center slots

of the channel and into the concrete anchors.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 32 of 70

System Installation Guide

4.8.5

4.8.6

4.8.7

Slide a M10 channel lock nut (6, Fig. 4-7) into the channel.

Establish the length for the threaded rod (7, Fig. 4-7) by measuring the distance from the concrete

to the top of the rail section when the rail is at the desired height above the oor. Subtract 200mm

for the turnbuckle adjustment portion. Cut the rod.

read M10 x 1.5 hex nuts (8, Fig. 4-7) on one end of the threaded rods. Install M10 spring lock

washers (9, Fig. 4-7) and square washers (10, Fig. 4-7) on the threaded rod.Screw this end into

the Twirl nut in the channel until the threaded rod almost bottoms out in the

channel, and then fasten hex nut nger tight. When you are ready to attach the threaded rods to

the rail, refer to paragraph 6.4 and 6.5.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 33 of 70

System Installation Guide

4.9 Fastening Support Hardware to Reinforced Concrete Beams

Figure 4-8 illustrates the attachment of channel to one type of reinforced concrete. If the system run is parallel

to beams (as shown), concrete anchors and lag bolts are used on each end of the channel spanning two beams.

is type of installation uses threaded rod assemblies to hang the rail.

4.9.1

4.9.2

4.9.3

4.9.4

Establish the location of the rst attachment hole. Place a carpenter’s square against the concrete

beam and squarely mark the location of the attaching holes in the adjoining beams. Use a length

of channel as a template for hole spacing.

Using a carbide– tipped concrete bit, drill holes at each location. e depth and diameter of

the holes drilled will be determined by the concrete anchors specied in the Bill Of Materials.

Fastening hardware can also vary, depending upon the installation. Drive anchors (1, Fig. 4-8)

into each hole.

Position channel (2, Fig. 4-8) as shown, and fasten with at washers (3, Fig.4-8), lock washers (4,

Fig. 4-8) and lag screws (5, Fig. 4-8).

Proceed to mark and drill sets of holes down the length of the system run. When ready to attach

threaded rod to the rail sections, refer to Figure 5-2.

When mounting to reinforced concrete

beams for perpendicular system runs,

installation will be the same as for ush

mount concrete. (See Figure 4-7.)

Turnbuckles must be used between the

threaded rod and the rail sections as shown

in Figure 5-3.

NOTE

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 34 of 70

System Installation Guide

5. Threaded rod installation

5.1 General

5.2 Cutting the threaded rod

Each rail section is suspended from the supporting structure using M10 threaded rod. Refer to Site Evaluation

and Planning, paragraph 3, and, more specically, Planning Installation of the System Run, paragraph 3.3,

for suggestions on determining drop distance.

e threaded rod is delivered to the job site in 3 meter lengths. Each rod must be cut to the required length.

Figure 5-1 illustrates the methods used to determine the proper length for the rods. Adding an additional

100mm to each rod will allow for alignment adjustments. Installations that require swivels on the beam

clamps should not add the 100mm to the threaded rod measurement, because all adjustment must be made

using the turnbuckles.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 35 of 70

System Installation Guide

Cut two equal lengths of rod for the rst two rail sections in the system run, and cut at least one more length

for each remaining rail section. On C– Purlin and steel beam perpendicular installations that allow the beam

clamps to be mounted in a vertical position, it is possible to run the threaded rod up and through the beam

clamp, eliminating the swivel. Measure to the top of the clamp for this type of installation. Subtract 200mm

from the total length of the threaded rod when using turnbuckles to adjust for the desired length.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 36 of 70

System Installation Guide

5.3 Installing threaded rod in channel for parallel runs

Figure 5-2 illustrates a typical threaded rod installation where there are no turnbuckles used. Without

turnbuckles, all height adjustments must be made from above the pre- installed support channel. If the threaded

rod exceeds 1.25 meters in length, it is dicult to see leveling devices placed on the track. erefore, when the

overall drop length exceeds 1.25 meters, or, when attaching rods to ush ceiling mounts, or Vertical Hangers,

install turnbuckles on the lower end of the threaded rod assemblies to facilitate adjustment. Refer to paragraph

5.4, Installing Turnbuckles on readed Rods.

Fasteners shown on the lower end of the threaded rod

may be pre-assembled and the rail section mounting

channels slid onto the Twirl nuts, or, the Twirl nuts may

be pre–installed in the rail mounting channels. In this

way, as the rails are lied into position, the threaded rods

can be turned into the Twirl nuts.

NOTE

5.3.1

5.3.2

5.3.3

5.3.4

Install two rods to suspend the rst two rail sections, and install at least one rod for each additional

pair of rail sections. It is not necessary to provide a dedicated rod drop for every section. It is

sucient to provide one rod drop for every second rail section. In this way, rail sections can be

assembled and hung in pairs. Distance between threaded rods, or drops, cannot exceed 5meters

(the combined length of two rail sections).

read M10 x 1.5 hex nuts (1, Fig. 5-2) on M10 threaded rods (2, Fig. 5-2) 165mm from the end.

Install M10 spring lock washers (3, Fig. 5-2) and square washers (4,Fig. 5-2) on the rods.

With the aid of a step ladder or li, insert the rod assemblies through the appropriate slotted

holes in the pre – installed channel (5, Fig. 5-2). Secure with at fender washers (6, Fig. 5-2), M10

spring lock washers (7, Fig. 5-2) and M10 x 1.5 hex nuts (8, Fig. 5-2).

read M10 x 1.5 hex nuts (9, Fig. 5-2) on the bottom of the threaded rod at 25mm

from the end. Install M10 spring lock washers (10, Fig.5-2), M10 square washers (11, Fig. 5-2),

and Twirl nuts (M10 channel lock nuts) (12, Fig. 5-2).

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 37 of 70

System Installation Guide

Leave fasteners at the top of the rods loose so that rods

can be turned into Twirl nuts i f you intend to pre–

install Twirl nuts into rail section mounting channels.

e hardware on each threaded rod is to be tightened

later as the corresponding rail sections are hung and

properly aligned.

NOTE

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 38 of 70

System Installation Guide

5.4 Installing turnbuckles threaded rods

Figure 5-3 illustrates the recommended hardware necessary for attaching turnbuckles between the threaded

rod assemblies and the rail sections. Turnbuckles may be used on all installations to aid in rail alignment, but

are recommended especially for threaded rod drops exceeding 1.25 meters.

5.4.1

5.4.2

5.4.3

5.4.4

Insert a M10 x 1.5, 125mm square head bolt (1, Fig. 5-3) through small O.D. at washer (2, Fig.

5-3) and into the non – threaded hole in turnbuckle (3, Fig. 5-3).

read M10 x 1.5 hex nut (4, Fig. 5-3), M10 spring lock washer (5, Fig. 5-3) and

turnbuckle (3, Fig. 5-3) onto bottom ends of threaded rod (6, Fig. 5-3) so that the threads extend

about halfway into the turnbuckles.

Install M10 spring lock washer (7, Fig. 5-3) and two M10 x 1.5 hex nuts (8, Fig.

5-3) on bolts (1, Fig. 5-3) so that lower hex nuts are 25mm from the end.

Install M10 spring lock washer (9, Fig. 5-3), M10 at washer (10, Fig. 5-3) and M10 channel lock

nut (11, Fig. 5-3).

Twirl nuts can also be inserted into rail section

mounting channels before or aer raising rails into

position. Turnbuckle bolts can then be turned into the

Twirl nuts.

NOTE

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 39 of 70

System Installation Guide

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 40 of 70

System Installation Guide

6. Rail section installation

6.1 Rail section inspection

6.2 Rail section cleaning

6.3 Rail section preparation

Each rail section is suspended from the supporting structure using M10 threaded rod. Refer to Site Evaluation

and Planning, paragraph 3, and, more specically, Planning Installation of the System Run, paragraph 3.3,

for suggestions on determining drop distance.

Clean interior surfaces of the rail section, as required, with a lint– free rag, slightly

dampened with

plain water. Do not use solvents or cleaning solutions of any kind.

6.1.1

6.1.2

6.1.3

6.1.4

Inspect all rail sections for obvious defects.

Working at oor level, take the rst two rail sections to be hung, and butt them up against each

other end – to–end. Check alignment of corresponding mating surfaces, especially in the area

where the carriage wheels will cross the seam.

Inspect the alignment of the plastic tracks inside the rail sections where they will be joined. If

alignment is poor, try another rail section to nd a better match.

Fasten the two rail sections together with a rail coupler. See Figure 6-1. Repeat the two previous

steps for each pair of adjoining rail sections. A rail coupler must also be installed at each end

of the system run to provide both hanging points for the ends of the system run and fastening

points for the bumper stops and the end caps.

Use extreme care when entering this phase of the installation. Handling heavy or

awkward objects at varying heights above oor level can be hazardous to personnel

and equipment.

One of the most eective ways to reduce installation time is to run a string line that

extends just beyond each end of the planned system run. Locate it so that it will

be level and parallel to the top edge of the rail sections. Use the string to help in

aligning the system run.

NOTE

DANGER

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 41 of 70

System Installation Guide

CAUTION

Raising and attaching rail sections require a minimum of two persons.

At exceptionally high installations, or when there are large, immovable

objects beneath the erection site, power lis or scaolding may be required.

6.3.1

6.3.2

Position two step ladders of sucient height below the intended location of the rst two rail

sections.

Li the rail sections by holding each end of the assembly rmly in a horizontal position and

“walking” it up to the attachment height.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 42 of 70

System Installation Guide

CAUTION

Raising and attaching rail sections require a minimum of two persons.

At exceptionally high installations, or when there are large, immovable

objects beneath the erection site, power lis or scaolding may be required.

6.3.3

6.3.4

6.3.5

6.3.6

Connect threaded rods to rail sections. Refer to paragraph 6.4 or 6.5, as applicable.

Check alignment of rail sections. Refer to paragraph 6.6.

Raise the next pair of rail sections to the far end of the rst or previous rail sections, making sure

that they are kept horizontal. As the installer holds the mating end of the next pair of rail sections

in position, snap a rail section coupler over the adjoining rail sections and secure it using the

supplied nylon insert lock nuts

Tighten the nylon insert lock nuts securing each rail section coupler.

6.4 Connecting Rail section to threaded rod assemblies - Method 1

NOTE

Guy wires (refer to paragraph 6-7) are always required

in order to stabilize the system run. A 7.5m rail will need

two guy wires at each end and another pair in the center.

Two more guy wires will be needed for each additional 3m

of rail. To accommodate fastening the guy wires, insert the

associated hardware in the rails a t t h i s po in t i n t h e

installation

If M10 channel lock nuts (11, Fig. 5-3) or (12, Fig. 5-2) have been attached to threaded rods or turnbuckles,

they must be carefully slid into the mounting channels of the rail section couplers. Do not exert excessive force

on the rod assemblies, as that could bend them out of alignment.

Using a level, adjust threaded rods so that they are plumb and parallel to each other.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 43 of 70

System Installation Guide

6.5 Connecting Rail section to threaded rod assemblies - Method 2

6.6 Alignement system run

NOTE

Refer to NOTE in paragraph 6.4.

If M10 channel lock nuts (12, Fig. 5-2) have been inserted, or will be inserted, into the rail section mounting

channels, make sure that the threaded rod assemblies are fastened to the support structure loosely enough to

allow the threaded rod to be screwed into the Twirl nuts. If turnbuckles are used, loosen the lock nut on the

turnbuckle bolt to allow the bolt to be screwed into the Twirl nuts.

As the rst installer supports one end of the rail section, the second installer supports the opposite end as

he places a M10 spring lock washer and a M10 at washer on the threaded rod or turnbuckle. e rods, or

turnbuckle bolts, are then threaded into the M10 channel lock nuts in the rail section mounting channels until

they nearly bottom out.

Verify that the rail section is level and adjust threaded rods as required.

Check for plumb, level, and alignment of each rail section pair before proceeding to install subsequent rail

sections. It is extremely important that the rst two rail sections be hung as accurately as possible.

6.6.1

6.6.2

Check for level by using a torpedo level at each end and the longest available level placed in

several locations along the length of the rails and across their width. To minimize errors caused

by a slight bow or arch in the rail, place the level at the end where the next rail section will be

joined. Make adjustments by changing fasteners on the threaded rods where they join the support

structure.

Adjust the alignment of the rails with the string line by sliding threaded rod assemblies in the

slotted holes in the channel, or by moving beam clamps or threaded rods on the support structure.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 44 of 70

System Installation Guide

Tutorial for the installation and the assembly of the CurveTrack® rails

1

2

Start by lining up two rail sections and

one aluminum coupler on the oor to x

them as described below.

To assemble a rail section properly with a coupler you need to:

Press the aluminum cap of

the rail section

Insert the rail section in

the screws of the couplers

starting with the top of the

rail. en, adjust the rail

section to insert the sides

of the cap

Insert the second rail

section at the other

extremity of the coupler,

following the same

procedure.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 45 of 70

System Installation Guide

Check that the sections

are perfectly aligned and

then start to x the nuts without

tightening them.

Pre-tighten the nuts and when you are sure that the plastic rails are perfectly aligned and pressed one

against the other, rmly hold them with one hand. With your second hand, screw the nuts diagonally

starting from the sides and then the back.

3

4

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 46 of 70

System Installation Guide

Turn the rail over and x the strut you have previously cut on the couplers. en insert a nut in the

strut on each coupler

Fix the pre-assembled rails on the threaded

rods that you have previously installed. en,

adjust with a spirit level to make sure that the

rail is perfectly straight and linear.

5

6

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 47 of 70

System Installation Guide

For the following sections: start again the same process with two sections and one coupler on the oor.

Each section assembled two by two is installed one aer the other.

e installation to the ceiling of each assembled

section is done in the same way as before: press

the aluminum cap and insert rst the top screws

and then side screws.

Pre-screw the nuts and adjust the plastic rails to make sure

that they are well aligned and on the same level. en you can

tighten the nuts rmly holding the plastic rails to avoid any

gaps. Still screw the nuts diagonally. Start with the nuts that are

on the sides of the plastic rails checking that the space between

both sections is the same on each side of the plastic rail.

7

8

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 48 of 70

System Installation Guide

Before the installation of the

copper pipes, you have to insert

shock absorbers at all plastic junctions and

all copper junctions. ose are 3M VHB

19mm

10

Once you have installed all the

sections, you can x the end caps to

both extremities of the rail.

9

Installation of the copper pipes

e copper pipes are clipped into the plastic rail

on the shock absorbers that wedge them.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 49 of 70

System Installation Guide

Adjustment:

If you observe an important gap aer the installation of the copper pipes you can x adjustment screws on the

junctions. ese screws will adjust the plastic rails depending on the screwing depth.

WARNING: never screw the adjustment screws to full capacity. eir only use is to slowly adjust the plastic rails.

Make sure to use a screw-gun

set up on a low torque. Always

hold the plastic rails with your

hand while screwing so you can

feel the adjustment and stop

screwing in time.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 50 of 70

System Installation Guide

The sanding:

To make sure that the plastic junctions are perfectly smooth you have to sand them with a 120 sandpaper.

Repeat this process for all the junctions of the entire rail.

First sand the at part of

the junctions with a sanding

block.

en sand the inside part of

the plastic rails to avoid any

obstacle on the wheel carriage

ways.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 51 of 70

System Installation Guide

6.7 Guy wire suspension

Figure 6-2 shows the recommended method for stabilizing a CurveTrack®™ system run with a threaded rod

drop of 1.5 meters or less.

NOTE

Guy wires must be used in both the center, and at each

end, of the rail for systems up to 76 meters in length.

An another set of guy wires must be added for each

additional 30 meters of length.

6.7.1

6.7.2

6.7.3

6.7.4

Slide M10 channel lock nuts (1, Fig. 6-2) into rail section mounting channels

near each end of the system run and, if needed, at the center.

Attach the following components: M10 square washer (2, Fig.6-2), M10 at washer (3, Fig. 6-2),

M10 spring lock washer (4, Fig. 6-2), M10 x 1.5 hex nut (5, Fig. 6-2), M10 x 1.5 x 50mm eye bolt

(6, Fig. 6-2), quick link (7, Fig. 6-2), midget– eye turnbuckle (8, Fig. 6-2), 1.5mm aircra cable

(9, Fig. 6-2), and 1.5mm wire rope clips (10, Fig.6-2).

Secure the free end of the cable with U – bolts.

Run the guy wires on a 45 degree angle from the system run, as shown in Figure 6-2.

CAUTION

Tighten turnbuckles until cables are taut,

but not so tight as to alter the alignment of

the rails.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 52 of 70

System Installation Guide

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 53 of 70

System Installation Guide

7. Installation of copper conductors

7.1 General

e copper conductors transmit video, power, and control signals between the carriage and the control

equipment. Figures 7-1 through 7-3 illustrate the recommended method for assembling and installing the

conductors. Before installation, inspect all copper conductors for kinks or deep scratches, and discard those

that are damaged. Conductors must be smooth and straight to give optimum transmission. roughout these

procedures, handle the copper conductors carefully with gloves.

Assembling the individual lengths of conductors will be made easier if they are temporarily supported below

the rail sections. Use wire, rope, strips of cloth, etc., to improvise slings for the copper conductors. Suspend the

conductors in the slings to position them for soldering and insertion in the plastic track as work progresses

down the length of the system run.

Conductors must be cut square and deburred so that mating ends

butt together tightly. If pipe cutters are used to cut the conductors,

they will compress the walls of the copper tubing and the inside

surface of the conductors will need to be reamed out to permit

insertion of connectors and end plugs.

NOTE

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 54 of 70

System Installation Guide

7.2 Soldering copper conductors

It is impossible to overstate the importance of proper copper conductor connector piece (coupler) installation.

Each and every connector must be cleaned, uxed, and soldered in a professional, workmanlike manner in

order to ensure conductivity and mechanical functionality. Cutting corners here will result in subsequent

service calls to x problems that are dicult to troubleshoot and expensive to correct.

e solder joints must have a smooth external surface on all sides. e

brushes on the camera carriage slide along the copper conductors. Rough

or uneven solder joints in a system run will quickly destroy the carriage’s

brushes. Smooth, straight, and clean copper conductors are essential for

long brush life and positive contact that will return maximum signal and

picture clarity.

Conductors and end plugs are joined using conventional soldering

techniques. e end plugs have shoulders (see Figure 7-3) and the joint

connector pieces t completely inside the conductor tubing as shown in

Figure 7-2.

NOTE

CAUTION

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 55 of 70

System Installation Guide

7.2.1

7.2.2

7.2.3

Clean two connector pieces (Fig. 7-2) and two end plugs (Fig. 7-3), if necessary, with a nonabrasive

cleaning pad, and coat lightly with ux.

Install conductor end plugs in one end of the rst two copper conductors (Fig.7-3), and insert the

connector pieces into the opposite end of the tubing as far as they will go.

Using a propane torch, heat areas to be joined until solder ows easily into the joint. While solder

is still molten, wipe o excess solder with a damp cotton rag or sponge. If excess solder or ux is

present, use a plastic non–abrasive pad laid lengthwise along the conductor to remove it.

Uneven solder joints, and / or gaps between conductor ends, will

result in noisy carriage operation, electronic interference, and rapid

destruction of the carriage brushes. If necessary, use a steel le to even

the surface area.

CAUTION

Installation and copper pipe welding tutorial

WARNING: make sure that the copper pipe welding is never in the same place as the rail junctions nor in the

curves

Hang up the copper pipes under the

aluminum sections (For example with

cables)

Make sure the copper pipes are well

aligned by adjusting the lenght of the

support cables

1 2

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 56 of 70

System Installation Guide

Cover the extremity of

the copper pipes with the

stripper paste and put

them closer to make sure that

they are well aligned.

Insert the coupler until the middle in one of the pipes and insert the other end in the

second pipe. Make sure that the coupler does not move and is inserted correctly in each

pipe.

3

5

Cover the extremity of the

copper pipes with the stripper

paste and put them closer to

make sure that they are well aligned.

You can then insert the couplers.

4

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 57 of 70

System Installation Guide

Start to heat the coppers with a welding torch. You need to press both pipes one against the other.

Make sure that the pipes are perfectly aligned and straight without any space at the junction. You can

stop heating as soon as you start to see the silver colour at the junction. en, immediately apply a wet

sponge to the copper pipes to take out the excess tin. Check that there is no defect around the junction.

When the copper has cooled down you have to sand it at the junction with a sandpaper of 80. Make sure

that the copper junction is perfectly smooth and that you do not see any defect.

6

7

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 58 of 70

System Installation Guide

7.3.1

7.3.2

Raise the rst two conductors up to the rst rail section and snap them into the plastic track. e

conductors should be positioned with the end plugs protruding approximately 12mm from the

beginning of the plastic track in the rst rail section.

Proceed down the length of the system run soldering connector pieces between conductor

lengths, smoothing joints, and pressing conductors into the track.

NOTE

7.3 Inserting Conductors into Plastic Track

e copper conductors should be pressed into the plastic track

sections only aer the solder joints have been allowed to cool and the

joints have been inspected and smoothed as necessary.

7.3.3

7.3.4

7.3.5

Allow 0.5 in. (12mm) of clearance between the end of the conductors and the end of the nal

track section on the Terminator board end of the system run. Hold the two conductor ends

together and, using a hacksaw, remove the excess copper squarely.

De-burr the conductor end surfaces.

Solder both end plugs in place.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 59 of 70

System Installation Guide

8. Installation of bumper stop brackets

8.1 General

8.2 Installation

Bumper stop brackets are installed at each end of the system run. ese brackets are fastened inside the rst

and last rail couplers. ey serve two purposes. eir primary function is to provide a margin of safety in the

event of a limit switch failure resulting in the carriage striking either end of the system run. (A foam bumper is

butted up against the inside of the bumper stop inside the rail for added protection.) e bumper stop bracket

at the service end of the system run also provides two of the four mounting points for the RF Adapter PCB.

Both bumper stop brackets provide mating mounting holes for the captive fasteners in the End Caps.

8.2.1

8.2.2

8.2.3

Hold the bracket with the top at a slight outward angle, position the bumper stop bracket over the

ends of the copper conductors so the end plugs protrude from the aperture in the bracket.

Square up the bracket and push it straight up until the threaded studs in the rail coupler align

with mounting points on the bracket and secure with four nylon insert lock nuts.

Repeat the procedure for the second bumper stop bracket.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 60 of 70

System Installation Guide

9. Installation of RF adapter and terminator boards

9.1 RF Adapter PCB Installation (See Figure 9-1)

9.2 Terminator board installation

9.1.1

9.1.2

9.1.3

9.2.1

9.2.2

Align the top, unthreaded hole on each extension bar with the corresponding hole in the

conductor end plug and install a screw with captive washer in each. Do not tighten either screw

yet.

Face the component side of the RF Adapter PCB down the system run. Align the two corner holes

on the top edge of the PCB with the standos on the bumper stop bracket. Install and tighten two

screws with captive washers.

Rotate the extension bars slightly to align the threaded bottom hole on each bar with the

corresponding center slots in the top edge of the PCB and install, but do not tighten, a screw with

captive washer in each slot. Next, tighten the screws in the conductor end plugs. en, li the two

conductors as far upward as possible and tighten the screws in the PCB slots

At the opposite end of the system run, position the Terminator PCB against the conductor end

plugs with the PCB components facing away from the system run.

Install and tighten two screws with captive washers to secure the PCB.

VIDEOSURVEILLANCE SYSTEMS

SENTRY

WAY

®

CT V2 001

Page 61 of 70

System Installation Guide

10. Installation of limit switch actuators

10.1 General

10.2 Installing limit switch actuators

Limit Switch Actuator Magnets are detected by the camera carriage as it travels back and forth on the plastic

track inside the rail enclosure. e two actuators are to be inserted into holes drilled in the plastic track at

opposite end of the system run–– one at the RF Adapter end, and one at the Terminator end. e limit switch