Page 1

TM

Sample Sequencer

Installation, Operation and

Maintenance Manual

SPD 5.5.5

Rev. 9

2/00

Web: www.sentry-equip.com

e-mail: sales@sentry-equip.com

Page 2

Sample Sequencer

Table of Contents

TABLE OF CONTENTS

Page

GENERAL SPECIFICATIONS ..........................................................................................5

Specification for Valve Output Board..................................................................6

Specification for Signal Switching Output Board ................................................6

Specification for 0-1 Volt DC Output Board ........................................................7

Specification for Remote Electronic Track & Hold Board ...................................7

Specification for Plug-In Track & Hold Board .....................................................8

SAFETY PRECAUTIONS................................................................................................10

GENERAL DESCRIPTION..............................................................................................11

Modes of Operation ..........................................................................................11

Output Boards and CRT Display ......................................................................15

Optional Manifolded Sampling Valve................................................................16

OPERATION ...................................................................................................................17

Description of Controls .....................................................................................17

I/O Board DIP Switches ....................................................................................19

Membrane Switch Keys ....................................................................................21

Programming ....................................................................................................21

Display Functions .............................................................................................23

Operating Modes ..............................................................................................25

Off ................................................................................................................25

Cycle............................................................................................................25

Batch............................................................................................................28

Turning Sample Streams On & Off ...................................................................29

Advancing Streams...........................................................................................30

Holding on One Sample Point ..........................................................................30

Alarms...............................................................................................................30

Sample Nametag .............................................................................................. 32

INSTALLATION...............................................................................................................33

Unpacking.........................................................................................................33

Mounting ...........................................................................................................33

Power and Ground Connection ........................................................................37

I/O board Connections and Settings.................................................................38

Sample Valve Electrical Connection to Valve Output Board ............................38

Sample Valve Piping........................................................................................ 40

Recorder Signal Connections ...........................................................................40

Signal Switching Output Board (P/N 6-02499C)...............................................42

O-1 Volt Signal Switching Output Board...........................................................44

Remote Electronic Track & Hold Boards (P/N 7-00839A) ............................... 46

Plug-In Track & Hold Board (P/N 6-02499E) ....................................................47

Alarm Signal Connections ................................................................................48

Starting Up the Sample Sequencer ..................................................................49

MAINTENANCE ..............................................................................................................50

Fuses ................................................................................................................50

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

1

Page 3

Sample Sequencer

Table of Contents

TABLE OF CONTENTS

Page

Calibration.........................................................................................................50

Analog Output Calibration of the Remote Electronic Track & Hold

Board (7-00839A) .............................................................................................51

Analog Output Calibration of the Plug-in Electronic Track & Hold Board

(P/N 6-02499E).................................................................................................51

TROUBLESHOOTING ....................................................................................................53

COMPUTER COMMUNICATIONS .................................................................................55

SEQUENCE Monitor Program..........................................................................55

Communication Protocol...................................................................................56

SERVICE.........................................................................................................................57

SPARE PARTS LIST.......................................................................................................58

ACCESSORIES...............................................................................................................59

WARRANTY....................................................................................................................60

APPENDIX A: Configuring Sample Sequencer to Output 6 Volt DC on Alarm

Contacts of Signal Switching Output Board......................................................63

APPENDIX B: Recommended Piping for Sample Sequencer.......................................64

APPENDIX C: Procedure to Configure Remote Electronic Track & Hold

Board for 220/240 VAC Operation....................................................................65

APPENDIX D: Instructions to Operate a Hach Series 5000 Analyzer with a

Sample Sequencer ...........................................................................................66

APPENDIX E: Sample Sequencer Basic Electrical Wiring Diagram ..............................73

APPENDIX F: Plug-In Track & Hold Dual Point Configuration .......................................74

APPENDIX G: Retrofitting a Plug-In (Internal) Track & Hold Board in the Field ............77

APPENDIX H: Procedure to Configure Remote Track & Hold Card for

Voltage Input...........................................................................................79

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

2

Page 4

Sample Sequencer

Table of Contents

List of Figures

Page

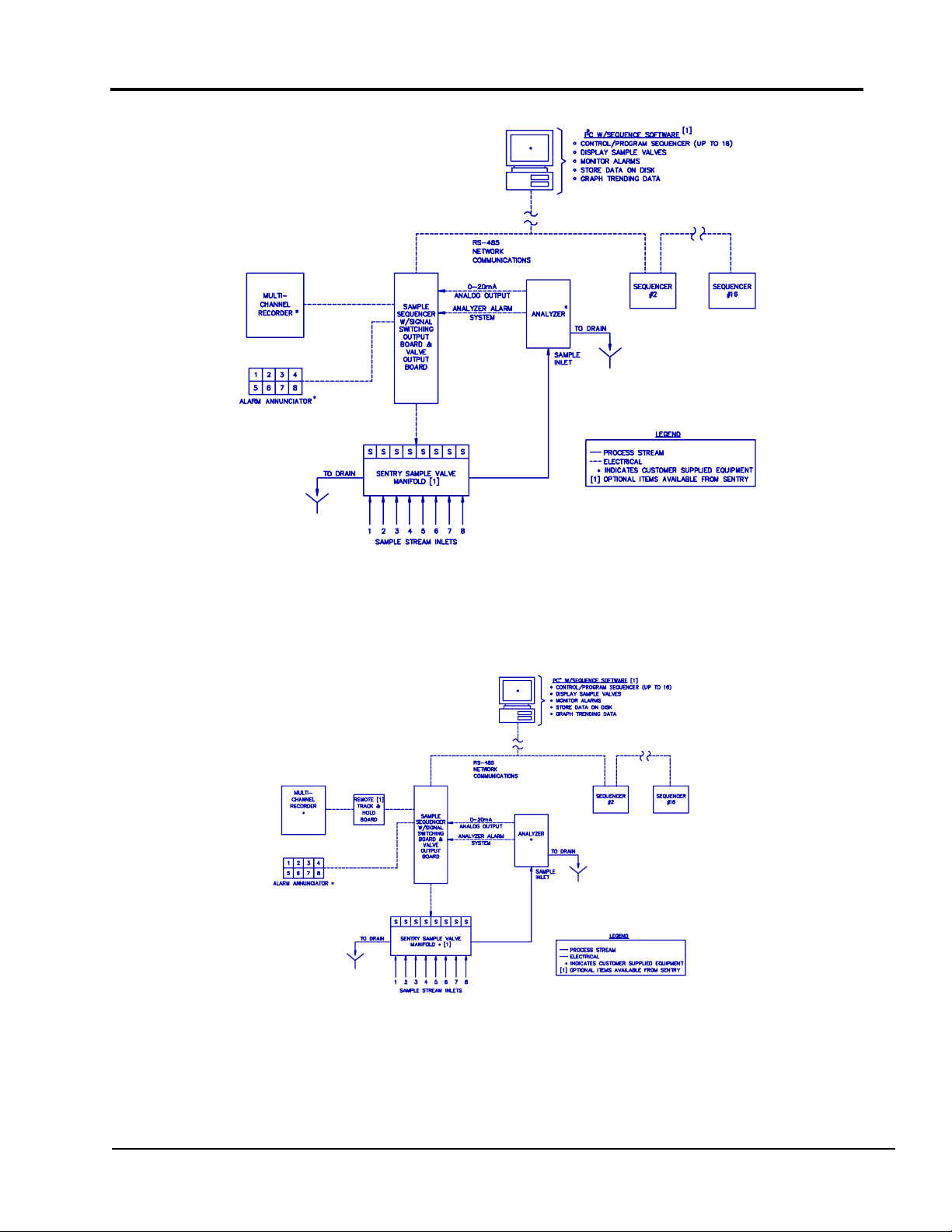

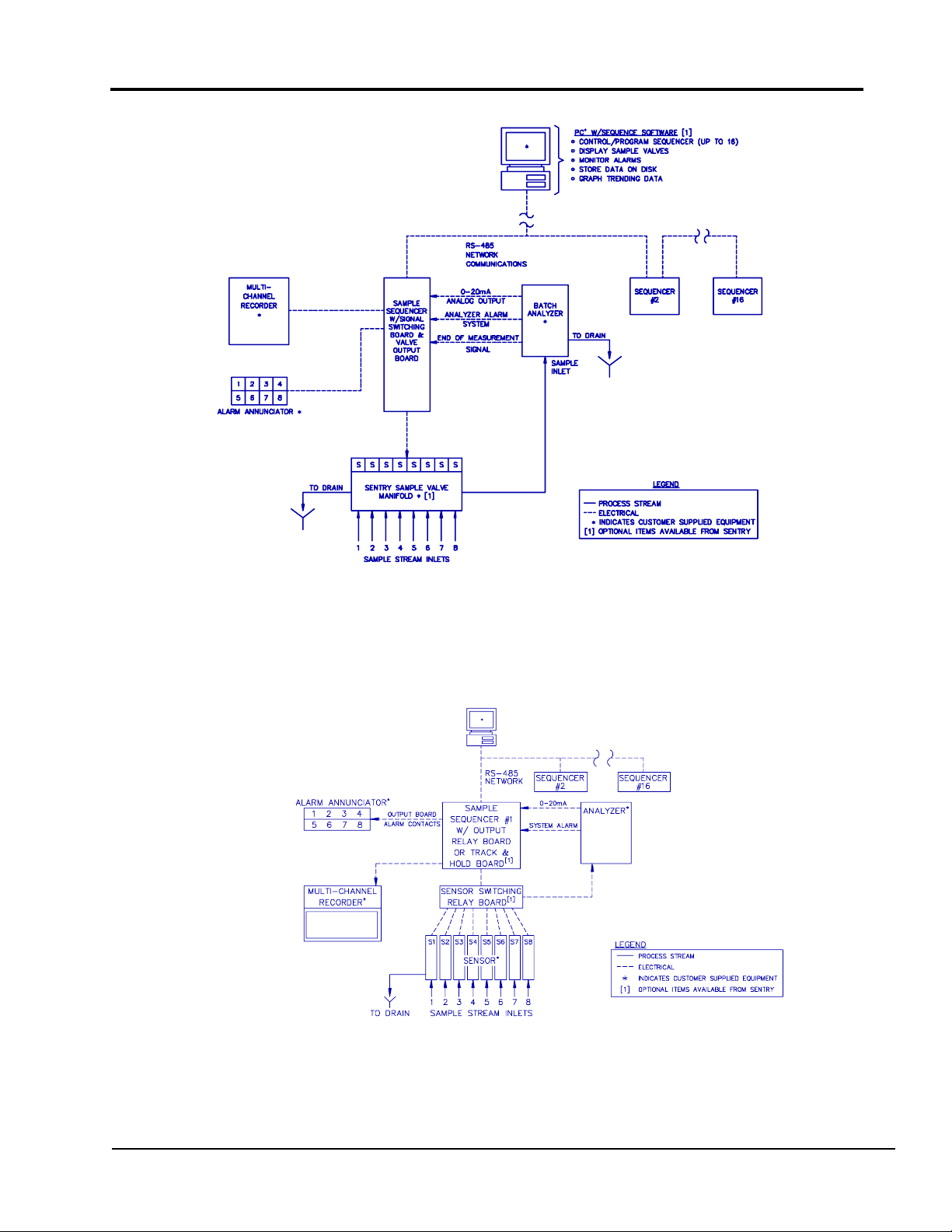

Figure 1: Sample Sequencer System with Manifolded Sample Valve,

Recorder, Alarm Annunciator and Network

Computer Communications ........................................................................12

Figure 2: Sample Sequencer with Remote Electronic Track & Hold Board,

Manifolded Sample Valve, Recorder, Alarm Annunciator and

Network Computer Communications ..........................................................12

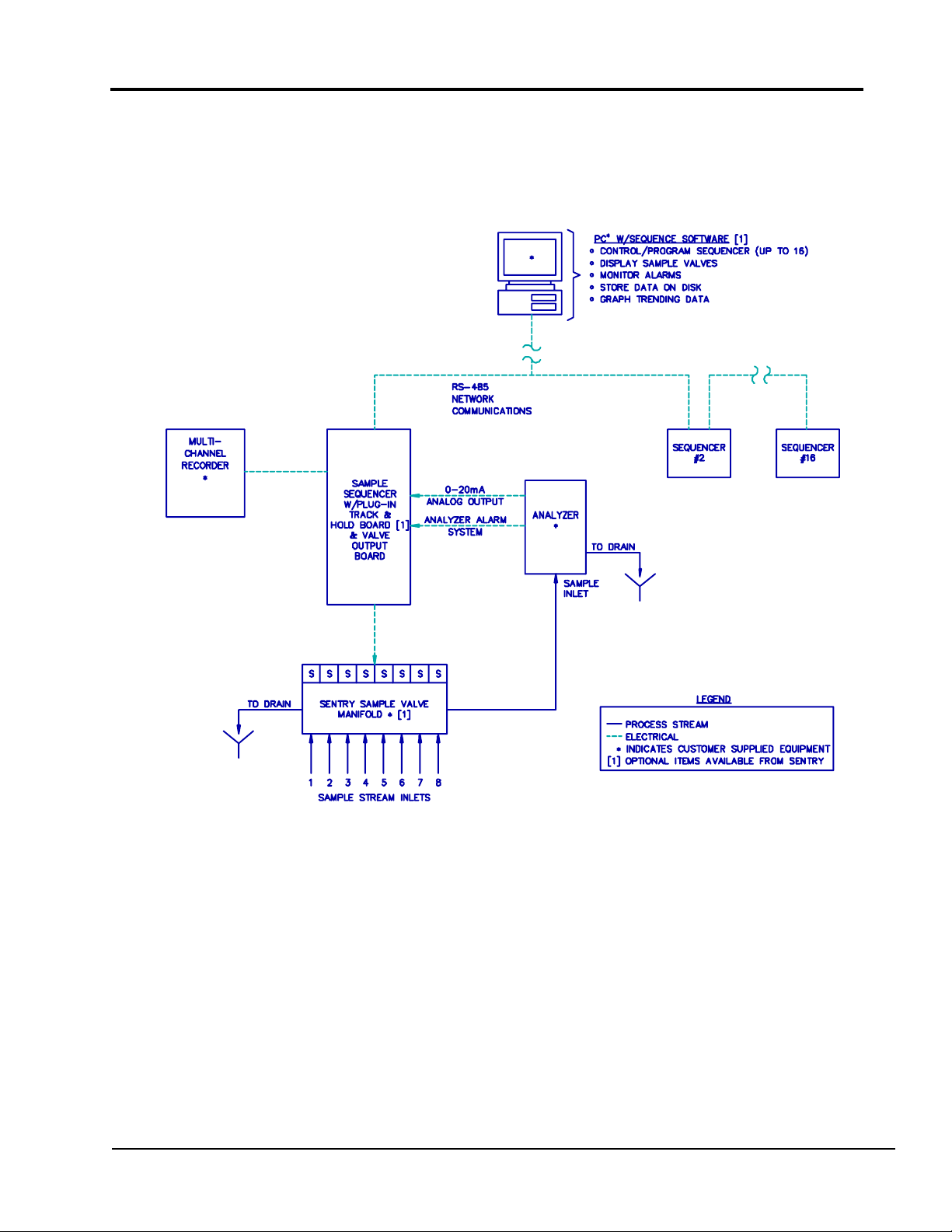

Figure 3: Batch Mode Sample Sequencer System with Manifolded Sample Valve,

Recorder, Alarm Annunciator and Network Computer Communications....13

Figure 4: Sample Sequencer System For Sensor Switching .....................................13

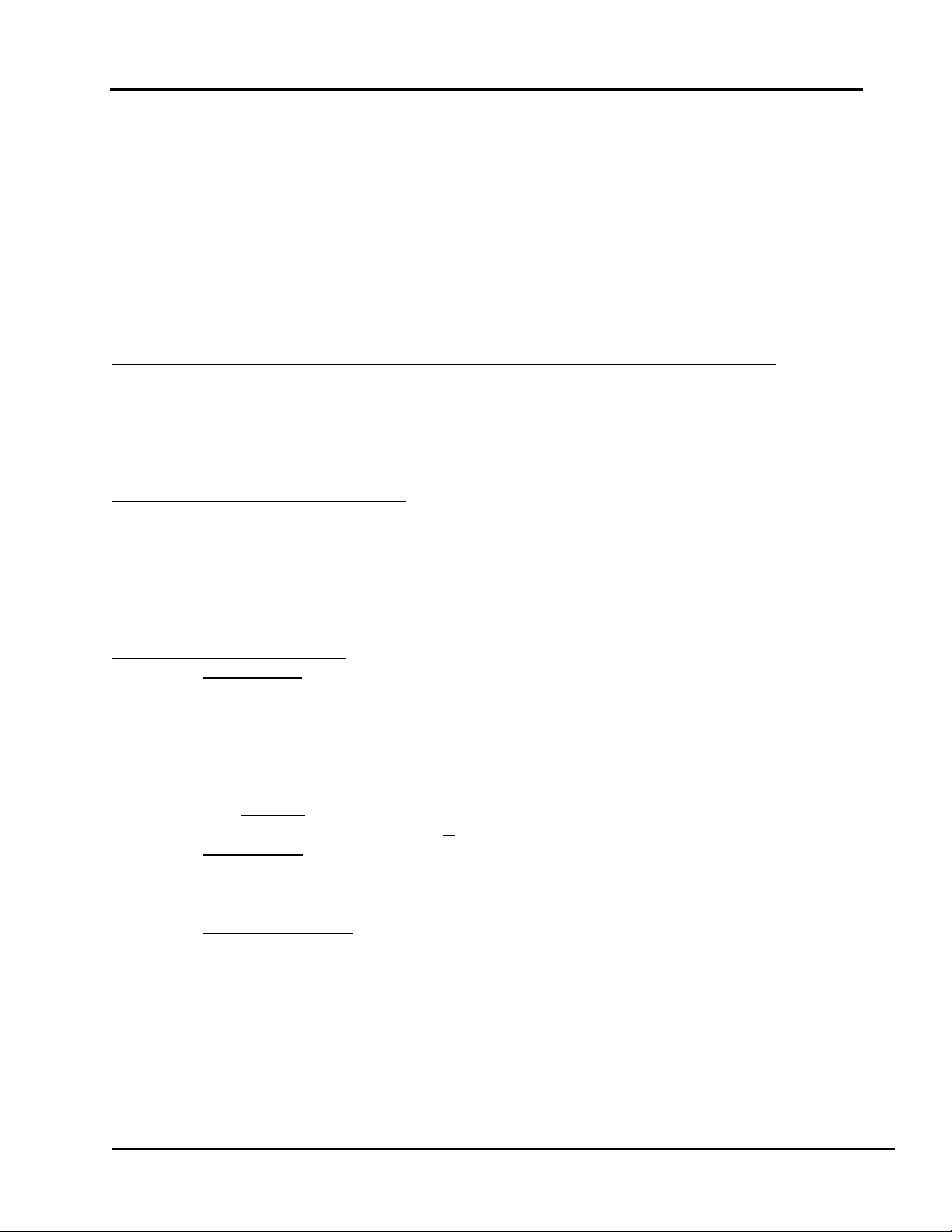

Figure 5: Sample Sequencer with Plug-In Electronic Track & Hold Board,

Manifolded Sample .....................................................................................14

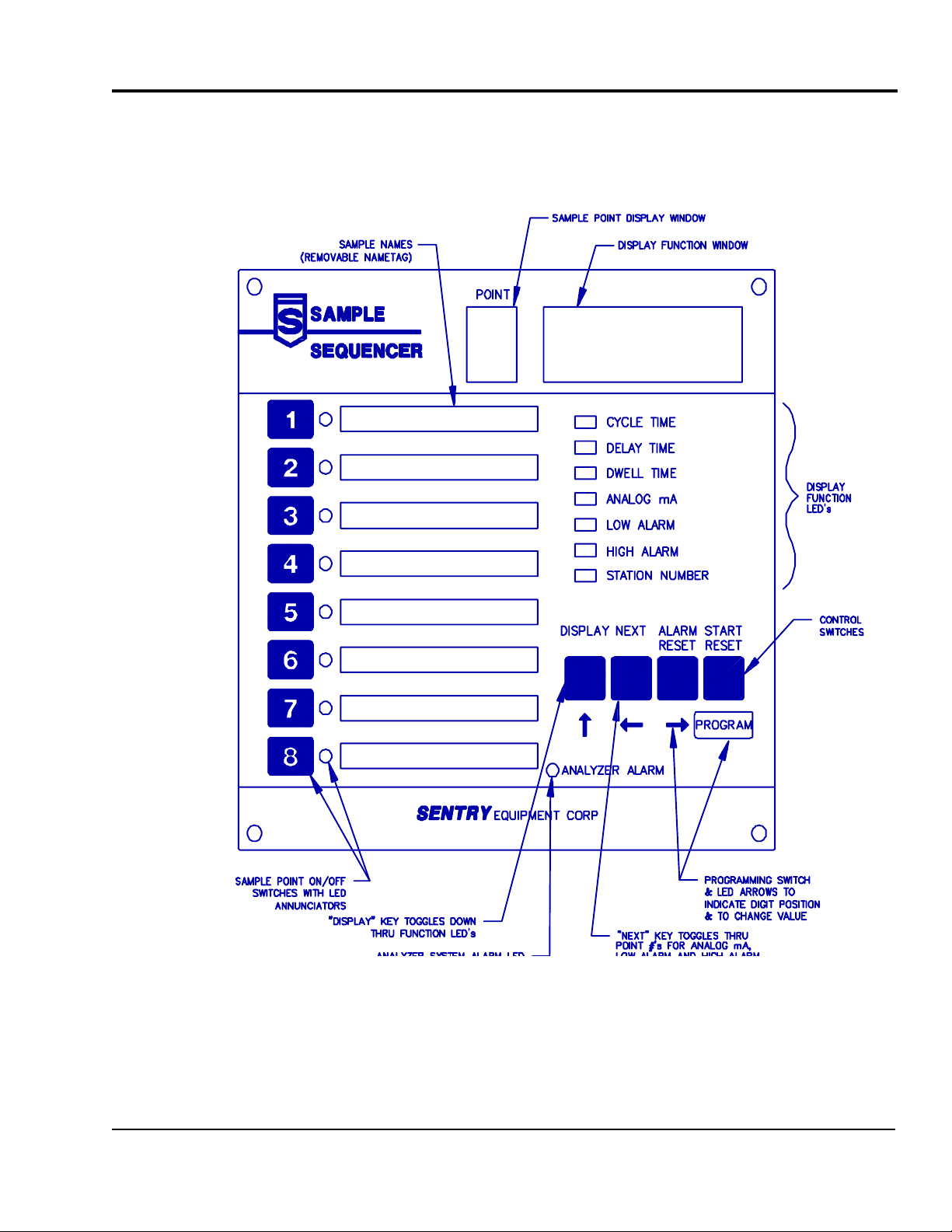

Figure 6: Sample Sequencer Membrane Switch........................................................18

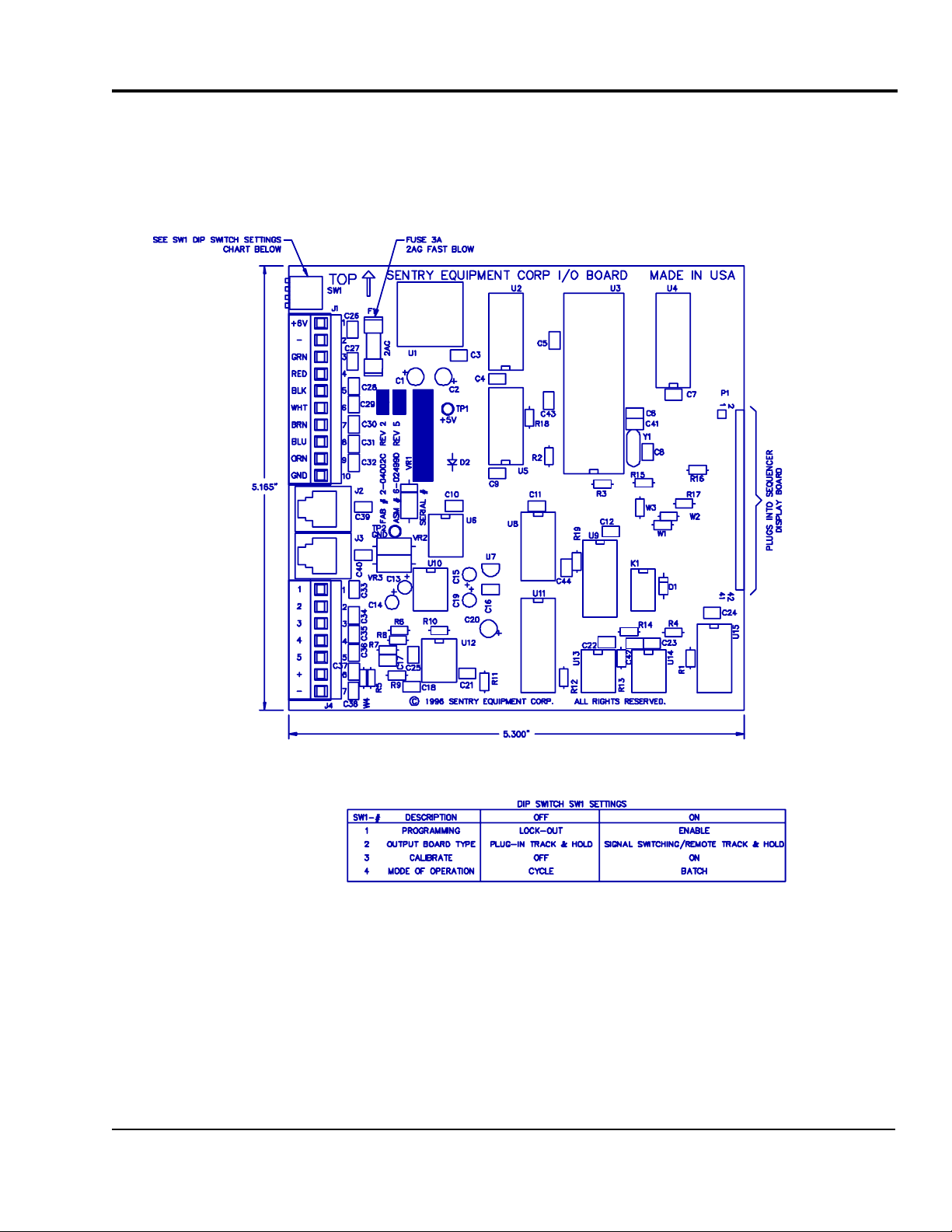

Figure 7: I/O Board Arrangement............................................................................... 20

Figure 8: Cycle Mode Timing Diagram.......................................................................27

Figure 9: Batch Mode Timing Diagram (for Batch-Type Analyzers)...........................28

Figure 10: Sample Nametag ........................................................................................32

Figure 11: Panel Mounting & Overall Dimensions, Sample Sequencer.......................34

Figure 12: NEMA 4X Rear Cover & Surface Mounting, Sample Sequencer................35

Figure 13: Enclosure Overall Dimensions, Remote Track & Hold ..............................35

Figure 14: Remote Valve Board Enclosure.................................................................. 36

Figure 15: I/O Board Connections ...............................................................................37

Figure 16: Solenoid Sample Valve Connections.......................................................... 39

Figure 17: Sample Sequencer Assembly (Rear View).................................................40

Figure 18: Sample Sequencer Assembly with Plug-In Track & Hold ...........................41

Figure 19: Recorder Connections: Signal Switching Using Signal Switching

Output Board ..............................................................................................42

Figure 20: Recorder Connections: Contact Closure Channel Indication Using

Signal Switching Output Board ...................................................................43

Figure 21: Recorder Connections for One or More Analyzers Using 0-1 VDC

Output Relay Board ....................................................................................44

Figure 22: Recorder Connections Using Remote Track & Hold Output Board(s) &

Signal Switching Output Board ...................................................................46

Figure 23: Recorder Connections Using Plug-In Track & Hold Output Board(s) .........47

Figure 24: Alarm Connections .....................................................................................48

Figure B1: Recommended Sample Conditioning for Switching Streams to an

Analyzer......................................................................................................64

Figure C1: Remote Electronic Output Board Arrangement ..........................................65

Figure D1: Wiring to Hach Series 5000 Analyzer, Models 60000 - 60004 ...................69

Figure D2: Recommended Sample Conditioning for

Switching Streams to a Hach 5000 Analyzer ............................................ 70

Figure D3: Electrical Transmittal Sample Sequencer & Manifold valves......................71

Figure D4: Valve Transmittal Sample Sequencer & Manifold Valves...........................72

Figure E1: Sample Sequencer Basic Electrical Wiring Diagram ..................................73

Figure F1: Component View......................................................................................... 74

Figure F2: Wiring Diagram - Dual Outputs from Plug-In Track Hold Board .................76

Figure H1: Remote T/H Board, Configuration for Voltage Input ...................................79

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

3

Page 5

Sample Sequencer

Page

Table 1: Control and Display Descriptions................................................................17

Table 2: I/O Board DIP Switch (SW1) Functions ......................................................19

Sample Sequencer models which have internal track and hold have passed

applicable tests for the European Community 89/336EEC EMC Directive. The

product is marked and shipped with a Declaration of Conformity. Contact Sentry

Equipment with further questions.

Table of Contents

List of Tables

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

4

Page 6

Sample Sequencer

GENERAL SPECIFICATIONS*

Applications: The Sample Sequencer is designed to support sample stream switching in the batch or

cycle modes. The Sample Sequencer can also switch sensor signals.

Design: Microprocessor-based with non-volatile memory and RS-485 communications

Maximum Number of Samples: 8

Power: 108-132/216-264 Vac, 47-63 Hz, Usage = 3.8VA without Plug-In Track & Hold (Uses external

UL/CSA or TUV-approved 6 VDC power supply.) Maximum 14VA with Plug-In Track & Hold.

Inputs from Analyzer:

• One analog input: 0-20 mA or 4-20 mA

• One digital input (dry contact closure) for indications of end-of-analysis signal for batch

mode operation

• One digital input (dry contact closure) for analyzer system alarm indication. This signal

shuts off Sample Sequencer and valves.

Outputs:

Standard Outputs:

• RS-485 serial communication port (for networking any RS-485 units to a PC)

• Valve Output Board to control maximum eight solenoid valves (DC or maximum 250 Vac

solenoids) for sample stream switching

• Plug-in Signal Switching Output Board with eight DPDT relays for analog signal switching

or contact closure for point number indication. The second pole of each point relay is used

for low voltage commutated analog alarm and analyzer system alarm indication for each

point.

Optional Input & Output Boards:

• Plug-in 0-1VDC Output Board with eight DPDT relays for 0-1 VDC output of sample point

number. The second pole of each point relay is used for low voltage commutated analog

alarm and analyzer system alarm indication for each point.

• Remote Electronic Track & Hold Board to output and hold analog signals (track & hold) of

four points. Two analog output boards may be used to provide eight total channels of

analog output. Use the remote electronic track & hold boards in combination with one

Plug-in Signal Switching Output Board.

• Remote Cell Switching Board to switch maximum eight cells

• Plug-In Track & Hold Board to output and hold four analog signals per circuit board. A

maximum of two plug-in Track & Hold boards may be installed in Sample Sequencer

enclosure. Use of two Plug-In Track & Hold boards requires that the valve circuit board be

mounted remote from Sample Sequencer.

Note: If you are retrofitting a Plug-In Track & Hold to an existing Sequencer in the field,

see Appendix G.

Accuracy of Sequencer: +/- 0.1% full scale, standard unit

+/- 0.2% full scale, with Internal Track & Hold Boards

User Interfaces: Integral membrane switch keypad and IBM compatible PC with serial port

* Sentry reserves the right to revise specifications at any time.

Specifications

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

5

Page 7

Sample Sequencer

Display: Red alphanumeric LED read-out display of channel number, time, alarms, analog signal and

station number. Eight red LEDs for point number indication and alarm annunciation.

Removable sample name tag.

Case: Material: Noryl; NEMA-4X on face-plate with NEMA 12 rear cover. Option: NEMA 4X

backplate for surface mounting. 5.35" x 5.35" x 6.26" deep.

Mounting: Panel or surface mount.

Ambient Temperature: 0-60C; RH 90% max. non-condensing at 40 C max.

Shipping Weight: 5 lbs (2.3 Kg)

Specification for Valve Output Board

Purpose: The valve output board controls contacts which supply power to solenoid valves.

Inputs: Logic-level signals from Sample Sequencer

Number

of Points: 8

Relays: DPDT sealed relays, contacts rated for 250 VAC, 220VDC maximum operating voltage.

Maximum switching capacity 30W, 62.5 VA for inductive loads.

Point number

indication: Nine red LEDs on circuit board with point number silkscreened on board. One LED is for Off

status and eight LEDs are for point number indication.

Enclosure (optional for remote mounting): NEMA 4X , IEC 529, IP 67 with knockouts.

Specification for Signal Switching Output Board

Purpose: The output relay board is used to switch analyzer 0-20 mA or 4-20 mA signals provide dry

contact sample point number indication. The board includes alarm contacts for normally-open

commutated alarm indication.

Inputs: 0-20 mA or 4-20 mA signal from analyzer (if signal switching)

Number

of Points: 8

Relays: DPDT sealed relays, contacts rated for 250 VAC, 220VDC maximum operating voltage.

Maximum switching capacity 30W, 62.5 VA for inductive loads. The alarm contacts are

normally-open dry contacts which may be powered by field voltage (less than 30 VDC and 0.5

A) from annunciator. In lieu of this standard alarm set-up, the board can be reconfigured to

supply 6 VDC to remote devices, i.e., relay coils, to accommodate required high voltage alarm

requirements. (See Appendix A.)

Specifications

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

6

Page 8

Sample Sequencer

Specification for 0-1 Volt DC Output Board

Purpose: The 0-1 VDC output board is used to provide 0-1 VDC sample point number indication. The

board includes alarm contacts for normally-open commutated alarm indication.

Inputs: None

Outputs: One 0-1 Volt DC signal to indicate respective sample point number currently in "dwell" time.

Number

of Points: 8

Relays: DPDT sealed relays, contacts rated for 250 VAC, 220VDC maximum operating voltage.

Maximum switching capacity 30W, 62.5 VA for inductive loads. The alarm contacts are

normally-open dry contacts which may be powered by field voltage (less than 30 VDC and 0.5

A) from annunciator. In lieu of this standard alarm set-up, the board can be reconfigured to

supply 6 VDC to remote devices, i.e., relay coils, to accommodate required high voltage

alarm requirements. (See Appendix A)

Specification for Remote Electronic Track & Hold Board Assembly (7-00839A)

Purpose: The remote track & hold card has four independently isolated channels which each operate in

two modes: the track mode, where the output follows proportionally to the input while contact

terminals are closed, and the hold mode, where the output value is held via digital memory

until the command is reset by contact closure.

This card is ideal for applications with analyzers being sequenced between multiple sample

lines. The hold feature permits the last reading for each of four channels to be held until the

next sequenced reading for the respective channel occurs. Use of the card prevents the nonactive channels from dropping to zero between readings thereby avoiding potential system

alarm problems.

The remote Track & Hold board is mounted in an enclosure remotely located from the Sample

Sequencer enclosure. The advantage of using the remote Track & Hold instead of the plug-in

type is that alarm contacts are available from the signal switching board. Another advantage

of the remote track and hold is that it can be configured to provide multiple isolated outputs.

If a sample point is not activated after four contact closure indications have occurred on the

board, the output of the unactivated point will become 4 mA. If no sample points on the board

are activated within 80 minutes, all four outputs will become 4 mA.

The card is versatile to accommodate many applications. Several cards may be wired

together to provide more than four channel outputs. The card is also useful for applications

where multiple outputs from one analog input signal are required. For instance, the card may

be used if separate analog signals for plant DCS and recorders are required.

Performance:

Accuracy ± .01% of span at 25°C

Response Time: One-second time constant

Temperature coefficient: ± 0.012% reading per 1°C

Specifications

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

7

Page 9

Sample Sequencer

Input Analog Signal: 0-20 mA or 4-20 mA or any voltage input between 0-10 V with proper

scaling resistor (plug-in socket scaling resistor - See Appendix H).

Output Analog Signals: Four 0-20 mA or 4-20 mA independently isolated at minimum 500 V

per channel

Maximum Load Resistance: 600 Ohms

Enclosure: NEMA 4X, IEC529, IP67 with knockouts.

General: Power: 108-132/216-264 Vac, 47-63 Hz (jumpers for 220 Vac applications - See Appendix F)

Wiring: Screw Terminals

Enclosure: ABS watertight NEMA 1,2,3,3R,4,4X, 5,12 & 13. Europe: IP 65 to DIN 40050

Enclosure Dimensions/Mounting: 9.44" x 6.29" x 3.54" / Wall or surface mounting

Adjustments: Offset and Gain potentiometers for each output channel

Hold Control: Holds when opening the input control terminals; tracks when closing the

control terminals (tracks one channel at a time)

Operating Temperature: -5 to +70°C

Operating Humidity: 90% RH max., non-condensing

Weight: 2.3 lbs.

Specification for Plug-In Electronic Track & Hold Board (6-02499E)

Purpose: The plug-in track & hold card has four independently isolated channels which each operate in

two modes: the track mode, where the output follows proportionally to the input during the

respective dwell time, and the hold mode, where the output value is held via digital memory

until the next dwell time.

This card is ideal for applications with analyzers being sequenced between multiple sample

lines. The hold feature permits the last reading for each of four channels to be held until the

next sequenced reading for the respective channel occurs. Use of the card prevents the non-

active channels from dropping to zero between readings thereby avoiding potential system

alarm problems.

The card is versatile to accommodate many applications. One or two circuit cards may be

plugged inside the Sample Sequencer to provide up to eight sample outputs.

The card can be used for applications where dual outputs from one analog input signal are

required. Dual outputs are obtained by field configuration. For instance, the card may be

used if dual analog signals for plant DCS and recorders are required. A maximum of four

outputs or two pairs, may be obtained from each card.

The plug-in track and hold board will output 0 mA on points which are turned off.

Input Analog Signal: 0-20 mA or 4-20 mA

Output Analog Signals: Four 0-20 mA or 4-20 mA independently isolated at minimum 500 V

per channel per circuit board.

Maximum Load Resistance: 525 Ohms

Specifications

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

8

Page 10

Sample Sequencer

General: Wiring: Screw Terminals

Circuit Board Dimensions: 5.165" x 5.6"

Adjustments: Offset and Gain potentiometers for each output channel.

Operating Temperature: -5 to +70°C

Operating Humidity: 90% RH max., non-condensing

Weight: 5 oz.

Specifications

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

9

Page 11

Sample Sequencer

Safety Precautions

SAFETY PRECAUTIONS

Before attempting to unpack, set up or operate this product, read the entire

manual. Pay careful attention to all warnings, cautions and notes. Failure

to do so could result in serious personal injury or equipment damage.

Product warranty may be affected.

Use of Hazard Information

If multiple hazards exist, the signal word corresponding to the greatest

hazard shall be used.

DANGER

Indicates an imminently hazardous situation which, if not avoided will result

in death or serious injury

WARNING

Indicates a potentially hazardous situation that could result in death or

serious injury

CAUTION

Indicates a potentially hazardous situation that may result in minor or

moderate injury

NOTE

Information that requires special emphasis.

SHALL

This word understood to be mandatory

SHOULD

This word understood to be advisory

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

10

Page 12

Sample Sequencer

General Description

General Description

The SENTRY Sample Sequencer is a microprocessor-based instrument capable of electronically

switching up to eight sample streams or sensors one at a time to one analyzer and of providing

signals to recorders, alarms and computers. A manifolded Sentry sampling valve specially designed

to obtain optimum representative samples is available for sample stream switching with the Sample

Sequencer. The Sample Sequencer reduces the number of required analyzers while maintaining

equivalent data accuracy. Reliable sample analysis comparison is obtained by using a Sample

Sequencer with one dedicated analyzer. In addition, significant operation cost savings are obtained

by not having to install, maintain and service multiple analyzers.

The Sample Sequencer is capable of operating in the cycle mode for continuous-type analyzers or in

the batch mode for batch-type analyzers. In addition, the Sequencer is capable of measuring the

analyzer analog output signal and converting the analog signal to digital data to be sent out via the

Sequencer's RS-485 serial data communication port. Using the RS-485 capability, one can connect a

PC via twisted pair cable to one or more sequencers for remote monitoring, control and data

acquisition.

Plug-in output boards are supplied to switch the analyzer analog signal to different recorder points or

to provide contact closure channel number indication for recorders. The boards also provide eight

independent commutated alarm contacts for low/high analog alarm and analyzer system alarm

indication. Optional boards are available to provide 0-1 VDC channel number indication for recorders

or to track and hold independently isolated analog signals.

Figures 1 - 3 illustrate a typical system arrangement for sample stream switching with the Sample

Sequencer. Optional boards and customer-supplied equipment are shown for clarification.

Figure 4 illustrates a typical system arrangement for sensor switching with the Sample Sequencer.

Optional boards and customer-supplied equipment are shown for clarification.

Modes of Operation

The Sample Sequencer has three programmable modes of operation:

BATCH - For analyzers that take a sample "bite" (or batch), produce an analytical result

and then provide a contact signal output, in typically one to 20 minutes.

CYCLE - For any continuous analysis (conductivity, dissolved oxygen, pH and sodium).

Note

If using the Sample Sequencer with a Hach analyzer, See Appendix D.

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

11

Page 13

Sample Sequencer

General Description

FIGURE 1 - Sample Sequencer System with Manifolded Sample Valve, Recorder, Alarm Annunciator and

FIGURE 1 - Sample Sequencer System with Manifolded Sample Valve, Recorder, Alarm Annunciator and

Network Computer Communications

Network Computer Communications

FIGURE 2 - Sample Sequencer with Remote Electronic Track & Hold Board, FIGURE 2 - Sample Sequencer with Remote Electronic Track & Hold Board,

Manifolded Sample Valve, Recorder, Alarm Annunciator and Network Computer Communications Manifolded Sample Valve, Recorder, Alarm Annunciator and Network Computer Communications

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

12

Page 14

Sample Sequencer

General Description

FIGURE 3 - Batch Mode Sample Sequencer System with Manifolded Sample Valve, Recorder, Alarm

Annunciator and Network Computer Communications

(See Appendix D for use with Hach analyzer.)

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

FIGURE 4 - Sample Sequencer System for Sensor Switching

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

13

Page 15

Sample Sequencer

General Description

Figure 5 - Sample Sequencer with Plug-In Electronic Track & Hold Board, Manifolded Sample

Valve, Recorder and Network Computer Communications

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

14

Page 16

Sample Sequencer

General Description

Output Boards and CRT Display

Output boards are available for the Sample Sequencer to provide a variety of outputs.

Valve Output Board

DC) electrically operated valves for switching up to eight sample streams to one analyzer. The board

may be located inside the Sample Sequencer. As an option, the valve output board may be housed in

a NEMA 4X enclosure for remote installations. The board includes lights to indicate current sample

point number. For use with the Sample Sequencer, Sentry offers a special sampling valve for stream

switching. The unique design prevents cross contamination and maintains continuously flowing

samples to help provide a representative sample.

Signal Switching Output Board for Signal Switching or Contact Closure Point Indication

switching output board with double pole, double throw relays is available to commutate the analyzer

analog signal (signal switching) and low voltage normally-open alarm outputs to eight individual outputs.

This output works well with a multipoint recorder with print holdout option. The signal switching output

board may also be used with a recorder which requires a contact closure to indicate the current sample

point number.

0-1 VDC Signal Output Board (optional)

an analog signal of 0 - 1 Volt DC indicating the current sample point number. For example, sample

point number one is indicated by an output of 0.1 Volt, point two by 0.2 Volt, ..., and point eight by 0.8

Volt. This option works well when there are insufficient channels on the recorder for all of the analog

signals. For example, it can be used when a two channel recorder is available to sequence more than

two streams. In addition, it can be used if each sample stream goes through multiple analyzers. The

board also provides eight commutated low voltage normally-open alarm contacts.

Electronic Track & Hold Boards:

Plug-in Type

Sequencer and is used to track and hold a 0 - 20 or 4 - 20 milliamp signal as output for that point in up

to four separately isolated outputs. Two plug-in (6-02499E) electronic track & hold boards may be

plugged into the Sample Sequencer to obtain maximum eight points of track and hold output. The

electronic track & hold board has no alarms. Use the remote type electronic track & hold board (below)

with a signal switching output board if alarm contacts are required.

NOTE: Only one type

electronic track & hold boards), may be used in

Remote Type

in type. However, it requires line power and contact closure inputs to indicate tracking sample point

number. This board is used in conjunction with the signal switching output board. See specification for

more information.

CRT Monitor Output

controller computer to a remote computer, controller, or annunciator as all the information is available

and can be transmitted using RS-485. Additional Sample Sequencers may also be connected on the

RS-485 network. Sentry offers a computer program, SEQUENCE, to control, monitor, graph and

record data from a Sample Sequencer.

: The valve output board uses relays to turn on and off maximum 250 Volts (AC or

: The signal

: The 0 - 1 Volt DC signal output board is available to provide

: The plug-in electronic track & hold board installs inside the Sample

of signal output board, (i.e., signal switching, 0-1 VDC output, or two plug-in

a Sample Sequencer at a time.

: The remote electronic track & hold board (7-00839A) is similar to the plug-

: A simple computer program can be written to communicate from the

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

15

Page 17

Sample Sequencer

OPTIONAL MANIFOLDED SAMPLING VALVE

Although the Sample Sequencer may be used to control most manifolded valve arrangements, the

Sentry Manifolded Sample Valve offers a convenient optional accessory to obtain a representative

sample. The patented design incorporates block and bleed design and provides continuously flowing

samples with no areas for cross contamination to occur. The valve is available with a variety of DC and

AC solenoid coils and comes in either four or eight sample line models. Contact Sentry for more

information about this special sampling valve.

General Description

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

16

Page 18

Sample Sequencer

Operation

OPERATION

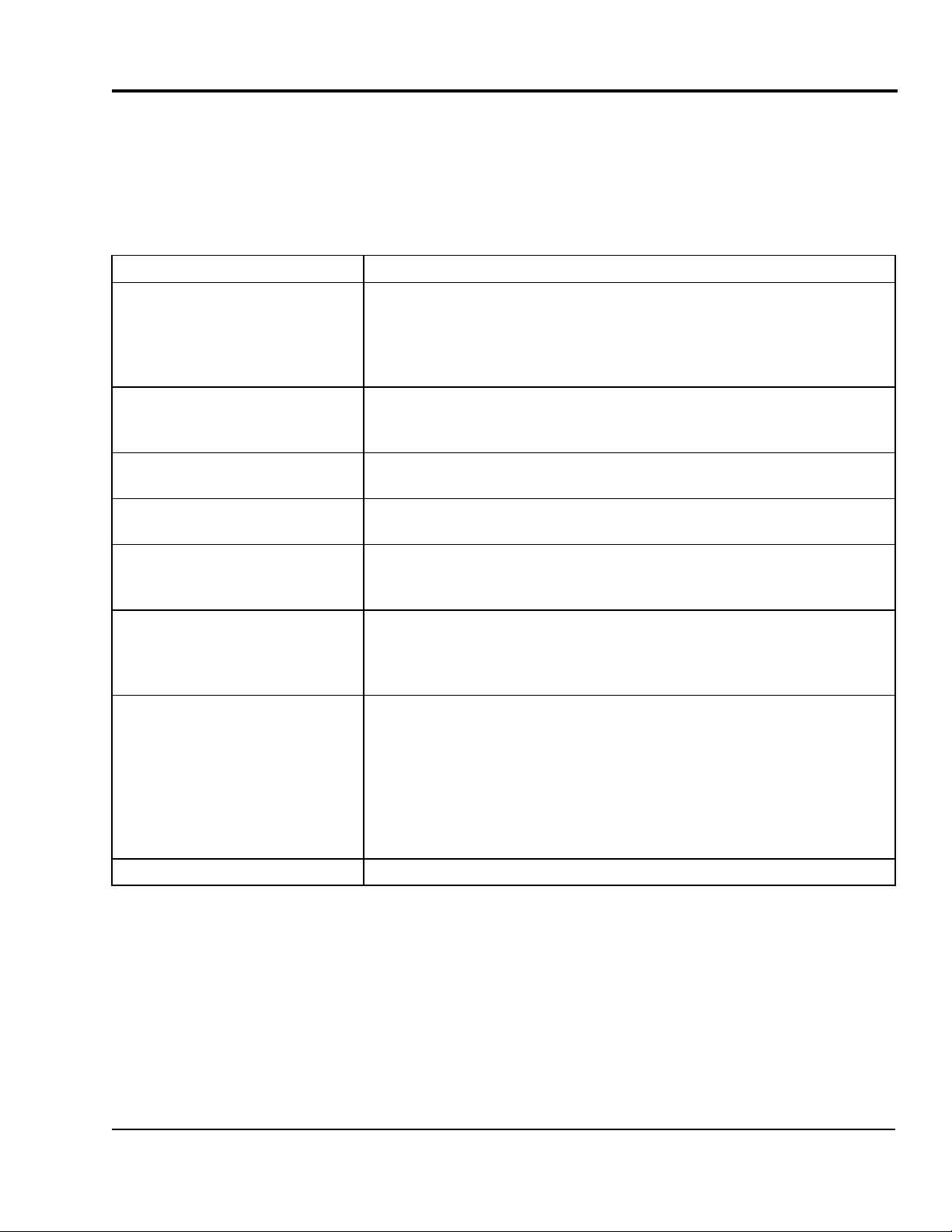

Description of Controls

Figure 6 and Table 1 describe controls on the Sample Sequencer membrane switch display.

Table 1 - Control and Display Descriptions

DESCRIPTION FUNCTION

Sample Point switches 1-8 with

light annunciators

Sample names The removable name tag allows the sample name to be typed and

Sample point display Indicates the sample point number corresponding to the value in the

Display function display window Indicates the value of the current function (indicated by the display

Display function lights Indicates which function (CYCLE TIME, DELAY TIME, DWELL TIME,

Control switches These tactile feedback switches control the displays, reset alarms and

Programming switch & arrows Activates the programming mode to program new values for all display

Analyzer system alarm light When lit, indicates an analyzer system alarm.

Pushing the switches turns the sample point on and off. The adjacent

light turns on when the point is on. The light blinks on and off when the

point is in alarm. When the point is on, the respective sample (when

sample switching) or cell signal (when sensor switching) will be

analyzed in sequence.

displayed through the clear pocket on the membrane switch. The

nametag is accessed by removing the front display plate.

display function window.

function light which is on).

ANALOG mA, LOW ALARM, HIGH ALARM or STATION NUMBER) is

currently being displayed.

start or restart the Sample Sequencer. The DISPLAY, NEXT and

ALARM RESET keys serve a different purpose when programming

(see below).

functions except ANALOG mA. For example, new values for CYCLE

TIME or LOW ALARMS can be programmed. The arrows light up

when the programming mode is activated. The control switches

immediately above the arrows control the digit position and value when

programming. For example, the DISPLAY switch becomes the "up

arrow" function to increase the function display digit value when

programming.

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

17

Page 19

Sample Sequencer

Operation

FIGURE 6 - Sample Sequencer Membrane Switch

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

18

Page 20

Sample Sequencer

Operation

I/O Board DIP Switches

Figure 7 shows the location of the four DIP switches at SW1 on the I/O board. The I/O board is

normally supplied in the Sample Sequencer and plugs into the display board with the long dual-row 42

pin connector. The SW1 DIP switch functions are described in Table 2 below.

Table 2 I/O Board DIP Switch (SW1) Functions

SW1

No.

1

2

3

4

SW1-1

position. The ON position enables programming form the front panel.

SW1-2

installed. The switch should be in the off position if the Plug-in electronic track & hold board(s) is

used. Select the ON position if either the Signal switching, 0-1 Volt DC output or remote

hold board are used.

SW1-3

must be calibrated. This forces the Sequencer into a fixed state to conveniently calibrate the

Sample Sequencer via the gain and offset potentiometers on the display board. (See the

Calibration section in this manual for more information.) Turning the switch OFF turns off the

calibration mode and permits normal operation. The START/RESET control switch on the front

display must be pushed to start sequencing after completing calibration and turning SW1-3 OFF.

Note: The Sample Sequencer is shipped factory-calibrated.

SW1-4

enables the cycle mode for continuous type analyzers. The ON position enables the batch mode

for batch type analyzers, such as Hach Series 5000.

Description

Programming

Type of plug-in output board

Calibration

Operation Mode

allows one to lock-out front panel programming by putting this switch in the lock-out (OFF)

configures the Sample Sequencer for the type of plug-in output board which has been

enables the calibration mode. Turn the switch On when the ANALOG mA signal display

configures the Sample Sequencer for the desired mode of operation. The OFF position

Function

OFF ON

Lock-out

Plug-in electronic track &

hold board

Normal Operation

Cycle Mode

Signal switching output,

Enable

0-1 volt or Remote

track & hold boards

Calibrate Mode

Batch Mode

track &

See Appendix D if using the Sample Sequencer

with Hach Series 5000 analyzers.

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

19

Page 21

Sample Sequencer

Operation

FIGURE 7 - I/O Board Arrangement

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

20

Page 22

Sample Sequencer

Operation

Membrane Switch Keys

Sample Point Numbers (1-8): The eight sample point number switches turn a sample point on or off.

When the point is on, the adjacent LED will light and the sample point will be analyzed sequentially.

DISPLAY

the next one down and back to the top. Normally the CYCLE TIME function is selected to keep

track of the analyzer cycling, or ANALOG mA output is selected to keep track of the analyzer output

value. The remaining functions are used predominantly for set up, troubleshooting or programming.

NEXT

selections, one for each point. Pressing the NEXT key displays the next higher POINT value and

then back to one again.

ALARM RESET

Alarms can be from a low or high analog mA output value or from the analyzer system alarm. Eight

successive analyzer system alarms will force the Sample Sequencer to an "OFF" mode.

START/RESET

reinitializes and restarts with the first on point. The previous programmed values are read in from

non-volatile memory.

PROGRAM

out DIP switch on the I/O board (SW1-1 in Off position) can defeat this external key and lock-out

programming from the membrane switches.

Programming

In order to operate, the Sample Sequencer must be initially programmed. Programming is

accomplished either with the front display membrane switch keys or from computer signals via the

built-in RS-485 serial communications.

The following items are programmed to meet analyzer and operational requirements:

• Cycle time (or batch time-out when in the batch mode)

• Delay time

• Dwell time

• Low alarm levels for each point

• High alarm levels for each point

• Station number for communications

Except for station number, the above items can also be remotely programmed using the

communications software from a connected computer.

: Pressing this key causes the function as indicated by the function lights to advance to

: With functions: ANALOG mA output, LOW ALARMS, and HIGH ALARMS, there are eight

: Resets all current alarms. Points will realarm if the current value is still in alarm.

: If the key is pressed or the power is turned on, the Sample Sequencer resets,

: Pressing this key starts and stops programming as described below. An internal lock-

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

21

Page 23

Sample Sequencer

Operation

To Program:

• Press the DISPLAY key to select desired function. To select desired POINT number

for the low and high alarms press the NEXT key.

• Press PROGRAM. The programming arrows light up and the current programmed

value is displayed.

• Starting at the right digit, pressing the key immediately above the up arrow

(DISPLAY) causes the digit to increment. Press repeatedly until the desired digit is

displayed.

• Each pressing of the key above the left arrow (NEXT) shifts the active digit one to

the left. The active digit may be incremented using the aforementioned up arrow

key.

• Each pressing of the key above the right arrow key (ALARM RESET) shifts the active

digit one to the right.

• Pressing the PROGRAM key again:

Turns the arrow lights off.

Saves the value in permanent memory.

Returns the Sample Sequencer to its normal display.

The newly programmed values are active on the next cycle. Press

START/RESET to restart the sequencer using the new values.

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

22

Page 24

Sample Sequencer

Operation

Display Functions:

Functions shown in Figure 6 may be displayed on the Sample Sequencer. Pressing the DISPLAY key

toggles through the below functions. The light adjacent to the display function lights to indicate the function

is displayed. The NEXT key toggles through successive function point numbers (1-8) for ANALOG mA,

LOW ALARM and HIGH ALARM.

• CYCLE TIME (or time-out count-down for batch mode) - time duration to sample a point

• DELAY TIME - time to delay the analysis signal upon starting the cycle

• DWELL TIME - time period that analysis signal is read and switched after delay

• The following three items display milliamp values of 0 to 20 mA . Values for each of the

eight points are displayed by pressing the NEXT key.

ANALOG mA - the input analysis signal value

LOW ALARM values

HIGH ALARM values

• STATION NUMBER used in communications (1-16).

CYCLE TIME, DELAY TIME and DWELL TIME are discussed in the operating mode section below.

ANALOG mA Input Analysis Value

milliampere range. On selection, the value for sample point number one is displayed. Pressing the NEXT

key will display the next higher point up to eight, and then from eight back to one. As the unit processes the

active sample points, any points not on will be skipped and the value zeroed. In cycle or batch mode

(described below) the values are retained only for the time required to complete an analysis circuit of the on

points. In manual mode only the active point is on. If the unit is in the OFF mode, all values are zeroed.

If an optional electronic track & hold board is used to provide individual milliampere outputs, all eight values

are refreshed each second. If a signal switching output board is used, the active value is output during the

dwell time only. All values are immediately available to a computer connected to the communication port.

LOW ALARM LEVEL:

Pressing the NEXT key displays successive values. To reprogram a low alarm value, press the

PROGRAM key and follow the directions in the section on programming. Pressing the PROGRAM key

again terminates programming and saves the value in non-volatile memory. These values are also

programmed by communicating the required protocol from a connected computer and current values can

be sent, on request, from the Sample Sequencer to a computer. Note: The low and high alarm values are

programmed in milliamp values. Selection of the appropriate value should take the analyzer's

measurement range and span into consideration.

During the valid dwell output time, depending on the mode, the input signal is compared to the low alarm

level and if the signal is less, an alarm state is initiated for that point. The respective sample point light on

the Sample Sequencer display at that point selection switch will blink each second. Pressing the alarm

reset key stops the blinking, but the alarm can reinitiate if the condition still exists and is dwelling on the

point number. If an optional signal switching output board is used, a low voltage (<30 VDC) dry contact

closure alarm signal or 6 VDC output signal is commutated, depending on board configuration.

HIGH ALARM LEVEL:

equal to the programmed high alarm value.

STATION NUMBER:

Sequencer unit. The station number identifies the unit when operated with the built-in RS-485 serial

communication network. This station number should be different from other Sample Sequencers on the

computer network. The station number assignment can only be performed with the front panel display

The programmable low alarm level in milliamps is displayed for each sample point.

Functions the same as for low alarms, but will go into alarm if the input signal is

The station number function assigns a station number of 1 to 16 to the Sample

: All analog values are in milliampere form for either 0 to 20 or 4 to 20

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

23

Page 25

Sample Sequencer

PROGRAM key on the Sample Sequencer. The programming procedure is similar to that described for

programming the alarms. See the manual section on communications for more information about the

network communications.

Operation

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

24

Page 26

Sample Sequencer

Operation

OPERATING MODES:

OFF, CYCLE, BATCH

OFF If there are no sample points on, or if a BATCH time out has occurred, or calibration has been used,

or after eight successive analyzer alarms, the Sample Sequencer goes into the OFF mode. This is

the normal preferred standby mode.

Even when the unit is "OFF", it is still able to:

Program

Calibrate

Communicate

A local or remote START/RESET starts the Sequencer again.

CYCLE This mode is for continuous output analyzers such as sodium, conductivity, pH, O

, some

2

colorimetric, and many others. Two system methods are used: sample stream switching

and sensor switching.

Sample Stream Switching

where successive sample streams are switched through the

same analyzer apparatus. An electrically actuated manifolded valve arrangement is

typically used to accomplish the stream switching. Sentry offers a technology-leading

sampling valve for stream switching.

Sensor Switching

where relatively simple sensors can be placed in each sample line and

the electrical leads to the analyzer can be successively switched to the analyzer.

Timing Considerations for the Cycle Mode:

Figure 8 illustrates the concept of cycle, delay and dwell times for the cycle mode of

operation. Figure 8 demonstrates how each sample stream is switched for the duration

called cycle time. The analyzer output signal is switched through the Sample Sequencer

after the delay time period for the dwell time duration. When using the Sample Sequencer

for sensor switching, the only difference from stream switching is that the sensor signal is

switched instead of a valve during the cycle time. The following considerations should be

made when determining the timing for your system.

CYCLE Time

is the time period of each sample point during which stream or sensor signal

switching occurs. Shorter cycle times yield faster analytical updates among the points while

longer cycle times provide sufficient time to recognize stable readings. Short cycle times

are achievable by minimizing sample line length from the manifolded valve to the analyzer,

eliminating dead legs and by short analyzer response time. The cycle time may be

optimized by determining the maximum time period required for each sample point to

stabilize and using this as the cycle time. Note, the cycle time value must provide enough

time to fulfill the requirements for delay and dwell. For example, the cycle time must be long

enough for delay and dwell to count down before the next dwell time period initiates. (In

other words, the dwell time must be set less than or equal to the cycle time.)

DELAY Time

. After switching to a successive stream or sensor, there will be a settling time

for the analyzer to stabilize to the new sample: This DELAY time could be seconds to a

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

25

Page 27

Sample Sequencer

minute or more for stream switching. The analyzer analog output signal is ignored during

the delay time. The necessary delay depends on the valve manifold design, sample line

length from the manifold arrangement, sample velocity, analyzer response time, sample

constituents and differences between the amount of constituents for each sample point.

When switching sensors, the sensor signals are usually recognized quickly by an analyzer

and the delay time should be set accordingly, i.e., approximately 1-2 seconds.

DWELL Time

Sample Sequencer during which time Sequencer alarms are commutated. The dwell time

required will depend on the destination device such as a data logger, computer, recorder,

etc., for both the analog data and the alarm output. The output signal must be valid for this

whole DWELL time.

For instance, if output is to an eight point recorder with a print-out cycle time of 3 seconds

per point, a minimum of 24 seconds plus would be the minimum DWELL time. Connecting

to a computer system could have a minimum DWELL time requirement of 3 to 5 seconds or

more. The only penalty for long dwell time is it may increase the cycle time and decrease

responsiveness.

The DWELL time can be left on until the next on sample begins to modify the result as

shown in Figure 8.

Alarms are evaluated only during the DWELL time.

The DELAY time and DWELL time must be at least one second less than the CYCLE time.

is the time period during which a valid analyzer signal is switched through the

Operation

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

26

Page 28

Sample Sequencer

Operation

FIGURE 8 - Cycle Mode Timing Diagram

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

27

Page 29

Sample Sequencer

BATCH The batch mode is for analyzers that take a "bite" or batch of sample and then spend some

time analyzing it before outputting a new fixed analog signal. Typical types are reagent

additive, chromatographs, etc. When these analyzers have completed an analysis there is

just one output value until the analyzer's next cycle is completed, (as opposed to a

continuous analyzer that shows the contemporary trend.) The Hach Series 5000 analyzer

operates in this manner.

See Appendix D for instructions about connecting a

An "End-of-Analysis" contact closure signal is often provided at the conclusion of a batch

by the batch type analyzers. Note: The term, End of Measurement, is often used in place

of "End of Analysis". Following the end-of-analysis, the analyzer provides a specific

protocol of the analog output values to the Sequencer.

Operation

Hach 5000 analyzer to the Sample Sequencer.

FIGURE 9 - Batch Mode Timing Diagram (For Batch-Type Analyzers)

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

28

Page 30

Sample Sequencer

Timing Considerations for the Batch Mode:

Figure 9 illustrates the concept of cycle, delay and dwell times for the batch mode of operation.

Figure 9 demonstrates how each sample stream is switched when the analyzer outputs an "endof-analysis" signal to the Sample Sequencer. If the Sample Sequencer doesn't receive an end-ofanalysis before the cycle time expires, the Sequencer goes into the off mode and the analyzer

alarm light on the front display goes on. Upon receiving an end-of-analysis signal from the

analyzer, the Sample Sequencer switches the analyzer output signal for the previous sample point

after the delay time period for a period of time equal to the dwell time. Note: The delay and dwell

time point numbers always lag the cycle time point number by one because it is a batch process.

Note: If using a Hach analyzer, see Appendix D.

The following considerations should be made when determining the timing for your batch mode

system:

End-of-Analysis

(at terminals J4-3 and J4-4 on the I/O board) when the analysis is completed and the analyzer

is ready to output the results and is available to begin a new analysis.

CYCLE TIME

of-analysis signal has not been received before cycle time counts down to zero, something is

wrong with the analyzer and any further processing is impossible. Upon cycle time expiring,

the ANALYZER ALARM light on the Sample Sequencer display is initiated and the unit goes

into the "OFF" mode. The cycle time should be set at a value greater than the analyzer batch

process time.

DELAY TIME

the analyzer are available. One second plus any programmed delay time will elapse before

the Sample Sequencer looks at the analyzer output signals. Set the delay time for the amount

of time it takes the analyzer to output a new signal after it has issued an end-of-analysis.

DWELL TIME

communicates as determined by output options and/or the value is communicated to a

computer, recorder, data logger, etc. The DWELL time must be long enough to satisfy the

output devices, (i.e., recorder computer, etc.), requirements. The sum of delay and dwell

times must be less than the analyzer end-of-analysis signal time period.

Turning Sample Streams On and Off

Sample streams may be removed from switching by turning the appropriate sample point number

off; streams may be turned on by turning the point number on. See the section in this manual

titled Membrane Switch Keys [sample point numbers (1-8)] for information about turning streams

on or off from the Sample Sequencer display. The points may also be controlled via a computer

using the built-in RS-485 network communications. See Communications section for more

information.

If the Sample Sequencer is currently on a sample point which you turn off, the point will complete

the entire cycle (including delay and dwell) and then be skipped on the next sequence occurrence.

If you wish to move on to the next point immediately, press the START/RESET switch on the front

display.

(or End-of-Measurement). This signal is received by the Sample Sequencer

. The cycle time period in batch mode is an alarm condition such that if an end-

begins when the end-of-analysis signal is received and until valid outputs from

. During the dwell time the Sequencer reads in the analysis value, saves it and

Operation

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

29

Page 31

Sample Sequencer

Advancing Streams

Sample streams may be advanced to any desired point number. Turn on the desired sample point

number by pressing the respective sample point number switch (1-8) and verifying the adjacent

point light is on. Then, turn off the intermediate point numbers and press the START/RESET key.

The desired sample point number will be on. Turn on previous sample points which are desirable.

Holding on One Sample Point

Occasionally, it is necessary to hold an analysis on one sample point. Simply turn off all the

undesired sample points by using the respective sample point number switch (numbered 1-8 on

front display). The adjacent lights should turn off. Now, the Sample Sequencer will keep

sequencing on the one point. Thus, the normal cycle time, delay time and dwell times will be

used. Depending upon the programmed values for these times, one may or may not receive a

continuous analog signal through the Sample Sequencer.

Alarms

The Sample Sequencer has several alarm capabilities. There are analog alarms and an analyzer

system alarm. These alarms may be annunciated in several ways. See Display Functions in this

manual for information about setting low and high alarm levels. See Programming to learn how to

program the analog alarm values from the Sequencer front display.

Analog Alarms:

analog alarms. The analog alarms may be annunciated in several ways, depending upon what

optional output boards are installed in the Sample Sequencer.

A low or high analog alarm is annunciated on the Sample Sequencer front display by blinking the

sample point number light. The blinking continues until: (1) the sample point alarm condition is

corrected and then sampled again, or (2) the ALARM RESET switch is pressed while not dwelling

on the alarming sample point.

The analog alarm may also be annunciated by contact closure using one of the optional signal

switching output boards, i.e., the Signal switching output board for signal switching or the 0-1 VDC

Signal switching output board. These boards have normally-open (N.O.) dry alarm contacts for

low voltage signals (<30 VDC) which are closed upon alarm during the dwell time period for the

respective point, i.e. commutated alarms. DANGER: Do not apply high voltage to the alarm

contact terminals!

The alarms may also be annunciated by connecting the Sample Sequencer to a computer via the

built-in RS-485 network communications.

In lieu of using dry alarm contacts, the Sample Sequencer may be configured to source (i.e.,

output), an unregulated 6 VDC 0.5 A maximum signal to indicate an analog alarm. The signal may

be used to power a remote relay having contacts suitable for a high voltage application. See

Appendix A for directions on the board configuration to accomplish this.

Analyzer System Alarm:

The analyzer system alarm is normally initiated by the analyzer if the analyzer has this capability

(e.g. Hach 5000 series analyzers) by a normally-open (N.O.) contact closure. The analyzer should

initiate this system alarm when a significant problem has occurred, i.e., loss of reagents, failure of

critical measurement components, loss of sample pressure, etc. The system alarm contact

closure is recognized at terminals J4-2 and J4-5 on the I/O board of the Sequencer. Note: Do not

connect the analyzer analog

The Sample Sequencer has the ability to determine and initiate low and high

The Sample Sequencer also recognizes one analyzer system alarm.

Operation

alarms to the system alarm terminals on the Sequencer as this

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

30

Page 32

Sample Sequencer

defeats the purpose of the Sequencer's analog alarms and may make the Sample Sequencer go

into the Off mode erroneously.

The analyzer system alarm is annunciated by the Analyzer Alarm light on the Sequencer display

(see Figure 6). The light will remain on until the analyzer system alarm stops. This alarm is also

annunciated by the commutating normally-open alarm contacts on the optional Signal switching

output board and 0-1 VDC Signal output boards. After two minutes, the Sequencer will switch to

the next point. The dwell cycle is still active. The user should program the analyzer to go low or

high, as desired, upon analyzer system alarm.

During batch mode operation, the Sample Sequencer will initiate an analyzer system alarm if an

end-of-batch signal is not received before the end of the cycle time count down. The Sample

Sequencer will also turn off when this condition occurs.

If at any time the analyzer outputs a system alarm to the Sample Sequencer on eight consecutive

points (regardless of the number of sample points turned on), the Sample Sequencer will turn off,

terminate sampling and light the analyzer system alarm LED on the front display. This condition

implies a problem with the analyzer or sample streams exists and must be corrected before

sample sequencing may proceed.

Operation

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

31

Page 33

Sample Sequencer

Operation

Sample Nametag

Figure 10 shows the sample nametag which may be removed from the rear of the display

assembly by removing the front display bezel and four screws. The bezel may be snapped off by

lightly prying with a flat screw driver on one of the corners. The nametag slips into the pocket on

rear of the display. One may type the desired sample names slightly above the respective lines

and insert the nametag back into the display. Sample number one is on the top line. Two

nametags are shipped with each Sample Sequencer.

FIGURE 10 - Sample Nametag

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

32

Page 34

Sample Sequencer

Installation

INSTALLATION

Some of the tasks in this section of the manual have safety issues associated with them. Sentry

Equipment Corp strongly recommends that qualified personnel conduct the installation, and that all

installation personnel study the associated instructions carefully.

Unpacking

After carefully removing the Sample Sequencer from its shipping carton, inspect it for any damage. If

damage is evident, please contact Sentry Equipment Corp immediately.

Mounting

It is recommended the Sample Sequencer be mounted close to the analyzer to permit viewing of both

devices at the same time. This allows a visual check by the operator to determine which sample point

is currently being sampled and relate it to the measurement being displayed on the analyzer and

signals being sent to nearby recorders.

The Sample Sequencer may be panel mounted with included hardware which slides onto the

enclosure mounting bosses. A panel gasket is also included and should be placed between the

Sequencer and panel front. See Figure 11 for panel mounting information.

If the Sample Sequencer will not be panel mounted, the optional NEMA-4X rear cover plate may be

purchased to protect the instrument from wet, dusty or corrosive ambient environments. The NEMA 4X

plate permits table-top usage or surface-mount installation. See Figure 12 for mounting dimensions.

Figure 13 shows mounting dimensions for the remote Track & Hold board enclosure.

Figure 14 shows mounting dimensions for the remote valve output board enclosure. This board is

mounted remote when two (2) Plug-In Track & Hold Boards are used.

Remove the rear cover plate prior to wiring the Sample Sequencer.

Conduit Connections

Knockouts for six 1/2 inch conduit connection or cord grips are provided on the bottom of enclosure. It

is recommended an additional conduit nut be installed on outside of box to prevent mechanical

interference between conduit connector and circuit board relays on the valve output and signal

switching boards.

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

33

Page 35

Sample Sequencer

Installation

FIGURE 11 - Panel Mounting & Overall Dimensions

Sample Sequencer

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

34

Page 36

Sample Sequencer

FIGURE 12 - NEMA 4X Rear Cover & Surface Mounting

FIGURE 13 - Enclosure Overall Dimensions

Installation

Remote Track & Hold

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

35

Page 37

Sample Sequencer

Installation

Figure 14 - Remote Valve Board Enclosure Dimensions

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

36

Page 38

Sample Sequencer

Power and Ground Connection

An external wall-mount type of power supply is shipped with each Sample Sequencer. The power

supply provides unregulated 6VDC power to the instrument. The power supply comes standard as a

120 VAC device. Optional power supplies for other line voltages and outlet plug styles are available

from Sentry Equipment Corp.

It is recommended the power supply be plugged into an electrical outlet or outlet strip with surge

suppression and filtering such as an Isobar made by Tripp Lite. The power supply may also be

installed in an electrical junction box and wired with conduit to instrument-quality power, if desired.

Install according to local codes and procedures. Any cables connecting to the Sequencer which are

over 32 ft. (10 m) in length should also have surge protection devices installed.

The power supply black lead is positive (+6VDC) and the white striped lead is negative (-). Connect

the respective lead to the +6V and - terminals on the I/O board terminal block J1. Attach a 14 gauge

conductor from an earth ground point to the braided drain wire crimp connector labeled "EARTH

GND". See Figures 7 and 15. Warning: The drain wire from the display board mounting screw must

be grounded to protect your unit from electrostatic discharge effects.

Installation

FIGURE 15 - I/O Board Connections

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

37

Page 39

Sample Sequencer

I/O Board Connections and Settings

CAUTION: Disconnect power to the Sample Sequencer before proceeding with installation.

Figure 13 shows connections made to the I/O board. All wiring to the I/O board should be performed

with 22 gauge conductor. However, the ground should be 14 gauge minimum.

Analog Input

gauge conductor. Maximum recommended length is 32 ft (10m).

RS-485

terminals may be daisy-chained to other devices on the same RS-485 network. See the I/O board

arrangement diagram for proper polarity of conductors. Only the two center conductors are used for

RS-485 communication. Long distances, i.e., greater than 100 feet, should use twisted pair cable to

eliminate RFI and EMI noise interference on the network.

Analyzer system alarm

J4. This should be a non-powered line used for dry-contact closure indication only. Use 22 gauge

conductor cable up to 32 ft. (10m) length. NOTE: Do not connect, analyzer analog alarms to these

terminals! See Alarms. If using a Hach 5000 analyzer, see Appendix D for wiring diagram.

End-of-Analysis

appropriate terminals from a batch type analyzer to terminals 3 and 4 on J4 using 22 gauge conductor

cable up to 32 ft. (10m) length. Consult the analyzer manual to properly configure the analyzer to send

an end-of-analysis signal. Note: These terminals are not used when operating the Sample Sequencer

in the cycle mode. If using a Hach 5000 analyzer, see Appendix D.

Connections to Valve Output Board

connect the appropriate color lead to the labeled terminals on J1. Maximum recommended cable

length is 32 ft. (10m).

DIP Switch Settings:

I/O board. These switches must be set correctly for the Sample Sequencer to operate as required.

Power:

Sample Valve Electrical Connection to Valve output board

1. Determine the power source for the electrical valves. Sentry Equipment offers a special sample

2. DANGER: To avoid danger, disconnect power before performing this step. Connect the valve

3. Connect one 22 gauge wire from each valve to terminals V1 through V8 on terminal block J1 of

: Connect the analog signal from the analyzer to the + and - terminals on J4 using 22

: Connect J6-6 modular plug with flat or round cable into terminals J2 and/or J3. These

: Connect the analyzer system alarm (not analog alarm) to terminals 2 and 5 on

: For batch mode operation (see Operating Modes in this manual), connect the

See Table 2 and Figure 7 for proper settings of the DIP switch bank (SW1) on the

See Power and Ground Connections

valve manifold with optional DC power supplies for DC solenoids if required

power source conductors (choose the appropriate gauge size for the breaker amp service at job

site) to terminals labeled + and - on J1 of the Valve output board. This board is installed inside

the Sample Sequencer or, as an option, in a remote NEMA 4X enclosure. Knockouts for 1/2"

conduit are provided. Seal any unused knockouts. See Figure 16 for the wiring drawing.

the valve output board. WARNING: If the Sentry sample valve with integral 3/8" cable grip

connector is used, the valve cable selected must fit snugly in the 3/8" connector. A

larger gauge size may be necessary to achieve snug fit.

Installation

: Using the supplied 22 gauge eight conductor (Belden 8456) cable,

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

38

Page 40

Sample Sequencer

4. Connect one 22 gauge wire from each valve to a neutral terminal labeled N on terminal block

J1 of the valve relay board. See above warning about using 3/8" cable with Sentry valve.

5. The valve board in the standard Sample Sequencer comes pre-wired to the I/O Board. If using

the optional remote valve output board, then connect the 22 gauge seven conductor cable

(Belden 9430) from the color coded J1 terminals on the Sample Sequencer I/O board to color

coded J2 terminals on the valve relay board. Knockouts for 1/2" conduits are provided in

remote valve board enclosure. The maximum cable length recommended is 32 ft. (10m).

Installation

FIGURE 16 - Solenoid Sample Valve Connections

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

39

Page 41

Sample Sequencer

Sample Valve Piping

Proper sample conditioning and sample switching is recommended to obtain a representative sample.

- See Appendix B

Recorder Signal Connections

The Sample Sequencer with optional output boards has the capability of outputting analog signals to

recorders. There are three types of optional signal output boards available: Signal Switching output

board; 0 - 1 VDC output board; and the plug-in electronic track & hold board. See General Description

for more information about these boards. Figure 17 and 18 shows the Sample Sequencer assembly

with these board options. Note: The signal switching board or 0-1 volt board cannot be used

with the plug-in electronic track & hold board.

Installation

FIGURE 17 - Sample Sequencer Assembly with Signal Switching Output Board (Rear View)

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

40

Page 42

Sample Sequencer

Installation

Figure 18 - Sample Sequencer Assembly with Plug-in Track & Hold

SENTRY Equipment Corp • P. O. Box 127 • Oconomowoc, WI 53066 • 262/567-7256 • FAX: 262/567-4523

Web: www.sentry-equip.com • e-mail: sales@sentry-equip.com

41

Page 43

Sample Sequencer

Installation

Signal Switching Output Board (part number 6-02547C)

commutate, (i.e., switch) an analog signal to eight individual outputs to a recorder or data acquisition

system as shown in the connection diagram of Figure 19, or (2) to provide only dry contact closures to

a recorder to indicate the current active channel as shown in the connection diagram Figure 20. All

wiring to this board may be performed with 22 gauge conductor cable (32 ft. or 10m maximum length)

as follows. CAUTION: Disconnect power to the Sample Sequencer before proceeding.

Wiring to Switch Analog Signals - Figure 19

1. The analyzer 0 - 20 mA (or 4-20 mA) analog output signal is connected in series to the I/O board

and terminals + and - on J1 of the signal switching output board.

2. Connect recorder signals, R1 through R8 on the output board to the corresponding input terminals

of the recorder or data acquisition system.

3. Connect one conductor to any one neutral terminal N on the output board to the (-) terminals of the

recorder. Jumper the recorder (-) terminals together.

4. Install the signal switching output board in slot marked on the Sample Sequencer enclosure as

shown in Figure 17. Install by plugging the board into the corresponding connector of the display