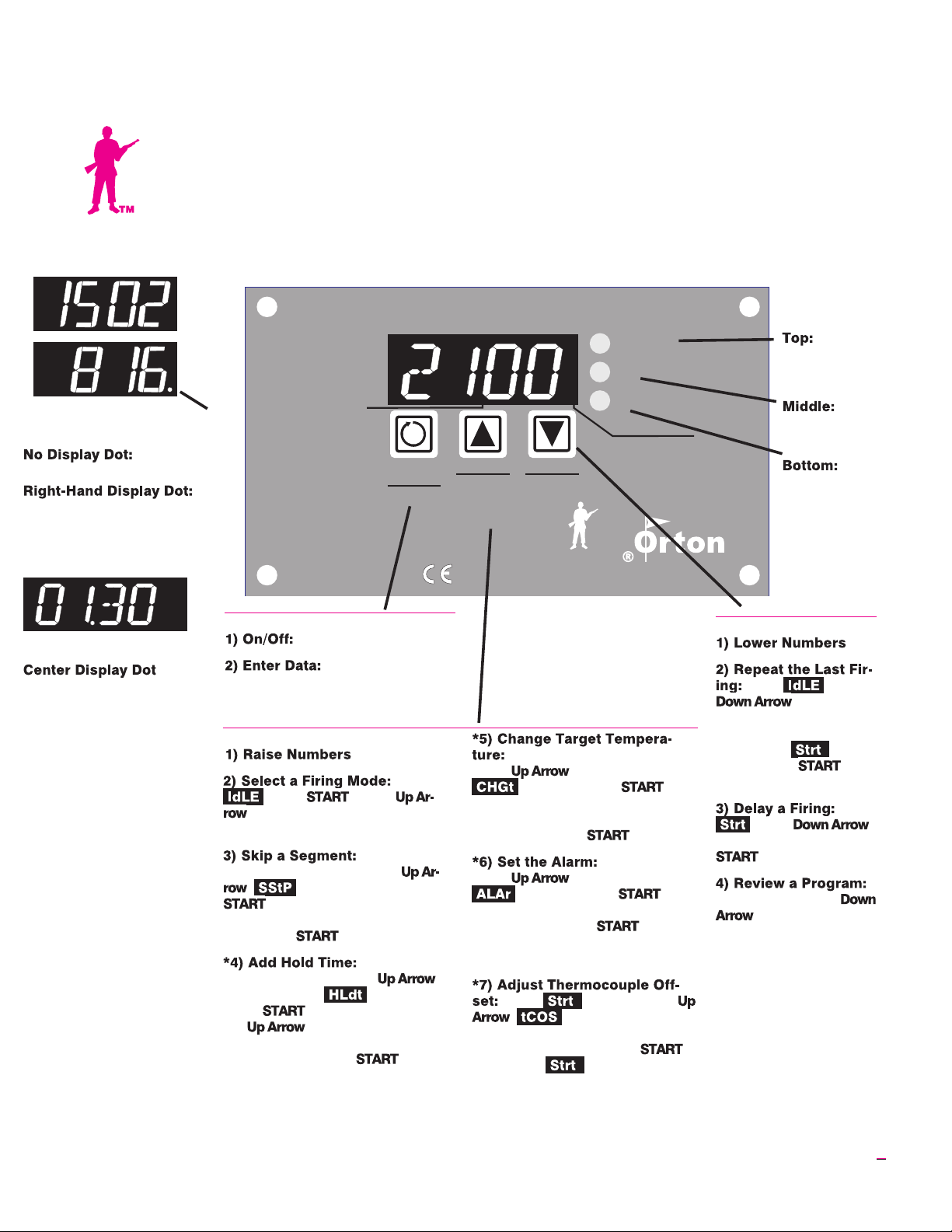

Page 1

Single-Speed / Ramp-Hold Version

Sentry Xpress

Digital Temperature Controller

°F

°C

°C Display Dot

Temperature Display

Temperature

display is in °F.

Tem

perature display is in °C.

Seepage13forinstructionson

selecting °F or °C.

Time Display

:Separates hours from minutes. Example: Display shown above

is 1 hour and 30 minutes.

Hr./Min.

When Lit

START/

-

STOP

Enter

Program

SENTRYXpress

MICRO PROCESSOR

START/STOP Key

Starts and stops a firing.

Press after each

programming step. It works like the

Enter key on a computer.

Up Arrow Key

From

press .Press

to select Single-Speed or

Ramp-Hold. Pages 6, 8

During a

Ramp-Hold firing, press the

. will appear. Press

. The current segment ramp

or hold number will appear. To

skip, press again. Page 8

During a

Ramp-Hold firing, press

repeatedly until appears.

Press .Eachtimeyoupress

the , the hold time for the

current segment will increase by 5

minutes. Then press .

Page 8

Program

Review

Run

°F

When Off

°C

When Lit

HIGHER

Skip Seg.

Add Hold

Change Temp.

T/C Offset

Alarm

The Sentry Xpress 4.0 micro processor is manufactured by the

Orton Ceramic Foundation and displays the CE mark.

press repeatedly until

the arrow keys to change the target

temperature for the current seg

ment. Then press .Page9

press repeatedly until

the arrow keys to change the alarm

temperature. Press .Tosi

lence the alarm, press any key.

Page 9

row keys to adjust the controller to

fire hotter or cooler. Press

to return to .Page12

LOWER

Delay

Review

4.0

During a Ramp-Hold firing,

appears. Press .Use

appears. Press .Use

At the display, press

. will appear. Use ar

TM

During a firing,

-

-

-

Indicator

Lights

Light is

on during pro

gramming.

Light is

on during pro

gram review.

Light

blinks during firing.

Down Arrow Key

From press

.Thepro

gram you have selected

will appear one step at a

time. When ap

pears, press .

Page 4

press .

Enter delay time. Press

twice. Page 4

During firing, press

. The program you

entered will appear one

step at a time. Page 4

-

-

From

-

-

IM-221/2-06

*These features are new with the Sentry Xpress 4.0. If your controller does

not have these features, it is an earlier controller.

1

Page 2

Introduction

Contents

The easiest way to learn to operate your

controller is to read this manual while

you are sitting in front of your kiln. Press

the keys as you read the instructions.

Do not worry if you hear a clicking noise

during operation. Mechanical relays click

as they turn the heating elements on and

off. This is normal.

When you first connect the power, the

controllerwilldisplayasoftwarecodeand

then .

If your controller shows instead of a

software code before appears, then

the controller includes only Skip Seg

ment from "Advanced Features" on pages

8 - 9. If your controller shows a software

code before appears, then the controller has all the features in this manual.

Please read the manual. Damage caused

by failure to follow instructions is not

covered by warranty.

Once you learn the basic features of the

Sentry Xpress, you will be able to control

every stage of firing. This offers learning

opportunities and convenience difficult

to imagine with a manual-controlled kiln.

General Guidelines . . . . . . . . . . . . . . . . . 3

Time and Temperature Display . . . . . . . . . . . . . . . . . . .3

Operation Begins from the IdLE Display. . . . . . . . . . . . 3

Thermocouple Inspection . . . . . . . . . . . . . . . . . . . . . . . 3

A Rapid Way to Scroll Numbers . . . . . . . . . . . . . . . . . . 4

Program Review & Repeat Firing . . . . . . . . . . . . . . . . . 4

Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Power Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

CPLt Message: Firing Completed . . . . . . . . . . . . . . . . . 4

Thunder Storms and Power Surges . . . . . . . . . . . . . . . 4

Canceling a New Program. . . . . . . . . . . . . . . . . . . . . . . 4

Theory of Operation . . . . . . . . . . . . . . . . 5

Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Two Firing Modes: Single-Speed and Ramp-Hold . . . . 5

Temperature Over-Shoot. . . . . . . . . . . . . . . . . . . . . . . . 6

Single-Speed Programming Instructions . . . . . . . . . . . 6

Ramp-Hold Mode. . . . . . . . . . . . . . . . . . . 7

Programming a Cooling Segment. . . . . . . . . . . . . . . . . 7

Ramp-Hold Programming Instructions. . . . . . . . . . . . . 8

Advanced Features . . . . . . . . . . . . . . . . . 8

Skip Segment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Add Hold Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Editing the Target Temperature During Firing . . . . . . . 9

The Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lost Wax Burnout . . . . . . . . . . . . . . . . . . 9

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Burnout Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Display Messages . . . . . . . . . . . . . . . . . 10

Error Messages. . . . . . . . . . . . . . . . . . . 11

bAdP / Bad Programming . . . . . . . . . . . . . . . . . . . . . . 11

EtH / Electronics Too Hot . . . . . . . . . . . . . . . . . . . . . . 11

FAIL / Thermocouple Failure . . . . . . . . . . . . . . . . . . . . 11

FE Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

FtL / Fired Too Long . . . . . . . . . . . . . . . . . . . . . . . . . . 12

HTdE / High Temperature Deviation . . . . . . . . . . . . . . 12

PF 1 / Power Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PF 2 / Power Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PF 3 / Power Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

tC / Thermocouple Failure. . . . . . . . . . . . . . . . . . . . . . 12

tCL / Thermocouple Lag . . . . . . . . . . . . . . . . . . . . . . . 12

tCr / Thermocouple Reversed . . . . . . . . . . . . . . . . . . . 12

©2004, by Paragon Industries, L.P. IM-221/2-06

2 Single-Speed/Ramp-Hold

Thermocouple Offset . . . . . . . . . . . . . . 11

Selecting °F or °C Display . . . . . . . . . . . 11

Trouble Shooter. . . . . . . . . . . . . . . . . . . 13

Controller display is blank. No heat in kiln.. . . . . . . . . 13

Controller display turns on. No heat in kiln. . . . . . . . . 14

Kiln switch box ½ amp fuses keep blowing.. . . . . . . . 15

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Shorthand Instructions. . . . . . . . . . . . . 16

Page 3

Safety

General

The warranty on your Sentry Xpress

controller does not cover damage from

overfiring, regardless of the

circumstances. It is the operator’s

responsibility to make sure the kiln turns

off at the proper time.

When the kiln is not in use, disconnect the

power.

Do not leave the kiln unattended, especially

near the expected shut-off time.

Wear firing safety glasses when looking into the

firing chamber of a hot kiln.

Do not touch hot sides of kiln. Keep unsuper

vised children away.

Install your kiln at least 12 inches from any wall

or combustible surface.

Do not open lidor dooruntil kiln has cooled and

all switches are off.

Fire only in a well-ventilated, covered and protected area away from combustible materials.

Keep cordset away fromhot sides of kiln or furnace.

DANGEROUS VOLTAGE! Do nottouch heating elements with anything. Disconnect before

servicing.

When vacuumingthe kiln, keepthe nozzle away

from the controller. Vacuum cleaners create a

static charge that can damage the controller.

Guidelines

Time and Temperature

Display

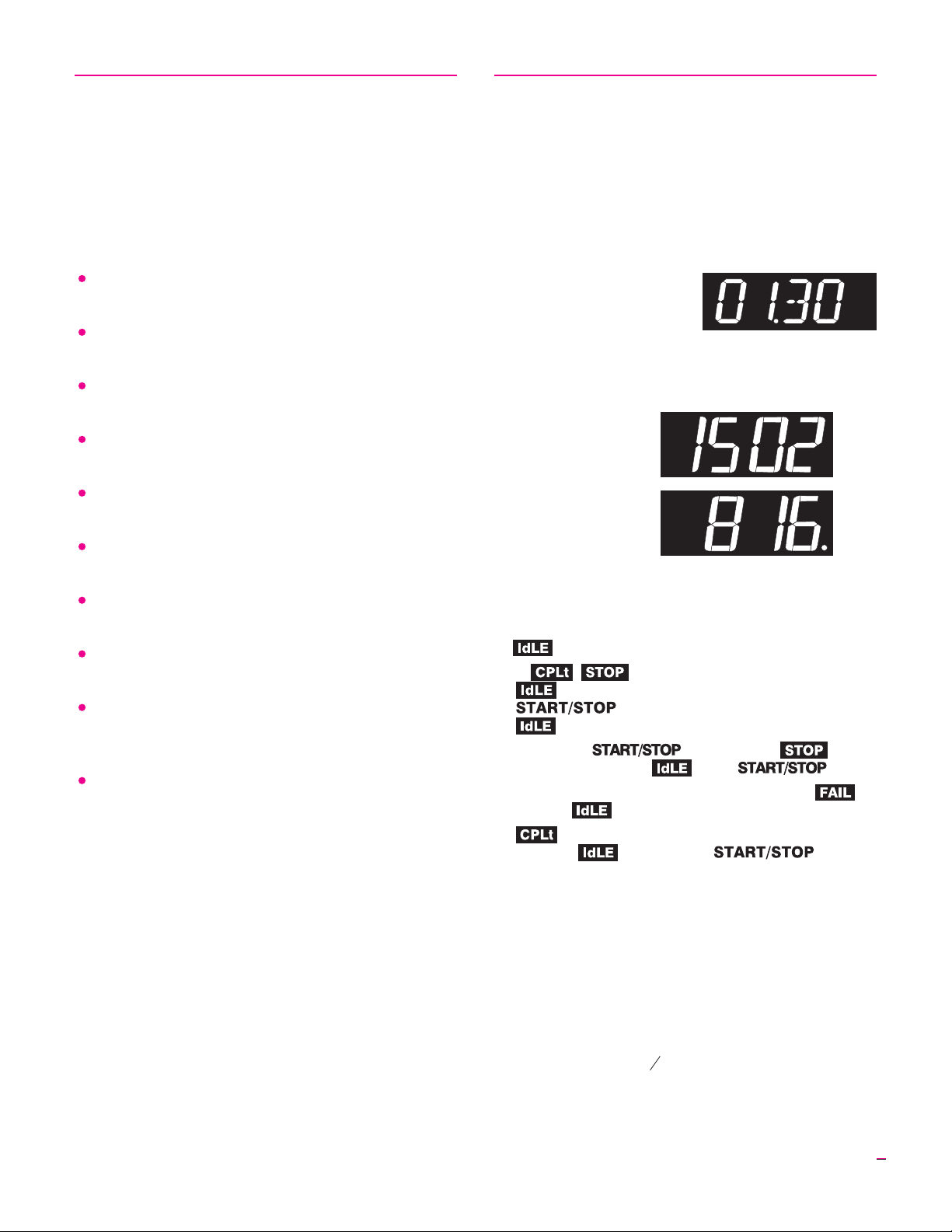

Center Dot: Time

A center dot appears dur

ing time display. It separates

hours from minutes. (Exam

ple: 1 hour, 30 minutes dis

plays as 01.30.) During tem

perature display, the dot

disappears.

Right-Hand Dot: °C

-

When temperature

is displayed in °C, a dot

appears in the lower

right. In °F display, it

disappears. You can

choose between Fahrenheit and Celsius display. See page 13.

Operation Begins from

the IdLE Display

must appear before you can fire the kiln.

I

If , , or other message appears instead of

when the kiln is first turned on, press the

key (the key with the circular arrow).

will appear.

I

If you press during a firing, will ap

pear. To get back to , press again.

I

If the display shows an error message such as in

stead of , see page 11.

I

(firing completed) appears at the end of a firing.

To make appear, press .

-

-

-

The center display dot indicates

-

time instead of temperature.

°F

°C

-

-

Thermocouple Inspection

The small rod protruding into the firing chamber is the

temperature sensor, or thermocouple.

CAUTION: Bumping the thermocouple can push it

out of the firingchamber. Thiscould causean overfire!

Bumping the thermocouple could also cause inaccu

rate readings.

I

A 1/8” diameter thermocouple should extend into the

firing chamber ½” -

I

A ¼”diameter thermocoupleshould extendinto thefir

ing chamber ¾ - 1” or more.

I

Keep shelves, posts and ware 1” - 1 ½” away from the

thermocouple.

5

”.

8

-

-

3

Page 4

ARapidWayto

Scroll Numbers

During programming, hold an arrow key down several

seconds, and numbers will begin to scroll rapidly. Ordi

narily, you would press to raise a number and

to lower it. But sometimes it is faster to press

the opposite key. This is because the numbers scroll below

0000 to the highest number, and vice versa. Examples:

I

To program a 99.59 hour Hold when the display shows

00.00, press the once.

I

To program a FULL rate when the display shows 0000,

press the once.

I

To program a temperature of 200°F when the display

shows 1800°F, press the . That is faster than

pressing the .

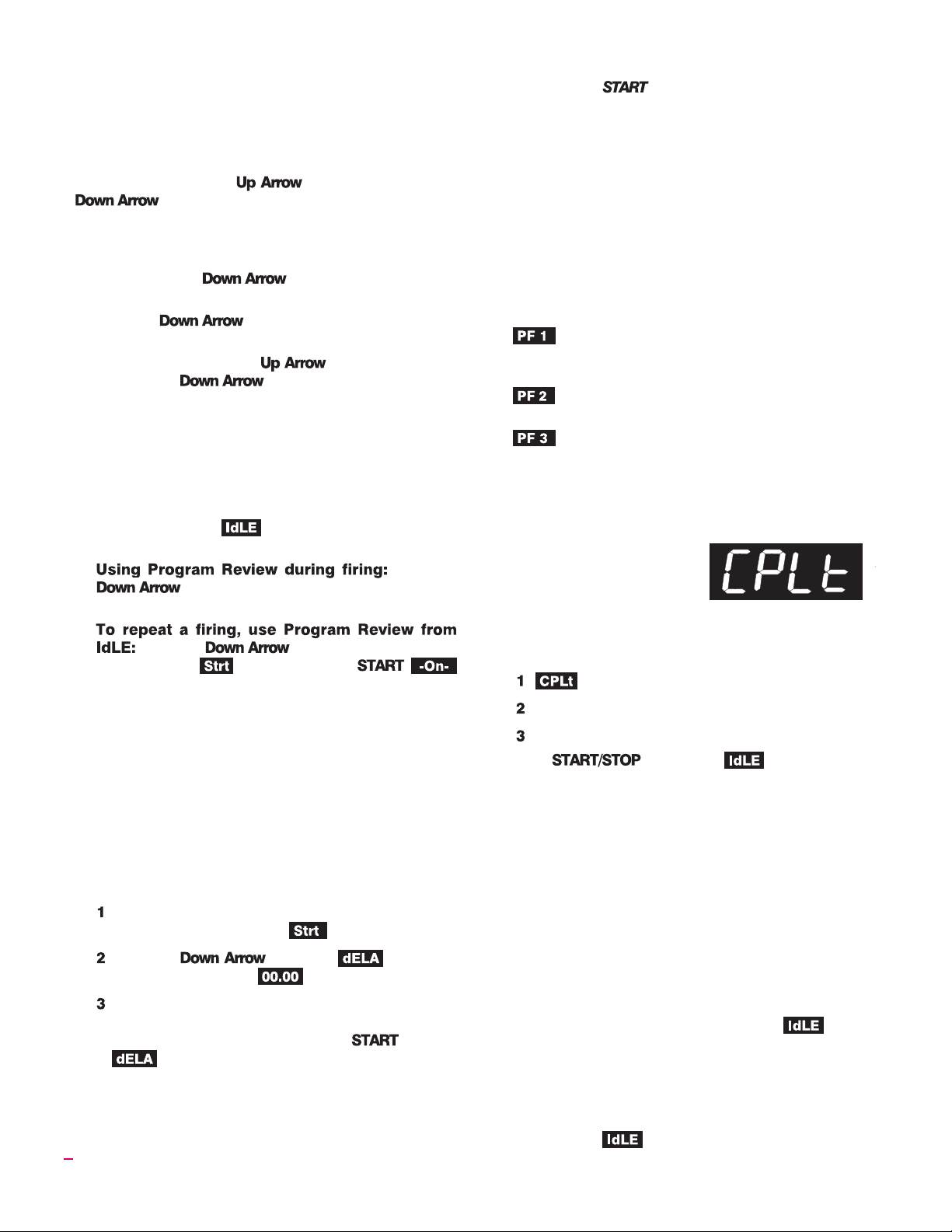

Program Review &

Repeat Firing

Program Review lets you check that the information

programmedinto thecontrolleris correct.ProgramReview

shows the values for the program in active memory. Use

Program Review from to repeatthe lastprogram you

fired.

I

key. The rate, temperature, hold, etc. will

display one after the other. Firing will continue.

I

Press the key. After rate, temperature, hold, etc., will appear. Press .

will appear, and the kiln will begin firing the program

just reviewed.

Press the

Note: Press during delay to end the delay and

begin the firing. The maximum delay is 99 hours and

59 minutes.

-

Power Failures

After a power failure, the controller will continue firing

provided that:

I

The kiln temperature is above 212°F / 100°C when the

power comes back on.

I

The temperature dropped no more than 72°F / 40°C

while the power was off.

Power Failure Messages (see page 12)

The power failed during a cooling segment, and

the kiln cooledpast thetarget temperaturewhile thepower

was off.

The power failed during firing and kiln tempera

turewas below212°F / 100°Cwhen thepower cameback on.

The power failed during firing and temperature

dropped more than 72°F / 40°Cby the time the power came

back on.

CPLt Message: Firing

Completed

When thefiring hassuccessfully completed, the Sentry

Xpress will shut off power to

the elements and sound an

alarmfor 30seconds. Thenthree messageswill cycle oneafter the other:

(complete)

Firing time in hours and minutes

-

Delay

Delay is a count-down timer.The kilnbegins firingwhen

the timerruns outof time.Use Delayto fit a firinginto your

schedule.

CAUTION: For safety,do not leavethe kilnalone dur

ing a delay or a firing. We cannot guarantee your kiln

against overfiring even though the controller is auto

matic.

After you have entereda program and the control

ler is ready to begin firing, will appear.

Press the key once. will ap

pear, alternating with .

Use the arrow keys to enter delay time. (The deci

mal separateshours andminutes. Example:1 hour

and 10 minutes = 01.10.) Then press twice.

will appear, alternating with time left until

the firing begins.

4 Single-Speed/Ramp-Hold

-

-

-

-

-

The current kiln temperature

Press to return to .

Thunder Storms and

Power Surges

Unplug the kiln or disconnect the power when the kiln is

not in use, especially during thunder storms and in areas

with frequent power surges. If the kiln is part way through a

firing when a storm begins, it is probably okay to continue

the firingwith closesupervision. Donot leavethe kilnunat

tended.

Canceling a New Program

If you do not touch the keys for one minute during pro

gramming, the controllerwill go back to the display.

The controller will also discard the program you were en

tering and will retain the previous program in memory.

This is useful if you change your mind during program

ming and decide to keep the previous program. Instead of

completing the newprogram, waita minuteand letthe con

troller return to .

-

-

-

-

-

Page 5

Theory of Operation

The temperature you are firing to is called the target

temperature. After the controller reaches the target tem

perature, it can also hold that temperature.

The controller firesat acontrolled heating rate.The rate

is figured in degreesper hour. If you selecteda rate of100°

per hour, it would take10 hours for the kiln toreach 1000°.

Rate is similar to “miles per hour.”

In summary, the controller does three basic tasks:

1) It fires at a controlled heating rate, or speed, mea-

sured in degrees of temperature change per hour.

2) It fires to a target temperature.

3) It can hold the target temperature.

The controller fires in segments, or stages. A segment is

a given heatingrate to atarget temperature. Shownabove is

a segmentwith arate of625° perhour, a target temperature

of 1250°, and a hold of one hour.

Heating rate is figured in degrees per hour. The recom

mended heating rate for the material you are firing is usu

ally available from your supplier. It also varies depending

on the thickness of the material.

To figure how long a firing segment will take, subtract

the current temperature from the target temperature and

divide the resultant temperature bythe heating rate.In the

diagramabove, thefiring timeis 1250°- 80° (roomtempera

ture) = 1170 ÷625 = 1.87 hours.

The controller can fire up to 8 segments per firing. One

segment is often all that is needed, though.

After the controller has finished firing the last segment,

it will turn off power to the elements.

Note: If youenter a rate of 0000 in segment 1,or if the

target temperature in segment 1 is lower than the cur

rent temperature, will appear in the display.

-

Rate

Each segment must include a rate, which is degrees of

temperature change per hour.

The kiln will fire at full power when the rate is

1799°F/999°C. Full power displays as .

-

Note: To enter full power from , press the

key once.

Hold

Hold is the length of time that you want the kiln to remain at the target temperature. Hold is also called soak or

dwell time. Hold maintains a steady temperature for the

length of time you specify. You can use Hold in both heating-up and cooling-down segments.

When Hold is set to 99.59 hours, the controller will remain at that temperature indefinitely, until you press

. To enter a 99.59 hour Hold, press the

once from 00.00 during programming.

Note: During a Hold, the display flashes between the

Hold temperature and time left in Hold.

Two Firing Modes:

-

-

Single-Speed and Ramp-Hold

To give you greater flexibility, your controller has two

firing modes:

Single-Speed Mode (see next page)

Often times, all you will need is Single-Speed mode,

which has one segment that includes a rate (temperature

change per hour), a target temperature, and (if needed)

hold time.

In Single-Speed mode, you can choose one of five firing

speeds. Then enter the temperature you are firing to.

Ramp-Hold Mode (see page 7)

Ramp-Hold mode offers much greater flexibility than

Single-Speed mode. Use Ramp-Hold to create custom fir

ings with up to 8 segments. The controller can store 4

-

5

Page 6

Ramp-Hold programs inmemory. Programsare numbered

Pro1 - Pro4.

Type of Firing Suggested Firing Mode

Enameling Single-Speed

Silver Clay Single-Speed

Glass Bead Annealing Ramp-Hold

Glass Fusing Ramp-Hold

Glass Slumping Ramp-Hold

Lost Wax Ramp-Hold

Selecting a Firing Mode

From display, press once.

Press the keyseveral times. You will see

the following display messages:

SPd1:

Single-Speed 1 / 200°F/111°C rate per hour

SPd2:

Single-Speed 2 / 500°F/277°C rate per hour

SPd3:

Single-Speed 3 / 1000°F/555°C rate per hour

SPd4:

Single-Speed 4 / 1500°F/833°C rate per hour

SPd5:

Single-Speed 5 / Maximum rate

PrO1:

Ramp-Hold, Program 1

PrO2:

Ramp-Hold, Program 2

PrO3:

Ramp-Hold, Program 3

PrO4:

Ramp-Hold, Program 4

Note: Your controllermay have moreRamp-Hold pro

grams than the 4 shown above.

To select a firing mode, see the boxed programming in

structions on this page and page 8. Or to get back to

, press several times until ap

pears.

-

Temperature Over-Shoot

When akiln is heatedtoo fast, it mayover-shoot the tar

get temperature,especially insmall kilns at lower tempera

tures. To avoidthis, add an extra segment in a Ramp-Hold

program to slow the firing. (See the next section.) The seg

ment with the slower rateshould begin approximately 40° 60° below the target temperature.

Single-Speed Programming

Instructions

Note: Single-Speed firingis allyou will everneed if

you are only going to a temperature and holding.

From , press .

Use the key (not the )to

select a firing rate (temperature rise perhour)

from 1 through 5. (Ignore - .)

/ (200°F or 111°C)

/ (500°F or 277°C)

/ (1000°F or 555°C)

/ (1500°F or 833°C)

/ (Full Power)

Then press .

or and the target temperature

from the last firing will appear. Use the arrow

keys to change the target temperature. Then

press .

and the hold time from the last firing

will appear (e.g. 1 hour 10 minutes = 01.10).

Use the arrow keys to change the hold time.

Then press . (No hold = 00.00)

will appear. Press to begin firing.

will appear, the Run indicator light will

begin blinking, and the kiln will begin firing.

To stop a firing before completion, press

. willappear, alternatingwith total

firing time and kiln temperature.

Note: Do not be concerned if your kiln makes a

clicking sound during firing. Kilns use relays to

power the elements. The relays click each time

-

-

-

-

-

their electrical contacts come together.

Note: The firing speed you select (see step 2

above) is a pre-programmed speed. The kiln’s ac

tual firing speed may be less, dependingon thekiln

model, available voltage, and density of the load

you are firing.

When thekiln fires to completion,the controllerwill

beep for 30 seconds. The display will show the follow

ing:

I

Firing time

I

Present temperature

I

To return to , press .

= Fired to completion

-

-

6 Single-Speed/Ramp-Hold

Page 7

Ramp-Hold Mode

You can make your own firing programs and store them

in the controller’s memory. A firing program tells the kiln

how fastto fire,and towhat temperature.The simplestpro

gram is one segment. You can use up to 8 segments with

your controller in Ramp-Hold mode.

Each segment includes a firing rate and firing tempera

ture. You canalso soak,or hold,the temperaturefora spec

ified period.

The Parts of a Segment

I

Rate (temperature change in degrees per hour)

I

Target temperature

I

Hold at the target temperature (not always used)

The controllercan retainfour programsin memoryeven

when power is turned off. Programs are numbered Pro1 Pro4.

The first message toappear afteryou plugin yourSentry

Xpress is . Press . Then use the key

to scroll through these messages:

.

To use Ramp-Hold mode for the first time, select

. Youdo that by pressing the key after

appears. Then follow the boxed instructions on page 8 to

enter temperature, heating rate, etc.

is Program 1. When you fire the kiln again, you

can repeat Program 1 by selecting . (See page 4.)

When you are ready to fire a different program, select

, which is Program2. Thenenter temperatures,heat

ing rates, etc. Select Program 3 and 4 the same way.

A program canhave up to8 segments,butyou don’thave

to use all 8 segments. Use only the number needed per fir

ing. Oftenone segmentis allyou willneed. Zeroout theun

used segments. The instructions on page 8 explain how to

do that.

To over-write a program, select it and enter new rates

andtemperatures. Thisautomaticallyover-writes theprevi

ous program.Write downyour programsin anotebook and

record firing results for all firings.

Programming a

Cooling Segment

For controlled cooling, program a segment to a lower

target temperature than that of the preceding segment.

Example: You fire at a rate of 500°F per hour to 1450°F

with your first segment. You want the kiln to cool at a rate

of 100°F per hour down to 700°F. Here is how you would

program the two segments:

Segment °F/°C °F/°C Hold

1 500/277 1450/788 00.00

2 100/55 700/371 00.00

The first segment is the heating segment. The second

one isthe cooling segment. The controller does not use mi

nus numbersfor cooling.Just entera lowertarget tempera

ture than that of the previous segment.

-

-

-

If you prop the lid or door for a fast cooling, program a

fast coolingrate forthat segment.If youlower thetempera

ture quicklyby propping the lid but programa slow cooling

rate, the controller will just raise the temperature again.

Example: Some glassartists flash-coolthe glass justafter

it fuses. They open the door a few inches to remove heat,

then close it again. This takes the glass down rapidly

through the devitrification range.To program a flash-cool,

use maximum rate. This shuts off the heating elementsdur

ing that segment, allowing the kiln to cool rapidly.

Note: During fastcooling, do not open thedoor all the

way. Do not force-cool the kiln with a fan.

Note: Youmay get anFTL error message(page 12) if

you program a cool-down target temperature that is

close to room temperature. This is because the kiln

cools more slowly as it approaches room temperature,

causing the error code.

Rate Temp.

A Ramp-Hold

Practice Program

To practiceusing the controller, we will enter a program

that includes three segments. The last segment is a cooling

segment.

-

-

-

-

Using the programming instructions on the next page,

enter this firing schedule. Then use Program Review (page

4) to check for accuracy.

Make asimple chart like the one above whenplanning a fir

ing program.

PrO1

rA1 = 250

°F1=750

HLd 1 = 00.00

rA2 = 900

°F 2 = 1425

HLd 2 = 00.30

rA3 = 150

°F3=750

HLd 3 = 00.00

rA4 = 0000 (zeroes cancel segments 4-8)

-

-

-

-

-

7

Page 8

Ramp-Hold Programming

Instructions

Advanced

Note: You have up to 8 segments available in

Ramp-Hold. If you don’t need all 8, zero out the

unused segments. (See step 6 below.)

From , press .

Press the key (not the ).

and are

Ramp-Hold programs. When the one you

want appears, press . (Ignore -

.)

will appear. Enter firing rate (tempera

ture change per hour) for segment 1. (1° =

slowest rate. 1799°F/999°C = full power.)

Then press .

or andthe targettemperature from

the last firing will appear. Use the arrow keys

tochange thetemperature.Then press .

and the hold time from the last firing

will appear (e.g. 1 hour 10 minutes = 01.10).

Use the arrow keys to change the hold time.

Then press . (No hold = 00.00)

Continue entering values for the segments

needed. When appears for thenext segment that you don’t need, select . Then

press . This will zero out the remaining

segments. (Example: You need only 1 segment. When appears, enter .)

will appear. Press to begin firing.

will appear and the Run indicator light

will begin blinking. The kiln is now firing.

To stop a firing before completion, press

. willappear, alternatingwith total

firing time and kiln temperature.

Features

Skip Segmentworks only inRamp-Hold programs. Add

Hold Time, Temperature Edit, and Alarm work in both

Single-Speed and Ramp-Hold firings.

Skip Segment

Skip Segment jumps the firing from the current segment

to the next one.

-

During a Ramp-Hold firing, press the .

will appear.

Press . The current segment ramp or hold

number will appear.

Press again. (If you change your mind and

don’t want toskip thatsegment, don’tpress

after appears. The firingwill continuein the

same segmentand the temperaturewill appear af

ter one minute.)

Skip Segment skipsto the rampof thenext segmentfrom

either a ramp or hold of the current segment. (Skip Segment does nothing during the final segment. To end the final segment, press .)

Skip Segment Example

You have programmed a target temperature of 1425°F for glass fusing,

followed by a segment for controlledcooling. Watching the

glass through the peephole, you notice that the glass edges

have rounded nicely at 1315°. Use Skip Segment to end the

firing segment and to begin the one for slow cooling.

Note: Make a note of the temperature at which the

glass fused. Program that temperature for the nextfir

ing of that type of glass.

-

-

Note: Do not be concerned if your kiln makes a

clicking sound during firing. Kilns use relays to

power the elements. The relays click each time

their electrical contacts come together.

Note: The kiln’sactual firingrate maybeless than

the rate you programmed, depending on the kiln

model, available voltage, and density of the load

you are firing.

When the kiln fires to completion, it will beep for30

seconds. The display will show the following:

I

Firing time

I

Present temperature

I

To return to , press .

= Fired to completion

8 Single-Speed/Ramp-Hold

Add Hold Time

Add Hold Time adds 5 minutes to a hold. It is designed

for ceramists who watch witness cones and for glass artists

who watch the glass near the end of firing.

During a firing, pressthe repeatedly un

til appears.

Press . The hold time for the current seg

ment will appear.

Press the .Each timeyou pressthe

, the hold time will increase by 5 minutes.

Press . The normaltemperaturewill appear.

Note: Add HoldTime willadd 5 minutesto ahold even

if no hold had been programmed.

-

-

Page 9

Editing the Target

Temperature

While the kiln is firing, you can change the target tem

perature of the current segment. (Ramp-Hold: You can

edit onlythe segment that is firing.So if thefirst segment is

the currentone, you can edit only the firstsegment. To edit

other segments, waituntil thefiring hasprogressed tothose

segments.)

Even if the current segment has already started its hold

time, you can still edit the segment's target temperature.

The controller will go back out of hold and fire to the new

target temperature at the original rate. (You cannot edit

the rate, however.)

During a firing, press the repeatedly until

appears.

Lost Wax

-

Burnout

CAUTION: Only kilns with vent holes are designed

for lost waxburnout. However,you maybe able touse a

kiln without the vent hole provided that you open the

door ½” during venting.

CAUTION: Always use a wax tray.

Note: These instructions apply to injection wax that

melts at 200°F, not pattern waxes and plastics that

melt at higher temperatures. If smoke appears during

wax elimination, turn off the kiln. Smoking wax means

the kiln fired hotter than 300° / 148°C.

Press . The target temperature for the cur

rent segment will appear.

Use the arrow keys to change the target tempera

ture.

Press . The normal kiln temperature will ap

pear, and the kiln will begin firing to the new target

temperature.

-

-

-

The Alarm

While the kiln is firing, you can set the alarm, which

sounds when the kiln reaches the alarm temperature. Use

the alarmas areminder to look at the glass during fusingor

slumping, to look at witness cones, to close the lid from

vented position, etc.

You can enter only one alarm temperature at a time.

However, after the alarm beeps, you can set the alarm for

another temperature, asmanytimes asyou want, duringthe

firing. Enteringan alarm temperatureautomatically erases

any previous alarm temperature.

Note: The alarm temperaturethat youset duringa fir

ing must be higher than the current display tempera

ture. The alarm is designed only for higher tempera

tures and not for cooling temperatures.

During a firing, press the repeatedly until

appears.

Press . The current alarm temperature will

appear.

Use the arrow keys to change the alarm tempera

ture.

Press . The normal kiln temperature will ap

pear.

To silence the alarm when it sounds, press any key.

Note: If youdo notwant touse the alarm,set the alarm

temperature to 32°F / 0°C. This setting will turn off the

alarm feature.

-

-

-

-

-

Overview

Lost waxcasting is theprocess of carving a shape in wax,

making a mold, and then casting that shape in metal. After

the wax has been carved, a mold is made of the wax shape.

The mold is a negative image of the wax. The wax is later

melted out of the mold through hollow channels called

sprues.

Lost wax burnout is the process of preparing a casting

mold for the melted metal that will be poured into it. The

steps in lost wax burnout:

Melt the wax from the mold.

Remove wax from the kiln before raising the tem-

perature higher than 300°F/148°C.

Harden the mold at high temperature.

Maintain the mold at the casting temperature rec

ommended forthe type of metal that willbe poured

into the mold.

CAUTION: Prevent wax or carbon from contacting

the kiln’s wallsand elements.Carbon build-upinside a

kiln ruinsthe interior. Carbon conducts electricity and

causes elements to short circuit. Damage to elements

from contact with foreign materials is not covered by

warranty.

-

A Sample Program

See instructions on page 8 to enter this program:

Rate Temp.

Segment °F/°C °F/°C Hold

1 500/277 300/148 01.00

2 500/277 1350/732 01.00

3 450/250 800/426 02.00

Segment 1 heats the wax to 300°F /148°C and holds it for

one hour, allowing it to drip from the mold.

Segment 2 hardens the mold.

9

Page 10

Segment 3 lowers temperature to 800°F/426°C, the typi

cal casting temperature for silver. (Most types of gold cast

at 900°F / 482°C.)

Note: Casting temperature depends on the size of the

mold. The temperatures above are only a guide. See

your jewelry supply dealer for temperature

recommendations.

Burnout Instructions

Place a metaltray insidethe kilnon three½” posts.

Place the mold on a wire mesh screenon topof the

tray. The mold’s sprue hole should be down. The

tray will catch melting wax as it drips from the

sprue hole.

Keep the kiln’s vent hole(s), if any, open during

wax elimination. If the kiln has no vent hole, leave

the dooropen ½”. This allows fumes to escape the

kiln. Heat the kiln to 300°F / 148°C and hold it at

that temperature for at least one hour.

-

Display Messages

(Page 9) Ready for you to enter an alarm

temperature. When the kiln reaches that tempera

ture, the alarm will sound. ( also flashes

when the alarm sounds.)

(page 9) Ready for you to edit the target

temperature of the current Ramp-Hold segment

during firing. Example: You are fusing glass to a

temperature of 1450°F. At 1445°F, you look at the

glass through a peephole and realize that the glass

will need at least another 50° to fuse fully. Change

the target temperature to 1500° without having to

turn off the kiln to reprogram it.

-

CAUTION: Do NOT heat the wax above 300°F /

148°C. Hold at 300°F / 148°C for at least one hour.

During this hour, the wax will melt from the mold and

drip into the tray. If the kiln gets hotter than 300°F /

148°C, the wax may smoke and deposit carbon inside

your kiln, causing expensive damage.

After one hour at 300°F / 148°C,open the kiln. Re-

move the moldand wax tray.Pour thewax fromthe

tray and leave the tray out of the kiln until your

next wax elimination. (Do not leave the trayin the

kiln!)

Heat the mold to the temperature recommended

by your jewelers’ supply house where you pur

chased the mold material. This is usually around

1350°F / 732°C.

Lower thetemperature to the casting temperature

of the metal. Hold at that temperature until you

are ready to begin casting. Remove the mold with

tongs. Wear protective gloves and safety glasses.

-

Saving a Carbon-Damaged Kiln

If you follow the above directions, your kiln should be

safe from wax damage. In some cases, a small amount of

carbon may form on the walls over a period of time. This is

due to the burning of wax residue that was leftin the mold.

For this reasonwe recommendthat youperiodically fire the

kiln to 1500°F / 815°C as follows:

Open the vent cover(s) or leave the door ajar ½”.

Fired to completion.

(page 4) Delay is a count-down timer that

starts the firing when the time runs out.

or (and temperature) (pages 6, 8)

The controller is ready for you to enter the target

temperature (the temperature that the kiln will fire

to). Each segment in Ramp-Holdmode has a target

temperature.

Full power firing rate. At this setting the kiln

will fire at its fastest rate. There are two ways to select full power:

1) Select in Single-Speed mode.

2) Select a rate of 1799°F/999°C at the prompt

in Ramp-Hold mode. A fast way to do this is to press

the key once from . will ap

pear.

(pages 6, 8) Hold time of a segment,

shown in hours and minutes. (Example: 2 hours

and 15 minutes = 02.15)

(Page 8) Add HoldTime: During a firing, you

can extend the hold time of a segment without hav

ing tofirst stopthe firing to reprogramthe controller.

-

-

Fire the kiln empty to 1500°F / 815°C at a rate of

300°F / 166°C with a one hour hold (01.00).

10 Single-Speed/Ramp-Hold

(page 3) The controller is ready for you to en

ter a program or to begin a repeat firing.

Firing has begun. A moment after ap

pears, you will hear the relay(s) clicking.

-

-

Page 11

(pages 7, 8) These

are Ramp-Hold programs stored in memory.

etc. (Rate) (page 8) This appears in

Ramp-Hold programming for each segment. 1, 2,

etc. are segment numbers. Enter the rate of temper

ature change for that segment. Rate is figured in de

grees of temperature change per hour. Example:

A temperature rise of 100° in two hours = 50° rate.

A temperaturedrop of200° in onehour =200° rate.

(page 6)

These are preset firing rates, or speeds, in Sin

gle-Speed mode.

(Skip Step) (page 8) This message appears

when you press the key during a

Ramp-Hold firing. You can skip out of a segment

into the next segment.

The firing was stopped by pressing

.

The "Ready to Start" message appears after

programming a firing. Press to begin firing.

Thermocouple Offset (press the ) and Delay (press the ) are accessed from the

message.

Error Messages

bAdP / Bad Programming

-

-

-

The kiln will not fire because a) the Ramp-Hold pro

gram just entered hasa rate of 0000 in segment 1, or b) the

target temperature in Single-Speed or segment 1 of

Ramp-Hold is lower than the current temperature.

EtH / Electronics Too Hot

The circuit board temperature is above 176°F / 80°C.

Press any key to return to .

To lower the board temperature, use a fan to blow air

across the kiln switch box into the louvers. (But do not blow

air into the kiln’s peepholes.) If you have more than one

kiln in the room, place them farther apart. Never allow the

firing room temperature to exceed 110°F / 43°C. (Measure

room temperature three feet away from the kiln.)

FAIL / Thermocouple Failure

The thermocouple, or temperature sensor, failed during

firing. Causes:

I

Defective thermocouple or disconnected/loose wires

I

Defective controller

I

Electrical noise

-

Thermocouple Offset (Page 12). Adjust the

controller to fire hotter or cooler.

Thermocouple Paperclip Test

Check the thermocouple wire connections. (See your

kiln instruction manual.) If connections are tight, perform

this test:

UNPLUG the kiln or disconnect the power. Re

move thecontroller. Removethe two thermocouple

wires from the back of the controller.

Cut a thin paperclip in half. Insert a U-shaped

paperclip piece, or other piece of thin wire, where

you removed the thermocouple wires.

Plug in the kiln. If the controller displays room tem

perature, replace the thermocouple. If it shows

, return the controller for repair or

replacement.

-

-

11

Page 12

FE Error Messages

FE 1 Memory Read/Write Failure

FE 2 RAM Failure

FE 3 OEM Factory Data Corruption

FE 4 Thermocouple “Noise”

FE 5 Software Error

To return to from an FE code

Trypressing anykey. If thatdoesn’t work, turnthe power

off for 10 seconds. Call the factory if the error message re

mains when you turn the power back on.

If youget an message, checkthe wireconnections

going from the back of the controller to the thermocouple.

A loose connection can cause the message.

FtL / Fired Too Long

This messageappears when both of the following condi

tions are met:

I

The temperature rise or fall is less than 27°F / 15°C per

hour.

I

The firing is 2 hours longer than programmed.

Programminga coolingsegmenttarget temperaturethat

is belowor even close to room temperaturecan also trigger

the message.

See “Controller display turns on. No heat in kiln,” page

14.

PF 3 / Power Failure

The power failedduring firing andtemperature dropped

more than72°F / 40°Cby the time the power came backon.

The kiln will not resume firing. To return to the dis

play, press any key.

tC / Thermocouple Failure

The thermocouple failed during the display. See

the "paperclip" test under "FAIL," page 11.

-

tCL / Thermocouple Lag

The heating rateis slower than9°F /5°C perhourand the

controller temperature is more than 100°F / 56°C away

from the actual kiln temperature. To return to the

display, press any key. Causes:

I

On kilns that use a portable controller, the thermocou

ple has fallen out of the firing chamber.

-

I

A bare spoton thethermocouple lead wireshas touched

a groundedobject inside the kiln switch box causing the

thermocouple to short out.

Check for wornor burnedout elements,defectiverelays,

low voltage and defective thermocouple.

tCr / Thermocouple Reversed

Thermocouple lead wires are reversed. Check that the

thermocouple lead wires are connected to the correct terminals. See your kiln’s wiring diagram.

-

-

HtdE / High Temperature

Deviation

Causes:

I

During a heating-upramp or a hold, the temperature is

100°F / 56°C above the programmed temperature.

I

During a cooling-down segment, the temperature is

100°F / 56°C higherthan the segment’s starting temper

ature.

I

A fastrate caused thecontroller to overshootthe target

temperature.

Also, check for a stuck relay.

PF 1 / Power Failure

The power failed during acooling segment, and the kiln

cooled pastthe targettemperature whilethe powerwas off.

The kiln will not resume firing. To return to the dis

play, press any key.

PF 2 / Power Failure

The powerfailed duringfiring and kiln temperature was

below 212°F / 100°C when the power came back on. The

kiln will not resume firing. To return to the display,

press any key.

Thermocouple Offset

-

-

You can adjust the controller to fire up to 20°F / 11°C

hotter or cooler than the zero factory setting.

From , press the key. Afterrate,

temperature, hold, etc., will appear.

With shown in the display, press the

key.

will appear. Press thearrow keys to change

the controller temperature.

Pressthe keyto returntothe display.

To fire the controller, press . will ap

pear. Or toreturn to , press two more

times.

-

12 Single-Speed/Ramp-Hold

Page 13

Selecting °F or

Trouble Shooter

°C Display

The controller can display temperature in either °F or

°C. If your controller showsa small display dot in the lower

right cornerof thedisplay, thetemperature shown is °C. No

dot means °F. To change temperature display:

UNPLUG kiln or disconnect power.

Remove the four screws that hold the controller to

the front ofthe kiln.Carefully remove thecontroller

from the kiln. Leave the wires attached to the con

troller.

Look atthe backof thecontroller. You willfind aset

of connector pins near the bottom labeled “C/F.”

When a jumperis placedon theC/F pins,the display

reads°F. Whenthejumper isremoved, display reads

°C. Remove or insert the jumper as desired. (You

can purchase the jumper from a computer supply

store if necessary.)

-

Problem: Controller display is

blank. No heat in kiln.

I

Is the kiln connected to the power?

I

Has the circuit breaker tripped or fuse blown?

I

Is power reaching the wall receptacle?

Test with a voltmeter or a test light if you are not sure.

I

Has the kiln switch box

½ amp fuse blown?

The kiln’s ½ amp fuse is

located in the kiln switch

box. Remove by pressing

the fuse holder and turning

counter-clockwise half a

turn. Check the fuse by

placing the probes of an

ohmmeter on the ends

of the fuse. If the ohm

meter reads less than

an ohm (digital meter)

or reads 0 ohms (analog meter), the fuse is

okay. If the reading is

OPEN (digital meter)

or infinity/no needle

movement (analogmeter), the fuse is bad.

Replacement fuse:

AGC 1/2 A 250V AC

I

Is the controller receiving power? Test the power IN

PUT connections on the back of the controller with a

voltmeter.

Controller Power Input Test

Unplug the kiln. Remove the 4 screws holding the con

troller faceplate to the switch box. Lift faceplateout of box

and let theboard hangon thebox withthe backof theboard

facing you. Plug the kiln back in. Touch voltmeter probes

-

-

-

The C/F jumper terminal is on the back of the controller, circled above.

Install thecontroller beingcareful not to jar compo

nents on the back of the controller against the kiln

case.

-

Touch the voltmeter probes to the white and orange wires to test voltage

going to the controller. The voltmeter must be in AC mode.

13

Page 14

(in AC mode) to both INPUT connections (the white and

orange wires). (See photo on previous page.)

CAUTION: Do not let the back of the board touch a

grounded object. Make sure the voltmeter is in the AC

modewhen placingtheprobes onINPUTconnections.

Problem: Controller display

turns on. No heat in kiln.

I

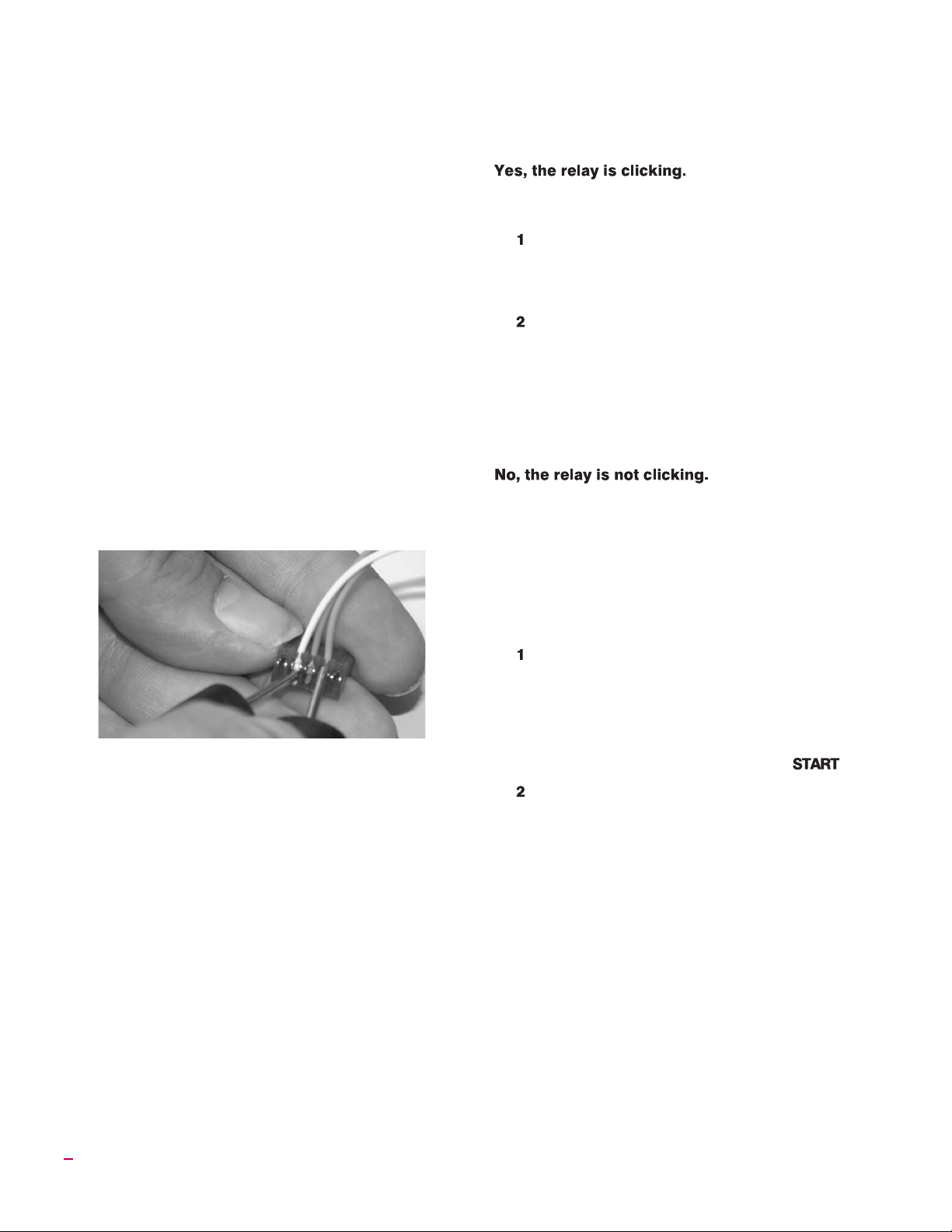

Is the relay making its normal clicking sound?

Controller Power Input Test Result: No voltage

UNPLUG kiln. Check the switch box for disconnected

wires betweenthe cord, transformer, and controller. If wir

ing is okay, replace the transformer.

Controller Power Input Test Result: 20 - 24 volts AC

Correct current is reaching the board from the trans

former. Butsince the boardis not lightingup, it isprobably

defective.Return thecontrollerfor repairor replacement.

Controller Power Input Test Result: less than 20 volts

Did you recently replacethe transformer? It maybe the

wrong voltage.The voltageis below20, whichis notenough

power for the controller. To find out the cause of low volt

age, continue below:

Controller Input Test #2

The back of the board is still facing you and the kiln is

pluggedin. RemovetheINPUT plug,which is thewhite, or

ange, and bluewires, fromthe backof the controller.Touch

a voltmeter probe to the white wire and the other probe to

the orange wire.

Input Test #2 with disconnected plug: Touch the voltmeter

probes to the white and orange wires to test voltage going to

the controller. The voltmeter must be in AC mode.

Input Test #2 Result: Less than 20 Volts AC

There are two possible reasons: 1) Low voltage at the

wall receptacle;2) defective transformer. Ifwall receptacle

voltage is correct, replace the transformer.

Input Test #2 Result: 20 - 24 Volts AC

The transformer is sending correct voltage to the con

troller. Yet when the INPUT plug was connected to the

controller, voltage wasless than20. This means thecontrol

ler isdraining the voltage and may bedefective. Returnthe

controller for repair or replacement.

Test the elements with an ohmmeter:

Element Resistance Test

-

-

-

-

-

-

UNPLUG kiln/disconnect the power. Open the

kiln’s switch box. Make sure the wires connecting

the relay to the elements are secure. If connec

tions are okay, continue to step 2:

Touch theohmmeter leadsto the twoelement con

nectors of each element. A no-needle-movement

reading on an analog meter, or OPEN on a digital

meter, indicates a broken element.

If the elements check out okay, replace the relay.

Note: To replace relay, see your kiln’s instruction and

service manual.

We know thecontroller isreceiving voltage,because the

display is lit. But the voltage from the transformer may be

too lowto powerthe relays.Perform the“Controller Power

Input Test,” page 13. If your controller passes the Input

Test, perform the “Controller Power Output Test”:

Controller Power Output Test

Is the controllersending voltagetothe relay?Test OUT-

PUT with a voltmeter:

UNPLUG thekiln/disconnect the power. Remove

the 4screws holdingthe controller faceplate to the

switch box. Lift faceplate out of box and let the

controller hang on the outside of the box with the

back of the board facing you. Then plug the kiln

back in.Program thecontroller tofire to 1000°F at

FULL rate in Ramp-Hold mode. Press .

Put the voltmeter in DC mode. (It must be in DC

mode when testing OUTPUT voltage.) Touch

probes to the red wire and black wire connections.

Measure voltage when the relay clicks on.

Output Test Result: No voltage at red and black wires

The controller is not sending powerto the relay.Return

the controller for repair or replacement.

Output Test Result: 10 - 14 v. at red and black wires

The controlleris sendingcorrect powerto therelay. Un

plug kiln/disconnect power. Remove the kiln switch box.

Look for disconnected wires between the controller, relay

and elements. Check the wiring diagram to be sure wires

are connected tothe correctterminals.Be sureconnections

are tight. If the wiring is okay, replace the relay.

-

-

-

14 Single-Speed/Ramp-Hold

Note: To replace relay, see your kiln’s instruction and

service manual.

Page 15

Problem: Kiln switch box ½

amp fuses keep blowing.

I

What size fuse are you using? Correct fuse:

AGC ½ A 250V AC

If the fuseis the correctsize, perform thefollowingtest:

Kiln Switch Box ½ Amp Fuse Power Test

UNPLUG the kiln/disconnect the power. Remove

the 4 screws holding the controller board faceplate

tothe switchbox. Lift faceplateoutof boxandlet the

board hang on the outside of the box with the back

of the board facingyou. Disconnect both wire plugs

from the back of the controller. Then plug the kiln

back in. Apply power to kiln. If the ½ amp fuse

blows, replacethe transformer. (If the fusedoes not

blow,the problemisa boardorrelay. Gotostep 2.)

Connect the INPUT plug (orange, blue, and white

wires) to the board again. Leave off the OUTPUT

wire plug (the one with the red and black wires).

Program the controller to fire to 1000°F at FULL

rate in Ramp-Hold mode. Press . If the fuse

blows, replaceor servicethe board. (If the fusedoes

not blow,the problemis causedby a short in thecoil

of a relay. Go to step 3.)

Index

Add Hold Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

bAdP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

calibrating the controller . . . . . . . . . . . . . . . . . . . . . . . . 12

casting temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

clicking sound . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6, 8, 14

cooling segment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CPLt (complete) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Delay timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

display dot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3, 13

editing target temperature . . . . . . . . . . . . . . . . . . . . . . . . 9

element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

EtH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

FAIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

FE error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

figuring firing time of a segment . . . . . . . . . . . . . . . . . . . 5

FtL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

fuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13, 15

hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5, 6

HtdE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

lost wax burnout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

PF 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PF 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PF 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

power failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4, 12

power surges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Program Review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Ramp-Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

repeating a firing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

scrolling numbers rapidly. . . . . . . . . . . . . . . . . . . . . . . . . 4

Single Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Skip Segment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

tC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

tCL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

tCOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

tCr . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

temperature display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

temperature over-shoot . . . . . . . . . . . . . . . . . . . . . . . . . . 6

temperature, °F and °C. . . . . . . . . . . . . . . . . . . . . . . . 3, 13

thermocouple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3, 11

thunder storms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

time display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

UNPLUG kiln/disconnect power. Reconnect the

OUTPUT wire plug. Reinstall the board in the

switch box. Replace the relay.

15

Page 16

Shorthand Instructions

These instructions may be confusing until you have read more detailed instructions on Single-Speed, page 6, or

Ramp-Hold,page 8.Read thesafetyguidelines, page3. Afterpressing thekeys inleft column,the centermessagewill appear.

Single-Speed

Keys to Press Display

thru

(Not Down Arrow) Select rate (Sample rate)

or

Enter temperature (Sample temperature)

Enter hold time (Or hold time)

The kiln is now firing.

Ramp-Hold

Keys to Press Display

thru

(Not Down Arrow) Select Program #1, 2, 3, or 4

Enter Segment 1 rate (Sample rate)

or

Enter Temperature (Sample temperature)

Enter Hold Time (Or hold time)

First segment not needed: enter a rate of 0000.

The kiln is now firing.

16 Single-Speed/Ramp-Hold

Loading...

Loading...