Page 1

MODEL 5000

S E N T R Y

GAS MONITORING SYSTEM

Version 6

APPLICABILITY & EFFECTIVITY

Effective for all Sentry systems manufactured after September 1, 1995.

Instruction Manual Part Number T12001-A1

Page 2

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

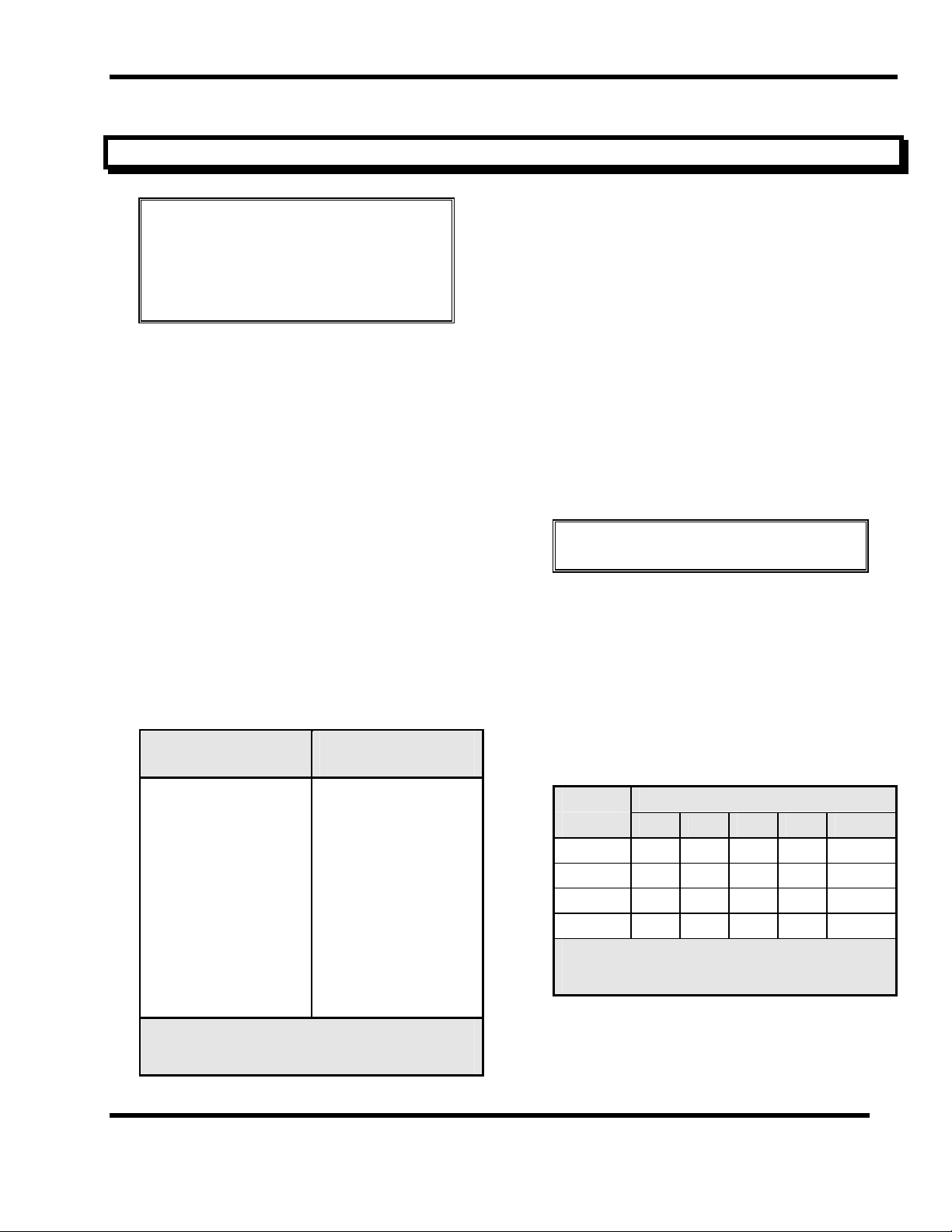

FMRC APPROVAL

ONLY THE FOLLOWING ITEMS, FUNCTIONS AND OPTIONS ARE FMRC* APPROVED

Sentry Model 5000 Gas Monitoring System

Controllers

Model 5000-02 Two Channel Controller

Model 5000-04 Four Channel Controller

Model 5000-08 Eight Channel Controller

Controller Options:

Model 5380-00

Rack Mount Configuration

Sensor Module

Model 5100-02 Combustible Gas Sensor Module

Model 5100-05 Hydrogen Sulfide Sensor Module - EC Cell

Calibration Equipment

Model 1200-26 Calibration Gas Delivery System

Model 1290-02 Combustible Gas Cylinder

Model 5358-00 Calibration Head, Magnetic

Model 5358-01 Calibration Head, Standard

Model 5360-00 Calibration Gas Delivery Fitting

Notes:

1) FMRC Approval applies only to conventional (one cable run per sensor module) or

multiplexed (multiple sensor modules per cable) installations. Apparatus must be

installed in accordance with National Electrical Code.

2) FMRC Approval of the RS232C Data Output option applies only if used as a printer

port and the apparatus connected to the controller does not use or generate greater

than 250 Vrms.

Model 5383-00

Model 5387-00

Model 5392-00

NEMA-4X Configuration

Printer Output Software

Individual Alarm Relays

3) FMRC Approval for Hydrogen Sulfide Sensor Module applies to Model 5100-05

electrochemical cell only. Model 5100-01 solid state sensor is not approved.

4) FMRC Approval allows the presence of MODBUS firmware in the Sentry controller

but does not cover the operation of the MODBUS firmware itself.

*FMRC: Factory Mutual Research Corporation

Page 3

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

TABLE OF CONTENTS

1. PRODUCT DESCRIPTION.............................................................................................................................................1

1.1 GENERAL.......................................................................................................................................................................1

1.2 CONTROLLER...............................................................................................................................................................1

1.2.1 ENHANCEMENT PACKAGE ...............................................................................................................................1

1.3 SENSOR MODULES......................................................................................................................................................1

1.4 INTERCONNECT WIRING...........................................................................................................................................2

1.5 DATA TRANSMISSION................................................................................................................................................2

1.6 POWER REQUIREMENTS............................................................................................................................................2

2. CAUTIONS & WARNINGS...........................................................................................................................................15

2.1 INTRODUCTION.........................................................................................................................................................15

2.2 CONTROLLER.............................................................................................................................................................15

2.3 WIRING ........................................................................................................................................................................15

2.4 SENSOR MODULES - GENERAL..............................................................................................................................15

2.4.1 COMBUSTIBLE SENSOR MODULES...............................................................................................................15

3. INSTALLATION.............................................................................................................................................................17

3.1 CONTROLLER LOCATION........................................................................................................................................17

3.2 SENSOR MODULE LOCATIONS..............................................................................................................................17

3.3 WIRING ........................................................................................................................................................................17

3.4 SENSOR MODULE INSTALLATION ........................................................................................................................18

3.5 CONTROLLER INSTALLATION ...............................................................................................................................19

3.5.1 CONTROLLER CONFIGURATIONS .................................................................................................................19

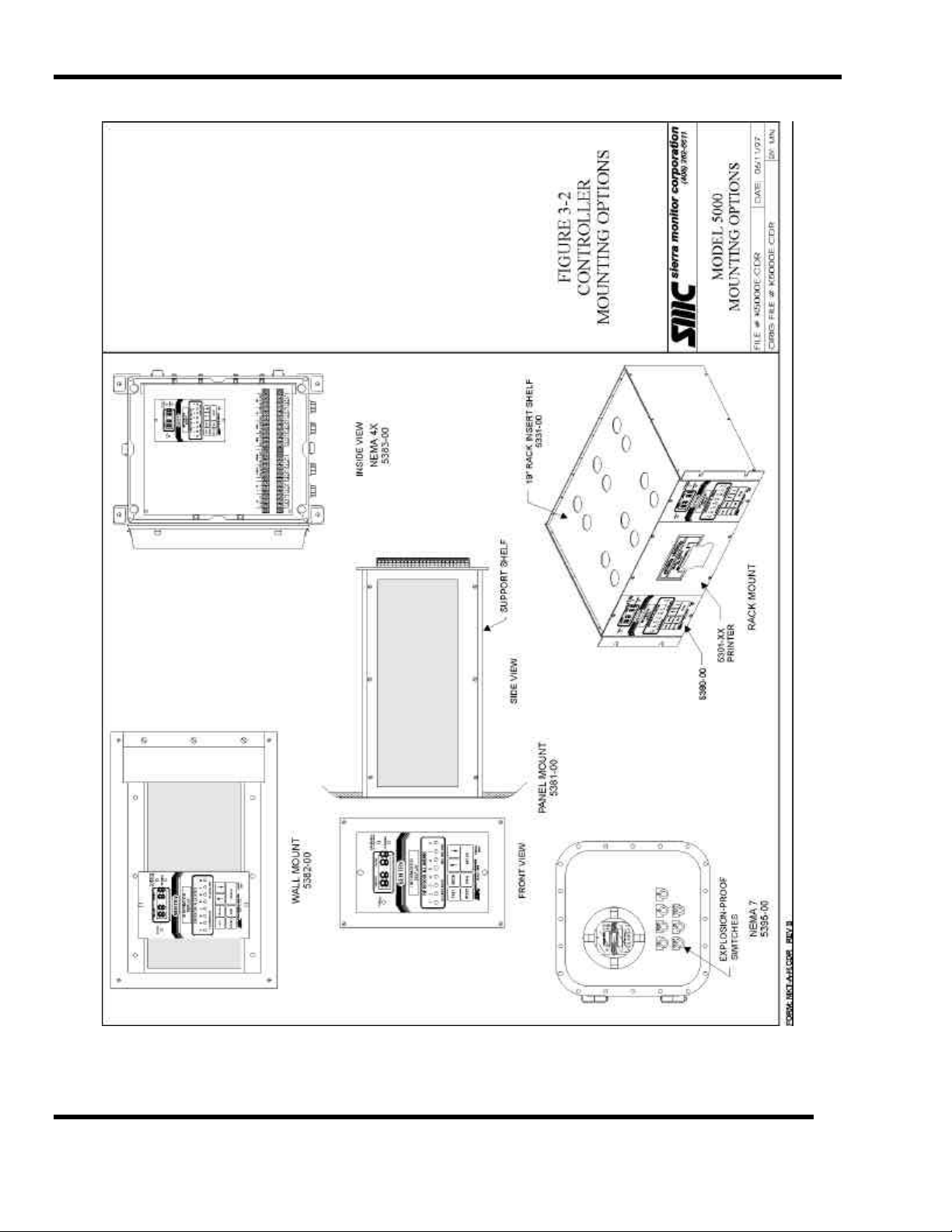

3.5.2 CONTROLLER MOUNTING...............................................................................................................................19

3.5.3 ALARM DEVICE INSTALLATION....................................................................................................................20

3.5.4 RELAY OUTPUTS...............................................................................................................................................20

3.5.5 DC POWER LOAD...............................................................................................................................................20

3.5.6 POWER UP ...........................................................................................................................................................21

3.5.7 POWER DOWN....................................................................................................................................................21

4. CONFIGURATION PROCEDURE...............................................................................................................................33

4.1 INTRODUCTION.........................................................................................................................................................33

4.2 START-UP PREPARATION........................................................................................................................................33

4.3 CONFIGURATION INSTRUCTIONS.........................................................................................................................35

4.4 SENTRY TRAINING....................................................................................................................................................35

4.5 SENTRY MENU...........................................................................................................................................................37

4.5.1 TEST KEY.............................................................................................................................................................37

4.5.2 TIME KEY ............................................................................................................................................................37

4.5.3 RESET KEY..........................................................................................................................................................38

4.5.4 MODE KEY - CALIB/CHANGE..........................................................................................................................38

4.5.5 MODE KEY - OTHER..........................................................................................................................................39

5. CALIBRATION...............................................................................................................................................................47

5.1 SENTRY CALIBRATION - AN OVERVIEW.............................................................................................................47

5.1.1 GLOBAL CALIBRATION....................................................................................................................................47

5.1.2 LOCAL CALIBRATION ......................................................................................................................................47

5.2 CALIBRATION INITIALIZATION.............................................................................................................................47

5.2.1 MODULES............................................................................................................................................................47

5.2.2 CALIBRATION PARAMETERS .........................................................................................................................48

5.3 CALIBRATION PROCEDURE....................................................................................................................................48

5.3.1 CONTROLLER SET-UP.......................................................................................................................................48

5.3.2 CALIBRATION GAS DELIVERY METHODS...................................................................................................51

5.3.3 SENSOR EXPOSURE TO GAS ...........................................................................................................................51

TABLE OF CONTENTS

Page 4

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

6. MAINTENANCE.............................................................................................................................................................53

6.1 MAINTENANCE REQUIREMENTS...........................................................................................................................53

7. SERVICE..........................................................................................................................................................................55

7.1 OVERVIEW ..................................................................................................................................................................55

7.1.1 GENERAL.............................................................................................................................................................55

7.1.2 INSTALLATION INSPECTION...........................................................................................................................55

7.1.3 DATA COLLECTION...........................................................................................................................................55

7.1.4 INSPECTION AND TROUBLESHOOTING GUIDE..........................................................................................55

7.2 CONTROLLER .............................................................................................................................................................58

7.2.1 MECHANICAL/FUNCTIONAL DESCRIPTION................................................................................................58

7.2.2 ELECTRICAL DESCRIPTION.............................................................................................................................58

7.3 COMMUNICATIONS...................................................................................................................................................63

7.3.1 DESCRIPTION OF COMMUNICATIONS..........................................................................................................63

7.3.2 WARNING AND ERROR MESSAGES...............................................................................................................64

7.3.3 WARM-UP TIMERS.............................................................................................................................................64

7.3.4 ACCESS CODES...................................................................................................................................................64

7.3.5 DIAGNOSTIC CODES .........................................................................................................................................64

7.3.6 DIAGNOSTIC REPORT.......................................................................................................................................65

7.4 HYDROGEN SULFIDE MODULE (5100-01).............................................................................................................66

7.4.1 DESCRIPTION......................................................................................................................................................66

7.4.2 TROUBLE ANALYSIS.........................................................................................................................................66

7.4.3 ADJUSTMENT PROCEDURE.............................................................................................................................66

7.4.4 SENSOR REPLACEMENT...................................................................................................................................67

7.5 COMBUSTIBLE GAS SENSOR MODULE (5100-02)................................................................................................69

7.5.1 DESCRIPTION......................................................................................................................................................69

7.5.2 TROUBLE ANALYSIS.........................................................................................................................................69

7.5.3 ADJUSTMENT PROCEDURE.............................................................................................................................69

7.5.4 SENSOR REPLACEMENT...................................................................................................................................70

7.5.5 COMBUSTIBLE GAS SCALING FACTORS......................................................................................................71

7.6 OXYGEN MODULE (5100-03)....................................................................................................................................72

7.6.1 DESCRIPTION......................................................................................................................................................72

7.6.2 TROUBLE ANALYSIS.........................................................................................................................................72

7.6.3 ADJUSTMENT PROCEDURE.............................................................................................................................72

7.6.4 SENSOR REPLACEMENT...................................................................................................................................72

7.7 CARBON MONOXIDE MODULE (5100-04)..............................................................................................................74

7.7.1 DESCRIPTION......................................................................................................................................................74

7.7.2 TROUBLE ANALYSIS.........................................................................................................................................74

7.7.3 ADJUSTMENT PROCEDURE.............................................................................................................................74

7.8 HYDROGEN SULFIDE MODULE (5100-05).............................................................................................................76

7.8.1 DESCRIPTION......................................................................................................................................................76

7.8.2 TROUBLE ANALYSIS.........................................................................................................................................76

7.8.3 ADJUSTMENT PROCEDURE.............................................................................................................................76

7.9 TOXIC GAS SENSOR MODULE ................................................................................................................................78

7.9.1 DESCRIPTION......................................................................................................................................................78

7.9.2 TROUBLE ANALYSIS.........................................................................................................................................78

7.9.3 ADJUSTMENT PROCEDURE.............................................................................................................................78

7.10 AMMONIA SENSOR MODULE (5100-25).................................................................................................................81

7.10.1 DESCRIPTION......................................................................................................................................................81

7.10.2 TROUBLE ANALYSIS.........................................................................................................................................81

7.10.3 ADJUSTMENT PROCEDURE.............................................................................................................................81

TABLE OF CONTENTS

Page 5

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

8. APPENDICES..................................................................................................................................................................83

8.1 APPENDIX A - SPECIFICATIONS.............................................................................................................................85

8.2 APPENDIX B - LIMITED WARRANTY ....................................................................................................................89

8.3 APPENDIX C - ACCESS CONTROL BY USER CODE.............................................................................................91

8.3.1 INTRODUCTION.................................................................................................................................................91

8.3.2 DEFINITIONS.......................................................................................................................................................91

8.3.3 USER CODE INSTALLATION............................................................................................................................91

8.3.4 USER CODE REMOVAL.....................................................................................................................................91

8.3.5 DIAGNOSTIC CODES:........................................................................................................................................91

8.3.6 LOST ENTRY CODE ...........................................................................................................................................92

8.4 APPENDIX D: - MODEL NUMBERS & PARTS LIST ..............................................................................................93

8.4.1 CONTROLLER ITEMS........................................................................................................................................93

8.4.2 SENSOR MODULE ITEMS.................................................................................................................................94

8.4.3 CALIBRATION EQUIPMENT ............................................................................................................................95

8.5 APPENDIX E - INSTRUCTIONS FOR PRINTER SOFTWARE OPTION...............................................................97

8.5.1 IDENTIFICATION ...............................................................................................................................................97

8.5.2 CAPABILITY........................................................................................................................................................97

8.5.3 REPORTS..............................................................................................................................................................97

8.6 APPENDIX F - MODEL 5392 INDIVIDUAL RELAY ..............................................................................................99

8.6.1 RELAY PANEL DESCRIPTION..........................................................................................................................99

8.6.2 RELAY PANEL ASSEMBLY ..............................................................................................................................99

8.6.3 INSTALLATION ..................................................................................................................................................99

8.6.4 OPERATION.........................................................................................................................................................99

8.6.5 INDIVIDUAL RELAY SPECIFICATIONS.........................................................................................................99

8.7 APPENDIX G - MODEL 4314 OUTPUT EXPANSION PANEL ............................................................................103

8.7.1 EXPANSION PANEL DESCRIPTION ..............................................................................................................103

8.7.2 EXPANSION PANEL ASSEMBLY...................................................................................................................103

8.7.3 INSTALLATION ................................................................................................................................................103

8.7.4 OPERATION.......................................................................................................................................................103

8.7.5 OUTPUT EXPANSION PANEL TESTING.......................................................................................................104

8.7.6 INDIVIDUAL RELAY SPECIFICATIONS.......................................................................................................104

8.8 APPENDIX H - MODEL 5100-99 ANALOG INPUT MODULE.............................................................................106

8.8.1 DESCRIPTION ...................................................................................................................................................106

8.8.2 INSTALLATION ................................................................................................................................................106

8.8.3 ADJUSTMENT PROCEDURE...........................................................................................................................106

8.9 APPENDIX I - MODEL 5100-90 8-CHANNEL ANALOG-DIGITAL CONVERTER............................................107

8.9.1 DESCRIPTION ...................................................................................................................................................107

8.9.2 INSTALLATION ................................................................................................................................................107

8.9.3 SERVICE.............................................................................................................................................................107

8.10 APPENDIX J - REFERENCE DRAWINGS...............................................................................................................109

9. INDEX ............................................................................................................................................................................119

10. LIST OF FIGURES...................................................................................................................................................121

11. LIST OF TABLES.....................................................................................................................................................122

TABLE OF CONTENTS

Page 6

Page 7

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

1. PRODUCT DESCRIPTION

1.1 GENERAL

The Sentry 5000 is a fixed installation gas monitoring

system designed for continuous operation in open or

confined areas. The system is comprised of a controller

and up to eight sensor modules. The sensor modules are

supplied for detection of combustible gas, oxygen

deficiency or various toxic gases and can be mixed within

one system as required.

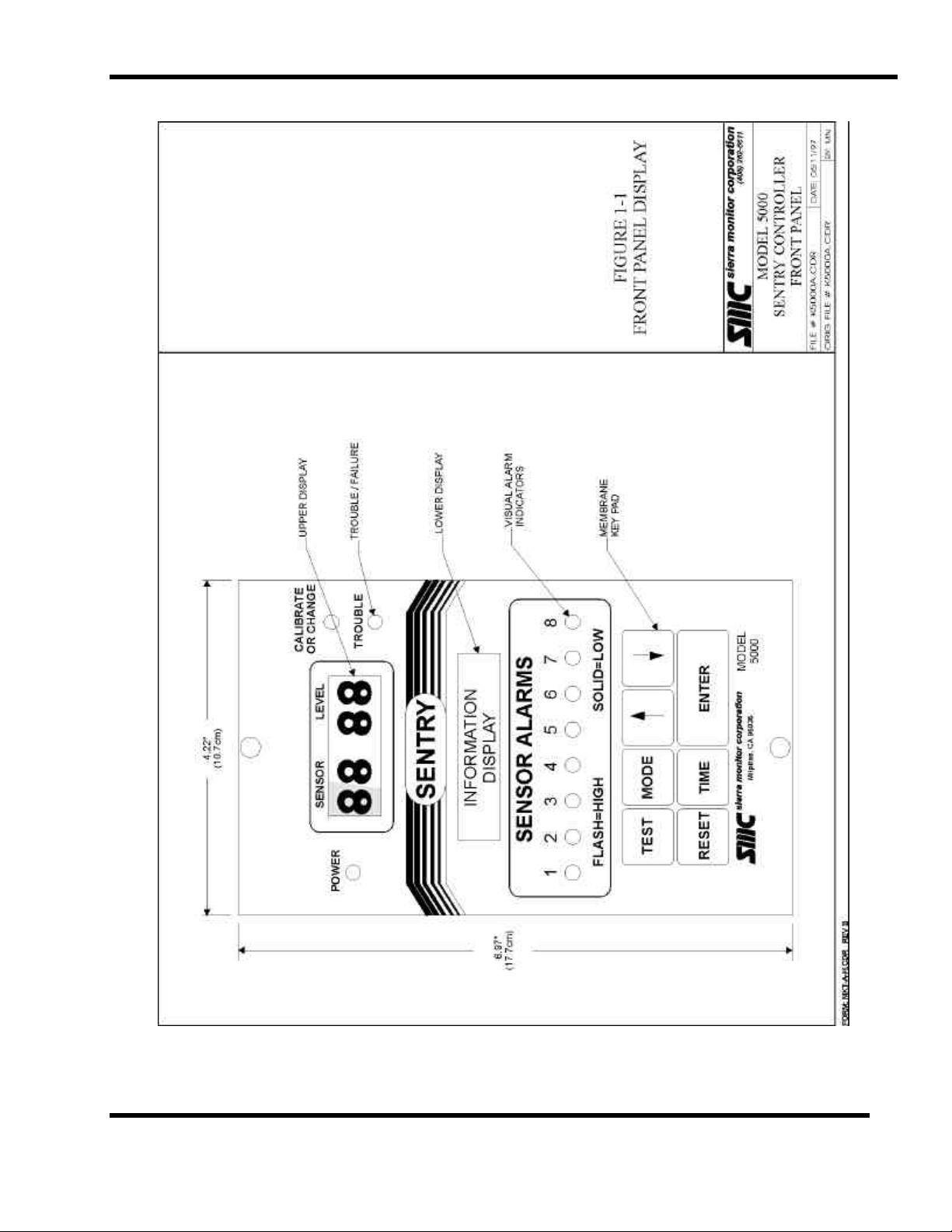

1.2 CONTROLLER

The Sentry controller is a microprocessor computer which

performs functions including management of the sensor

modules, management of alarm relays and interface with

the user via the front panel which includes a concentration

display, an alphanumeric display, keypad and status

indicators. The microprocessor functions are permanently

installed in the controller. They cannot be changed or

damaged by the user and will not be altered by loss of

power.

Configuration variables, such as alarm levels, can be

changed via a simple keypad sequence. Information

provided to the controller in this manner is retained even

when the power is interrupted. This information can be

protected by a "user code" to avoid unauthorized

modification.

Sentry continually scans all modules for alarm conditions.

No sequence of key presses can prevent the scanning

except specific actions during calibration or deliberate

disabling of the sensor module.

The Sentry controller is provided in a rack or panel mount

version for control rooms, an environmental enclosure for

outdoor, stand alone applications, or other packages for

specialty applications.

1.2.1 ENHANCEMENT PACKAGE

Various factory installed firmware enhancements are

available for the Sentry controller. These are selected at

the time of purchase or subsequent upgrade. The

enhancements, which are described in detail in the

appropriate sections of this manual, include:

− Addition of printer output firmware for models

5000-04 or 5000-02. Printer output is standard

on model 5000-08.

− Replace printer output firmware with MODBUS

data address protocol for host computer or DCS

interface. MODBUS is an industry standard

communication protocol which allows bidirectional communication via the controller RS232C serial port.

− High Alarm Acknowledge function for alarm

reset.

− Low Alarm Acknowledge function for alarm

reset

− Emergency Alarm function adds a third alarm

level.

− Zone and Voting assignment of individual alarm

relays.

− Analog Output software driver for use with

Model 4314-01 output module.

− Custom default Gas Tags and Engineering Units

Tags for up to eight input devices.

− Custom default Module Tags for up to eight

module addresses.

− Configure alarm relays to be normally energized

in the safe condition.

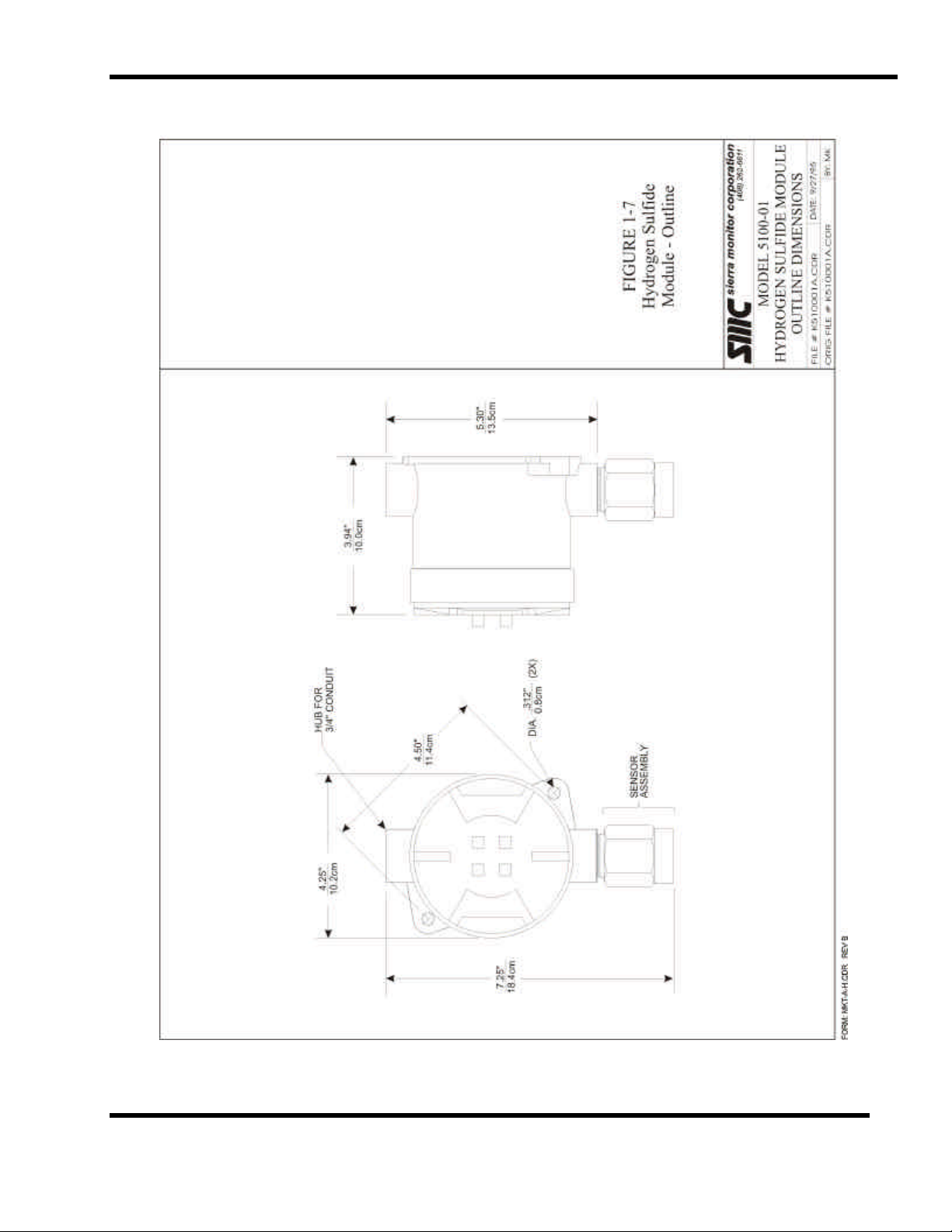

1.3 SENSOR MODULES

Each sensor module ("module") is labeled internally to

identify the type of gas it is designed to detect. For each

gas group, the sensor and the electronics board in the

explosion proof housing is different. During installation,

switches in the electronics are set by the user to give the

module an address (module number) to make it unique

from others in the same system. Sentry then

"communicates" with each module to determine its

number, the type of gas it detects, the gas concentration

and other information.

Inside the module housing is an electronic assembly

consisting of two printed circuit board assemblies mounted

under a metal top plate. The address switches and

adjustment potentiometers are accessible through the plate

and electrical test points (test lead jacks) are installed in

the plate. Connectors for wiring from the controller and

the sensor are located on the bottom of the electronic

assembly. The sensor is installed in one hub of the

enclosure.

PRODUCT DESCRIPTION

Page: 1

Page 8

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

1.4 INTERCONNECT WIRING

Not supplied with Sentry, but necessary to the installation

and operation is the three conductor wiring which connects

the controller to the modules. Before this wiring is

installed it is important to read and understand the

installation instructions (Chapter 3) because significant

economies can be realized by connecting more than one

module onto a common wiring run. This standard feature

is accomplished by multiplexing the signals from the

modules to the controller.

1.5 DATA TRANSMISSION

Transparent to the user is the data transfer which occurs on

the installed interconnect wiring. Two of the conductors

are used to pass direct current (DC) from the controller to

the modules. The third wire transfers a series of very rapid

pulses between the controller and the sensor modules. This

digital transfer of information is an important feature of the

system which significantly reduces RFI and EMI problems.

1.6 POWER REQUIREMENTS

The standard system requires 120 VAC, 60 Hz, at 0.5 Amp

electrical supply. A factory option can be ordered for

220 VAC operation. DC voltage (12 to 28 VDC) can be

used for standby power. The system will automatically

switch to supplied DC operation at any time the AC

voltage is interrupted.

The system includes a lithium battery for RAM memory

retention during power interruptions. To ensure

continuous trouble free operation, however, the primary

power source must be one which is continuous and reliable,

preferably dedicated to this equipment. Battery back-up or

emergency power is recommended to insure continuous

operation.

PRODUCT DESCRIPTION

Page: 2

Page 9

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

Figure 1-1

Front Panel Display

PRODUCT DESCRIPTION

Page: 3

Page 10

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

Figure 1-2

Rack Mount Configuration - Outline

PRODUCT DESCRIPTION

Page: 4

Page 11

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

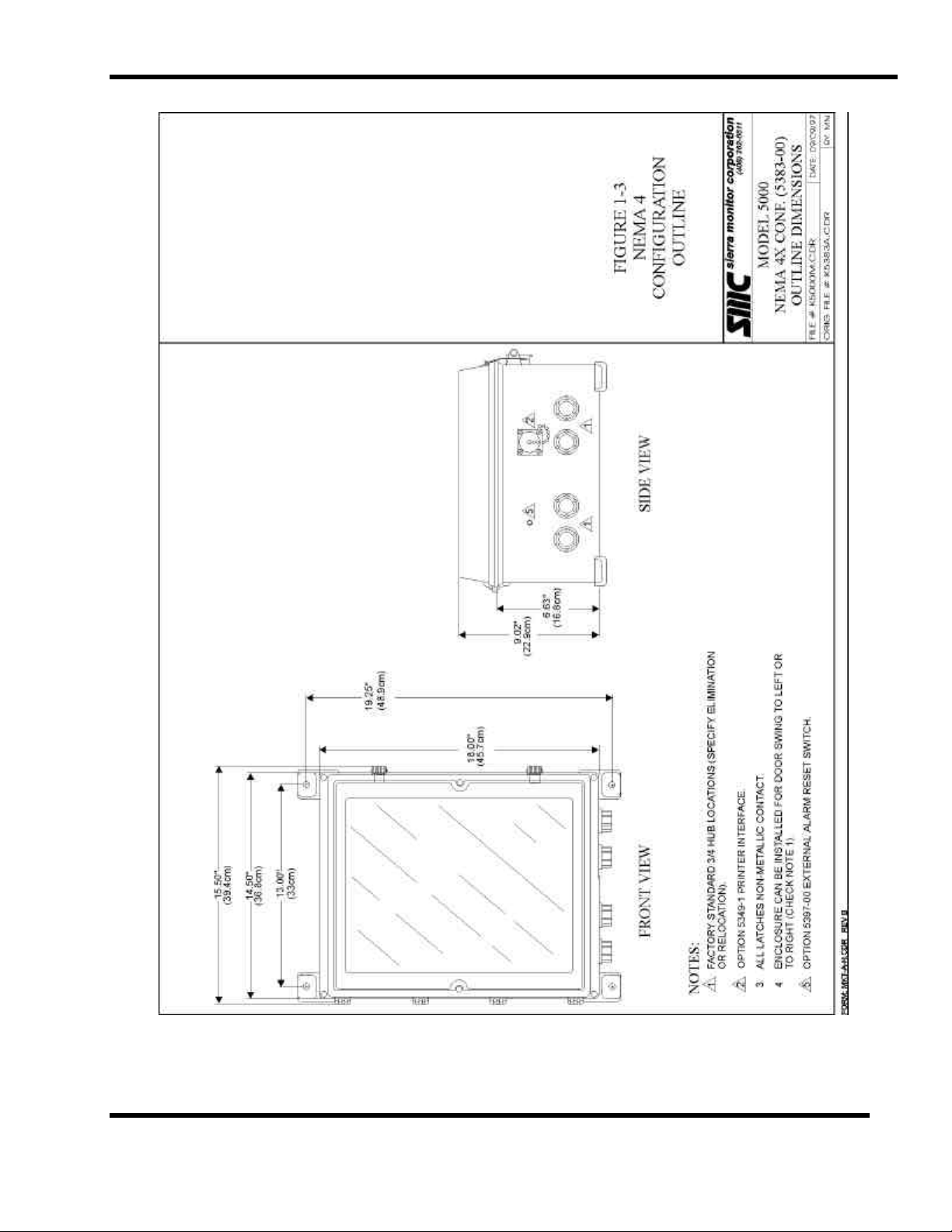

Figure 1-3

NEMA-4 Configuration - Outline

PRODUCT DESCRIPTION

Page: 5

Page 12

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

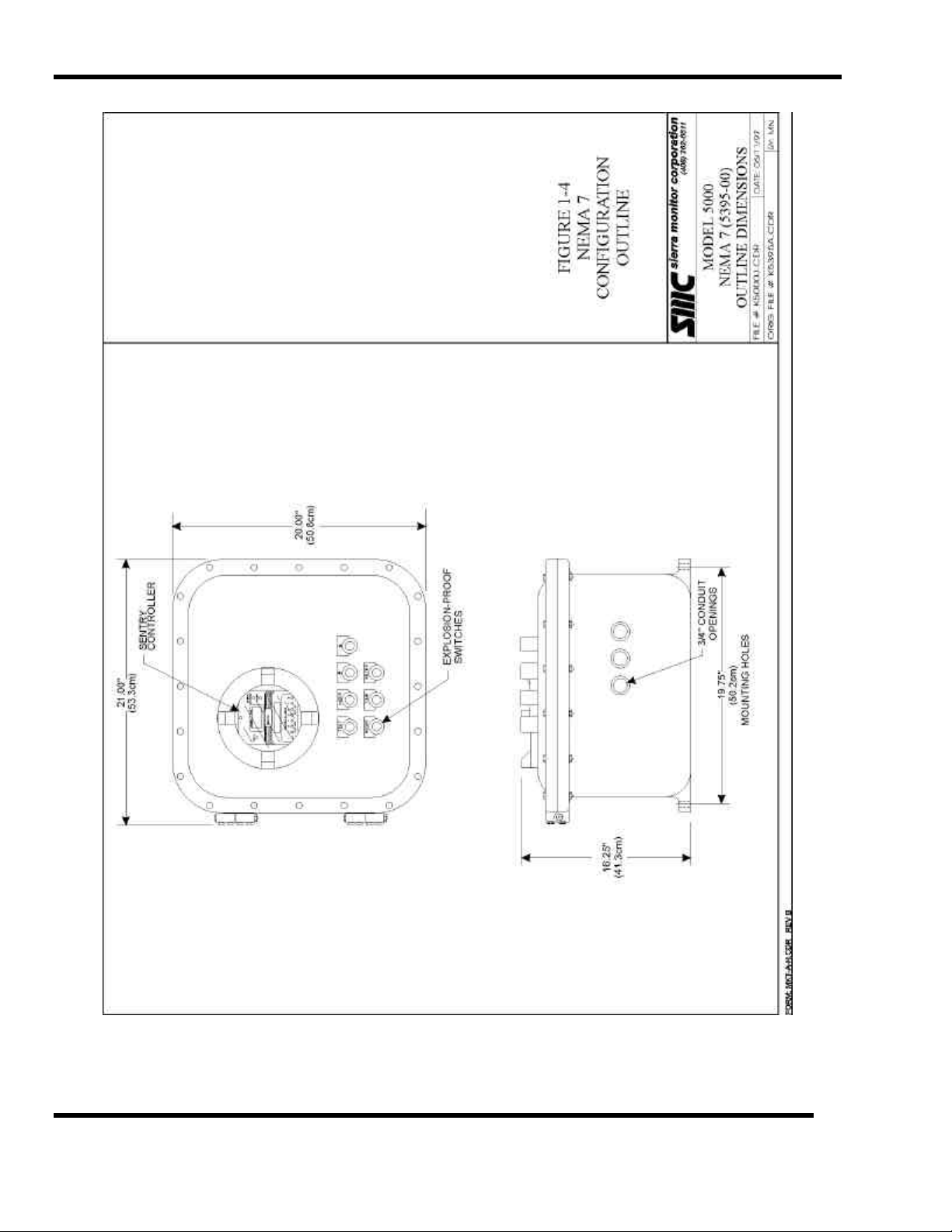

Figure 1-4

NEMA-7 Configuration - Outline

PRODUCT DESCRIPTION

Page: 6

Page 13

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

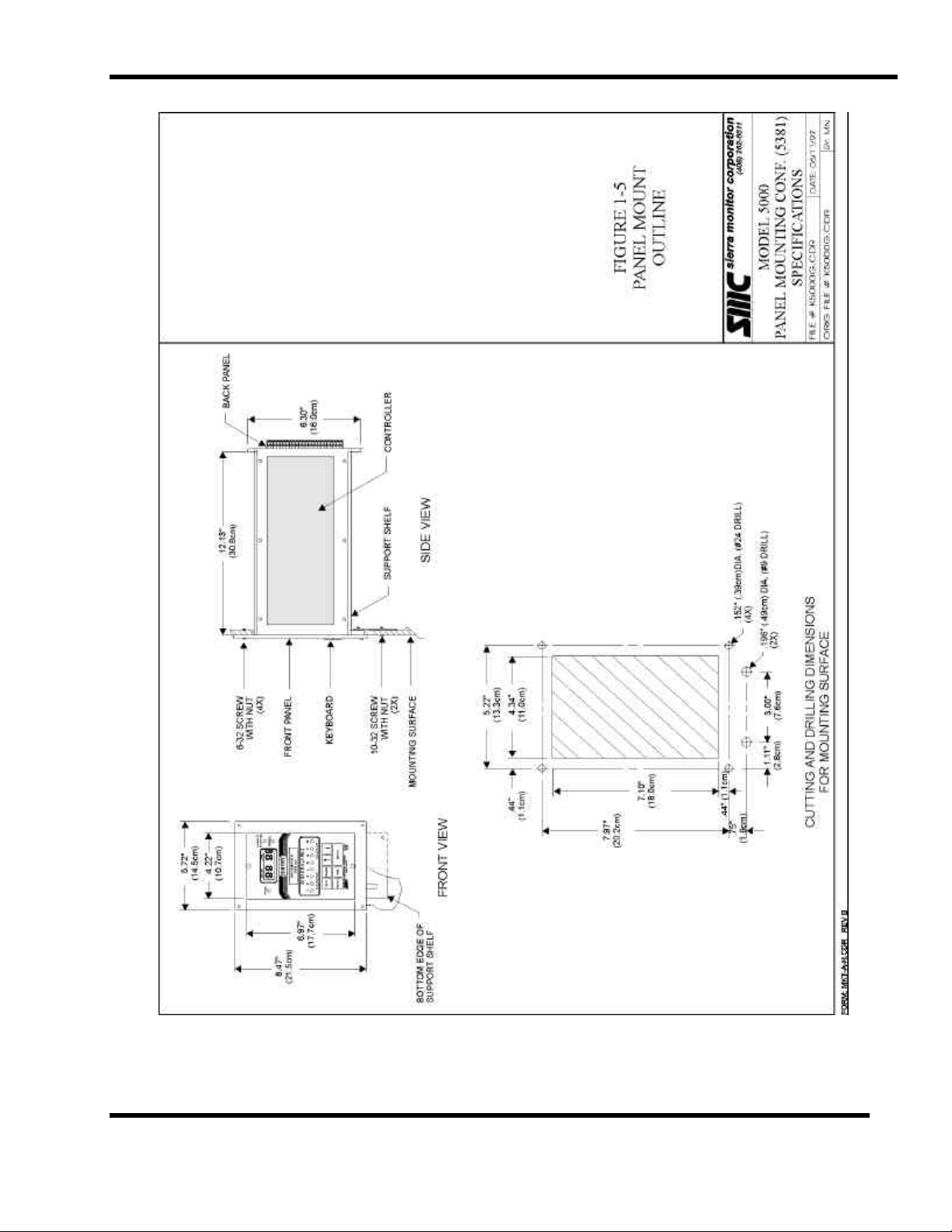

Figure 1-5

Panel Mount Configuration Outline

PRODUCT DESCRIPTION

Page: 7

Page 14

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

Figure 1-6

Wall Mount Configuration Outline

PRODUCT DESCRIPTION

Page: 8

Page 15

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

Figure 1-7

Hydrogen Sulfide Module - Outline

PRODUCT DESCRIPTION

Page: 9

Page 16

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

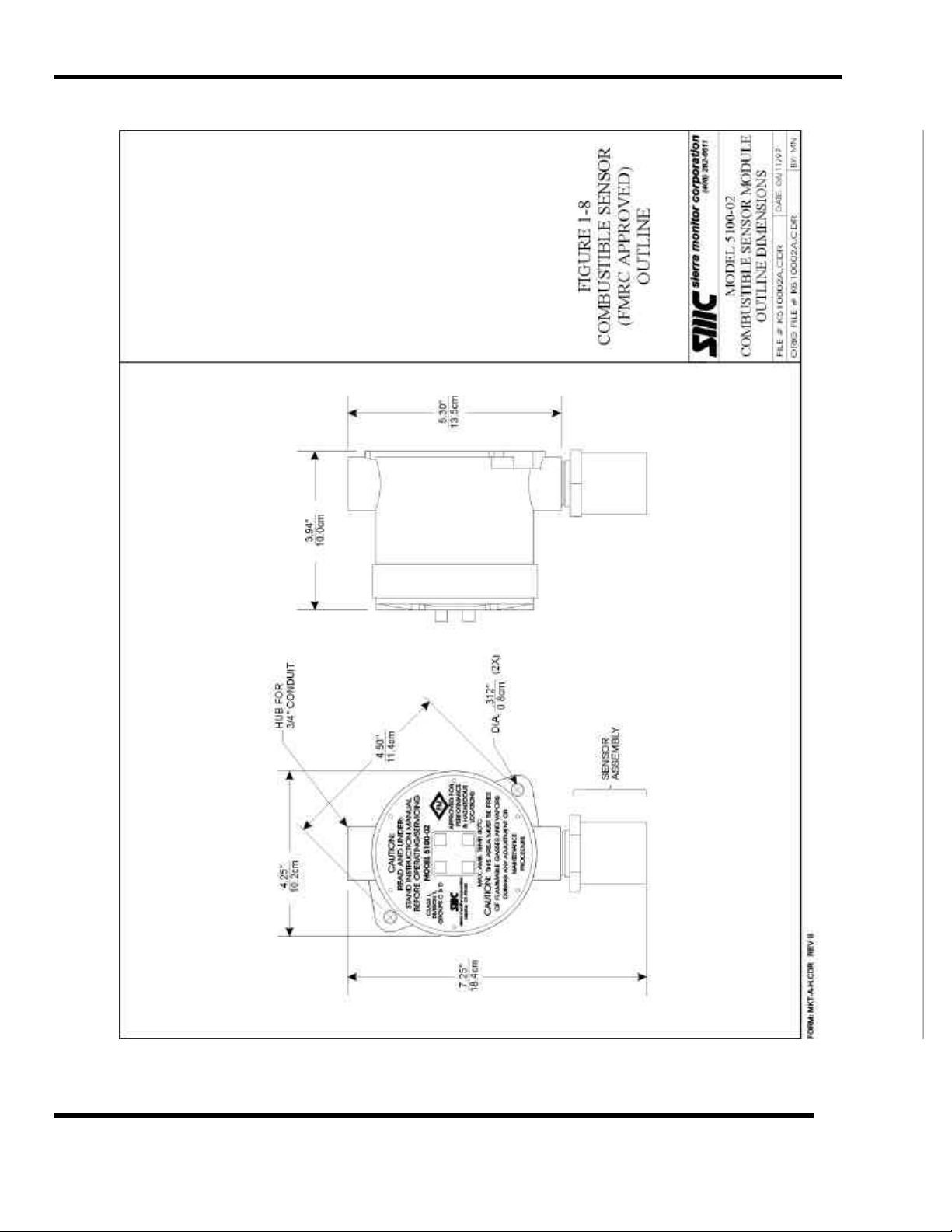

Figure 1-8

Combustible Sensor - Outline

PRODUCT DESCRIPTION

Page: 10

Page 17

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

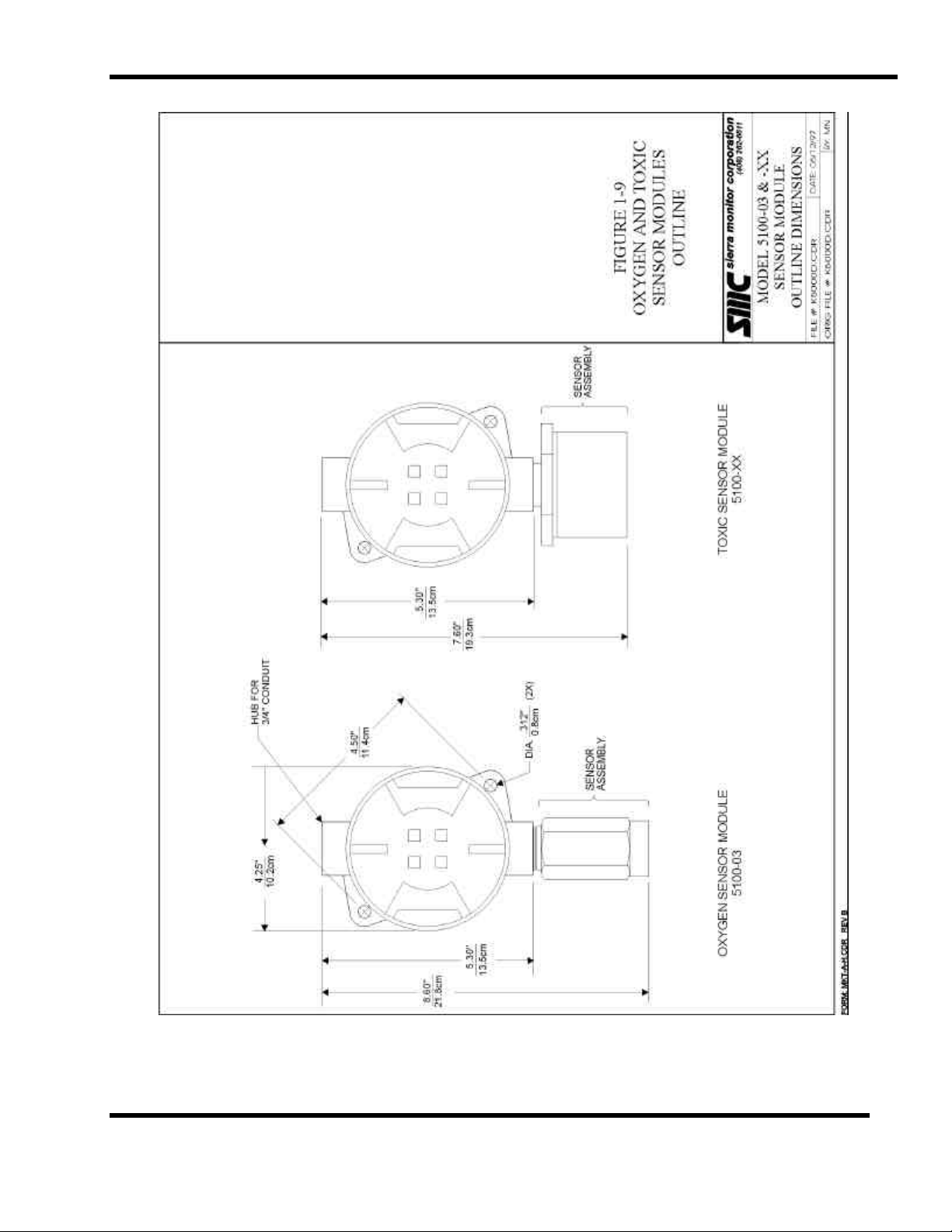

Figure 1-9

Oxygen and Toxic Sensor Modules - Outline

PRODUCT DESCRIPTION

Page: 11

Page 18

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

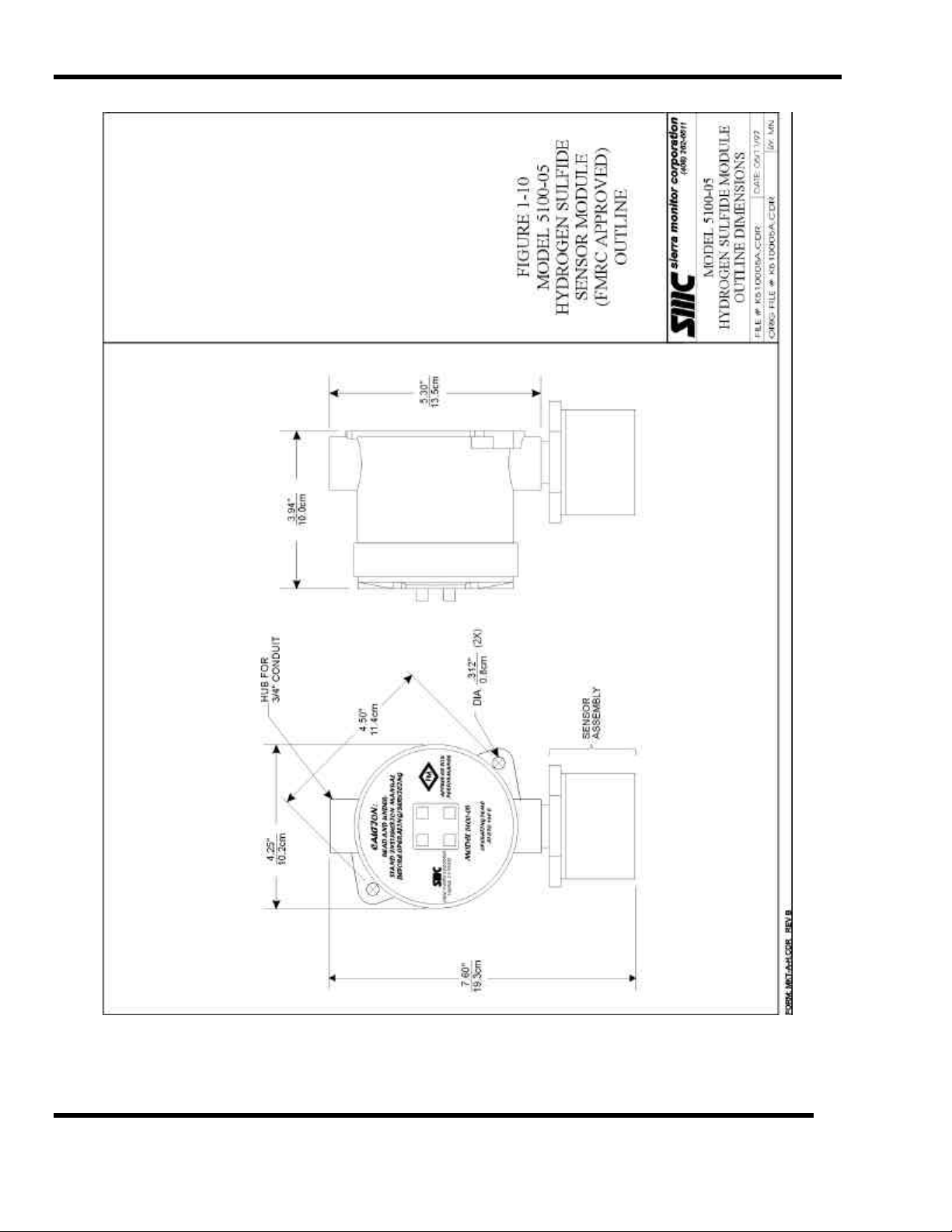

Figure 1-10

Model 5100-05 Hydrogen Sulfide Sensor Module (FMRC Approved) - Outline

PRODUCT DESCRIPTION

Page: 12

Page 19

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

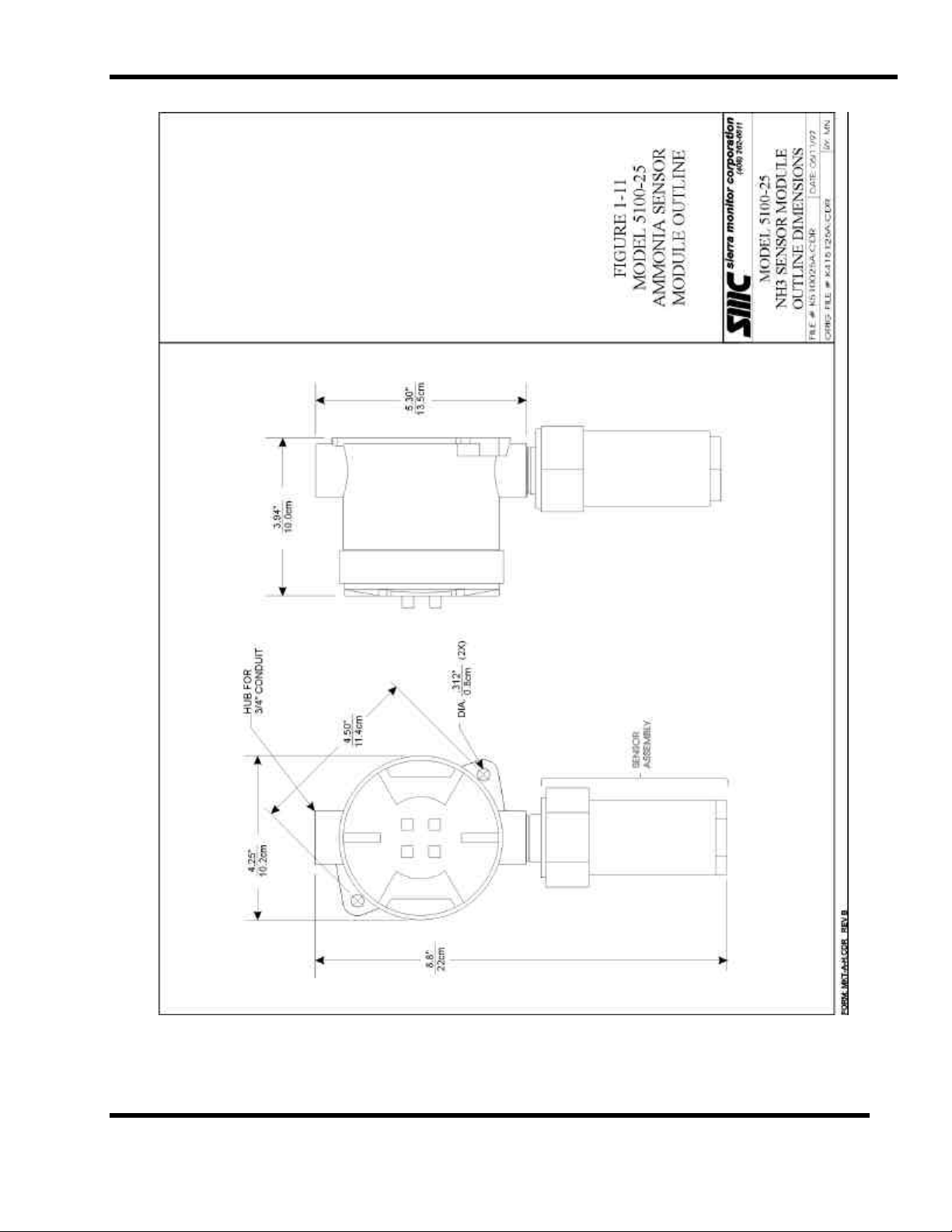

Figure 1-11

Model 5100-25 Ammonia Sensor Module - Outline

PRODUCT DESCRIPTION

Page: 13

Page 20

Page 21

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

2. CAUTIONS & WARNINGS

2.1 INTRODUCTION

Although the Sentry system is designed and constructed

for installation and operation in industrial applications

including "hostile" environments, caution should be taken

to insure that the installation is made in compliance with

this instruction manual and that certain procedures and

conditions are avoided. This chapter discusses the

necessary cautions. Read the entire chapter prior to

installation of the equipment.

2.2 CONTROLLER

The controller should be installed in a location which is

safely accessible during a gas alarm.

Avoid installing the controller where it will be

unnecessarily exposed to wind, dust, shock or vibration or

direct sun. Observe temperature range limitations.

Adhere to standard electrical installation procedures. The

chassis ground on the controller must be connected to

earth ground.

2.3 WIRING

While the digital communication method used between

the controller and modules will greatly reduce problems

associated with electromagnetic and radio frequency

interference the manufacturer recommends that extra

caution be taken where the installation is near any sources

of these interferences:

• Avoid running sensor module cable close to high

power cables, radio transmission lines, or cables

subject to pulses of high current.

• Avoid running cables near large electric motors or

generators.

• When the risk of interference is present use shielded

cables. In conduit installations the shield should be

connected to the conduit. In cable applications the

shield should be connected to the cable connector.

• All splices must be via either a lug and terminal

system or soldered. Improperly spliced cable can

result in corrosion, resistance changes and system

errors.

NOTE

Installation and wiring must be in accordance with the

National Electrical Code

2.4 SENSOR MODULES - GENERAL

Avoid installing sensor modules where they will be

unnecessarily exposed to wind, dust, water (esp. direct

hose down), shock, or vibration. Observe temperature

range limitations.

Sensors may be adversely affected by prolonged exposure

to certain materials. Loss of sensitivity, or corrosion, may

be gradual if such materials are present in low

concentrations. These materials include: Halides

(compounds containing chlorine, fluorine, bromine,

iodine), silicones, acid vapors, caustic liquids or mists.

Care has been taken by the manufacturer to ship your

modules in protective packaging to avoid contamination

prior to installation. It is recommended that the sensors

remain protected during installation and that the covering

be removed immediately prior to system start-up.

During normal use the sensor is protected from dirt and

oil contamination by a sintered metal cover. If this cover

becomes clogged, the response of the sensor will be

reduced. Protect the sensor from contamination by careful

placement, or by use of rain and dust shields.

Sensor modules must not be painted. Paint may contain

compounds which will contaminate the sensor. Paint will

cause clogging of the sintered metal cover and will cause

difficulties during attachment of the calibration head or

other maintenance activity. It is recommended that the

module be tagged "DO NOT PAINT".

When sensors are replaced the thread must be Teflon

taped to avoid metal to metal binding which will damage

the housing threads.

2.4.1 COMBUSTIBLE SENSOR MODULES

Catalytic type combustible gas sensors may be poisoned

by exposure to silicones. Sierra Monitor Corporation

supplies resistant sensors, but care should be taken to

avoid exposure to silicones. No Silicone caulking (RTV)

should be used near the sensors. No other silicone based

compounds should be used near the sensors unless they

are fully protected during the entire cure cycle. If the

sensors will be exposed to silicone during normal

operation the manufacturer's sensor warranty is void.

CAUTIONS & WARNINGS

Page: 15

Page 22

Page 23

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

3. INSTALLATION

All systems are factory are pre-configured and calibrated.

NOTE

All sensors are tagged to indicate the controller (alpha)

and the sensor module number (1 - 8).

Identify all components of the system during unpacking

and install using the factory configuration.

The system will power up in a calibrated and fully

functional condition.

3.1 CONTROLLER LOCATION

Rack mounted controllers should be installed in a control

room environment where they will be relatively free from

dust and temperature extremes. For ease of operation

select a rack window space at approximately eye level.

Four controllers can be installed side by side in a 19"

instrument shelf.

Enclosed controllers for outdoor applications should be

located in the most protected location available with

consideration for easy access for installation and

calibration. The enclosures should be mounted on a

vertical surface with the key board at approximately eye

level. The enclosure should not face directly into the sun.

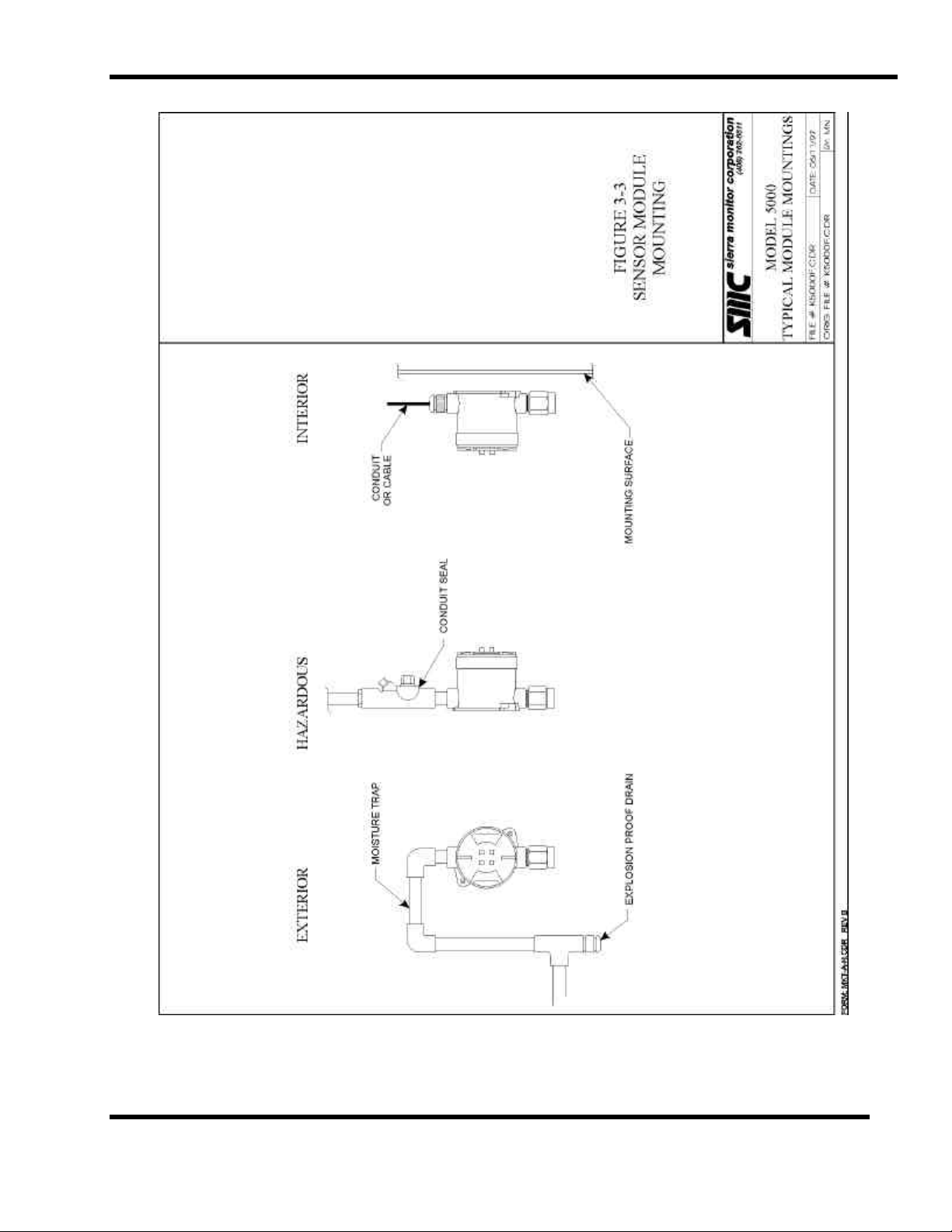

3.2 SENSOR MODULE LOCATIONS

Select locations for each of the sensor modules based on

the following:

• Consider the density, relative to dry air, of the gas to

determine height of module above floor or ground

level:

Gas Density

(Air = 1.00)

Air 1.00

Ammonia 0.60

Carbon Monoxide 0.97

Chlorine 2.49

Ethylene Oxide 1.52

Hydrogen 0.07

Hydrogen Chloride 1.27

Hydrogen Cyanide 0.94

Hydrogen Sulfide 1.19

Methane 0.55

Nitrogen Dioxide 1.58

Oxygen (Air) 1.10

Sulfur Dioxide 2.26

• Modules should be placed close to the potential source

of gas.

• Modules should be placed in areas accessible for

calibration.

• Sensors should be pointed down and the conduit

should include an inverse trap to reduce moisture

(condensation) from accumulating in the electronics

enclosure Figure 3-3.

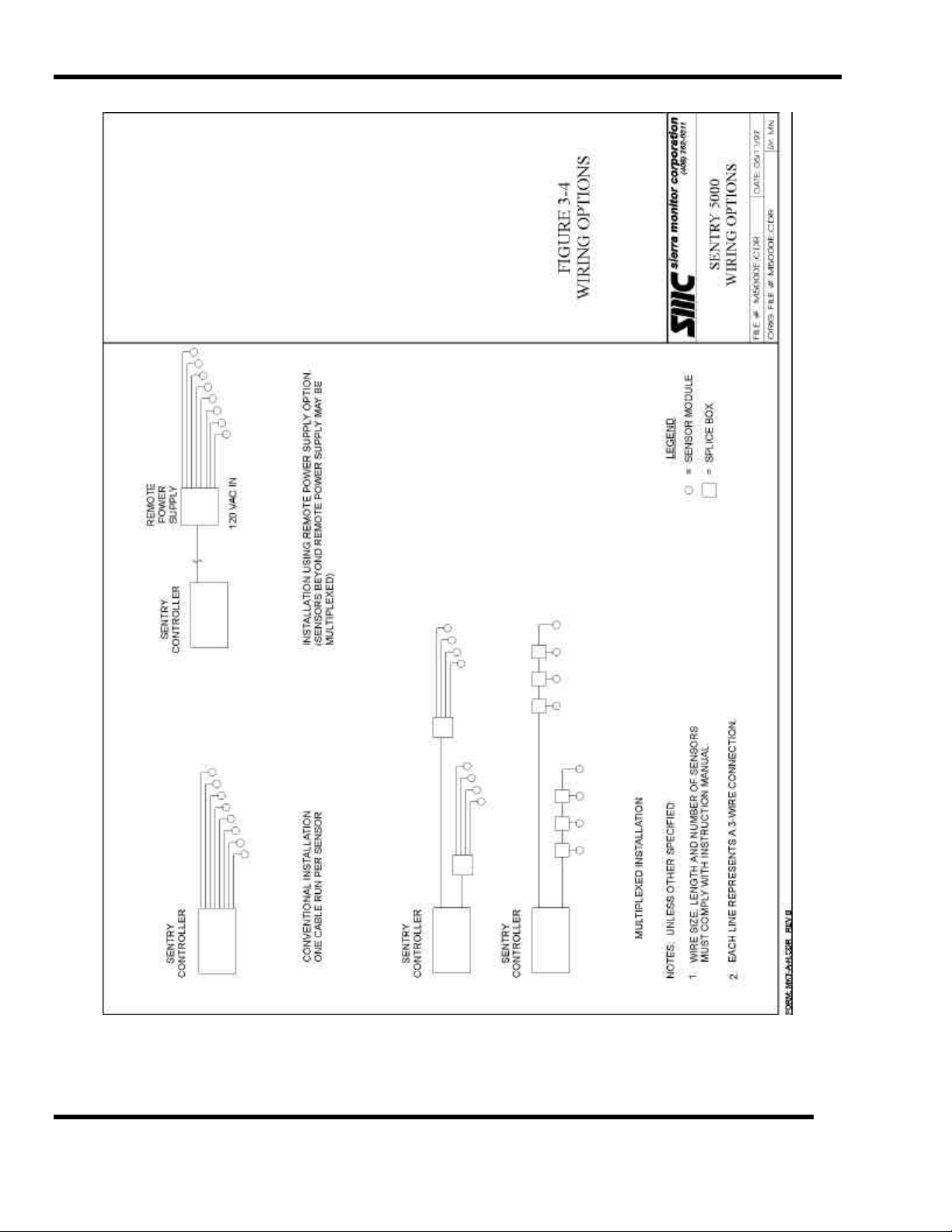

3.3 WIRING

Plan the wiring arrangement to minimize installation

expense but with redundancy for critical locations. Wire

shall be Belden (or equivalent) 949X (where X = 2, 3, 4, or

5 depending on wire gauge). If high RFI or EMI levels

exist wiring should be protected by conduit or shield.

Shielded wire shall be Belden (or equivalent) 936X.

In no case should the drain wire of shielded cable be used

as one of the conductors.

NOTE

• Any modules which are located in a common

geographical area a long distance from the controller

can be connected to the same three conductor wire run

installed from the controller to that area. Table 3-2,

Figure 3-4.

• The remote auxiliary power supply option can be used

for installation of one or more modules a long distance

from the controller location. The connection from the

controller to the remote power supply is via a two

conductor "data link" Figure 3-4.

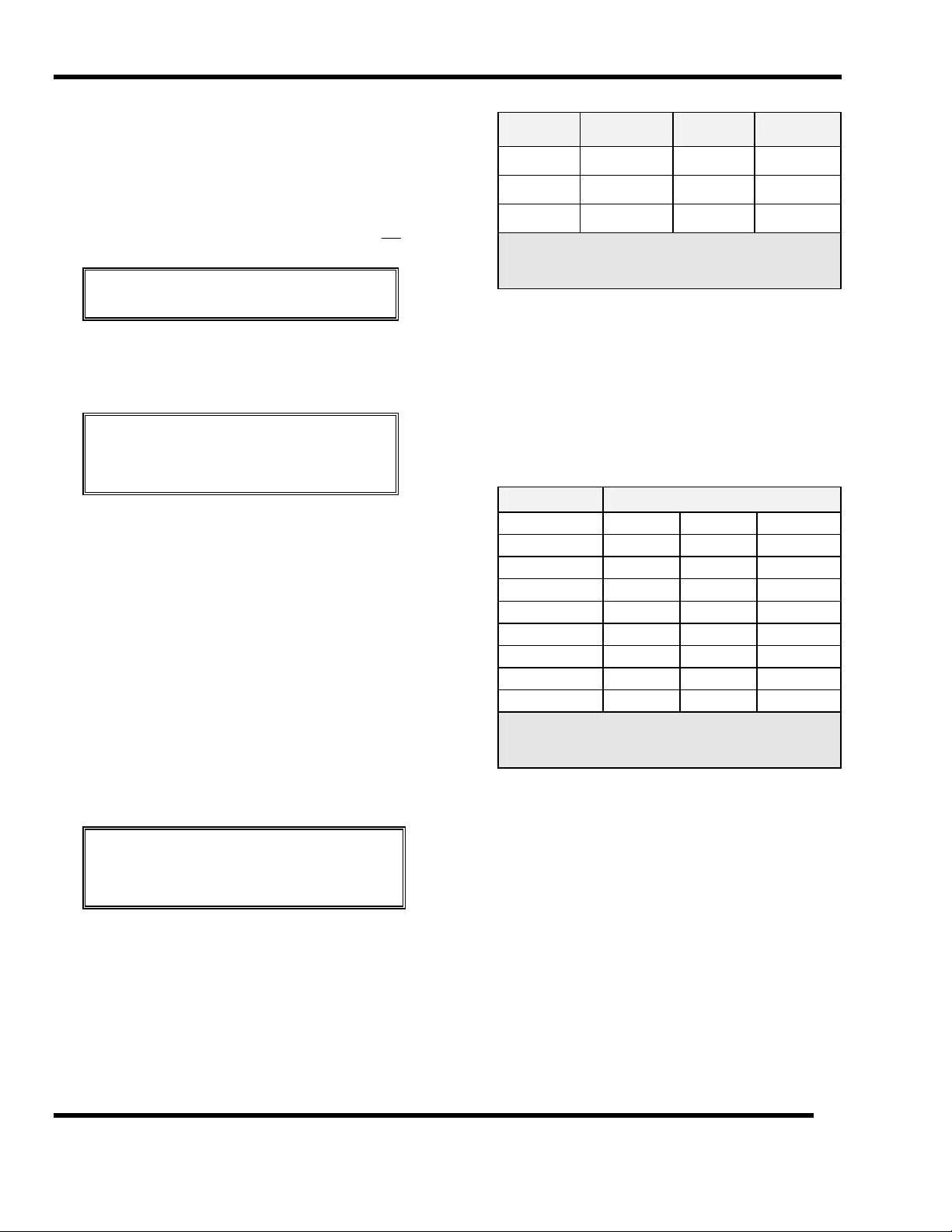

Number of Maximum length of wire run (feet)

modules 500 1,000 2,000 3,000 5,000

1

2

3

4

20 20 18 16 14

20 18 14 12 xx

18 16 12 xx xx

16 14 12 xx xx

Table 3-2

Minimum Wire Gauges

Table 3-1

Specific Gravity of Selected Gases

INSTALLATION

Page: 17

Page 24

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

Install conduit as required. Provide for splice boxes where

multiple modules will be wired to a single run. Pull 3

(typical: white, black, green) conductors of the correct

gauge wire from the controller to each splice box and from

the respective splice box to each planned module location.

See Figure 3-5 for proper wire termination in the splice

box. Twisted wire secured with wire nuts is not an

acceptable splice.

NOTE

Installation and wiring must be in accordance with the

National Electrical Code

In installations where redundancy of module locations is a

requirement do not install multiple modules on one cabling

run as any damage to the primary wiring will disable all the

modules.

NOTE

Temperature rating of cable wire insulation must be

above 75oC (85oC or greater rating wiring is

recommended). If cable runs through higher temperature

environments, it should be specified for that environment.

3.4 SENSOR MODULE INSTALLATION

Note: Remove spring from the electromechanical

sensor (5100-04 through 5100-23) prior to installation.

See technical note provided with sensor module.

1. Remove the electronics from the module housing

by:

• Unscrew the two captive panel screws in the

top plate.

• Lift the electronics out of the housing.

• Unplug the sensor harness from the bottom

electronics board.

2. Install the module housing onto the end of the

supply conduit and/or bolt into position as

required.

Note

If housing grounding is required for the installation a

grounding lug is located under the two printed circuit

assemblies in the housing. Install the ground wire under

the green lug. Figure 3-5

Controller

Marking

Function Module

Marking

Color

1 +VDC P White

2 Signal S Black

3 DC Return G Green

Table 3-3

Sensor Module Wiring

4. Reconnect the sensor harness to the sensor

connector on the bottom of the electronic

assembly. Figure 3-7.

5. Twist the assembly 180o to take up the service

loop on both the incoming wire and the sensor

harness. With the sensor facing down the wording

on the cover plate will be correctly oriented.

6. Carefully fit the electronics over the two posts in

the housing and tighten the captive panel screws.

Module Switch Positions

# 1 2 3

1 ON ON ON

2 OFF ON ON

3 ON OFF ON

4 OFF OFF ON

5 ON ON OFF

6 OFF ON OFF

7 ON OFF OFF

8 OFF OFF OFF

Table 3-4

Sensor Module Binary Switch Positions

7. Set the dip switch Figure 3-8 on each module to

indicate the module number (Table 3-4). Each of

the modules connected to one controller must have

a different address. (Note: Switch position 4 is not

used.)

3. Connect the three wires which run from the

controller to the three position terminal strip on the

bottom of the electronics assembly. See Table 3-3

for terminal markings and normal wiring color

code conventions. Figure 3-7 shows the correct

wiring connections and the operation of the

connector mechanism.

INSTALLATION

Page: 18

Page 25

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

3.5 CONTROLLER INSTALLATION

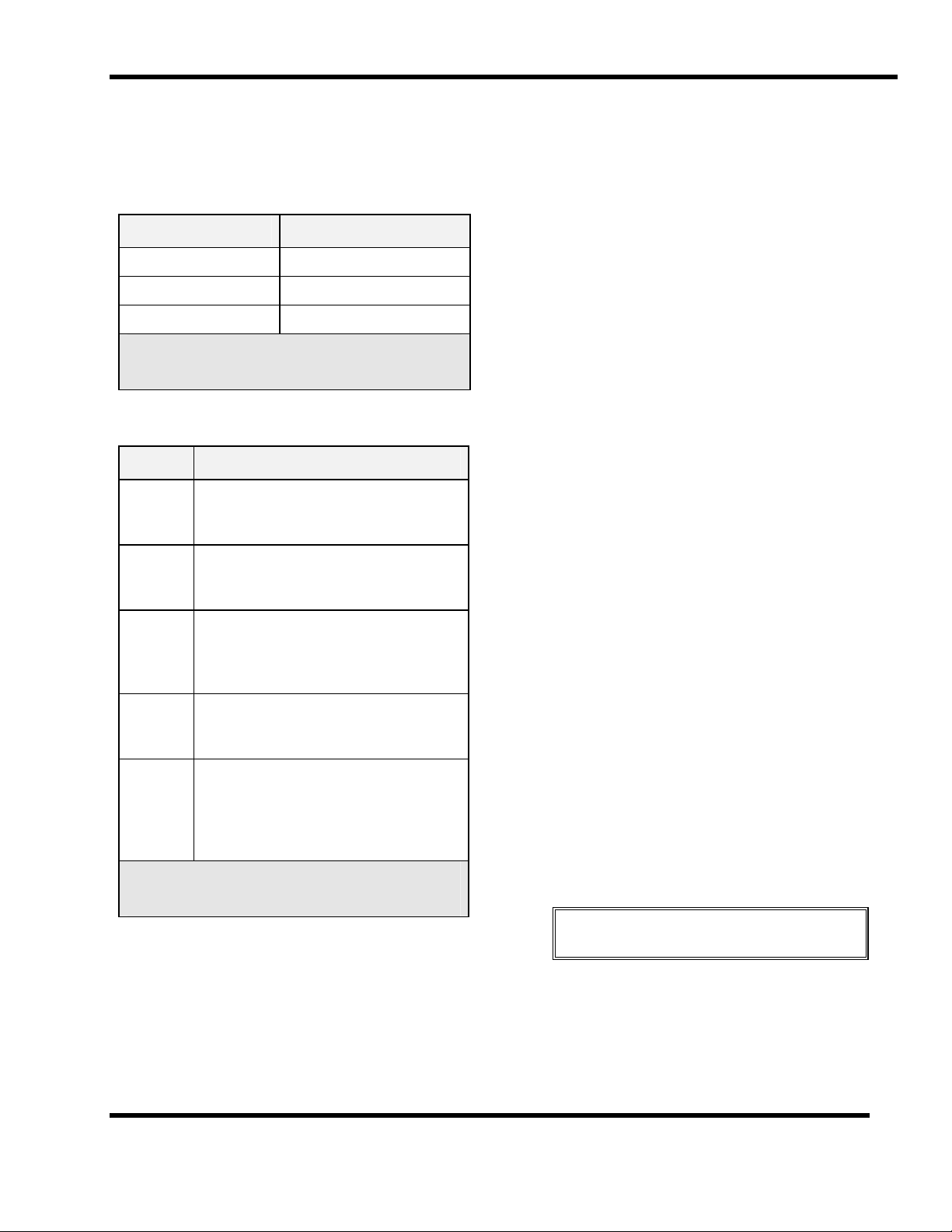

3.5.1 CONTROLLER CONFIGURATIONS

Table 3-5 lists the number of sensor modules which can be

operated on each controller model.

Model Controller Capacity

5000-02 2 Sensor Modules

5000-04 4 Sensor Modules

5000-08 8 Sensor Modules

Table 3-5

Sentry Controller Capacity

Table 3-6 lists and describes Sentry controller enclosure

options.

Model Description

5380-00 Standard configuration, controller

intended for installation in instrument

rack. Wiring to back connector panel.

5381-00 Controller supplied with bezel for panel

or chassis installation. Wiring to back

connector panel.

3.5.2.2 CHASSIS MOUNTED CONTROLLER

The chassis mounted controller is provided with a preinstalled bezel and a template for the chassis cut-out. An

angle bracket is also provided to support the cantilever of

the controller. Select an appropriate location at

approximately eye level providing rear access for the

module and alarm wiring.

3.5.2.3 WALL MOUNTED CONTROLLER

The wall mounted controller is provided on a sheet metal

panel containing brackets which allow for removal of the

controller. Select a location, where module and alarm

wiring can be run up or down the wall for distribution, and

bolt the panel to the wall.

3.5.2.4 NEMA ENCLOSED CONTROLLER

Mount the NEMA enclosed controller on a vertical surface

with the display at approximately eye level. Mounting feet

are supplied with the enclosure for external mounting bolts.

Figure 1-3. Although the enclosure is designed for

exposure to weather, normal measures to protect the

system from harsh conditions are recommended. It is

particularly important to avoid exposure of the display to

direct sunlight as this can cause fading of the display

during very hot weather.

5382-00 Wall mount configuration includes a

mounting panel and brackets, display is

side mounted. Wiring to side facing

panel.

5383-00 NEMA-4X Enclosure with latching front

door and window for viewing display.

Wiring to front facing terminal strips.

5395-00 NEMA-7 Explosion Proof Enclosure

with screw in window for viewing of

display and external switches for

operation of keypad. Wiring to side

facing panel.

Table 3-6

Sentry Enclosure Options

3.5.2 CONTROLLER MOUNTING

3.5.2.1 RACK MOUNTED CONTROLLER

The instrument rack should be installed in a 19" electronic

cabinet at eye level. Care should be taken to avoid heat

from other instruments under the controller.

3.5.2.5 WIRING CONNECTIONS

Channel wiring connections at the controller (except

NEMA-4X) and at the module are made using a quick

connect terminal strip. Figure 3-7. The terminal can be

operated using an actuator (supplied in the system

accessory bag) or by pressing a small screwdriver into the

actuator slot.

It is important to understand that, because of multiplexed

communication, there is a difference between "channel"

numbers and "module" numbers. Channels are the physical

connectors at the controller. Module numbers are the

switched addresses on each module. More than one

module number may be installed on a channel, up to a

maximum of four modules.

NOTE

Installation and wiring must be in accordance with the

National Electrical Code

Make the following connections at the controller.:

• Attach the three wires for each channel to separate

channel connectors on the terminal strip marked CH1

through CH8. The sequence should exactly match that

at the sensor assembly. (Typical: White 1, Black 2,

Green 3.)

INSTALLATION

Page: 19

Page 26

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

• Connect the necessary remote audible and visual

alarms or other process control equipment to the

"HIGH", "LOW" and "TROUBLE" dry contact relays on

the connector panel.

The Double Pole/Double Throw (DPDT) relay

connections are marked to indicate Normally Open

(N/O) , Normally Closed (N/C) and Common (COM)

terminals for each pole. No voltage is applied to the

terminals internally.

Typical wiring configuration is described in Figure

3-11. The trouble relay is fail safe so that it will

switch from Normally Closed to Normally Open if all

system power is lost.

NOTE

It may be preferably to delay wiring the alarms, or delay

powering them, until the detection system has been fully

activated, tested and calibrated.

Connect 120 volts AC wiring to the terminals marked Hot

(black), Neutral (white), and Ground (Green).

If a 12-28 VDC supply is to be used as either back-up or as

the primary operating voltage make the necessary

connections to the terminal marked "DC INPUT 12 - 28V"

"+" (Red) & "-" (Black).

NOTE

When a battery is to be used for back-up DC supply only,

a Sentry feature provides protection against battery

damage by shutting off the battery before complete

discharge. When this feature is used, the Sentry

controller can only be restarted by AC voltage.

To implement the battery protection feature, two red

jumper wires located on the power supply board must be

cut. See Figure 7-3.

If splice boxes are used to combine multiple modules on a

channel the splice connections should be made using a

terminal block/wire lug assembly or all wires should be

soldered and insulated. Figure 3-5.

3.5.3 ALARM DEVICE INSTALLATION

Alarm devices must be installed according to the

manufacturer's instructions for the particular device.

Sentry dry contact relays provide switching capability as

rated in the specifications. (See Appendix A.)

NOTE

Certain warning strobes have a very high peak current

which is dependent upon the phase angle of the AC line at

the precise moment the strobe is switched on. A high

current at the time of switching may cause the relay

contacts to stick together.

The corrective action to avoid contacts sticking together is

to install a 10 Ohm, 5 Watt resistor in series with the

strobe power, preferably close to the relay.

3.5.4 RELAY OUTPUTS

Three relays on the standard Sentry controller are for: high

alarm, low alarm and trouble. The trouble relay is

normally energized (power applied to coil). The gas alarm

relays (high and low) are normally not energized.

Individual low and high alarm relays are optional

hardware.

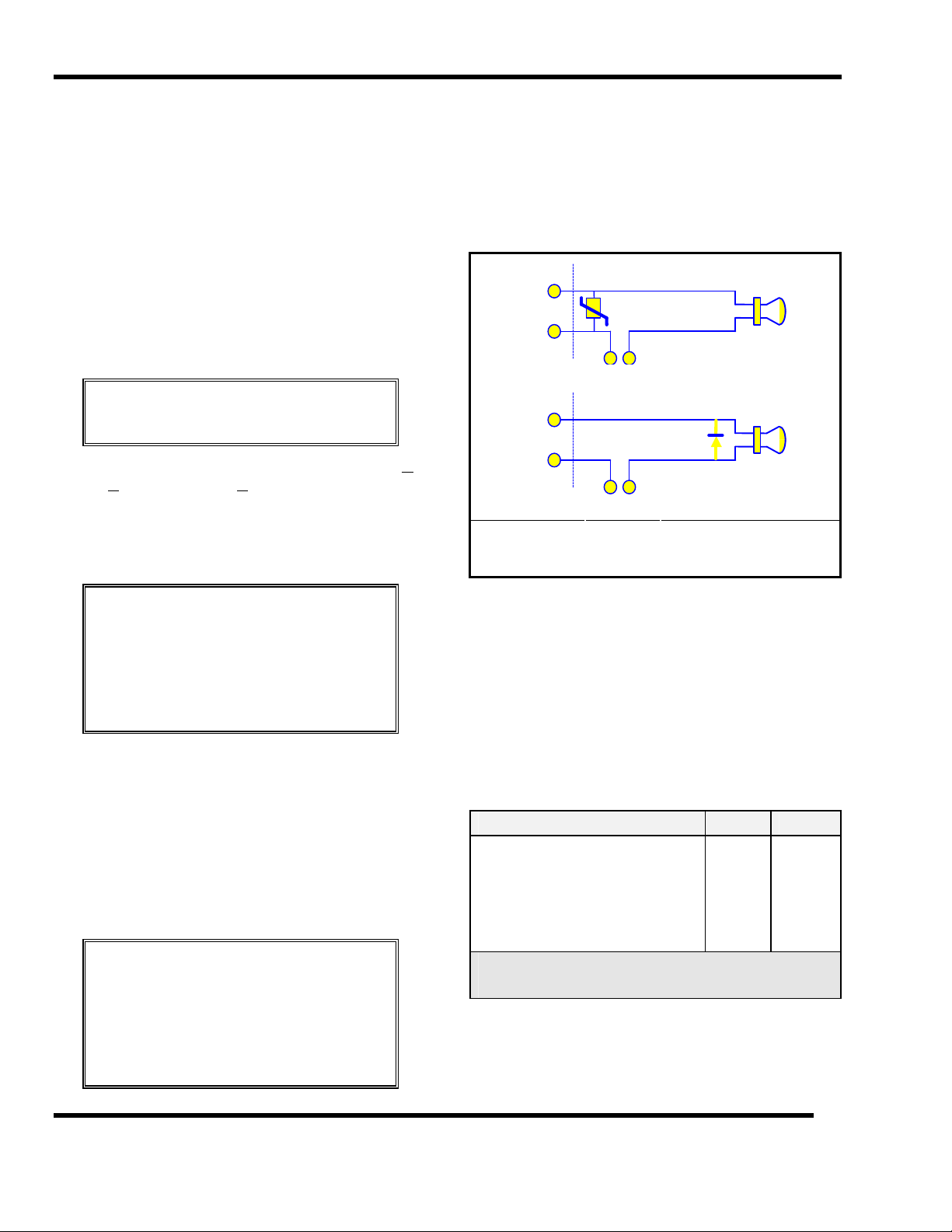

NO

RELAY

COM.

110 VAC

NO

RELAY

COM.

+ -

MOV

1N4005

DC

Install MOV

close to switch

Install diode

close to load

Figure 3-1

Typical Protection Circuit

The relays are dry contact and may be used to actuate bells,

lights, sirens, solenoid valves, or contactors as required. It

is recommended that for 120 VAC circuits a metal oxide

varistor (MOV) rated for 150 Vrms be place across the

load (Figure 3-1). (General Electric V150LA20A or

equivalent). For DC circuits a general purpose rectifier

diode should be placed across the load (1N4005).

3.5.5 DC POWER LOAD

Table 3-7 is provided to allow correct sizing of battery

back-up. To determine total load add the applicable

individual loads. (All measurements are at 12 VDC.)

Test Condition Amps Watts

Controller, No Sensors, No Alarms 0.560 6.7

Controller, No Sensors, All Alarms 0.660 8.0

Controller, 8 Combust, All Alarms 4.000 48.0

Individual Relay Board 0.750 9.3

Hydrogen Sulfide (Type 1) Module 0.260 3.1

Combustible (Type 2) Module 0.420 5.0

Electrochemical Sensor (typical) 0.050 0.6

Table 3-7

Sentry Power Load

INSTALLATION

Page: 20

Page 27

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

3.5.6 POWER UP

Systems shipped complete from the factory are preconfigured and calibrated. When power is turned on the

power light will start flashing and the alpha-numeric

display will indicate "SYSTEM WARM-UP" "PLEASE WAIT

MM:SS" (where MM:SS is a five minute count-down

clock). When the warm-up ends the two displays will

begin functioning in the "continuous scan" mode which is

described in the next chapter. The large display will cycle

through each module number for any modules which have

been installed.

If modules have been added to the system since it was

factory configured, those modules will have a blank (“—“)

concentration display and the lower display will show the

module type and units with "FACTOR MISSING" or

"UNCALIBRATED" messages.

If the display indicates module numbers which match the

numbers used in installation, the wiring is correct and

module configuration can begin. If any number is omitted

the controller is not recognizing that module and the wiring

should be checked for errors (the system will display "NO

MODULE" when any attempt is made to obtain information

on that module).

If the controller does not recognize any modules the

display will read "NO MODULES INSTALLED".

NOTE

On 2 and 4 Channel systems any module set with a

number higher than four will cause the lower display to

indicate "MODULE # MUST BE 1 THROUGH 4" and

the upper display to display "#E --" (where # = the

erroneous module number).

3.5.7 POWER DOWN

If it is necessary to remove the power all operator

configured data and parameters will be saved by Sentry. (It

is important to turn off the main power prior to

disconnection of any module wiring because while under

power Sentry will interpret certain changes as errors.)

INSTALLATION

Page: 21

Page 28

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

Figure 3-2

Controller Mounting Options

Page: 22

Page 29

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

Figure 3-3

Sensor Module Mounting

Page: 23

Page 30

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

Figure 3-4

Wiring Options

Page: 24

Page 31

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

Figure 3-5

Typical Splice Box Wiring

Page: 25

Page 32

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

Figure 3-6

Sensor Module Cross Section

Page: 26

Page 33

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

Figure 3-7

Sensor Module Connector Detail

Page: 27

Page 34

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

Figure 3-8

Sensor Module Top Plate Detail - Typical

Page: 28

Page 35

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

Figure 3-9

Controller Connector Panel - Rack Configuration

Page: 29

Page 36

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

Figure 3-10

Controller Connector Panel - NEMA-4X Configuration

Page: 30

Page 37

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

Figure 3-11

Typical Alarm Wiring Configuration

Page: 31

Page 38

Page 39

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

4. CONFIGURATION PROCEDURE

4.1 INTRODUCTION

Sentry is operated via the seven keys on the front panel.

Operation includes initial set-up, periodic calibration,

recall of history, and changes to configuration.

Certain procedure and message conventions are used to

provide consistency. A knowledge of these conventions

will aid in understanding of the set-up and operation steps.

The UP and DOWN arrow keys change information

displayed on the alpha-numeric (lower) display. Changes

made by using the arrows are not "implemented" until the

ENTER key is pressed.

The ENTER key is used to access the selected activity or to

enter selected data or status information into the controller

memory.

When any of the four activity keys TEST, RESET, TIME,

MODE are depressed the SENSOR/LEVEL display is

cleared and the activity information is displayed on the

alpha-numeric display.

The messages PRESS ENTER TO or ENTER TO indicate that

the selected activity can be accessed via the ENTER key.

If the ENTER key is pressed once during normal operation

the display locks onto the current module number and can

be advanced using the UP and DOWN arrow keys. When

the display is locked onto one module number the gas type

and units display is shown in round parenthesis “( )”.

If any module is force calibrated, the gas type and units

display for that module number is shown in square

parenthesis “[ ]”.

The message USE ARROWS/ENTER indicates that the

arrows can be used to change the module number or other

data on the second line and the ENTER can be used to

access the selected activity or module number.

Successive presses of any one of the four activity keys

will cycle through each option available and will return

the system to the normal operating mode..

When any activity key cycle has been started and not

completed the remaining activity keys are disabled except

that the RESET key can be used to return the system to

normal OPERATE mode.

When the system is in the CHANGE mode the CALIBRATE

OR CHANGE light is ON.

4.2 START-UP PREPARATION

The worksheet, Figure 4-1, will aid in understanding the

type of information required to set-up the system, it

should be completed prior to system power-up.

The message USE ARROWS/ENTER indicates that module

numbers or other variables can be changed with the

arrows prior to entering the activity with the ENTER key.

The message PRESENT CONFIG is used in system

responses during CHECK activities. Variables displayed

as PRESENT CONFIG can be changed via the CHANGE

mode.

Positive response messages such as SYSTEM RESET

COMPLETE are displayed for 1.5 seconds to confirm that

the activity has been completed.

Activity names are displayed bracketed by "<" and ">"

signs.

Normal operation is the condition where the change and

calibrate light is off and the display cycles continuously

between all active module numbers.

CONFIGURATION PROCEDURE

Page: 33

Page 40

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

MODULE

ADDRESS

1

2

3

4

5

6

7

8

LOCATION SENTRY

CHANNEL

GAS

TYPE

LOW HIGH LATCH SCALING

FACTORS

SENSOR

SERIAL #

Figure 4-1

System Configuration Worksheet

NOTES

1 Module Address Dip switch setting for each sensor module

2 Location Describe the physical location of the module

3 Sentry Channel Log the channel number to which the module is wired

4 Gas Log the name of the gas which is to be detected

5 Low Alarm Enter the value for the low alarm

Default values are: H2S: 10 PPM, Combustible 20% LEL, Oxygen 19.5%, Toxic 10 PPM

6 High Alarm Enter the value for the high alarm

Default values are: H2S: 20 PPM, Combustible 60% LEL, Oxygen 16.5%, Toxic 20 PPM

Note: Combustible Alarms cannot be set greater than 60% LEL.

7. Latch L?/H? Determine if any module will require a latching alarm and write "Y" in the appropriate

position (e.g.: N/Y indicates a non-latching low alarm and latching high alarm, Y/Y

indicates both relays will be latching). The system "defaults are N/Y.

Note: Combustible High Alarms are Latching Only

8 Factors For H2S (5100-01): Record the three (three digit) numbers which are written on the sensor

connector on each sensor.

For Combustibles: If the gas to be detected and the gas to be used for calibration are the

same write "100".

If the calibration gas is methane and a different gas is to be detected select the correct factor

from XXXXX.

Note: Combustible Gas Scaling Factors are not FMRC approved.

No factors are required for Oxygen or Toxic sensors.

9 Sensor Serial Number Record the serial number from the label on the connector of each sensor

CONFIGURATION PROCEDURE

Page: 34

Page 41

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

4.3 CONFIGURATION INSTRUCTIONS

Sentry controllers which are components of complete systems

are factory configured and generally do not require changes

prior to being placed in service.

Sentry controllers which have not been factory configured can

be placed into operation with default values for all configuration

parameters by using the diagnostic code “0021” described in

Section 8.3 of this manual.

The following are step-by-step configuration instructions which

can be used to customize the operation of the controller for

specific applications. After initial configuration the controller

can be placed in service or used for training as described in the

this section.

If an error is made, or suspected, press the RESET key until the

display reads <RESET SYSTEM> and then press the ENTER

key, the system will reset and the set-up routine can be restarted.

STEP KEY LOWER DISPLAY

1 RESET <RESET ALARMS>

2 RESET <RESET SYSTEM>

3 ENTER SYSTEM RESET COMPLETE

<UNCALIBRATED>

Displays continue cycling through each

module number. Power light changes from

flashing to solid.

4 MODE <CALIB/CHANGE>

5 ENTER CHANGE MODE SELECTED

Note that if a user entry code has been

initiated it must be input here.

Change/Calibrate light turns on.

READ INSTRUCTION MANUAL FIRST

PRESS ENTER TO CALIB ALL [GGGG]

Where GGGG is the gas type.

6 MODE <CHANGE CALIB>

7 MODE <CHANGE MODULE>

STEP KEY LOWER DISPLAY

15 ENTER FACTOR = 100

Linearizing factors are required for sensor

modules 5100-01 (H2S) .

Scaling factors can be used for sensor

module 5100-02 (Combustibles)

16 ENTER MODULE # = 2

Repeat steps 9 through 15 for each module.

17 MODE <SET USER CODE>

18 MODE <CHANGE PRINTER>

or

<CHANGE MODBUS>

Displays only if printer or MODBUS

option is installed.

19 MODE CHANGE GAS TAG

20 MODE CHANGE MOD TAG

21 MODE CHANGE ENG UNITS

22 MODE <OPERATE MODE>

23 ENTER OPERATE MODE SELECTED

24 TIME <CHECK HISTORY>

25 TIME <HISTORY REPORT>

For printer option only.

26 TIME <SYSTEM REPORT>

For printer option only.

27 TIME <STATUS REPORT>

For printer option only.

28 TIME <SET DATE & TIME>

29 ENTER D&T MM/DD HH:MM

Set each digit using the arrows, then

ENTER to advance to the next digit.

28 RESET H2S PPM

Display will scan through all active gas

sensor modules.

8 ENTER USE ARROWS/ENTER

MODULE # = 1

9 ENTER GAS TYPE : GGGG

10 ENTER # 1 GGGG IS: ON

11 ENTER LO ALM: NONLATCH

Use arrows to change.

12 ENTER HI ALM: LATCH

Use arrows to change.

13 ENTER HIGH ALARM = XX

Use arrows to change each digit.

14 ENTER LOW ALARM = XX

Use arrows to change each digit.

4.4 SENTRY TRAINING

After the controller is configured use this section in conjunction

with the Sentry MENU, Table 4-2, and Sentry

FLOWCHARTS, Figure 4-3 through Figure 4-7 to develop an

understanding of keyboard operation.

To begin, press the RESET key until the lower display reads

PRESS ENTER TO RESET SYSTEM then press ENTER.

The system is now in "normal operate mode". The Sensor/Level

display will cycle through each of the module numbers

(CONTINUOUS SCAN). If any module is indicated as

MODULE OFF use steps 9 through 15 of Section 4.3 to turn

that module ON.

CONFIGURATION PROCEDURE

Page: 35

Page 42

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

In NORMAL OPERATE mode Sentry scans all modules in

sequence and displays their current readings. For any

modules which are not correctly initiated and calibrated

the status will be indicated. This scanning sequence is by

module number by type. (Type 1 = H2S solid state, Type

2 = Combustible, Type 3 = Oxygen and Type 4 = all

others)

For H2S, Combustible and Toxic modules the upper

(Sensor/Level) display indicates the module number and

the concentration. The lower display shows the gas tag

and the engineering unit.

For Oxygen the upper display indicates the module

number and its deficiency status. The lower display will

read the oxygen concentration (e.g.: 20.9%).

Table 4-1 indicates display conditions for each module

type.

Type Gas/Status Upper Lower

1 H2S Normal 00 H2S PPM%

2 Combustible Normal 00 COMB* %LEL

3 Oxygen Normal 00 OXY 20.9%

3 Oxygen Below Normal LO OXY <20.7%

3 Oxygen Above Normal HI OXY >21.1%

4 Toxic Normal 00 TOXIC* PPM

* “COMB” and “TOXIC” gas tags can be modified to any six

character tag using CHANGE GAS TAGS.

Table 4-1

Display Conditions

CONTINUOUS SCAN is Sentry's default display mode. To

"lock" the display onto one module wait till that module is

displayed and press ENTER. While the "lock" is in effect

the arrows can be used to change to other module

numbers. The lock is indicated by "( )" around the top

line of the lower display. To return to CONTINUOUS SCAN

press ENTER.

Other user selectable display modes are described later in

this manual.

Press the TEST button, read the display, then press the

TEST button again. Repeat until the system returns to the

continuous scan display. The two test conditions which

are displayed are: <TEST SYSTEM> and <TEST ALARMS>.

Neither of these tests were implemented because the

ENTER key was not pressed.

Model number, software level, and traceability

descriptors.

MODEL 5000 VERS 6.3

8 CH 951234

Low Alarm Test with relays inactive.

RELAYS PASSIVE

TEST LOW ALARMS

High Alarm Test with relays inactive.

RELAYS PASSIVE

TEST HIGH ALARMS

Trouble Alarm Test with relays inactive.

RELAYS PASSIVE

TEST TROUBLE

ALARM

Full Display Test with all display segments and LED’s on.

X X X X X X X X X X X

X X X X X X X X X X X

Warm-up Time-out.

SYSTEM WARM-UP

PLEASE WAIT 5:00

Return to normal scan.

COMB %LEL

MODULE TAG

Press the TEST key twice and the display will read TEST

ALARMS. Press the ENTER key and Sentry will execute

LOW, HIGH & TROUBLE alarms and then return to the

operate mode. During this test the respective alarm relays

will throw. The user code described later in this manual

can be used to protect against unauthorized activation of

the alarm relays.

Read the Sentry menu, Table 4-2 to find the TEST key. It

should now be easy to understand that each step in the

menu can be implemented by using the enter key or

bypassed by continuing to press the activity key. This

process is further described in the flowcharts. Figure 4-3

through Figure 4-7.

To implement the tests, press the TEST key once; display

will read <TEST SYSTEM>. Press the ENTER key. Sentry

will then step through the following series of displays:

CONFIGURATION PROCEDURE

Page: 36

Page 43

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

4.5 SENTRY MENU

Table 4-2 describes the primary activities that can be accessed

via the Sentry keyboard. Each activity which involves submenu selection is identified by an asterisk Menu selections

which refer to printer are standard in eight channel systems,

optional in two and four channel systems. The MODBUS

option replaces Printer software.

Menu selections are further described in the following

paragraphs. Press the respective key to select the sub-routines

and press the ENTER key to access them. Follow the sequence

in the flow charts.

MENU KEYS

TEST RESET TIME MODE

SYSTEM ALARMS HISTORY CALIBRATE/

ALARMS SYSTEM PRINT HISTORY SELECT SCAN

HISTORY PRINT SYSTEM

REPORT

PRINT STATUS

REPORT

SET DATE &

TIME

CHANGE

CHECK CALIB

CHECK MODULE

CHECK PRINTER

− Lowest concentration LC with date and time

− Last Calibration with date and time.

− Last logged error with date and time (if applicable).

At the end of the sequence the display will indicate the next

module number and will continue to automatically increment as

the data is recalled. If the data from a particular module is not

required press the UP arrow to manually increment the number.

As this recall sequence is a continuous "loop", press the RESET

key at any time to return to the OPERATE MODE.

The history information may be collected on a continuous basis

without clearing the data because only the last occurrence of

each level will be retained. History data can be cleared by using

the RESET HISTORY menu selection. Error messages are

cleared by using the RESET SYSTEM menu selection.

4.5.2.2 PRINT HISTORY

PRESS ENTER TO

PRINT HISTORY

When the printer option is installed in Sentry this menu choice

can be used to print all the module history.

4.5.2.3 PRINT SYSTEM

Sentry Primary Menu Selection

Table 4-2

4.5.1 TEST KEY

The TEST KEY activities are described in the training exercise

in Section 4.4.

4.5.2 TIME KEY

4.5.2.1 CHECK HISTORY

PRESS ENTER TO

CHECK HISTORY

The first display in the CHECK HISTORY menu shows the

system clock date and time D/T on the first line. The second

line shows the date and time at which the history information

was last cleared HR.

The second display indicates the last time the power was

interrupted. PD is the Power Down time and PU is the Power

Up time. After any interruption of power to the controller the

POWER light will flash until the system is reset.

The third display begins the sequence in which the history for

any module can be recalled. The display will indicate

MODULE NUMBER 1. Successive presses of the ENTER

key will result in display of:

PRESS ENTER TO

PRINT SYSTEM

When the printer option is installed in Sentry this menu choice

can be used to print a complete system configuration report.

4.5.2.4 PRINT STATUS

PRESS ENTER TO

PRINT STATUS

When the printer option is installed in Sentry this menu choice

can be used to print a status report which indicates the present

status and concentration for each module.

− Date and time of the last low alarm LA and high alarm

HA

− Highest concentration HC with date and time

CONFIGURATION PROCEDURE

Page: 37

Page 44

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

4.5.2.5 SET DATE/TIME

PRESS ENTER TO

SET DATE & TIME

Set the Sentry clock in the same manner as any digital clock is

set. The format is MM/DD HH:MM, with the hours set in

military time (24 hours). If a user code has been set-up it will be

required prior to changing the clock. The cursor is initially

under the month MM, set the correct month with the arrow and

press ENTER to advance to the day DD. Repeat the process to

set day, hour and minute. When the time is correct, press

RESET to exit.

4.5.3 RESET KEY

4.5.3.1 RESET ALARMS

PRESS ENTER TO

RESET ALARMS

The RESET ALARMS activity will reset any latched alarm

relay when the condition which caused the alarm has been

corrected. If RESET ALARMS is selected before the

correction has been made, the respective LED and relay will

remain in the alarm condition.

4.5.3.2 RESET SYSTEM

PRESS ENTER TO

RESET SYSTEM

4.5.3.5 EXTERNAL RESET KEY

The external RESET key on NEMA units implements RESET

ALARMS and eliminates the need to open the enclosure for this

purpose.

4.5.4 MODE KEY - CALIB/CHANGE

The first menu choice under the MODE key is

CALIB/CHANGE when the ENTER key is pressed the

"Calibrate or Change" light will turn on and the display will

indicate ENTER TO CALIB (GAS TYPE) (SPAN VALUE).

After initial system set-up the CALIBRATE OR CHANGE

activity should be protected via the user access code described

in Section 7.3.4. When the user code has been installed only

authorized operators may access this activity.

4.5.4.1 CALIBRATE

ENTER TO CALIB

COMB 50% LEL

The calibration activity is described in detail in the next chapter.

4.5.4.2 CHANGE CALIB

PRESS ENTER TO

CHANGE CALIB

The change calibration activity is described in detail in the next

chapter.

The RESET SYSTEM activity wi ll reset all trouble conditions.

If the trouble still exists the condition will re-display

immediately. RESET SYSTEM can be used at any time to

return the system to normal operation and clear all error

messages.

4.5.3.3 RESET HISTORY

PRESS ENTER TO

RESET HISTORY

The RESET HISTORY activity clears all module history

information which is normally accessed via the TIME key. The

highest concentration is set to 00 and the lowest concentration is

set to HI. The history reset date/time is set to the current system

date/time. Sentry will immediately begin collecting new history

information. When a user code has been installed the code will

be required before the history can be reset.

4.5.3.4 OTHER USE OF RESET KEY

During CHANGE activity if the RESET key is pressed once

the display will return to its normal scan operation but the

CHANGE/CALIBRATE light will remain on. The MODE

key can then be used to return to configuration activities without

re-entering a user code. This action is helpful if module scan

information is required during a configuration step.

4.5.4.3 CHANGE MODULE

PRESS ENTER TO

CHANGE MODULE

Each module in the installation must be initialized via the

change module activity. The CHANGE MODULE activity is

detailed in step by step form in Section 4.3 steps 6 through 18.

The CHANGE MODULE activity should also be used after

any sensor or module has been replaced to insure that the correct

alarm limits and factors have been established.

CONFIGURATION PROCEDURE

Page: 38

Page 45

SMC sierra monitor corporation Sentry Instruction Manual - Version 6

4.6 SET USER CODE

PRESS ENTER TO

SET USER CODE

To avoid unauthorized access to the configuration activity the

USER CODE should be set as soon as the Sentry has been put

on line. User codes are described in Section 8.3. Special

diagnostic routines, also accessible via the user code, are

describe in the same section.

4.6.1.1 CHANGE PRINTER / MODBUS

PRESS ENTER TO

CHANGE PRINTER

CHANGE MODBUS

The CHANGE PRINTER or CHANGE MODBUS sub menu

will appear if printer or MODBUS software is installed on the

Sentry. Printer and MODBUS software is described in Section

8.5.

4.6.1.2 CHANGE GAS TAG

PRESS ENTER TO

CHANGE GAS TAG

The system default GAS TAG list contains eight common toxic

gas names. (CO, H2S, CL2, SO2, NO2, HCL, H2, NH3). The gas

tag names, and their corresponding engineering units can be

changed. At the menu prompt press ENTER and the first gas

tag will appear. Press ENTER to begin edit, or press ARROW

to select a different gas tag.

Edit the tag by pressing the ARROW unit the correct character

is selected, then ENTER to advance to the next character. The

gas tag allows six characters, the engineering units allow four

characters.

4.6.1.3 CHANGE MODULE TAG

PRESS ENTER TO:

CHANGE MOD

TAG

The system default MODULE TAGS are blank for all modules