Sentry Voyager 12V 60A, Voyager 12V 90A, Voyager 24V 60A, Voyager 24V 100A, Voyager 24V 40A Installation & Operation Manual

Page 1

MARINE BATTERY CHARGERS

Voyager Elite Series

Installation/ Operation

Linear Devices Corporation

dba Sentry

11126 Air Park Rd, Suite G

Ashland, VA 23005

December 2017

www.sentrychargers.com

Phone: 804-368-8428

Fax: 804-368-8438

Page 2

2

Table of Contents

Safety Precautions

3-4

Serial Number

4

Model Number

5

General Instructions

5

Installation Instructions

6

Connection Details

7-9

AC Cables and Circuit Breaker Sizing

10

DC Cables and Fuses

11-12

Setting Charging Curve and Battery Types

12-15

Operation of Battery Temp Sensor

16

LED Display Indicators

17

Mode and Display Operation

18

Fault Indicators and Description

19

Technical Specifications

20-22

Dimensions

23

Warranty

24

Page 3

3

SAFETY PRECAUTIONS

TO PREVENT ANY RISK OF ELECTRIC SHOCK OR FIRE, READ THIS MANUAL

CAREFULLY BEFORE INSTALLING THE EQUIPMENT.

This equipment is not designed for use by people (including children) with diminished

physical, sensory or mental capacities, or people without experience or knowledge of

such equipment, unless they have received prior instruction in the use of the equipment

from a person responsible for their safety or are under the supervision of such a person.

Ensure that children are supervised in order to prevent them playing with the device.

Warning: This equipment contains components that may cause electric arcs or sparks,

when connecting cables. To prevent any risk of fire or explosion, do not install this

equipment close to flammable materials, liquids or gases.

Installation precautions

To prevent any risk of irreversible damage to the equipment, ensure that you comply

with the following recommendations.

• This device must not be installed close to a heat source or any

flammable liquids or gases such as a gas engine room.

• It must not be installed in an airtight or poorly-ventilated

compartment.

• The ventilation inlets must not be obstructed.

• Clearance of at least 4” (10 cm) must be allowed around the housing to

guarantee adequate circulation.

• This device must not be exposed to running water, water spray and dust of any

kind.

• We recommend securing the device in a vertical position, with the cable outlet

pointing downwards.

• You are prohibited from making mechanical alterations to the housing,

including making additional holes, for example.

Connection Precautions

To prevent any risk of electric shock or irreversible damage to the equipment,

you should comply strictly with the following recommendations.

• The installation to which this device is connected must comply with any

applicable regulations such as ABYC.

• This device is designed to be connected to 220-240V 50/60Hz or 100-

120V 60Hz single phase circuits. 115V / 230V selection is automatic.

220-240V only for 24V, 80A, 100A version.

• The main power line must utilize a circuit breaker, to Protect individuals

against electric shocks. Refer to the device’s electrical specifications to select

the size and type of circuit breaker.

Prior to main power connection, the cable gland in the packaging must be assembled and

Page 4

4

correctly attached to the housing (using the nut provided), in the hole designed for this

purpose.

For safety reasons, the device’s EARTH Ground terminal (PE “Protective Earth” terminal),

must be connected to the system’s physical earth ground (yellow & green wire of the

main power). Refer to the wiring diagram for more information.

To prevent wire or terminal heating, ensure that the cable size is correct and the

connectors are properly tightened.

WARNING: This device is not Protected against battery polarity reversals. A battery

connection error automatically causes the battery fuses to blow as well as irreversible

damage to the circuit board.

Operational safety precautions

To prevent any risk of electric shock on activation or during operation, the Protective

cover must be correctly positioned and screwed into the housing.

This device complies with the applicable regulations governing transmitted interference

and immunity from external disturbances (see EMC paragraph in the Technical

specifications section).

When in operation, take particular care that this device is not subjected to conducted or

radiated interference at levels higher than the legal limits otherwise malfunctions may

occur (e.g.: device too close to a powerful transmitter).

This device transmits conducted and radiated interference at levels that comply with the

applicable regulations. Ensure that other sensitive equipment used in the vicinity is

compatible with this device otherwise malfunctions may occur.

Charger serial number

The serial number appears on the data plate label on one side of the device. This

number is aligned vertically and comprises a first number indicating the year of

manufacture (e.g.: 12 for 2012), a letter indicating the month of manufacture (e.g.: C for

the month of March).

Important note about charging curves

It is important to note that the use of an incorrect charging cycle for the

battery type may extensively impair or even damage the battery and/or charger.

This is particularly true for cycles where the charge voltages are higher than the

levels recommended by the battery manufacturers.

Example: A serious risk of overheating the batteries and releasing gases that are harmful

to users’ health or could cause an explosion.

Page 5

5

Curve no. 9 is compatible with a LiFeSo4 battery provided that the battery is equipped

with BMS-type battery Protection (Battery Management System) within the actual

battery. In this case, refer to the battery manufacturer’s recommendations for the

choice of charging cycle.

GENERAL INSTRUCTIONS

Maintenance precautions

To prevent any risk of electric shock during maintenance operations, ensure that the

following recommendations are studied carefully before performing any maintenance

on the device:

• All maintenance operations must only be carried out by a suitably

qualified technician.

• In the event of damage to the main power and/or batteries, these may only be

replaced by a qualified person, to avoid any danger.

• The main power supply must be disconnected (cable or

switch).

• The -DC or -BAT supply on the battery must also be disconnected to prevent

any transfer of power.

• To allow the high voltage capacitors to discharge (on the circuit board), wait

for 5 minutes before carrying out any work inside the housing.

• The fuses must be replaced by fuses with strictly identical characteristics and

performance levels.

Model Number

The model number can be determined by the following code:

SVE = Sentry Voyager Elite series

12 or 24 = DC Voltage Output

20, 40, 60… = DC Amp Output

/3 = 3 battery banks

X = 115/230vac or C = 230vac only

J = 50/60 Hz

CONTENTS OF THE BOX

RECEIPT OF THE PRODUCT

Contents of the packaging

The charger.

The user manual.

The main power cable gland and mounting nut (to be installed

Page 6

6

on the housing prior to connection).

The battery temperature sensor (24V100A version only)

Verify

Verify the Product’s data plate label, attached to one side of the Product, to ensure that

the technical details actually meet your needs (main supply voltage, charger capacity,

etc.).

INSTALLATION INSTRUCTIONS

The charger is attached using 4 x #8 (4mm Ø) screws (not supplied), to a secure

mounting frame or wall.

Ideally, the charger should be in a vertical position, with the cable outlet pointing

downwards. Clearance of at least 4” (10 cm) must be allowed around the device to

guarantee optimum convection, in particular along the sides allowing the air needed

for ventilation to flow in and out.

The circulation and convection direction of the air inside the charger is from right to left,

viewed from the front of the Product.

CONNECTIONS

Ventilation direction

Warm ←←← Cool

CONNECTIONS

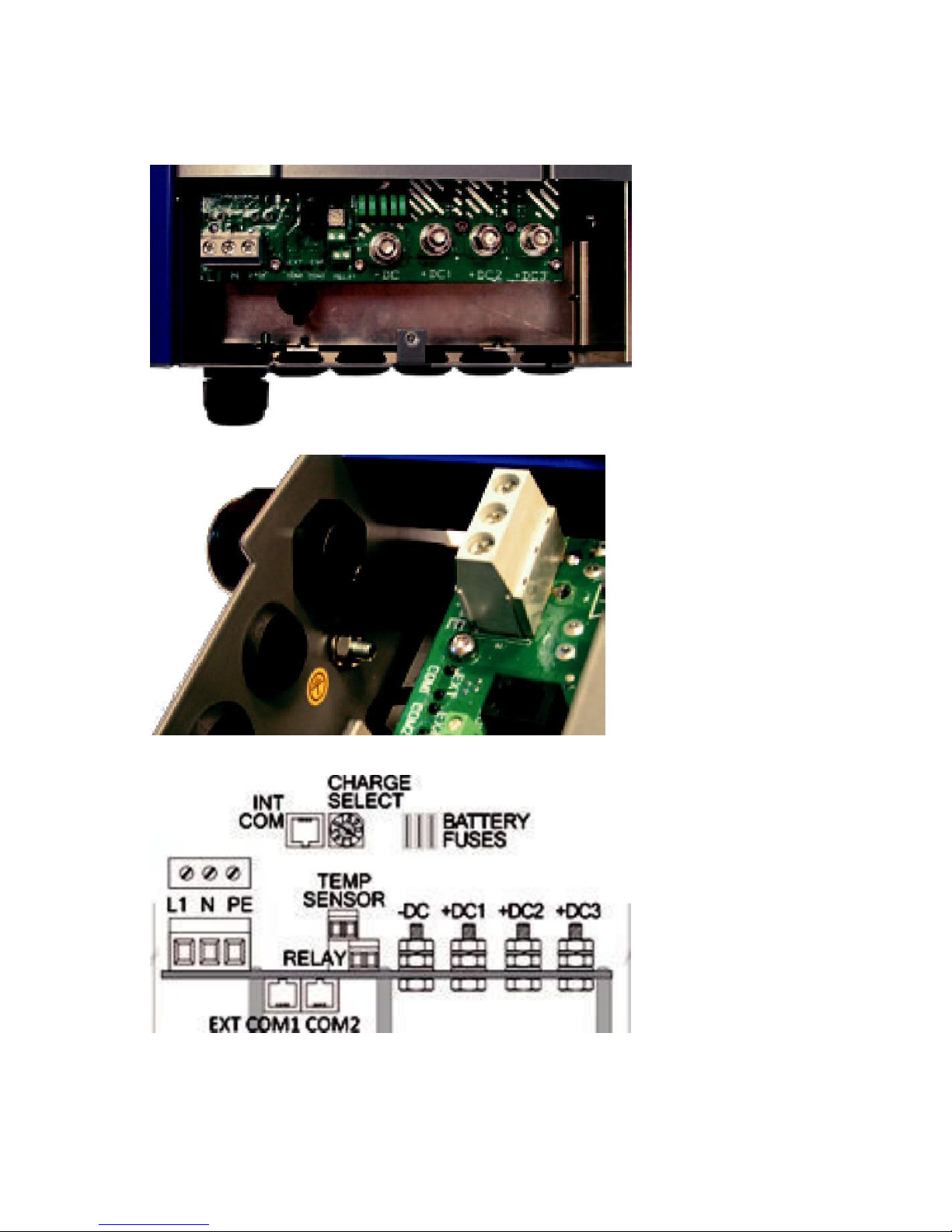

To gain access to the charger’s connections, the front cover must be removed. To do

this, simply unscrew the screw on the front cover. The cover is removed by rotating it.

Prior to making connections, the main power cable gland must be positioned and

attached to the housing in the hole designed for this purpose (hole on the left, when

viewed from the front of the charger).

The plastic nut supplied with the cable gland allows it to be attached to the housing.

This nut is positioned on the inside of the housing. Ensure the correct tightening torque

is applied.

Page 7

7

CONNECTION DETAILS

Page 8

8

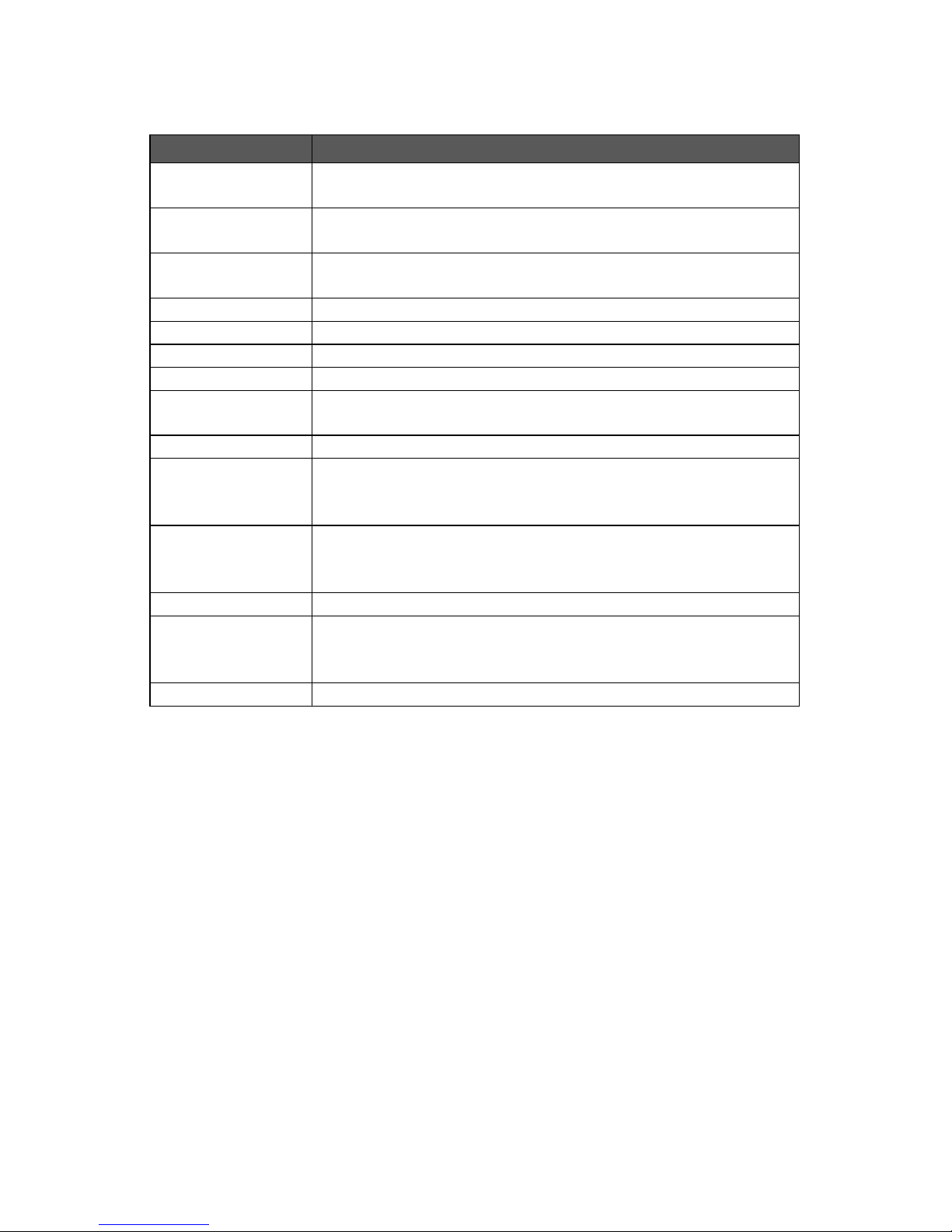

Marking

Description

L1

AC main, 8 AWG (10mm2) max (wire color code: brown or

black)

N/L2

AC neutral or L2, 8 AWG (10mm2) max (wire color code: blue,

white or red)

PE (Ground)

AC ground, 8 AWG (10mm2) max (wire color code: green &

yellow or green)

-DC

Battery negative (common), pin M8 (wire color code: black)

+ DC1

Main battery positive, pin M8 (wire code: red)

+ DC2

Auxiliary battery 2 positive, pin M8 (wire color code: red)

+ DC3

Auxiliary battery 3 positive, pin M8 (wire color code: red)

CHARGE

SELECT

Charge curve and battery charging mode selector, 10 positions

(from 0 to 9) (refer to curve settings p14)

BATTERY FUSES

Battery Protection fuses (on the –DC supply)

EXT COM 1

External communication bus (CAN bus)

(for an external digital display or communication between

chargers)

EXT COM 2

External communication bus (CAN bus)

(for an external digital display or communication between

chargers)

INT CoM

Communication bus for a digital display built into the charger

TEMP SENSOR

Battery temperature sensor (2 non-polarized wires, no

polarity)

Connect to the positive terminal of the main battery

RELAY

Dry alarm contact

Page 9

9

Example of connection on the basis of 3 distinct sets of

batteries

Important

Check for proper torque and crimp of connections and terminals.

Page 10

10

AC CABLES AND CIRCUIT BREAKER SIZING

AC wiring

Check the quality of connections and proper tightening of connections.

For main power, preferably use a HO7RNF-type industrial cable. Ensure that you

comply with the following recommendations.

Charger

220-240V AC 50/60Hz

100-120V AC 60Hz

capacity

Length < 5m (16ft)

Length < 5m (16ft)

12V

60A

2.5mm2 / AWG12

4mm2 / AWG10

12V

90A

2.5mm2 / AWG12

4mm2 / AWG10

24V

40A

2.5mm2 / AWG12

4mm2 / AWG10

24V

60A

2.5mm2 / AWG12

4mm2 / AWG10

24V

100A

4mm2 / AWG10

6mm2 / AWG8

The AC main power line must feature a cut-off device with differential

protection(GFCI), to specifically Protect individuals against electric shock.

The circuit breaker’s sensitivity must be 30mA. Its current capacities comply with

the charger’s power consumption. Comply with the following

recommendations in this respect.

Main power 220-

Main power 100-

Charger

240V 50/60Hz

120V 60Hz

capacity

12V

60A

8A – 30mA

16A – 30mA

12V

90A

8A – 30mA

16A – 30mA

24V

40A

8A – 30mA

16A – 30mA

24V

60A

10A – 30mA

20A – 20mA

24V

100A

20A – 30mA

-

Note: The charger has an internal Protection fuse on the L1 supply, in the event

of a general fault on the circuit board in particular. Due to the irreversible

nature of this fault, the fuse is not accessible for maintenance of any kind.

Page 11

11

DC CABLES AND FUSES

DC wiring

Check the quality of connections and Proper tightening of connections.

Battery cables must be as direct and short as possible.

Each battery output can Provide the charger’s full amperage and all the cables

must have identical cross-sections. Ensure that you comply with the following

recommended cross-sections.

Charger

Length < 2m (6ft)

Length between 3

capacity

and 5m (10 to 16ft)

12V

60A

25mm2 / AWG3

35mm2 / AWG2

12V

90A

35mm2 / AWG2

50mm2 / AWG0-1

24V

40A

16mm2 / AWG5

20mm2 / AWG4

24V

60A

25mm2 / AWG3

35mm2 / AWG2

24V

100A

35mm2 / AWG2

50mm2 / AWG0-1

These chargers are equipped with airtight grommets with

“automatic” opening.

Simply pressing the center section of the membrane is sufficient to allow

the cable to pass through the grommet.

Page 12

12

DC fuses

When maintaining the charger’s internal fuses, these must be replaced by fuses with

strictly identical characteristics and performance levels. Risks of irreversible damage

to the equipment.

It is essential and highly recommended that you install, as close as possible to each

positive output on the battery, a fuse to Protect connections, specifically in the

event of a short circuit and/or overheating of the battery cables, as the result of

damage to the Protective sleeves, for example.

Internal charger

External battery

Charger

fuse fuse

capacity

(+BAT supply for

(–DC supply)

each battery)

12V

60A

3 x 25A 32V rapid

80A 32V rapid

(mini automotive fuse)

12V

90A

4 x 30A 32V rapid

100A 32V rapid

(mini automotive fuse)

24V

40A

3 x 25A 32V rapid

60A 32V rapid

(mini automotive fuse)

3 x 25A 32V rapid

24V

60A

(mini automotive fuse)

80A 32V rapid

24V

100A

5 x 30A 32V rapid

150A 32V rapid

(mini automotive fuse)

CHARGE CURVE SELECTION

The digital electronics, based on an RSC microcontroller,

monitor the charging process by optimizing, the voltage,

current and recharging time parameters. This is based on

the initial charge level of the batteries, using the

exclusive “scanning charge” function.

Page 13

13

The performance and usable life of batteries are thereby maximized.

By virtue of fully automated charging cycles, the batteries are protected against

surges, providing a permanent connection for the charger.

Selection of the charging Program takes place on installation using the

“CHARGE SELECT” dial on the charger board.

The position of the arrow indicates the number of the Program selected (e.g.:

Program No. 1 in the photograph above). Selection is made using a small flathead screwdriver.

CAUTION

It is important to note that the use of an inappropriate charging cycle for

the battery technology may extensively impair or even damage the

latter.

This is particularly true for cycles where charge voltages are higher than the

levels recommended by the battery manufacturers.

A serious risk of overheating the batteries and releasing gases that are

harmful to users’ health.

Curve no. 9 is compatible with a LiFeSo4 battery, provided that the battery is

equipped with BMS-type battery Protection (Battery Management System)

within the actual battery. In this case, refer to the battery manufacturer’s

recommendations for the choice of charging cycle.

Page 14

14

CHARGER CURVE SETTINGS

CURVE BAT TYPE

PHASE

12V

24V

0

Open

V. BOOST

14.4V

28.8V

Lead

V. FLOAT

13.2V

26.4V

1

Sealed

V. BOOST

14.2V

28.4V

lead

V. FLOAT

13.6V

27.2V

2

Lead

V. BOOST

14.8V

29.6V

calcium

V. FLOAT

13.8V

27.6V

3

«Delphi»

V. BOOST

15.4V

30.8V

type

V. FLOAT

13.8V

27.6V

Charge

curve

«Op-

V. BOOST

14.8V

29.6V

4

tima»

V. MAX

15.5V

31.0V

type

V. FLOAT

13.8V

27.6V

Charge

curve

Winter

5

V. BOOST

14.4V

28.8V

Open

V. FLOAT

13.2V

26.4V

lead

Charge

curve

Page 15

15

Winter

6

V. BOOST

14.2V

28.4V

Sealed

V. FLOAT

13.6V

27.2V

lead

Charge

curve

7

GEL &

V. BOOST

14.4V

28.8V

AGM

V. FLOAT

13.8V

27.6V

Charge

curve

8

Power

V. FLOAT

13.6V

27.2V

supply

Charge

curve

LiFeSo4

9

+ inte-

V. FLOAT

14.4V

28.8V

grated

BMS

Charge

curve

Page 16

16

OPERATION of BATTERY TEMPERATURE SENSOR

The temperature sensor allows the charging voltage to be

automatically adjusted depending on the battery and ambient

temperature.

This function increases battery life, by reducing output voltage and current

due to high ambient and/or battery temperature.

This sensor is screwed onto the main battery’s positive terminal (a

service/house battery as a general rule). The 2 wires are connected to the

“TEMP SENSOR” connector on the charger board (not polarity sensitive).

The compensation level is around

+/-25mV per °C for a 24V battery and between +/-12mV per °C for a 12V

battery (see curves below).

Reference voltage

Battery temperature in °C

The temperature sensor initially simulates a temperature of 77⁰F (25°C). The action of the

battery temperature sensor allows the charge to be adjusted, upwards or downwards,

depending on the battery temperature, i.e.:

+/- 15 mV per °C at 12 V

+/- 30 mV per °C at 24 V

Page 17

17

LED DISPLAY

The Voyager Elite charger is equipped with a local multifunction LED display,

which, among other things, shows the details of the key stages of the battery

charging process.

BOOST phase: The battery is in its recharging phase, reaching a level of charge of

close to 80%. This recharging phase is limited to a period of

6 hours.

ABSORPTION phase: The voltage is maintained and the amperage is reduced

until the battery returns to a level of charge approaching 100%. This phase is

limited to a period between 30 minutes and 4 hours, depending on the

battery’s initial charge level.

FLOAT phase: The voltage and the amperage are reduced to maintain the

battery at 100% full charge. During the Floating phase, the charger only delivers

what the battery requires to prevent overcharging.

Fault Indicators: The Temperature (TEMP), Battery (BAT) and fuse (FUSE) fault

indicators are shown on the LED display.

Screen

Page 18

18

Mode and display operation

MODE

DESCRIPTION

SOLID LED

FLASHING

LED

Charger powered

All LEDs

on and/or Chan-

INITIALIZATION

for 3

-

ge of charging

cycle

seconds

Batteries in

POWER ON

BOOST

charging phase

-

PHASE

(charge from 0 to

BOOST

80%)

Batteries in

POWER ON

charging phase

-

ABSORPTION/

EQUALIZATION

(charge from 80%

ABS

to 100%)

PHASE

End of the equali-

zation cycle within

POWER ON

ABS

a period of 30

minutes

FLOATING

Charging cycle

POWER ON

completed

-

PHASE

(charge at 100%)

FLOAT

Main voltage

fault, excessively

high or abnormally

MAIN

Low voltage

POWER

VOLTAGE

-

Immediate auto-

ON

FAULT

matic restart,

subject to

disappearance of

the fault

Excessive charger

temperature fault

CHARGER

Automatic restart

after a

TEMPERATURE

TEMP

-

min delay

FAULT (TEMP)

for 30 seconds,

subject to

disappearance of

the fault

Page 19

19

MODE

DESCRIPTION

SOLID LED

FLASHING

LED

Excessive battery

temperature fault

BATTERY

Automatic restart

TEMPERATURE

after a min delay

-

TEMP

FAULT

for 30 seconds,

subject to

disappearance of

the fault

External tempera-

ture sensor fault

BATTERY

Automatic restart

TEMP

SENSOR

after a min delay

-

FAULT

for 30 seconds,

BAT

subject to

disappearance of

the fault

Charging voltage

fault, excessively

high or abnormally

low

OUTPUT

VOLTAGE

Automatic restart

BAT

-

FAULT

after a min delay

for 60 seconds,

subject to

disappearance of

the fault

Output fuse fault

OUTPUT

Restart following

FUSES

a main reset,

FUSE

-

FAULT

subject to

disappearance of

the fault

CAN

CAN fault

TEMP

-

BAT

FAULT

secure load

FUSE

Page 20

20

Technical specifications

12V 60A

12V 90A

24V 40A

24V 60A

24V 10 0A

MAIN POWER CHARACTERISTICS

Main

100V-120V 60Hz and/or 220-240V 50/60Hz

220-240V

voltage

(+/-15%)

(+/-15%)

Power

typically 0.9

factor

Output

typically 83%

typically 87%

Inrush

< 60A

< 30A, limited by soft start

< 60A

current

Current

12A/5A

16A/7A

14A/6A

15A/9A

15A

Draw

Active

1200VA

1500VA

1350VA

2000VA

3500VA

power

70% of

Derating

Without derating

Pnom

-

@ 115V

(rated

power

Main

T16A

T20A

T20A

T20A

2xT20A

(6.3x32

(6.3x32

(6.3x32

(6.3x32

(6.3x32

fuse

mm)

mm)

mm)

mm)

mm)

BATTERY CHARGING CHARACTERISTICS

Number

of 3 independent supplies

outputs

Number

10 charging cycles (from 0 to 9), setting

of

by means of a dial

cycles

Charge

In general 3 status, type I.U.Uo

curves

Open

V.BOOST = 14.4V

V.BOOST = 28.8V

lead

V.FLOAT = 13.2V

V.FLOAT = 26.4V

Sealed

V.BOOST = 14.2V

V.BOOST = 28.4V

lead

V.FLOAT = 13.6V

V.FLOAT = 27.2V

Lead

V.BOOST = 14.8V

V.BOOST = 29.6V

calcium

V.FLOAT = 13.8V

V.FLOAT = 27.6V

«Delphi»

V.BOOST = 15.4V

V.BOOST = 30.8V

Type

V.FLOAT = 13.8V

V.FLOAT = 27.6V

«Op-

V.BOOST = 14.8V

V.BOOST = 29.6V then 31.0V

tima»

then15.5V

V.FLOAT = 27.6V

Type

V.FLOAT = 13.8V

Winter

Off Season

V.BOOST = 14.4V

V.BOOST = 28.8V

open

V.FLOAT = 13.2V

V.FLOAT = 26.4V

lead

Page 21

21

12V 60A

12V 90A

24V 40A

24V 60A

24V 10 0A

Winter

Off Season

V.BOOST = 14.2V

V.BOOST = 28.4V

Sealed

V.FLOAT = 13.6V

V.FLOAT = 27.2V

lead

Gel &

V.BOOST = 14.4V

V.BOOST = 28.8V

AGM

V.FLOAT = 13.8V

V.FLOAT = 27.6V

Power

V.FLOAT = 13.6V

V.FLOAT = 27.2V

supply

LifeSo4 +

integra-

V.FLOAT = 14.4V

V.FLOAT = 28.8V

ted

BMS

Tempe-

+/-12mV / °C

+/-25mV / °C

rature

(by an external

(by an external

compen-

sensor)

sensor)

sation

Voltage

tole-

+/-2%

rance

Ripple < 1% (BW < 20MHz)

Maxi-

60A

90A

40A

60A

100A

mum

(+/-5%)

(+/-5%)

(+/-5%)

(+/-5%)

(+/-5%)

current

3 x F30A

4 x F30A

5 x 30A

(minia-

(minia-

3 x F25A

(minia-

Supply

ture

ture

(miniature automo-

ture

fuse -DC

automo-

automo-

tive

automo-

tive

tive

fuse)

tive

fuse)

fuse)

fuse)

PROTECTION

Output

“Current limited” type

surge

Output

“Shutdown” type with automatic restart

short circuit

onc e the fault has disappeared

Excessive output

“Shutdown” type with automatic restart

voltage

onc e the fault has disappeared

Battery

polarity

Output fuse

reversal

Excessive

“Shutdown” type with automatic restart

internal

onc e the fault has disappeared

temperature

Page 22

22

12V 60A - 12V 90A

24V 100A

24V 40A - 24V 60A

HS

“Shutdown” type with automatic restart

temperature

onc e the fault has disappeared

sensor

General

main supply

Main fuse

fault

General

battery supply

Output fuses on –DC supply

fault

Circuit Board

Conformal Coated protection on

circuit board

Operating

14°F to +130°F

(-10°C to +55°C)

temperature

Storage

-4°F to +158°F

(-20°C to +70°C)

temperature

Humidity

10% to 90% (without condensation)

Convection

Forced by thermostat-controlled fan

Housing

Wall-m ounted housing in painte d

aluminium

Protection

IP20

rating

Mounting

Using 4 x #8 (4mm Ø) screws

Overall dimen-

125 x 340 x 360 mm

190x340x 360

sions (Depth x

4.9 x 13.4 x 14.2 inches

7.5x13.4x 14.2

Width x Height)

Weight 13.2lbs (6 Kg)

25.4lbs (11.5

kg)

EMC

EN55014-1

SAFETY

EN60335-2-29

Front LED display

Display

Main

3-point cage terminal for cables with a

connector

cross-section of 6AW G10mm2 max

Battery

M8 pins

connectors

Battery sensor

2-point cage terminal for cables with a

connector

cross-section of 16AWG1.5m m2 max

Alarm relay

2-point cage terminal for cables with a

connector

cross-section of 16AWG1.5m m2 max

External

CAN bus

2 x RJ11 connectors (CAN bus)

connectors

Page 23

23

Dimensions

12V 60A

12V 90A

24V 40A

24V 60A

24V 10 0A

Height A

14.2 inch (360 mm)

Width B

13.4 inch (340 mm)

Depth C

4.9 inch (125 mm)

(190 mm)

7.5 inch

Page 24

24

Warranty

TO PREVENT ANY RISK OF INCORRECT

USE OF THE CHARGER, CAREFULLY READ THE LIST OF POTENTIAL

SCENIROS OR FAULTS NOT COVERED BY THE PRODUCT WARRANTY

This device is not protected against battery polarity reversals. Risk of

irreversible damage to the equipment.

Should the device be dropped, this could cause irreversible distortion of the

housing as well as damaging internal fans and certain electronic components.

Modifications to the housing (additional holes in particular) could result in the

scattering of metal filings onto the circuit board and, consequently,

malfunctions or irreversible damage to the equipment.

Interference with or modifications to the circuit board could result in operating

modes not originally anticipated, and consequently, in malfunctions or

irreversible damage to the equipment.

Powering the device from an unsuitable power source (example: supply voltage

that is too high).

Accidental original main supply surge or lightning strike generally causes

irreversible damage to the equipment.

Replacement of fuses with fuses with different characteristics could

cause irreversible damage to the equipment.

Obvious connection errors causing irreversible damage to the equipment.

Water spray or running water inside the device could result in irreversible

electronic damage.

Precautions for disposal

This device contains electronic components and materials that must be recycled at

the end of the Product’s usable life for environmental reasons.

At the end of the devices usable life, all devices must be returned either to the

local distributor or properly disposed of.

EC compliance

This device complies with the applicable European standards and has a CE

mark. Its certificate of compliance is available on request.

Loading...

Loading...