Sentry Voyager 12V 60A,Voyager 12V 90A,Voyager 24V 60A,Voyager 24V 100A,Voyager 24V 40A Installation & Operation Manual

MARINE BATTERY CHARGERS

Voyager Elite Series

Installation/ Operation

Linear Devices Corporation

dba Sentry

11126 Air Park Rd, Suite G

Ashland, VA 23005

December 2017

www.sentrychargers.com

Phone: 804-368-8428

Fax: 804-368-8438

2

Table of Contents

Safety Precautions

3-4

Serial Number

4

Model Number

5

General Instructions

5

Installation Instructions

6

Connection Details

7-9

AC Cables and Circuit Breaker Sizing

10

DC Cables and Fuses

11-12

Setting Charging Curve and Battery Types

12-15

Operation of Battery Temp Sensor

16

LED Display Indicators

17

Mode and Display Operation

18

Fault Indicators and Description

19

Technical Specifications

20-22

Dimensions

23

Warranty

24

3

SAFETY PRECAUTIONS

TO PREVENT ANY RISK OF ELECTRIC SHOCK OR FIRE, READ THIS MANUAL

CAREFULLY BEFORE INSTALLING THE EQUIPMENT.

This equipment is not designed for use by people (including children) with diminished

physical, sensory or mental capacities, or people without experience or knowledge of

such equipment, unless they have received prior instruction in the use of the equipment

from a person responsible for their safety or are under the supervision of such a person.

Ensure that children are supervised in order to prevent them playing with the device.

Warning: This equipment contains components that may cause electric arcs or sparks,

when connecting cables. To prevent any risk of fire or explosion, do not install this

equipment close to flammable materials, liquids or gases.

Installation precautions

To prevent any risk of irreversible damage to the equipment, ensure that you comply

with the following recommendations.

• This device must not be installed close to a heat source or any

flammable liquids or gases such as a gas engine room.

• It must not be installed in an airtight or poorly-ventilated

compartment.

• The ventilation inlets must not be obstructed.

• Clearance of at least 4” (10 cm) must be allowed around the housing to

guarantee adequate circulation.

• This device must not be exposed to running water, water spray and dust of any

kind.

• We recommend securing the device in a vertical position, with the cable outlet

pointing downwards.

• You are prohibited from making mechanical alterations to the housing,

including making additional holes, for example.

Connection Precautions

To prevent any risk of electric shock or irreversible damage to the equipment,

you should comply strictly with the following recommendations.

• The installation to which this device is connected must comply with any

applicable regulations such as ABYC.

• This device is designed to be connected to 220-240V 50/60Hz or 100-

120V 60Hz single phase circuits. 115V / 230V selection is automatic.

220-240V only for 24V, 80A, 100A version.

• The main power line must utilize a circuit breaker, to Protect individuals

against electric shocks. Refer to the device’s electrical specifications to select

the size and type of circuit breaker.

Prior to main power connection, the cable gland in the packaging must be assembled and

4

correctly attached to the housing (using the nut provided), in the hole designed for this

purpose.

For safety reasons, the device’s EARTH Ground terminal (PE “Protective Earth” terminal),

must be connected to the system’s physical earth ground (yellow & green wire of the

main power). Refer to the wiring diagram for more information.

To prevent wire or terminal heating, ensure that the cable size is correct and the

connectors are properly tightened.

WARNING: This device is not Protected against battery polarity reversals. A battery

connection error automatically causes the battery fuses to blow as well as irreversible

damage to the circuit board.

Operational safety precautions

To prevent any risk of electric shock on activation or during operation, the Protective

cover must be correctly positioned and screwed into the housing.

This device complies with the applicable regulations governing transmitted interference

and immunity from external disturbances (see EMC paragraph in the Technical

specifications section).

When in operation, take particular care that this device is not subjected to conducted or

radiated interference at levels higher than the legal limits otherwise malfunctions may

occur (e.g.: device too close to a powerful transmitter).

This device transmits conducted and radiated interference at levels that comply with the

applicable regulations. Ensure that other sensitive equipment used in the vicinity is

compatible with this device otherwise malfunctions may occur.

Charger serial number

The serial number appears on the data plate label on one side of the device. This

number is aligned vertically and comprises a first number indicating the year of

manufacture (e.g.: 12 for 2012), a letter indicating the month of manufacture (e.g.: C for

the month of March).

Important note about charging curves

It is important to note that the use of an incorrect charging cycle for the

battery type may extensively impair or even damage the battery and/or charger.

This is particularly true for cycles where the charge voltages are higher than the

levels recommended by the battery manufacturers.

Example: A serious risk of overheating the batteries and releasing gases that are harmful

to users’ health or could cause an explosion.

5

Curve no. 9 is compatible with a LiFeSo4 battery provided that the battery is equipped

with BMS-type battery Protection (Battery Management System) within the actual

battery. In this case, refer to the battery manufacturer’s recommendations for the

choice of charging cycle.

GENERAL INSTRUCTIONS

Maintenance precautions

To prevent any risk of electric shock during maintenance operations, ensure that the

following recommendations are studied carefully before performing any maintenance

on the device:

• All maintenance operations must only be carried out by a suitably

qualified technician.

• In the event of damage to the main power and/or batteries, these may only be

replaced by a qualified person, to avoid any danger.

• The main power supply must be disconnected (cable or

switch).

• The -DC or -BAT supply on the battery must also be disconnected to prevent

any transfer of power.

• To allow the high voltage capacitors to discharge (on the circuit board), wait

for 5 minutes before carrying out any work inside the housing.

• The fuses must be replaced by fuses with strictly identical characteristics and

performance levels.

Model Number

The model number can be determined by the following code:

SVE = Sentry Voyager Elite series

12 or 24 = DC Voltage Output

20, 40, 60… = DC Amp Output

/3 = 3 battery banks

X = 115/230vac or C = 230vac only

J = 50/60 Hz

CONTENTS OF THE BOX

RECEIPT OF THE PRODUCT

Contents of the packaging

The charger.

The user manual.

The main power cable gland and mounting nut (to be installed

6

on the housing prior to connection).

The battery temperature sensor (24V100A version only)

Verify

Verify the Product’s data plate label, attached to one side of the Product, to ensure that

the technical details actually meet your needs (main supply voltage, charger capacity,

etc.).

INSTALLATION INSTRUCTIONS

The charger is attached using 4 x #8 (4mm Ø) screws (not supplied), to a secure

mounting frame or wall.

Ideally, the charger should be in a vertical position, with the cable outlet pointing

downwards. Clearance of at least 4” (10 cm) must be allowed around the device to

guarantee optimum convection, in particular along the sides allowing the air needed

for ventilation to flow in and out.

The circulation and convection direction of the air inside the charger is from right to left,

viewed from the front of the Product.

CONNECTIONS

Ventilation direction

Warm ←←← Cool

CONNECTIONS

To gain access to the charger’s connections, the front cover must be removed. To do

this, simply unscrew the screw on the front cover. The cover is removed by rotating it.

Prior to making connections, the main power cable gland must be positioned and

attached to the housing in the hole designed for this purpose (hole on the left, when

viewed from the front of the charger).

The plastic nut supplied with the cable gland allows it to be attached to the housing.

This nut is positioned on the inside of the housing. Ensure the correct tightening torque

is applied.

7

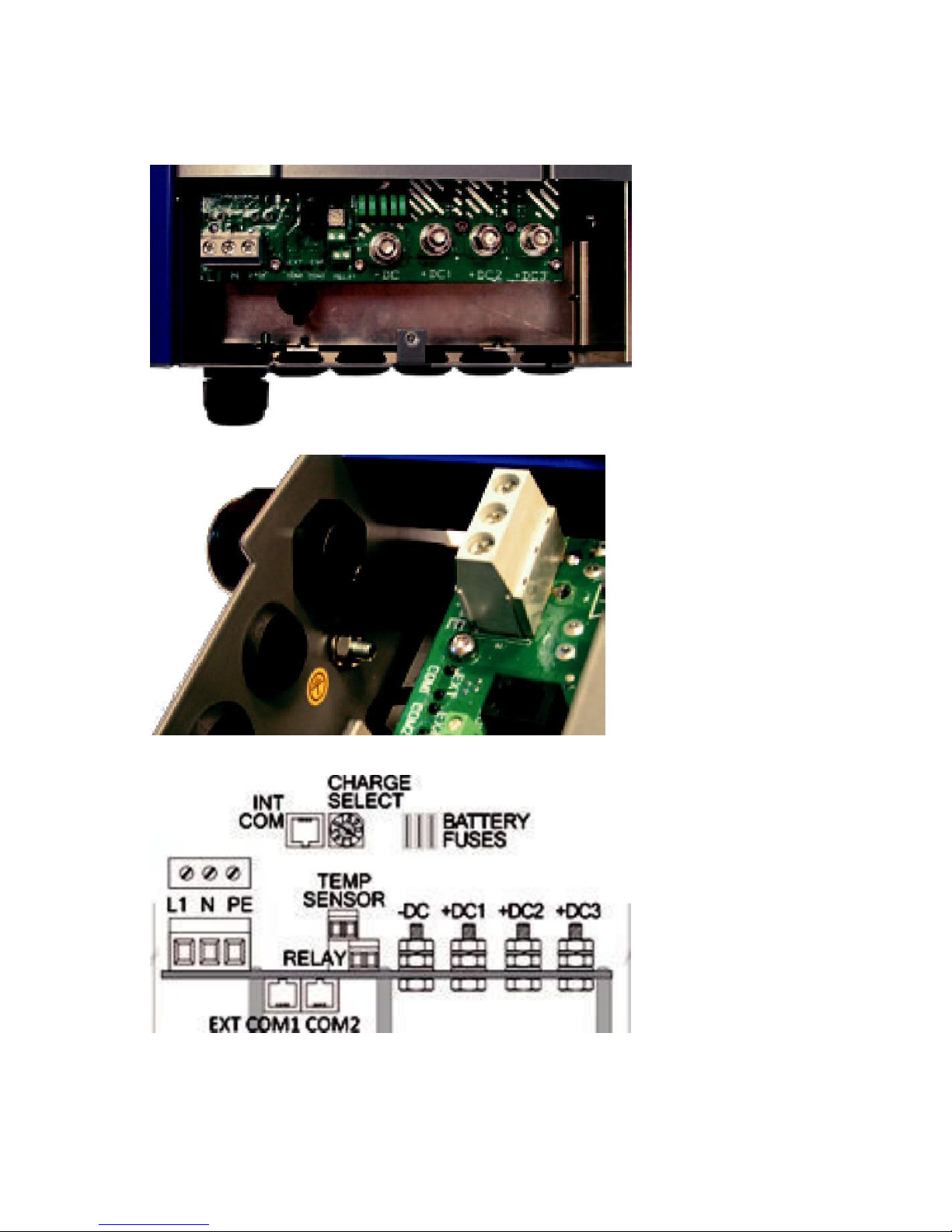

CONNECTION DETAILS

8

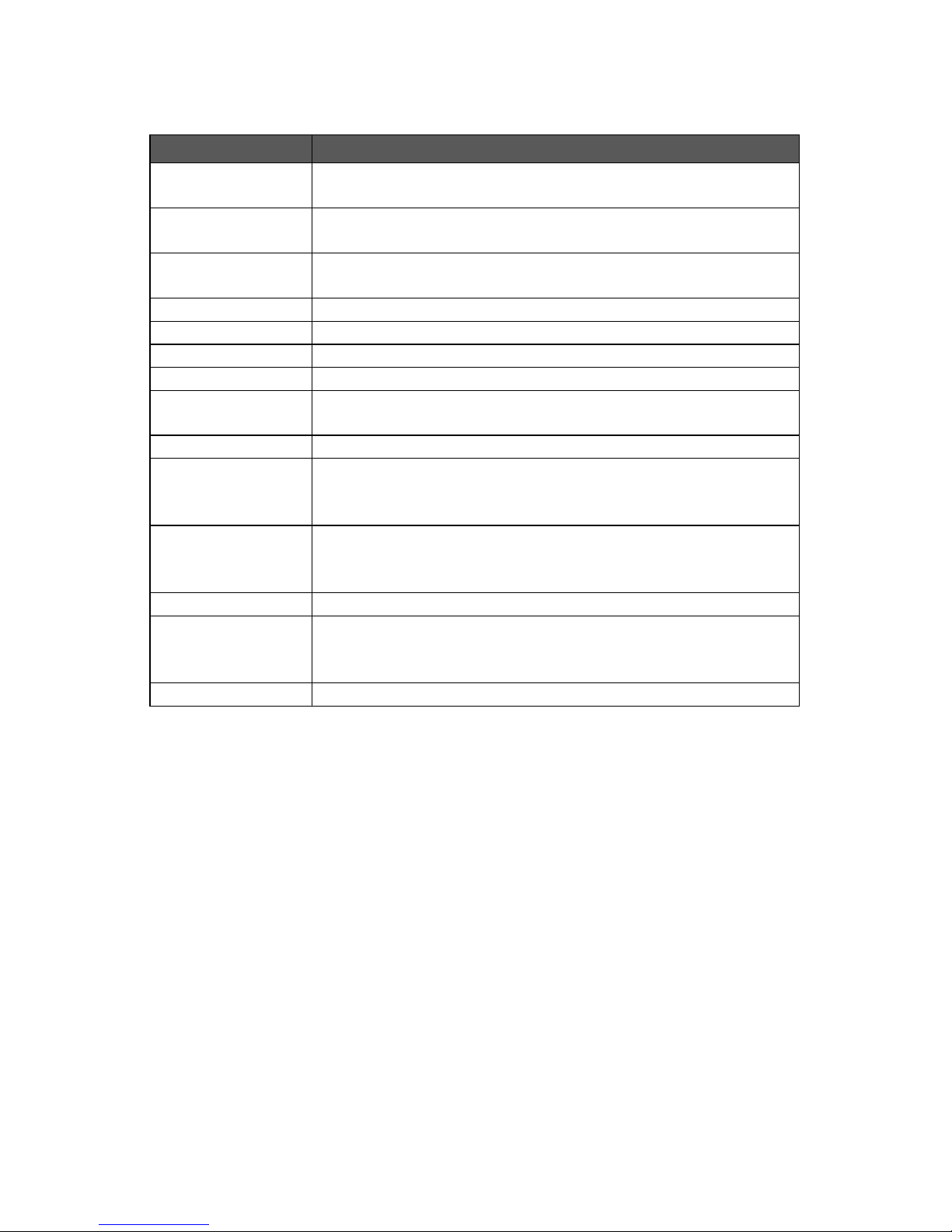

Marking

Description

L1

AC main, 8 AWG (10mm2) max (wire color code: brown or

black)

N/L2

AC neutral or L2, 8 AWG (10mm2) max (wire color code: blue,

white or red)

PE (Ground)

AC ground, 8 AWG (10mm2) max (wire color code: green &

yellow or green)

-DC

Battery negative (common), pin M8 (wire color code: black)

+ DC1

Main battery positive, pin M8 (wire code: red)

+ DC2

Auxiliary battery 2 positive, pin M8 (wire color code: red)

+ DC3

Auxiliary battery 3 positive, pin M8 (wire color code: red)

CHARGE

SELECT

Charge curve and battery charging mode selector, 10 positions

(from 0 to 9) (refer to curve settings p14)

BATTERY FUSES

Battery Protection fuses (on the –DC supply)

EXT COM 1

External communication bus (CAN bus)

(for an external digital display or communication between

chargers)

EXT COM 2

External communication bus (CAN bus)

(for an external digital display or communication between

chargers)

INT CoM

Communication bus for a digital display built into the charger

TEMP SENSOR

Battery temperature sensor (2 non-polarized wires, no

polarity)

Connect to the positive terminal of the main battery

RELAY

Dry alarm contact

Loading...

Loading...