Page 1

Sentry

AC Power Distribution Unit

- PTPD-V0, PTPD-H0

- PTPD-VE, PTPD-HE

Installation and Operations Manual

Page 2

Instructions

This symbol is intended to alert the user to the presence of important operating and maintenance (servicing)

instructions in the literature accompanying the appliance.

Dangerous Voltage

This symbol is intended to alert the user to the presence of un-insulated dangerous voltage within the product’s

enclosure that may be of sufficient magnitude to constitute a risk of electric shock to persons.

Protective Grounding Terminal

This symbol indicates a terminal that must be connected to earth ground prior to making any other connections to

the equipment.

Life-Support Policy

As a general policy, Server Technology does not recommend the use of any of its products in the following situations:

• life-support applications where failure or malfunction of the Server Technology product can be reasonably expected

to cause failure of the life-support device or to significantly affect its safety or effectiveness.

• direct patient care.

Server Technology will not knowingly sell its products for use in such applications unless it receives in writing assurances

satisfactory to Server Technology that:

• the risks of injury or damage have been minimized,

• the customer assumes all such risks, and

• the liability of Server Technology is adequately protected under the circumstances.

The term life-support device includes but is not limited to neonatal oxygen analyzers, nerve stimulators (whether used for

anesthesia, pain relief or other purposes), auto-transfusion devices, blood pumps, defibrillators, arrhythmia detectors and

alarms, pacemakers, hemodialysis systems, peritoneal dialysis systems, neonatal ventilator incubators, ventilators (for

adults or infants), anesthesia ventilators, infusion pumps, and any other devices designated as “critical” by the U.S. FDA.

Compliance

Units have been safety tested/certified to the following standards: USA and Canada to UL 60950:2000 and CAN/CSA

22.2 No. 60950-00, European Union to EN60950:2000

USA Notification

Warning: Changes or modifications to these units not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment under FCC rules.

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment is a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

Canadian Notification

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the

Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils

numériques de la classe A prescrites dans le Règlement sur le brouillage radioélectrique édicté par le Ministère des

Communications du Canada.

Japanese Notification

Page 3

Table of Contents

CHAPTER 1: INTRODUCTION 1

Features and Benefits ........................................................................................2

Quick Start Guide..............................................................................................2

CHAPTER 2: INSTALLATION 3

Standard Accessories.........................................................................................4

Additional Required Items ................................................................................4

Equipment Overview.........................................................................................4

Safety Precautions.............................................................................................5

Verify Input Voltage Selection (PTPD-VE18 models only).............................5

Mounting ...........................................................................................................6

Connecting to the Power Source .......................................................................6

Connecting Devices to the PTPD......................................................................7

Connecting to the PTPD (PTPD-x0 models only) ............................................7

CHAPTER 3: OPERATIONS (PTPD-X0 MODELS ONLY) 9

Interface...........................................................................................................10

Displaying the Control Screen ........................................................................10

Using the Control Screen ................................................................................10

CHAPTER 4: APPENDICES 13

Appendix A: Resetting to Factory Defaults ....................................................14

Appendix B: Verifying/Setting the Operational Voltage................................15

Appendix C: Technical Specifications............................................................16

Appendix D: Warranty, Product Registration and Support.............................20

Page 4

Page 5

Chapter 1: Introduction

FEATURES AND BENEFITS 2

Power Distribution ...........................................................................................................................2

Load Measurement...........................................................................................................................2

Over-Threshold Notification............................................................................................................2

Technical Support ............................................................................................................................2

QUICK START GUIDE 2

Page 6

Chapter 1: Introduction

The Server Technology Inc. Sentry family of products provides easy, practical, and secure solutions for

power distribution, power management and load-measurement for remote internetworking equipment

and branch AC circuits.

The Sentry Power Distribution Unit (PTPD) provides simple power distribution with cumulative load

monitoring for environments without a requirement for remote power management.

Features and Benefits

Sentry Power Distribution Units are available in 8-outlet, 16-outlet and 18-outlet configurations for

100-120VAC or 208-240VAC up to 30A. See Standard Models in Appendix C: Technical

Specifications.

Power Distribution

A Sentry Power Distribution Unit distributes a maximum of 30A AC power (dependant on PTPD

model) across a maximum of sixteen attached devices.

Load Measurement

The Sentry Power Distribution Unit’s load measurement feature eliminates guesswork by supplying the

cumulative operating load in amperes. This allows on-site technicians to maximize the equipment

installed and operated on a circuit without worry. Use of the circuit is maximized, while effectively

allowing a 10% to 20% safety margin. Remote users also may access this information at any time from

the Control Screen interface (Remote access not available on PTPD-xE models).

Over-Threshold Notification

Sentry Power Distribution Units features two standard over-threshold alarms; an audible alarm for the

local technician and a contact-closure alarm circuit which allows over-threshold alerts to be sent a third

party device (Not available on PTPD-xE models).

Technical Support

Server Technology understands that there are often questions when installing and/or using a new

product. Free Technical Support is provided from 8:30 AM to 5:00 PM, Monday-Friday, Pacific Time.

See Technical Support in Warranty, Product Registration and Support for more information.

Server Technology, Inc.

1040 Sandhill Drive Tel: 775.284.2000 Web: www.servertech.com

Reno, Nevada 89521 USA Fax: 775.284.2065 Email: support@servertech.com

Quick Start Guide

The following instructions will help you quickly install and configure your Sentry Power Distribution

Unit for use on your network. For detailed information on each step, go to the page number listed to

the right.

1. Review all safety notices............................................................................................................5

2. Verify input voltage selection (PTPD-VE18 models only).......................................................15

3. Mount the Sentry Power Distribution Unit.................................................................................5

4. Connect to the power source ......................................................................................................6

5. Connect the devices to the Sentry Power Distribution Unit .......................................................7

6. Configure the Sentry Power Distribution Unit (PTPD-x0 models only).....................................9

Configure location ............................................................................................................10 •

• Configure overload threshold ...........................................................................................10

7. Connect to the Sentry Power Distribution Unit..........................................................................7

2 • Introduction Sentry Power Tower Power Distribution Unit

Installation and Operations Manual

Page 7

Chapter 2: Installation

STANDARD ACCESSORIES 4

A

DDITIONAL REQUIRED ITEMS 4

E

QUIPMENT OVERVIEW 4

S

AFETY PRECAUTIONS 5

V

ERIFY INPUT VOLTAGE SELECTION (PTPD-VE18 MODELS ONLY) 5

M

OUNTING 6

Horizontal/Rack PTPD.....................................................................................................................6

Vertical PTPD ..................................................................................................................................6

C

ONNECTING TO THE POWER SOURCE 6

C

ONNECTING DEVICES TO THE PTPD 7

C

ONNECTING TO THE PTPD (PTPD-X0 MODELS ONLY) 7

Page 8

Chapter 2: Installation

8

8

Before installing your Sentry Power Distribution Unit, refer to the following lists to ensure that you

have all the items shipped with the unit as well as all other items required for proper installation.

Standard Accessories

• Mounting bracket hardware:

Vertical - two mounting brackets, two nut plates and four sets of screws and washers

Horizontal/Rack – two mounting brackets and four screws

• Outlet retention clips, one per outlet (208-240V units only)

• Separate power input cord (208-240V units with < 30A total output capability only)

PTPD-x0 models only

• RJ45 to RJ45 crossover cable

• RJ45 to DB9F serial port adapter (for connection to standard DB9M DTE serial port)

Additional Required Items

• Phillip screwdriver

• Screws, washers and nuts to attach the PTPD to your rack

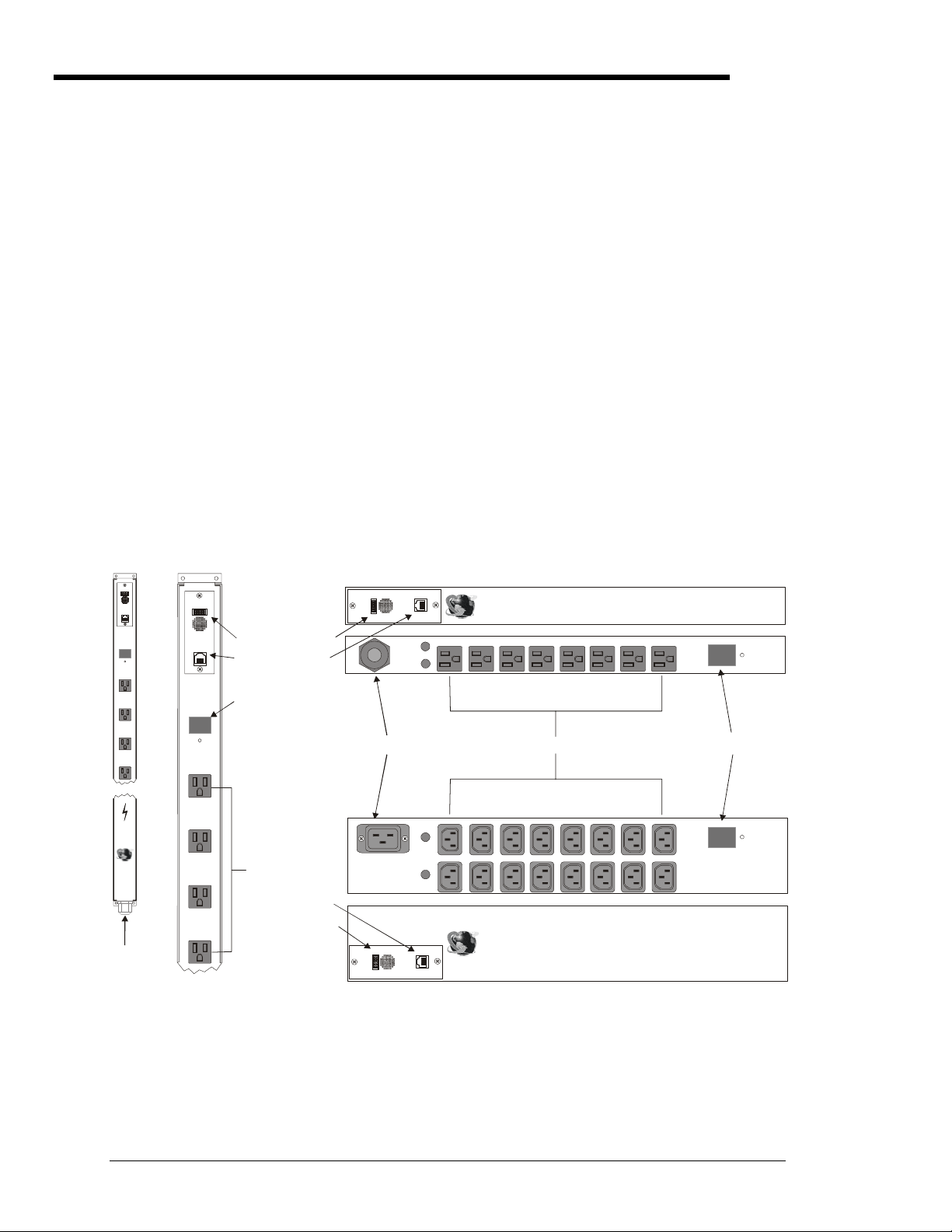

Equipment Overview

A letter/number combination is printed above each PTPD port. The ports are labeled A1 through A4,

B1 through B4, C1 through C4 and D1through D4. The power inlet of the PTPD connects the PTPD to

the electrical power source. See Appendix C: Technical Specifications for more information.

Alarm

Input

Current

88

Sentry

Power

Tow er

Server

Techno logy

www.ser vertech.c om

Output

RS-232

Alarm

Reset

A1

A2

A3

A4

Inc.

Alarm

Output

RS-232

Inp ut

Current

8888

Alarm

Reset

A1

A2

A3

IDC10 Connector

RJ45 Connector

Input Current LED

Ports

t

2

u

m

r

a

l

A

3

p

2

t

-

u

S

R

O

AC Power Inlet

RJ45 Connector

IDC10 Connector

t

u

m

r

p

t

a

l

u

A

O

AC Power Inlet

100-120V Vertical

(Fuses not shown)

A4

Figure 2.1 PTPD Views (PTPD-x0 model types shown)

100-120V Horizontal/Rack 8-port

Sentry Power Tower

Server Technolog y, Inc.

www.servertech.com

B4 B3 B2 B1 A4 A3 A2 A 1

Fuse A

Fuse B

Ports

B4 B3 B2 B1 A4 A3 A2 A1

Fuse A

D4 D3 D2 D1 C4 C3 C2 C1

Fuse B

Sentry Power Tower

Server Technology, Inc.

2

3

2

S

R

www.servertech.com

208-240V Horizontal/Rack 16-port

TM

Input

Current

88

Alarm

Reset

8

Input Current LED

Input

Current

TM

88

Alarm

Reset

8

4 • Installation Sentry Power Tower Power Distribution Unit

Installation and Operations Manual

Page 9

Safety Precautions

This section contains important safety and regulatory information that should be reviewed before

installing and using the Sentry Sentry Power Distribution Unit. For input and output current ratings,

see Ratings in Appendix C: Technical Specifications.

Only for installation and use in a

Service Access Location in accordance

with the following installation and use

instructions.

This equipment is designed to be

installed on a dedicated circuit.

Dedicated circuit must have circuit

breaker or fuse protection. Sentry

Power Distribution Units have been

designed without a master circuit

breaker or fuse to avoid becoming a

single point of failure. It is the

customer's responsibility to provide

adequate protection for the dedicated

power circuit. Protection of capacity

equal to current rating of equipment,

and must meet all applicable codes and

regulations. Circuit breaker or fuse for

installation in North America must have

10,000A interrupt capacity.

The plug on the power supply cord

shall be installed near the equipment

and shall be easily accessible.

Installation Orientation: PTxx-Vxxx-x

units are design to be installed in

vertical orientation.

Always disconnect the power supply

cord before opening to avoid electrical

shock.

WARNING! High leakage current!

Earth connection is essential before

connecting supply!

Warning: 208-240/230V models only:

Outlets are not fused. Outlet circuit

protection is provided by the building

installation, which shall not exceed 30A

branch circuit protection

For PTPD-VE18 models, verify input

voltage selection PRIOR to connection.

See Appendix B: for more information.

Destiné à l'installation et l'utilisation

dans le cadre de Service Access

Location selon les instructions

d'installation et d'utilisation.

Cet équipement est conçu à être

installé sur un circuit spécialisé.

Le circuit spécialisé doit avoir un

disjoncteur ou une protection de

fusible. Des Sentry Power Distribution

Units ont été conçus sans disjoncteur

général ni fusible pour éviter que cela

devient un seul endroit de panne.

C’est la responsabilité du client de

fournir une protection adéquate pour le

circuit-alimentation spécialisé.

Protection de capacité équivalant à la

puissance de l'équipement, et

respectant tous les codes et normes

applicables. Les disjoncteurs ou

fusibles destinés à l'installation en

Amérique du Nord doivent avoir une

capacité d'interruption de 10 000 A.

La prise sur le cordon d’alimentation

sera installée près de l’équipement et

sera facilement disponible.

Installation Orientation : Les unités

PTxx-Vxxx-x sont conçues pour être

installées dans une orientation

verticale.

Toujours déconnecter le cordon

d’alimentation avant d’ouvrir pour

éviter un choque électrique.

ATTENTION ! Haut fuite très

possible ! Une connection de masse

est essentielle avant de connecter

l’alimentation !

Attention: les modèles 208-240/230V

seulement : Les prises n’ont pas de

fusible incorporé. Une protection de la

prise du circuit est fournie par

l’installation du bâtiment, qui ne devrait

pas dépasser 30A protection d’une

branche de circuit.

Pour PTPD-VE18 modèles, vérifier de

la sélection de tension de données

AVANT la connexion. Voir le B

d'Appendice: pour plus amples

renseignements.

Nur für Installation und Gebrauch an

Anschlusszugriffspunkten gemäß der

folgenden Installations- und

Gebrauchsanweisungen.

Diese Ausrüstung ist zur Installation in

einem festen Stromkreis vorgesehen.

Der feste Stromkreis muss mit einem

Schutzschalter oder einem

Sicherungsschutz versehen sein.

Ein Sentry Power Distribution Units

verfügt über keinen

Hauptschutzschalter bzw. über keine

Sicherung, damit kein einzelner

Fehlerpunkt entstehen kann. Der

Kapazitätsschutz entspricht der

aktuellen Stromstärke der Geräte und

muss alle relevanten Codes und

Bestimmungen erfüllen. Für Installation

in Nordamerika müssen Ausschalter

bzw. Sicherung über 10.000 A

Unterbrechungskapazität verfügen.

Der Stecker des Netzkabels muss in

der Nähe der Ausrüstung installiert

werden und leicht zugänglich sein.

Installationsausrichtung: PTxx-Vxxx-x

Einheiten sind zur vertikalen Installation

vorgesehen.

Ziehen Sie vor dem Öffnen immer das

Netzkabel heraus, um die Gefahr eines

elektrischen Schlags zu vermeiden.

ACHTUNG! Hoher Verluststrom! Ein

Erdungsanschluss ist vor dem

Einschalten der Stromzufuhr

erforderlich!

Achtung: Nur für 208-240/230VModelle: Die Anschlussstellen sind

nicht gesichert. Der

Ausgangsstromkreisschutz erfolgt

durch die elektrische

Gebäudeinstallation, die einen

Abzweigschutz von 30A nicht

übersteigen darf.

Für PTPD-VE18 entwerfen Sie,

Überprüfen Sie Eingabespannung

Auswahl VOR Anschluß. Siehe

Anhang B: für mehr Informationen.

Verify Input Voltage Selection (PTPD-VE18 models only)

Verify input voltage selection PRIOR to connection. See Appendix B: on page 15 for instructions.

Vérifier de la sélection de tension de données AVANT la connexion. Voir le B d'Appendice: à la page 15 pour les instructions.

Uberprüfen Sie Eingabespannung Auswahl VOR Anschluß. Siehe Anhang B: Auf Seite 15 für Anweisungen.

Sentry Power Tower Power Distribution Unit Installation • 5

Installation and Operations Manual

Page 10

Mounting

Horizontal/Rack PTPD

1. Select the appropriate bracket mounting points for proper mounting depth within the rack.

2. Attach one bracket to these mounting points with two screws.

3. Repeat with the other mounting bracket on the opposite side of the enclosure.

4. Install the enclosure into your rack, using the slots in each bracket. The slots allow about ¼ inch

of horizontal adaptability to align with the mounting holes of your rack.

NOTE: A mounting bracket kit for 23” wide rack or cabinets is available. Contact your Server Technology Sales

Representative for more information.

Vertical PTPD

1. Attach one of the removable flanges to the mount points on the top rear of the enclosure using M4

screws.

2. Repeat with the other flange for the bottom mount points on the enclosure.

3. Attach one mounting bracket to the top flange with one set of screws and washers through each of

the slots in the bracket into the nut plate, as shown in Figure 2.2 (brackets may differ from the

illustration). The slots allow about 1½ inches of vertical adaptability.

4. Repeat with the other mounting bracket on the bottom flange.

5. Attach the top and bottom brackets to your rack.

NOTE: Contact your Server Technology Sales Representative for information regarding custom bracket design and

fabrication services if you are unable to find a suitable manner for utilizing the included mounting brackets.

Connecting to the Power Source

On all 100-120V units and 208-240V units with a total output rating of 30A, the input power cord is

attached to the base of the PTPD unit. On 208-240V units with a total output rating <30, you must first

attach the power cord to the PTPD unit before connecting the PTPD to the power source.

To attach a 230V power cord to the 230V PTPD unit:

1. Plug the female end of the power cord firmly into its connector at the base of the PTPD.

2. Use a screwdriver to tighten the two screws on the retention bracket.

To connect the PTPD to the power source:

Plug the male end of the PTPD power cord into the AC power source.

On power up, PTPD-x0 models perform a self-test and display the results on the terminal screen:

• The Input Current LED displays ‘On’, then switches to the cumulative input load.

• The audible alarm and contact-closure output relay are triggered for one second.

Power Tower PDU Version 1.0b

Booting...

Display Detected, Status OK, Configured.

Power Supply Detected, Status OK, Configured, ADC Enabled.

EEPROM Detected, Configuration Loaded.

Boot Complete.

Figure 2.2 Example of power up self-test results.

6 • Installation Sentry Power Tower Power Distribution Unit

Installation and Operations Manual

Page 11

Connecting Devices to the PTPD

To avoid the possibility of noise due to arcing:

Keep the device’s on/off switch in the off position until after it is plugged into the PTPD port.

On 115V units, connect devices to the PTPD ports.

On 230V units, install a retention clip on each port. Pull the open prongs out slightly and insert them

into holes on the sides of the PTPD adjacent to the port. Then insert the device’s power cord and gently

snap the retention clip over the cord.

NOTE:

1. Server Technology recommends even distribution of attached devices across the all available outlets to avoid

exceeding the outlet, quad or octet ratings limitations. See Ratings in Appendix B: for more information.

2. The outlet retention clips on the 230V PTPD are designed for use with Server Technology’s IEC 60320/C13 to IEC

60320/C14 cable (CAB-1302). The retention clip may not properly fit 3

Always disconnect the power supply cord before opening to avoid electrical shock.

Afin d’éviter les chocs électriques, débranchez le cable électrique avant d’ouvrir.

Immer Netzleitung auskuppeln vor den Aufmachen um elektrischen Schlag zu vermeiden.

rd

party cables.

Connecting to the PTPD (PTPD-x0 models only)

The Sentry Power Distribution Unit is equipped with a single RJ45 RS-232 serial port for attachment to

a PC or networked terminal server using the supplied RJ45 to RJ45 crossover cable and RJ45 to DB9F

serial port adapter as required. Additionally, the PTPD is equipped with a single IDC10 alarm port for

connection to contact-closure overload alarm circuits. See Chapter 4: Appendices for more

information these ports.

Sentry Power Tower Power Distribution Unit Installation • 7

Installation and Operations Manual

Page 12

Page 13

Chapter 3: Operations (PTPD-x0 models only)

INTERFACE 10

D

ISPLAYING THE CONTROL SCREEN 10

To display or refresh the Control Screen: ............................................................................10

USING THE CONTROL SCREEN 10

Location field .................................................................................................................................10

To specify a location: ...........................................................................................................10

Input Current field..........................................................................................................................10

Threshold field ...............................................................................................................................10

To adjust the overload threshold:.........................................................................................10

Alarm Status field...........................................................................................................................11

Clearing an Over-Threshold Alarm......................................................................................11

To clear an alarm from the Control Screen: ........................................................................11

To clear an alarm using the reset button:.............................................................................11

Ending a Session ............................................................................................................................11

Page 14

Chapter 3: Operations (PTPD-x0 models only)

Interface

The Sentry Power Distribution Unit has one interface: the Control Screen. This screen displays all data

from the Power Distribution Unit.

Displaying the Control Screen

Displaying the Control Screen of a PTPD requires the use of a terminal or terminal emulation software.

The terminal or emulation software must be configured to support ANSI or VT100, a supported data

rate (300, 1200, 2400, 4800, 9600, 19200, or 38400 BPS)- 8 data bits-no parity-one stop bit and Device

Ready output signal (DTR or DSR).

To display or refresh the Control Screen:

Press Enter.

Using the Control Screen

The Control Screen displays all status information for the Sentry Power Distribution Unit. Figure 3.1

shows an example of the Control Screen.

Power Tower PDU Version 1.0b

Location:

Input Current: 0.00 Amps

Alarm Status: No Alarm

Threshold: 30 Amps

Press ‘L’ to edit Location

Press ‘T’ to adjust Threshold

Press ‘Enter’ to refresh

Figure 3.1 Example Control Screen

Control Screen Key Commands

Key Action

L Pressing L allows editing of the Location field.

T Pressing T allows editing of the overload threshold.

Enter Displays or refreshes the Control Screen.

The following sections describe each Control Screen field.

Location field

The editable Location field may contain a descriptive location for the PTPD.

To specify a location:

Type L. If you are changing an existing name, press the Backspace key to erase characters. Enter a 130 character string and press Enter.

Input Current field

The display-only Input Current field indicates the current cumulative input load for the PTPD, in

quarter-ampere granularity. Additionally, the digital LED above the ports on the PTPD indicates the

total input load in half-ampere granularity to 10 amperes and whole ampere granularity above 10

amperes.

Threshold field

The editable Threshold field indicates the PTPD ’s current overload threshold setting. If the Input

Current exceeds the Threshold by 1/8 ampere the PTPD will trigger the audible alarm and the contactclosure alarm output.

To adjust the overload threshold:

Type t. Use the + and – key to increase or decrease the threshold value in Amperes. The threshold

may be set from 1-31. Press Enter.

10 • Operations (PTPD-x0 models only) Sentry Power Tower Power Distribution Unit

Installation and Operations Manual

Page 15

Alarm Status field

The display-only Control Status field indicates the PTPD ’s current alarm state.

Alarm Status Field Values

Display Description

No Alarm Current PTPD load is under overload threshold setting.

ALARM -> Over Threshold Current PTPD load exceeds overload threshold setting.

ALARM (Cleared) -> Over Threshold Alarm reset - Current PTPD load exceeds overload threshold setting.

Power Tower PDU Version 1.0b

Location:

Input Current: 20.25 Amps

Alarm Status: ALARM -> Over Threshold

Threshold: 20 Amps

Press ‘C’ to clear Alarm

Press ‘L’ to edit Location

Press ‘T’ to adjust Threshold

Press ‘Enter’ to refresh

Figure 3.2 Example Control Screen in an over-threshold condition

Clearing an Over-Threshold Alarm

The over-threshold alarm may be cleared from the Control Screen or by pressing the Alarm Reset button.

Clearing the alarm resets both the audible alarm and the contact-closure alarm output.

NOTE: The alarm is automatically cleared if the Input Current returns to 1/8 ampere below the overload threshold.

To clear an alarm from the Control Screen:

Type c.

To clear an alarm using the reset button:

On the front of the PTPD, locate the recessed reset button directly below the Input Current LED. You

will need a non-conductive, non-metallic tool that fits inside the recess.

Insert the tool, then depress and hold the reset button until the audible alarm is silenced.

NOTE: The reset button should be released immediately after the audible alarm is silenced. Failure to release within 7

seconds will result in resetting the PTPD to factory defaults. See Appendix A: Resetting to Factory Defaults for more

information.

Power Tower PDU Version 1.0b

Location:

Input Current: 20.25 Amps

Alarm Status: ALARM (Cleared) -> Over Threshold

Threshold: 20 Amps

Press ‘L’ to edit Location

Press ‘T’ to adjust Threshold

Press ‘Enter’ to refresh

Figure 3.3 Example Control Screen with a cleared over-threshold condition.

Ending a Session

Sessions are ended automatically after each refresh of the Control Screen.

Sentry Power Tower Power Distribution Unit Operations (PTPD-x0 models only) • 11

Installation and Operations Manual

Page 16

Page 17

Chapter 4: Appendices

APPENDIX A: RESETTING TO FACTORY DEFAULTS 14

To reset the PTPD to factory defaults using the reset button: ........................................................14

APPENDIX B: VERIFYING/SETTING THE OPERATIONAL VOLTAGE 15

A

PPENDIX C: TECHNICAL SPECIFICATIONS 16

Standard Models.............................................................................................................................16

Ratings............................................................................................................................................17

Fuses...............................................................................................................................................17

Data Connection (PTPD-x0 models only)......................................................................................18

RJ45 to DB9F serial port adapter...................................................................................................18

IDC10 alarm port ...........................................................................................................................19

APPENDIX D: WARRANTY, PRODUCT REGISTRATION AND SUPPORT 20

Warranty and Limitation of Liability .............................................................................................20

Product Registration.......................................................................................................................20

Technical Support ..........................................................................................................................20

Return Merchandise Authorization ................................................................................................20

Page 18

Chapter 4: Appendices

Appendix A: Resetting to Factory Defaults

You may reset the non-volatile RAM that stores all configurable Sentry Power Distribution Unit

options. This clears all editable fields on the Control Screen.

You may reset the Sentry Power Distribution Unit to factory defaults by pressing the reset button.

To reset the PTPD to factory defaults using the reset button:

On the front of the PTPD, locate the recessed reset button directly below the Input Current LED. You

will need a non-conductive, non-metallic tool that fits inside the recess.

Insert the tool in the recess, then depress and hold the reset button for at least 8 seconds. A reset is

indicated by three side-by-side pairs of horizontal lines in the top, middle and bottom of the display. At

this point, you may release the reset button. The PTPD will perform a power up self-test and then

return to displaying the cumulative input load on the Input Current LED.

14 • Appendices Sentry Power Tower Power Distribution Unit

Resetting to Factory Defaults Installation and Operations Manual

Page 19

Appendix B: Verifying/Setting the Operational Voltage

Vérification/réglage de la tension de service

Überprüfen/Einstellen der Betriebsspannung

PTPD-VE18 models are equipped with an internal input voltage selector switch, for operation in either

a 100-120V or a 208-240V environment.

THIS OPERATION SHOULD ONLY BE PERFORMED BY A QUALIFIED TECHNICIAN.

The customer is responsible for proper identification of required input voltage and configuration of the Sentry

Power Distribution Unit.

The customer assumes responsibility and liability for possible damage to the Sentry Power Distribution Unit, 3

party equipment and/or injury to personnel due to improper configuration.

CETTE OPERATION NE DOIT ETRE FAIRE QUE PAR UN TECHNICIEN QUALIFIE.

Il incombe au client de déterminer correctement la tension d’entrée et la configuration du Sentry Power

Distribution Unit.

Le client prend la responsabilité si la Tour Electrique est endommagée, autre équipement/ou blessure de

personnels à cause d’une configuration incorrecte.

DIESE ARBEITEN SOLLTEN NUR VON EINEM QUALIFIZIERTEN TECHNIKER DURCHGEFÜHRT

WERDEN.

Der Kunde ist für die Ermittlung der erforderlichen Eingangsspannung und die Konfiguration des Sentry Power

Distribution Unit verantwortlich.

Der Kunde die Verantwortung und Haftung für eine etwaige Beschädigung des Sentry Power Distribution Unit,

der Ausrüstung von Fremdfirmen und/oder Verletzungen von Mitarbeitern durch Falsche Konfiguration.

Tools needed:

1. Philips screwdriver

Outils nécessaires:

1. Tournevis cruciforme

Benötigtes Werkzeug Teile:

1. Kreuzschlitzschraubenzieher

rd

230V

Voltage selector switch

Sélecteur de tension

Spannungswahlschalter

Procedure:

1. Unplug Sentry Power

Distribution Unit.

2. Open the rear access plate.

2.1. Remove both screws from

access plate on the back of

the Sentry Power

Distribution Unit.

2.2. Remove the access plate.

3. Verify the proper setting on the

voltage selector switch.

Correct as necessary.

115V – for 100-120V

230V – for 208-240V

4. Replace rear access plate and

secure with original screws.

NOTE:

Changing the voltage setting of the Sentry Power Distribution Unit may require changing of the input power cord. For

information on changing the input power cord, go to www.servertech.com.

Le changement du réglage de tension du Sentry Power Distribution Unit peur exiger le changement du cordon

d’alimentation. Pour toute information concernant le changement du cordon, consulter le site www.servertech.com.

Bei einer Änderung der Spannungseinstellung des Sentry Power Distribution Unit muss unter Umständen das Netzkabel

ausgetauscht werden. Informationen über den Austausch des Netzkabels finden Sie unter www.servertech.com.

Procédure:

1. Débrancher la Sentry Power

Distribution Unit.

2. Ouvrir la plaque d’accès de

dernière.

2.1. Enlever les deux vis de la

plaque d’accès dernière la

Power Twoer.

2.2. Enlever la plaque d’accès.

3. Vérifier que le sélecteur de

tension est correctement

positionné. Changer le réglage

selon le besoin.

115V – pour 100 -120V

230V – pour 208-240V

4. Remettre la plaque de dernière

et fermer bien avec les vis

original.

Vorgangsweise:

1. Ziehen Sie den Stecker des

Sentry Power Distribution

Unit heraus.

2. Öffnen Sie die hintere

Abdeckung.

2.1. Entfernen Sie beide

Schrauben aus der

hinteren Abdeckung des

Sentry Power Distribution

Unit.

2.2. Nehmen Sie die

Abdeckung ab.

3. Vergewissern Sie sich, dass

der Spannungswahlschalter

richtig eingestellt ist. Ändern

Sie die Einstellung bei

Bedarf.

115V - für 100 - 120 V

230V - für 208 - 240 V

4. Bringen Sie die hintere

Abdeckung wieder an, und

befestigen Sie sie mit den

Originalschrauben.

Sentry Power Tower Power Distribution Unit Appendices • 15

Installation and Operations Manual Verifying/Setting the Operational Voltage

Page 20

Appendix C: Technical Specifications

Standard Models

Vertical Installation

Model Voltage Inlet Cordset (10’) Outlets

PTPD-V008-1-01 100-120V, 50/60Hz Hardwired NEMA 5-20P, 20A/125V straight 8 NEMA 5-20R

PTPD-V008-1-03 100-120V, 50/60Hz Hardwired NEMA 5-15P, 15A/125V straight 8 NEMA 5-20R

PTPD-V008-1-04 100-120V, 50/60Hz Hardwired NEMA L5-20P, 20A/125V locking 8 NEMA 5-20R

PTPD-V008-1-05 100-120V, 50/60Hz Hardwired NEMA L5-30P, 30A/125V locking 8 NEMA 5-20R

PTPD-V008-2-02 208-240V, 50/60Hz IEC 60320/C20 *

PTPD-V008-2-06 208-240V, 50/60Hz Hardwired NEMA L6-30P, 30A/230V locking 8 IEC 60320/C13

PTPD-V016-1-01 100-120V, 50/60Hz Hardwired NEMA 5-20P, 20A/125V straight 16 NEMA 5-20R

PTPD-V016-1-03 100-120V, 50/60Hz Hardwired NEMA 5-15P, 15A/125V straight 16 NEMA 5-20R

PTPD-V016-1-04 100-120V, 50/60Hz Hardwired NEMA L5-20P, 20A/125V locking 16 NEMA 5-20R

PTPD-V016-1-05 100-120V, 50/60Hz Hardwired NEMA L5-30P, 30A/125V locking 16 NEMA 5-20R

PTPD-V016-2-02 208-240V, 50/60Hz IEC 60320/C20 * 16 IEC 60320/C13

PTPD-V016-2-06 208-240V, 50/60Hz Hardwired NEMA L6-30P, 30A/230V locking 16 IEC 60320/C13

PTPD-VE16-1-01 100-120V, 50/60Hz Hardwired NEMA 5-20P, 20A/125V straight 16 NEMA 5-20R

PTPD-VE16-1-03 100-120V, 50/60Hz Hardwired NEMA 5-15P, 15A/125V straight 16 NEMA 5-20R

PTPD-VE16-1-04 100-120V, 50/60Hz Hardwired NEMA L5-20P, 20A/125V locking 16 NEMA 5-20R

PTPD-VE16-1-05 100-120V, 50/60Hz Hardwired NEMA L5-30P, 30A/125V locking 16 NEMA 5-20R

PTPD-VE18-0-01 100-240V, 50/60Hz Hardwired NEMA 5-20P, 20A/125V straight 18 IEC 60320/C13

PTPD-VE18-0-03 100-240V, 50/60Hz Hardwired NEMA 5-15P, 15A/125V straight 18 IEC 60320/C13

PTPD-VE18-0-04 100-240V, 50/60Hz Hardwired NEMA L5-20P, 20A/125V locking 18 IEC 60320/C13

PTPD-VE18-0-05 100-240V, 50/60Hz Hardwired NEMA L5-30P, 30A/125V locking 18 IEC 60320/C13

PTPD-VE18-0-06 100-240V, 50/60Hz Hardwired NEMA L6-30P, 30A/230V locking 18 IEC 60320/C13

Horizontal/Rack Installation

Model* Voltage Inlet Cordset Outlets

PTPD-H008-1-01 100-120V, 50/60Hz Hardwired NEMA 5-20P, 20A/125V straight 8 NEMA 5-20R

PTPD-H008-1-03 100-120V, 50/60Hz Hardwired NEMA 5-15P, 15A/125V straight 8 NEMA 5-20R

PTPD-H008-1-04 100-120V, 50/60Hz Hardwired NEMA L5-20P, 20A/125V locking 8 NEMA 5-20R

PTPD-H008-1-05 100-120V, 50/60Hz Hardwired NEMA L5-30P, 30A/125V locking 8 NEMA 5-20R

PTPD-H008-2-02 208-240V, 50/60Hz IEC 60320/C20 *

PTPD-H008-2-06 208-240V, 50/60Hz Hardwired NEMA L6-30P, 30A/230V locking 8 IEC 60320/C13

PTPD-H016-1-01 100-120V, 50/60Hz Hardwired NEMA 5-20P, 20A/125V straight 16 NEMA 5-20R

PTPD-H016-1-03 100-120V, 50/60Hz Hardwired NEMA 5-15P, 15A/125V straight 16 NEMA 5-20R

PTPD-H016-1-04 100-120V, 50/60Hz Hardwired NEMA L5-20P, 20A/125V locking 16 NEMA 5-20R

PTPD-H016-1-05 100-120V, 50/60Hz Hardwired NEMA L5-30P, 30A/125V locking 16 NEMA 5-20R

PTPD-H016-2-02 208-240V, 50/60Hz IEC 60320/C20 * 16 IEC 60320/C13

PTPD-H016-2-06 208-240V, 50/60Hz Hardwired NEMA L6-30P, 30A/230V locking 16 IEC 60320/C13

* Input cordset selected at time of purchase. Current options available (Contact your account representative for more

information):

1. IEC 60320/C19 to CEE7/7 Schuko for use in continental Europe.

2. IEC 60320/C19 to NEMA L6-20P for use in North America.

3. IEC 60320/C19 cable-mount connector.

8 IEC 60320/C13

8 IEC 60320/C13

16 • Appendices Sentry Power Tower Power Distribution Unit

Technical Specifications Installation and Operations Manual

Page 21

Ratings

V

s

t

l

g

A

g

POWER RATINGS INDICE D’ALIMENTATION NENNLEISTUNG

PTPD-V0##-y-0z*

* ## - Number of outlets

y - Input Voltage (1-100-120V, 50/60Hz

w/NEMA outlets, 2-100-240V 60Hz &

230V 50/60Hz w/IEC 60320/C13 outlets)

z - Power input configuration

PTPD-V0##-y-0z*

* ## - Nombre de prises

y - Tension d’entrée (1-100-120V,

50/60Hz w/NEMA prises, 2-100-240V

60Hz & 230V 50/60Hz w/ IEC

60320/C13 prises)

z – Configuration de l’entrée de

l’alimentation

PTPD-V0##-y-0z*

* ## - Anzahl der Anschlussstellen

y - Eingangsspannung (1 - 100-120V,

50/60Hz mit NEMA-Anschlussstellen, 2 100-240V, 60Hz, und 230V, 50/60Hz mit

IEC 60320/C13-Anschlussstellen)

z - Eingangskonfiguration

Available Configurations

L’indice du courant d’entrée L’indice du courant de sortie

Configurations Disponibles

Input Current Ratings

Verfügbare Konfigurationen

1,2

6

Output Current Ratings

Eingangsstromstärke Ausgangsstromstärke

Outlets

Prise

Anschlussstellen Spannun

oltage Current Outlet Total

Tension Courran

Prise

Strom Anschlussstelle

Quad

3

Octet

4

BCD A&B C&D

08 100-120V 50/60Hz 15 10 15 15 15 15

08 100-120V 50/60Hz 20 10 15 15 20 20

08 100-120V 50/60Hz 30 10 15 15 30 30

16 100-120V 50/60Hz 15 10 15 15 15 15 15 15 15

16 100-120V 50/60Hz 20 10 15 15 15 15 15 15 20

16 100-120V 50/60Hz 30 10 15 15 15 15 15 15 30

18 100-120V 50/60Hz 15 10 10 15

18 100-120V 50/60Hz 20 10 10 20

18 100-120V 50/60Hz 30 10 10 30

08 208-240V 60Hz 20 6 10 10 20 20

08 208-240V 60Hz 30 6 15 15 30 30

16 208-240V 60Hz 20 6 10 10 10 10 20 20 20

16 208-240V 60Hz 30 6 15 15 15 15 24 24 30

18 208-240V 60Hz 20 6 10 20

18 208-240V 60Hz 30 6 10 30

08 230V 50/60Hz 16 6 10 10 16 16

08 230V 50/60Hz 30 6 15 15 30 30

16 230V 50/60Hz 16 6 10 10 10 10 16 16 16

16 230V 50/60Hz 30 6 15 15 15 15 24 24 30

18 230V 50/60Hz 16 6 10 16

18 230V 50/60Hz 30 6 10 30

1

All current ratings are in amperes.

Tous les indices de courant sont en ampères.

Alle Angaben der Stromstärke erfolgen in Ampere.

2

Input current ratings are based on the power input configuration.

Les indices du courant d’entrée sont basés sur la configuration de tension d’entrée.

Die Eingangsstromstärke hängt von der Eingangskonfiguration ab.

3

A=A1+A2+A3+A4 or 1+2+3+4, B=B1+B2+B3+B4 or 5+6+7+8, C=C1+C2+C3+C4 or 9+10+11+12, D=D1+D2+D3+D4 or 13+14+15+16

4

A&B=A1+A2+A3+A4+B1+B2+B3+B4 or 1+2+3+4+5+6+7+8, C&D=C1+C2+C3+C4+D1+D2+D3+D4 or 9+10+11+12+13+14+15+16

5

1+2+3+4+5+6 OR 7+8+9+10+11+12 OR 13+14+15+16+17+18

6

The following configurations are NOT available:

100-120V units with 16A input current rating.

208-240V and 230V units with 15A input current rating.

Les configurations suivantes NE SONT PAS disponible:

Unités de 100-120V avec indice de courant d’entrée de 16A.

Unités de 208-240V et 230V avec indice de courant d’entrée de 15A.

Die folgenden Konfigurationen sind NICHT verfügbar:

100-120V-Einheiten mit einer Eingangsstromstärke von 16A

208-240V und 230V-Einheiten mit einer Eingangsstromstärke von 15A

Sextet

Tota

5

esamt

Ins

Physical Specifications

Model PTPD- Vx08 Vx16 Vx18 Hx08 Hx16

Size (H, W, D): ‘0’ series

‘E’ series

43.0 x 1.75 x 2.25 in

N/A

65.0 x 1.75 x 2.25 in

63.0 x 2.0 x 1.75 in

N/A

62.0 x 2.0 x 1.75 in

1.75 x 17.25 x 5.5 in

N/A

33.0 x 1.75 x 2.25 in

N/A

Weight: 8.0 lb 10.9 lb 10.6 lb 7.0 lb 7.8 lb

Temperature: Operating

Storage

Elevation: Operating

(above MSL): Storage

Rel. humidity: Operating

Storage

Approvals cTUVus, TUV-GS1

1

cTUVus - UL 60950:2000, CAN/CSA 22.2 No. 60950-00, TUV-GS - EN60950:2000

0° to 50° C (32° to 122° F)

-40° to 85° C (-40° to 185° F)

0 to 10,000 ft (0 to 3000 m)

0 to 50,000 ft (0 to 15 000 m)

10 to 90%, non-condensing

10 to 90%, non-condensing

Sentry Power Tower Power Distribution Unit Appendices • 17

Installation and Operations Manual Technical Specifications

Page 22

Fuses

100-120V Sentry Power Distribution Units may be equipped with fuses to protect each internal power

branch. Replacement fuses must meet the following requirements:

PTPD-x0xx models PTPD-VE18 models

Type Fast-acting ceramic Time-delay ceramic

Form factor ¼”x 1-¼” 5mm x 20mm

AC Voltage Rating 250V 250V

Amperage Rating 15A 10A

Interrupt Rating @125V 10000A N/A

Cooper-Bussman Part Number* ABC-15 S505-10A

* Server Technology recommends the use of Cooper-Bussman fuses available through Graybar or Brill Electronics

NOTE: PTPDs have two or three internal power branches.

8-port: Branch A – ports A1-A4 or 1-4, Branch B – ports B1-B4 or 5-8

16-port: Branch A – ports A1-A4 & B1-B4 or 1-8, Branch B – ports C1-C4 & D1-D4 or 9-16

18-port: Branch A – ports 1-6, Branch B – ports 7-12, Branch C – ports 13-18

Data Connection (PTPD-x0 models only)

RS-232 Serial port

Sentry Power Distribution Units are equipped standard with an RJ45 RS-232c serial port. This

connector may be used for direct local access or from other serial devices such as a terminal server. An

RJ45 crossover cable is provided for connection to an RJ45 DTE serial port.

Pin DTE Signal Name Input/Output

1 Request to Send RTS Output

2 Data Terminal Ready DTR Output

3 Transmit Data TD Output

4 Signal Ground

5 Signal Ground

6 Receive Data RD Input

7 Data Set Ready DSR Input

8 Clear to Send CTS Input

67543218

RJ45 to DB9F serial port adapter

Additionally, an RJ45 to DB9F serial port adapter is provided for use in conjunction with the RJ45

crossover cable to connect to a PC DB9M DTE serial port. The adapter pinouts below reflect use of the

adapter with the provided RJ45 crossover cable.

Pin DCE Signal Name Input/Output

1

2 Receive Data RD Output

3 Transmit Data TD Input

4 Data Terminal Ready DTR Input

5 Signal Ground

6 Data Set Ready DSR Output

7 Request to Send RTS Input

8 Clear to Send CTS Output

12345

6789

18 • Appendices Sentry Power Tower Power Distribution Unit

Technical Specifications Installation and Operations Manual

Page 23

IDC10 alarm port

Sentry Power Distribution Units are equipped standard with an IDC10 alarm port for use with contactclosure overload alarm circuits. (Pins 1-7 are not used.)

Pin

8 Normally Open

9 Common

10 Normally Closed

NOTE:

1. Normally Open: The relay switches to close the circuit in response to an over-threshold alarm.

Normally Closed: The relay switches to open the circuit in response to an over-threshold alarm.

2. Relay specifications:

Manufacturer’s rating

• Maximum switching voltage – 220V DC, 250V AC

• Maximum switching current – 2A DC, AC

UL/CSA rating

• 0.6A, 125V AC

• 0.6A, 110V DC

• 2A, 20V DC

246810

13579

Sentry Power Tower Power Distribution Unit Appendices • 19

Installation and Operations Manual Technical Specifications

Page 24

Appendix D: Warranty, Product Registration and Support

Warranty and Limitation of Liability

Server Technology, Inc. agrees to repair or replace Products that fail due to a defect within twelve (12)

months after the shipment date of each Product unit to Buyer (“Warranty Period”). For purposes of this

Agreement the term “defect” shall mean the Product fails to operate or fails to conform to its applicable

specifications. Any claim made pursuant to this Agreement shall be asserted or made in writing only

by Buyer. Buyer shall comply with Server Technology’s Standard Return Merchandise Authorization

(“RMA”) procedure for all warranty claims as set forth in Server Technology’s operation manual.

Buyer must return Products in original packaging and in good condition. This limited warranty

does not include labor, transportation, or other expenses to repair or reinstall warranted Products on site

or at Buyer’s premises.

Server Technology reserves the right to investigate any warranty claims to promptly resolve the

problem or to determine whether such claims are proper. In the event that after repeated efforts Server

Technology is unable to repair or replace a defective Product, then Buyer’s exclusive remedy and

Server Technology’s entire liability in contract, tort, or otherwise shall be the payment by Server

Technology of Buyer’s actual damages after mitigation, but shall not exceed the purchase price actually

paid by Buyer for the defective Product.

Server Technology shall have no responsibility or liability for any Product, or part thereof, that (a) has

had the Serial Number, Model Number, or other identification markings altered, removed or rendered

illegible; (b) has been damaged by or subject to improper installation or operation, misuse, accident,

neglect and/or has been used in any way other than in strict compliance with Server Technology’s

operation and installation manual; (c) has become defective or inoperative due to its integration or

assembly with any equipment or products not supplied by Server Technology; (d) has been repaired,

modified or otherwise altered by anyone other than Server Technology and/or has been subject to the

opening of any sealed cabinet boxes without Server Technology’s prior written consent. If any

warranty claim by Buyer falls within any of the foregoing exceptions, Buyer shall pay Server

Technology its then current rates and charges for such services.

THE ABOVE WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ALL OF WHICH ARE EXPRESSLY DISCLAIMED. SERVER SHALL NOT BE

LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, SPECIAL, OR EXEMPLARY DAMAGES;

EVEN OF IT HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

For warranty issues, contact the Product Support Department at the number listed above. All repair and

return shipments must be approved by Server and must be accompanied by a RMA (Return

Merchandise Authorization) number and dated proof of purchase.

Product Registration

Registration is your key to special offers and services reserved for Registered Users.

• Excellent Technical Support Services

• Special Update and Upgrade Programs

• Warranty Protection

• Extended Warranty Service

• New Product Information

Register your products online today!

www.servertech.com\support\supportindex.htm

Technical Support

Server Technology understands that there are often questions when installing and/or using a new

product. Free Technical Support is provided from 8:30 AM to 5:00 PM, Monday-Friday, Pacific Time.

Server Technology, Inc.

1040 Sandhill Drive Tel: 775.284.2000 Web: www.servertech.com

Reno, Nevada 89521 USA Fax: 775.284.2065 Email: support@servertech.com

20 • Appendices Sentry Power Tower Power Distribution Unit

Warranty, Product Registration and Support Installation and Operations Manual

Page 25

Return Merchandise Authorization

If you have a unit that is not functioning properly and is in need of technical assistance or repair:

Submit a request for support by phone at the above number, or via the web at

www.servertech.com/forms/techrequest.htm.

Be ready to provide: Company Name

Contact Name, Phone Number, and Email address

Model or Part Number (from the label on the equipment)

Server Technology Serial Number

Version of code (type ‘vers’ at the Sentry: prompt)

Description of problem

1. Technical Support will work to diagnose/resolve the problem remotely, if possible. If the problem

cannot be resolved, Technical Support will then issue an RMA# for the return/repair of the

equipment in question. RMA#’s are valid for 30 days only from the issue date.

2. Shipping charges for the return of the equipment to Server Technology shall be the responsibility

of the customer. For warranty repairs, Server Technology shall assume return shipping charges but

for non-warranty repairs, the shipping charges shall be billed.

3. The RMA# shall be placed conspicuously on all shipping documentation, associated

correspondence, and the shipping container.

4. Equipment must be returned in proper/original packaging to protect the equipment in transit. The

customer shall be financially responsible for any damage/destruction of the equipment due to

improper packaging.

5. Equipment shall typically be turned around within 48-72 hours of receipt at Server Technology.

Equipment under warranty shall be repaired at no cost. Equipment NOT under warranty shall be

repaired at the standard labor rate plus parts. Upon diagnosis of the equipment, the customer shall

be notified of estimated charges prior to repair.

6. For non-warranty repairs, return of the equipment will be expedited with the inclusion of a

Purchase Order or credit card number for incurred charges.

Sentry Power Tower Power Distribution Unit Appendices • 21

Installation and Operations Manual Warranty, Product Registration and Support

Page 26

Server Technology, Inc.

1040 Sandhill Drive, Reno, Nevada 89521 • (775) 284-2000 • Fax: (775) 284-2065

E-mail: sales@servertech.com • World Wide Web: www.servertech.com

Sentry, and Sentry Power Distribution Unit are trademarks of Server Technology, Inc.

© 2002 Server Technology, Inc. All rights reserved.

301-0121-1 Rev. C (060603)

Loading...

Loading...