Page 1

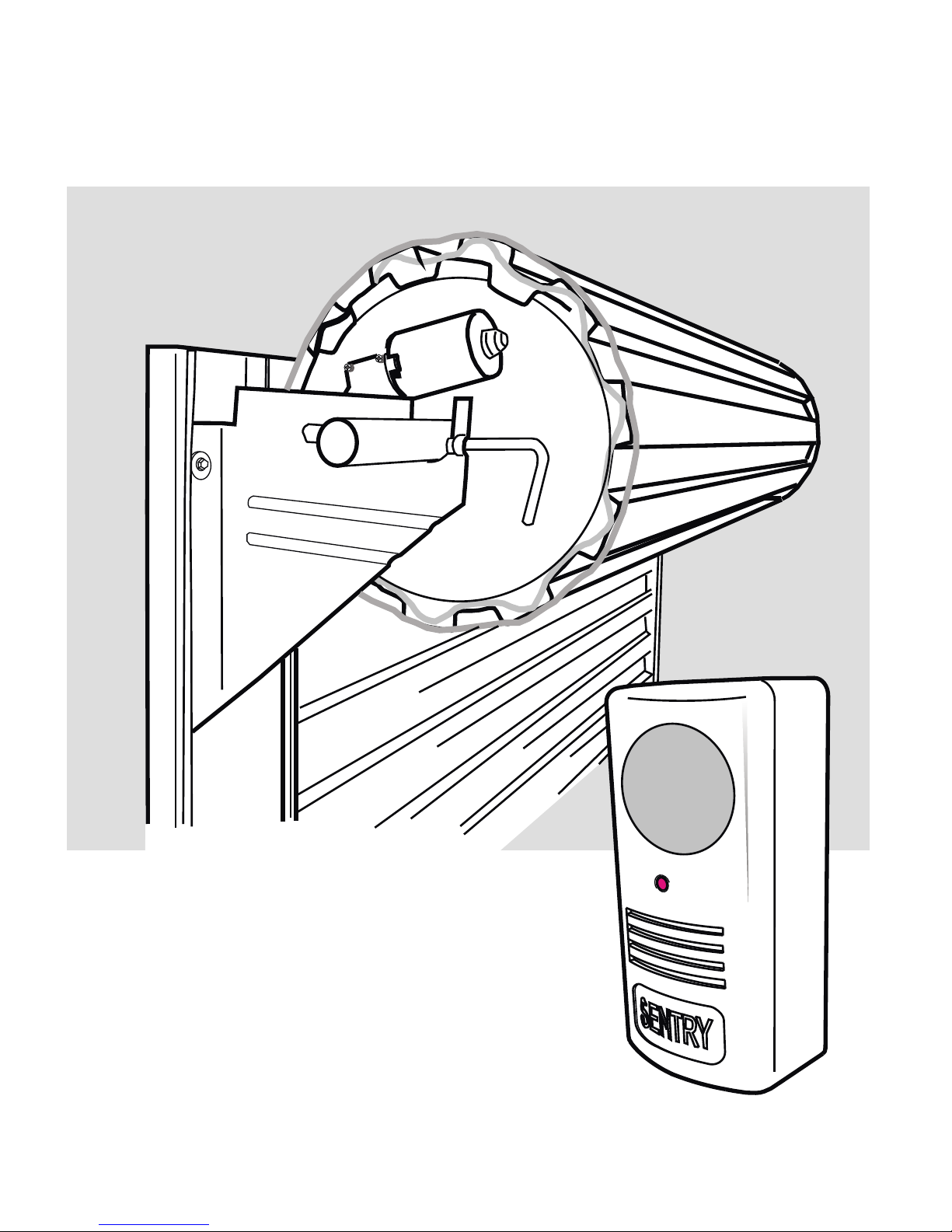

SENTRY

DCC02 Roll-up Garage

Door Automation

Installation and User Manual

Page 2

Technical Support

+27 11 433 4084

For technical

queries relating

to use/installation

of this product!

POWERED BY

ENG

Manufactured By Martin Electronics cc

PO BOX 49284, ROSETTENVILE 2130

Republic of South Africa

AFR

Vervaardig Deur Martin Electronics cc

Posbus 49284, ROSETTENVILE 2130

Republiek van Suid Afrika

ESP

Fabricado por Martin Electronics cc

PO BOX 49284, ROSETTENVILE 2130

la República Surafricana

DEU

Hergestellt durch Martin Electronics cc

PO-Kasten 49284, ROSETTENVILE 2130

Republik Südafrika

Page 3

Table of ContentsTable of Contents

Company Profile ...........................................................................................

Warnings and Cautions for Use .................................................................

Introduction ..................................................................................................

Package Contents ............................................................................

Door Types and Considerations .......................................................

Door Checklist ..................................................................................

Required Equipment ...................................................................................

Component Details .....................................................................................

Head Unit .........................................................................................

Wall Console ....................................................................................

Fitting Wall Console Cables .............................................................

Fitment of Motor to Door ............................................................................

Motor orientation and motor wire sequence ....................................

Fitment to standard platform doors ..................................................

Fitment to other door types (KRAZI-DOOR, etc...) ..........................

Fitment of Wall Console ..............................................................................

System Commissioning ..............................................................................

Connection Diagram For External Receiver .....................................

Connection Diagram For IR Beams .................................................

Connection Diagram for Remote Status LED ..................................

Powering Up The System ................................................................

Setting Up Door Limits .....................................................................

Adding weight to very light doors .....................................................

Programming Remote Controls .................................................................

Selecting Remote Control Storage Slots ..........................................

Erasing all the remote controls .........................................................

Advanced Features .....................................................................................

Activating and Deactivating auto-close ............................................

Adjusting the auto-close timer .........................................................

Troubleshooting Guide ..............................................................................

Limit Programming Troubleshooting .................................................

Operational and General Troubleshooting ........................................

Error codes and STATUS LED flashes .............................................

Product Specification ..................................................................................

4

5

6

6

7

8

9

10

10

11

12

14

15

16

22

25

27

28

29

30

31

33

36

37

38

40

41

42

43

44

44

45

47

48

LISH

E

N

G

3

Page 4

Company ProfileCompany Profile

Martin Electronics is a

respected and well-known

manufacturer of RF

remote controls and security

products and has

established itself as the

leader in RF remote control

for the past 20 years.

The company manufactures

remote controls, receivers,

infrared beams and garage

door automation products

under the Sentry brand

name.

The company also manufactures products for OEM (Original

Equipment Manufacturers) and custom markets and is deeply

respected in this regard as it designs and manufactures not only

its own products but specialised and custom products for

specific customers and provides support for these products.

MARTIN ELECTRONICS strives to give service and backup

second to none. Technical staff, as well as our engineers are

available to give answers to technical or installation problems.

The equipment is installed countrywide and is available through

a network of distributors in South Africa.

Further information is available on our website

www.martin-electronics.co.za

© Martin Electronics cc 2009

Martin Electronics cc. reserves the right to make changes to the products described in this manual without notice and without obligation of

Martin Electronics cc to notify any persons of any such revisions or changes. Additionally, Martin Electronics cc. makes no representations

or warranties with respect to this manual.

No part of this document may be copied, stored in a retrieval system or transmitted in any form or by any means electronic, mechanical,

optical or photographic, without the express prior written consent of Martin Electronics cc.

LISH

E

N

G

Page 5

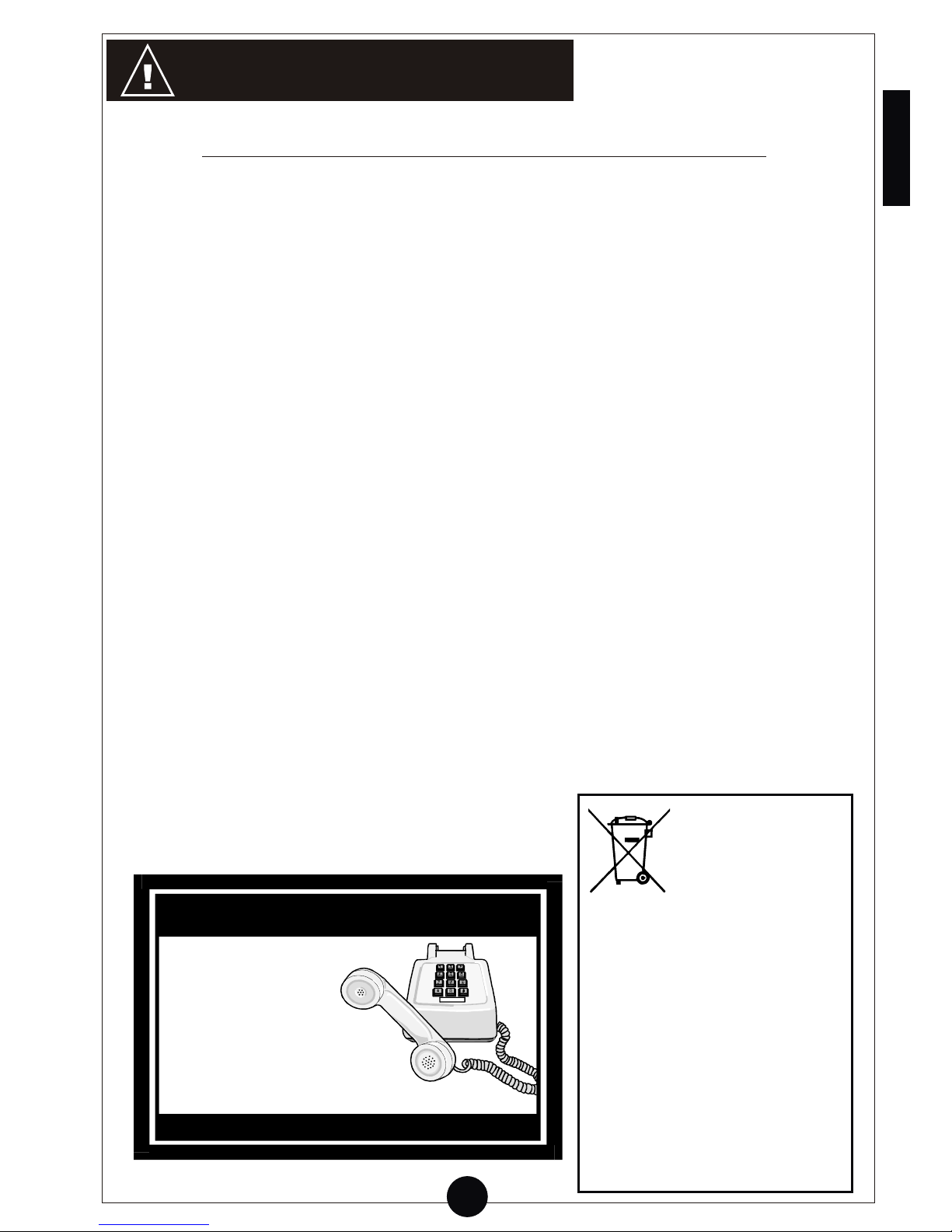

WARNINGS AND CAUTIONS

PLEASE READ THE FOLLOWING WARNINGS AND CAUTIONS

BEFORE INSTALLING OR USING THE PRODUCT.

RISK OF ELECTRIC SHOCK AND/OR FIRE

DO NOT TOUCH ANY COMPONENTS WHEN POWER IS APPLIED

1. Read all instructions and warnings

carefully before installing the product

2. The product must only be installed by suitably

qualified persons.

3. NEVER allow children to play with the door or

its remote controls and keep children and pets

away from the door, especially when it is being

used.

4. Secure all remote controls and opening

devices to prevent unauthorized access to the

door.

5. Before attempting any work or

maintenance on the product, disconnect

the power and remove the batteries (if

applicable)

6. All modifications not expressly approved by

the manufacturer are forbidden.

7. Do not install the product in an explosive

atmosphere or in any location subject to heavy

moisture ingress.

8. Safety devices i.e. IR beam, must be fitted to

prevent death or injury by crushing due to

persons or pets being in the path of the door

curtain.

9. Always keep objects, pets, and people away

from the path of a moving door.

10. Never short circuit any wiring to and from

this equipment

11. The installer has a responsibility to explain to

the owner/user how the system operates

and how to deal with potential emergencies

that may arise during the scope and course

of the product's application. The installer

must also pass on these instructions to the

owner/user

12. The product is designed and manufactured

only for the applications intended in this

manual. Any other use renders the warranty

null and void and neither the manufacturer or

its distributors, affiliates, servants, etc. shall

be held liable for any loss or damages

whatsoever.

13. This product employs double insulation, and

therefore does not require an earth

conductor.

14. Always ensure the manual override cord is

easily accessible at all times.

15. Never short circuit the wiring between the

wall console and the motorised head unit, of

this product.

Technical Support

+27 11 433 4084

For technical

queries relating

to use/installation

of this product!

LISH

E

N

G

5

NOTICE

REGARDING

BATTERIES

This product contains leadacid batteries, which may not

be disposed of by way of

regular household refuse.

Please consult with your

local authorities as to the

safe procedure of disposal

when the batteries are

replaced or product

disposed of.

DO NOT DISASSEMBLE

BATTERIES! CORROSIVE

SULPHURIC ACID!

Page 6

IntroductionIntroduction

The SENTRY DCC02 is a second-generation roll-up door automation product

designed for domestic and light industrial applications.

The product is designed to fit most roll-up garage doors that have plastic or metal

spool wheels. It operates by applying a rotational force to one of these spool wheels

which then in turn opens, or closes the door curtain as desired.

The DCC02 system consists of two parts, one of which is the motorised portion, that

drives the door, and fits inside the door curtain roll. This is known as the “head unit”.

This part is controlled, electronically, from the wall console. The wall console

contains the power source, and the remote control receiver and includes a courtesy

light and a control button on the front cover. To keep wiring to a minimum, only a

total of three wires are used between the units. This is made possible using a digital

one-wire bus.

The system provides limited battery back-up for mains failure situations. Alerts are

provided for both mains failure and low battery conditions. The system integrates a

learning remote control receiver which is compatible with SENTRY code hopping

remote control transmitters. A maximum of 8 remote controls may be learnt into the

system in total.

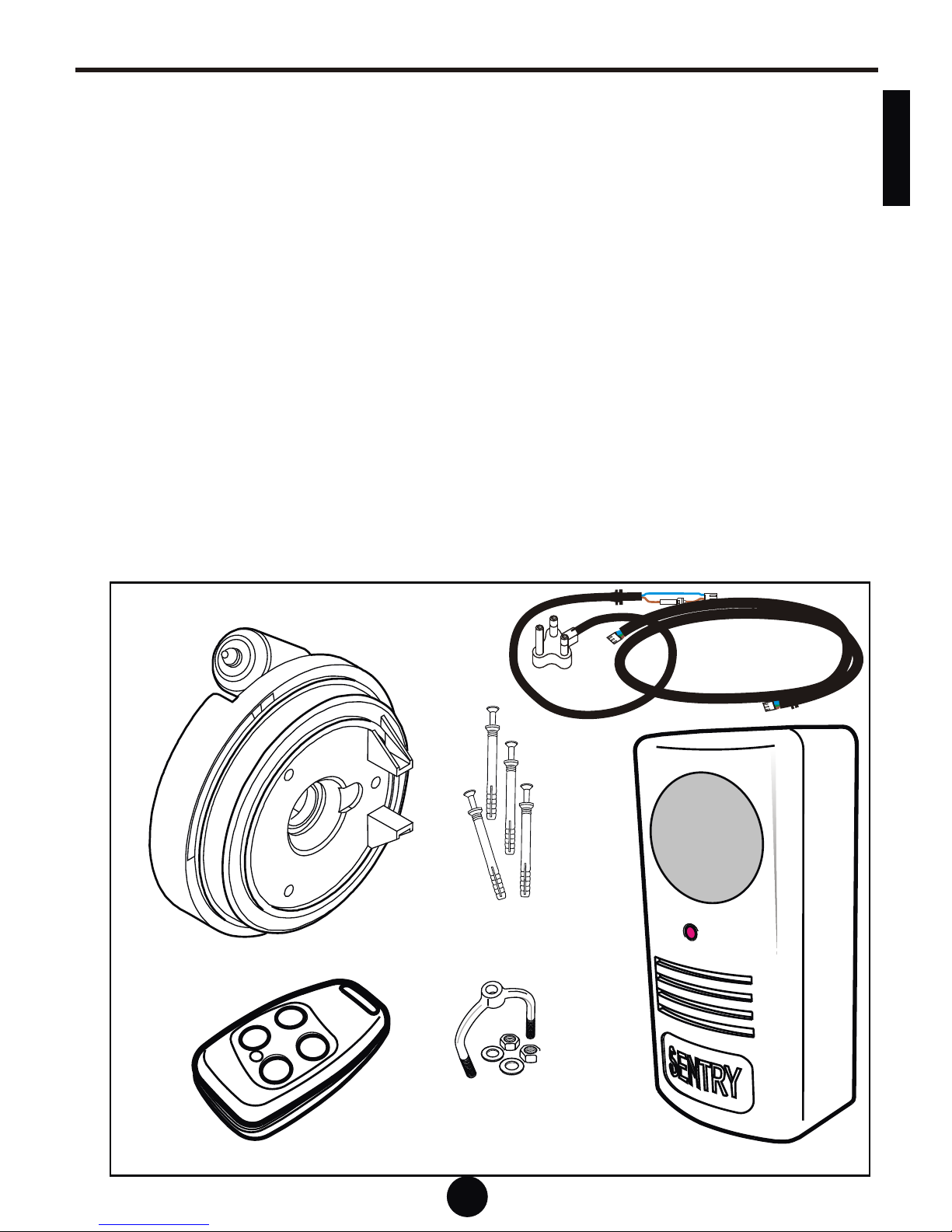

Wall Console

Motorised Head Unit

Code Hopping Remote Control (2 pcs)

Package Contents

U-bolt mounting kit

LISH

E

N

G

6

Masonry anchors

(4 pcs 6x60)

Power &

Interconnect

cables

Page 7

Door Types and ConsiderationsDoor Types and Considerations

IMPORTANT - PLEASE READ THIS SECTION CAREFULLY TO

ENSURE THAT THE DOOR YOU INTEND TO AUTOMATE, MEETS

THE REQUIREMENTS FOR SUCCESSFUL AND TROUBLE-FREE

OPERATION!

Door Brands

This product is designed to operate, primarily with common types of roll-up door makes

and models found in the South African market. These include the WISPECO™ brand

and the KRAZI-DOOR brand. Other types are suitable, provided they meet the criteria

listed below.

Door Type

In general, the DCC02 is designed to operate the standard low-cost roll-up doors

commonly used in domestic applications- doors which are fabricated from thin

laminated steel or aluminium. It is not recommended for use with the 1970’s era heavy

steel roll-up type doors, which are much heavier than the common roll-up door types.

Door Sizing

The DCC02 is designed to drive a single door by itself. For particularly wide doors, the

product must be installed in the centre of the door, by fitting an additional adapter

wheel. It is not possible to fit two motor head units to a single door. The height of the

door is not a factor, therefore, standard height doors as well as “caravan doors” are

suitable candidates for this product.

Door Condition

The condition, and quality of the installation of the door plays a MAJOR role in whether

the installation of this product (or any other garage door automation product) will be

successful or not. Common problems that cause this product to fail, either immediately,

or after some time include:

Doors that are not true- These are doors that are installed skew, leading to the

formation of gaps at the bottom when the door is fully closed. The DCC02 does

close the door completely to the floor but it was not designed to drive the door

curtain into the floor to seal against flooding etc...

Doors that are not balanced- These are doors that, although they appear to be

light to move by hand, either suffer from tight spots during travel, or get stiff in

cold weather. The DCC02 can compensate to a large degree, for cold stiffness

but beyond this, will consistently go into over-current to protect the motor.

Doors that are too light- A frequent problem is a door that is too light, causing

the door to unravel at the top, when closing. In these cases, it is necessary to add

weight to the bottom of the door, in the form of a steel bar or angle iron. Doors

that are too light also cause the system to exhibit various symptoms. These

symptoms include moving short distances, stopping shortly after opening, etc..

LISH

E

N

G

7

Page 8

Door Types and ConsiderationsDoor Types and Considerations

Doors with bent take-up spools- These are doors with bent spools, that

pull the head unit’s driving wheel proportionately skew. The product suffers

damage and exhibits all kinds of fault conditions, most commonly that of

moving short distances.

Door Condition Checklist

Uneven Floor / Door Mounted Skew

üü

ýý

ýý

Unbalanced door (tends to open by itself due to

over-tensioned springs)

Door equally easy to lift, or to pull down

üü

Tube

Internal wheel

(plastic or metal)

Door

Curtain

ýý

Bent, warped, or skew spool wheels

This causes damage to the product and is

very common on badly installed doors and/or

very cheap doors!!

Door lands flat on floor and doesn’t recoil

The start of the door curtain must be affixed at

the end, to the door spools using a tek screw. This

helps prevent problems and also secures the door

better against intrusion

üü

LISH

E

N

G

8

Page 9

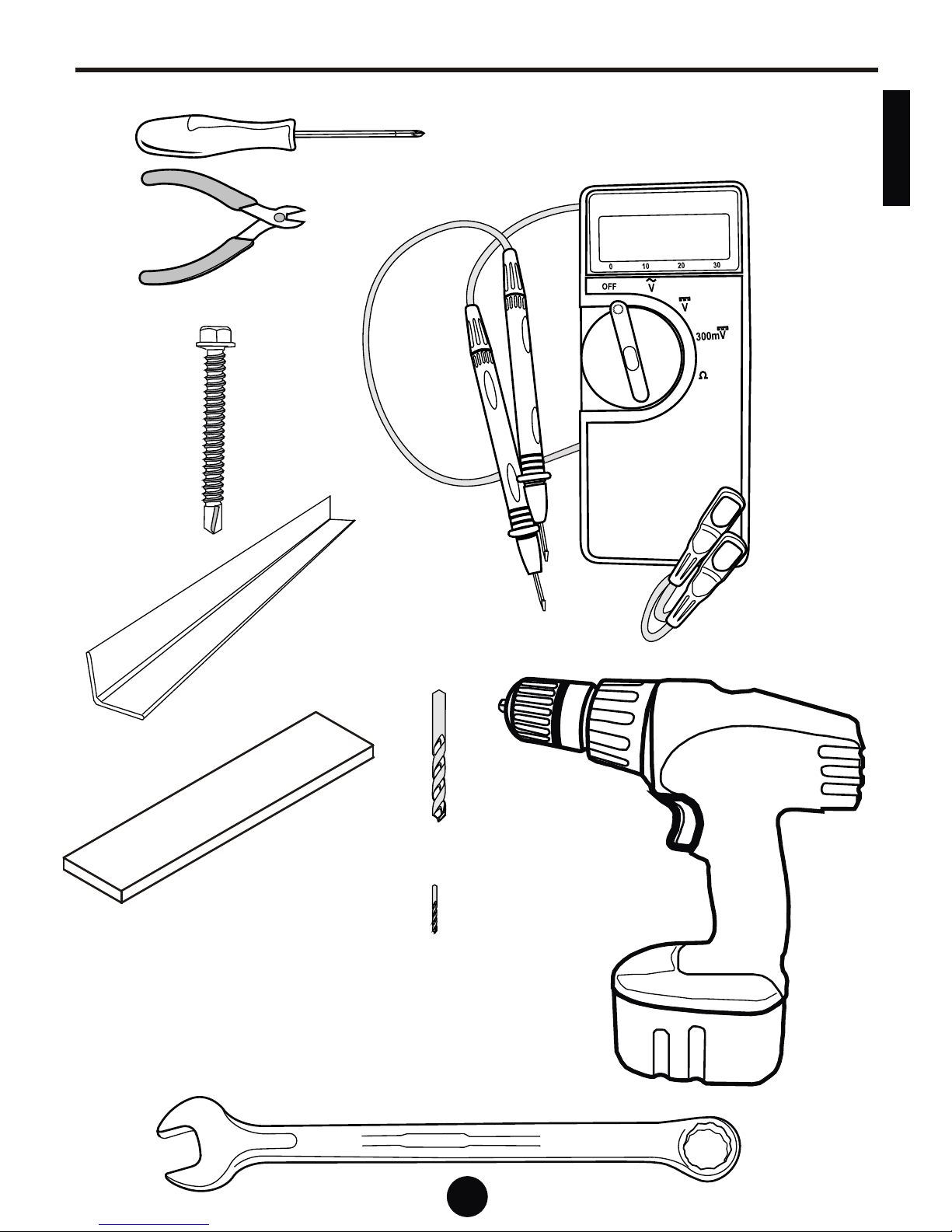

Required Equipment for InstallationRequired Equipment for Installation

Philips screwdriver & Flat screwdriver

Small Side Cutter

Multimeter

Impact Drill

Drill with

impact setting

Masonry Drill Bit

(6 ~ 6.5mm)

Spanner set (17 ~ 21)

Tek Screws

Length of

Angled Steel

HSS Drill Bits

(6 ~ 10mm)

Length of

Rectangular steel bar

(To fabricate a base-

LISH

E

N

G

9

Page 10

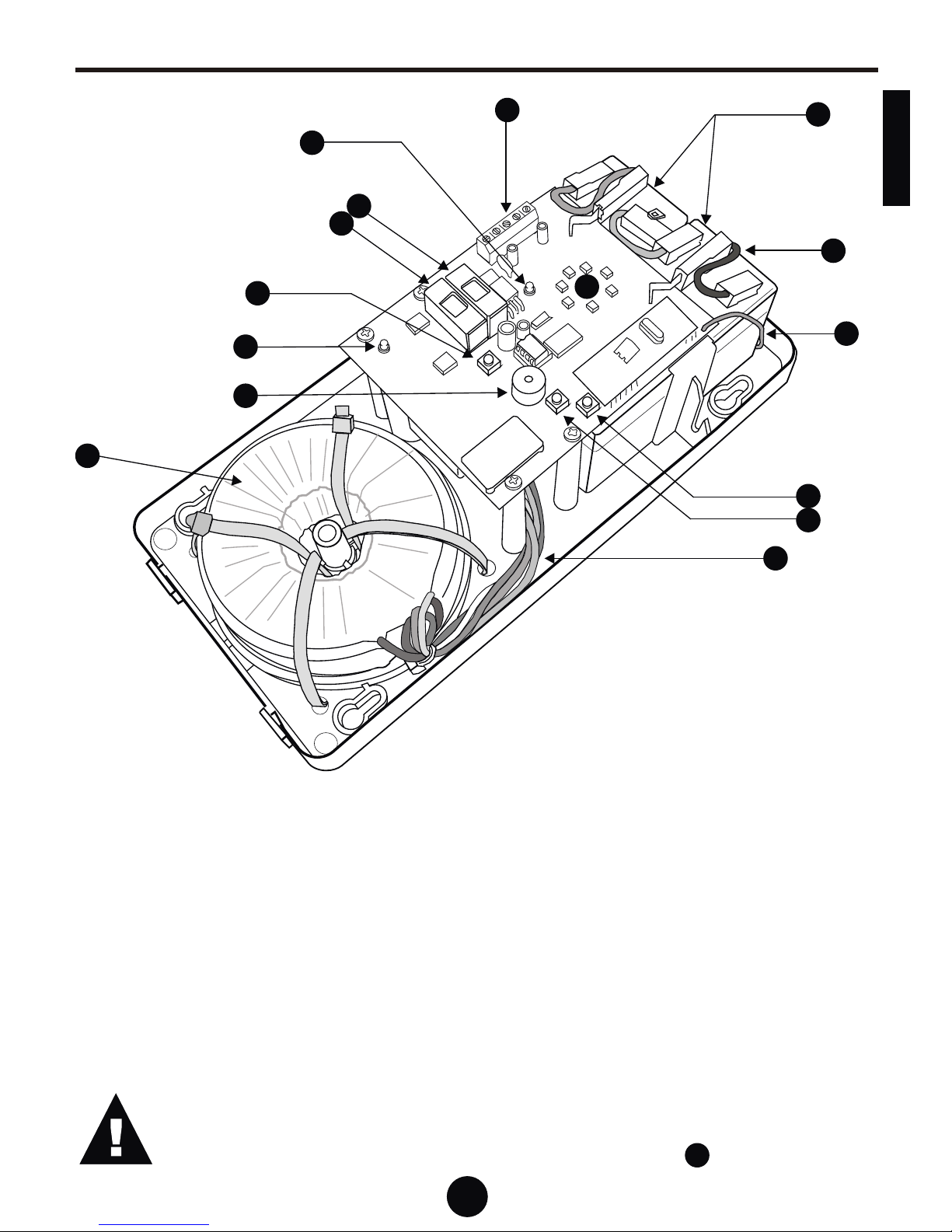

Component Detail - Head UnitComponent Detail - Head Unit

5

1

2

3

4

8

6

7

1. DC Motor

2. Plastic unit housing

3. Motor wires (green & brown)

4. Head unit controller PCB

5. Manual Override Engage/disengage lever

6. Manual Override lanyard guide

7. Optical Pick-up

8. Optical encoder gear

9. Power and signaling connector

Shown with cover removed

9

THE POWER AND SIGNALING CABLE (3 CORE) CAN ONLY GO INTO

THE PCB IN ONE ORIENTATION WITH THE RELEASE TAB FACING

DOWNWARDS. FORCING IT IN ANY OTHER WAY WILL CAUSE

DAMAGE TO THE PRODUCT AND MAY LEAD TO BURNS AND/OR

FIRE FROM THE RESULTING SHORT CIRCUIT.

üü

CORRECT

WRONG

ýý

LISH

E

N

G

10

Page 11

Component Detail - Wall ConsoleComponent Detail - Wall Console

1

2

3

7

8

4

5

6

9

10

11

12

13

14

1. Lead-acid battery (12V 1.3Ah x 2)

2. Battery interconnects

3. Remote receiver antenna lead (BROWN)

4. SET button

5. LEARN button

6. Transformer wiring loom (6 cores terminated onto

Molex connector)

7. Auxillary connection terminals

8. STATUS LED indicator

9. Auxillary supply fuse (1 AMP)

10. Main fuse (5 AMP)

11. TRIGGER button

12. POWER GOOD LED indicator

13. Buzzer

14. Toroidial transformer

15. LED lamp

Shown with cover removed

The product is supplied without the power and interconnecting leads fitted to the

wall console. The leads are to be plugged into the wall console PC board as shown

in the next section.

15

TAKE CARE WHEN REMOVING OR REPLACING THE COVER OF THE

WALL CONSOLE, OR DURING TRANSPORTATION AS DAMAGE

COULD RESULT TO THE LED LAMP

15

LISH

E

N

G

11

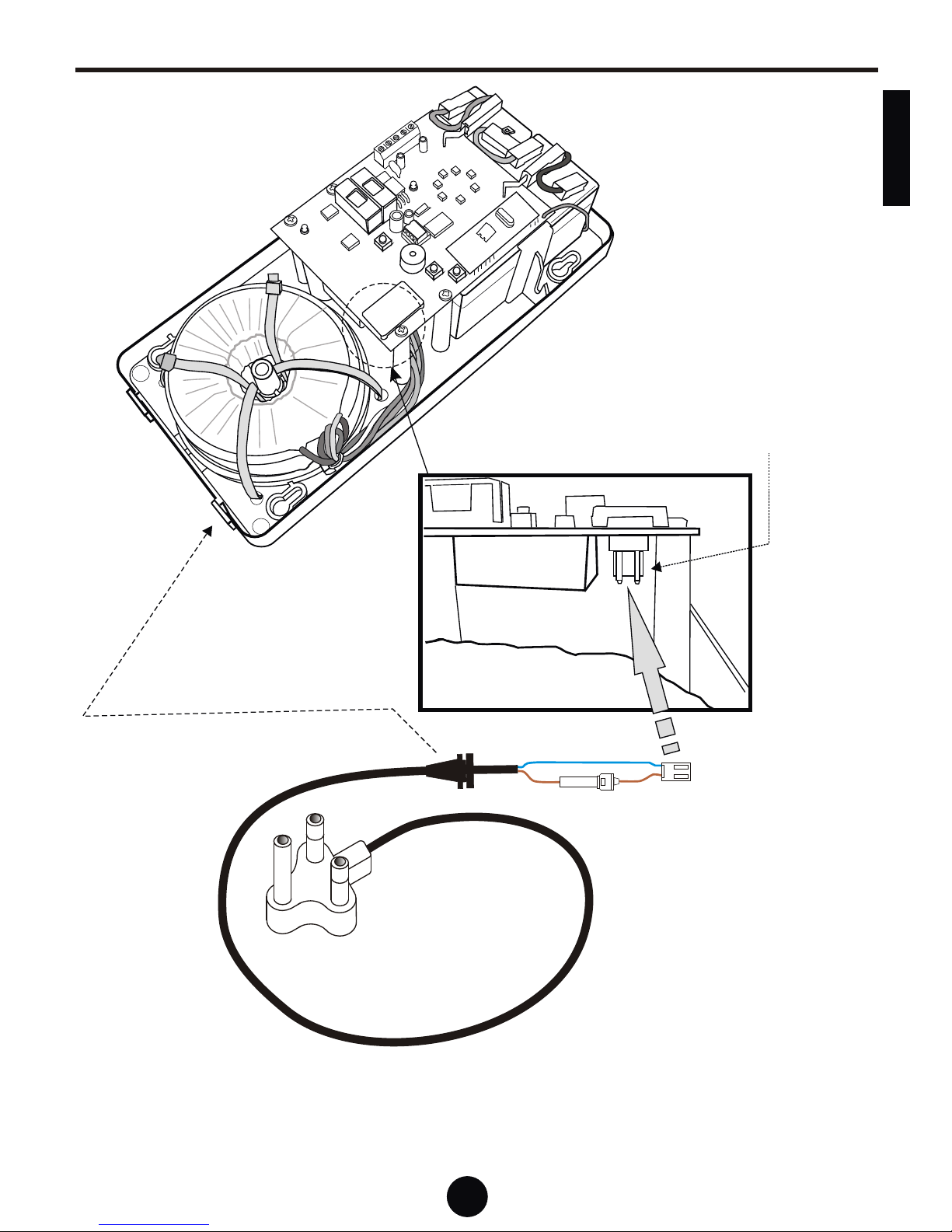

Page 12

Wall Console - Fitting the cablesWall Console - Fitting the cables

2 pin header

(AC MAINS)

SUPPLIED MAINS LEAD

WITH PLUG

(Plug fitted varies according

to region and local mains voltage)

Locate the two pin header on the underside of the wall console PCB as shown

above. Plug the two pin receptacle on the one end of the mains lead, as shown, into

the receptacle. The moulded grommet, on the cable is designed to slot into a mating

receptacle in the base of the wall console as shown above.

FUSE

LISH

E

N

G

12

Page 13

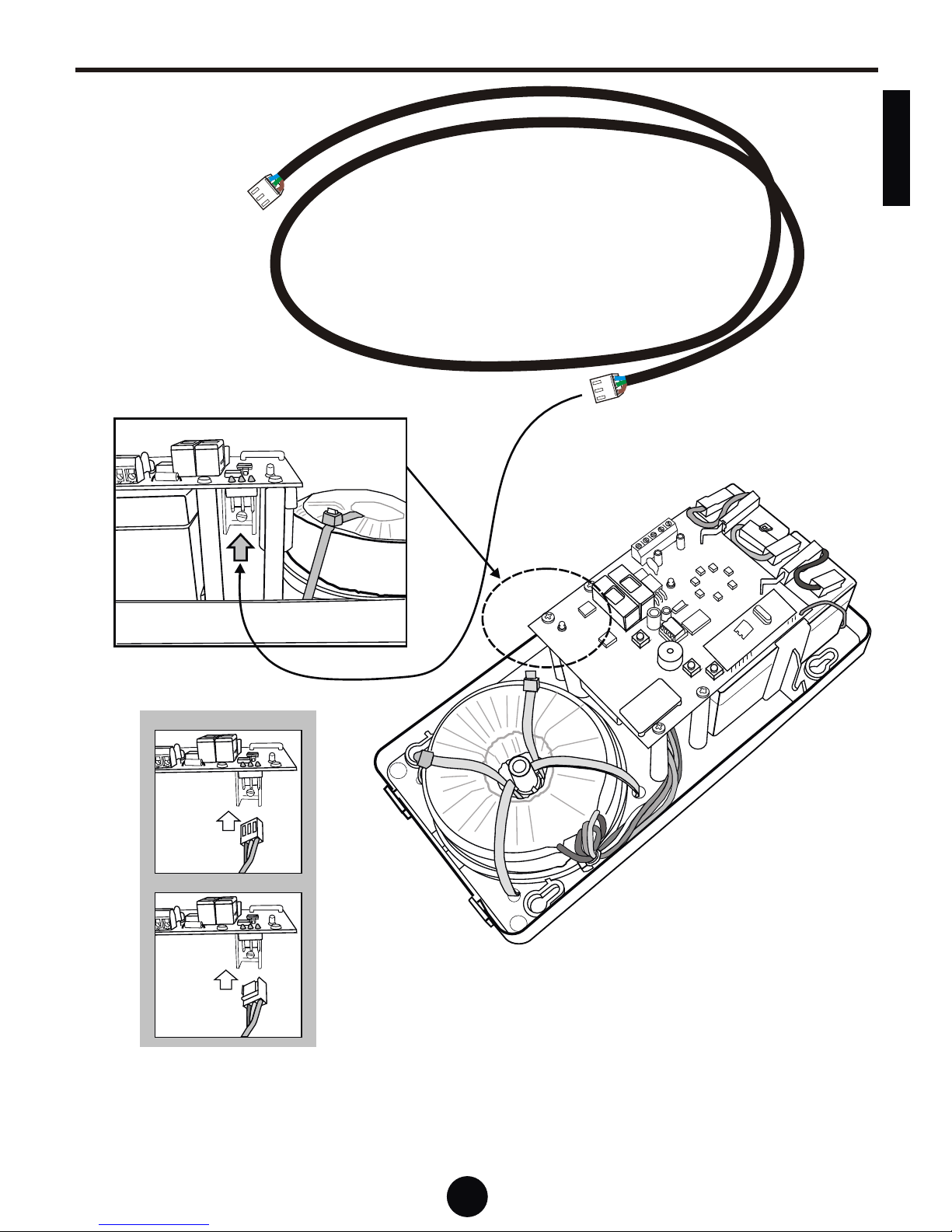

Wall Console - Fitting the cablesWall Console - Fitting the cables

Locate the three pin header on the underside of the wall console PCB as shown

above. Plug either end of the interconnecting cable into the receptacle. The moulded

grommet, on the cable is designed to slot into a mating receptacle in the base of the

wall console as shown above.

SUPPLIED INTERCONNECT

CABLE

üü

ýý

LISH

E

N

G

13

Page 14

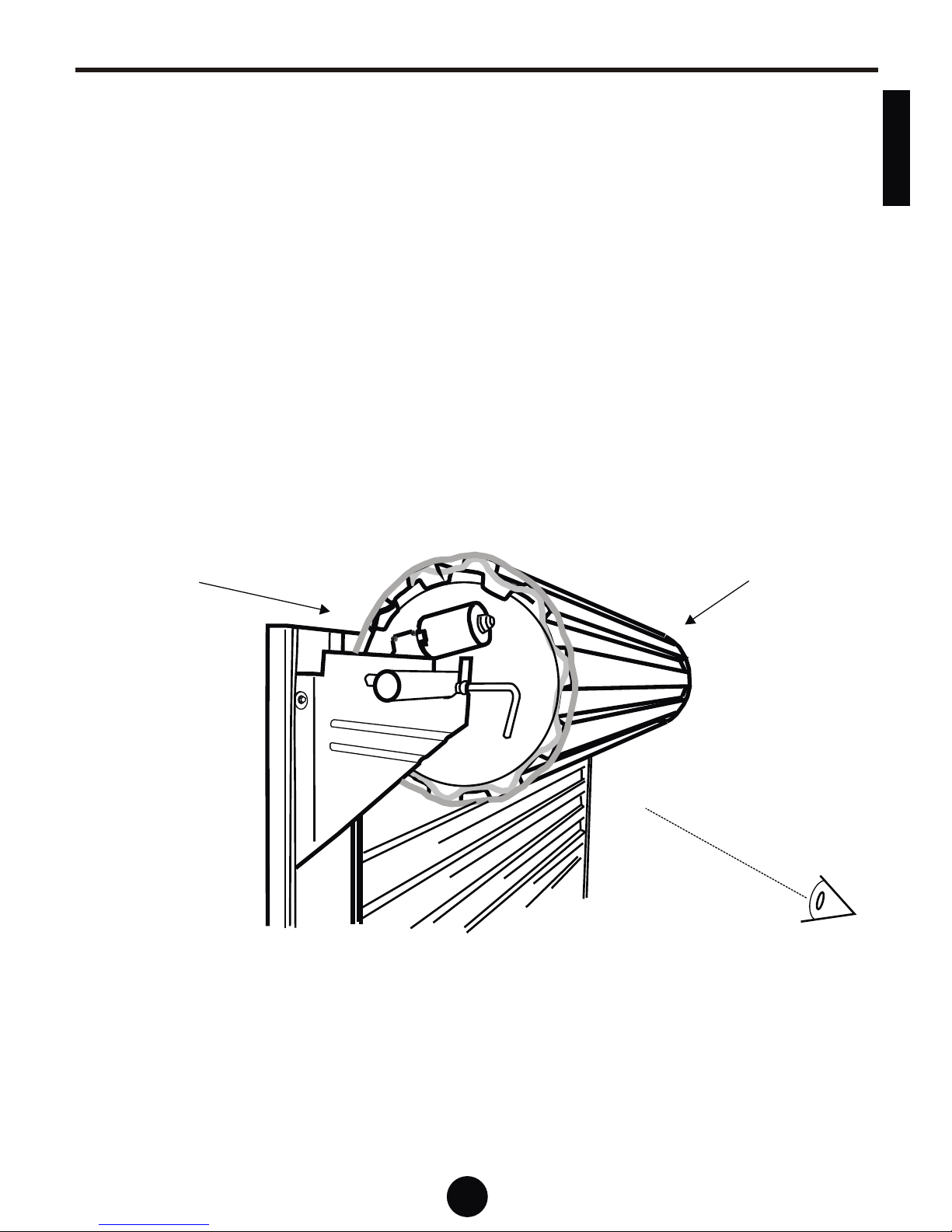

Motor Head Unit InstallationMotor Head Unit Installation

The following sections detail how to install the motor head onto the door. Please pay

special attention to the various aspects of installation as failure to do so will lead to

product failure and/or malfunction.

In general, two types of door design exist, the first type is the “Wispeco” type door

where the door pole is mounted on a platform. The second, more common door type

are those doors consisting of a retaining plate. Both types will be covered in the

following sections.

In all cases, you will need to loosen one end of the door, and re-balancing will

inevitably required once the motor is fitted.

The motor may be mounted either side, where space permits, however pay special

attention to the motor polarity wires as this will need to be changed according to which

side the motor is installed.

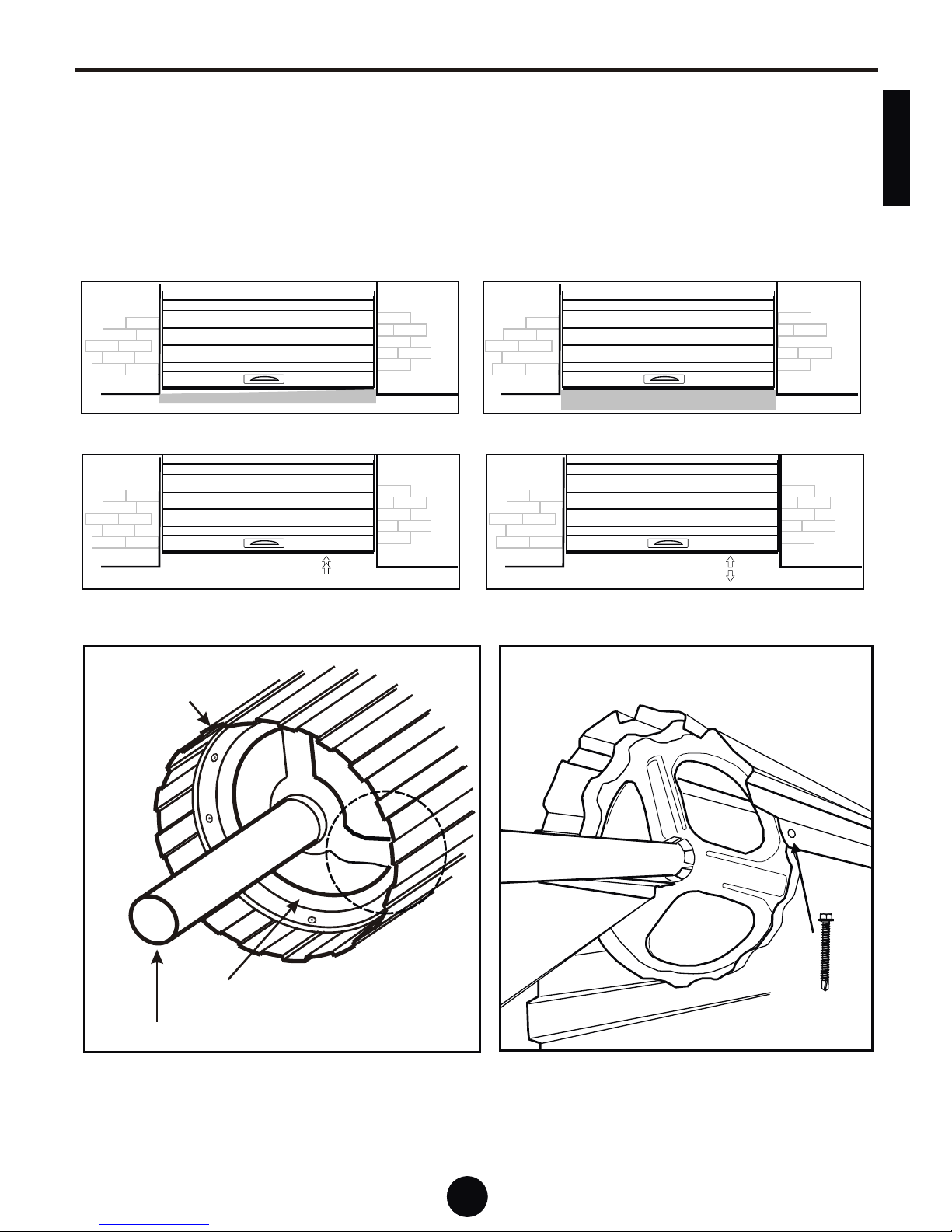

Determining which side of the door is the left and right

Left Hand Side Right Hand Side

From inside the garage, i.e. where the roll is situated, looking at the door as shown,

the left hand side is to your left, the right hand side is to your right. The motor is

factory shipped by default for a left hand side install. If you would like to install

the motor on the right hand side, it is necessary to swap the motor wires on the motor

PCB as shown on the next page.

Viewed from

inside garage

LISH

E

N

G

14

Page 15

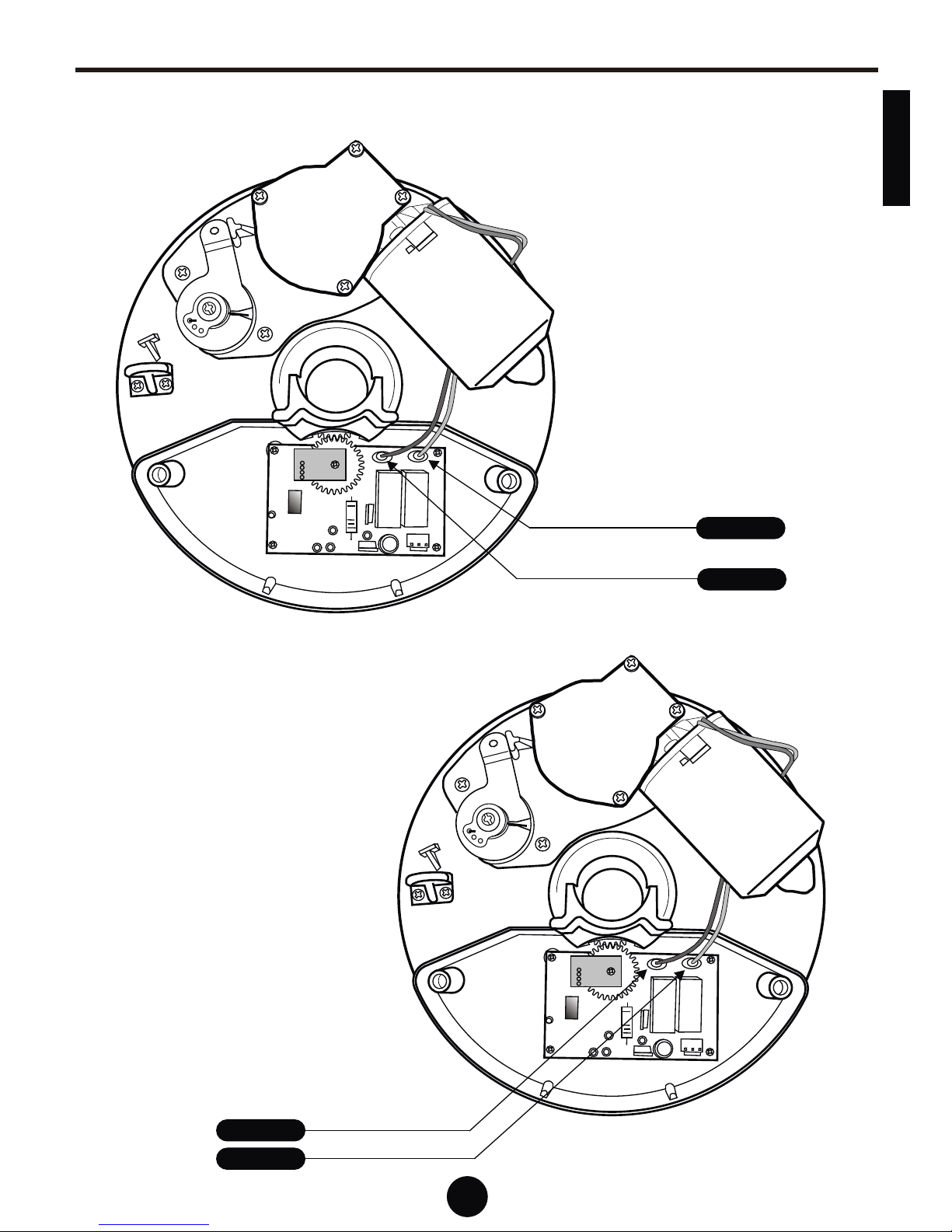

Motor Head Unit InstallationMotor Head Unit Installation

8

8

Factory Shipped

Configuration

Left Hand Side

Install

Right Hand Side

Install

BROWN

GREEN

BROWN

GREEN

LISH

E

N

G

15

Page 16

Motor Head Unit InstallationMotor Head Unit Installation

Once you have determined where you would like to install the motor, and have

changed the motor wires accordingly (if necessary) the next step required is to loosen

the desired end of the door. The tube is moved away from the door support so that the

motor can be slipped onto the tube.

Most doors, predominantly the WISPECO™ doors are platform mount doors i.e.

the tube rests on platforms to which it is affixed with u-bolts. Many other doors

have different types of fixing systems, but the principle remains the same.

Loosen and remove

the existing u-bolt

completely.

LISH

E

N

G

1

Lift tube off from the

platform and away from it

and lower downwards as

shown.

Support using a trestle or

scaffold, ensure

enough space to fit motor.

Note: Other types of doors

do not have platforms but

side panel brackets, the

procedure is the same, lift

the tube off the bracket

and support it as shown.

2

16

Page 17

Motor Head Unit InstallationMotor Head Unit Installation

LISH

E

N

G

3

With the motor gearbox

disengaged, push the

motor onto the tube until it

is supported on the tube.

Do not yet push it against

the spool wheel.

4

With the motor head unit on

the edge of the steel tube,

align the two drive hooks

on the driving wheel, so that

it will brace against one of

the spokes of the spool

wheel.

17

Page 18

Motor Head Unit InstallationMotor Head Unit Installation

LISH

E

N

G

5

With the two drive hooks aligned as shown in the previous step, gently press the

motor and the spool wheel together as shown. The motor must fit snugly against

the spool wheel. Lift the door tube back onto the platform, the stem of the motor

unit resting on the platform.

WARNING: if it does not fit, do not force it, instead acquire an

adaptor wheel and fit it to the door, or replace the spool wheel

with a SENTRY adaptor wheel.

The drive hooks are critical items and must not be damaged in any way

due to being forced to fit, or by being machined. This could lead to product

failure, resulting in potential injury, and damage to property. Machining of

the drive hooks and/or damage to them will render the warranty null and

void!

An acceptable alternative approach, is to machine material off the spoke to allow

enough clearance for the drive hooks. Please be aware that there is a limit to how

much this can be done, and in any case, a retrofit of an adaptor wheel is always

recommended.

18

Page 19

Motor Head Unit InstallationMotor Head Unit Installation

LISH

E

N

G

19

6

Looking at the opposite side of the motor, that is, from the driving wheel side,

ensure that both drive hooks fit snugly as shown in the above diagram.

The maximum amount of clearance between the surfaces of the

spool wheel and the drive hooks is approximately 1.5mm.

Too much free play on either or both drive hooks, will cause

product malfunction (false collisions and stopping short)

7

Reposition the tube, as

shown here, on the

platform, ensuring it is in

the same position when

you removed it originally.

Attach the supplied release

lanyard to the release pawl

and route the nylon lanyard

as shown in this diagram.

Caution: ensure the

release lanyard is clear of

the door curtain edge at

all times. Route the cord

in a manner that is kept

clear of the door curtain.

Release LanyardRelease Lanyard

Page 20

Motor Head Unit InstallationMotor Head Unit Installation

LISH

E

N

G

20

Tightening the motor and tube assembly

For platform type (WISPECO™) doors, replace the original u-bolt. Inspect the

washers and nuts and replace if needed

For other types of doors, you will need to use the supplied u-bolt, cut and drill a

baseplate, and install as shown in the following sections from page 22 onwards.

8

Reinstall and tighten the original

u-bolt as shown alongside. Be

sure to tighten the u-bolt nuts

sufficiently so that the stem of

the motor unit is clamped

securely, and cannot slip

sideways off the platform. It

may be necessary to fit washers

beneath the nuts to achieve

optimal tightness.

Note: In some instances it will

be necessary to fit the cover

before tightening the motor

as it will be difficult to get the

cover on afterwards.

9

Connect the free end of the

supplied interconnect cable to

the receptacle on the PCB as

shown. Route the cable along

the platform edge to keep it

away from the door curtain edge.

Caution: Ensure there is

enough cable slack in the

portion that enters the PC

board compartment so that

fitment of the cover is not

problematic!

Refer to Page 10 for

correct plug orientation!

Page 21

21

Motor Head Unit InstallationMotor Head Unit Installation

LISH

E

N

G

When fitting the cover, route the

motor wires and the

interconnecting cable through the

slots in the cover as shown. The

cover is a press-fit, it is not

affixed with screws.

10

Once the motor is attached to the door, the u-bolt may be fastened. With the motor

disengaged, the door needs to be checked for balance, and if necessary,

adjustments made. Additionally if the door is light, it will be necessary to add weight

at the bottom, using a length of angled steel as listed under “Required Equipment”

Page 22

Motor Head Unit InstallationMotor Head Unit Installation

LISH

E

N

G

22

Tightening the motor unit on a door with side plates

(KRAZI-DOOR, etc..)

For KRAZI DOOR (and other similar doors) it is

necessary to fabricate a steel baseplate and use

it in conjunction with the supplied u-bolt. This

configuration is the only acceptable one - not

doing this exactly as shown will lead to product

failure which is not covered by warranty!

Using steel bar, as indicated in "Required Tools and Equipment",

fabricate a steel baseplate with the following dimensions:

70mm

97mm

25mm

48.5mm

12.5mm

DIA TO SUIT TEK SCREW USED

DIA = 10mm

PLATE THICKNESS = 5~7mm

Notes:

Ensure all holes are drilled correctly- if they are too small it will be difficult to install

the u-bolt assembly with this baseplate.

Use of material thinner than 5mm is not recommended as it will distort and fatigue

due to the forces the door exerts on this part.

Page 23

Motor Head Unit InstallationMotor Head Unit Installation

LISH

E

N

G

23

The above figure shows how the u-bolt fits over the tube, and restrains the motor

unit to the tube, without reliance on a platform or interfering with the side plates.

The motor can be mounted, on these kinds of doors, in any position. Generally the

position is chosen to best permit the routing of the power cable and the release

lanyard.

On the next page, the sequence to assemble the u-bolt is shown.

Page 24

24

LISH

E

N

G

Motor Head Unit InstallationMotor Head Unit Installation

1

2

3

5

4

Step 1 - Fit the u-bolt over the motor unit stem as shown

Step 2 - Fasten the u-bolt to the tube by means of a tek screw

(a hole will now be made in the tube, locking the u-bolt

securely in place)

Step 3 - Fit the baseplate onto the ends of the u-bolt

Step 4 - Fit the washers and the nuts

Step 5 - Tighten the nuts, reasonably tight. DO NOT

OVERTIGHTEN

Once the motor is attached to the door, the tube may be reinserted into the

bracket and the steel retaining pin replaced. With the motor disengaged, the door

needs to be checked for balance, and if necessary, adjustments made.

Additionally if the door is light, it will be necessary to add weight at the bottom,

using a length of angled steel as listed under “Required Equipment”

Page 25

Wall Console InstallationWall Console Installation

25

LISH

E

N

G

The wall console is designed to be affixed to any surface using a variety of screws.

Four keyhole style mounting holes are provided in the base of the wall console for

easy mounting on a variety of surfaces. In most cases the unit will be affixed to a wall,

and the four supplied masonry wall anchors provided, should be used.

Mounting Distance From Motor Head Unit

In most cases, the length of the supplied interconnect cable is the general rule of

thumb. However in some instances it may not be possible to mount the wall console

this close to the motor. The interconnect cable may be lengthened, but by an

additional 2 metres only. This is achieved using three core cabtyre (1,25mm² or

greater).

Mounting Template

To assist with marking off hole locations on the surface where the wall console is to be

mounted, a template is provided, which is located in the centre of this manual and may

be pulled out.

Mounting Considerations

The wall console should be mounted in a location that is dry and not subject to

moisture. It should also preferably be mounted at a convenient height, but not too low

as this would affect remote control reception. Mounting on or near very large metal

structures should be avoided.

4

5

15

Wall console base with

arrows showing keyhole style

mounting holes

Page 26

26

LISH

E

N

G

Wall Console InstallationWall Console Installation

For typical masonry

(brick wall) mounting, it

is recommended to

install the nail in

anchors as shown.

The plastic sleeves are

inserted into the wall

first after being drilled

with the hammer drill.

1

2

Once the sleeves are

inserted into the wall, the

wall console may be

mounted onto the wall.

Be careful when

inserting the steel screws,

do NOT hammer them in,

use a screwdriver (or

cordless screwdriver) to

gently screw them into

the wall.

Once the wall console is

mounted, ensure that is

secure and cannot be

pulled from the wall or

mounting surface.

Note how

screw is

inserted

into keyhole

mounting hole

Page 27

LISH

E

N

G

27

System CommissioningSystem Commissioning

System Commissioning Procedure

This section explains the steps to be followed to commission the DCC02 post fitment

and installation on the door. Commissioning involves powering the system for the first

time, programming the limits, as well as additional electrical connections as may be

required for some applications.

Standard Installation

In most cases, the DCC02 will be installed in a stock-standard configuration without

any ancillary systems attached (beams, status indication extension, external

receiver). If this is the case, you can proceed directly to the section “System PowerUp”

Enhanced Installation

The DCC02 supports the use of safety beams to prevent injury to persons who are

likely to come into the path of a closing door. The use of a beam also offers peace of

mind when a door is likely to be triggered whilst a vehicle is moved in or out of the

garage.

The use of a beam is MANDATORY when the auto-close feature is enabled!

Failure to install a beam when auto-close is enabled can lead to property

damage and/or injury from a door that starts without warning.

In addition to beams, the DCC02 also supports the use of other remote control

receivers, as may be necessary in some installations (particularly when a

compatibility issue arises and the existing systems cannot be migrated to a SENTRY

remote control product).

Enhanced Installation Detail

The following sections explain electrical and other details pertaining to enhanced

installations

Using an external receiver with the DCC02

The DCC02 accommodates most any type of external receiver and provides a

convenient power source for the receiver, which should be mounted externally to the

wall console. The wall console provides a 24V DC supply for ancillary items, therefore

it is important to ensure that the receiver you intend using, can operate from 24 volts.

Most third-party receivers are able to operate from a 24 volt supply.

The receiver you intend to use, must have a normally-open potential free relay

contact. Receivers that output a “logic level” are not suitable.

Page 28

28

LISH

E

N

G

System Commissioning - External RcvrSystem Commissioning - External Rcvr

Connection Diagram for External Receiver

Close up of wall console

Ancillary terminals

External Receiver

GRN

BLK

RED

RED

GRNBLK

Cable: 4 core “comms” cable

Note that the common of the relay contact on the

receiver is connected to the negative terminal of

the receiver, therefore only three wires are

needed.

TRG

COM

B+

Trigger

Common

24V Positive Supply

N/O

- & COM

+ or +12/24

Wall Console Terminal Description Receiver Terminal

Ensure that the receiver you intend to use, can operate from a 24

volt DC supply.

Page 29

LISH

E

N

G

System Commissioning - BeamsSystem Commissioning - Beams

Connection Diagram for Infra-Red Safety Beams

29

Close up of wall console

Ancillary terminals

2

4

12

0

NC

NO

CO

M

Receiver

Transmitter

SENTRY IR BEAM

WALL CONSOLE TERMINALS

BEAM TX

BEAM RX

24

12

0

24

12

0

NC

NO

COM

TRG BM COM B+ LED

RED

BLK

BLU

RED

RED

BLK

BLK

BLU

BLU

RED

BLK

Cable: 4 core “comms” cable

Colour code: As per suggested

Page 30

30

LISH

E

N

G

System Commissioning - Remote LEDSystem Commissioning - Remote LED

Close up of wall console

Ancillary terminals

GRN

Connection Diagram for installing a remote status LED

A remote STATUS LED allows the user to know the status of the garage door

(open, closed or trouble) from a remote location within his/her residence. A standard

5mm RED LED is required for this feature (not supplied).

No series resistor is required and the line has protection against lightning.

Long Lead (ANODE)

Short Lead (CATHODE)

Flat notch (DENOTES CATHODE)

A

C

RED

RED

BLK

BLK

Take care when mounting the LED on a panel or when bending the

leads apart to solder the wires to them.

The maximum length of cable run is 15 -20 metres. Use thicker crosssection solid copper wire for longer runs otherwise LED brightness will

be imparied!

Page 31

System Commissioning - Powering UpSystem Commissioning - Powering Up

LISH

E

N

G

31

Powering Up the System

Once installation is complete, and, if applicable, the connections to beams and/or an

external receiver has been made, the system can be powered up by connecting the

batteries first (linking the terminal as shown below) and then by plugging in the mains

lead into an outlet and turning it on.

Powering Up

1. Connect the batteries by connecting the loose terminal, to the battery as shown

2. Plug the mains lead into a wall outlet and turn it on.

1

When power is applied, the system will give two high frequency beeps, signalling

that the system has powered up. The system signals various conditions using

audio-visual indications. The POWER GOOD LED lights when power is present.

e high frequency beep, generally indicating confirmation or a change in status.

e# low frequency beep, generally indicating error conditions or trouble.

POWER GOOD

LED

2

MAIN

FUSE

(F2)

On the drawing opposite, note the location of

the main fuse F2. This is the first point to check

when troubleshooting. Also see Page 32 for a

detailed description

Page 32

LISH

E

N

G

System Commissioning - Powering UpSystem Commissioning - Powering Up

32

Powering Up (cont..)

If the system has powered up correctly, there will be no further beeps. However, if

there is a problem, the system will emit error beeps and flash an error code on the

STATUS LED. These issues MUST be resolved before the system can enter limit

programming. Two possible situations could exist post power-up:

x 2 - two low-frequency beeps! This indicates MAINS FAILURE

x 4 - four low-frequency beeps! This indicates

COMMUNICATIONS FAILURE!

These system errors can be resolved by working through the “Troubleshooting”

section on page 44. However the following quick checks can be performed:

MAINS FAILURE: Check inline fuse on the supplied mains lead. If blown,

replace with a 1 AMP SLOW BLOW glass cartridge fuse.

COMMUNICATIONS FAILURE: Check if there is power on the head unit by

removing the cover and seeing if the STATUS LED on the PC board flashes

(see below), if not, measure the two outer terminals of the interconnecting

cable with a multi-meter. The reading should be 25-29V DC. If no voltage is

present, check the main fuse on the wall console designated F2. Replace if

blown. If this fuse continues to blow, check the interconnect lead orientation,

and especially the wiring if you have extended the lead.

When F2 blows on the wall console, it is generally indicative of a short

circuit on the DC supply. Replacing this fuse with a fuse of higher rating

can cause a fire, serious burns and severe product damage, which is not

covered by warranty. If in doubt, please call Technical Support.

e#

STATUS

Indicator

This STATUS indicator

flashes continuously during

normal operation, indicating

that communication is taking

place between the wall

console and the motor unit

Page 33

LISH

E

N

G

33

System Commissioning - LimitsSystem Commissioning - Limits

Limit Programming

Before the garage door operator can be used, the door limits have to be programmed.

This is an automated process, that involves little user input. Assuming the system has

powered up correctly (no beeping) the limits can then be programmed by following the

procedure in the following sections.

In the factory shipped state, the system will only accept a Limit Setup

command, all triggers are ignored until the door is set up correctly. This

is not a fault, it is for your safety.

To invoke Limit Programming

1. Close the roll-up door completely and ensure that the door seats properly on the

floor. Ensure the door is ENGAGED. If you cannot lift the door, it is engaged, if

not, pull the mechanical release cord until the door is locked.

2. Remove the wall console cover, and press and HOLD SET, until a beep is heard.

The door will begin to open slowly.

When running the Limit Programming utility, please ensure that the

batteries have had sufficient time to charge (usually 3-4 hours from the

factory) and that the batteries are connected. Performing Limit

Programming without batteries connected is not permitted, and will lead

to product failure.

Press and Hold “SET”Press and Hold “SET”

e

Single BeepSingle Beep

Page 34

Limit Programming (cont)

The door will open slowly until the end-stop is encountered. When the endstop is

encountered, the door will stop for a few seconds, then close at full speed, then stop.

It will wait for a few seconds and then open fully at full speed. This is done in order to

measure various parameters needed to set the collision sensitivity automatically,

amongst other parameters.

System Commissioning - LimitsSystem Commissioning - Limits

LISH

E

N

G

34

1

Door opens slowly in the first stage of limit programming

2

Door homes against metal endstop, this registers the limit.

The motor then stops.

The door will open slowly until the

end-stop is encountered as

shown.

The endstops MUST be

secure or the setup will fail.

The endstops must also be

straight and equally spaced on

both sides to prevent the

formation of gaps when the

door is closed.

Safety inputs (BEAM) and

the trigger input are

unresponsive during this

procedure. Ensure no people,

pets or property can land in the

path of the moving door

curtain.

Page 35

System Commissioning - LimitsSystem Commissioning - Limits

LISH

E

N

G

35

3

Door closes at full rated speed

Once the upper limit has been

registered (stall against

endstop) the door will close

automatically at full speed.

The door will slow down and

stop fully closed.

4

Door opens at full rated speed

The door will then open at

the full rated speed and will

stop at the end limit.

Instead of homing against

the end stop, a small gap

will be evident between the

door curtain edge and the

endstop. This gap is

computed by the system

and varies from door to

door.

On very light doors

there may be no gap at

all, which is a sign that

weight may need to be

added.

Once the door is fully opened, the limit setup will be complete. The wall console will

beep twice, indicating successful limit programming. From this point on, the trigger

button on the wall console, as well as the trigger input and safety beam input will be

active.

If, for some reason, the Limit Programming routine fails, the system will

issue one single error beep and exit the limit programming routine. The system

will then be in standby and will await another Limit Programming command.

Refer to the troubleshooting section in this manual for possible solutions.

Page 36

System Commissioning - LimitsSystem Commissioning - Limits

LISH

E

N

G

36

Adding weight to very light doors

In general, when the roll-up door is very light, a number of symptoms may become

apparent and cause temporary malfunctions of the product. These include stopping

after moving short distances and not closing completely. In these cases, it is

necessary to add weight to the bottom edge of the door curtain. The recommended

way of adding weight is to affix a length of angled steel to the bottom edge of the door

curtain as shown:

Angled Steel

Aluminum door edge

Tek ScrewsTek Screws

The angled steel is attached directly to the aluminium edging of the door curtain with

tek screws. Depending on the door type, other screws may be used. The steel is

mounted on the inside of the door i.e. the side facing the inside of the garage.

Once weight is added to the door, it may need adjustment. Ensure that

the door is consistently easily lift-able once the weight is added.

Use short screws, long ones may damage the rubber at the bottom of the

door curtain.

Page 37

37

LISH

E

N

G

System Commissioning - Programming RemotesSystem Commissioning - Programming Remotes

Programming Remote Controls into the system

The DCC02 is supplied with two four code-hopping remote controls which are

intended for use with this product. The user can purchase additional remote controls

and add them to the system up to a maximum of 16 remote controls into the

memory of the built-in receiver at any given time.

The system is shipped from the factory in a blank state, i.e. there are no remote

controls learnt into the system.

When learning remote controls, always operate the remote control at

least 5 metres away from the wall console.

Ensure that no other remote controls are operating in the near vicinity

during this procedure as these remotes will be inadvertently learnt into

the system.

Learning a new remote into the system

The DCC02 stores remote controls in what is called “slots”. Each remote control

added to the system occupies a slot. A slot can generally only be overwritten or all

slots mass erased. The most common mistake is to not select an unallocated slot

when adding remotes to the system, which leads to the previous remotes learnt,

being overwritten. The following explains how to program the remotes correctly into

the system.

1

Press and release “LRN”Press and release “LRN”

2

e

Single BeepSingle Beep

Page 38

38

LISH

E

N

G

System Commissioning - Programming RemotesSystem Commissioning - Programming Remotes

As shown on the previous page, pressing and releasing the LRN button, switches

the system into remote programming mode. A single beep indicates this.

When in learn mode, the current slot selected is slot 1. To advance to the next slot,

press LRN again to advance the slot number to slot 2. When a slot is selected, and

unoccupied, the STATUS LED will be off, if a slot is occupied, the STATUS LED will

be lit. This aids the user in avoiding active memory locations when adding new

remote controls.

LRN

E

Press and release

LRN button

LEARN MODE

Slot 1 (Default)

LRN

E

Press and release

LRN button

LRN

E

Press and release

LRN button

LRN

E

Press and release

LRN button

e

x1

Slot 2

Slot 16 (Last)

Slot 15

e

x1

e

x1

e

x1

If no remote control is learnt into

the system within 15 seconds,

the system will return to normal

operation, which is signaled

with an error beep!

If you inadvertently enter learn

mode, simply allow the system

to time-out and return to normal

operation after the 15 second

delay.

If the product is used in the

vicinity where many other

remote controls are active, we

recommend that the slot 1 be

skipped. This will help prevent

unintended learning of

transmitters in the area.

Page 39

39

LISH

E

N

G

System Commissioning - Programming RemotesSystem Commissioning - Programming Remotes

Once the desired slot has been selected, operate the desired button on the remote

control, to program it into the system.

Upon successful learning, the wall console will issue two confirmation beeps and

exit learn mode.

To add more remotes, you will need to enter learn mode again and select

the desired slot.

4

e

Double BeepDouble Beep

3

Always operate the remote control

at least 5m away from the wall

console when learning it into the

system

Once a remote control (and the chosen button) is learnt into the system

successfully, pressing the learnt button on the remote control will open and close

the door.

Learning another remote control into a given slot will erase the

previously learnt remote control (and button). Be careful!

Page 40

40

LISH

E

N

G

System Commissioning - Erasing RemotesSystem Commissioning - Erasing Remotes

Erasing all the remote controls in the system

To erase all the remote controls in the system, in cases where there has been a

security breach or to reset the remote control storage to factory defaults, the

following procedure will erase all the remote controls.

Performing this operation will render all remote controls useless. This

could lead to you being locked into your own garage! Proceed with this

step only if you have access to the trigger button or the manual override.

LRN

E

Press and hold

LRN button

~5 secs

e

x1

e

x2

STATUS LED

Flashes Rapidly

LRN

E

Release LRN button

e

x1

~1 sec

All remotes erased

Returns to normal operation

Once all remotes are erased, any existing remotes will have to be

reprogrammed into the system from scratch!

Page 41

41

LISH

E

N

G

Advanced FeaturesAdvanced Features

Advanced Features

The DCC02 is equipped with a programmable auto-close timer, which is accessible

via a menu termed the “advanced features menu”. The structure of this menu is

shown as follows:

SET

E

Press and release

SET button

e

x1

ADVANCED FEATURES

MENU

ADVANCED FEATURES

MENU

AUTO-CLOSE OPTION

MENU ITEM

STATUS LED:

1 SHORT FLASH / 2 sec

AUTO-CLOSE TIMER

MENU ITEM

STATUS LED:

2 SHORT FLASH / 2 sec

SET

E

Press and release

SET button

e

x1

TRIGGER

E

Press and release

TRIGGER button

e

x1

Normal

Operation

When the advanced features menu is engaged, all triggers are ignored.

It is not possible to invoke the menus if the door is in motion.

Trigger Exits Menu

Page 42

42

LISH

E

N

G

Advanced Features - Auto-Close SelectionAdvanced Features - Auto-Close Selection

Auto-Close Function Enable/Disable

The auto-close function can be enabled/disabled as follows. Please be aware that

when auto-close is enabled, there MUST be a safety beam present.

AUTO-CLOSE OPTION

MENU ITEM

STATUS LED:

1 SHORT FLASH / 2 sec

LRN

E

Press and release

LRN button

e

x1

AUTO-CLOSE OPTION

SUB-MENU

STATUS LED:

AC ON

AC OFF

LRN

E

Press and release

LRN button

e

x2

SET

E

Press and release

SET button

e

x2

AUTO-CLOSE ON AUTO-CLOSE OFF

TO MAIN MENU

(ADVANCED FEATURES)

Enabling Auto-close Feature

1. Press SET

2. Press LRN

3. Press SET

4. Press TRIGGER

Disabling Auto-close Feature

1. Press SET

2. Press LRN

3. Press LRN

4. Press TRIGGER

Page 43

43

LISH

E

N

G

Advanced Features - Auto-Close TimerAdvanced Features - Auto-Close Timer

Auto-Close Timer Adjustment

When enabled, the auto-close timer can be adjusted for time-out periods between

10 seconds and 250 seconds. Adjustment below or above this range will result in an

error indication. The factory default is 30 seconds.

AUTO-CLOSE TIMER

MENU ITEM

STATUS LED:

2 SHORT FLASH / 2 sec

LRN

E

Press and release

LRN button

e

x1

AUTO-CLOSE TIMER

SUB-MENU

LRN

E

Press and release

LRN button

e

x1

SET

E

Press and release

SET button

e

x1

Increase Time

by 10 seconds

Decrease Time

by 10 seconds

TRIGGER

E

Press and release

TRIGGER button

e

x2

Return to Main Menu

(Advanced Features)

Save Changes and Exit

Page 44

LISH

E

N

G

Troubleshooting GuideTroubleshooting Guide

Troubleshooting Guide

The following is a thorough guide to solving problems that occur with the DCC02. It

is split into two sections, one for diagnosing troubles during limit programming, the

other for diagnosing problems during normal running. These are by no means

exhaustive lists of all the possible combinations of problems that occur, but these

guides do cover over 90 percent of the problems that our customers experience with

this product and how to best resolve them.

Always work through these guides first when solving problems, before calling

technical support. This will allow us to provide the best possible support to every

single customer. Where a particular problem is not described in these guides, you

are encouraged to call us or e-mail us for prompt resolution to your query. We also

publish a FAQ on our website, be sure to have a look at that as well for any latebreaking issues that have come to light since publication of this manual.

SECTION A: LIMIT SET-UP TROUBLESHOOTING

Problem Likely Cause(s) Possible solution(s)

Cannot set the door up, system

constantly beeps four times when

power is applied.

• Power Problem

• Problem with

interconnecting cable

• Main fuse (F2) in console

blown or fatigued.

• Check fuse F2

• Check the wiring, especially if

you lengthened the cable.

Check for voltage across the

two outer terminals of the

interconnecting cable. If none

present, replace F2 in the wall

console.

The door moves a short distance,

then stops with an error beep

when attempt is made to program

the limits.

• Door not balanced

• Spool wheel bent

• Dirt/foreign matter on

encoder wheel.

• Check the door, if there’s a

tight spot during upwards

travel, you will need to fix it.

• A bent spool wheel pulls the

driving wheel away from the

motor chassis, leading to it

coming off the chassis

altogether and the encoder no

longer rotates. Replace spool

wheel or fit an adaptor wheel

available from the place where

you purchased this product.

• Sometimes, dust and dirt from

the installation gets onto the

encoder wheel, blocking the

holes and the system can no

longer measure distance

traveled. Ensure the area is

clean and free of dust/foreign

matter.

44

6

Page 45

45

LISH

E

N

G

SECTION A: LIMIT SET-UP TROUBLESHOOTING (cont)

Troubleshooting GuideTroubleshooting Guide

Problem Likely Cause(s) Possible solution(s)

The door moves slowly, reaches

the endstop and then fails to stop

with a loud “clack clack clack”

noise.

• Door too light

• Endstops not secure

enough.

• Add weight to door as shown

on page 36.

• Make sure the endstops are

secure, if not you may need to

retrofit additional endstops.

SECTION B: GENERAL OPERATING MODE TROUBLESHOOTING

Problem Likely Cause(s) Possible solution(s)

Wall console constantly beeps

twice

• No mains present

• Mains fuse blown

• Check plug socket, and circuit

breaker.

• Replace the fuse (1A Time lag

glass cartridge). It is an inline

fuse fitted on the mains lead.

Wall console constantly beeps

four times

• MAIN FUSE (F2) in wall

console blown.

• Interconnection lead

problem.

• Check the fuse (F2) in the wall

console and replace if blown or

faulty. If the fuse repeatedly

blows, please contact

technical support.

• Check the interconnection

lead, make sure it is plugged

in securely at both ends.

The lead can be checked by

measuring the outer terminals

for voltage (between 23 and

30 volts DC, depending on

mains voltage)

Door opens a short distance, then

stops. Cannot open door greater

than this distance.

• Encoder problem

• Disengage the door, and open

and close fully, and ensure that

the gear turns all the time

when the door is closed and

opened fully. If it does not, the

spool wheel has likely

damaged the drive wheel and

pulled it off the chassis. This

occurs due to incorrect

installation!

• Encoder dirty, ensure it is

clean and free of debris.

Sometimes insects and other

objects get into the encoder.

Page 46

46

LISH

E

N

G

Troubleshooting GuideTroubleshooting Guide

SECTION B: GENERAL OPERATING MODE TROUBLESHOOTING

Problem Likely Cause(s) Possible solution(s)

Cannot enter limit programming • Door not closed fully

• Ensure the door has been

closed fully, if not the cause,

power cycle the system and

then try again.

Door moves short distances when

opened and repeated triggers

result in further normal operation

sometimes after several attempts

• Cold Start issue (pre Jan

2009)

• Units manufactured prior to

January 2009 had a software

issue, this has been resolved

(see website for further details)

Door closes by itself • Auto-close inadvertently

engaged

• Disengage auto-close mode as

per page 42

Door moves consistently short

distances, will not open further

than 10 cm.

• Encoder problem

• Bad installation

• Door very light

• Check encoder

• If installation not carried out as

per this manual, that is the

likely reason why.

• Add weight to the door.

Door doesn’t close properly, there

is always a gap at the bottom

• Bad insallation

• Door not straight

• Door very light

• Rectify any installation

problems first.

• If the door is not straight it is

most likely impossible to rectify

as it involves removal of the

entire door. Add self-adhesive

foam rubber to the bottom

edge of the door to resolve.

• Add weight to the door.

Each new remote learnt into the

system, erases the previous one I

just learnt in.

• Procedure Incorrect

• Carefully follow the procedure

as shown on page 38. Note

that this product learns slightly

differently compared to other

SENTRY products

No auxillary power/ beams and/or

external receiver connected does

not work.

• Blown AUX FUSE (F1) in

wall console.

• Check (and replace) this fuse.

Frequently, the door opens slowly

when opened and then runs as

normal

• Play on the door

• There is likely free play on the

door somewhere. The DCC02

is sensing movement on the

encoder wheel when the door

is stationary.

The door opens by itself at

random times

• Another transmitter,

elsewhere was

inadvertently learned into

the system.

• Perform complete erasure of

all stored remotes and learn

them in again.

Page 47

47

LISH

E

N

G

Troubleshooting Guide - Error and Status CodesTroubleshooting Guide - Error and Status Codes

NORMAL OPERATION

OFF = DOOR CLOSED

STATUS LED

SLOW FLASH = DOOR OPENING

ON = DOOR FULLY/PARTIALLY

OPEN OR PARTIALLY

CLOSED

FAST FLASH = DOOR CLOSING

ERROR CONDITION

(ONLY INDICATED WHEN

DOOR IS STATIONARY)

OFF = DOOR CLOSED

STATUS LED

2 SHORT FLASHES

e# x2

MAINS FAILUREMAINS FAILURE

3 SHORT FLASHES

e# x3

BATTERY LOWBATTERY LOW

4 SHORT FLASHES

e# x4

COMMS FAILURECOMMS FAILURE

Page 48

48

LISH

E

N

G

Product SpecificationProduct Specification

Product Type: DC drive reduction gear motor for roll up doors

Voltage: 24 volts DC

Power Source: 200 - 250V AC 50/60Hz 120VA

Battery Back-up: Internal 12V 1.3AH batteries (2 pcs)

Max Lift mass: Equivalent to 6kg

Receiver Frequency: 433.92MHz

Remote Control Type: Code-hopping (KEELOQ)

Remote Control Storage: Up to 16 remote control buttons

Back-up duration: Max 10 cycles (dependent on battery condition)

Collision Sensitivity: Automatic with counter (stops after 3 collisions)

Specification subject to change without prior notice

Page 49

49

This page intentionally left blank

Page 50

Ref: DCC02 User Manual Rev1_1.cdr

Loading...

Loading...