Sentry CPS-10 w/ Batt, CPS-10 w/o Batt, CPS-10HP w/ Batt, CPS-10HP w/o Batt, CPS-11 w/ Batt Installation, Operation & Maintenance Manual

...

Original Instructions

Installation, Operation

&Maintenance Manual

Sentry CPS Sampler

Corrosion Sampler

S-SW-IOM-00252-17 12-18

2 Sentry Equipment Corp

Do not install, maintain, or operate this equipment without reading,

understanding, and following the appropriate Sentry Equipment Corp

instructions. Otherwise, injury, damage, or both may result.

Copyright

© 2018 by Sentry Equipment Corp. All rights reserved. All product and company names

are property of their respective owners. This document contains proprietary information.

No part of this document may be photocopied or reproduced without the prior written

consent of Sentry Equipment Corp.

Limit of Liability

Sentry Equipment Corp, its employees, agents, and the authors and contributors to this

document speci cally disclaim all liabilities and warranties, express or implied (including

warranties of merchantability and tness for a particular purpose), for the accuracy,

currency, completeness, and/or reliability of the information contained herein and/or

for the tness for any particular use and/or for the performance of any material and/or

equipment selected in whole or part with the user of/or in reliance upon information

contained herein. Selection of materials and/or equipment is at the sole risk of the user of

this publication.

Note

The information contained in this document is subject to change without notice.

Table of Contents

Safety Information ......................... 3

General Safety Precautions ................. 4

General Description ........................ 5

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation .................................. 12

Maintenance ............................... 14

Consumables .............................. 19

Spare Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Standard Warranty ......................... 21

Customer Support .......................... 22

Sentry CPS Sampler 3

Safety Information

Please read the entire manual before attempting to unpack, set up, or operate this

product. Pay careful attention to all Warnings, Cautions, and Notes. Failure to do so could

result in serious personal injury and/or equipment damage.

Use of Hazard Information

If multiple hazards exist, the signal word corresponding to the greatest hazard shall be

used.

De nitions

DANGER indicates a hazardous situation

which, if not avoided, will result in death or

serious injury.

WARNING indicates a hazardous situation

which, if not avoided, could result in death or

serious injury.

CAUTION, used with the safety alert symbol,

indicates a hazardous situation which, if not

avoided, could result in minor or moderate

injury.

NOTICE is used to address practices not

related to personal injury.

NOTE

Information that requires special emphasis.

TIP

Alternate techniques or clarifying information.

SHALL:

This word is understood to be mandatory.

SHOULD:

This word is understood to be advisory.

4 Sentry Equipment Corp

General Safety Precautions

Product Selection, Installation, and Use

Improper selection, installation, or use can cause personal injury or property damage. It is solely

the responsibility of users, through their own analysis and testing, to select products suitable

for their speci c application requirements, ensure they are properly maintained, and limit their

use to their intended purpose.

Follow proper local, state, and federal regulations for proper installation and operational

requirements.

Always use caution and common sense when working with any chemical. Read the product

label and Material Safety Data Sheets (MSDS) carefully and follow the instructions exactly.

Potential Equipment Hazards

Hot surfaces! This equipment may have very hot surfaces. If an operator contacts a hot surface,

injury may occur. Use protective clothing to prevent injury. If other equipment comes in contact

with a hot surface, damage to the equipment may occur. Ensure the area around this equipment

is kept clear to prevent this damage from occurring.

High pressures! This equipment may contain uids at very high pressures. Prior to installing,

removing, or maintaining this equipment, ensure that the equipment is isolated from all

connecting piping, the equipment is depressurized, the contents have been drained, and the

equipment is cool.

Sentry CPS Sampler 5

General Description

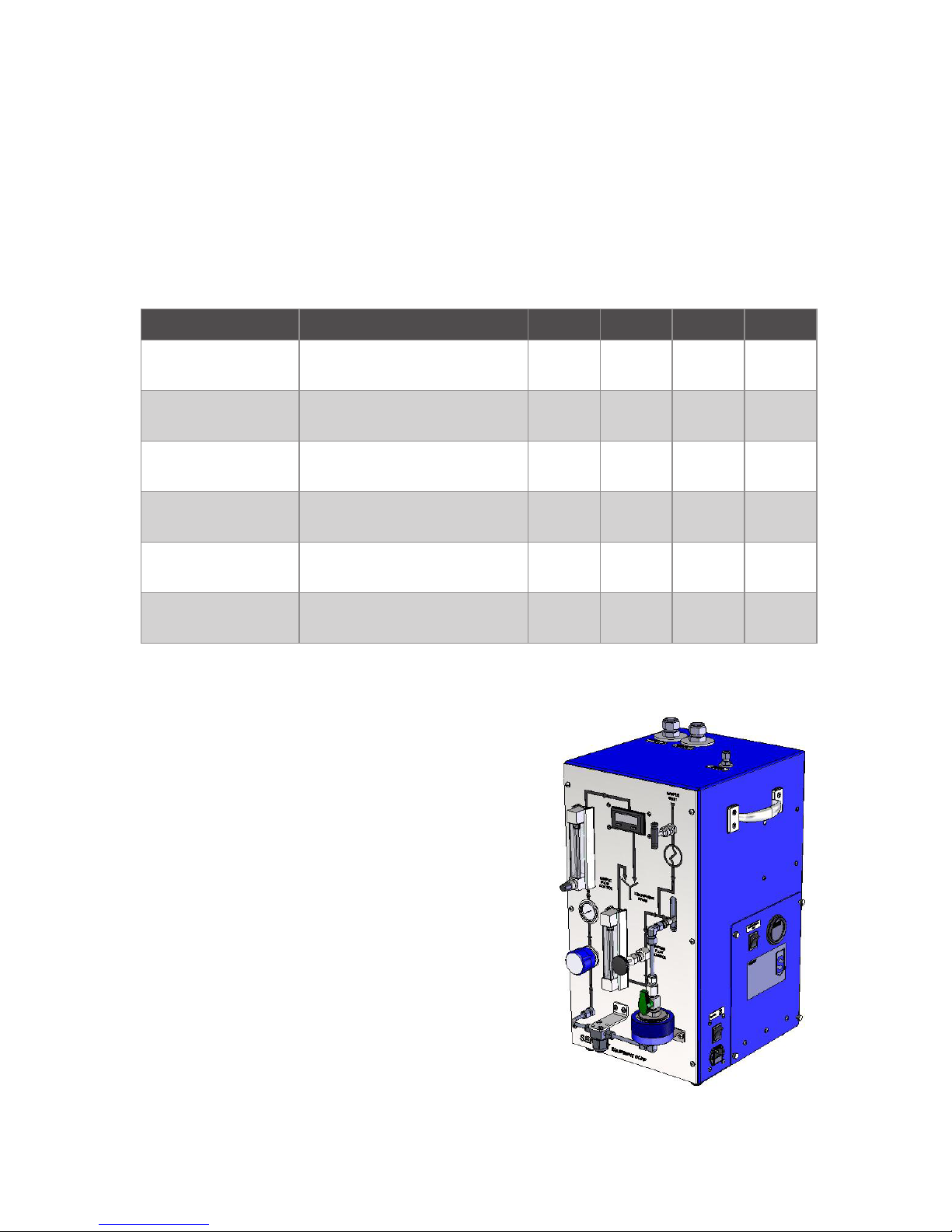

The Sentry® CPS Sampler is a stand-alone unit for collecting and eventual quantifying of

particulate and ionic matter (corrosion products) circulating in the secondary piping of

nuclear power plants and condensate/feedwater systems of fossil-fueled plants. The CPS

sampler collects sample material on lters. The lters are removed for laboratory analysis.

Accurate ow totalizing assures precise species concentration determination. The CPS

sampler is available in several single line congurations. Verify which model you have

when referring to this manual. Some of the illustrations may or may not include options,

which you have.

Model Description psig Barg °F °C

CPS-10 w/ Batt Single Stream w/ bypass &

battery

2850 196 131 55

CPS-10 w/o Batt Single Stream w/ bypass,

w/o battery

2850 196 131 55

CPS-10HP w/ Batt Single Stream w/ bypass &

battery

5000 344 131 55

CPS-10HP w/o Batt Single Stream w/ bypass,

w/o battery

5000 344 131 55

CPS-11 w/ Batt Single Stream w/ bypass &

cooler w/ battery

2850 196 1000 537

CPS-11 w/o Batt Single Stream w/ bypass &

cooler w/o battery

2850 196 1000 537

Power:

90 - 264 VAC, 47 - 63 Hz, 120 VA

Cooling Water (Model-11 only):

5 gpm (1136 L/H) minimum;

7 gpm (1590 L/H) maximum at 90°F (32°C)

Component arrangement as seen

by the operator from the front

Figure 1. Corrosion Products

Sampler (CPS-11)

6 Sentry Equipment Corp

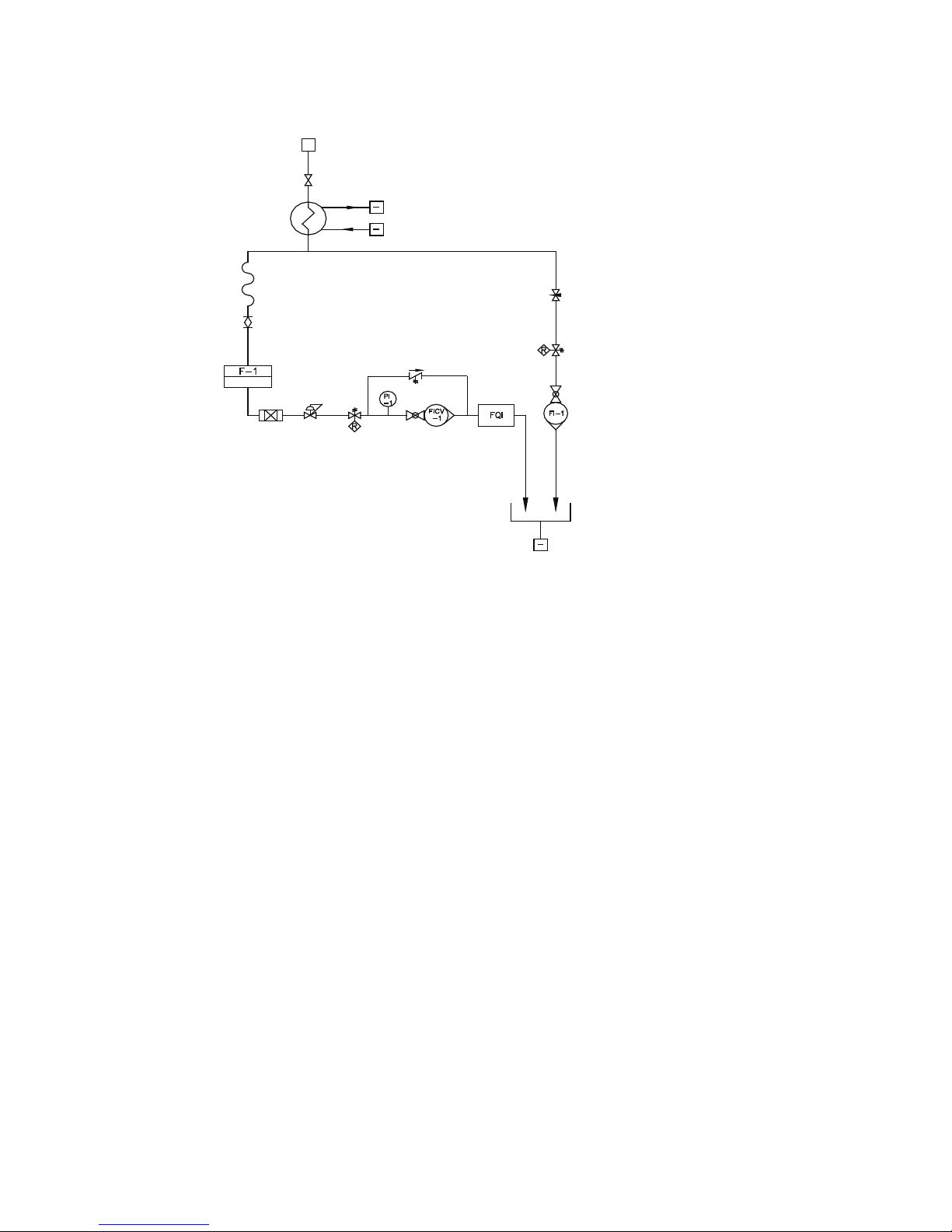

Figure 2. Corrosion Products Sampler Flow Schematic with bypass and cooler

Sample Drain

Cooling Water

Cooling Water

V-1

Sample Inlet

Isolation Valve

Sample

Cooler

Sample

Inlet

(Optional Bypass)

V-2

V-3

Bypass Flow

Control Valve

TSV (opt.)

Bypass Flow

Indicators

0 - 1800 cc/min

RV-1 (opt.)

F-1 PR-1 TSV-1

(opt.)

Flow

Indicator

w/ Control

Valve

Flow

Totalizer

Flexible

Hose*

Filter

Isolation

Valve

Filter Holder

*Flexible hose not supplied on HP models

The CPS sampler can automatically maintain a sample ow rate up to 330 cc/min in

the branch to the sample lter. Typically, greater ow rates are required to maintain

incoming sample line velocities of 5-6feet per second as recommended by EPRI. This ow

requirement is especially important, given the sole purpose of CPS sampling is to measure

sample constituents that can easily plate out on the sample tubing if the sample velocities

are below 5-6ft/s. The optional bypass loop can provide a path for 1500cc/min of sample

ow in addition to the ow to the sample lter branch.

The constant ow feature is accomplished by using a pressure regulator downstream of

the collection lter. The regulator maintains the inlet of the ow control valve at constant

pressure. Since the control valve outlet pressure is constant, CPS sampler ow is constant.

A sample throughput totalizer that is resettable, with ± 3% full-scale accuracy, measures

the total volume of liquid sample passing through the lter holder.

Sentry CPS Sampler 7

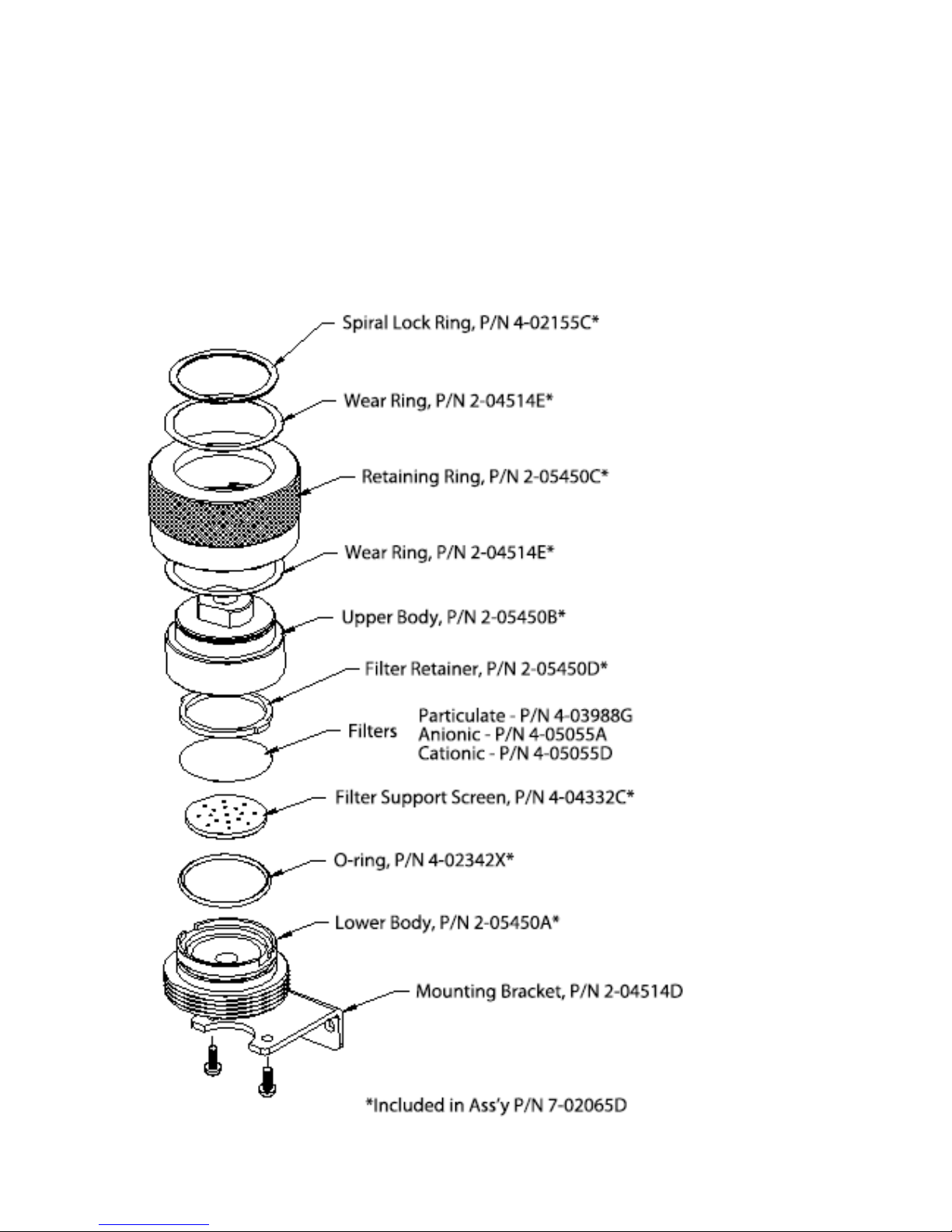

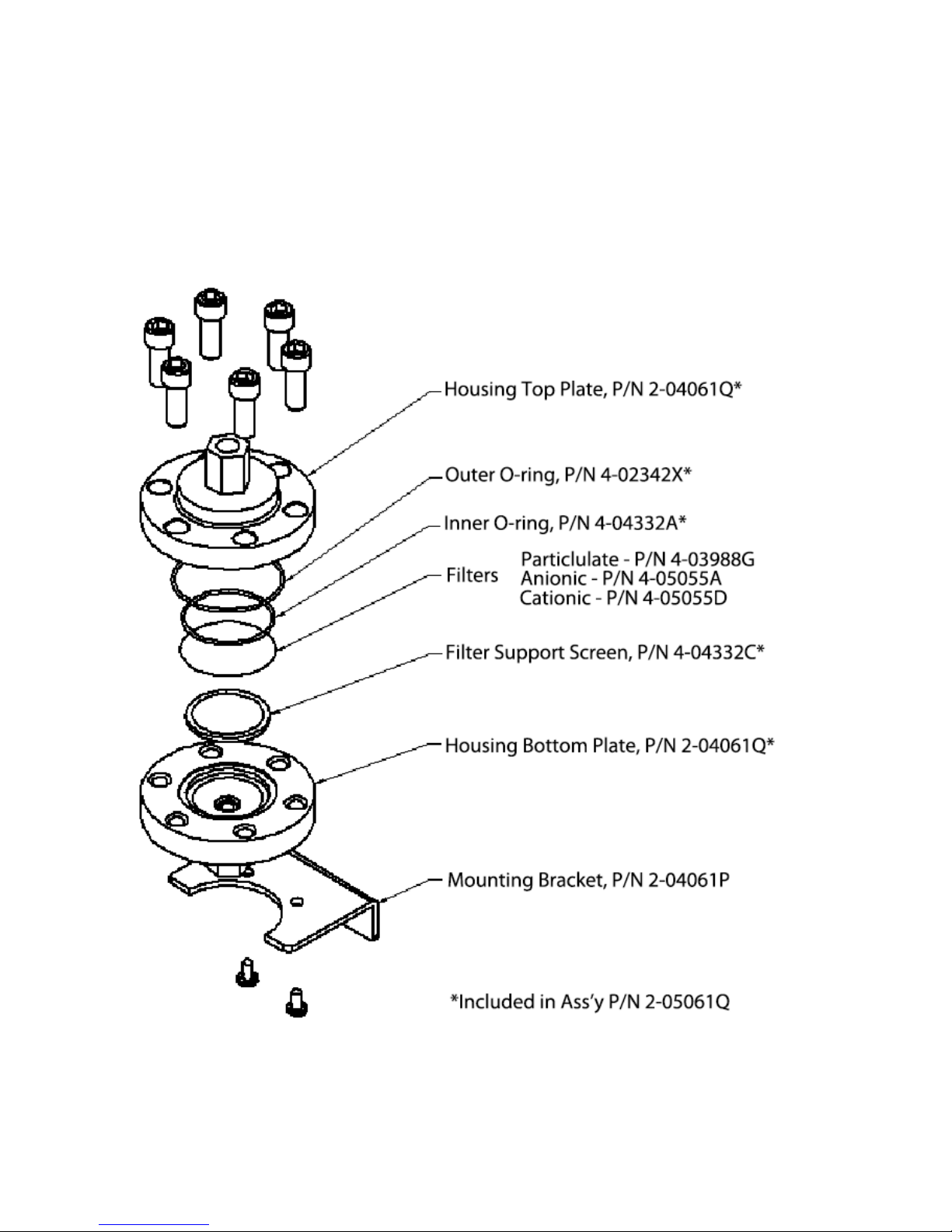

Standard Filter Holder

The Sentry Standard Filter Holder (refer to Figure 3) was developed to allow the operators

of Corrosion Product Samplers to install multiple lter papers in their samplers without

leakage and without the need for tools to open and close the housing. It is designed

such that varying stack heights of lter papers do not interfere with the housing’s sealing

capabilities. All wetted metal surfaces are of T316SS construction. The lter holder accepts

47mm diameter membrane lters. Replacement lters can be ordered through Sentry

Equipment.

Figure 3. Filter Holder Assembly for Standard Units

8 Sentry Equipment Corp

HP High Pressure Filter Holder

The HP High Pressure Filter Holder (refer to Figure 4) was developed for high-pressure

applications. A 5/16inch hex Allen wrench is required to allow the operators of Corrosion

Products sampler to open and close the housing for lter replacement. Stacking more

than three lter papers is not recommended or leakage will occur. All wetted metal

surfaces are of Stainless Steel construction. The lter holder accepts 47mm diameter

membrane lters. Replacement lters can be ordered through Sentry Equipment.

Figure 4. HP High Pressure Filter Housing

Loading...

Loading...