Sentry CPS-10 w/ Batt, CPS-10 w/o Batt, CPS-10HP w/ Batt, CPS-10HP w/o Batt, CPS-11 w/ Batt Installation, Operation & Maintenance Manual

...Page 1

Original Instructions

Installation, Operation

&Maintenance Manual

Sentry CPS Sampler

Corrosion Sampler

S-SW-IOM-00252-17 12-18

Page 2

2 Sentry Equipment Corp

Do not install, maintain, or operate this equipment without reading,

understanding, and following the appropriate Sentry Equipment Corp

instructions. Otherwise, injury, damage, or both may result.

Copyright

© 2018 by Sentry Equipment Corp. All rights reserved. All product and company names

are property of their respective owners. This document contains proprietary information.

No part of this document may be photocopied or reproduced without the prior written

consent of Sentry Equipment Corp.

Limit of Liability

Sentry Equipment Corp, its employees, agents, and the authors and contributors to this

document speci cally disclaim all liabilities and warranties, express or implied (including

warranties of merchantability and tness for a particular purpose), for the accuracy,

currency, completeness, and/or reliability of the information contained herein and/or

for the tness for any particular use and/or for the performance of any material and/or

equipment selected in whole or part with the user of/or in reliance upon information

contained herein. Selection of materials and/or equipment is at the sole risk of the user of

this publication.

Note

The information contained in this document is subject to change without notice.

Table of Contents

Safety Information ......................... 3

General Safety Precautions ................. 4

General Description ........................ 5

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation .................................. 12

Maintenance ............................... 14

Consumables .............................. 19

Spare Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Standard Warranty ......................... 21

Customer Support .......................... 22

Page 3

Sentry CPS Sampler 3

Safety Information

Please read the entire manual before attempting to unpack, set up, or operate this

product. Pay careful attention to all Warnings, Cautions, and Notes. Failure to do so could

result in serious personal injury and/or equipment damage.

Use of Hazard Information

If multiple hazards exist, the signal word corresponding to the greatest hazard shall be

used.

De nitions

DANGER indicates a hazardous situation

which, if not avoided, will result in death or

serious injury.

WARNING indicates a hazardous situation

which, if not avoided, could result in death or

serious injury.

CAUTION, used with the safety alert symbol,

indicates a hazardous situation which, if not

avoided, could result in minor or moderate

injury.

NOTICE is used to address practices not

related to personal injury.

NOTE

Information that requires special emphasis.

TIP

Alternate techniques or clarifying information.

SHALL:

This word is understood to be mandatory.

SHOULD:

This word is understood to be advisory.

Page 4

4 Sentry Equipment Corp

General Safety Precautions

Product Selection, Installation, and Use

Improper selection, installation, or use can cause personal injury or property damage. It is solely

the responsibility of users, through their own analysis and testing, to select products suitable

for their speci c application requirements, ensure they are properly maintained, and limit their

use to their intended purpose.

Follow proper local, state, and federal regulations for proper installation and operational

requirements.

Always use caution and common sense when working with any chemical. Read the product

label and Material Safety Data Sheets (MSDS) carefully and follow the instructions exactly.

Potential Equipment Hazards

Hot surfaces! This equipment may have very hot surfaces. If an operator contacts a hot surface,

injury may occur. Use protective clothing to prevent injury. If other equipment comes in contact

with a hot surface, damage to the equipment may occur. Ensure the area around this equipment

is kept clear to prevent this damage from occurring.

High pressures! This equipment may contain uids at very high pressures. Prior to installing,

removing, or maintaining this equipment, ensure that the equipment is isolated from all

connecting piping, the equipment is depressurized, the contents have been drained, and the

equipment is cool.

Page 5

Sentry CPS Sampler 5

General Description

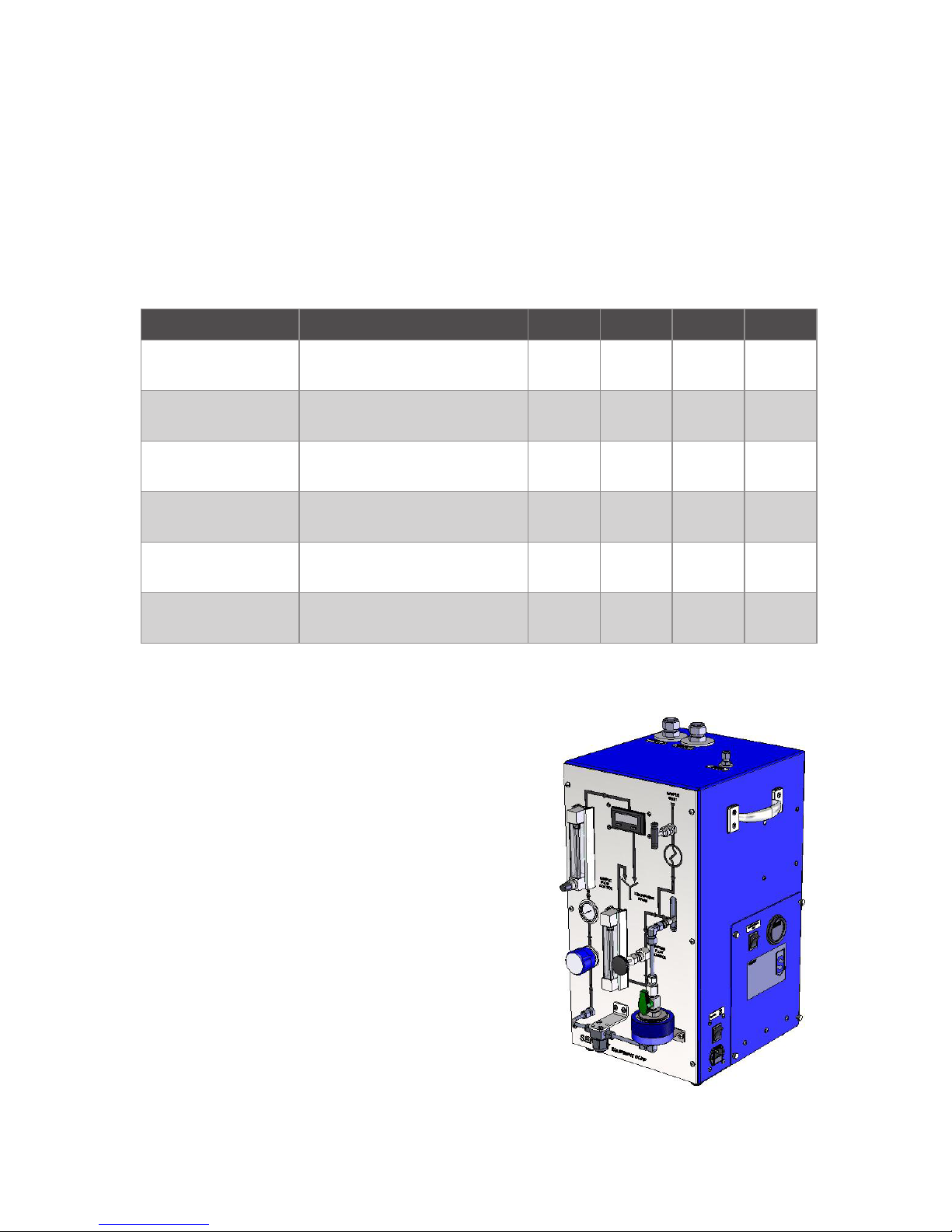

The Sentry® CPS Sampler is a stand-alone unit for collecting and eventual quantifying of

particulate and ionic matter (corrosion products) circulating in the secondary piping of

nuclear power plants and condensate/feedwater systems of fossil-fueled plants. The CPS

sampler collects sample material on lters. The lters are removed for laboratory analysis.

Accurate ow totalizing assures precise species concentration determination. The CPS

sampler is available in several single line congurations. Verify which model you have

when referring to this manual. Some of the illustrations may or may not include options,

which you have.

Model Description psig Barg °F °C

CPS-10 w/ Batt Single Stream w/ bypass &

battery

2850 196 131 55

CPS-10 w/o Batt Single Stream w/ bypass,

w/o battery

2850 196 131 55

CPS-10HP w/ Batt Single Stream w/ bypass &

battery

5000 344 131 55

CPS-10HP w/o Batt Single Stream w/ bypass,

w/o battery

5000 344 131 55

CPS-11 w/ Batt Single Stream w/ bypass &

cooler w/ battery

2850 196 1000 537

CPS-11 w/o Batt Single Stream w/ bypass &

cooler w/o battery

2850 196 1000 537

Power:

90 - 264 VAC, 47 - 63 Hz, 120 VA

Cooling Water (Model-11 only):

5 gpm (1136 L/H) minimum;

7 gpm (1590 L/H) maximum at 90°F (32°C)

Component arrangement as seen

by the operator from the front

Figure 1. Corrosion Products

Sampler (CPS-11)

Page 6

6 Sentry Equipment Corp

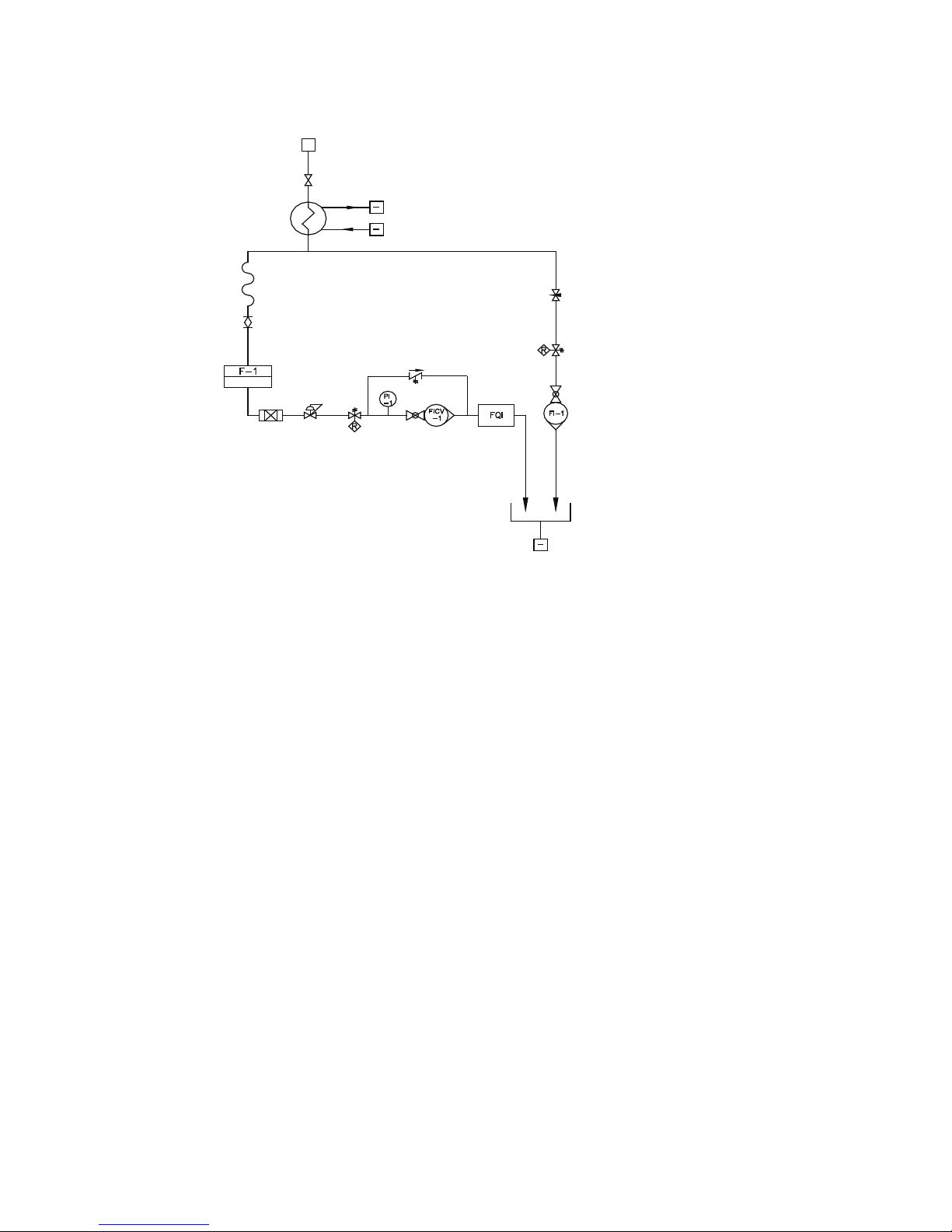

Figure 2. Corrosion Products Sampler Flow Schematic with bypass and cooler

Sample Drain

Cooling Water

Cooling Water

V-1

Sample Inlet

Isolation Valve

Sample

Cooler

Sample

Inlet

(Optional Bypass)

V-2

V-3

Bypass Flow

Control Valve

TSV (opt.)

Bypass Flow

Indicators

0 - 1800 cc/min

RV-1 (opt.)

F-1 PR-1 TSV-1

(opt.)

Flow

Indicator

w/ Control

Valve

Flow

Totalizer

Flexible

Hose*

Filter

Isolation

Valve

Filter Holder

*Flexible hose not supplied on HP models

The CPS sampler can automatically maintain a sample ow rate up to 330 cc/min in

the branch to the sample lter. Typically, greater ow rates are required to maintain

incoming sample line velocities of 5-6feet per second as recommended by EPRI. This ow

requirement is especially important, given the sole purpose of CPS sampling is to measure

sample constituents that can easily plate out on the sample tubing if the sample velocities

are below 5-6ft/s. The optional bypass loop can provide a path for 1500cc/min of sample

ow in addition to the ow to the sample lter branch.

The constant ow feature is accomplished by using a pressure regulator downstream of

the collection lter. The regulator maintains the inlet of the ow control valve at constant

pressure. Since the control valve outlet pressure is constant, CPS sampler ow is constant.

A sample throughput totalizer that is resettable, with ± 3% full-scale accuracy, measures

the total volume of liquid sample passing through the lter holder.

Page 7

Sentry CPS Sampler 7

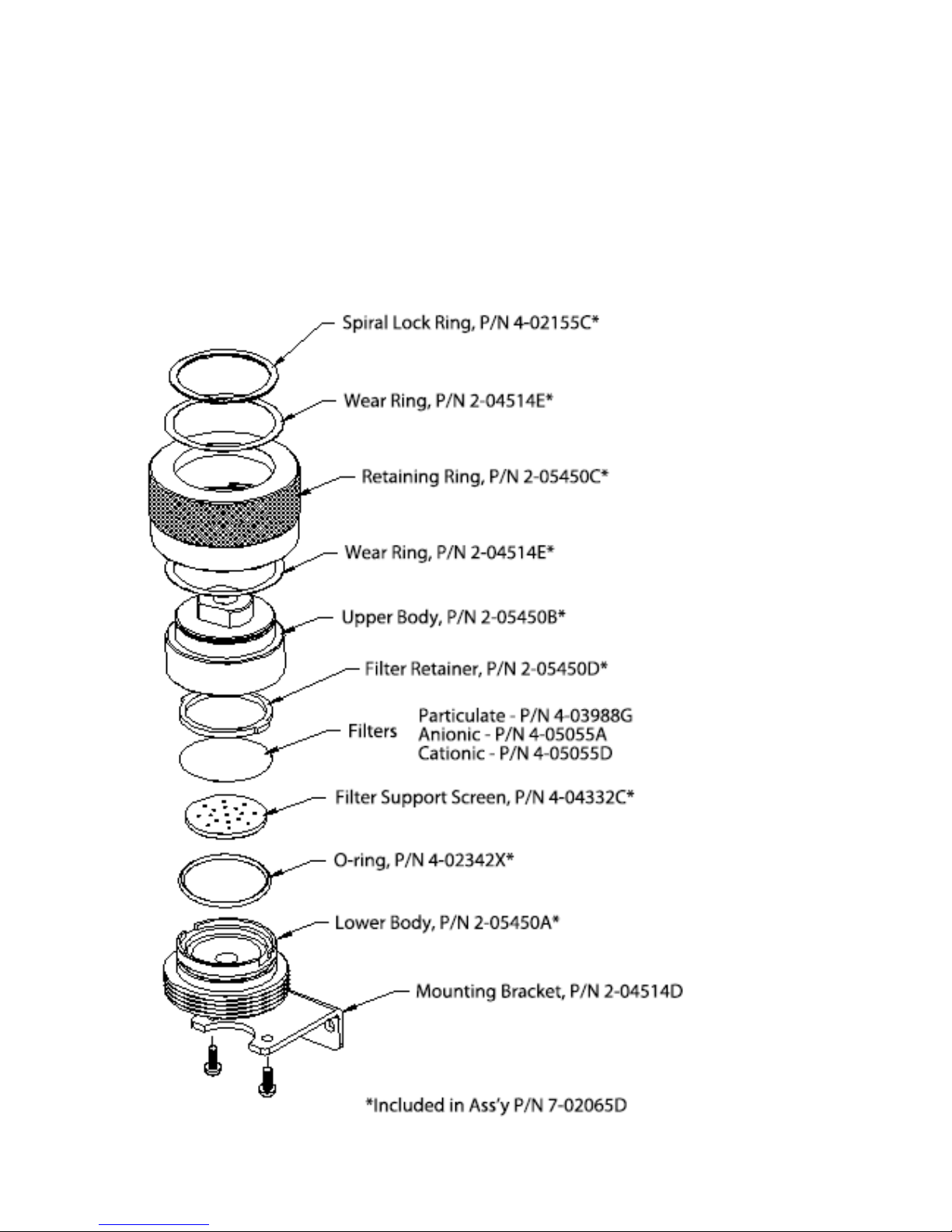

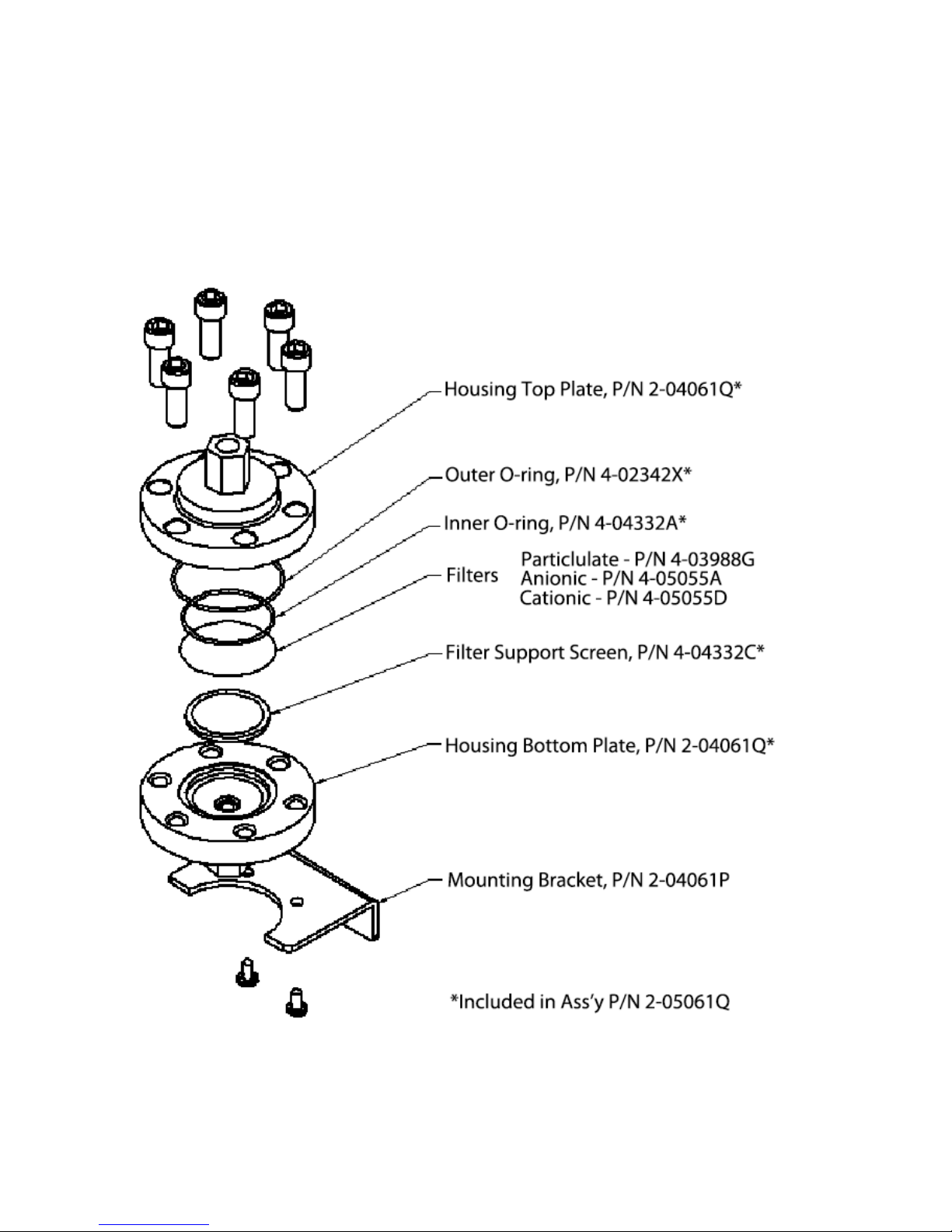

Standard Filter Holder

The Sentry Standard Filter Holder (refer to Figure 3) was developed to allow the operators

of Corrosion Product Samplers to install multiple lter papers in their samplers without

leakage and without the need for tools to open and close the housing. It is designed

such that varying stack heights of lter papers do not interfere with the housing’s sealing

capabilities. All wetted metal surfaces are of T316SS construction. The lter holder accepts

47mm diameter membrane lters. Replacement lters can be ordered through Sentry

Equipment.

Figure 3. Filter Holder Assembly for Standard Units

Page 8

8 Sentry Equipment Corp

HP High Pressure Filter Holder

The HP High Pressure Filter Holder (refer to Figure 4) was developed for high-pressure

applications. A 5/16inch hex Allen wrench is required to allow the operators of Corrosion

Products sampler to open and close the housing for lter replacement. Stacking more

than three lter papers is not recommended or leakage will occur. All wetted metal

surfaces are of Stainless Steel construction. The lter holder accepts 47mm diameter

membrane lters. Replacement lters can be ordered through Sentry Equipment.

Figure 4. HP High Pressure Filter Housing

Page 9

Sentry CPS Sampler 9

Filter Membranes (Technical Information)

Particulate Filter Sentry p/n 4-03988G

Usage Collection of undissolved particles

Bubble Point at 23°C > 2.2 bar

Gravimetric Extractables 2.5%

Porosity 79%

Refractive Index 1.51

Filter Diameter 47 mm

Filter Surface plain

Max. Operating Temp 75°C

Filter Color white

Filter Material Mixed Cellulose Esters

Filter Type Screen Filter

Filter Pore Size 0.45 μm

Wettability Hydrophilic

Qty/Pkg 100

Thickness 180 μm

Anion Exchange Filter Sentry p/n 4-05055A

Usage Collection of dissolved negatively charged ions

(anions) (i.e., Cl-, Br-, OH-)

Filter Diameter 47 mm

Filter Surface plain

Filter Color white

Filter Material Cellulose

Filter Type Screen Filter

Ion Exchange Capacity 1.7 μeq/cm

2

Thickness 230 μm

Cation Exchange Filter Sentry p/n 4-05055D

Usage Collection of dissolved positively charged ions

(cations) (i.e., Fe+, Cu+, Na+, Mg+)

Filter Diameter 47 mm

Filter Surface plain

Filter Color white

Filter Material Cellulose

Filter Type Screen Filter

Ion Exchange Capacity 50.0 μeq/cm

2

Thickness 200 μm

Page 10

10 Sentry Equipment Corp

Liquid Totalizer

The liquid totalizer is a Pelton-type microturbine meter designed for low ow rates in

water systems.

The totalizer can display ow rate, total volume and is resettable by the customer. The

instrument has an accuracy of ±3.0% of its full scale value, which is 500cc/min.

Installation

Lifting hazard. Use proper lifting techniques when handling this equipment.

The CPS sampler is designed to be portable to allow for sampling in numerous locations.

Select a location that provides adequate support, operator accessibility, close proximity

to the sample being analyzed, access to cooling water (if required) and access to a gravity

drain. Samples in excess of 131°F/55°C will require cooling. It is highly recommended that

the CPS sampler be installed in a high-pressure portion of the sample line to ensure the

sample ow rate meets the EPRI guidelines for representative sampling.

Standard Customer Connections

Sample Inlet: 1/4” Compression tting

Sample Outlet/Drain: 3/4” O.D. Tube Stub (SS) (See note below)

Cooling Water Inlet/Outlet (if installed): 3/4” Compression ttings

NOTE

Since the liquid euent is at atmospheric pressure, the method of connection can be either soft

(using hose clamps provided by others) or rigid tubing.

Filter Replacement - Standard Filter Housing (Refer to Figure 3)

Verify that the pressure regulator is fully closed (turned fully counterclockwise), the bypass

ow control valve is fully closed, the sample inlet valve is fully closed and the lter inlet

isolation valve is fully closed.

Open the collection lter housing and remove the lter retainer and any lter papers. The

lter housing is opened by unscrewing the blue anodized retaining ring and removing the

upper body. No tools are necessary.

Re-install the upper body and retaining ring and hand tighten only. Because the seal is

made around the circumference of the housing and not the face, it is not necessary to

use extreme force to close the lter holder. When the lter holder is properly assembled

and tightened, the bottom edge of the retaining ring will be ush with the bottom of the

lower housing.

Page 11

Sentry CPS Sampler 11

Filter Replacement - HP High Pressure Filter Housing (Refer to Figure 4)

Verify that the pressure regulator is fully closed (turned fully counterclockwise), the bypass

ow control valve is fully closed, the sample inlet valve is fully closed and the lter inlet

isolation valve is fully closed.

Open the collection lter housing and remove the lter papers. The lter housing is

opened by removing the six cap screws with a 5/16inch hex Allen wrench.

Re-install the housing top plate. Place the six cap screws in their original locations and

give each bolt a few turns, rst one, then the one opposite, working around the housing

in a star pattern. Try not to tighten adjacent bolts consecutively. Tighten with a 5/16inch

hex Allen wrench. Because the seal is made around the housing face, it is recommended

to tighten the bolts using the opposite star pattern method. When the lter holder is

properly assembled and tightened, it will not leak.

Establish cooling water ow to the sample cooler (if required).

Assure that cooling water is owing before establishing sample ow.

Open all uid sample supply valves. Open the inlet isolation valve. Open the lter inlet

isolation valve and adjust both the pressure regulator and sample ow control valve to

simultaneously give 14psig on the downstream pressure gauge and near 75cc/min on

the ow indicator.

The system should be primed with liquid and ow started gradually. This will prevent trapped

air or gas from being forced through the sensor at a high velocity that may damage the ow

totalizer. If the ow through the unit exceeds 120% of the maximum rate (full scale), the ow

totalizer may be damaged.

Page 12

12 Sentry Equipment Corp

Operation

For units with a battery option, the battery must be fully charged by connecting the unit to AC

power before the rst use.

Sampling

Do not open the lter housing without rst isolating the sample inlet.

The lter housing is opened, as explained in “Installation”, by removing the upper body.

The lter element is centered on the lower half of the housing. When using anionic and

cationic lters, it is recommended that particulate lters be placed both above and below

the anionic and cationic lters. This will help prevent corrosion, which has been found to

occur between these lters and the stainless steel housings.

Replace the upper body and tighten.

Assure that cooling water is owing before establishing sample ow.

Sample is introduced into the CPS sampler from customer supplied piping at full system

pressure. Start sampling by rst assuring the lter element is in the CPS lter housing and

the housing is securely closed. Verify that the pressure regulator is fully closed (turned fully

counterclockwise), the bypass ow control valve is fully closed, the sample inlet valve is

fully closed and the lter inlet isolation valve is fully closed. Reset the totalizer reading, by

pressing the RST button while on the totalized volume screen.

Open all uid sample supply valves. Open the inlet isolation valve. Open the bypass ow

control valve to set the desired bypass ow rate. Open the lter inlet isolation valve and

adjust both the pressure regulator and sample ow control valve to simultaneously give

14 psig on the downstream pressure gauge and near 75 cc/min on the ow indicator.

Readjust bypass ow control valve as necessary to achieve desired total ow rate.

Maintain sample ow until the desired volume has passed through the lter. Typically

this is somewhere between 150 & 1000liters. The ideal volume should be determined by

trial and error as excessive ow may actually remove deposits from the lter media. After

collecting the required sample volume, the inlet isolation valve at the top of the lter

housing is closed.

The displayed reading is the total volume that passed through the lter housing (in liters).

Do not open the lter housing without rst isolating the sample inlet.

Page 13

Sentry CPS Sampler 13

The lter housing should be disassembled as shown in Figure 3 or Figure 4 and the

sample lter assembly transported to the chemistry department for subsequent chemical

and radioisotope analysis. The sample lter assembly should be bagged based on

contamination levels and plant rules.

The Corrosion Products Sampler can be provided with two (2) optional Thermal Shut O

Valves (TSV-1). The TSV is a device designed to shut o sample ow to components down

stream from the TSV if a thermal excursion (high temperature) occurs in the sample. The

TSV is equipped with an indicating reset button. When the valve is in the tripped mode

(closed), the red indicating band on the reset button is visible. If the valve is received in

the tripped position it must be reset to allow sample ow. This is accomplished by pushing

in the reset button until it latches. In conditions where ambient temperatures are above

the valve trip point, it will be necessary to hold the reset button in until cooled sample

allows the valve to latch.

If the TSV trips during sampling operations, isolate the analyzers on the line or lines

aected. Correct the problem causing the excessive sample temperature and reset

the TSV. It may be necessary to hold the reset button in momentarily until all high

temperature sample is ushed from the system. After the TSV is reset, reinitialize sample

ow to the analyzers.

Display

The display has two screens; the Total Volume screen and the Flow Rate screen. Pressing

the T/R button will toggle between the two screens. An R on the left side of the screen

indicates the Flow Rate screen. The Totalized Volume is displayed in liters. Pressing the RST

button while the Totalized Volume is displayed will reset the Totalized Volume. Contact

Sentry Equipment for instructions if you do not want the totalized volume operator

resettable.

NOTE

Do not introduce instrument air into the totalizer. Keep the amount of air entering the totalizer

to a minimum. Minimizing air entering the totalizer will minimize totalizer error.

Page 14

14 Sentry Equipment Corp

Maintenance

The CPS sampler requires little maintenance. Flushing with ltered demineralized water

after each use can minimize problems. The lter holder, pressure regulator and ow

indicator require some occasional inspection and maintenance. If the CPS sampler is not

being used during freezing temperatures, it is recommended that the unit be drained to

prevent damage.

Do not ow any gas through the ow meter. Do not blow unit dry with compressed air. This may

damage the micro-turbine assembly. Do not exceed the pressure and temperature ranges for the

unit.

Battery Maintenance

For units with a battery option, the battery voltage level can be checked by pressing the

Battery Condition Test button. The meter will display the current condition of the battery

charge. To prevent damage to the battery, the unit must be connected to AC power to

recharge the battery when the meter reads 3 bars or less.

Do not allow the battery voltage to drop below 11.5 VDC. Permanent damage to the battery may

result. Also, due to the self-discharge characteristics of this type of battery, the manufacturer

recommends recharging the battery at least once a month for optimal battery life.

Figure 5. Battery Shelf Life and Storage

Page 15

Sentry CPS Sampler 15

Procedure to Verify CPS Flow Meter Calibration

1. Set ow rate of CPS sampler near 75cc/min. Use the display to set ow rate. Flow Rate

and Totalized Volume screens can be toggled by pressing the T/R button. An R on the

left hand side of the screen indicates the Flow Rate screen.

2. Verify ow rate using the 250cc graduated cylinder and stopwatch. Ensure there is no

air in the sample line.

3. Conrm the displayed ow rate on the CPS sampler matches the graduated cylinder

measurement within ± 3%.

NOTE

Averaging ow rate over an extended period of time will reduce the signicance of human

errors.

4. Use the 4000cc graduated cylinder and reset the displayed total volume. Pressing the

RST button resets the Total Volume. Fill graduated cylinder to 2000cc. Maintain a ow

rate near 75cc/min. Ensure there is no air in the sample line.

5. When displayed total volume reaches 2000cc, stop ow through CPS sampler and

read value on graduated cylinder.

6. Verify the displayed total volume is within ± 4% or ± 80cc of 2000cc. If values are not

within the stated range, repeat test.

7. If values exceed 16%, it is probable that damage to the sensor has occurred. If values

are between 4% and 16%, recalibration is necessary.

Recalibrating Flow Meter

NOTE

It is necessary to document programmed values prior to reprogramming the totalizer. Failure to

do so will result in incorrect scaling and error in totalized volume. The factory calibrated values

are located on the ow sensor unit.

If the totalizer/display stated value is within 16% of the actual value and a recalibration

is desired, the totalizer and ow rate multipliers can be adjusted for a more accurate

reading. Follow the procedure below. Ensure there is no entrapped air in the sample line.

Entrapped air will cause excess error in the totalizer reading. If the totalizer/display stated

value is not within 16% of the actual value, it is probable that the ow sensor has been

damaged and will require replacement.

1. Disconnect power from the unit. Verify the display screen is on.

2. Place unit into calibration mode. On some models, using the meter calibration switch

located on the CPS sampler will do this. Otherwise, remove the cover from the Flow

Totalizer display enclosure, and then connect the female push-on disconnect (located

at terminal 5 on the Flow Totalizer display) to the male push-on disconnect (located at

TB1-1 in the electrical enclosure).

Page 16

16 Sentry Equipment Corp

3. The ow totalizer/display is now in programming mode. Screen indication is on the

left side of the display. Press both buttons at the same time to go to the next screen

selection.

4. Verify that the values on screens 1 and 3 match the values noted on the ow sensor. If

values match, proceed to step 8.

5. If you do not have the necessary recorded values, it will be necessary to program

accordingly. You will rst need the Full Scale Pulsed Output Value.

a. Screen 1 – 83.3333R/(Full Scale Pulse Output)

b. Screen 2 – 00.0000

c. Screen 3 – (500/(Full Scale Pulse Output))

d. Screen 4 – 0.000

e. Screen 5 – Not Used – 1

f. Screen 6 – Reset Enable – R

6. If you do not have the Full Scale Pulse Output value, connect a digital multimeter with

frequency capability onto the back of the display/totalizer to pin INA (3). Set ow to

500cc/min. Record frequency value. This is your Full Scale Pulsed Output value.

7. Once you have the necessary recorded values, continue by following the steps below.

8. Connect Power to the unit.

9. Take unit out of calibration mode. On some models, using the meter calibration switch

located on the CPS sampler will do this. Otherwise, disconnect the male and female

push-on disconnects and replace enclosure cover.

10. Set ow rate of CPS sampler near 75cc/min. Use the display to set ow rate. Flow Rate

and Totalized Volume screens can be toggled by pressing the T/R button. An R on the

left hand side of the screen indicates the Flow Rate screen.

11. Verify ow rate using the 250cc graduated cylinder and stopwatch. Ensure there is no

air in the sample line.

NOTE

Averaging ow rate over an extended period of time will reduce the signicance of human

errors.

12. Record the actual value and the displayed value. The ow rate adjustment value is

calculated by dividing the actual value by the displayed value. Repeat step 11 two

more times and average the values from the readings.

13. Use the 4000cc graduated cylinder and reset the displayed total volume. Pressing the

RST button resets the total volume. Fill graduated cylinder to 2000cc. Maintain a ow

rate near 75cc/min. Ensure there is no air in the sample line.

Page 17

Sentry CPS Sampler 17

14. When displayed total volume reaches 2000cc, stop ow through CPS sampler and

read the value on graduated cylinder.

15. Record the actual value and the displayed value. The totalizer adjustment value is

calculated by dividing the actual value by the displayed value. Repeat steps 13-14 two

more times and average the values from the readings.

16. Place unit into calibration mode. On some models, using the meter calibration switch

located on the CPS sampler will do this. Otherwise, remove the cover from the Flow

Totalizer display enclosure. Connect the female push-on disconnect (located at

terminal 5 on the Flow Totalizer display) to the male push-on disconnect (located at

TB1-1 in the electrical enclosure).

17. Adjust the number on screen 1 by the percentage that the value is o. For example:

Old screen 1 value = 25.7998, display total volume = 5L, Actual total volume = 4.95L,

New screen 1 value = 25.5418 [old screen 1 value(actual total volume ÷ display total

volume)]

18. Adjust the number on screen 3 by the percentage that the value is o.

19. Take unit out of calibration mode. On some models, using the meter calibration switch

located on the CPS sampler will do this. Otherwise, disconnect the male and female

push-on disconnects and replace enclosure cover.

Page 18

18 Sentry Equipment Corp

Replacing Totalizer/Display Battery

NOTE

It is necessary to document programmed values prior to replacement of the totalizer battery.

Failure to do so will result in incorrect scaling and error in totalized volume. The factory

calibrated values are located on the ow meter.

The totalizer/display battery will last up to ve years under normal circumstances.

The factory calibrated values for the ow meter are located on the ow meter. It is

recommended to record the programming values of the totalizer prior to experiencing a

dead battery. If you do not have these values, it will be necessary to recalibrate the ow

meter. To replace the battery and reset the ow totalizer, follow the below procedure.

1. Disconnect power from the unit.

2. Remove dead battery by sliding o battery cover, pulling out the old battery and

installing the new battery, noting the polarity.

3. Verify the display screen is on.

4. Place unit into calibration mode. On some models, using the meter calibration switch

located on the side of the CPS sampler will do this. Otherwise, use a jumper to connect

terminal 5 to terminal 4 on TB1 located in the electrical enclosure.

5. Using your recorded programming values, reenter these values into the display on the

appropriate screen.

6. Take unit out of calibration mode. On some models, using the meter calibration switch

located on the side of the CPS sampler will do this. Otherwise, disconnect terminal 5

from terminal 4 on TB1 located in the electrical enclosure.

Filter Holder

Refer to Figure 3 & Figure 4 for identication of lter assembly components.

The lter retainer is designed to prevent distortion of the lter papers when opening and

closing the lter housing. The retainer can be easily removed by grasping the locating ears

between your thumb and forenger.

Periodically inspect the o-ring for wear. Replace as necessary.

The lter support is made of a delicate microscopic screen; handle it with care. Inspect it

before each use for dents and punctures. Replace if damaged.

On the Standard Filter Housing, keep the threads on both the retaining ring and the lower

housing clean. Dirt may cause galling of the threads. Occasionally the inside surfaces may

become lmed. Clean with commercial grade detergent soap and water.

Page 19

Sentry CPS Sampler 19

Regulator Protection Filter (F-1)

A 7-µm lter is located between the sample collection lter and the pressure regulator.

This lter is designed to provide protection to the regulator should sample be introduced

into the CPS sampler without a collection lter in place or if there should be any leakage

around the collection lter. It is mounted on the front of the CPS sampler to provide easy

access. If you are unable to achieve the recommended pressure of 14.5 psig /1 bar, clean

or replace the lter element by loosening the union nut and removing the bonnet.

Thermal Shuto Valve (TSV-1)

The Thermal Shuto Valve provides for automatic shutdown of the sample ow in the

event the sample temperature goes beyond a preset limit. As an added precaution this

option requires a manual restart after shutdown. There are two TSVs provided with this

system. One provides over temperature protection for the Flow Totalizer loop and the

other for the by-pass loop.

Pressure Regulator (PR-1)

Little if any maintenance is required. If you are unable to achieve the recommended

pressure of 14.5 psig/1 bar, and it has previously been determined that sucient sample

pressure is available at the CPS sampler inlet, remove the center cap from the regulator

knob and loosen the locknut retaining the knob. While holding the valve stem, turn the

knob counterclockwise approximately ½ turn. Retighten the locknut and verify that

this procedure has improved the performance. Additional adjustment may be required.

Replace center cap.

Consumables

The lter papers inserted into the lter holder (item 4 of Figure 6) and the lter elements

for the regulator protection lter (item 12 of Figure 6) are consumable items. Replacement

lters may be purchased from Sentry Eqiupment using the following part numbers (you

may also refer to Figure 3 & Figure 4 ).

Sentry Part No. Description

4-03988G Filter, 0.45 µm pore, white, plain surface

4-05055A Filter, 2µm pore, Anionic

4-05055D Filter, 4–12µm pore, Cationic

4-00361E Filter, 7 µm pore, regulator protection

Page 20

20 Sentry Equipment Corp

Spare Parts

The following is a list of recommended spare parts available for the Corrosion Products

Sampler (see Figure 6). Spare parts are available from Sentry Equipment Parts Department:

(262) 567-7256.

Item Description Part Number

1 Inlet Valve 4-01297B

2 Flex Hose (standard press. only) 4-01146H

3 Filter Isolation Valve:

Standard

HP High Pressure

4-03654A

4-05264B

4 Standard Filter Housing (particulate)

O-ring

HP High Pressure Filter Housing (particulate)

Inner O-ring (TFE Encapsulated)

Outer O-ring

7-02065D

4-02342X

2-04061Q

4-04332A

4-02342X

5 Regulator:

Standard

HP High Pressure

Replacement Diaphragm

4-01433T

4-01433G

4-00367B

6 Pressure Gauge 4-04139J

7 Sample Flow Indicator 6-02671C

8 Totalizer:

Flow meter

Display

Cable (Flow meter to Display)

4-05953D

4-05953E

4-05953F

9 Bypass Flow Control Valve 4-01237F

10 Bypass Flow Indicator 4-04112B

11 Sample Cooler 7-00759A

12 Filter (regulator inlet)

Replacement Element

4-01669E

4-00361E

13 Power Cord, 120 VAC 4-05953A

14 Battery Charger 6-04631W

15 N/A N/A

16 12 VDC SLA Battery 4-05953G

17 Voltage Indicator 4-05953H

18 Diode 4-05953L

19 Voltage Indicator Switch 4-05953J

20 Flow Meter Disconnect Switch 4-05953K

Page 21

Sentry CPS Sampler 21

Item Description Part Number

21 Totalizer/Display Battery 4-05953P

22 Power Input Fuse, 10A 4-05953V

23 Battery In-line Fuse, 10A 4-05953X

24 TSV, Thermal Shut o Valve (120°F) 7-01137E

25 Relief Valve, 30 psi Fixed Cracking Pressure 4-01233L

NOTE

Some components not applicable to all models.

Figure 6. Spare Parts

Page 22

22 Sentry Equipment Corp

Standard Warranty

Sentry Equipment Corp (“Seller”) warrants products manufactured by it and supplied

hereunder (“Products”) to be free from defects in workmanship and, to the extent

materials are selected by Seller, to be free from defects in materials, in each case for a

period as de ned in the table below:

Product Line Product Category Warranty Period

Sentry® 1. Automatic Sampling

2. Corrosion Monitoring

3. Manual Sampling

4. Sample Conditioning

5. Sampling & Analysis Systems

6. Replacement Parts (without expiration dates)

Eighteen months

from date of

shipment or twelve

months from

startup, whichever

occurs rst

Waters

Equipment

1. Sampling & Analysis Systems

2. Replacement Parts (without expiration dates)

Twelve months from

date of shipment

To view the full warranty, go to

www.sentry-equip.com/warranty.

Page 23

Sentry CPS Sampler 23

Customer Support

With proven sampling expertise since 1924, Sentry products and services provide business

operations the critical insights to optimize process control and product quality. We deliver

true representative sampling and analysis techniques to customers around the globe,

empowering them to accurately monitor and measure processes for improved production

e ciency, output, and safety. Standing behind our commitments, we are determined to

tackle any application, anywhere.

We know that running an e cient operation isn’t easy. It requires thorough, careful

analysis of controlled, real-time data achieved through reliable, accurate, and repeatable

process monitoring and measuring. By e ectively conditioning, sampling, and measuring

gas, liquid, slurry, powder, solids, steam, or water within their production environments,

our customers obtain the critical insights they need to control and optimize their

processes.

Yet, controlling your processes also means reliable customer support throughout the life

cycle of your equipment.

Customer Service—General information, warranty claims, order management.

Installation Service—For systems that require specialized expertise upon installation.

Technical Support—Troubleshooting, training, and technical manuals.

Field Service & Retro ts—When a problem needs immediate attention.

Replacements Parts & Consumables—Order your replacement parts and consumables.

Sentry ProShield Services—Select from four ProShield Guardian service plans

providing di erent levels of support to protect your large system investments with

regularly scheduled maintenance.

To learn more, go to

www.sentry-equip.com/support.

Page 24

sentry-equip.com

966 Blue Ribbon Circle North, Oconomowoc, WI 53066 U.S.A. | +1-262-567-7256 | support@sentry-equip.com

Serving customers

in more than 50 countries

across six continents worldwide.

Loading...

Loading...