Sentrol ZX400, ZX410 Installation Manual

SENTROL ZX400/ZX410

Security System Control

Installation

1

2

Table of Contents

New Features............................................................................................................. 5

ZX400/ZX410 Wiring Diagrams................................................................................ 6

ZX400/ZX410 Terminal Descriptions........................................................................ 8

“2 in 1” Zoning™ ...................................................................................................... 9

Conventional Methods of Wiring ........................................................................... 11

Class ‘B’ End-Of-Line Resistor Supervised Zones ..................................................... 11

Non-Supervised Closed Circuit Loop (No EOL Resistor Supervision) ...................... 11

Control Station Addressing and Supervision ......................................................... 12

SSD, LCD, and VFD Control Stations ...................................................................... 12

LED Control Stations .............................................................................................. 12

TABLE OF CONTENTS

Control Station Troubleshooting ............................................................................ 13

Clearing Trouble Messages ..................................................................................... 13

12 VDC Outputs ...................................................................................................... 14

Additional Outputs.................................................................................................. 14

Expansion Zones ..................................................................................................... 16

ZXEXP Zone Expander Module............................................................................... 17

Installation ............................................................................................................. 17

Wireless Devices ...................................................................................................... 18

Fire Zone Modules .................................................................................................. 19

ZEM Zone Expansion Module ................................................................................ 19

ZRM Zone Relay Module ........................................................................................ 21

ZXCFK Fire Module Kit ........................................................................................... 21

Power Issues ............................................................................................................ 22

Optional Battery Configurations ............................................................................. 22

ZX400/ZX410 Power Worksheet ............................................................................ 22

Auxiliary Power Supply Installation ......................................................................... 23

ZXPTR Printer Interface Module............................................................................. 24

3

TABLE OF CONTENTS

Specifications And Features .................................................................................... 25

Control Board ........................................................................................................ 25

Power Supply ......................................................................................................... 25

Recommended Battery ........................................................................................... 25

Recommended Transformer ................................................................................... 25

Enclosure................................................................................................................ 25

Digital Communicator............................................................................................ 25

Control Stations ..................................................................................................... 26

ZXLCD Control Station........................................................................................... 26

ZXVFD Control Station ........................................................................................... 26

ZXLED12 Control Station ....................................................................................... 26

ZXSSD Control Station ........................................................................................... 26

Optional Accessories .............................................................................................. 26

Output Provisions ................................................................................................... 27

List Of Compatible Accessories ............................................................................... 28

ESL Two-Wire Smoke Detectors .............................................................................. 28

ESL Four-Wire Smoke Detectors.............................................................................. 28

System Sensors Two-Wire Smoke Detectors............................................................ 28

System Sensors Four-Wire Smoke Detectors ........................................................... 28

Wheelock ............................................................................................................... 28

Compatible Central Station Receivers ..................................................................... 28

Agency Requirements ............................................................................................. 29

UL and ULC Listings ............................................................................................... 30

National Fire Protection Association (NFPA) Rules ................................................ 31

Smoke Detector Locations ...................................................................................... 31

Testing ................................................................................................................... 31

System Troubleshooting ......................................................................................... 32

FCC Compliance ...................................................................................................... 34

4

New Features

• 12 Zones with Sentrol’s unique “2 in 1” Zoning™

• Plus one 2-wire fire zone

• Expandable to 28 zones, plus two 2-wire fire zones

• Integrated Sentrol Series 4000 Wireless

• Two truly independent partitions

• Up to 50 user codes with 15 levels of authority

• 75 event log

• Four interchangeable Control Stations to choose from

• Customized scheduling with special supervisory report

• Ideal for residential, commercial, and industrial applications

• Control Station programming in less than 2 minutes with factory defaults

NEW FEATURES

The Sentrol ZX400/ZX410 Security Control features

ease of installation and programming. The ZX400/

ZX410 is easily programmed with any one of four

Control Stations (LCD, LED, SSD, or VFD). The control may also be programmed remotely with the aid

of a personal computer (PC) and a modem using

Sentrol’s remote programming software (RPM2PRO)

and a panel support module (PRO400). The Control

Stations are easy-to-operate and contain features

such as cross-zoning, delay-before-dialing and an

audibles “mute” function to help reduce false alarms.

The ZX400/ZX410 Security Control is pre-programmed from the factory with twelve burglar zones

(one delay, two interior, and nine instant) and one

2-wire smoke detector zone to allow for out-of-box

power-up and operation. The twelve burglar zones

have been configured in a ‘paralleled’ condition using Sentrol’s unique “2 in 1” Zoning™. A zone expander may be added to provide an additional 2wire smoke detector zone and, with the use of “2 in

1” Zoning™, up to 16 additional zones.

Sentrol Series 4000 RF Gateway receivers and sensors allow you to overcome installation obstacles and

increase profit potential. The wireless sensors have

been engineered for long term stability and reliabil-

ity. Using the Series 4000 Wireless System, you can

expand the ZX400/ZX410 to include up to 16 wireless zones.

The Control’s on-board RAM maintains its data even

with the power disconnected. A “Watchdog” timer

monitors the microprocessor to ensure the operational integrity of the system. The ZX400/ZX410

Control Board is equipped with one low current programmable output (PGO1) and one high current bell

output (BELL) which may be used for Fire, Burglar,

Auxiliary and/or Holdup alarms. In addition, two

ZXODMs (Output Driver Modules) can be added to

provide 20 more programmable low current outputs which may be used to trigger other devices.

The ZX400 Security Control may be purchased in

the ZX410 pre-configured package assembly. This

assembly incorporates the ZX400 Control Board

mounted inside a larger 14" x 14" x 3.5" enclosure,

EX1414. The ZX410 must be purchased for Commercial and Industrial UL Listed applications. For UL

Listed Commercial Fire applications, the ZX440F is

available. It consists of the ZX400 Control Board in

a red EX1414 enclosure, with a ZXCFM (Commercial Fire Module), a CR860 dual battery harness and

other cabling.

5

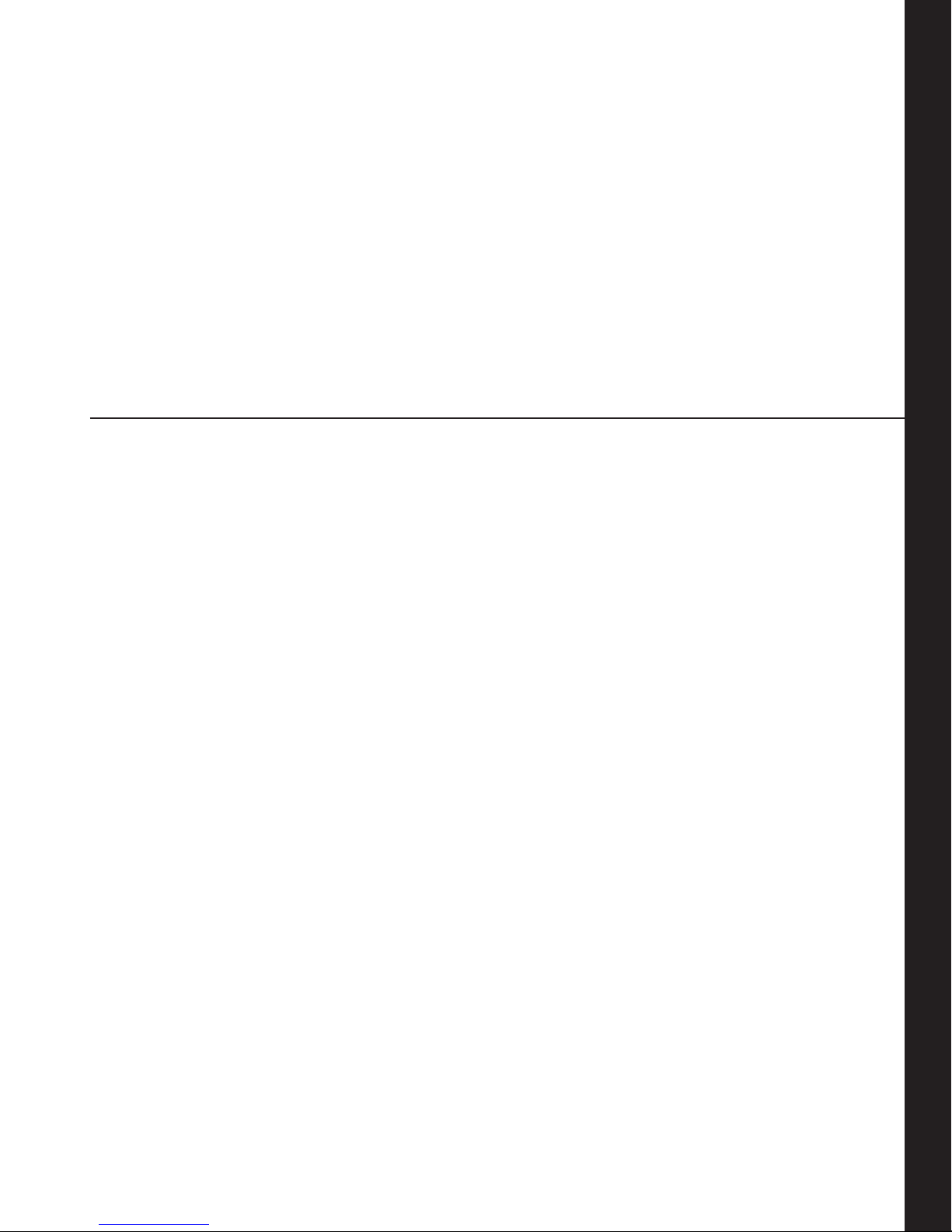

ZX400/ZX410 WIRING DIAGRAMS

ZX400/ZX410 Wiring Diagrams

J-3

7

6

NEG8DAT A

2WS

LISTED RATE OF RISE OR

FIXED TEMPERATURE THERMOSTAT

RED

BLACK

BROWN

9

DAT B10KP+1211NEG

GREEN

WHITE

CONTROL STATIONS

ZONE EXPANDER

PRINTER INTERFACE

ODMs

TO ANY ZONE DEFINED

AS 24-HOUR FIRE

POWER SUPERVISION UNIT

ESL MODEL 204-12/24V OR EQUIV.

Class II

PowerLimited

RED

BLACK

BROWN

Z1/7

12

13

Z2/814NEG

N.O.

N.C. ZONE 1

1500Ω

1/2 WATT

--

1500Ω (CR854)

(CONV ZONING)

GROUND

SCREW

Enclosure

Door

Ground

Wire

UNIFIED

EARTH

GROUND

Internally Fused.

Do Not Connect

Red and Black Leads RED = POS. (+) BLACK = NEG. (-)

12V SEALED

LEAD ACID BATTERY

Yuasa B-1270

FLOAT BATTERY VOLTAGE:

13.6 - 13.8V

Max. current: 500mA.

QUIESCENT CHARGE

CURRENT: 20mA.

Replacement: Every 3 - 5 years.

UL LISTED RESISTORS

MODEL CR853 - 825Ω E.O.L.

MODEL CR854 - 1500Ω E.O.L.

ON

OFF

1 2

~

AC XFMR

TRANSFORMER

Basler BE 116235

16.5VAC/35VA

U.L. Class II 50/60Hz

WARNING

Do Not Short.

To A Switched

Receptacle.

+--

+

POWER

SENTROL 4-WIRE MODELS

(See ZX400/ZX410 Interconnect Label

4

3

AUX125BELL

SW NEG

SIGNALING DEVICE

ALARM

CONTACTS

SMOKE DETECTOR

P/N 64600310-NOTE 2)

Class II

PowerLimited

1500Ω EOL

SUPERVISION

UL LISTED

Ademco AB12M

15

16

Z4/10

NEG

17

Z3/9

METHOD 1

ZONE 3

N.C.

1500Ω

1/2 WATT

ZONE 9

POWER

+

+

MOTION

DETECTOR

1500Ω (CR854)

(EOL DEVICE)

SMOKE DETECTOR

SENTROL 2-WIRE MODELS

(See ZX400/ZX410 Interconnect Label

P/N 64600310-NOTE 2)

825Ω

1/4 WATT

N.C.

18

Z5/11

I.C. Load Number 1

PG01

19

Z6/1220NEG

METHOD 2

ZONE 5

N.C.

1500Ω

1/2 WATT

ZONE 11

N.C.

825Ω

1/4 WATT

CONNECT

RJ31/33/45

CONNECTION OF UL COMMERCIAL

BURGLAR AUDIBLE

POLARIZATION AND

NOISE SUPPRESSION

DIODE

-

+

JUMPER

CORD

7

BELL

NEG

1500Ω (CR854)

(EOL DEVICE)

5

TEL

SUPV

J-10

J-4

13

Z2/8

ALL WIRING

BETWEEN CONTROL

& BELL MUST BE IN

CONDUIT.

ADEMCO AB12M

GRADE A BELL

COMMERCIAL

See Specification and Features section for a complete list of compatible accessories.

FIGURE 1 Suggested UL Household Burglar Alarm and/or Fire (ƒƒ) Alarm Hookup

6

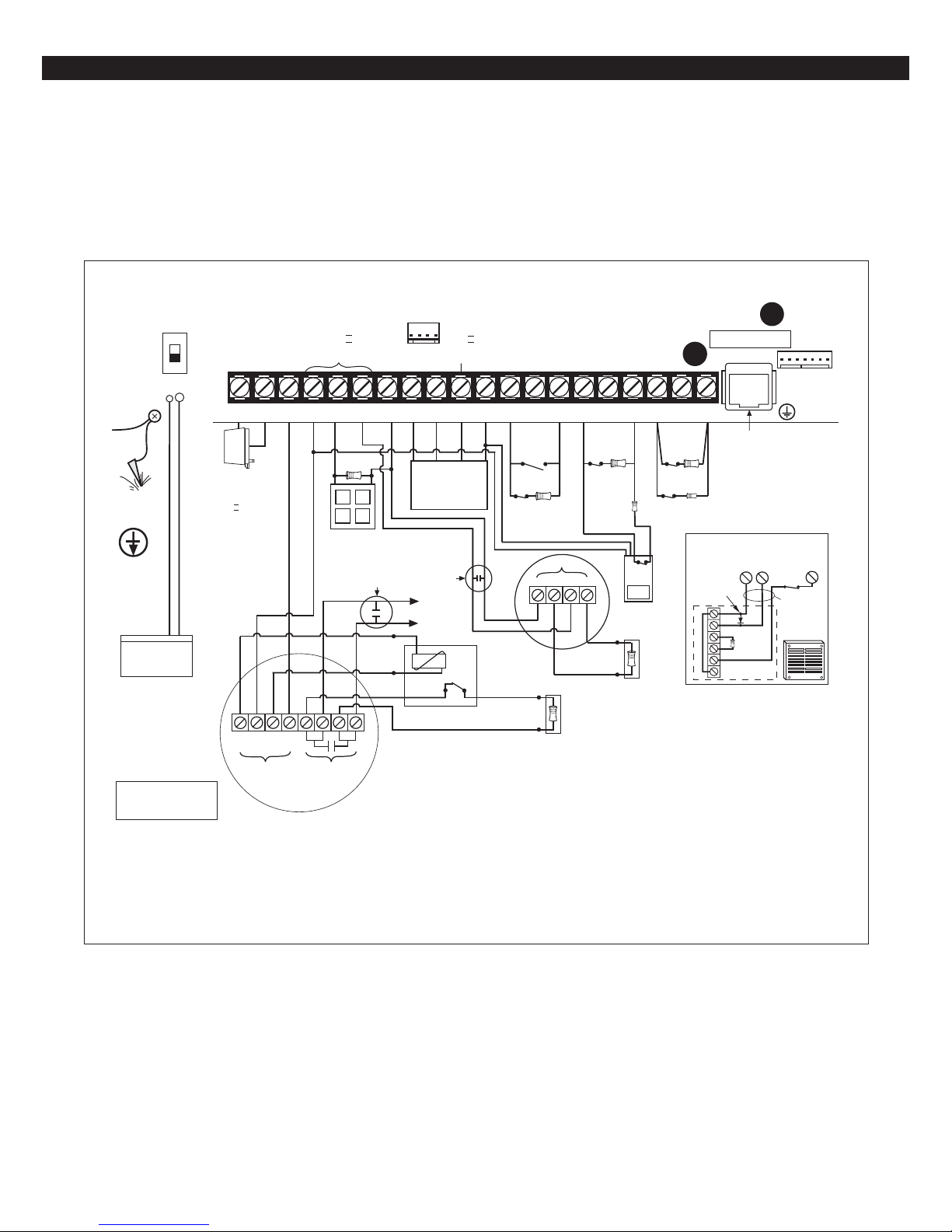

ZX400/ZX410 WIRING DIAGRAMS

MPI-206

TEL

SUPV

INSTALL

JUMPER

TELEPHONE

SUPERVISION

TG - COM NC NO

CONNECTION

TG+

MPI-206

TG - COM NC NO

TG+

+12V NEG

TO TERMINAL 10

TO TERMINAL 20

OPTIONAL - When relay is required

PROGRAMMABLE

OUTPUT 1

CONNECTION

PG01

TO TERMINAL 7

TO TERMINAL 4

CUT

JUMPER

J4

SENTROL RJ38 CORD

(shown)

OPTIONAL - When Telco Supervision is required

+12V NEG

ORANGE

BLUE

FIGURE 2 Programmable Output And Telco Supervision Wiring Diagram

7

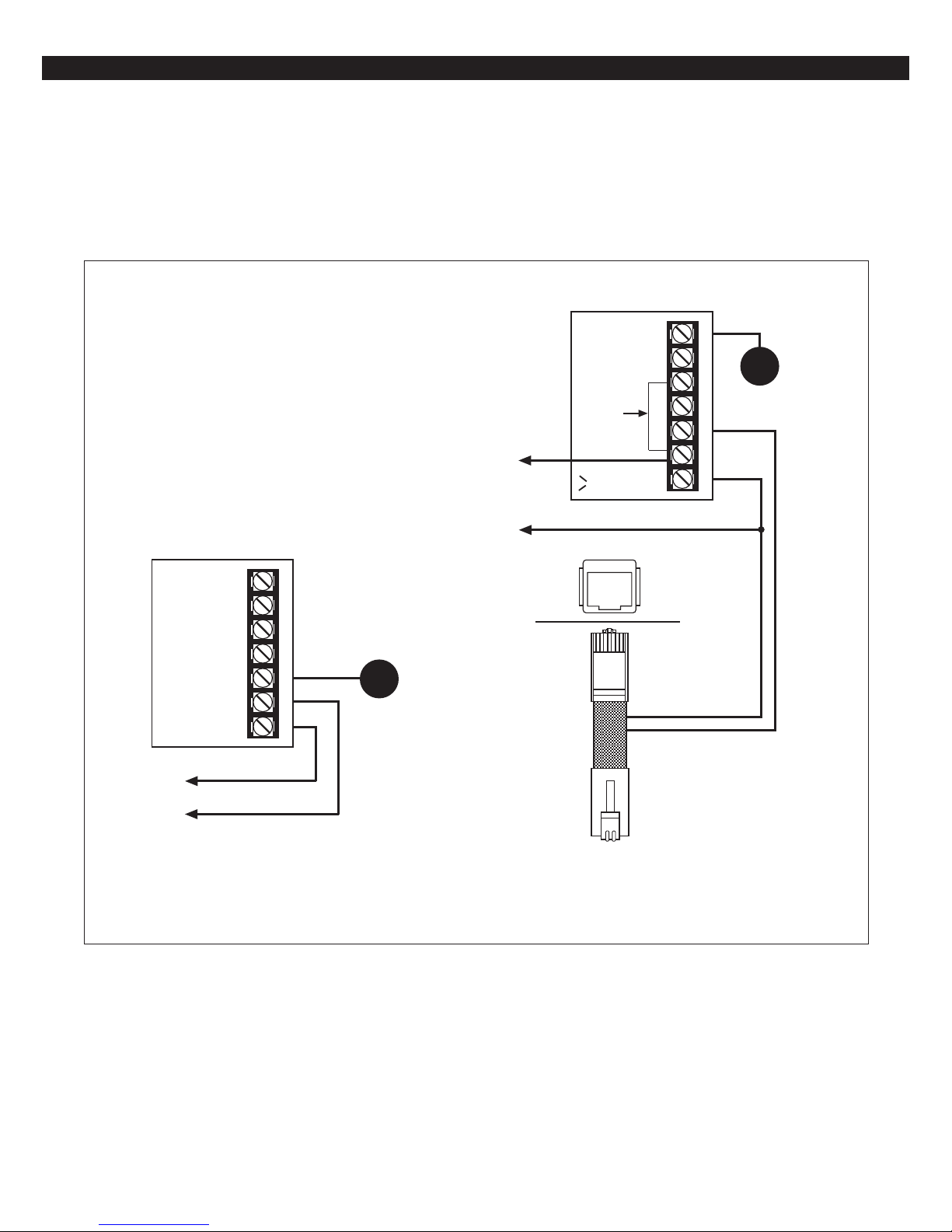

ZX400/ZX410 TERMINAL DESCRIPTIONS

ZX400/ZX410 Terminal Descriptions

TERMINAL FUNCTION DESCRIPTION

1, 2 AC Input Connect the appropriate UL Class II transformer using 18 gauge minimum 2

conductor wire. Do not exceed 50 feet. Use a 16.5 VAC 35 VA transformer or an

optional 16.5 VAC 20 VA transformer.

CAUTION: Do not short the terminals of the transformer together. This

causes the internal fuse to blow. The transformer must be connected to a

120 VAC, 24-hour outlet not controlled by a switch other than an approved

over-current protection device.

3 Switched Negative (-) Current limited 100 mA terminal. Negative connection for 4-wire smoke

4 Auxiliary Power (+)12 VDC 500 mA continuous power. Overcurrent protected at 1.35 amps

5 Supervised Bell Output (+)12 VDC. Combined alarm current should not exceed 1.5 amps. Overcurrent

(power-limited)

6 Two Wire Smoke (Zone 30) (+)12VDC of two-wire smoke detectors connected to this terminal. A 1500

(power-limited) Ohm EOL resistor (CR854) must be connected between terminals 6 and 7

7, 11 Common Negative BLACK WIRE - (-)12 VDC. Negative connection for Control Stations, zone

(power-limited)

8 Local Data Bus In (A) GREEN WIRE - Connection for Control Stations, zone expander, printer

9 Local Data Bus Out (B) WHITE WIRE - Connection for Control Stations, zone expander, printer

10 Control Station Power RED WIRE - (+)12 VDC 500 mA continuous power connection for control

(power-limited)

12 Zone 1/7 Loop (+)

13 Zone 2/8 Loop (+)

14 Common Negative

15 Zone 3/9 Loop (+)

16 Zone 4/10 Loop (+)

17 Common Negative

18 Zone 5/11 Loop (+)

19 Zone 6/12 Loop (+)

20 Common Negative

PGO1 Programmable Output 1 Use PGO1 as a +12V, 40 mA programmable output (see Figure 2).

TEL SUPV Telephone Supervision Use TEL SUPV as a telephone line trouble input (see Figure 2).

J4 Telco Jack RJ-31X connection.

detectors, glass break detectors, and devices requiring resettable power.

(PTC4). Used for powering motion detectors, 4-wire smoke detectors, glass

break detectors, and other accessories.

CAUTION: Use terminals 4 and 10 when calculating total current drain.

protected at 1.85 amps (PTC2). A 1500 Ohm EOL resistor (CR854) must be connected between terminals 5 and 7; otherwise a bell output fault will occur.

regardless of whether a two-wire smoke detector is used or not. The maximum

series resistance is 60 Ohms.

expander, printer interface, RF Gateway, ODMs, 2-wire smoke detectors,

motion detectors, and other devices.

interface, RF Gateway and ODMs. Use 22 guage wire up to 1000 ft. Use 18

guage wire up to 2000 ft.

interface, RF Gateway and ODMs. Use 22 guage wire up to 1000 ft. Use 18

guage wire up to 2000 ft.

stations, zone expander, printer interface, RF Gateway and ODMs. Overcurrent

protected at 1.35 amps (PTC4).

CAUTION: Use terminals 4 and 10 when calculating total current drain.

Each loop requires a 1500 Ohm end-of-line resistor (P/N CR854) for the primary

zone, and an 825 Ohm end-of-line resistor (P/N CR853) for the secondary zone.

A common negative is shared among all zones. The need for end-of-line resistors

may be eliminated on all Burglar defined zones through programming. See

Figure 1 for “2 in 1” Zoning™ wiring examples.

8

Secondary Zone

825Ω 1/4W

1500Ω 1/2W

Primary Zone

“2 in 1” Zoning™

“2 in 1” Zoning

™

NOTE

If a Normally Open Device (i.e., 4-wire

smoke detector) is used with “2 in 1”

Zoning™, a short will occur across

both zone loops when that device

goes into alarm. It is recommended

that these types of devices be used

with Conventional Zone wiring only.

The Sentrol ZX400/ZX410 Security Control introduces an all new method of wiring zones that saves

both time and wire costs. “2 in 1” Zoning™ allows

the installer to wire two separate zones in parallel

into one set of terminals.

Each zone is uniquely identified by its end-of-line resistor. The Primary Zone (zones 1-6) in each terminal is identified by a 1500 Ohm EOL resistor. The

Secondary Zone (zones 7 - 12) is identified by an

825 Ohm EOL resistor. The Primary and Secondary

zones operate as two independent zones to provide

separate reporting, programming, and displays. Each

zone is fully programmable as described in the

ZX400/ZX410 Programming Manual. The zones are

for Form A, Form B, or Form C sensors. Maximum

total loop wire and contact resistance (not including EOL) must not exceed 100 Ohms for the loop

to function properly.

There are two methods of wiring for “2 in 1” Zoning™. Method 1 wires one zone loop back to the

control while a second zone loop is added in parallel

off the first. This method may be employed in system retrofits, system expansions, or just simply to

save wire cost and labor.

1500Ω 1/2W

Primary Zone

Method 2 wires two separate zone loops back into

one set of terminals. The panel recognizes each

loop independently because two different EOL resistor values are used to differentiate between the

Primary Zone (1500 Ohm 1/2 Watt) and the Secondary Zone (825 Ohm 1/4 Watt). This method

provides two zones with one set of terminals and is

ideal for pre-wire or already installed wiring.

Figure 4 “2 in 1” Zoning™ Wiring - Method 2

NOTE

The resistors in Figure 3 & 4 are 1%

values to maintain proper loop resistance values. If replacements are required, please refer to the manufacturer for correct replacements. The

1500 ohm resistor is color coded

Brown•Green•Black•Brown•Brown.

The 825 ohm resistor is color coded

Gray•Red•Green•Black•Brown.

All zones sense five different voltage levels enabling

one zone to act as two. Troubleshooting is simple

using just a voltmeter at the control. The control

monitors the voltage level across the zone and uses

the voltage levels in Table 1 to determine whether

the zone is normal, open, or shorted.

Secondary Zone

825Ω 1/4W

Figure 3 “2 in 1” Zoning™ Wiring - Method 1

9

“2 in 1” Zoning™

CONDITION NOMINAL LOOP RESISTANCE VOLTAGE READING

Primary Zone and Secondary Zone Infinite Ohms 5.24 - 8.25 V

Open Contacts; Loop Cut or Open

Secondary Zone Open Contact, 1500 Ohms 4.24 - 5.23 V

Primary Zone Normal

Primary Zone Open Contact, 825 Ohms 3.24 - 4.23 V

Secondary Zone Normal

Primary Zone and Secondary Zone 825 Ohms in parallel with 2.00 - 3.23 V

Normal 1500 Ohms = 532 Ohms

Primary Zone and Secondary Zone 0 Ohms 0 - 1.99 V

Shorted

TABLE 1 “2 in 1” Zoning™ Troubleshooting Chart

10

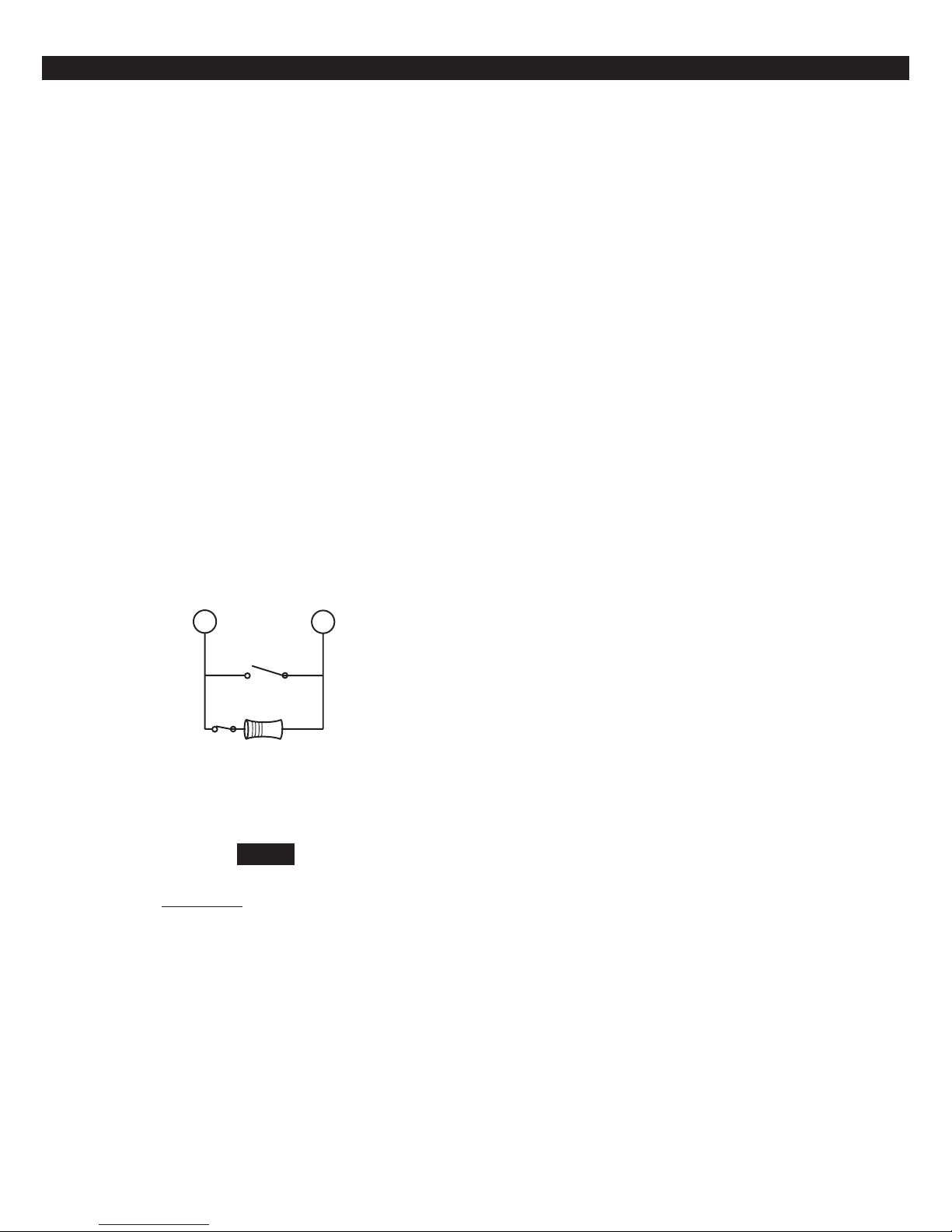

Conventional Methods of Wiring

CONVENTIONAL WIRING

Class ‘B’ End-Of-Line Resistor

Supervised Zones

A Class ‘B’ zone must be supervised with a 1500

Ohm 1/2 Watt end-of-line resistor (P/N CR854). This

resistor should be installed in series at the furthest

point from the control. This configuration must be

used whenever both Form A and Form B devices are

connected and provides a high degree of protection against compromise or tampering. The control

monitors the voltage level across the Primary zone

and uses the Primary zone voltage levels in Table 1

to determine whether the zone is normal, open, or

shorted. The operation of a zone is programmable

as described in the ZX400/ZX410 Programming

Manual. Maximum total loop wire and contact

resistance (not including EOLs) must not exceed

100 Ohms for the loop to function properly. The

1500 Ohm EOL resistor is optional for Form A connections but is required for Form B.

Normally

Open

Non-Supervised Closed Circuit

Loop (No EOL Resistor

Supervision)

The EOL resistor is not required on Burglar zones. A

conventional closed circuit loop may be connected

directly to a primary zone and the zone will have

either a short or an open condition. See the ZX400/

ZX410 Programming Manual for programming an unsupervised zone. Fire zones may not be installed as

unsupervised. Only Burglar defined zones may be

wired non-supervised. “2 in 1” Zoning™ is not

allowed.

1500Ω 1/2W

Primary Zone

Normally

Closed

Figure 5 Conventional Zone Wiring Method

NOTE

For UL Listed systems, EOL Supervi-

is required.

sion

11

Loading...

Loading...