Sentrol ZX300, SENTROL ZX310 Installation & Programming

SENTROL ZX300/ZX310

Expandable Security System Control

Installation/

Programming

1

2

Table of Contents

ZX300/ZX310 Wiring Diagram......................................................................................5

Control Board T erminal Descriptions.........................................................................6

Zone Wiring.................................................................................................................... 7

Class ‘B’ End-Of-Line Resistor Supervised Zones ......................................................7

Non-Supervised Closed Circuit Loop (No EOL Resistor Supervision)........................7

ZXEX08 Zone Expander Module............................................................................. ... 7

Wireless Devices ..........................................................................................................8

Control Station Addressing and Supervision............................................................9

SSD, LCD, and VFD Control Stations......................................................................... 9

ICON Control Stations..................................................................................................9

LED Control Stations..............................................................................................9

Unsupervised and Supervised Control Stations..................................................... 9

T ABLE OF CONTENTS

Control Station Troubleshooting..............................................................................10

12 VDC Outputs .........................................................................................................11

Operating the System ................................................................................................13

Powering Up The Control ...........................................................................................13

Testing ...............................................................................................................13

Installer Arming and Disarming ..................................................................................13

Trouble Conditions .....................................................................................................1 3

Clearing Trouble Messages .......................................................................................13

Installer on Premises..................................................................................................13

Programming the Control.................................................................................................14

Introduction ...............................................................................................................14

Local Programming ....................................................................................................1 4

Programming Zone Names....................................................................................... 14

Installer Level Programming .....................................................................................15

Menu Options .............................................................................................................15

Program Function Map....................................................................................15

Entering a New Value at a Location................................................................15

Programming the Account Code and Telephone Number Digits....................16

Additional Programming Notes .......................................................................16

Program User Codes.......................................................................................16

Restore Factory Defaults ................................................................................16

Hours Until Next Comm Test...........................................................................1 7

Program RF Data............................................................................................17

Programming RF Zone Devices Into the RF Gateway ...................................17

Programming RF User Devices Into the RF Gateway....................................18

Programming RF Devices Into the Control Panel...........................................18

3

T ABLE OF CONTENTS

Specifications And Features .....................................................................................19

List of Compatible Accessories................................................................................22

SIA and Contact ID Formats......................................................................................23

Agency Requirements ...............................................................................................25

National Fire Protection Association (NFPA) Rules................................................27

FCC Compliance.........................................................................................................30

4

ZX300/ZX310 Wiring Diagram

WIRING DIAGRAM

7167-1459:114

FIGURE 1 Suggested UL Household Burglar Alarm and/or Fire (ƒƒ) Alarm Hookup

5

TERMINAL DESCRIPTIONS

Control Board Terminal Descriptions

TERMINAL FUNCTION DESCRIPTION

AC

BELL

NEG

KP+12V

GREEN

DAT A

WHITE

DAT A

NEG

Zone 1

Zone 2

Zone 3

Zone 4

NEG

Zone 5

Zone 6

NEG

Zone 7

Zone 8

AC Input

Supervised Bell Output

(power-limited)

Common Negative

Keypad Power

(power-limited)

Local Data Bus In

Local Data Bus Out

Zone Inputs

Connect a 16.5 VAC 15 VA UL Class II transformer minimum using 18 gauge

minimum 2 conductor wire. Do not exceed 50 feet.

(+)12 VDC. Combined alarm current should not exceed 1.0 amps.

Overcurrent protected at 1.35 amps (PTC2). A 1500 Ohm EOL resistor

(CR854)

a bell output fault will occur.

BLACK WIRE - (-)12 VDC. Negative connection for Control Stations, ODM,

RF receiver, zone expander, motion detectors, bell output, and other devices.

RED WIRE - (+)12 VDC 500 mA continuous power connection for Control

Stations, ODM, zone expander, and RF Gateway. Overcurrent protected at

1.35 amps (PTC1). CAUTION: Use the KP+12V and the +12V AUX

terminals when calculating total current drain.

GREEN WIRE - Connection for Control Stations, zone expander, ODM and RF

receiver. Use 22 gauge wire up to 1000 ft. Use 18 gauge wire up to 2000 ft.

WHITE WIRE - Connection for Control Stations, zone expander, ODM and RF

receiver. Use 22 gauge wire up to 1000 ft. Use 18 gauge wire up to 2000 ft.

Each loop requires a 1500 Ohm end-of-line resistor (P/N CR854). A common

negative is shared among all zones. The need for end-of-line resistors may be

eliminated on all Burglar defined zones through programming.

must be connected between the Bell and Neg terminals; otherwise

2WS

+12V AUX

Two-Wire

Smoke Terminal

Auxiliary Power

(power-limited)

Current limited 100 mA terminal. Connection for two-wire/four-wire smoke

detectors, glass break detectors, and devices requiring resettable power. The

maximum series loop resistance for a two-wire smoke loop is 20 ohms. The

maximum Alarm Impedance is 500 ohms.

(+)12 VDC 500 mA continuous power. Overcurrent protected at 1.35

amps (PTC1). Used for powering motion detectors, CO detectors, and other

accessories. CAUTION: Use the KP+12V and the +12V AUX terminals when

calculating total current drain.

6

Zone Wiring

ZONE WIRING

Class ‘B’ End-of-Line Resistor

Supervised Zones

A Class ‘B’ zone must be supervised with a 1500

Ohm 1/2 Watt end-of-line resistor (P/N CR854). This

resistor should be installed in series at the furthest

point from the control. This configuration must be

used whenever both Form A and Form B devices

are connected and provides a high degree of protection against compromise or tampering. The control monitors the voltage level across the zone and

uses the zone voltage levels in Table 1 to determine

whether the zone is normal, open, or shorted. The

operation of a zone is programmable (see Programming Record Book). Maximum total loop wire and

contact resistance (not including EOLs) must not

exceed 100 Ohms for the loop to function properly . The 1500 Ohm EOL resistor is optional for

Form A connections but is required for Form B.

Normally

Open

Non-Supervised Closed Circuit

Loop (No EOL Resistor

Supervision)

The EOL resistor is not required on Burglar zones.

A conventional closed circuit loop may be connected

directly to a zone and the zone will have either a

short or an open condition. See Programming

Record Book for programming an unsupervised

zone. Fire zones may not be installed as unsupervised. Only Burglar defined zones may be wired nonsupervised.

NOTE

For UL Listed systems, EOL Supervision is required.

ZXEX08 Zone Expander Module

This module provides an additional 8 zones (zones

9-16) for the ZX300/ZX310 control. These zones are

wired the same as the 8 on-board zones and the

JP1 jumper must be in place.

1500Ω 1/2W

Primary Zone

Normally

Closed

Figure 2 Zone Wiring

CONDITION NOMINAL LOOP RESISTANCE VOL TAGE READING

Mount the module in a ZX310 enclosure as shown

in the ZXEX08 insert using the screws and standoffs provided. For mounting with the ZX300 or in a

remote location, use a suitable enclosure, like the

EB1511.

Connect the module to the ZX300/ZX310 local data

bus using either the "quick connection" or the data

bus terminals on the module. The "Active" LED

flashes to indicate the module is communicating with

the control.

NOTEONLY BURGLAR DEFINED ZONES MAY

Zone Open Infinite Ohms 9.75 - 13.85 V

Zone Normal 1500 Ohms 2.82 - 9.74 V

Zone Shorted 0 Ohms 0.00 - 2.81 V

Table 1 Zone Troubleshooting Chart

7

WIRELESS DEVICES

Wireless Devices

The ZX300/ZX310 provides an option for including

Wireless (or RF) Devices. The RF Devices may consist of RF Zone Devices (Universals, Door Contacts, Glassbreaks, PIRs and Smoke Detectors) and

RF User Devices (Handhelds). These RF Devices

require that an RF Gateway be attached to the system. The ZX300/ZX310 is compatible with either a

model 4710 or 4720 RF Gateway which are UL listed

for household fire and burglary and commercial fire.

If a 4720 RF Gateway is used, it must be set to address ‘1’. Refer to the RF Gateway instructions for

address selection.

• 4710 RF Gateway - provides up to 8 RF Zone

Devices and up to 8 RF User Devices. It can

only provide for zones 9-16.

• 4720 RF Gateway - provides up to 16 RF Zone

Devices and up to 8 RF User Devices. It can

provide for zones 1-16.

Mount the RF Gateway as described in the RF Gateway instructions. Wire the local data bus to the terminals: +12V - RED; DATA A - GREEN; DATA B WHITE; NEG - BLACK. Set Address switch. Reinstall the cover.

See Installer Level Programming - Programming RF

Data Into the RF Gateway . An RF User Device must

be mapped to a valid user passcode by programming.

The RF Gateway and RF Zone Devices should be

temporarily mounted in their desired locations until

they have been tested with the Control Panel. These

devices may need to be re-oriented or moved to

achieve optimal reception. After testing has been

completed, they should be permanently mounted.

ceived Signal Strength of the last transmission sent

by the RF Zone Device. See results below:

Strong Signal (5 Control Station beeps): a strong or

high level RF signal was measured by the receiver

for that location of the transmitter. This is a good

location for the transmitter and receiver.

Acceptable (3 Control Station beeps): a normal or

acceptable level of RF signal was measured by the

receiver for that location of the transmitter. This is a

good location for the transmitter and receiver.

Low Signal (1 Control Station beep): a low or

acceptable level of RF signal was measured by the

receiver for that location of the transmitter. Make

multiple test transmissions, making sure that obstructions between the transmitter and receiver are normal but minimized (hands away from units, metal

ladders away from receiver, etc.) during these tests.

The transmitter and/or receiver will need to be relocated to obtain ACCEPTABLE level readings.

No Signal (1 long Control Station beep): no RF signal or an extremely low RF signal was measured by

the receiver for that location of the transmitter. Bring

the transmitter to the RF Gateway and activate the

transmitter. The red LED on the RF Gateway should

blink. If it does not, then the transmitter is not working. If the red LED does blink, but the signal strength

is still NO SIGNAL, then a programming error exists. Check the programming of the zone in the RF

Gateway. If the signal strength is STRONG or ACCEPT ABLE, then the transmitter and/or receiver will

need to be relocated to obtain ACCEPTABLE level

readings. Be sure to power down the control to clear

out all signal strength levels before testing the transmitter at its new location.

After testing has been completed, the RF Gateway

and RF Zone Devices should be permanently mounted.

not

To test the Received Signal Strength of each RF

Zone Device, use Test 6 - RF Signal Strength Test.

From the Control Station press the “8” key , followed

by the Installer Code (9632) and then press the “6”

key . Next press the RF Zone Device Number (1-16).

The Control Station will display and sound the Re-

NOTE

Series 4000 RF Gateways and transmitters

which are not UL labeled are not allowed in

UL Certificated installations.

8

CONTROL STATION ADDRESSING AND SUPERVISION

Control Station Addressing and

Supervision

All LCD Control Stations are shipped from the factory as Control Station #1 (#3 for Icon Control Stations) and supervised. They may be set to other addresses and to unsupervised as described below.

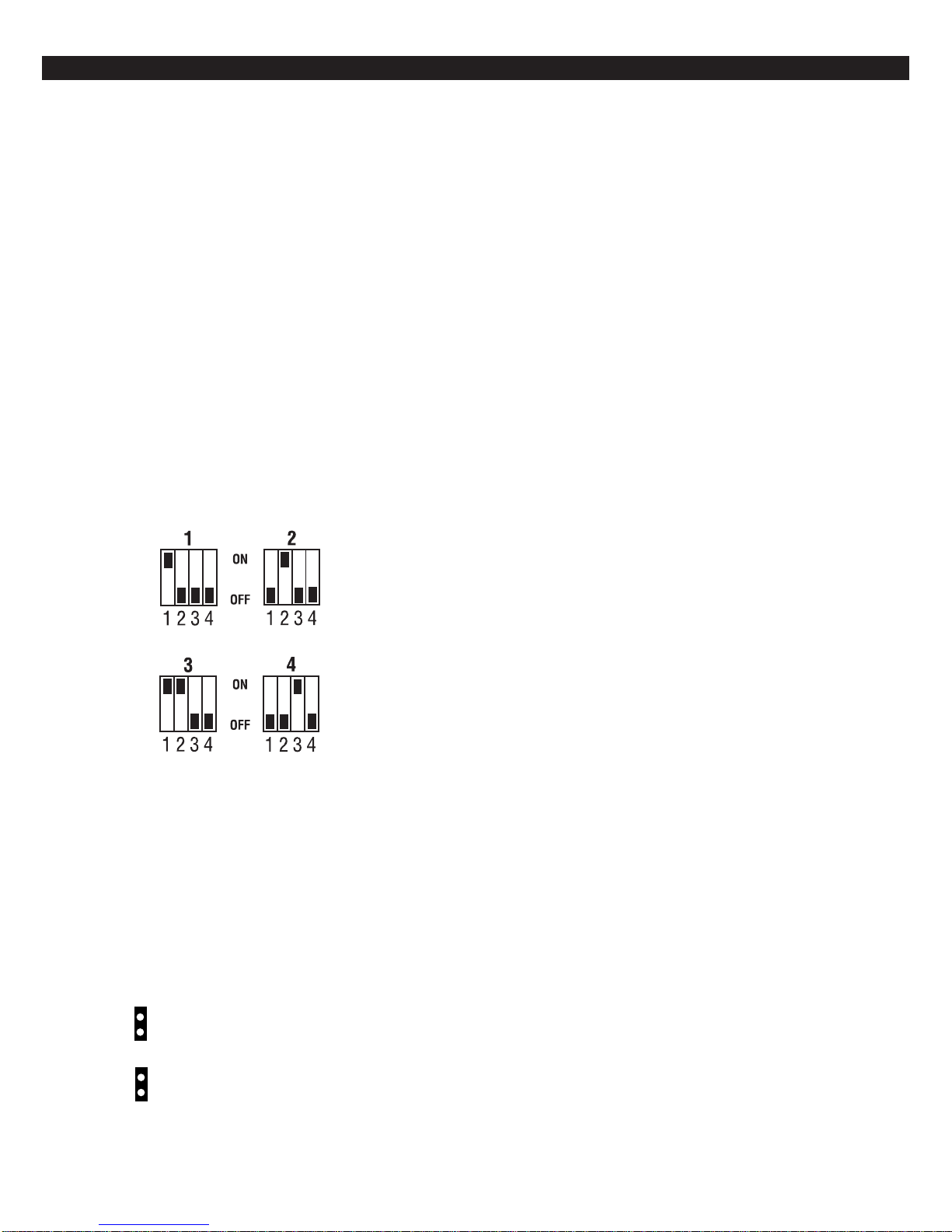

SSD, LCD, and VFD Control

Stations

These Control Stations have a four position DIP

switch on the circuit board to set the address and

supervision. To change the Control Station to unsupervised, move DIP switch 4 to the ON position. To

change the address, the DIP switch setting must be

positioned according to Figure 3.

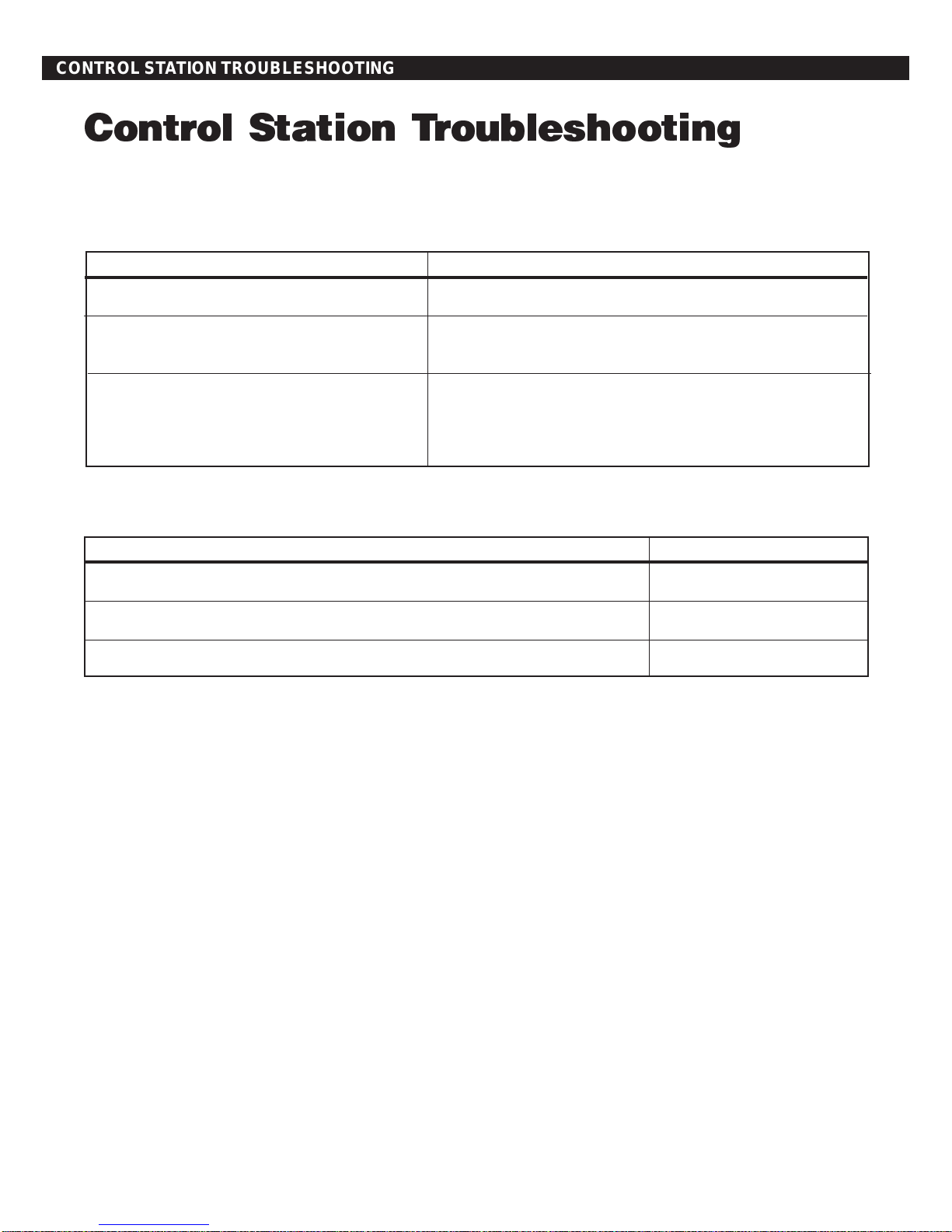

LED Control Stations

These Control Stations have two jumpers on the circuit board to set the address and supervision. To

change the address of Control Station #1 to Control

Station #2, remove JP2 (see Figure 4). To change a

Control Station to unsupervised, remove JP1 (see

Figure 4).

Supervised and

Unsupervised Control

Stations

Figure 3 Control Station DIP Switch Settings

ICON Control Stations

These Control Stations have two jumpers on the circuit board to set the address and supervision. To

change the address of Control Station #3 to Control

Station #4, remove JP2 (see Figure 4). To change a

Control Station to unsupervised, remove JP1 (see

Figure 4).

Remove JP1 to unsupervise

JP1

Remove JP2 for keypad 2 (LED) or

keypad 4 (ICON)

JP2

A supervised Control Station is reported as missing

when the system fails to get any response from it.

If more than one supervised Control Station is set to

a particular address, then none of those Control Stations will function properly. Only one supervised

Control Station may be used at an address.

An unsupervised Control Station can be removed

from the system without the system detecting that it

is missing. The advantage of an unsupervised Control Station is that a system can have as many Control Stations as the power supply can support. Multiple unsupervised Control Stations may be used at

any address. When unsupervised SSD, LCD, and

VFD Control Stations are used, they must be set to

address 3 or 4. By adding additional power supplies,

like the HCP12SULC, Control Stations may be added

up to a total of 18 bus devices on the system.

For UL listed systems, unsupervised Control Stations are not allowed.

If an unsupervised Control Station is set to the same

address as a supervised Control Station, then the

unsupervised Control Station will not function. Do

not mix a supervised Control Station with unsupervised Control Stations at the same address.

Figure 4 LED & ICON Control Station Jumpers

9

CONTROL ST A TION TROUBLESHOOTING

Control Station Troubleshooting

If a Control Station is incorrectly wired, it will not accept keystroke entries. The following symptoms may appear:

SYMPTOM CONDITION

No Control Station display or LEDs Black or Red Wire removed or cut

No response from key presses Green Wire removed or cut

Two supervised Control Stations at the same address

LEDs flash and may display White Wire removed or cut

“No Communication From Control” code Green/White Wires reversed

Green & White Wires shorted together

The nominal voltage at the control (with a single Control

Station connected) should measure as follows:

TERMINAL VOLTAGE

from Common Negative to GRN DATA ~ 9.3 VDC

from Common Negative to WHT DATA ~ 10.7 VDC

from Common Negative to KP+12V ~13.8 VDC

10

Loading...

Loading...