Sentrol ZX200, ZX210 Installation And Programming Manual

SENTROL ZX200/ZX210

Security System Control

Installation/

Programming

1

2

Table of Contents

Feature Overview ..................................................................................................... 5

A New Standard For Value ........................................................................................5

ZX System Advantages..............................................................................................5

”More Than A Security System“ ................................................................................5

”Self-Watch“ Fire Zone Features................................................................................5

ZX200/ZX210 Wiring Diagram ................................................................................ 6

Control Board Terminal Descriptions ...................................................................... 7

“2 in 1” Zoning™ ..................................................................................................... 8

Conventional Methods of Wiring .......................................................................... 10

Class ‘B’ End-Of-Line Resistor Supervised Zones ......................................................10

Non-Supervised Closed Circuit Loop (No EOL Resistor Supervision) ........................ 10

TABLE OF CONTENTS

Wireless Devices ..................................................................................................... 11

Control Station Addressing and Supervision ........................................................ 12

SSD, LCD, and VFD Control Stations .......................................................................12

LED Control Stations ...............................................................................................12

Control Station Troubleshooting ........................................................................... 13

12 VDC Outputs ..................................................................................................... 14

Direct Connection to a PC for Remote Programming .......................................... 16

Operating the System ............................................................................................ 17

Powering Up With The Control Station ...................................................................17

Installer Arming and Disarming ............................................................................... 17

Installer On Premises ...............................................................................................17

Trouble Conditions .................................................................................................17

Clearing Trouble Messages ......................................................................................17

Testing ....................................................................................................................17

Programming the Control ..................................................................................... 18

Introduction ...........................................................................................................18

Local Programming .................................................................................................18

Remote Programming (RPM/2 Pro).........................................................................18

LED Control Station Programming ..........................................................................18

Programming Zone Names .....................................................................................19

3

TABLE OF CONTENTS

Installer Level Programming .................................................................................. 20

Menu Options.........................................................................................................20

Function Map ......................................................................................................... 24

Programming Notes ...............................................................................................40

Remote Connect ...........................................................................................20

Edit Function Map .........................................................................................20

Entering a New Value at a Location..................................................... 20

Programming the Account Code, Report Code, and Telephone Number Digits ..

Additional Programming Notes .......................................................... 21

Program User Codes......................................................................................21

Restore Factory Defaults ................................................................................21

Hours Until Next Comm Test.........................................................................22

Call RPM ....................................................................................................... 22

Program RF Data ...........................................................................................22

Programming RF Zone Devices Into the RF Gateway ............................22

Programming RF User Devices Into the RF Gateway .............................23

Programming RF Devices Into the Control Panel ..................................24

System Times ................................................................................................25

System Options .............................................................................................26

Keypad Options ............................................................................................ 27

Zone Definitions ............................................................................................ 28

User Authority Levels .....................................................................................29

Bell Output Activation ...................................................................................30

Programmable Outputs ................................................................................. 30

Programmable Output Activation.........................................................31

Communicator Options ................................................................................32

Event Reporting Phone Selection ................................................................... 33

Telephone Numbers ......................................................................................34

Dialed Digits Allowed ...........................................................................34

Account Numbers .........................................................................................34

Zone Report Code Digits ...............................................................................35

User Report Code Digits ................................................................................36

Auxiliary Key Alarm Report Code Digits .........................................................37

Other Trouble Report Code Digits .................................................................37

Other Event Report Code Digits ....................................................................39

21

Specifications And Features ................................................................................... 43

List of Compatible Accessories .............................................................................. 46

Digital Communicator Table For Contact ID Formats........................................... 47

Agency Requirements ............................................................................................ 49

National Fire Protection Association (NFPA) Rules ............................................... 51

FCC Compliance ..................................................................................................... 54

4

Feature Overview

FEATURE OVERVIEW

• 8 zones

• 2 or 4-wire fire zone capability

• Integrated Sentrol Series 4000

wireless

• Compatible with ESL 521 Smoke

Detector for automatic “Clean Me”

maintenance reporting

• Four exciting new keypads

• Pager reporting

A New Standard For Value

The ZX200/ZX210 Control System sets a new standard for value and end-user benefits. Highlights include 8 zone hardwire/wireless flexibility, unique

Lifestyle Enhancement features, and an easy to use

family of keypads. The ZX200/ZX210 control is preprogrammed at the factory with eight burglary zones

so it’s ready to power up and operate out of the

box. An optional output driver module provides 10

additional programmable outputs when desired.

ZX System Advantages

• Built-in telephone line monitor

• Supervised bell circuit

• Temporal rhythm fire bell coding

• Automatic Smoke Detector Reset

feature

• Fuse-Free

• 14" x 14" ‘Big Box’ enclosure available (model ZX210)

system at night can be as easy as saying…or pressing

“Night, Night”.

“More Than A Security System”

The ZX200/ZX210 does more than provide reliable

home security - it provides features that complement

family lifestyles. User On Premise lets you know

when someone’s arrived.

Pager Reporting notifies users of trouble, alarm conditions, or other reportable conditions on pagers with

digital displays.

The new ZX Control System offers significant benefits

for both the installer and end user. Commonality in

programming, operation, and accessories mean ZX

controls are easier to install and program and reduce

inventory and installation costs.

Compatible wireless receivers and sensors overcome

installation obstacles and increase sales and profit potential. Sensors have been engineered for long-range

stability and reliability and the modular 8-zone receiver,

with true diversity antenna, mounts anywhere for improved reception and performance.

Four all-new keypads provide unique features and displays for easy end-user operation. Each keypad features three distinct arming levels (Away, Stay & Night)

with backlit keys that show system status at a glance

and an easy to find Off key with automatic “Mute”

feature. Arming the system is easy with quick Two-

Button Arming or Double Press Arming. Arming the

“Self-Watch” Fire Zone Features

The ZX200/ZX210 ensures optimum fire zone performance and safety with unique “Self Watch” features. The ZX200/ZX210 is compatible with ESL’s

new 521 series smoke detectors for “Clean Me” Au-

tomatic Self-Diagnostic Reporting. This feature enables the panel to sense when the smoke detector

needs cleaning or maintenance over the same two

wires used for power and alarm signaling. The control will then signal the Central Station that a smoke

detector maintenance trouble signal has occurred letting you know

For added security, the ZX200/ZX210 incorporates

Automatic Smoke Detector Reset which automatically resets the smoke detectors following a manual

disarm of the fire system. The ZX200/ZX210 also

complies with new NFPA requirements for residential fire installations by providing Temporal Rhythm

Fire Coding and a Supervised Bell Circuit.

5

before a problem occurs.

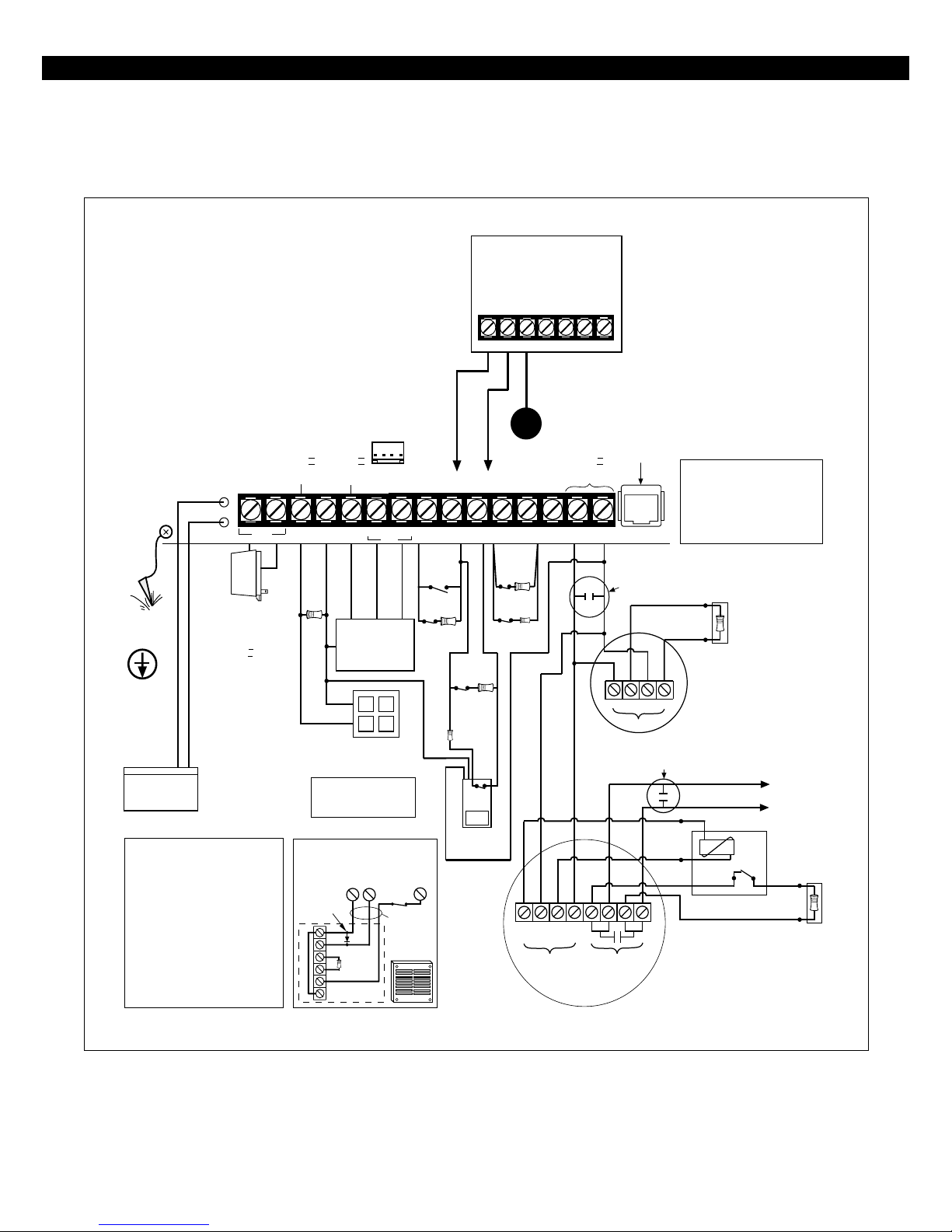

WIRING DIAGRAM

ZX200/ZX210 Wiring Diagram

+12V NEG

KEYPAD

EARTH

GROUND

UNIFIED

EARTH

GROUND

BATT

XFMR

TRANSFORMER

Recommended:

Basler BE 116220

16.5V / 20VA MIN.

U.L. CLASS II 50/60Hz

WARNING

Internally Fused.

Do Not Short.

Do Not Connect

To A Switched

Red and Black Leads RED = POS. (+) BLACK = NEG. (-)

Receptacle.

12V SEALED

LEAD ACID BATTERY

Yuasa B-1270

QUIESCENT CHARGE CURRENT: 20mA.

Replace: Every 3 - 5 years.

OWNERS INSTRUCTION

THIS EQUIPMENT SHOULD BE INSTALLED

IN ACCORDANCE WITH THE NATIONAL

FIRE PROTECTION ASSOCIATION’S

STANDARD 72 (NATIONAL FIRE

PROTECTION ASSOCIATION,

BATTERYMARCH PARK, QUINCY, MA

02269). PRINTED INFORMATION

DESCRIBING PROPER INSTALLATION,

OPERATION, TESTING, MAINTENANCE,

EVACUATION PLANNING AND REPAIR

SERVICE IS TO BE PROVIDED WITH THIS

EQUIPMENT.

FLOAT BATTERY

VOLTAGE:

13.6 - 13.8V

Max. current: 500mA.

NOTICE -

Class II

PowerLimited

AC

BELL

NEG

1500Ω

1/2 WATT

UL LISTED RESISTORS

MODEL CR853 - 825Ω E.O.L.

MODEL CR854 - 1500Ω E.O.L.

CONNECTION OF UL COMMERCIAL

POLARIZATION AND

NOISE SUPPRESSION

DIODE

JUMPER

Class II

PowerLimited

KP

+12V

BLACK

CONTROL STATIONS

AND OTHER

PERIPHERALS

UL LISTED

SIGNALING DEVICE

Ademco AB12M

BURGLAR AUDIBLE

-

+

1500Ω (CR854)

(EOL DEVICE)

GREEN WHITE

DATA

RED

BELLNEG

J-4

WHITE

GREEN

ZONE

2/6

ALL WIRING

BETWEEN CONTROL

& BELL MUST BE IN

CONDUIT.

ADEMCO AB12M

GRADE A BELL

COMMERCIAL

TO +12V AUX TERMINAL

ZONE

1/5

NEG

N.O.

N.C. ZONE 1

1500Ω

1/2 WATT

ZONE

METHOD 1

N.C.

1/2 WATT

ZONE 6

825Ω

1/4 WATT

MOTION

DETECTOR

TO NEG TERMINAL

ZONE

2/6

3/7

METHOD 2

N.C.

N.C.

ZONE 2

1500Ω

N.C.

TG+

PG01

NEG

ZONE 3

1500Ω

1/2 WATT

ZONE 7

825Ω

1/4 WATT

+

MPI-206

TG - COM NC NO

PROGRAMMABLE

OUTPUT 1

CONNECTION

Class II

PowerLimited

ZONE

2WS

4/8

SWNEG

+--

POWER

CONNECT

RJ31/33/45

CORD

+12V

TELCO

AUX

JACK

LISTED RATE OF RISE OR

FIXED TEMPERATURE THERMOSTAT

--

+

+

POWER

LISTED RATE OF RISE OR

FIXED TEMPERATURE THERMOSTAT

RED

BLACK

BROWN

ALARM

CONTACTS

SENTROL 4-WIRE MODELS

Telephone connection of the fire

alarm signal from this system to a

fire alarm headquarters or central

station is permitted only with the

approval of the authority having

jurisdiction.

1500Ω (CR854)

(EOL DEVICE)

SMOKE DETECTOR

SENTROL 2-WIRE MODELS

(See ZX200/ZX210

Interconnect Label

P/N 64600285-NOTE 2)

TO ANY ZONE DEFINED

AS 24-HOUR FIRE

BROWN

POWER SUPERVISION UNIT

ESL MODEL 204-12/24V OR EQUIV.

1500Ω (CR854)

SMOKE DETECTOR

(See ZX200/ZX210

Interconnect Label

P/N 64600285-NOTE 2)

(CONV ZONING)

FIGURE 1 Suggested UL Household Burglar Alarm and/or Fire (ƒƒ) Alarm Hookup

6

Control Board Terminal Descriptions

TERMINAL FUNCTION DESCRIPTION

AC

XFMR

BELL

AC Input

Supervised Bell Output

(power-limited)

Connect a 16.5 VAC 35 VA UL Class II transformer minimum using 18 gauge

minimum 2 conductor wire.Do not exceed 50 feet.

(+)12 VDC. Combined alarm current should not exceed 1.5 amps.

Overcurrent protected at 1.85 amps (PTC2). A 1500 Ohm EOL resistor

(CR854)

bell output fault will occur.

must be connected between the Bell and Neg terminals; otherwise a

TERMINAL DESCRIPTIONS

NEG

KP

+12V

GREEN

DATA

WHITE

DATA

ZONE 1/5

NEG

ZONE 2/6

ZONE 3/7

NEG

ZONE 4/8

2WS

SWNEG

+12V

AUX

Common Negative

Keypad Power

(power-limited)

Local Data Bus In

Local Data Bus Out

Zone 1/5 Loop (+)

Common Negative

Zone 2/6 Loop (+)

Zone 3/7 Loop (+)

Common Negative

Zone 4/8 Loop (+)

Two-Wire/Four-Wire Smoke

Switched Negative

Auxiliary Power

(power-limited)

BLACK WIRE - (-)12 VDC. Negative connection for Control Stations, ODM,

RF receiver, motion detectors, bell output, and other devices.

RED WIRE - (+)12 VDC 500 mA continuous power connection for Control

Stations, ODM, and RF Gateway. Overcurrent protected at 1.85 amps

(PTC1). CAUTION: Use the KP+12V and the +12V AUX terminals when

calculating total current drain.

GREEN WIRE - Connection for Control Stations, ODM and RF receiver. Use 22

gauge wire up to 1000 ft. Use 18 gauge wire up to 2000 ft.

WHITE WIRE - Connection for Control Stations, ODM and RF receiver. Use 22

gauge wire up to 1000 ft. Use 18 gauge wire up to 2000 ft.

Each loop requires a 1500 Ohm end-of-line resistor (P/N CR854) for the

primary zone and an 825 Ohm end-of-line resistor (P/N CR853) for the

secondary zone. A common negative is shared among all zones. The need for

end-of-line resistors may be eliminated on all Burglar defined zones through

programming. See Figure 2 and 3 for “2 in 1” Zoning™ wiring examples.

(-) Current limited 60 mA terminal. Negative connection for two-wire/fourwire smoke detectors, glass break detectors, and devices requiring resettable

power. The maximum series loop resistance for a two-wire smoke loop is 20

ohms. The maximum Alarm Impedance is 500 ohms.

(+)12 VDC 500 mA continuous power. Overcurrent protected at 1.85

amps (PTC1). Used for powering motion detectors, two-wire/four-wire smoke

detectors, glass break detectors, and other accessories. CAUTION: Use the

KP+12V and the +12V AUX terminals when calculating total current drain.

7

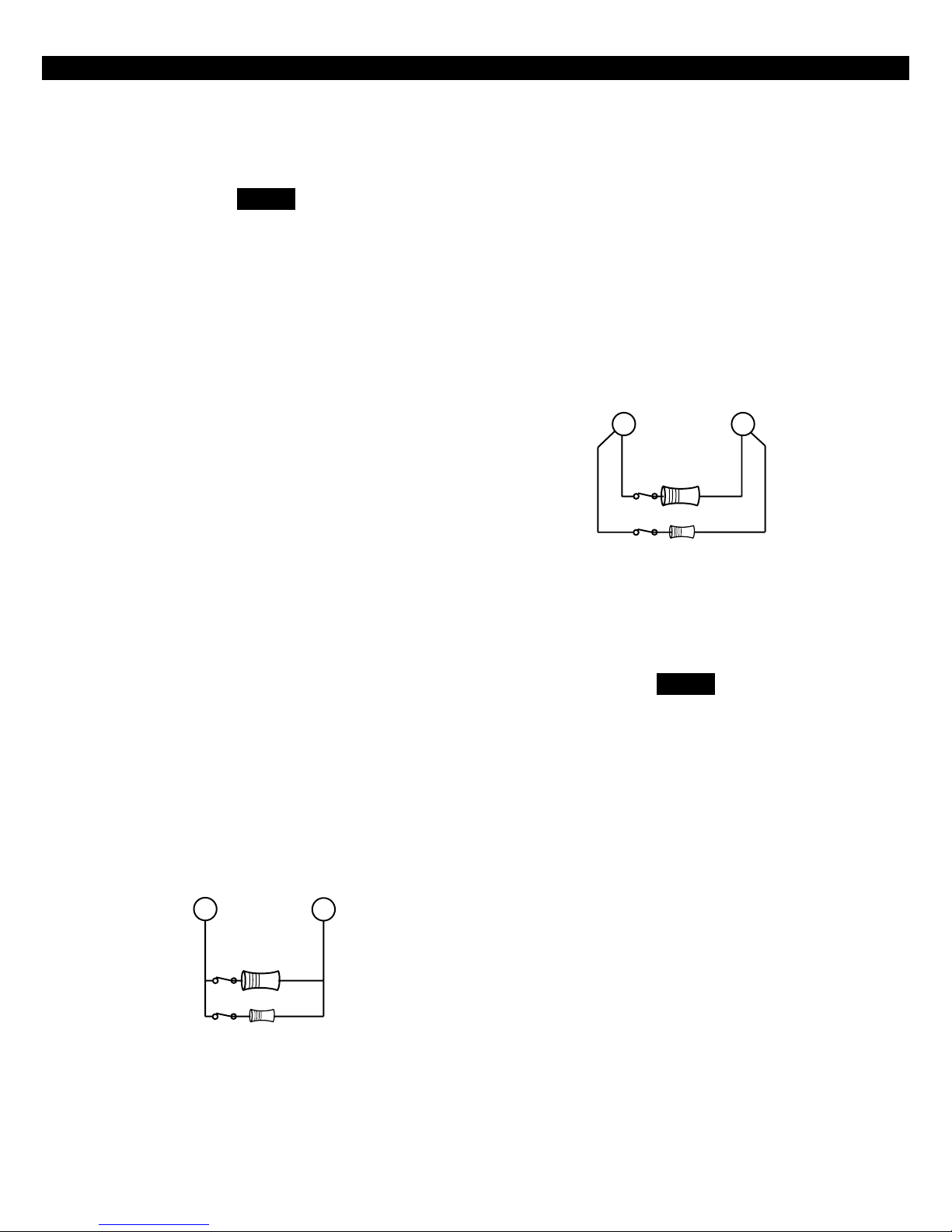

“2 in 1” Zoning™

“2 in 1” Zoning

™

NOTE

If a Normally Open Device (i.e., 4wire smoke detector) is used with

“2 in 1” Zoning™, a short will occur across both zone loops when

that device goes into alarm. It is

recommended that these types of

devices be used with Conventional

Zone wiring only.

The ZX200/ZX210 Security Control uses the “2 in

1” Zoning™ method that allows the installer to wire

two separate zones in parallel into one set of terminals that will save both time and wire costs.

Each zone is uniquely identified by its end-of-line

resistor. The Primary Zone (zones 1-4) in each terminal is identified by a 1500 Ohm EOL resistor. The

Secondary Zone (zones 5 - 8) is identified by an 825

Ohm EOL resistor. The Primary and Secondary zones

operate as two independent zones to provide separate reporting, programming, and displays. Each

zone is fully programmable (See Installer Level Programming). The zones are for Form A, Form B, or

Form C sensors. Maximum total loop wire and con-

tact resistance (not including EOL) must not exceed 100 Ohms for the loop to function properly.

There are two methods of wiring for “2 in 1” Zoning™. Method 1 wires one zone loop back to the

control while a second zone loop is added in parallel off the first. This method may be employed in

system retrofits, system expansions, or just simply

to save wire cost and labor.

Method 2 wires two separate zone loops back into

one set of terminals. The panel recognizes each loop

independently because two different EOL resistor

values are used to differentiate between the Primary

Zone (1500 Ohm 1/2 Watt) and the Secondary Zone

(825 Ohm 1/4 Watt). This method provides two

zones with one set of terminals and is ideal for prewire or already installed wiring.

1500Ω 1/2W

Primary Zone

Secondary Zone

825Ω 1/4W

Figure 3 “2 in 1” Zoning™ Wiring - Method 2

NOTE

The resistors in Figures 2 & 3 are

1% values to maintain proper loop

resistance values. If replacements

are required, please refer to the

manufacturer for correct replacements. The 1500 Ohm resistor is

color coded Brown•Green•

Black•Brown•Brown. The 825

Ohm resistor is color coded

Gray•Red•Green•Black•Brown.

1500Ω 1/2W

Primary Zone

Secondary Zone

825Ω 1/4W

Figure 2 “2 in 1” Zoning™ Wiring - Method 1

All zones sense five different voltage levels enabling

one zone to act as two. Troubleshooting is simple

using just a voltmeter at the control. The control

monitors the voltage level across the zone and uses

the voltage levels in Table 1 to determine whether

the zone is normal, open, or shorted.

8

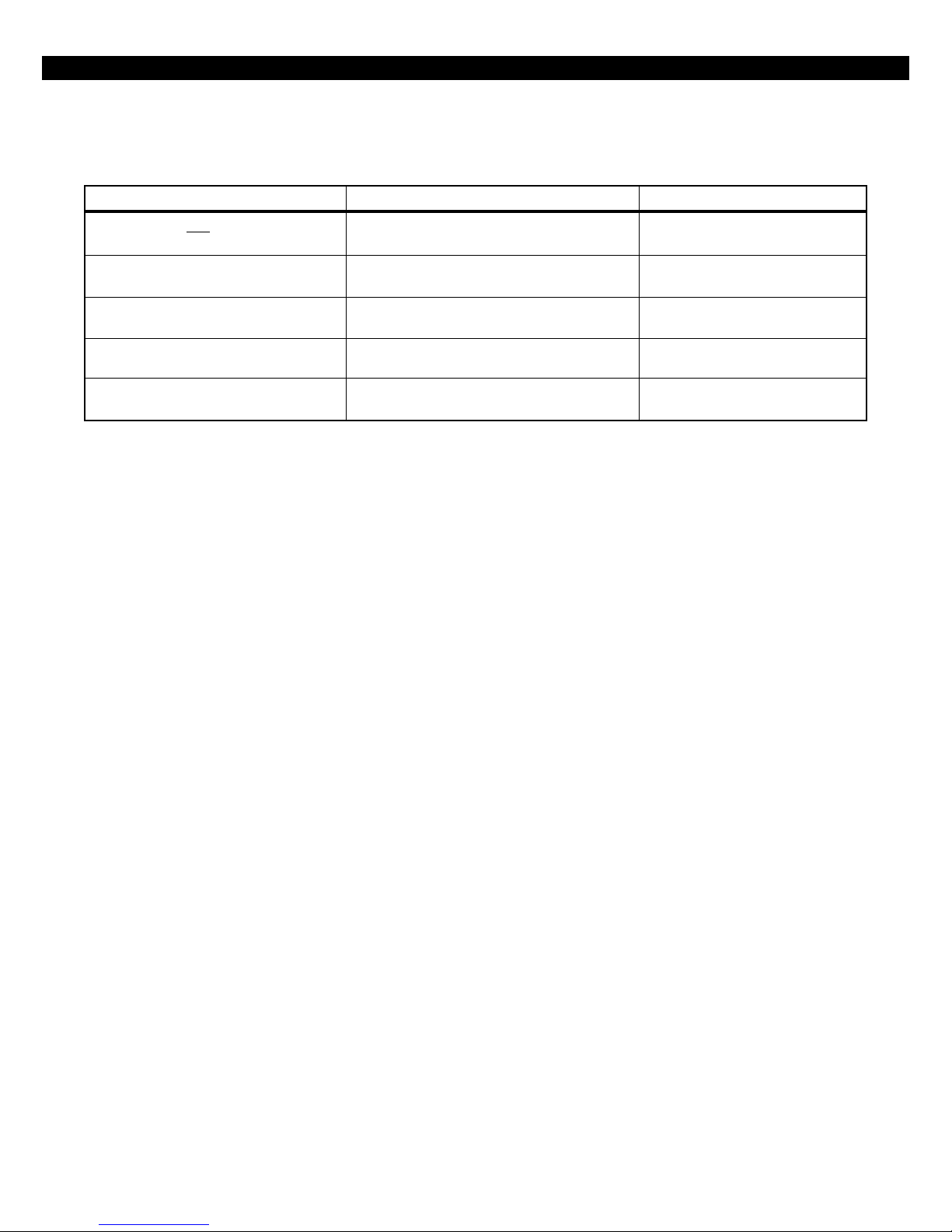

“2 in 1” Zoning™

CONDITION NOMINAL LOOP RESISTANCE VOLTAGE READING

Primary Zone and Secondary Zone Infinite Ohms 5.24 - 8.25 V

Open Contacts; Loop Cut or Open

Secondary Zone Open Contact, 1500 Ohms 4.24 - 5.23 V

Primary Zone Normal

Primary Zone Open Contact, 825 Ohms 3.24 - 4.23 V

Secondary Zone Normal

Primary Zone and Secondary Zone 825 Ohms in parallel with 2.00 - 3.23 V

Normal 1500 Ohms = 532 Ohms

Primary Zone and Secondary Zone 0 Ohms 0 - 1.99 V

Shorted

Table 1 “2 in 1” Zoning™ Troubleshooting Chart

9

CONVENTIONAL WIRING

Conventional Methods of Wiring

Class ‘B’ End-Of-Line Resistor

Supervised Zones

A Class ‘B’ zone must be supervised with a 1500

Ohm 1/2 Watt end-of-line resistor (P/N CR854). This

resistor should be installed in series at the furthest

point from the control. This configuration must be

used whenever both Form A and Form B devices are

connected and provides a high degree of protection against compromise or tampering. The control

monitors the voltage level across the Primary zone

and uses the Primary zone voltage levels in Table 1

to determine whether the zone is normal, open, or

shorted. The operation of a zone is programmable

(see Installer Level Programming). Maximum total

loop wire and contact resistance (not including

EOLs) must not exceed 100 Ohms for the loop to

function properly. The 1500 Ohm EOL resistor is

optional for Form A connections but is required

for Form B.

Normally

Open

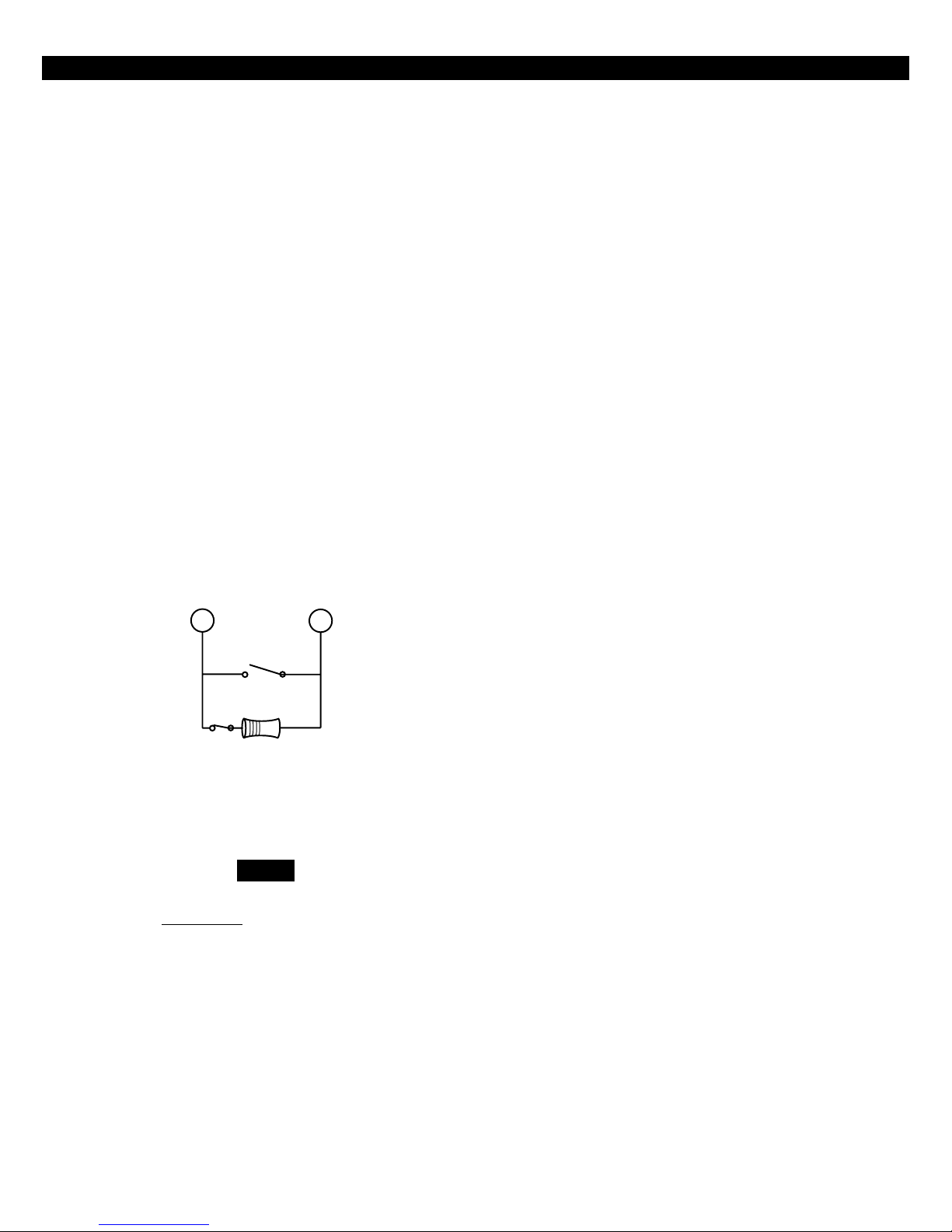

Non-Supervised Closed Circuit Loop

(No EOL Resistor Supervision)

The EOL resistor is not required on Burglar zones. A

conventional closed circuit loop may be connected

directly to a primary zone and the zone will have

either a short or an open condition. See Installer Level

Programming for programming an unsupervised

zone. Fire zones may not be installed as unsupervised. Only Burglar defined zones may be wired

non-supervised. “2 in 1” Zoning™ is not allowed.

NOTEONLY BURGLAR DEFINED ZONES MAY

BE WIRED NON-SUPERVISED. “2 IN 1” ZON-

ING™ IS NOT ALLOWED.

1500Ω 1/2W

Primary Zone

Normally

Closed

Figure 4 Conventional Zone Wiring Method

NOTE

For UL Listed systems, EOL Supervi-

is required.

sion

10

Wireless Devices

WIRELESS DEVICES

The ZX200/ZX210 provides an option for including

Wireless (or RF) Devices. The RF Devices may consist

of RF Zone Devices (Universals, Door Contacts,

Glassbreaks, PIRs and Smoke Detectors) and RF User

Devices (Handhelds). These RF Devices require that

an RF Gateway be attached to the system. The

ZX200/ZX210 is compatible with either a model

4710 or 4720 RF Gateway. If a 4720 RF Gateway is

used, it must be set to address ‘1’. Refer to the RF

Gateway instructions for address selection.

Mount the RF Gateway as described in the RF Gateway instructions. Wire the local data bus to the terminals: +12V - RED; DATA A - GREEN; DATA B WHITE; NEG - BLACK. Set Address switch. Reinstall

the cover.

Each of the eight zones on the ZX200/ZX210 may

be programmed to be wireless (see Installer Level

Programming - Zone Definitions). If a zone is programmed to be wireless, then its hardwire connection is ignored and the zone’s status is retrieved from

the RF Gateway.

Up to eight RF Zone Devices and six RF User Devices

may be used (see Installer Level Programming - Programming RF Data Into the RF Gateway). An RF Zone

must be mapped to a zone by programming. An RF

User Device must be mapped to a valid user passcode

by programming.

The RF Gateway and RF Zone Devices should be temporarily mounted in their desired locations until they

have been tested with the Control Panel. These devices may need to be re-oriented or moved to achieve

optimal reception. After testing has been completed,

they should be permanently mounted.

Strong Signal (HOT or 5 Control Station beeps):

a strong or high level RF signal was measured by the

receiver for that location of the transmitter. This is a

good location for the transmitter and receiver.

Acceptable (ACC or 3 Control Station beeps): a

normal or acceptable level of RF signal was measured by the receiver for that location of the transmitter. This is a good location for the transmitter

and receiver.

Low Signal (LO or 1 Control Station beep): a low

or

not acceptable level of RF signal was measured

by the receiver for that location of the transmitter.

Make multiple test transmissions, making sure that

obstructions between the transmitter and receiver

are normal but minimized (hands away from units,

metal ladders away from receiver, etc.) during these

tests. The transmitter and/or receiver will need to

be relocated to obtain ACCEPTABLE level readings.

No Signal (NO or 1 long Control Station beep):

no RF signal or an extremely low RF signal was measured by the receiver for that location of the transmitter. Bring the transmitter to the RF Gateway and

activate the transmitter. The red LED on the RF Gateway should blink. If it does not, then the transmitter

is not working. If the red LED does blink, but the

signal strength is still NO SIGNAL, then a programming error exists. Check the programming of the

zone in both the RF Gateway and the panel. If the

signal strength is STRONG or ACCEPTABLE, then the

transmitter and/or receiver will need to be relocated

to obtain ACCEPTABLE level readings. Be sure to

power down the control to clear out all signal

strength levels before testing the transmitter at its

new location.

After testing has been completed, the RF Gateway and

RF Zone Devices should be permanently mounted.

To test the Received Signal Strength of each RF Zone

Device, use Test 6 - RF Signal Strength Test. From

the Control Station press the “8” key, followed by

the Installer Code (9632) and then press the “6”

key. Next press the RF Zone Device Number (1 to

8). The Control Station will display and sound the

Received Signal Strength of the last transmission sent

by the RF Zone Device.

NOTE

Series 4000 RF Gateways and transmitters which are not UL labeled are not

allowed in UL Certificated installations.

11

CONTROL STATION ADDRESSING AND SUPERVISION

Control Station Addressing and Supervision

All Control Stations are shipped from the factory as

Control Station #1 and supervised. They may be set

to other addresses and to unsupervised as described

below.

A supervised Control Station is reported as missing

when the system fails to get any response from it.

In order to maintain supervision, each supervised

Control Station must have its own unique address.

An unsupervised Control Station can be removed

from the system without the system detecting that

it is missing. The advantage of an unsupervised Control Station is that a system can have as many Control Stations as the power supply can support. By

adding additional power supplies, like the HCP12SUL, Control Stations may be added up to a total

of 18 bus devices on the system. For UL listed systems, unsupervised Control Stations are

not allowed.

SSD, LCD, and VFD Control Stations

When unsupervised Control Stations

are used, ALL unsupervised LED Control Stations

or 2, ALL unsupervised SSD, LCD, and

VFD Control Stations must be addressed as 3 or 4. You cannot mix a

supervised keypad and an unsupervised keypad with the same address

setting.

NOTE

must be addressed as 1

LED Control Stations

These Control Stations have two jumpers on the circuit board to set the address and supervision. To

change the address of the Control Station #1 to

Control Station #2, remove JP2 (see Figure 6). To

change a Control Station to unsupervised, remove

JP1 (see Figure 6).

These Control Stations have a four position DIP

switch on the circuit board to set the address and

supervision. To change the Control Station to unsupervised, move DIP switch 4 to the ON position. To

change the address, the DIP switch setting must be

positioned according to Figure 5.

1

ON

OFF

1234

3

ON

OFF

1234

Figure 5 Control Station DIP Switch Settings

2

1234

4

1234

Remove JP1 to unsupervise

JP1

Remove JP2 for keypad 2

JP2

Figure 6 LED Control Station Jumpers

12

CONTROL STATION TROUBLESHOOTING

Control Station Troubleshooting

If a Control Station is incorrectly wired, it will not

accept keystroke entries. The following symptoms

may appear:

SYMPTOM CONDITION

No Control Station display Black or Red Wire removed or cut

No response from key presses Green Wire removed or cut

Displays “No Communication From Control” code White Wire removed or cut

Green/White Wires reversed

Green & White Wires shorted together

The nominal voltage at the control should measure

as follows:

TERMINAL VOLTAGE

from Common Negative to GRN DATA ~ 8.7 VDC

from Common Negative to WHT DATA ~ 3.5 VDC

from Common Negative to KP+12V ~13.8 VDC

13

12 VDC OUTPUTS

12 VDC Outputs

The control is supplied with one keypad power

output, one auxiliary power output, one bell output, and one programmable (PGO1) low current

output. (See Figure 1). The low current output on

the control can supply 10 mA @ 3VDC.

Additional outputs can be added with the ZXODM

Output Driver Module. The module receives its

data from the local data bus and provides ten additional programmable outputs. The ODM outputs

provide +12 VDC on activation and must be limited to 40 mA of current draw.

The ODM must be addressed as ODM1. The ODM

comes defaulted from the factory as ODM1. You

may use multiple ODMs provided that power restrictions are followed. Connect the ODM to the

control as shown in Figure 7. Use the twelve (12)

wire cable provided with the ODM for the outputs as shown.

Output conditions can be programmed as one of

many conditions. Refer to Installer Level Programming for programming information and restrictions.

J3 CONNECTIONS

OUTPUT

WIRE COLOR

1Tan

2Pink

3Gray

4 Violet

5 Yellow

6 Orange

7Blue

8 Dk Brown

9 Green

10 White

NEG Black

12V* Red

DATA BUS CONNECTION

RED Connect to Control KP+12V

GREEN Connect to Control GREEN

WHITE Connect to Control WHITE

BLACK Connect to Control NEG

R19

C7

R21

C3

+

D9D7D6

R18

C5

R25

R29

HICKORY, NC

ASSEMBLED

IN USA

R22

R23

R28

60821484 REV A

COPYRIGHT 1996

D4

C11

D5

D10

R12

R15

R20

R16

D2C6D1

V3

V2

R27

Q2

ACTIVE

C10

D3

Q1

R14

R13

U2

C4

+

V1

J2

B NEG

A

12V

R24

R26

J1

U1

R2

1234

SENTROL

CONTROLS GROUP

Y1

C8

R17

PC BOARD

MADE IN (USA)

R3R4R5R6R7

OUTPUTS

5678

C2

C9

C1

R1

D8

+

U4

R9

R8

R11

R10

J3

NEG

910

12V

14

Data bus connection

Figure 7 ZXODM Wiring Diagram

NOTE

The outputs on this module have limited transient immunity and should

not leave the enclosure. Mount module via the double-sided tape provided

on the back of the ODM to the inside

of the control enclosure.

J3 Connector

12 VDC OUTPUTS

Outputs may be wired to indicator devices or relay

module triggers (like the MPI-206) provided the 40

mA current draw condition is not exceeded. Figure

8 shows a wiring example for a relay to ODM 1

Output 2. Figure 9 shows a wiring example of ODM

1 Output 1 to trigger an LED.

MPI-206

+12V NEG

Red Wire

TG+

Black Wire

TG - COM NC NO

Pink Wire

Connects to J3 (part of 12-wire cable)

Neg

TAN WIRE

BLACK WIRE

* A 470-1000Ω resistor may be used

Output 1

Figure 9 Output Connected to an LED

NOTE

NOTE

The LED and current limiting resistor

shown in Figure 9 are not supplied.

*

Figure 8 Output Connected to a Relay

NOTE

Do not exceed 250 mA of total current through the Red (+12V) and

Black wires (Negative) of the twelve

wire cable. Add 18 gauge wire from

the appropriate control panel terminals for total current drains in excess

of 250 mA.

15

DIRECT CONNECTION TO A PC

Direct Connection to a PC for Remote

Programming

This system requires that a line voltage be provided

in order for the telephone interface to operate. This

is normally provided via the telephone lines. When

performing a direct connection between the system

and a modem on a PC, the line voltage must be

ZX200/ZX210

ZONE

ZONE

2/6

3/7

NEG

ZONE

4/8

Red

1 Watt

Resistor

2WS

SWNEG

100Ω

Green

provided from the control panel’s terminal strip.

Connect a cable as shown below. This cable may be

purchased (P/N ZXDCC01 - ZX200 PC Direct Connection Cable) from Sentrol.

+12V

TELCO

AUX

JACK

RJ11

Red

Green

RJ11

Telco In

MODEM

Figure 10 Direct Connection to a PC

16

Operating the System

OPERATING THE SYSTEM

Powering Up With The Control

Station

The control comes from the manufacturer with a

factory set (default) program. The factory default

code for user passcode No. 1 is “1234”. This

passcode is authorized to perform all user level functions. The default setting for the installer passcode

is “9632”. The installer passcode performs the installer level functions. For purposes of discussion, the

installer and the end user are both considered system users, but have different levels of authorization.

(See Installer Level Programming - User Authority

Levels).

When a Control Station is powered-up, it briefly displays a test pattern followed by its data bus address.

The Control Station will then begin displaying information from the control panel. During the first fifteen seconds after power-up, the control panel will

instruct the Control Station to display the panel’s

software revision and flash the AWAY, STAY, NIGHT,

READY, and TROUBLE LEDs.

Installer Arming and Disarming

The installer passcode may be used to arm the system. It may be used to disarm, but only if the system was armed by the installer passcode. It may be

used to silence alarms and to silence trouble conditions. When it is used to silence a Burglar alarm, it

will not disarm or cancel the alarm unless the system was armed by the installer passcode. For a detailed description of arming and disarming procedures, see the appropriate User Guide.

Installer On Premises

The first time that an Installer level passcode is used

to perform a function, an “Installer On Premises”

event is logged to be reported. Before leaving the

premises, press and hold the CLEAR key for three

seconds and an “Installer Off Premises” event will

be logged to be reported.

Trouble Conditions

The possible trouble conditions are:

AC Power Failure Fire Trouble

Low Battery Silenced Fire Alarm

Memory Error Zone Missing

Communication Failure RF Point Not Reporting

Missing Keypad Smoke Trouble

RF Jamming RF Point Tamper

Bell Fault RF Point Low Battery

Telco Line Fault RF User Device Low Battery

Zone Trouble

If RF Jamming is detected for at least 90 seconds, then

all RF Burglar zones will be faulted.

Clearing Trouble Messages

Most trouble conditions are cleared automatically

when the condition that initiated the trouble is restored or is eliminated. Three trouble conditions

(Memory Error, Smoke Trouble and Missing Keypad)

may be cleared manually by pressing and holding

the Clear key for three seconds (until two beeps are

heard). This action is also required to turn off the

Duress output after it has been activated and to cause

an “Installer Off Premises” event (see Operating the

System - Installer On Premises).

Testing

The ZX200/ZX210 provides the following testing capabilities: Walk Test, Battery Test, Bell Test, Communicator Test, Keypad Test and RF Signal Strength Test.

Refer to the appropriate User Guide for instructions

on performing these tests. Always ensure that a Walk

Test (and an RF Signal Strength Test when applicable)

is performed on a new installation.

17

Loading...

Loading...