Page 1

sentrol

Wireless

U

L

LISTED

D

E

T

B

S

Y

I

L

U

A

N

D

D

A

E

N

R

A

W

C

R

F

I

T

O

E

R

S

S

E

I

L

R

A

O

B

T

O

A

R

4300 Series

4300 Series

Wireless Smoke Detector

Wireless Smoke Detector

DESCRIPTION

The Sentrol 4300 Series smoke detector requires a

Sentrol 4000 RF gateway receiver with Rev J or higher

software and a compatible control panel sold separately. To install the detector, you will need the

programming guide for the control panel.

Depending on the model, the detector provides the

following features:

CleanMe

™

self-diagnostics monitors its own sensitiv-

ity and operational status. If the detector drifts out of

the UL listed sensitivity range or fails internal diagnostics, it extinguishes its LED and sends a trouble signal

to the control panel.

Detector/base lock discourages unauthorized removal

of the detector by requiring a screwdriver to remove

the detector from the base.

Optional base tamper sends a trouble signal to the

control panel when the detector is removed from its

mounting base.

Optional mercury-tilt tamper

sends a trouble signal

to the control panel when the detector is not upside

down and/or horizontal. Used for installations on

removeable ceiling panels

Optional integrated fixed 135°F temperature and

rate of rise heat detector trips an alarm based on

temperature detected.

Optional low temperature supervision sends a low

temperature signal when the ambient temperature

around the detector reaches approximately 43°F (6°C).

A separate transmitter signal (secondary address) is

assigned to a Critical Condition Monitoring(CCM) zon

TRANSMITTED SIGNAL OUTPUTS

Depending on the model, the detector transmits the

following signals to the control panel:

• Alarm

• Alarm restore

• Tamper

• Low battery

• CleanMe

• Maintenance alert

• Supervisory

• Low temperature supervison

™

U

CSFM

L

LISTED

Sounder vent

LED

Optional temperature sensor

T est/Silence button

Figure 1 - Detector Features

SELECTING A LOCATION

Selecting a suitable location is critical to the operation

of smoke detectors. This equipment should be installed

in accordance with the National Fire Protection

Association’s (NFPA) Standard 72. See Figure 2.

A-8-1.2.1.C Are More Smoke Detectors Desirable?

The required number of smoke detectors might not

provide reliable early warning protection for those areas

separated by a door from the areas protected by the

e.

required smoke detectors. For this reason, it is recommended that the householder consider the use of

additional smoke detectors for those areas for increased protection. The additional areas include the

basement, bedrooms, dining room, furnace room, utility

room, and hallways not protected by the required

smoke alarms. The installation of smoke detectors in

kitchens, attics (finished or unfinished), or garages is

not normally recommended, as these locations occasionally experience conditions that can result in improper operation.

Bedroom

Living

Room

Basement

= Required smoke detectors

Bedroom

Dining

Room

= Additional smoke detectors required for new construction

TV Room

Bedroom

Figure 2 - Detector Placement

Dining

Room

Living Room

Kitchen Bedroom

Bedroom

Important: Regulations pertaining to smoke detector

installations vary from state to state. For more information, contact your local fire department or local

authority having jurisdiction.

1

Page 2

In addition to NFPA 72, use the following location guidelines to optimize performance and reduce the chance of

false alarms from the detector:

•

Locate ceiling-mounted smoke detectors in the center

of a room or hallway at least 4 inches from any walls

or partitions.

• Locate wall-mounted smoke detectors so the top of

the detector is 6 to 12 inches below the ceiling.

• Locate in a suitable environment as follows:

- T emperature between 40°F (4.4°C) and 100°F (37.8°C)

- Humidity between 0 and 95% non-condensing

• Locate away from air conditioners, heating registers

and any other ventilation source that may interfere

with smoke entering the detector.

• Mount smoke detectors on a firm permanent surface.

If the detector has a tilt tamper, it can be mounted on

removable ceiling panels.

Knockout

Knockout

Figure 3 - Base Lock Knockouts

• Locate away from large metallic objects.

INSTALLING THE DETECTOR

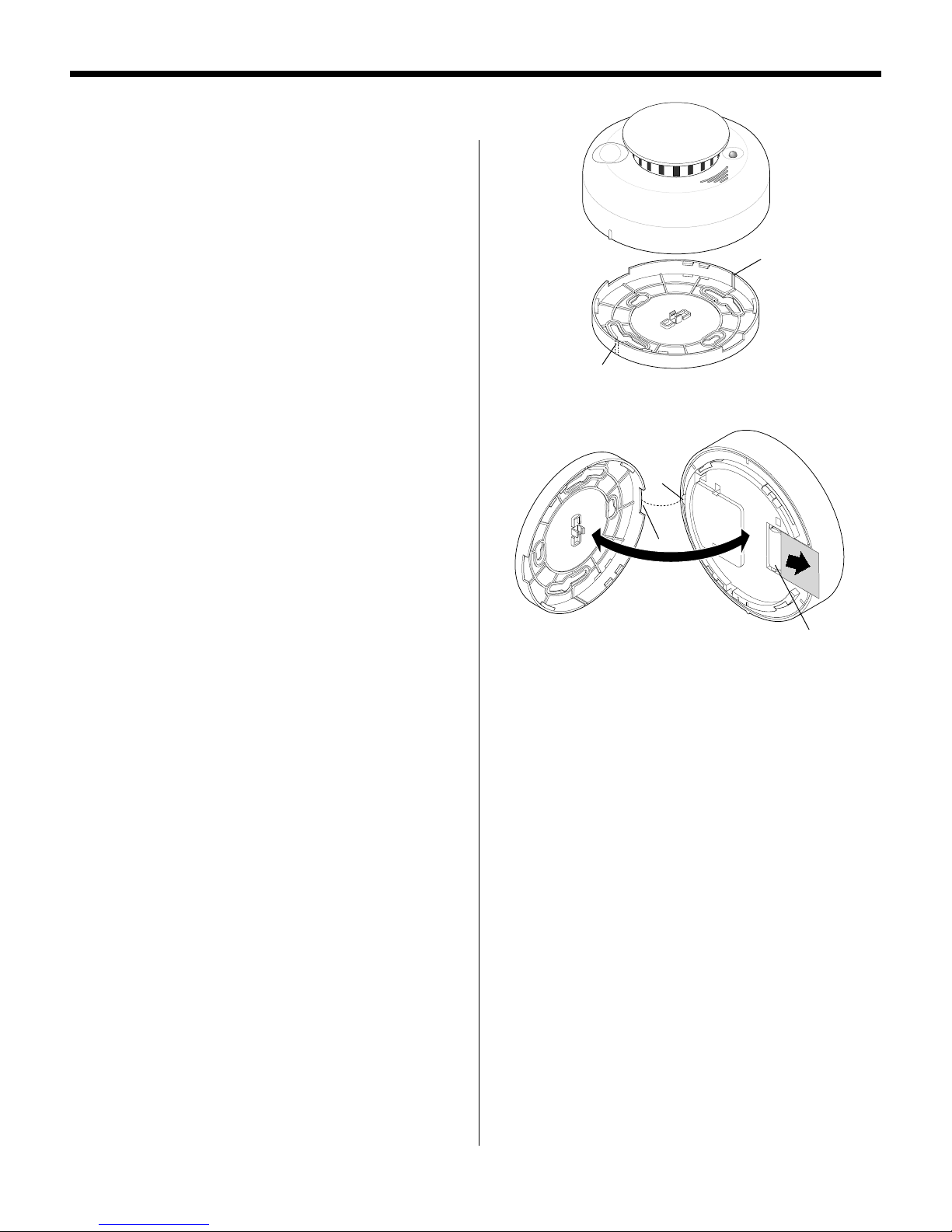

1. If you are using the detector/base lock, remove the

two knockouts on the mounting base. See Figure 3.

2. Slide the battery compartment cover away from the

detector to unsnap it and lift it off. See Figure 4.

3. Observing proper polarity, insert the two lithium

batteries provided into the detector battery compartment and replace the battery compartment cover.

4. Record the seven digit ID address from the label on

the backside of the detector. This address must be

programmed into the RF gateway receiver. See the

control panel programming guide.

For an L model detector, program the “Fire Address

plus 1” secondary address into the panel in a separate

non-fire CCM non-supervised or 24hr non-supervised

auxiliary zone.

5. Program the RF gateway receiver and the control

panel. See the control panel programming guide.

6. Remove the red plastic dust cover from the detector.

The detector is shipped with a dust cover for protection on construction sites with dusty environments.

7. Disconnect the alarm notification appliances, service

release devices, and extinguishing systems and test

the communication between the control panel and

each smoke detector before permanently mounting the

detectors as follows:

- Press the Test/Silence button on the detector for

2 seconds. The detector sends a test signal to the

control panel.

- At the control panel, verify the test signal

was received and the RF signal strength is ad equate. If no signal is received or the RF signal is

low, relocate the detector and retest.

8. Using the two screws and anchors provided, mount

the base.

Tab

Slot

Battery

compartment

Figure 4 - Detector-to-Base Alignment

9. Attach the detector to the mounting base as follows:

- Line up the raised tab on the lip of the detector with the

slot on the lip of the mounting base. See Figure 4.

- Insert the detector into the base and turn clockwise

approximately 15 degrees. It should snap firmly into

place.

Important: The detector cannot be attached to the

mounting base if no batteries are installed.

10.Test the communication between the control panel

and each smoke detector as follows:

- One at a time, press the Test/Silence button on the

detector for 2 seconds. The detector sends a test

signal to the control panel.

- At the control panel, verify the test signal was

received.

11. Test each detector (see

Detector)

and reconnect all alarm notification

Smoke Testing the

appliances, service release devices, and extinguish ing systems.

Important: The control panel alarm and all auxiliary

functions should be verified for a complete test of the

system.

2

Page 3

SMOKE TESTING THE DETECTOR

Smoke detectors should be tested in place annually

using smoke or canned aerosol simulated smoke.

Follow the instructions on the canned smoke or use the

following steps to test the detector with smoke:

1. Hold a smoldering punk or cotton wick close to the

smoke entry openings.

2. Gently direct the smoke into the detector for 20

seconds or until an alarm is indicated.

BE SURE TO PROPERLY EXTINGUISH THE SMOKE

SOURCE AFTER TESTING! The detector LED should

remain on while the built-in transmitter sends an alarm

signal to the control panel. The detector will sound a

temporal rhythm until the Test/Silence button is pressed.

The detector automatically resets when smoke is no

longer present.

TESTING THE DETECTOR SENSITIVITY

The 4300 Series provides a sensitivity level test mode that

allows you to check the detector sensitivity using the Test/

Silence button and the LED indicator on the detector as

follows:

1. Press the Test/Silence button on the detector for 2

seconds. The detector performs a test, and the LED

flashes one to nine times.

2. Count the number of times the LED flashes and use the

following table to determine the status of the detector

sensitivity and what action to take, if any.

sehsalF noitarucsbO

1A/NelbaecivresnU

3-2A/NtonsirotceteD

4 tf/%1.3 nihtiwsirotceteD

5 tf/%6.2

6 tf/%1.2

7 tf/%6.1

9-8A/NootsirotceteD

)xorppA(

After the flashes, if the sensitivity is within limits

and all other tests pass, the detector goes into

alarm and resets after 5 seconds.

If the sensitivity is not within limits, or an unservice-

able hardware fault is detected, the LED extinguishes

until the detector is serviced and the built-in transmitter

™

sends a CleanMe

or maintenance alert signal to the

control panel.

noitacidnI noitcA

.detceted

.egnar

.evitisnes

tluaferawdrah

.hguoneevitisnes

A/N

ytivitisneslamron

nurerdnatinuteseR

rorreehtfI.tsetytivitisnes

.tinuehtecalper,stsisrep

tinuteseR.tinuehtnaelC

.tsetytivitisnesnurerdna

,stsisreprorreehtfI

.tinuehtecalper

ekomsehttahtyfireV

deppanssirebmahc

.tinunaelC.ylerucesnwod

Detector/base lock

Figure 5 - Detector/Base Lock

UNDERSTANDING THE TEST/SILENCE BUTTON

Depending on the model, the Test/Silence button on

4300 Series performs three functions as follows:

Testing = Press the Test/Silence button for 2 seconds.

The detector performs a sounder test (4310 models

only) and a sensitivity test and then sends a test signal

to the control panel.

Silence alarm = Press to silence the sounder during

an alarm. After a few minutes, the sounder and alarm

resume if smoke is still present.

Silence trouble chirp = Press to silence a trouble

chirp. The trouble chirp resumes after 24 hours if the

trouble condition is not corrected.

UNDERSTANDING THE LED

The LED on the 4300 Series indicates the status of the

detector as follows:

FLASHING = Flashes every 9 seconds to indicate normal

operation.

ON = Detects smoke, sending an alarm.

OFF = Trouble or maintenance is required. Check the

control panel to determine what action to take.

ATTACHING AND REMOVING THE DETECTOR

To remove the detector from the mounting base,

grasp the detector and turn it counterclockwise approximately 15 degrees. The detector should snap off of the

mounting base.

To remove the detector from the mounting base

when the detector/base lock is used, insert a small

screwdriver into the locking tab slot on the side of the

base and press in while simultaneously turning the

detector counterclockwise 15 degrees. See Figure 5.

3

Page 4

Attach the smoke detector to its mounting base as

S

Q

U

E

E

Z

E

H

E

R

E

follows:

- Line up the raised tab on the lip of the smoke detector

with slot on the lip of the mounting base. See

Figure 4.

- Insert the smoke detector into the base and turn

clockwise approximately 15 degrees. It should snap

firmly into place.

WHEN TO REPLACE THE BATTERIES

When the batteries are low, the detector sends a low

battery signal to the control panel, waits several days

and then chirps every 30 seconds until the batteries are

replaced. The sounder can be silenced for 24 hours by

pushing the Test/Silence button. See

Specifications

for

battery type list.

REPLACING THE BATTERIES

Use only 3V lithium batteries listed in

the detector.

1. Remove the detector from the mounting base. See

Attaching and Removing the Detector.

2. Slide the battery compartment cover away from the

detector to unsnap it and lift it off. See Figure 4.

3. Remove the batteries and dispose of properly.

4. Observing correct polarity, insert two new 3V lithium

batteries into the battery compartment and replace

the cover.

5. Reattach the detector to the mounting base. See

Attaching and Removing the Detector.

6. Test the system.

Specifications

in

Figure 6 - Removing Detector Cap

Smoke

chamber

Optical base

Figure 7 - Detector Parts

Indentation

Smoke

Detector

6. Blow out or use a soft-bristled brush to remove dust

and dirt from the smoke chamber base.

CLEANING THE DETECTOR

Clean the detector cover with a dry or damp (water)

cloth as needed to keep it free from dust and dirt.

When necessary, clean the detector interior and

replace the smoke chamber as follows:

1. Disconnect the alarm notification appliances, service

release devices and extinguishing systems.

2. Remove the detector from its mounting base. See

Attaching and Removing the Detector.

3 Remove the batteries. See

4. Slide a flat-blade screwdriver in the slot on the

detector cap and gently push the handle down to pry

the cap up and off. See Figure 6.

5. Press in on the sides of the smoke chamber and pull

it up and away from the detector and discard. See

Figure 7.

Replacing the Batteries.

7. Line the new smoke chamber up with the smoke

chamber base and snap down into place.

8. Replace the detector cap as follows:

-Line the cap up with the smoke detector.

-Insert the cap into the smoke detector and turn

clockwise approximately 15 degrees. It should

snap firmly into place.

9. Observing the proper polarity, put the batteries back

in the detector and replace the battery compartment

cover.

10.Reattach the detector to its mounting base. See

Attaching and Removing the Detector.

11.Test the detector sensitivity (See

Sensitivity)

and reconnect all alarm notification

Testing the Detector

appliances, service release devices and extinguish ing systems.

Important: The control panel alarm and all auxiliary

functions should be verified for a complete test of the

system.

4

Page 5

✄

MAINTAINING THE DETECTOR

The 4300 Series smoke detectors are designed for

easy field service and maintenance. When installed

and used properly, they require minimal maintenance.

The smoke detector should be tested weekly. See

Testing the Detector Sensitivity

Detector

When the detector requires maintenance, it extinguishes its LED and sends a signal to the control panel

as described in the following table.

.

langiS deriuqerecnanetniaM

eMnaelCdnaegnarfotuosiytivitisnesrotcetedekomS

trelaecnanetniaMamrofreP.tsetflespurewopdeliafrotceteD

ytivitisneS

.rotceted

yrettabwoLehtecalpeR.wolerarotcetedehtniseirettaB

.seirettab

and

Smoke Testing the

eeS.gninaelcsdeen

eeS.tsetytivitisnes

FIRE PREVENTION AND ESCAPE

The purpose of an early warning smoke detector is to

detect the presence of fire in its early stages and

sound an alarm giving the occupants time to exit the

premises safely.

Avoid Fire Hazards

No detection device can protect life in all situations.

Detach and leave with the end user

Therefore, safeguards should be taken to avoid

potentially dangerous situations as follows:

• Do not smoke in bed

• Do not leave children home alone

• Never clean with flammable liquids such as gaso-

line.

• Properly store materials. Use general good housekeeping techniques to keep your home neat and

tidy. A cluttered basement, attic, or other storage

area is an open invitation to fire.

• Use combustible materials and electrical appliances

carefully and only for their intended uses. Do not

overload electrical outlets

• Do not store explosive and/or fast burning materials

in your home.

• Even after proper precautions have been taken, fires

can start. Be prepared.

In Case of Fire

In the event of a fire, you should do the following:

• Leave immediately. Don’t stop to pack or search for

valuables.

• In heavy smoke, hold your breath and stay low,

crawl if necessary. The clearest air is usually at the

floor.

• If you have to go through a closed door, carefully

feel the door and door knob to see if undue heat is

present. If they seem cool, brace your foot against

the bottom of the door with your hip against the door

and one hand against the top edge. Open it slightly.

If a rush of hot air is felt, slam the door quickly and

latch it. Unvented fire tends to build up considerable

pressure. Be sure all members of the household

realizes and understands this danger.

• Use your neighbor’s phone or a street fire alarm box

to call the fire department. The job of extinguishing

rotceteDehtgninaelC

.

rotceteDehtgnitseT

ehtecalper,stsisrepmelborpehtfI.

the fire should be left to the professionals.

Be Prepared

Practice the following steps to prepare you and your

family in the event of a fire:

• Perform fire drills regularly. Use them to assure

recognition of an alarm signal.

• Draw a floor plan and show two exits from each

room. It is important that children be instructed

carefully, because they tend to hide in times of

crisis.

• Establish one meeting place outside the home.

Insist that everyone meet there during an alarm.

This will eliminate the tragedy of someone reentering the house for a missing member who is actually

safe.

• If you have children and/or physically challenged

people residing in your household, use window

decals to help emergency personnel identify the

sleeping quarters of these individuals.

LIMITED WARRANTY

Sentrol is a brand name of SLC Technologies,Inc. The

manufacturer warrants this smoke detector (except

batteries) to be free from defects in material and workmanship under conditions of normal use for a term of 3

years from the date of manufacture.

During the warranty period, if a Sentrol product or any of

its components becomes defective, it will be repaired or

replaced without charge.

Out-of-warranty units will be repaired at the discretion of

the manufacturer or, if not, a card will be forwarded to the

customer suggesting a replacement unit and the cost of

that unit.

This warranty does not apply to units which have been

subject to abuse, misuse, negligence or accident, or to

which any modifications, alterations or repairs have been

made or attempted.

This warranty is extended only to the original purchaser of

the smoke detector and may be enforced only by such

person. During the warranty period, if the detector or any

✄

5

Page 6

✄

warranted components thereof becomes defective, it will

be replaced or repaired without charge at the

manufacturer’s discretion if returned in accordance with

the following instructions:

Obtain a Return Authorization Number by calling 1-800648-7422 or 503-692-4052, then carefully pack it in a well

padded and insulated carton and return, postal charges

prepaid to:

Customer Service

Sentrol

12345 SW Leveton Drive

Tualatin, OR 97062-9938

A note should be included advising the nature of the

malfunction. Care must be exercised in the proper

packing of detectors returned under this warranty as

Sentrol will not be responsible for warranty repairs to

equipment damaged because of improper packing.

THE ABOVE WARRANTY IS IN LIEU OF ALL OTHER

EXPRESS WARRANTIES, AND IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE LIMITED IN DURATION

FOR A PERIOD OF THREE YEARS FROM THE DATE

OF MANUFACTURE. UNDER NO CIRCUMSTANCES

SHALL MANUFACTURER BE LIABLE TO THE PURCHASER OR ANY OTHER PERSON FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES OF ANY NATURE,

INCLUDING WITHOUT LIMITATION DAMAGES FOR

PERSONAL INJURY OR DAMAGES TO PROPERTY,

AND HOWEVER OCCASIONED, WHETHER ALLEGED

AS RESULTING FROM BREACH OF WARRANTY BY

MANUFACTURER, THE NEGLIGENCE OF MANUFACTURER OR OTHERWISE. MANUFACTURER’S LIABIL-

ITY WILL IN NO EVENT EXCEED THE PURCHASE

PRICE OF THE PRODUCT. SOME STATES DO NOT

ALLOW LIMITATIONS ON HOW LONG AN IMPLIED

WARRANTY LASTS, OR THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIONS AND EXCLUSIONS MAY NOT APPLY TO YOU. UNLESS A LONGER

PERIOD IS REQUIRED BY APPLICABLE LAW, ANY

ACTION AGAINST MANUFACTURER IN CONNECTION

WITH THIS SMOKE DETECTOR MUST BE COMMENCED WITHIN ONE YEAR AFTER THE CAUSE OF

ACTION HAS ACCRUED.

No agent, employee or representative of the Manufacturer

nor any other person is authorized to modify this warranty

in any respect. Repair or replacement as stated above is

the exclusive remedy of the purchase hereunder. This

warranty gives you specific legal rights and you also

have other rights which vary from state to state.

WARNING

!

Smoke detectors CANNOT provide warnings

for fires resulting from explosions, smoking in

bed or other furniture, ignition of flammable

liquids, vapors and gases, children playing with

matches or lighters.

WARNING! LIMIT ATIONS OF SMOKE DETECTORS

Wireless smoke detectors are very reliable, but may not

work under all conditions. No fire detector provides total

protection of life or property. Smoke detectors are not a

substitute for life insurance.

Smoke detectors require a source of power to work.

This smoke detector will not operate and the alarm will

not sound if batteries are dead or not installed properly.

Unreliable transmission or receiving of radio frequency (RF) signals may occur if the system is not

installed, located, serviced and repaired properly.

RF signals sent by this detector may be blocked or

reflected by metal objects. Adjacent devices or systems

using radio frequency signals may interfere with the

operation of this detector. Test the system often to be

sure that signals are being sent and received properly.

Smoke detectors may not be heard. A sound sleeper

or someone who has taken drugs or alcohol may not may

not awaken if the detector is installed outside a bedroom.

Closed or partially closed doors and distance can block

sound. This detector is not designed for the hearing

impaired.

Smoke detectors may not always activate and provide

warning early enough. Smoke detectors only activate

when enough smoke reaches the detector. If a fire starts

in a chimney, wall, roof, on the other side of closed doors,

or on a different level of the property enough smoke may

not reach the detector for it to alarm.

SMOKE DETECTORS ARE A SIGNIFICANT HELP IN

REDUCING LOSS, INJURY AND EVEN DEATH. HOWEVER, NO MATTER HOW GOOD A DETECTION

DEVICE IS, NOTHING WORKS PERFECTLY UNDER

EVERY CIRCUMSTANCE AND WE MUST WARN YOU

THAT YOU CANNOT EXPECT A SMOKE DETECTOR

TO ENSURE THAT YOU WILL NEVER SUFFER ANY

DAMAGE OR INJURY.

FCC COMPLIANCE

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference,

and (2) this device must accept any interference

received, including interference that may cause

undesired operation.

FCC ID: A794300

INDUSTRY CANADA COMPLIANCE

This Class B digital apparatus meets all requirements

of the Canadian Interference-Causing Equipment

Regulations.

IC ID: 145 5102 1202

Detach and leave with the end user

6

✄

Page 7

7

Page 8

SPECIFICATIONS

Voltage............................................................3VDC

Typical average standby current ........................ 25

Typical test current............................................ 2mA

Typical alarm current ....................................... 70mA

Battery type .................. Duracell

®

3V lithium, DL123A

.......................Duracell® 3V lithium, MN1500

........................Panasonic® lithium, CR123A

.............................Sanyo ® lithium, CR123A

................Eveready Energizer ® lithium, E91

Low battery threshold...2.70V causes low battery signal

Sounder ......................... 85dB at 10' temporal pattern

Low battery beep rate ............1 every 30 sec. ± 2 sec.

Sensitivity ............................................. 2.3% ±0.8%

Operating temperature ................40°-100°F (4.4°-37.8°C)

Operating humidity range ......... 0-95% non-condensing

RFI Immunity ................ 20V/m minimum; 0-1000MHz

Color ...............................................................white

Detector dimensions ........ 5.5" x 2.3" (14 cm x 5.6 cm)

mA

Base dimensions ...........4.88" x 0.38" (12.3 cm x 0.95 cm)

Drift compensation adjustment .............. 0.5%/ft. max.

Heat detector specifications (T, H Models):

Rate of rise.......15°F/min>105°F (8.3°C/min>40.6°C)

Fixed .........................135°F ± 5°F (57.2°C ± 2.8°C)

RF frequency................................................418MHz

Transmitter ID............Pre-programmed, 1 Million codes

Modulation type...........................................FM, FSK

Signal format.............................Manchester Encoded

Signal types:

Primary address........alarm, restore, tamper, low battery,

trouble(maint./CleanMe),1 hour supervisory

Secondary address(L models)................alarm, restore

Listings:

4310 Series .....................................UL 217, CSFM

4330 Series......................................UL 268, CSFM

Approvals.....................................................FCC, IC

PRODUCT ORDERING

ledoM noitpircseD

S0134 detsiL712LU,rednuosBd58,seirettabmuihtilV3owt,rotcetedekomssseleriwlortneS

TLS0134 taehesirfoetar/dexifeerged531,rednuosBd58,seirettabmuihtilV3owt,rotcetedekomssseleriwlortneS

S0334 detsiL862LU,repmatesab,rednuosBd58,seirettabmuihtilV3owt,rotcetedekomssseleriwlortneS

MTLS0334 eerged531,repmattlityrucrem,rednuosBd58,seirettabmuihtilowt,rotcetedekomssseleriwlortneS

seirosseccA

002-MS srotcetedekomsfognitsetlanoitcnufrof)ekomsdennac(naCani!ekomS

1-TXEMSnaCani!ekomSrofebutnoisnetxE

112)01fotes(srebmahcekomstnemecalpeR

CORPORATE HEADQUARTERS

12345 SW Leveton Dr., Tualatin, OR 97062

Tel.: 503.692.4052 Fax: 503.691.7566

http://www.sentrol.com

U.S. & Canada: 800.547.2556

Technical Service: 800.648.7424

SENTROL

FaxBack: 800.483.2495

detsiL712LU,noitpoerutarepmetwol,rotceted

detsiL862LU,noitpoerutarepmetwol,rotcetedtaehesirfoetar/dexif

Sentrol reserves the right

to change specifications

without notice.

© 2000 Sentrol

15800 Rev B 0400

8

Loading...

Loading...