Sentinel KalGuard Installation Manual

Page 1

KalGUARD

®

Installation Manual

Water Treatment Equipment to

Manage Hardwater Limescale

Version 3 – April 2018

IMPORTANT

Please leave a copy of this

manual with the KalGUARD

equipment in its plant room

Page 2 KalGUARD

®

Installation Manual V3 04/18

WARNING:

The KalGUARD Controller circuit boards

have live connections and should only

be accessed by a competent person.

Page 3 KalGUARD

®

Installation Manual V3 04/18

Index

Section Page

Installation Advice 4

System and Component Arrangement 4

Typical Installation 5

General Notes 6

Specification Tables 7

Component Checklist 8

Principle Installation Guidelines 9

Installation Schematics 10–12

Concluding the Installation 13

Pipework Sanitation 13

Preparing the KalGUARD for Commissioning 14

Technical Description: MK1 Controller 15–17

Technical Description: MK2 Controller 18–19

Water Meter 20

Water Filtration 21

Pulse Splitter User Instructions 22–23

Health & Safety 24

Servicing & Monitoring 25

Service Contract 25

Recommended Monitoring 25

Other Service Considerations 25

Automatic Servicing 25

Commissioning Details 26

Trouble Shooting 27–28

Service Log 29–31

Please copy page 31 if additional sheets are needed

Please visit www.sentinelprotects.com/uk/guarantee-registration

for Guarantee Registration and Terms and Conditions.

KalGUARD is a registered Trade Mark and is protected by

CTM 012658688 owned by Sentinel Performance Solutions Limited.

Page 4 KalGUARD

®

Installation Manual V3 04/18

Installation Advice

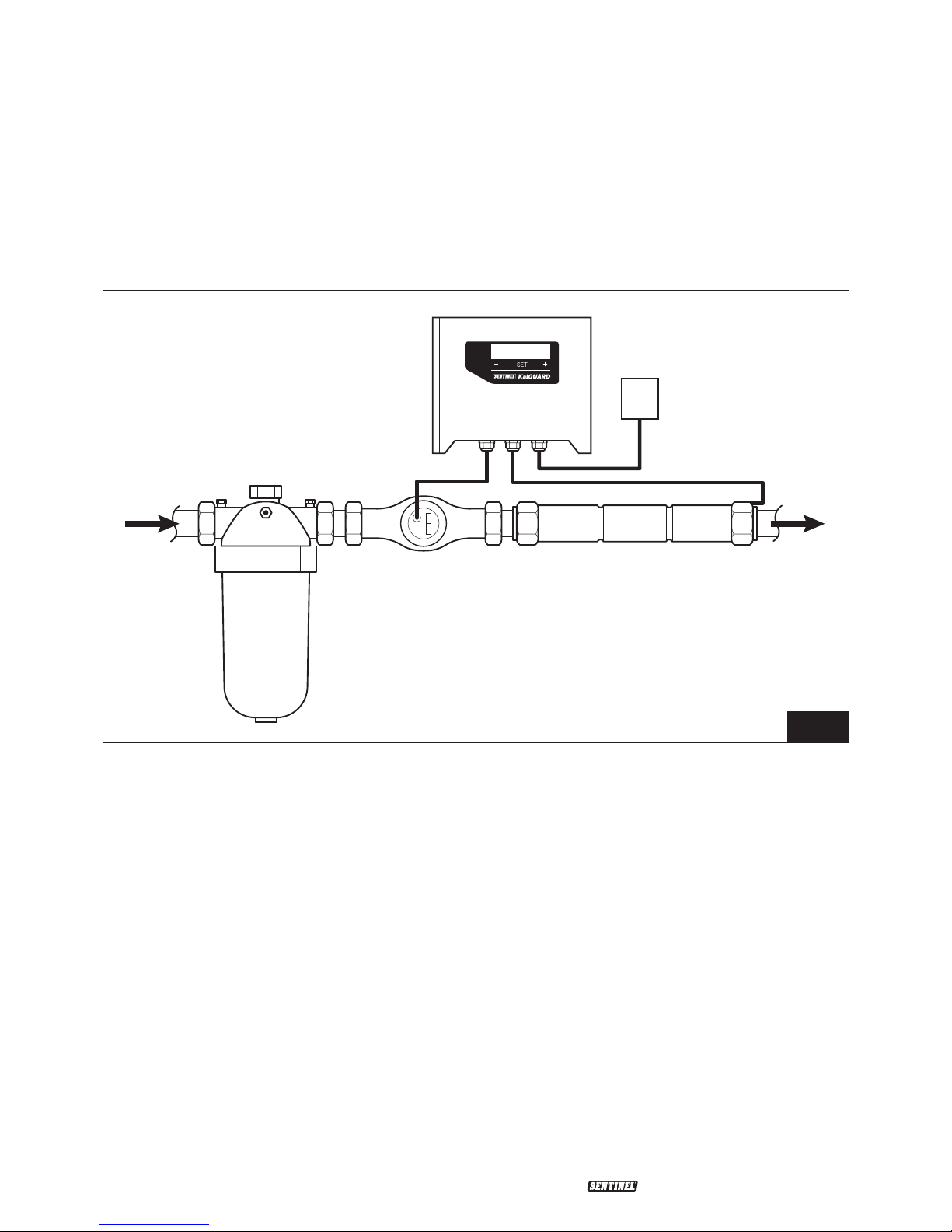

SYSTEM AND COMPONENT ARRANGEMENT

It is important to ensure that the KalGUARD system components are installed in the same

water flow line, as per Fig. 1. They should typically be arranged in a ‘side-stream loop’ to the

main water feed line. It should be possible to place the side-stream loop in or out of service by

the operation of isolation valves on the loop and a by-pass valve on the main water feed line.

KalGUARD Anode Unit

This component contains a zinc anode

which continuously doses small amounts of

zinc ions into the water passing through it to

inhibit scale formation.

KalGUARD Controller

The controller links with the water meter to

automatically match the output of zinc ions

to water flow.

25/55 µM Water Filter

Filtration of incoming mains water to

≤50µm is recommended to ensure

optimum performance of the equipment.

For all pipe sizes up to 108mm (4"), the filter

supplied will be a “stacked disc" type. The

filter must always be installed upstream of

the KalGUARD anode unit.

Water Meter

The water meter provides essential data

to the KalGUARD controller to ensure

intelligent activation of the KalGUARD anode

unit. It is NOT intended for direct paralleling

with a BMS for volumetric water coupling

(see later – “Installation of Electrics/

Electronics").

Following the completion of the

installation, please refer to the check list

on page 14 before contacting Sentinel on

01928 704 330 to arrange

COMMISSIONING.

Filter

Controller

Anode UnitWater

Meter

Mains System

Mains 240V/50Hz

(Single phase)

Fig. 1

Page 5 KalGUARD

®

Installation Manual V3 04/18

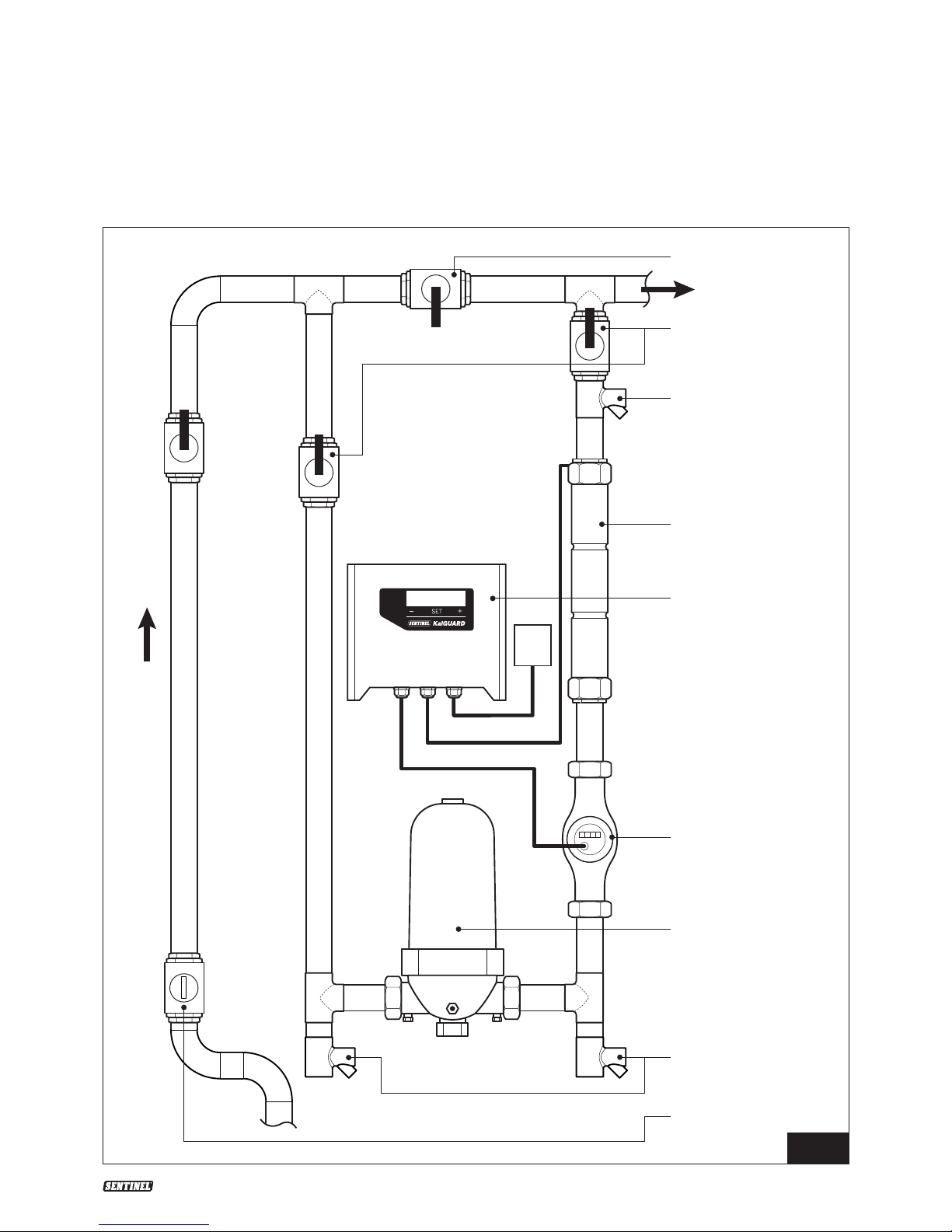

Installation Advice

TYPICAL INSTALLATION

When installed, the KalGUARD ‘kit’ will have this general appearance.

By-pass Valve

Side-stream

Isolation Valves

Drain Valve

Anode Unit

Controller

Flow Meter

Filter 55µM

Drain Valves

Non-return

Valve

Fig. 2

Water Flow Direction

Earth Strapping Clip

Anode Unit Supply Cable

Power Cable

Page 6 KalGUARD

®

Installation Manual V3 04/18

Installation Advice

Note 4:

The combination of the water flow meter

and system controller provides intelligent

operation of the KalGUARD anode unit. This

reactive intelligence limits operation of the

KalGUARD system during periods when

there is low or no water flow and maximises

effective treatment at other times.

Note 5:

It is important that ALL INSTALLATIONS

HAVE EASY ACCESS FOR MAINTENANCE

PURPOSES.

Note 6:

The side-stream configuration allows the

maintenance engineer to divert the water

flow via the by-pass section during servicing

and thus ensure no interruption of the water

supply to the building. The only variation

that can apply is that the water flow meter

may instead be mounted in the adjacent

common pipework. Where the unit feeds

a cold water storage tank, the side-stream

configuration can sometimes be omitted.

This is only the case where the storage tank

will supply adequate water to allow servicing

to take place.

Note 7:

The KalGUARD anode unit is WRAS

approved and is safe to install in drinking

water pipework.

Note 8:

Only the water meter supplied by Sentinel

can be used with the KalGUARD system.

GENERAL NOTES

Note 1:

The following items are also required for

installation, but not provided with the

KalGUARD ‘kit’ depending on installation

configuration: (See fig 2 for reference)

• Delayed action inlet valve

Where the equipment is installed on a

water system feeding a preliminary break

tank of < 10m

3

(prior to a water system

booster set) the break tank inlet water

valve should be a “delayed action" type.

This is to ensure fast or full flow from the

mains when actuated.

• Non-return valve

• Quarter-turn isolating valves

Up to three required – refer to the

appropriate installation diagram.

• Drain valves

Up to four required – refer to the

appropriate installation diagram.

Note 2:

Lagging is recommended. All cold metal

pipework surfaces encourage condensation

which can be prevented by appropriate

fixed lagging. The KalGUARD anode unit

should have a removable insulating jacket

held closed by Velcro strips and its ends

closed with draw strings or tapes. A similar

arrangement will protect the flow sensor

water meter.

Note 3:

It is preferable to install the KalGUARD onto

the incoming mains water line for whole

water system protection. Where this is

not possible, it can be applied to just the

hot water system to protect commercial

and industrial water heaters. The intention

is also to maximise protection for the

downstream hot water pipework. This can

also become fouled in areas where water

supplies have high mineral content (‘hard’

water) and consequently high potential for

causing flow-restricting limescale deposits.

Page 7 KalGUARD

®

Installation Manual V3 04/18

Installation Advice

KALGUARD SPECIFICATION TABLE – ANODE UNITS

Product

Code

Length Diameter

(Main

Body)

Weight

(KG)

Design Flow

(l/m)

Design

Fl ow m³/ h

Connection ΔP (bar)

@ Design

Flow

KALG22 375 42 2.5 37 2.22 ¾" BSP Female 0.15

KALG28 450 54 3.1 64 3.84 1" BSP Female 0.13

KALG 35 484 67 4.6 96 5.76 1 ¼" BSP Female 0.23

KALG 42 505 67 4.9 142 8.52 1 ½" BSP Female 0.26

KALG 54 525 76 6.4 255 15.3 2" BSP Female 0.26

KALG 67 650 108 16.8 423 25.38 2 ½" 8 bolt DIN/ANSI Flange 0.20

KALG76 650 134 30.0 523 31.38 3" 8 bolt DIN/ANSI Flange 0.23

KALG108 650 160 3 7.0 1099 65.94 4" 8 bolt DIN/ANSI Flange 0.20

KALGUARD SPECIFICATION TABLE – CONTROLLERS

Version For Width

(mm)

Height

(mm)

Depth

(mm)

Display Display BMS Connectivity IP Rating

Mk 1 67, 76, 108mm KG 193 180 103 LCD 240 V ACFault Alert, Optional Pulse Splitter 65

Mk 2 22, 28, 35, 42 &

54mm KG

259 213 66 OLED 240 V ACFault Alert, Remote Switching (on/

off), Optional Pulse Splitter

65

KALGUARD SPECIFICATION TABLE – WATER METERS

KG Size Water

Meters

(in)

Length

(mm)

Width

(mm)

Height

(mm)

Weight

(KG)

Connections Qmax*

(m³/h)

Qn*

(m³/h)

Qmin

(l/h)

Max

Pres.

(bar)

K Value

(litre)

ΔP

(bar) @

Design

Flow

22 ¾" 190 99 107 1.7 ¾" BSP Male 5 2.5 50 16 1 0.20

28 1" 160–260 104 115 2.6 1" BSP Male 7 3.5 70 16 1 0.35

35 1 ¼" 160–260 104 120 3.1 1 ¼" BSP Male 12 6 100 16 1 0.38

42 1 ½" 200–300 125 14 8 5.2 1 ½" BSP Male 20 10 200 16 1 0.20

54 2" 300 125 173 8.5 2" BSP Male 30 15 450 16 1 0.23

67 2 ½" 200 65 200 10.1 PN16 Flanges 50 25 750 16 10 0.06

76 3" 200 80 270 13.8 PN16 Flanges 80 40 1200 16 10 0.03

108 4" 250 100 270 18.2 PN16 Flanges 120 60 1800 16 10 0.05

*Qmax = Max flow (short period)

*Qn = Nominal flow

KALGUARD SPECIFICATION TABLE – FILTERS

Connection

Size

For Length

(mm)

Width

(mm)

Height

(mm)

Weight

(KG)

Connection

Diameter (mm)

Average Flow

(m³/h) @ 55u

ΔP (bar) @

Design Flow

1" Short 22mm KG 158 130.0 233 1.1 25 3.15 0.11

1" Super 28mm KG 158 130.0 340 1.42 25 4.2 0.05

1 ½" Super 35mm KG 200 130.0 350 1.5 40 6.3 0.12

2" Leader 42 &

54mm KG

230 215.0 425 3.2 50 11 0.28

3" Leader 67m m KG 742 228.0 320 6.3 90 22 0.17

4" Leader 76mm KG 1188 319.0 445 28.8 110 42 0.05

6" Leader 108mm KG 1188 319.0 415 30.4 160 49 0.06

Page 8 KalGUARD

®

Installation Manual V3 04/18

Installation Advice

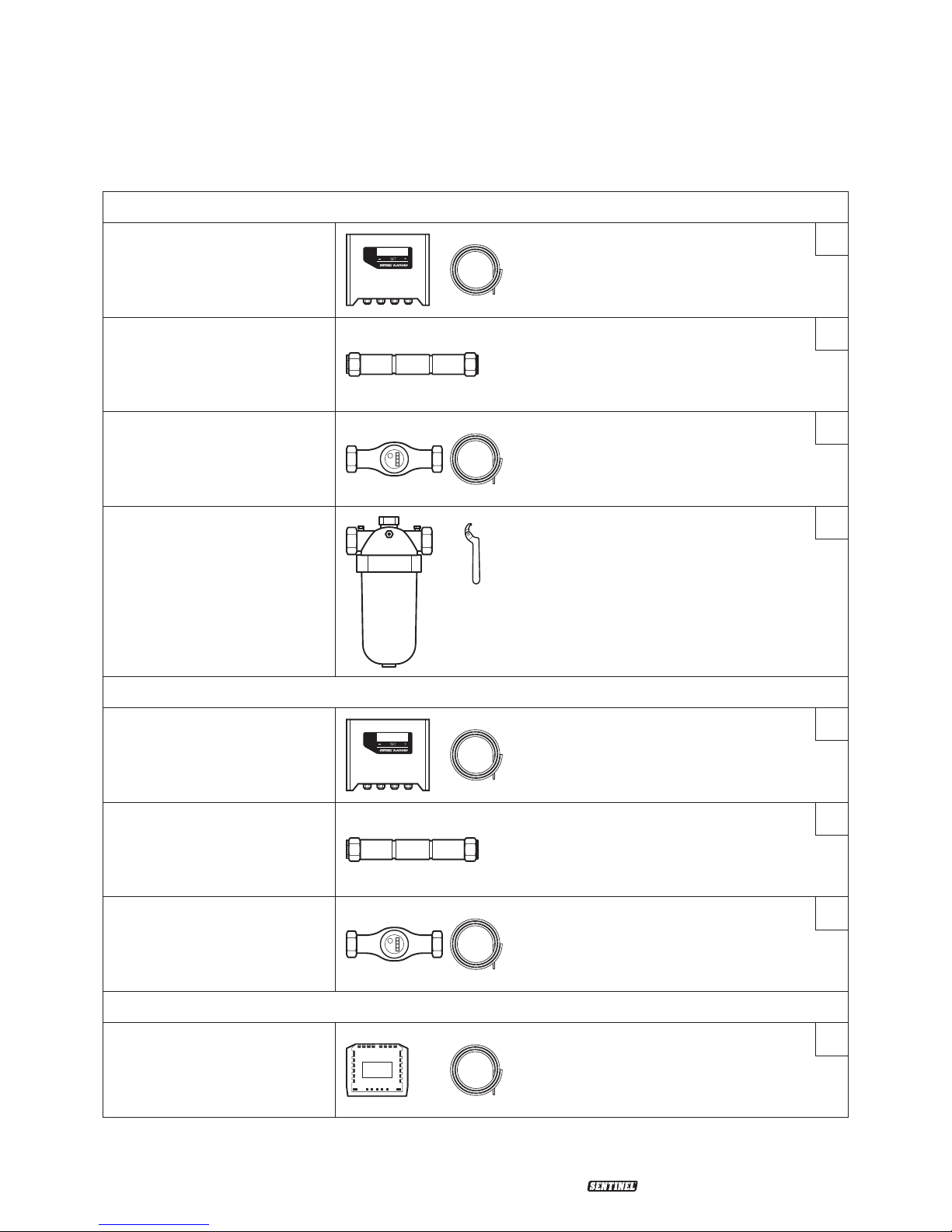

COMPONENT CHECKLIST

Full Pack

Controller with anode unit

supply cable

Anode Unit

Water Meter with cable

Filter (with C-spanner on

22mm – 54mm range)

Part Pack

Controller with anode unit

supply cable

Anode Unit

Water Meter with cable

Optional extra for both packs

Pulse Splitter with cable

Page 9 KalGUARD

®

Installation Manual V3 04/18

Installation Advice

• At least 50mm (2”) vertical clearance

must be allowed for the filter bowl (to

facilitate servicing).

• The water flow meter can be installed

anywhere on the side-stream loop or,

if necessary, on adjacent common

pipework. It must always be mounted in

the same water flow as the anode unit.

• Use a NRV (non-return valve), “¼ turn”

isolating valves and drain valves as shown

in the schematic diagrams.

• All pipework and fittings should be

assembled to facilitate easy access for

maintenance.

• Pipework earthing must comply with the

latest electrical safety regulations.

PRINCIPLE INSTALLATION GUIDELINES

• Mechanical connections to the anode

unit and water flow meter must be

demountable to facilitate the servicing of

both units.

• There must be at least three metres of

direct pipeline between the anode unit

and the plant. Additional pipework should

be added (as a coil or serpentine) to

ensure this is achieved.

• The equipment should always be installed

as a side-stream to the main water feedline so that it can be easily isolated for

maintenance.

• The filter must always be installed

upstream of the anode unit.

• If the anode unit can be placed on the

in-coming water main then the whole

building will benefit from the protection

the unit can provide.

• The single bowl filter orientation must

always be vertical. Ensure, however, that

the orientation is such that the bowl

sits ‘below’ for sizes 1", 1¼" and 1½"

and ‘above’ for 2". The 2" size has a drain

valve into the pipework body part for ease

of maintenance.

Page 10 KalGUARD

®

Installation Manual V3 04/18

Installation Advice

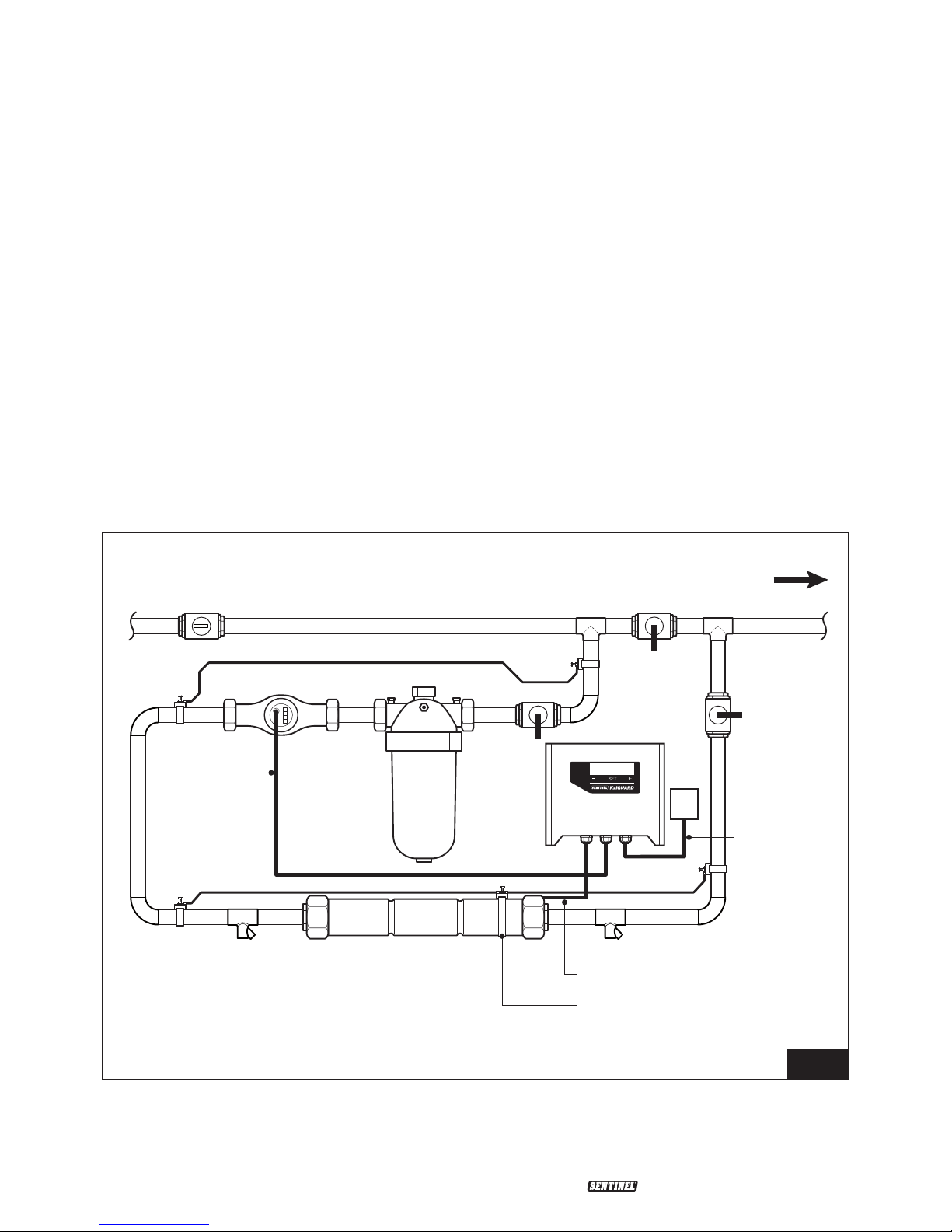

INSTALLATION SCHEMATICS

Note:

All the installations on the following pages show two drain valves to which hoses may be

connected. This is to facilitate draining the side-stream prior to servicing and to assist

cleaning.

Schematic 1: Horizontal Pipe

For horizontal pipe mounted along a wall well above ground level.

This is the most typical installation where the incoming pipe to the building, or main feed to

the water system involved, is mounted on a wall and is a metre or more from the ground.

The installation point should allow full service access and should not be obscured by other

equipment.

Servicing the filter requires 50mm vertical clearance for removal of the filter bowl. There must

also be good access to the anode unit. Access for periodic inspection of electrical components

should also be available.

Water Flow Direction

NRV

Drain Drain

Anode Unit

Earth Strapping Clip

Anode Unit Supply Cable

Power Cable

Controller

Signal Cable

Fig. 3

Loading...

Loading...