Page 1

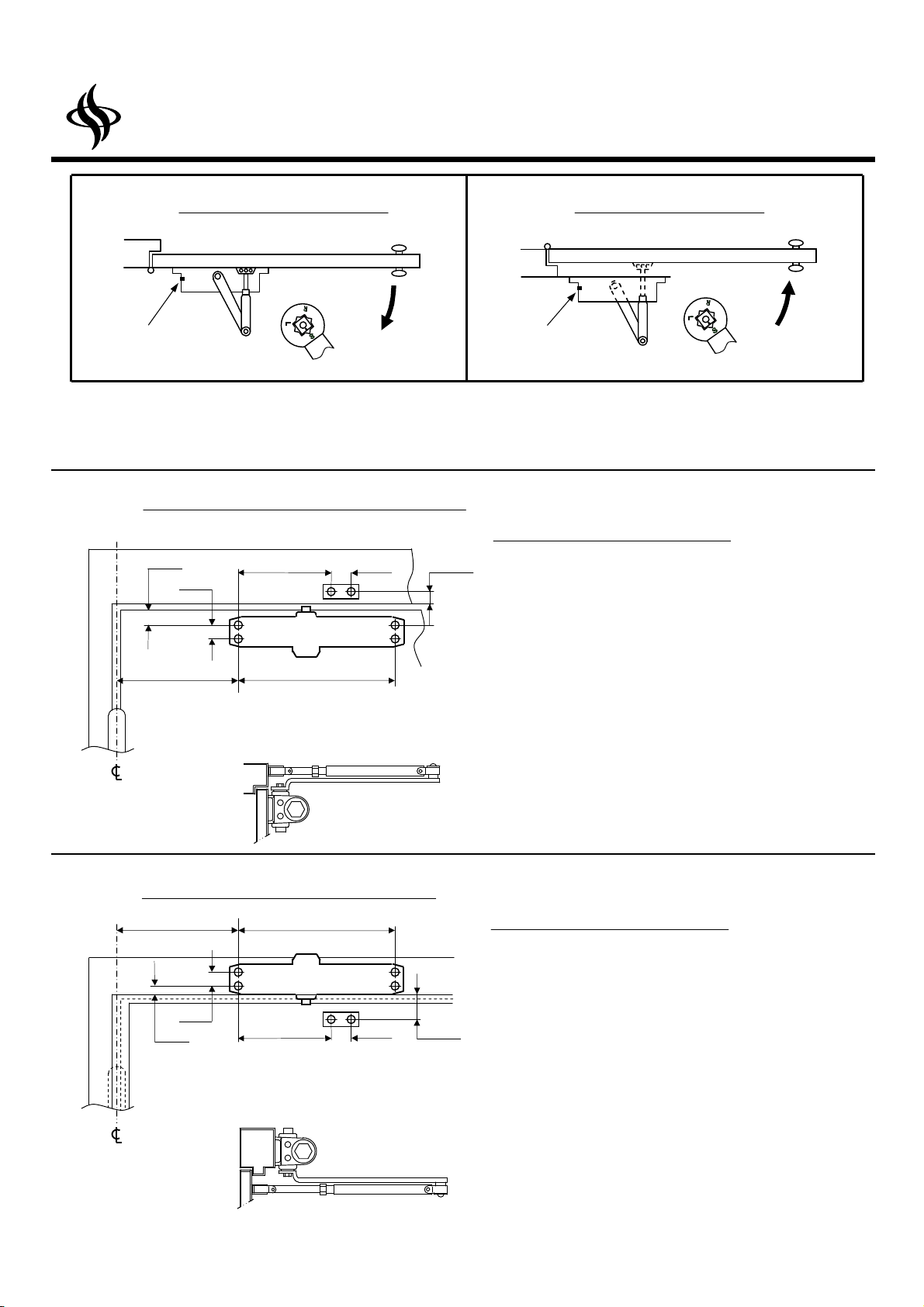

STANDARD (PULL SIDE) Mounting

TOP JAMB (PUSH SIDE) Mounting

This drawing is not to full scale. Therefore, do not use it as your template to locate the hole positions while you fabricate your

Hinge or Pivot

Hinge or Pivot

Instructions

SENTINEL

Installation

Series 5000

A

Type

Standard Installation

Right hand door

B

Type

Top Jamb Installation

Left hand door

SPEED

ADJUSTING

VALVE

PULL

side of door

SPEED

ADJUSTING

VALVE

PUSH

side of door

Please note

door and frame for the installation of this product. Instead, make the measurements needed manually without the use of the

enclosed template which is not to full scale.

AType

1

(25)

3/4

(19)

6 1/2

(165)

1 3/4

(44.4)

(25.4)

4

(101)

Right hand door shown.

Left hand door opposite.

Dimensions: inches (mm)

9 1/16

(230)

INSTALLATION INSTRUCTIONS

1. Using template dimensions shown above, mark FORE(4)

1

HOLES ON DOOR for door closer and TWO(2) HOLES

ON FRAME for arm shoe.

2. Drill pilot holes in door and frame for #14 all-purpose screws

or drill and tap for 1/4-20 machine screws.

3. Install adjustable forearm/arm shoe to frame using screws provided.

4. Mount closer on door using screws provided.

VALVE MUST BE POSITIONED TOWARD HINGE EDGE

5. Install main arm to top pinion shaft, perpendicular to door as shown

below. Secure tightly with arm screw/washer assembly provided.

6. Adjust length of forearm so that forearm is perpendicular to frame

when assembled to preloaded main arm(Illustration below).

Secure forearm to main arm with screw/washer assembly provided.

7. Adjust closing speed of door,

8. Snap pinion cap over shaft at bottom of closer.

SPEED ADJUSTING

.

BType

4

(101)

3/4

(19)

1/2

(12.7)

Left hand door shown.

Right hand door opposite.

Dimensions: inches (mm)

6 1/4

(159)

9 1/16

(230)

1 3/4

(44.4)

1 3/4

(44.4)

INSTALLATION INSTRUCTIONS

1. Using template dimensions shown above, mark FORE(4)

HOLES ON FRAME for door closer and TWO(2) HOLES

ON DOOR for arm shoe.

2. Drill pilot holes in door and frame for #14 all-purpose screws

or drill and tap for 1/4-20 machine screws.

3. Install adjustable forearm/arm shoe to door using screws provided.

4. Mount closer on frame using screws provided.

VALVE MUST BE POSITIONED TOWARD HINGE EDGE.

5. Install main arm to top pinion shaft, perpendicular to door as shown

below. Secure tightly with arm screw/washer assembly provided.

6. Adjust length of forearm so that forearm is perpendicular to door

when assembled to preloaded main arm(Illustration below).

Secure forearm to main arm with screw/washer assembly provided.

7. Adjust closing speed of door, Snap pinion cap over shaft at

bottom of closer.

SPEED ADJUSTING

Page 2

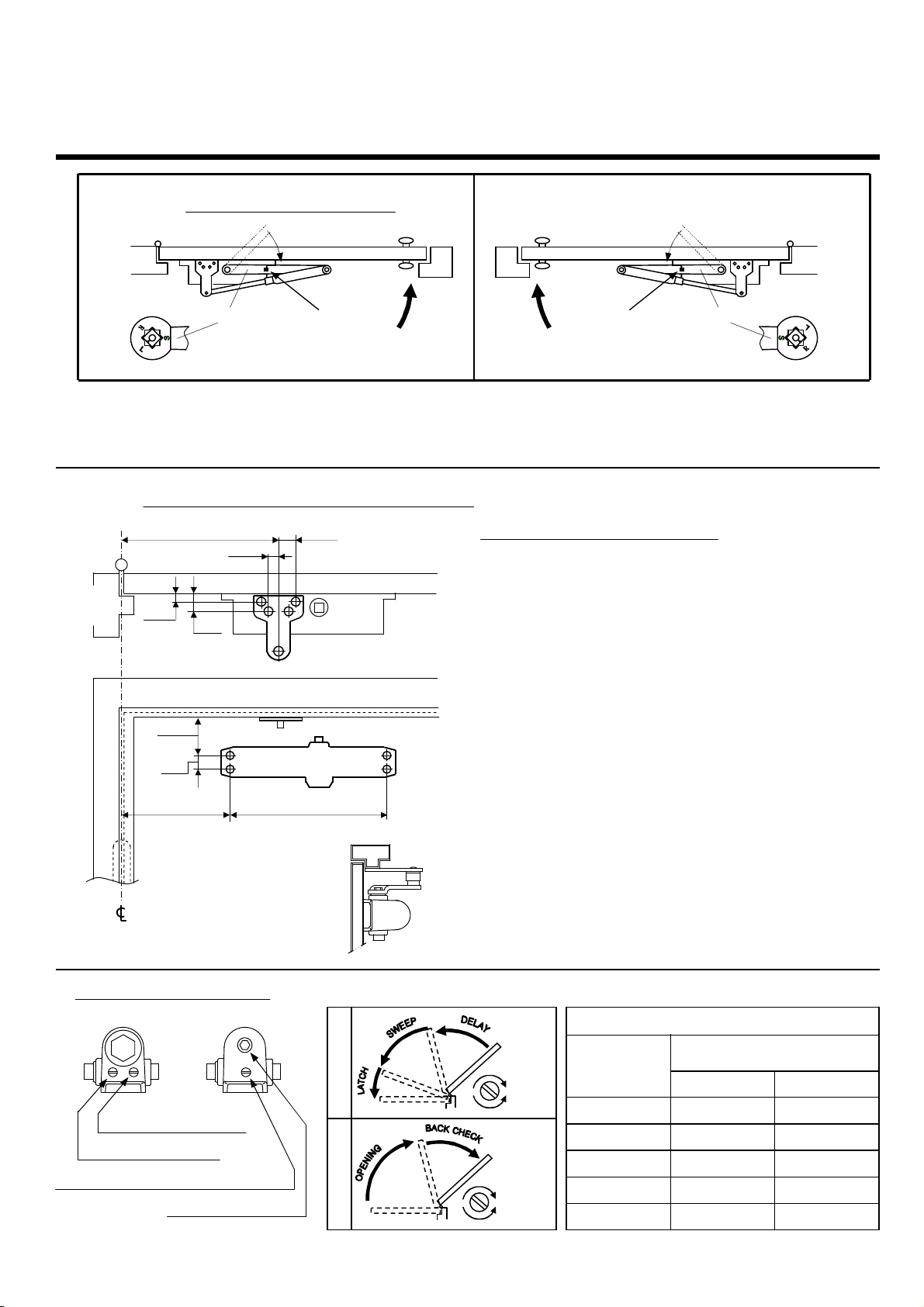

PARALLEL ARM (PUSH SIDE) Mounting

full scale. Therefore, do not use it as your template to locate the hole positions while you fabricate your

Hinge or Pivot

(121)

1

-8 -3

5000

5000BF

CLOCKWISE TURNS OF

Installation Instructions

C

Type

Please note

This drawing is not to

door and frame for the installation of this product. Instead, make the measurements needed manually without the use of the

enclosed template which is not to full scale.

Parallel Arm Installation

Left hand door

Main arm

SPEED

ADJUSTING

VALVE

side of door

PUSH

C

Type Opposite

Right hand door

PUSH

side of door

SPEED

ADJUSTING

VALVE

Series 5000

Main arm

CType

8 3/10

(211)

3/8

(9.5)

3 3/8

(86)

3/4

(19)

1

(25.5)

13/16

(20.5)

4 3/4

Left hand door shown.

Right hand door opposite.

Dimensions: inches (mm)

9 1/16

(230)

1 3/8

(35)

INSTALLATION INSTRUCTIONS

1. Using template dimensions shown above, mark FORE(4)

HOLES ON DOOR for door closer and FORE(4) HOLES

ON FRAME for parallel bracket.

2. Drill pilot holes in door and frame for #14 all-purpose screws or

drill and tap for 1/4-20 machine screws.

3. Install Parallel Arm Bracket shoe to frame using screws provided.

4. Mount closer on door using screws provided.

VALVE MUST BE POSITIONED TOWARD AWAY FROM HINGE

EDGE.

5. Install main arm to top pinion shaft, with arm pointing toward speed

adjusting screw. Secure tightly with arm screw/washer assembly provided.

6. Remove arm shoe from fore arm and discard. Install ROD end of fore

arm to bracket using screw/washer assembly provided. Adjust length

of fore arm to set arm elbow approximately 1-1/2"(38mm) from

door(refer to Illustration below). Attach fore arm to main arm by

rotating main arm away from door. Secure forearm to main arm using

screw/washer assembly provided.

7. Adjust length of fore arm so when it is attached to main arm the main

arm will be slightly away from parallel with closed door and assemble

at elbow then tighten locknut.

8. Adjust door closing speed by speed adjusting valves.

9. Snap pinion cap over shaft at bottom of closer.

SPEED ADJUSTING

CLOSER ADJUSTMENT

POWER ADJUSTMENT CHART

CLOSER

Slow

Closing cycle

SWEEP Adjusting Valve

LATCH Adjusting Valve

BACKCHECK or DELAY Adjusting Valve

Power Adjusting Nut

Opening cycle

Fast

Decreas

Increase

SIZE

2

3

4

5

ADJUSTING NUT

-

-4

0

6

12

0

6

-

Loading...

Loading...