Page 1

MULTIFUNCTIONAL LOGIC

MCS -1-LCD

Mounting and operating instructions

CONTROLLER

Page 2

MULTIFUNCTIONAL LOGIC

MC S -1- LC D

CONTROLLER

Table of contents

SAFETY AND PRECAUTIONS 4

PRODUCT DESCRIPTION 5

ARTICLE CODES 5

INTENDED AREA OF USE 5

TECHNICAL DATA 5

STANDARDS 6

WIRING AND CONNECTIONS 6

OPERATIONAL DIAGRAMS 7

MOUNTING INSTRUCTIONS IN STEPS 8

VERIFICATION OF THE CORRECT INSTALLATION . . . . . . . . . . . . . . . . .10

OPERATING INSTRUCTIONS 12

CONTROLLER OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

CONTROL FUNCTIONS OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . .12

PARAMETERS AND DEFAULT SETTINGS . . . . . . . . . . . . . . . . . . . . . .14

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 2 - 33

www.sentera.eu

Page 3

MULTIFUNCTIONAL LOGIC

MC S -1- LC D

CONFIGURING THE PARAMETERS 15

USING PREDEFINED TEMPLATES . . . . . . . . . . . . . . . . . . . . . . . . . .16

CUSTOMISING THE SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3SMONITOR SOFTWARE. . . . . . . . . . . . . . . . . . . . . . . . .17

3SMODBUS SOFTWARE . . . . . . . . . . . . . . . . . . . . . . . . .18

4-BUTON KEYBOARD INTERFACE . . . . . . . . . . . . . . . . . . .19

MAIN MENU STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

DEVICE FUNCTIONALITY SELECTION . . . . . . . . . . . . . . . . .21

ANALOGUE INPUTS SETUP . . . . . . . . . . . . . . . . . . . . . . .22

DIGITAL INPUTS SETUP . . . . . . . . . . . . . . . . . . . . . . . . .23

CONTROLLER

ANALOGUE OUTPUTS SETUP . . . . . . . . . . . . . . . . . . . . . .24

RELAY CONTACT SETUP . . . . . . . . . . . . . . . . . . . . . . . . .25

SCHEDULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

RUN SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

MODBUS REGISTER MAPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

TRANSPORT AND STOCK KEEPING INFORMATION 33

WARRANTY INFORMATION AND RESTRICTIONS 33

MAINTENANCE 33

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 3 - 33

www.sentera.eu

Page 4

MULTIFUNCTIONAL LOGIC

MC S -1- LC D

CONTROLLER

SAFETY AND PRECAUTIONS

Read all information, the datasheet, mounting instructions and wiring scheme

before working with the product. For personal and equipment safety, and for

optimum product performance, make sure you entirely understand the contents

before installing, using, or maintaining this product.

For safety and licensing (CE) reasons, unauthorised conversion and/ or modifications

to the product are not permitted.

e product must not be exposed to abnormal conditions, such as: extreme

temperatures, direc t sunlight or vibrations. Chemical vapours with high concentration

in combination with long exposure times can affect the product performance. Make

sure the work environment is as dry as possible; check for condensation spots.

All installations shall comply with the local health and safety regulations and local

electrical codes. is product can only be installed by an engineer or a technician

who has an expert knowledge of the product and safety precautions.

Avoid contacts with energised electrical parts; always treat the product as if it

is life. Always disconnect the power source before connecting the power cables,

servicing or repairing the product.

Always verify that you apply appropriate power supply to the product and use wires

with appropriate size and characteristics. Make sure that all the screws and nuts are

well tightened and fuses (if any) are fitted well.

Recycling of equipment and packaging should be taken into consideration and

disposed in accordance with local and national legislation/regulations.

In case there are any questions that are not answered, please contact your technical

support or consult a professional.

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 4 - 33

www.sentera.eu

back to the table of contents

Page 5

MC S -1- LC D

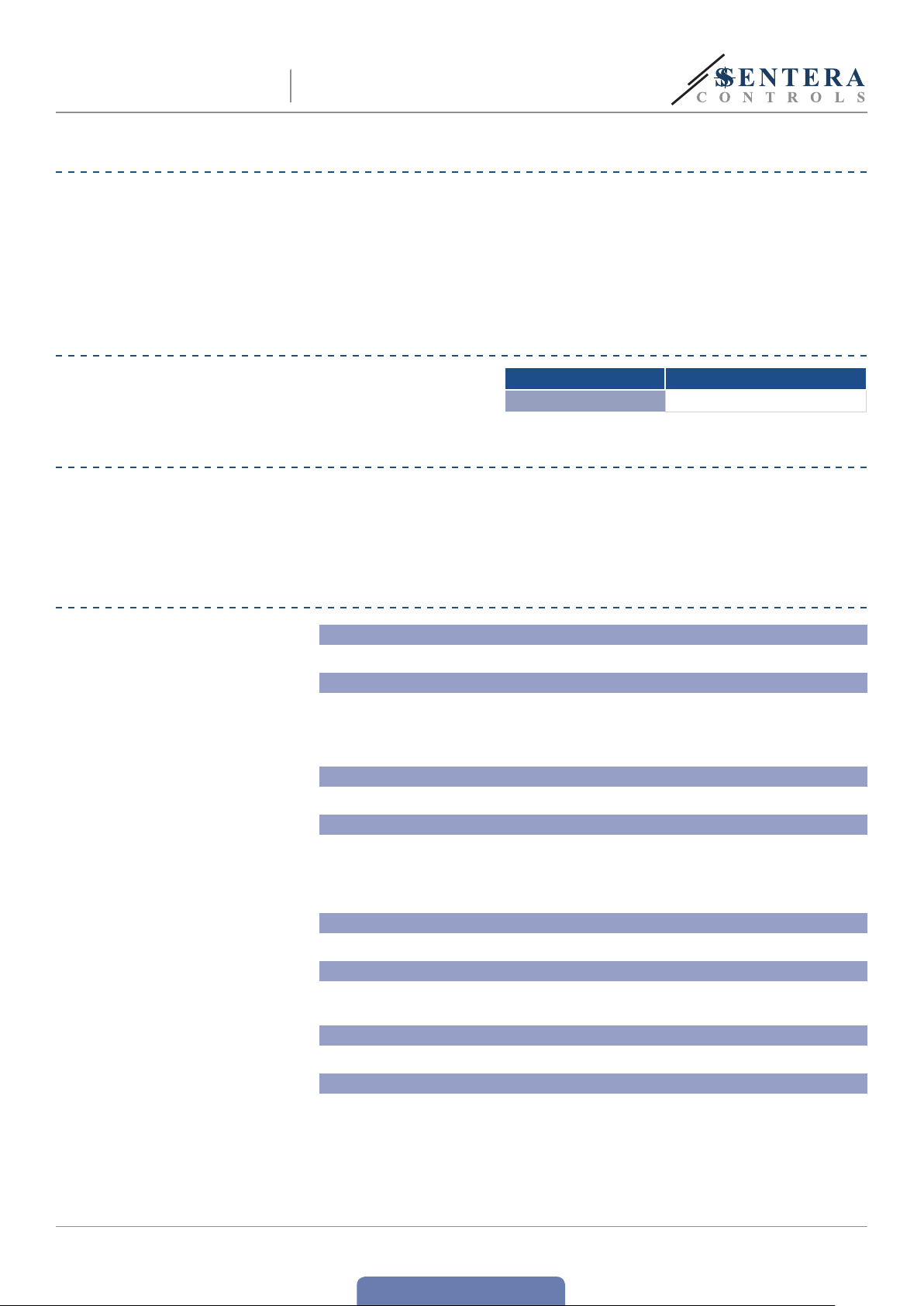

PRODUCT DESCRIPTION

ARTICLE CODES

INTENDED AREA OF USE

MULTIFUNCTIONAL LOGIC

CONTROLLER

e MCS-1-LCD multifunctional logic controller has integrated analogue, digital

and relay outputs which are free configurable. Its multiple analogue, digital and

temperature inputs ensure functionality in a large range of HVAC applications. All

functional parameters and settings are accessible either via a 4-button interface

with LCD display, via a user-friendly monitoring software application for Windows or

via 3SModbus. A bootloader makes firmware updates via USB possible.

Code Supply

MC S -1-LC D 85—264 VAC / 47—63 Hz

■

Fan speed control and monitoring

■

Air curtain control

■

Advanced HVAC systems for maintaining stable environment and improved

comfort

■

For indoor use only

TECHNICAL DATA

Temperature inputs

■

2 temperature inputs: PT500 & PT1000 compatible (automatic detection)

Analogue inputs

■

2 analogue inputs Ai1 and Ai2: (0—10 VDC / 2—10 VDC / 0—20 mA / 4—20 mA / PWM)

►

Input impedance (0—10 VDC mode): 136 kΩ

►

Input impedance (0—20 mA mode): 505 Ω

►

Input impedance (PWM mode): 131 kΩ

Digital inputs

■

4 digital inputs

Analogue outputs

■

2 analogue outputs: (0—10 VDC / 2—10 VDC / 0—20 mA / 4—20 mA / PWM)

►

Load resistance in 0—10 VDC mode: ≥ 50 kΩ

►

Load resistance in 0—20 mA mode: ≤ 500 Ω

►

Load resistance in PWM mode: ≥ 50 kΩ

Relay outputs

■

2 relay outputs: C/O, 250 VAC / 16 A (resistive load)

PWM outputs

■

Internally supplied (Fig. 3a) or

■

Open collector (Fig. 3b)

Supply outputs

■

1 supply output: 24 VDC / 200 mA

Other specifications

■

Leakage current: < 0,25 mA

■

Power consumption:

►

no load: max. 2 W

►

full load: max. 11 W

■

USB 2.0 interface

■

Modbus RTU (RS485) communication

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 5 - 33

back to the table of contents

www.sentera.eu

Page 6

MULTIFUNCTIONAL LOGIC

MC S -1- LC D

CONTROLLER

■

Enclosure:

►

►

■

Operating ambient conditions:

►

►

■

Storage temperature: -10—50 °C

STANDARDS

■

Low Voltage Directive 2014/35/EC

■

EMC Directive 2014/30/EC: EN 61326

■

WEE E Directive 2012/19/EU

■

RoHs Directive 2011/65/EU

WIRING AND CONNECTIONS

ABS plastic, grey (RAL7035)

IP54 (according to EN 60529)

temperature: 0—40 °C

rel. humidity: 0—80 % rH (non-condensing)

L Power supply, Line

N Power supply, Neutral

NC1 Normally closed contact, relay 1

COM1 Common contact, relay 1

NO1 Normally open contact, relay 1

NC2 Normally closed contact, relay 2

COM2 Common contact, relay 2

NO2 Normally open contact, relay 2

T1 Temperature input 1 (PT500 or PT1000)

GND Ground, common ground reference for T1 and T2

T2 Temperature input 2 (PT500 or PT1000)

Ai1 Analogue input 1 (0—10 VDC / 2—10 VDC / 0—20 mA / 4—20 mA / PWM)

GND Ground, common ground reference for Ai1 and Ai2

Ai2 Analogue input 2 (0—10 VDC / 2—10 VDC / 0—20 mA / 4—20 mA / PWM)

Di1 Digital input 1 (GND reference)

Di2 Digital input 2 (GND reference)

Di3 Digital input 3 (GND reference)

Di4 Digital input 4 (GND reference)

Ao1 Analogue output 1 (0—10 VDC / 2—10 VDC / 0—20 mA / 4—20 mA / PWM)

GND Ground, common ground reference for Ao1 and Ao2

Ao2 Analogue output 2 (0—10 VDC / 2—10 VDC / 0—20 mA / 4—20 mA / PWM)

GND Ground reference for supply output

+24 V D C Supply output (24 VDC / 200 mA)

/B Modbus RTU (RS485) signal /B

A Modbus RTU (RS485) signal /A

2

Connections

Cable cross section: max. 1,5 / 2,5 mm

Cable gland clamping range: 3—6 mm

2 USB sockets, type Mini B

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 6 - 33

back to the table of contents

www.sentera.eu

Page 7

[x]

A

A

[x]

A

t,[s ]

Tix/Aix,

t,[s ]

[x]

A

t, [s]

Ti

t, [s]

A

ox, [%]

t,[s]

A

ox, [%]

MULTIFUNCTIONAL LOGIC

MC S -1- LC D

CONTROLLER

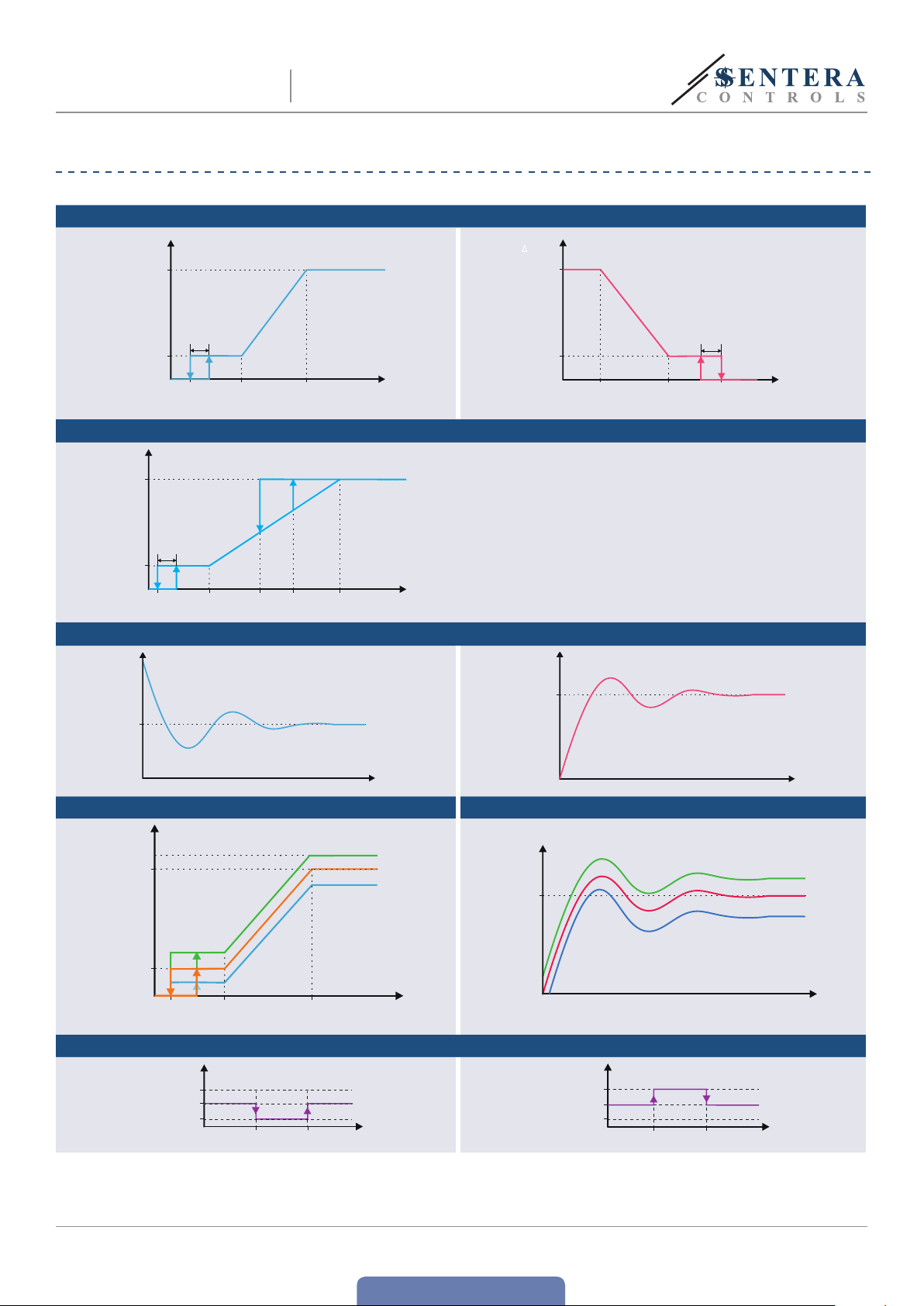

OPERATIONAL DIAGRAMS

LINEAR FUNCTION

ox, [%]

Max

Linear

(Cool , Dry, Drain

0–10 0 %)

5 %

Min

Off

level

CONTROL FUNCTION

ox, [%]

Max

Controlled output

5 %

Min

Off

level

cont rol

range

PID CONTROL

[X]

SP

Min

cont rol

range

Min

SP-

Hysteresis

PID cont rol

(Cool, Dry, Drain 0–100 %)

Max

cont rol

range

Output (normal)

Output (high priority)

SP

cont rol

range

Max

Tix/Aix,

Tix/Aix,

[x]

ox, [%]

Max

Min

Tix/Aix,

[X]

Linear (Heat, Humidify, Obtain, 100–0 %)

5 %

Off

level

SP

PID control

(Heat, Humidify, Obtain, 100–0 %)

Min

cont rol

range

Max

cont rol

range

Tix/Aix,

UNBALANCED LINEAR MODE UNBAL ANCED PID MODE

ox, [%]

Max

Ao2 output

with positive

unbalanced

coefficient

Ao1 output

Ao2 output

with negative

unbalanced

coefficient

x/Aix,

[X]

SP

Positive unbalanced

coefficient

Negative unbalanced

coefficient

Min

Off

level

Min

cont rol

range

Max

cont rol

range

Tix/Aix,

ANALOGUE OUTPUTS IN FUNCTION OF DIGITAL INPUTS

Maximum

Related value

0

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 7 - 33

DIX remote Off

Active state

event

Inactive state

event

www.sentera.eu

Maximum

Related value

DIX maximum speed

0

Active state

event

Inactive state

event

back to the table of contents

Page 8

[x]

t, [s]

x,

[x]

t,[s]

MULTIFUNCTIONAL LOGIC

MC S -1- LC D

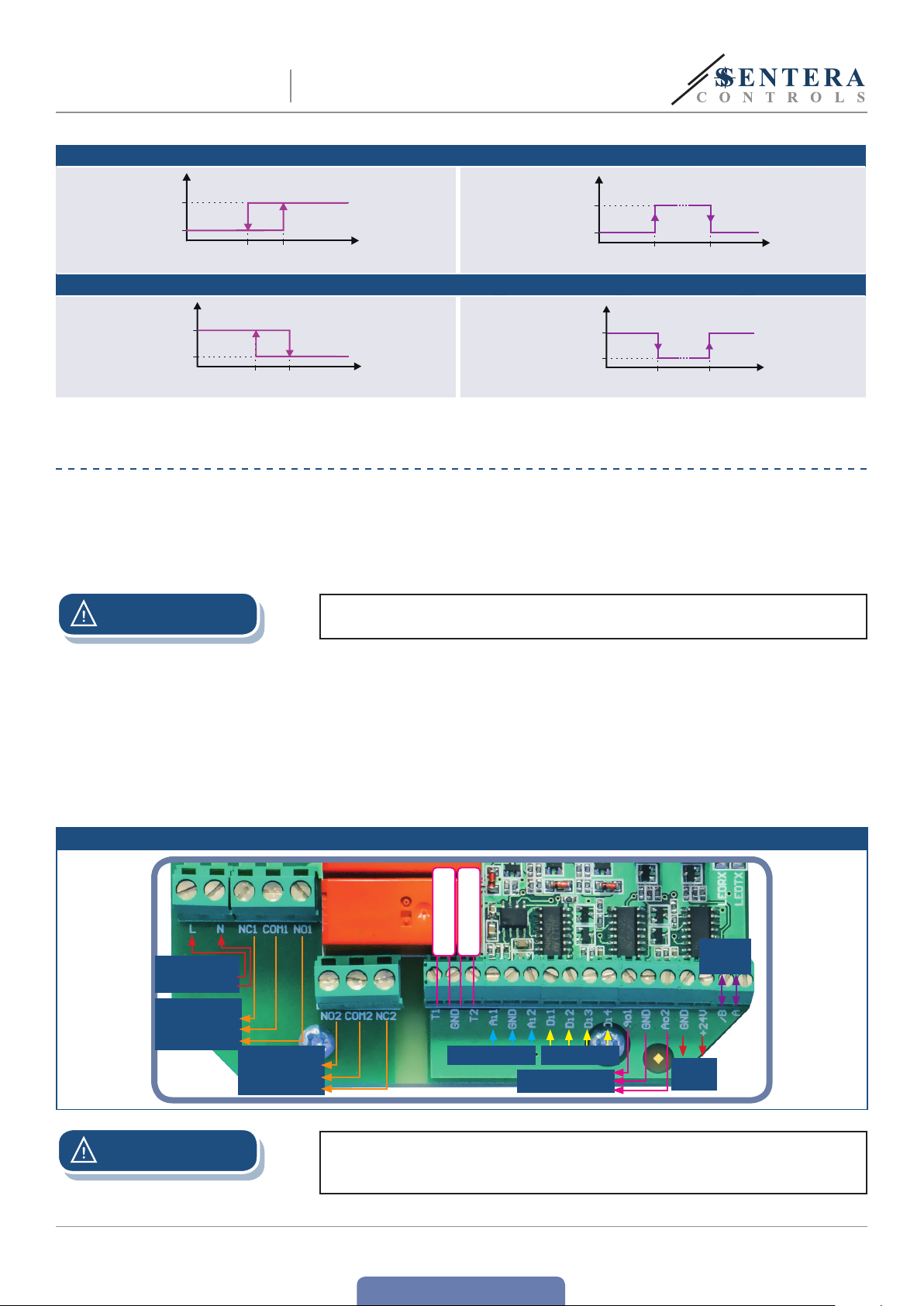

RELAY CONTACT FUNCTION ACTIVE STATE COM - > NO

Rcx,

[state]

COMNO

COMNC

RELAY CONTACT FUNCTION ACTIVE STATE COM -> NC

Rcx,

[state]

COMNO

COMNC

TIX/AIX function

SP-

Hysteresis

TIX/AIX function

SP-

Hysteresis

CONTROLLER

Tix/Aix,

SP

Tix/Ai

SP

MOUNTING INSTRUCTIONS IN STEPS

Before you start mounting your controller read carefully “Safety and

Precautions”. Choose a smooth surface for an installation location (a wall,

panel and etc.). Then proceed with the following mounting steps:

1. Switch off the power supply.

2. Unscrew the four screws on the front cover and open it carefully.

Rcx,

[state]

COMNO

COMNC

Rcx,

[state]

COMNO

COMNC

DIX function

Active state

event

Active state

event

Inactive state

DIX function

Inactive state

event

event

ATTENTION

Fig. 1 Wiring and connections

Power supply

Relay contac t 1

Normally closed

Line

Neutral

Common

Normally open

Relay contac t 2

Normally closed

Normally open

Common

Make sure the flat cable, connecting the motherboard with the LCD printed circuit

board remains in place!

3. Insert the connecting cables through the cable glands of the unit.

4. Do the wiring according to the wiring diagram (see Fig. 1) using the information

from section “Wiring and connections”. Connect the controlled equipment and

the sensors (if necessary). Use cables with recommended length and type with

respect to your application. Mind the following recommendations:

►

Use shielded cables for the analogue inputs / outputs in case the cable length

is between 4 and 12 m and voltage (VDC) mode is used.

►

When the cable length exceeds 12 m, use the analogue inputs / outputs in

current (mA) mode.

PT 500 / PT1000

PT 500 / PT1000

Analogue inputs

Digital inputs

Analogue outputs

Suppl y

output

Modbus

RTU

ATTENTION

When you first use the unit make sure that the load corresponds to the default

output values. If the default values do not fit the load used, configure the unit

first, then connect the load. Improper load may cause damage to the controller.

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 8 - 33

back to the table of contents

www.sentera.eu

Page 9

RX

MC S -1- LC D

MULTIFUNCTIONAL LOGIC

CONTROLLER

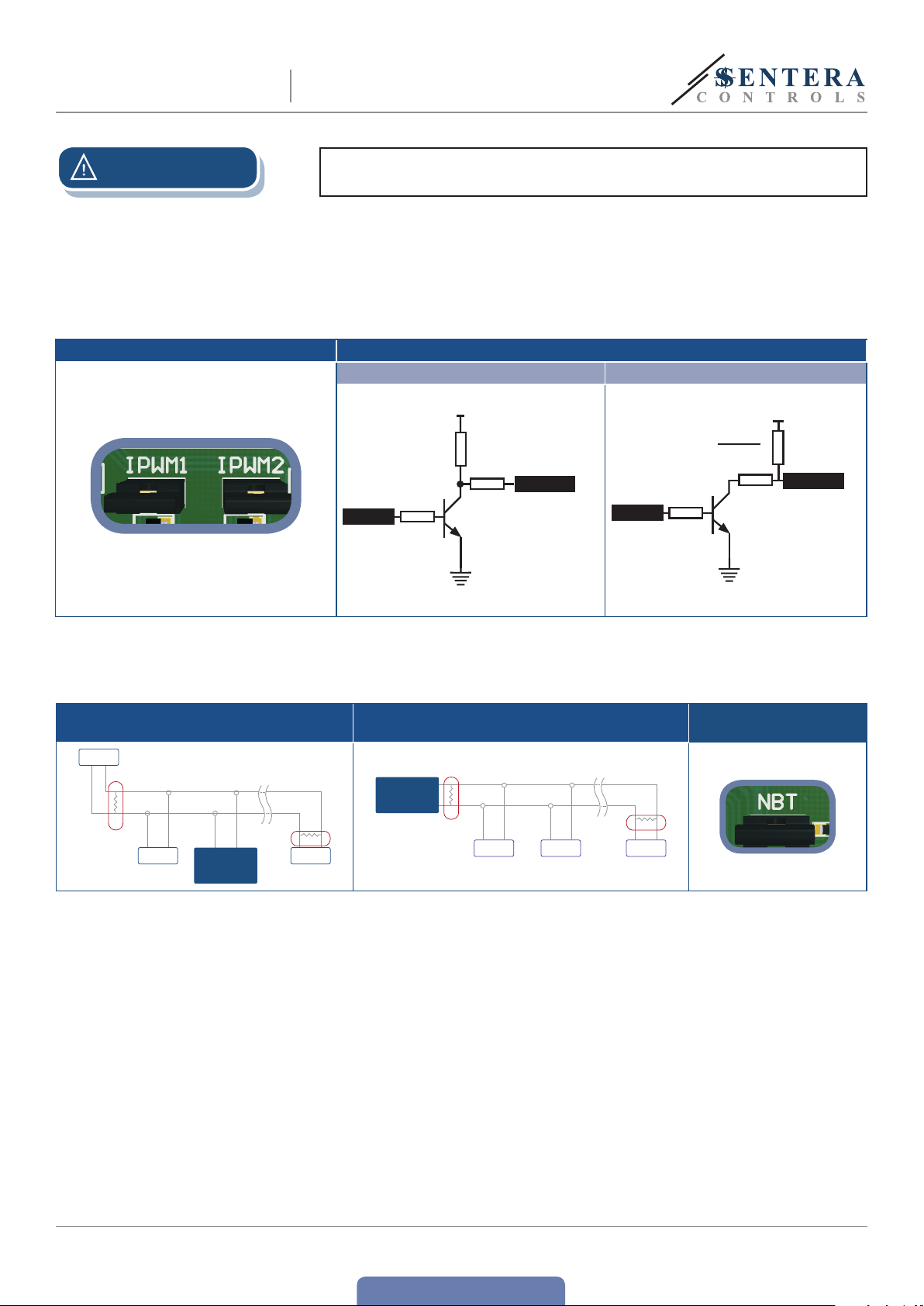

ATTENTION

Do not mix the temperature ground (GND) with other ground (GND) terminals!

5. Customise the factory settings for the PWM outputs to the desired ones if you

are going to use a PWM output. By default the IPWM1 and IPWM2 jumpers (Fig.

2) are closed and the PWM outputs 1 and 2 are connected to an internal voltage

source of +12 VDC. See Fig. 3a Internally supplied PWM schematic. Remove

the jumpers (Fig. 2) if you need PWM open collector outputs. See Fig. 3b Open

collector schematics.

Fig. 2 PWM jumpers Fig. 3 PWM schematics

3a Internally supplied PWM schematic 3b Open collector schematic

+12 VDC

2,2 kΩ

100 Ω

Control

4,7 kΩ

BC 817

GND

PWM out

Control

4,7 kΩ

5 VDC ≤ +Vcc ≤ 24 VDC

Vcc

R

=

EXT

5 mA

100 Ω

BC 817

GND

R

EXT

PWM out

6. Check if your unit starts or terminates the network (see Example 1 and

Example2). If it does, connect the NBT resistor. Place the NBT jumper (Fig.4)

onto the pins. Otherwise leave it disconnected (default setting).

Example 1 Example 2

Slave 1

RX

NBT

NBT

Slave 2

Master

ТX

NBT

Slave n

Master

7. Fix the rear lid of the enclosure on the wall/panel by the delivered dowels and

screws. Mind the correct mounting position and unit mounting dimensions.

(SeeFig. 5 Mounting dimensions and Fig.6Mounting position.)

Fig. 4 Network bus

resistor jumper

NBT

Slave 1

Slave 2

ТX

NBT

Slave n

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 9 - 33

www.sentera.eu

back to the table of contents

Page 10

4x

MULTIFUNCTIONAL LOGIC

MC S -1- LC D

Fig. 5 Mounting dimensions Fig.6Mounting position

115

CONTROLLER

4,50

Acceptable Not acceptable

102

201

63

ATTENTION

140

8. Close the enclosure and fix the cover.

9. Switch on the power supply.

If an AC power supply is used with any of the units in a Modbus network the

GND terminal should NOT BE CONNECTED to other units on the network or

via the CNVT‑USB‑RS485 converter. is may cause permanent damage to the

communication semiconductors and / or the computer!

10. If necessary, customize the other factory settings to the desired ones. Use

3SModbus software, 3SMonitor software or the 4-button menu and LCD display

VERIFICATION OF THE CORRECT INSTALLATION

When you first switch on the power supply, the display will illuminate and show the

time and date, Temp. °C (the default operational mode) and the active working mode

(Run or Stand-by). If this is not the case, open the enclosure and check the status of

the power on green LED. See Fig. 7 Operating indication.

■

If the LED is off, your unit is not supplied. Check the connections again.

■

If the LED is on, but the LCD display is off, check the connection of the ribbon

(flat)cable.

Fig. 7 Operation indication

ATTENTION

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 10 - 33

Be careful when you are handling with the ribbon cable. It must not touch the

power supply block. is will damage your unit. See Fig. 8.

www.sentera.eu

back to the table of contents

Page 11

MC S -1- LC D

Fig. 8 MCS-1-LCD PCB

MULTIFUNCTIONAL LOGIC

CONTROLLER

Power supply module

Ribbon cable

e ribbon cable must not touch

the power supply module.

Check the status of the both LEDs (LEDRX and LEDTX). See Fig. 9 Modbus

communication indication. If they blink your unit has detected a Modbus network. If

they do not, check the connections again.

Fig. 9 Modbus communication indication

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 11 - 33

back to the table of contents

www.sentera.eu

Page 12

MULTIFUNCTIONAL LOGIC

MC S -1- LC D

CONTROLLER

OPERATING INSTRUCTIONS

CONTROLLER OVERVIEW

T1

T2

Ai1

Ai2

Di1

Di2

Di3

PROBE TYPE:

PT500

PT1000

REFERENCE:

CO2

Rel.humidity

Temp

AIR quality

Diff. pressure

ACTIVE STATE :

H IGH

L OW

TYPE :

0–10 VDC

2–10 VDC

0–20 mA

4–20 mA

PWM

RANGE

FIXED or

TIMESCHEDULE

SETPOINT

FIXED or

TIMESCHEDULE

Ao1 to

MAX

Ao1 to

OFF

Ao2 to

MAX

Ao2 to

OFF

LINEAR

HEATING COOLING

HUMIDIFY DRY

OBTAIN DRAIN

CONTROL

PID

HUMIDIFY COOL

OBTAIN DRAIN

FUNCTION

0–10 VDC, 2-10 VDC

0–20 mA, 4-20 mA

PWM

0–10 VDC, 2-10 VDC

0–20 mA, 4-20 mA

PWM

Free

(Independent to Ao1)

DIGITAL OVER RULE

Balanced to Ao1

Unbalanced to Ao1

Ao1

Ao2

Relay 1

Relay 2

DI - FUNCTION

Di4

RELAY

Control

CONTROL FUNCTIONS OVERVIEW

e MCS-1-LCD controller features integrated analogue and relay outputs which can

be controlled either in one of the pre-configured modes or they can be personalised.

Its numerous different analogue, digital and temperature inputs ensure a large range

of functional control. You can choose the control function between:

LINEAR FUNCTION

Analogue outputs in linear function of the inputs

In cool mode the value of the analogue output rises linear in function of a higher

measured input value (according to the sensor(s) selected). is linear function goes

from the minimum to the maximum range of the assigned input and drops to 0 VDC

when off level is reached. e off level can be selected over the full sensor range.

In heat mode the value of the analogue output drops linear in function of a higher

measured input value.

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 12 - 33

www.sentera.eu

back to the table of contents

Page 13

MC S -1- LC D

MULTIFUNCTIONAL LOGIC

CONTROLLER

CONTROL FUNCTION

Analogue outputs in function of the normal priority and high priority inputs

e value of an analogue output in control mode follows a linear function of the

input with normal priority until the high priority assigned input reaches its setpoint.

e value then rises to the maximum value in the selected “time to maximum”

timespan. e output stays at maximum until the high priority input value reaches

SP – hysteresis, and then it drops following the linear function of the input with

normal priority.

PID CONTROL

During the PID control the analogue output changes to keep the assigned normal

input value at its selected setpoint level. e proportional gain (Kp), integration

period (Ti) and derivation period (Td) of the PID control are free configurable to set

the required slope, gain or magnitude.

e implemented autotune function calculates the parameters automatically

according to the system.

ANALOGUE OUTPUTS IN FUNCTION OF THE DIGITAL INPUTS

e analogue outputs can individually correspond to the state of the digital input.

When a digital input with remote off function becomes ‘active’, the related analogue

output drops to 0 and goes back to the current function value (Linear, Control or PID)

when it becomes ‘inactive’. When a digital input with ‘maximum output’ func tion

becomes ‘active’, the related analogue output rises to maximum and goes back to

the current function value (Linear, Control or PID) when it becomes ‘inactive’. All the

digital inputs have priority to all the other inputs (Ai1, Ai2, T1 and T2).

FREE

e second analogue output Ao2 is independent from the first analogue output Ao1.

BALANCED

e value of the second analogue output Ao2 follows the value of the first output Ao1.

UNBALANCED

In unbalanced mode the value of the se cond analogue ou tput Ao2 follows the func tion

of the first output Ao1 according to the set offset values. See the operational

diagrams with positive and negative unbalanced (offset) coefficient.

RELAY CONTACT FUNCTION

Depending on the pre-selected active state of a relay, the relay contact switches

open or closed at the previously set setpoint of the assigned analogue or temperature

input, and switches back (closed or open) at the SP - hysteresis value.

In case there is an assigned digital input for relay switching, the relay contact

switches open or closed at the event of active state and switches back (closed or

open) when the state changes to inactive.

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 13 - 33

back to the table of contents

www.sentera.eu

Page 14

MULTIFUNCTIONAL LOGIC

MC S -1- LC D

CONTROLLER

PARAMETERS AND DEFAULT SETTINGS

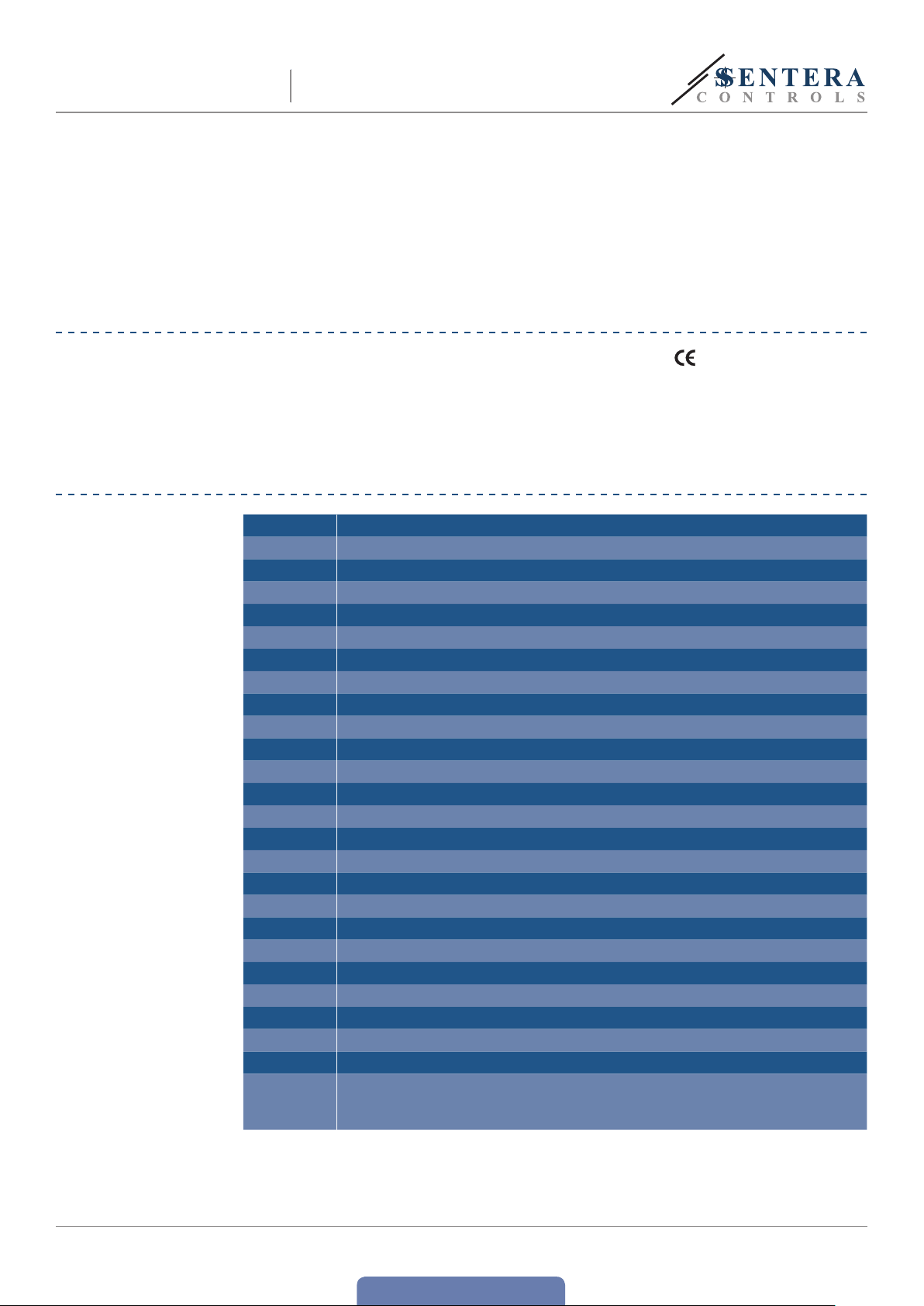

GENERAL

Parameter Default value

Temperature input 1 and 2 (T1 & T2) Input state In use

Sensor range -30—70 °C

Control range 0—40 °C

Off level -10 °C

Setpoint 20 °C

Hysteresis 2 °C

Units Celsius

Calibration Stand-by

Analogue input 1 and 2 (Ai1 & Ai2) Input type Not in use

Sensor range 0—10,0 VDC

Measured quantity Relative humidity

Reference sensor range 20—80 % rH

Control range 20—80 % rH

Off level 20 % rH

Setpoint 50 % rH

Hysteresis 6 % rH

Free units Empty

Digital input 1, 2, 3 and 4 (Di1, Di2, Di3 & Di4) Function Not in use

Active state Low

Analogue output 1 and 2 (Ao1 & Ao2) Output type 0—10,0 VDC

Output function Linear

Output mode Cool

Minimum value 0 %

Maximum value 100 %

Time to maximum 60 s

Kp value 1,0 gain

Ti value 10 s

Td value 1 s

Autotune PID control Stand-by

Analogue output 1 (Ao1) Assigned normal input Temperature input 1 (T1)

Assigned high priority input Analogue input 2 (Ai2)

Analogue output 2 (Ao2) Assigned normal input Temperature input 2 (T2)

Assigned high priority input Analogue input 1 (Ai1)

Analogue output relation Free

Unbalance coefficient 0 %

Relay contacts 1 and 2 (Rc1 & Rc2) Assigned input(s) Not in use

Functionality Device functionality Temperature Cool

Passwords Installer password 0000

User password 0000

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 14 - 33

back to the table of contents

www.sentera.eu

Page 15

BOOT

MODE

J4

RUN

MULTIFUNCTIONAL LOGIC

MC S -1- LC D

Parameter Default value

Scheduling Scheduled number of run periods 1

Scheduled run period 1 duration 8:30 - 17:00

Scheduled run period 2 duration --:-- - --:--

Scheduled run period 3 duration --:-- - --:--

Scheduled run period 4 duration --:-- - --:--

Scheduled run period 1 days of week Monday, Tuesday, Wednesday, ursday, Friday

Scheduled standby period 1 duration dd mmm yyyy - dd mmm yyyy

Scheduled standby period 2 duration dd mmm yyyy - dd mmm yyyy

Scheduled standby period 3 duration dd mmm yyyy - dd mmm yyyy

Scheduled standby period 4 duration dd mmm yyyy - dd mmm yyyy

CONTROLLER

CONFIGURING THE PARAMETERS

e default parameters can be modified by using either one of predefined userfriendly templates or by customising them freely.

ATTENTION

NOTE

e mode selector (Fig. 10) should always be in run mode except for firmware

updates.

Fig. 10 Mode selector

e USB interface allows LCD display and control board firmware updates. To

update contact the technical support.

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 15 - 33

www.sentera.eu

back to the table of contents

Page 16

MULTIFUNCTIONAL LOGIC

MC S -1- LC D

CONTROLLER

USING PREDEFINED TEMPLATES

See table Tabl e below to know about the available templates that pre-define the

device functionality.

Device functionality

Predefined templates

Parameters

Control range (T1) 0—40°C 0—40°C N/A N/A N/A N/A 0—40°C 0—40°C 0—40°C

Off level (T1) -10°C 40°C N/A N/A N/A N/A -10°C -10 ° C -10° C

Setpoint (T1) N/A N/A N/A N/A N/A N/A N/A 20°C N/A

Control range (T2) 0—40°C 0—40°C N/A N/A N/A N/A N/A N/A 0—40°C

Off level (T2) 0°C 40°C N/A N/A N/A N/A N/A N/A -10 °C

Setpoint (T2) N/A N/A N/A N/A N/A N/A N/A N/A N/A

Control range (Ail) N/A N/A 20—80 % rH 0—2.000 ppm 0—2.000 ppm 0—2.000 Pa 0—2.000 ppm 0—2.000 Pa 0—10.000

Off level (Ail) N/A N/A 20 % rH 0 ppm 0 ppm 0 Pa 0 ppm 0 Pa N/A

Setpoint (Ail) N/A N/A N/A N/A N/A N/A 1000 ppm N/A 5.000 units

Control range

(Ai2)

Off level (Ai2) N/A N/A N/A N/A N/A N/A N /A N/A N/A

Setpoint (Ai2) N/A N/A N/A N/A N/A N/A N /A N/A 5.000 units

Analog output

function (Aol)

Analog output

mode (Aol)

Assigned normal

input (Aol)

Assigned high

priority input (Aol)

Analog output

function (Ao2)

Analog output

mode (Ao2)

Assigned normal

input (Ao2)

Assigned high

priority input

(Ao2)

Temperature

cool

Temperature

heat

N/A N/A N /A N/A N/A N /A N/A N/A 0—10.000

Linear Linear Linear Linear Linear Linear Controlled Controlled Controlled

Cool Heat 0—10 VD C 0 —10 VD C 0—10 V DC 10— 0 VDC N/A N/A N/A

T1 T1 A i1 Ai1 A i1 Ai1 T1 Ai1 T1

N/A N/A N /A N/A N/A N /A Ai1 T1 Ai1

Linear Linear N/A N/A N/A N/A Linear Linear Controlled

Cool Heat N/A N/A N/A N/A 0 —10 VD C Cool N/A

T2 T2 N/A N/A N/A N/A Ai1 T1 T2

N/A N/A N /A N/A N/A N /A N/A N/A Ai2

Relative

humidity

CO

2

Air quality Differential

pressure

Temperature

and CO

2

Differential

pressure and

temperature

Free

units

units

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 16 - 33

www.sentera.eu

back to the table of contents

Page 17

MC S -1- LC D

CUSTOMISING THE SETTINGS

MULTIFUNCTIONAL LOGIC

CONTROLLER

ere are 3 possible ways to customize the default parameters:

■

using 3SMonitor software

■

using 3SModbus software, and

■

with the help of the 4-buton interface

3SMONITOR SOFTWARE

3SMonitor application is a free Sentera software. You can download it from our

website at http://www.senteracontrols.com/3smodbus/Setup3SM.msi

ATTENTION

Before you download it, make the connections carefully. Connect a USB cable

between connector J1 (Fig. 11) and the computer USB port.

Fig. 11 USB connector J1

e USB connector J4 shown in F ig. 12 is for firmware updates only.

Fig. 12 USB connector J4

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 17 - 33

back to the table of contents

www.sentera.eu

Page 18

MC S -1- LC D

MULTIFUNCTIONAL LOGIC

CONTROLLER

When you run the 3SMonitor application, the home screen shown in Fig. 13 will

appear on your screen. Installer access level provides full control over the device

inputs and outputs configuration, time schedule and firmware update. e user

access level provides only monitoring, scheduling and setting time and date. If you

log in as Installer, you can choose between setup wizard and monitoring (Fig. 14).

Fig. 13 3SMonitor home screen

NOTE

e password box is not available when password is removed.

Fig. 14 Wizard / Monitoring screen

For further information about parameter configuring refer to the chapter “Main

menu structure”.

3SMODBUS SOFTWARE

3SModbus is a free application for Windows. You can download it from our website

at http://www.senteracontrols.com/3smodbus/3smodbus.exe

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 18 - 33

back to the table of contents

www.sentera.eu

Page 19

MC S -1- LC D

MULTIFUNCTIONAL LOGIC

CONTROLLER

Before you download it, make the connec tions carefully. Connect A and /B terminals

with A and /B of a CNVT-USB-RS485 converter (Fig. 15).

Fig. 15 CNVT-USB-RS485 converter

ATTENTION

Do NOT connect the GND signal of the CNVT‑USB‑RS485 converter! (See section

“Wiring and Connections”.) is may damage the computer’s USB port.

When you run the 3SModbus application, the home screen shown in Fig. 16 will

appear on your screen.

Fig. 16 3SMоdbus home screen

For parameter settings refer to Chapter “Modbus register maps”.

4-BUTON KEYBOARD INTERFACE

Fig. 17 LCD display home screen

To configure the MCS-1-LCD, use the 4-button interface and LCD display following

the menu structure. (See chapter “Main menu structure”.). For the parameter

default values, please refer to “Modbus register maps” chapter.

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 19 - 33

back to the table of contents

www.sentera.eu

Page 20

6

7

8

9

1

2

1

345

MC S -1- LC D

MAIN MENU STRUCTURE

MULTIFUNCTIONAL LOGIC

CONTROLLER

NOTE

Home screen

User or installer

password prompt

e framed menu is only available

User

if logged in as installer

Output screen

Schedule

installer settings

To configure the MCS‑1‑LCD using the 4‑button interface and LCD display, you can

follow the next menu structure. e possible parameter values and their default

values can be found in the table “Modbus register maps”.

Temperature

inputs screen

Device

functionality

Analogue inputs

Digital inputs

Analogue outputs

Analogue inputs

screen

Digital inputs

Time and date

setup

Run periods

Run days

Standby periods

Run per iods

parameters

screen

Change installer

password

Remove installer

password

Reset installer

password

Change user

password

Remove user

password

Reset user

password

Installer command

prompt

User or installer

password prompt

Relay contacts

installer password

options

Bootloader

Reset to def ault

Clear schedule

User password

options

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 20 - 33

back to the table of contents

www.sentera.eu

Page 21

1

MC S -1- LC D

MULTIFUNCTIONAL LOGIC

CONTROLLER

DEVICE FUNCTIONALITY SELECTION

Temperature cool

Temperature heat

Relative humidity

CO

2

Air quality

Differential pressure

Temperature and CO

Differential pressure and

temperature

Free

2

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 21 - 33

back to the table of contents

www.sentera.eu

Page 22

2

MC S -1- LC D

MULTIFUNCTIONAL LOGIC

CONTROLLER

ANALOGUE INPUTS SETUP

T1

T2

Ai1

T1 state Not in use

T1 uni ts In use

Calibration

rH

AQ

CO

DP

Not in use

In use

2

T2state

T2 uni ts

Calibration

T1 state

Measured

quantity

Celsius

Fahrenheit

Celsius

Fahrenheit

Set range reference

Set range reference

Set range reference

Set range reference

Start callibration

Rese t to fac tor y

callibration

Start callibration

Rese t to fac tor y

callibration

Not in use

0—10 VDC

0—20 m A

2—10 VD C

4—20 m A

PWM

Celsius

Fahrenheit

Ai2 Input type

Celsius

Units

Set range reference

Measured

quantity

Units

Free

Tem p

rH

AQ

CO

DP

Free

Tem p

Enter units

Set range reference

Not in use

Set range reference

Set range reference

2

Set range reference

Set range reference

Enter units

Set range reference

0—10 VDC

0—20 m A

2—10 VD C

4—20 m A

PWM

Fahrenheit

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 22 - 33

Set range reference

www.sentera.eu

back to the table of contents

Page 23

3

MC S -1- LC D

MULTIFUNCTIONAL LOGIC

CONTROLLER

DIGITAL INPUTS SETUP

Di1

Di2

Di3

Di4

Assign function

Active state

Backlight

High

Low

On

Off

Assign function

Active state

Backlight

Not in us e

Remot e off Ao1

Maxim um output Ao1

Mode se lect ion Ao1

Remot e off Ao2

High

Low

On

Off

Not in us e

Remot e off Ao1

Maxim um output Ao1

Mode se lect ion Ao1

Remot e off Ao2

Maxim um output Ao 2

Mode se lect ion Ao2

Relay control

Assign function

Active state

Backlight

Assign function

Active state

Backlight

High

Low

On

Off

High

Low

On

Off

Not in us e

Remot e off Ao1

Maxim um output A o1

Mode se lect ion Ao1

Remot e off Ao2

Maxim um output A o2

Mode se lect ion Ao2

Relay control

Not in us e

Remot e off Ao1

Maxim um output A o1

Mode se lect ion Ao1

Remot e off Ao2

Maxim um output Ao 2

Mode se lect ion Ao2

Relay control

Maxim um output A o2

Mode se lect ion Ao2

Relay control

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 23 - 33

www.sentera.eu

back to the table of contents

Page 24

4

MC S -1- LC D

MULTIFUNCTIONAL LOGIC

CONTROLLER

ANALOGUE OUTPUTS SETUP

If Controlled function

typ e is selec ted

If Controlled function

typ e is selec ted

If PID fu nction

is selected

If PID fu nction

is selected

If PID fu nction

is selected

If PID fu nction

is selected

Set ou tput t ype

Set relation

Set mi n and max

output value

Assi gn norm al

T/Ai

Assi gn high

priority T/Ai

Time to maximum

Kp val ue

Ti val ue

Td va lue

Autotune

Ao1

Ao2

Balanced

Unbalanced

Free

Not in us e

0—10 VDC

2—10 VD C

0—20 m A

4—20 m A

PWM

Coefficient

Set funct ion ty pe Linear

If linear fun ctio n

typ e is selec ted

If con troll ed

func tion type is

selected

If con troll ed

func tion type is

selected

If PID fu nct ion is

selected

If PID fu nct ion is

selected

If PID fu nct ion is

selected

If PID fu nct ion is

selected

Controlled

PID

Set ou tput t ype

Set relation

Set mi n and max

output value

Assi gn norm al

T/Ai

Assi gn high

priority T/Ai

Time to maximum

Kp val ue

Ti val ue

Td va lue

Autotune

Heat

Cool

Heat

Cool

Not in us e

0—10 VDC

2—10 VD C

0—20 m A

4—20 m A

PWM

Linear

Controlled

PID

Heat

Cool

Heat

Cool

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 24 - 33

back to the table of contents

www.sentera.eu

Page 25

5

MC S -1- LC D

MULTIFUNCTIONAL LOGIC

CONTROLLER

RELAY CONTACT SETUP

Rc1

Rc2

Assign input

Assign input Not in use

T1

T2

Ai1

Ai2

Di1

Not in use

T1

T2

Ai1

Ai2

Di1

Di2

Di3

Di2

Di3

Di4

Only active or related

inputs are listed

Di4

Only active or related

inputs are listed

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 25 - 33

back to the table of contents

www.sentera.eu

Page 26

MC S -1- LC D

MULTIFUNCTIONAL LOGIC

CONTROLLER

SCHEDULE

Run days

6

Peri od 1 Monday Enable

Peri od 2

Peri od 3

Peri od 4

Only active periods are

list ed. e submenus f or

all periods are identical

Tuesday

Wednesday

ursday

Friday

Saturday

Sunday

e subm enus fo r all

periods are identical

Disable

Run periods Standby periods

7

Peri od 1

Peri od 2

Peri od 3

Peri od 4 Set

Set

Set

Set

8

Peri od 1

Peri od 2

Peri od 3

Peri od 4 Set

Set

Set

Set

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 26 - 33

www.sentera.eu

back to the table of contents

Page 27

MC S -1- LC D

MULTIFUNCTIONAL LOGIC

CONTROLLER

RUN SETTINGS

9

Peri od 1

Peri od 2

Peri od 3

Peri od 4

Only active period are

list ed. e submenus

for all perio ds are

identical

Control range

Off lev el

If assi gned in linear

or primary controlled

analogue output

T1

T2

Ai1

Ai2

Only active or related

inpu ts are listed

Setpoint

Hysteresis

If assi gned in

secondary controlled

analogue output

Control range

Off lev el

If assi gned in linear

or primary controlled

analogue output

Setpoint

If assi gned in r elay

cont acts or in PID

controlled analogue

output

Setpoint

Hysteresis

If assi gned in

secondary controlled

analogue output

Control range

Off lev el

If assi gned in linear

or primary controlled

analogue output

Control range

Off lev el

If assi gned in linear

or primary controlled

analogue output

Setpoint

If assi gned in r elay

cont acts or in PID

controlled analogue

output

Setpoint

Hysteresis

If assi gned in

secondary controlled

analogue output

Setpoint

Hysteresis

If assi gned in

secondary controlled

analogue output

Setpoint

If assi gned in r elay

cont acts or in PID

controlled analogue

output

Setpoint

If assi gned in r elay

cont acts or in PID

controlled analogue

output

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 27 - 33

www.sentera.eu

back to the table of contents

Page 28

MULTIFUNCTIONAL LOGIC

MC S -1- LC D

CONTROLLER

MODBUS REGISTER MAPS

INPUT REGISTERS

Data type Description Data Values

1 Temperature level (T1) signed int. Temperature level (T1) -300—700 500 = 50,0°C

2 Temperature level (T2) signed int. Temperature level (T2) -300—700 500 = 50,0°C

3 Analogue input level (Ai1) signed int. Analogue input level (Ai1) 0—1.000

4 Analogue input level (Ai2) t tsigned int. Analogue input level (Ai2) 0—1.000

5 Digital input s tatus (Di1) signed int. Digital input status (Di1) - act ive / in active 0—1

6 Digital input status (Di2) signed int. Digital input s tatus (Di2) - act ive / inactive 0—1

7 Digital input s tatus (Di3) signed int. Digital input s tatus (Di3) - act ive / in active 0—1

8 Digital input s tatus (Di4) signed int. Digital input s tatus (Di 4) - active / inact ive 0—1

9-10 Reserved, re turns 0

11 Anal ogue ou tput value ( Ao1) signed int. Value of t he analogue outpu t (Ao1) - 0—10 VDC 0—1.000

12 Analogue out put va lue (Ao2) signed int. Value of th e analo gue output (Ao2) - 0—10 VDC 0—1.000

13 Relay 1 st atus signed int.

14 Relay 2 status signed int.

15 Current year unsigned int. Current year 2000—2099

16 Current month unsigned int. Current month 1—12

17 Current day unsigned int. Current day 1—31

18 Current hour unsigned int. Current hour 0—23

19 Current minutes unsigned int. Current minutes 0—59

20 Current seconds unsigned int. Current seconds 0—59

21 Temperature input sensor range (T1) signed int.

22 Temperature input control range (T1) signed int.

23 Off level for t emper atur e inpu t (T1) signed int. S elec ted off level f or temp erat ure input ( T1) -200—600 500 = 50,0 ° C

24 Setpoint for temperature input (T1) signed int. Selected setpoint for temperature input (T1) -200—600 500 = 50,0 °C

25 Hys tere sis for temperature inpu t (T 1) signed int. Se lected hys tere sis for temperature input (T 1)

26 Sens or type (T 1) unsigned int. Current sensor t ype co nnec ted to t he input (T1) 0—1

27 Temperature input sensor range (T2) signed int.

28 Temperature input control range (T2) signed int.

29 Off level for temper atur e inpu t (T2) signed int. S elec ted off level for temperat ure input ( T2) -200—600 500 = 50,0 °C

30 Setpoint for temperature input (T2) signed int. Selected setpoint for temperature input (T2) -200—600 500 = 50,0 ° C

31 Hy ster esis for temperature inp ut ( T2) signed int. Selec ted hy ster esis f or temp erat ure input ( T2)

32 Sensor type (T 2) unsigned int. Current sensor t ype co nnec ted to t he input (T2) 0—1

33 Analogue input sensor range (Ai1) unsigned int.

34 Analogue input control range (Ai1) unsigned int.

Relay 1 s tatus. When it i s NO, the contact between

COM1 and NO1 is closed.

Relay 2 s tatus. When it i s NO, the contact between

COM1 and NO1 is closed.

Selected temperature input sensor range (T1),

calculated from holding registers values

Selected temperature input control range (T1),

calculated from holding registers values

Selected temperature input sensor range (T2),

calculated from holding registers values

Selected temperature input control range (T2),

calculated from holding registers values

Selected analogue input sensor range (Ai1),

calculated from holding registers values

Selected analogue input control range (Ai1),

calculated from holding registers values

0—1

0—1

-300—700 0—500 = 0—50,0 °C

-300—700 0—500 = 0 —50,0 °C

5, 10, 15,

20, 25, 30

-300—700 0—500 = 0—50,0 °C

-300—700 0—500 = 0 —50,0 °C

5, 10, 15,

20, 25, 30

0—1.000 0—1.000 0 —10 V DC

0—1.000 0—1.000 0 —10 V DC

300 =

300 =

300 =

300 =

0 =

1 =

0 =

1 =

0 =

1 =

0 =

1 =

300 =

300 =

300 =

300 =

0 =

1 =

0 =

1 =

1 =

12 =

5 =

10 =

15 =

20 =

25 =

30 =

0 =

1 =

5 =

10 =

15 =

20 =

25 =

30 =

0 =

1 =

3,0 VDC ( 30 %)

6 mA (30 %)

3,0 VDC ( 30 %)

6 mA (30 %)

inactive

inactive

inactive

inactive

3,0 VDC ( 30 %)

6 mA (30 %)

3,0 VDC ( 30 %)

6 mA (30 %)

January

December

PT500

PT1000

PT500

PT1000

active

active

active

active

NC

NO

NC

NO

0,5 °C

1,0 ° C

1,5 ° C

2,0 °C

2,5 °C

3,0 °C

0,5 °C

1,0 ° C

1,5 ° C

2,0 °C

2,5 °C

3,0 °C

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 28 - 33

www.sentera.eu

back to the table of contents

Page 29

MULTIFUNCTIONAL LOGIC

MC S -1- LC D

INPUT REGISTERS

35 Off level fo r analo gue input (Ai1) unsigned int. Selecte d off level for an alogu e input (Ai1) 0—950

36 Setpoint for analogue input (Ai1) unsigned int. Selec ted setpoint for analogue input (Ai1) 200—1.000

37 Hysteresis fo r analogue input (Ai1) unsigned int. Selected hys tere sis for analogue inpu t (Ai1)

38 Reserved, re turn s 0

39 Analogue input sensor range (Ai2) unsigned int.

40 Analogue input control range (Ai2) unsigned int.

41 Off level f or analogue input (A i2) unsigned int. Select ed off level for a nalog ue inpu t (Ai2) 0—950

42 Setpoint for analogue input (Ai2) unsigned int. Selected setpoint for analogue input (Ai2) 200—1.000

43 Hy ster esis f or analogue input (A i2) unsigned int. S elec ted hy ster esis for analogue input (A i2)

44-46 Reserved , retu rns 0

HOLDING REGISTERS

Data type Description Data Default Values

1 Device slave address unsigned int. Modbus device address 1—247 1

2 Modbus baud rate unsigned int. Modbus communication baud rate 1— 4 2

3 Modbus parity unsigned int. Parity check mode 0—2 1

4 Device type unsigned int. Device type (Read only )

5 HW version unsigned int.

6 FW version unsigned int.

7 Operating mode unsigned int.

8 Output override unsigned int.

9 Device functionality unsigned int. Selec ts the operational mode 0—8 0

11 Tempera ture inpu t state (T 1) unsigned int.

14 Minimum control range (T1) signed int. Minimum control range value for T1 -300—700 0 0 = 0 °C

15 Maximum control range (T1) signed int. Maximum control range value for T1 -300—700 400 400 = 40 °C

16

17

18

19

20 Temperature input state (T2) unsigned int.

23 Minimum control range (T2) signed int. Minimum control range value for T2 -300—700 0 0 = 0 °C

24 Maximum control range (T2) signed int. Maximum control range value for T2 -300—700 400 400 = 40 °C

25

26

Off level for temperature

inpu t (T1)

Setpoint for temperature

inpu t (T1)

Hysteresis for temperature

inpu t (T1)

Calibration of temperature

inpu t (T1)

Off level for temperature

inpu t (T2)

Setpoint for temperature

inpu t (T2)

signed int. O ff level f or temperature input T 1 -200—600 -100 -100 = -10 ° C

signed int.

signed int.

unsigned int.

signed int. O ff level f or temperature input T 2 -200—600 -100 -100 = -10 ° C

signed int.

CONTROLLER

Data type Description Data Values

50, 100,

150 , 2 00

Selected analogue input sensor range (Ai2),

calculated from holding registers values

Selected analogue input control range (Ai2),

calculated from holding registers values

Hard ware version of the device (Read

only)

Firmware versi on of th e device (Read

only)

Enables Modbus control and disables the

jumpers

Enables the direct control over the

outputs. Always settable. Active only if

holding register 7 is set to 1.

Enables or disables the temperature input

(T 1)

Setpoint f or temperature in put T1. Used

only if assigned to a controlled analogue

output, PID or relay output.

Hysteres is for temper atur e input T1.

Used only i f assigne d to controlled

analogue output.

Star t or reset factor y cal ibra tion o f

temperature input T1

Enables or disables the temperature input

(T2)

Setpoint f or temperature in put T2. Used

only if assigned to a controlled analogue

output, PID or relay output.

MCS-1-LCD = 2003

XXXX 0 x 0160 = HW version 1.60

XXXX 0 x 0120 = F W version 1.20

0—1 0

0—1 0

0—1 1

-200—600 200 200 = 20 °C

5, 10, 15, 20,

25, 30

0—2 0

0—1 1

-200—600 200 200 = 20 °C

0—1.000 0—1.000 0 —10 V DC

0—1.000 0—1.000 0 —10 V DC

50, 100,

150 , 2 00

1 =

2 =

3 =

4 =

0 =

1 =

2 =

0 =

1 =

0 =

1 =

0 = Temperature cool

1 = Temperature heat

2 = Relative humidity

3 = CO

4 = Air quality

5 = Differential pressure

6 = Temperature and CO

7 =

8 = Free

0 =

1 =

20 20 = 2,0 °C

0 =

1 =

2 =

0 =

1 =

300 =

300 =

300 =

300 =

50 =

0,5 VDC = 1 m A (0,5 %)

100 =

1,0 VDC = 2 mA (10 %)

150 =

1,5 VDC = 3 mA (15 %)

200 =

2,0 VDC = 4 m A (20 %)

300 =

300 =

300 =

300 =

50 =

0,5 VDC = 1 m A (0,5 %)

100 =

1,0 VDC = 2 mA (10 %)

150 =

1,5 VDC = 3 mA (15 %)

200 =

2,0 VDC = 4 m A (20 %)

Differential pressure and

Start user calibration

Reset factory calibration

3,0 VDC ( 30 %)

6 mA (30 %)

3,0 VDC ( 30 %)

6 mA (30 %)

3,0 VDC ( 30 %)

6 mA (30 %)

3,0 VDC ( 30 %)

6 mA (30 %)

19.200

38.400

57.600

Standalone mode

Modbus mode

Disabled

Enabled

temperature

Not in use

Stand-by

Not in use

9.600

8N1

8E1

8O1

In use

In use

2

2

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 29 - 33

www.sentera.eu

back to the table of contents

Page 30

MULTIFUNCTIONAL LOGIC

MC S -1- LC D

HOLDING REGISTERS

Data type Description Data Default Values

27

28

29 Analogue inpu t type (Ai1) unsigned int.

32 Minimum control range (Ai1) signed int. Minimum control range value for Ai1 0—1.000 0 300 = 3,0 VDC = 6,0 mA (3 0 %)

33 Maximum control range (Ai1) signed int. Maximum control range value for Ai1 0—1.000 1.000 1.000 = 10,0 VDC = 20,0 mA (100 %)

34

35

36

37 Reserved , retu rns 0

38 Analogue input t ype (Ai2 ) unsigned int.

41 Minimum control range (Ai2) signed int. Minimum control range value for Ai2 0—1.000 0 300 = 3,0 VDC = 6,0 mA ( 30 %)

42 Maximum control range (Ai2) signed int. Maximum control range value for Ai2 0—1.000 1.000 1.000 = 10,0 VDC = 20, 0 mA (100 %)

43

44

45

46 Reser ved, retur ns 0

47 Digital input function (Di1) unsigned int.

48 Digital input ac tive state (D i1) unsigned int. S elec ts active sta te for digital inp ut Di1 0—1 0

49 Digital input function (Di2) unsigned int.

50

51 Digital input func tion (Di3) unsigned int.

52

53 Digital input function (Di4) unsigned int.

54

Hysteresis for temperature

inpu t (T2)

Calibration of temperature

inpu t (T2)

Off lev el for analogue inpu t

(Ai1)

Setpoint for analogue input

(Ai1)

Hysteresis for analogue input

(Ai1)

Off lev el for analogue inpu t

(Ai2)

Setpoint for analogue input

(Ai2)

Hysteresis for analogue input

(Ai2)

Digi tal inp ut ac tive s tate

(Di2)

Digi tal inp ut ac tive s tate

(Di3)

Digi tal inp ut ac tive s tate

(Di4)

signed int.

unsigned int.

signed int. O ff level f or analogue input A i1 0—950 0 300 = 3,0 V DC = 6,0 mA (30 %)

signed int.

signed int.

signed int. O ff level f or analogue input A i2 0—950 0 300 = 3,0 V DC = 6,0 mA (30 %)

signed int.

signed int.

unsigned int. Sele cts a cti ve state for digit al inpu t Di2 0 —1 0

unsigned int. Sele cts a cti ve state for digit al inpu t Di3 0 —1 0

unsigned int. Sele cts a cti ve state for digit al inpu t Di4 0 —1 0

CONTROLLER

Hysteres is for temper atur e input T2.

Used only i f assigne d to controlled

analogue output.

Star t or reset factor y cal ibra tion o f

temperature input T2

Disables or selects the analogue input

typ e for Ai1

Set point fo r analogue i nput Ai1. Used only

if assigned to controlled analogue output,

PID or relay output.

Hysteres is for analogue input Ai1. Used

only if assigned to controlled analogue

output.

Disables or selects the analogue input

typ e for Ai2

Setpoint f or analogue in put Ai2. Used

only if assigned to controlled analogue

output, PID or relay output.

Hysteres is for analogue input Ai2. Used

only if assigned to controlled analogue

output.

Disables or selects a digital input function

for Di1

Disables or selec ts a digital input

function for Di2

Disables or selec ts a digital input

function for Di3

Disables or selec ts a digital input

function for Di4

5, 10, 15, 20,

25, 30

0—2 0

0—5 1

200—1.000 500 500 = 5,0 V DC = 10,0 mA (50 %)

50, 100, 150, 200 10 0 100 = 1,0 VDC = 2,0 mA (10 %)

0—5 1

200—1.000 500 500 = 5,0 V DC = 10,0 mA (50 %)

50, 100, 150, 200 10 0 100 = 1,0 VDC = 2,0 mA (10 %)

0—7 0

0—7 0

0—7 0

0—7 0

20 20 = 2,0 °C

0 =

1 =

2 =

0 =

1 =

2 =

3 =

4 =

5 =

0 =

1 =

2 =

3 =

4 =

5 =

0 =

1 =

2 =

3 =

4 =

5 =

6 =

7 =

0 =

1 =

0 =

1 =

2 =

3 =

4 =

5 =

6 =

7 =

0 =

1 =

0 =

1 =

2 =

3 =

4 =

5 =

6 =

7 =

0 =

1 =

0 =

1 =

2 =

3 =

4 =

5 =

6 =

7 =

0 =

1 =

Start user calibration

Reset factory calibration

Maximum output for Ao1

Maximum output for Ao2

Maximum output for Ao1

Maximum output for Ao2

Mode selection Ao2

Maximum output for Ao1

Mode selection Ao1

Maximum output for Ao2

Mode selection Ao2

Maximum output for Ao1

Mode selection Ao1

Maximum output for Ao2

Mode selection Ao2

Stand-by

Not in use

0—10 VDC

2—10 VD C

0— 20 mA

4—20 m A

Not in use

0—10 VDC

2—10 VD C

0— 20 mA

4—20 m A

Not in use

Remote off for Ao1

Mode selection Ao1

Remote off for Ao2

Mode selection Ao2

Relay control

Not in use

Remote off for Ao1

Mode selection Ao1

Remote off for Ao2

Relay control

Not in use

Remote off for Ao1

Remote off for Ao2

Relay control

Not in use

Remote off for Ao1

Remote off for Ao2

Relay control

PWM

PWM

High

Low

High

Low

High

Low

High

Low

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 30 - 33

www.sentera.eu

back to the table of contents

Page 31

MC S -1- LC D

HOLDING REGISTERS

Data type Description Data Default Values

55 Ana logue o utpu t typ e (Ao1) unsigned int.

56

57 Analogue outpu t mode ( Ao1) unsigned int.

58

59

60

61

62

63 K p valu e (Ao1) unsigned int.

64 Ti v alue (Ao1) unsigned int.

65 Td value ( Ao1) unsigned int.

66

67 Unbalanced coefficient (Ao2) signed int.

68 Analogue output ty pe (Ao 2) unsigned int.

69

70 Analogue ou tput mode (A o2) unsigned int.

78 Td value (A o2) unsigned int.

71

72

73

Analogue output function

(A o1)

Minimum value of the

analo gue output ( Ao1)

Maximum val ue of th e

analo gue output ( Ao1)

Assi gn normal input to

analo gue output ( Ao1)

Assi gn high p rior ity input to

analo gue output ( Ao1)

Time t o maximum output

(A o1)

Anal ogue ou tput (Ao2)

relation to

(A o1)

Analogue output function

(Ao2)

Minimum value of the

analo gue output ( Ao2)

Maximum val ue of th e

analo gue output ( Ao2)

Assi gn normal input to

analo gue output ( Ao2)

unsigned int. Set s the ou tput f unction for Ao1 0—2 0

unsigned int.

unsigned int.

unsigned int.

unsigned int.

unsigned int.

unsigned int.

unsigned int.

unsigned int.

unsigned int.

unsigned int.

MULTIFUNCTIONAL LOGIC

CONTROLLER

Disables or selec ts the a nalog ue out put

typ e for Ao1

Analogue output mode: Cool

(0—10 VDC ) / Heat (10—0 VD C)

Minimum value of the analogue output

Ao1, calculated from the control range

of the n ormally assigned input, in

percentages

Maximum value of the analogue output

Ao1, calculated from the control range

of the n ormally assigned input, in

percentages

Assigns normal analogue or temperature

inpu t to analogue ou tput A o1

Assigns high priority analogue or

temperature input to analogue output

Ao1. Active only if controlled output is

selected.

Time f or the o utpu t to ris e to maximum

value. Active only if control function is

selected.

Proportional gain value for Ao1.

Active only if a PID functi on is selected.

Integrat ion per iod value for Ao1.

Active only if a PID functi on is selected.

Deri vative pe riod v alue for Ao1.

Active only if a PID functi on is selected.

Sets the relation between analogue

output Ao1 and analogu e outp ut Ao2

Difference between analogue output Ao1

and analogue output Ao2 in percents.

Active only in unbalanced mode.

Disables or selec ts the a nalog ue out put

typ e for Ao2

Sets the output f unction for Ao2. Active

only if not in relation.

Anal ogue outp ut mode: Coo l (0—10 VDC)

/ Heat (10—0 VDC )

Deri vative pe riod v alue for Ao2.

Active only if a PID functi on is selected.

Minimum value of the analogue output

Ao2, calculated from the control range

of the n ormally assigned input, in

percentages

Maximum value of the analogue output

Ao2, calculated from the control range

of the n ormally assigned input, in

percentages

Assigns normal analogue or temperature

inpu t to analogue ou tput A o2. Active

only if not in relation.

0 =

1 =

0—5 1

0—1 0

0—40 0

60—100 100

0—3 0

0—3 2

0—10 0 s 60 s 60 = 60 s

1—1.000 10 10 = 1,0 gain

1—6.000 10 0

0—6.000 10

0—2 0

-200—200 0 200 = 20 %

0—5 1

0—2 0

0—1 0

0—6.000 10

0—40 0

60—100 100

0—3 0

2 =

3 =

4 =

5 =

0 =

1 =

2 =

0 =

1 =

0 =

40 =

60 =

100 =

0 =

1 =

2 =

3 =

0 =

1 =

2 =

3 =

1 =

100 =

0 =

10 =

0 =

1 =

2 =

0 =

1 =

2 =

3 =

4 =

5 =

0 =

1 =

2 =

0 =

1 =

0 =

10 =

0 =

40 =

60 =

100 =

0 =

1 =

2 =

3 =

0—10 VDC (2—10 VDC )

0—20 mA (4—20 mA)

10—0 VDC (10—2 VDC )

20—0 mA (20 —4 mA)

Free (without relation)

0—10 VDC (2—10 VDC )

0—20 mA (4—20 mA)

10—0 VDC (10—2 VDC )

20—0 mA (20 —4 mA)

Not in use

0—10 VDC

2—10 VD C

0—20 m A

4—20 m A

PWM

Linear

Control

PID

Cool

0—10 0 %

Heat

100 —0 %

0 %

40 %

60 %

100 %

Ai1

Ai2

Ai1

Ai2

0,1 s

10 s

0 s

1 s

Balanced

Unbalanced

Not in use

0—10 VDC

2—10 VD C

0—20 m A

4—20 m A

PWM

Linear

Control

PID

Cool

0—10 0 %

Heat

100 —0 %

0 s

1 s

0 %

40 %

60 %

100 %

Ai1

Ai2

T1

T2

T1

T2

T1

T2

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 31 - 33

www.sentera.eu

back to the table of contents

Page 32

MULTIFUNCTIONAL LOGIC

MC S -1- LC D

HOLDING REGISTERS

Data type Description Data Default Values

74

75

76 Kp va lue (Ao2) unsigned int.

77 T i value (Ao2) unsigned int.

78 Td value (A o2) unsigned int.

79 A ssigned input to relay 1 unsigned int.

80 A ssign ed input to relay 2 unsigned int.

81 Hour unsigned int. Current hour 0—23

82 Minutes unsigned int. Current minutes 0—59

83 Seconds unsigned int. Current seconds 0—59

84 Date unsigned int. Current date and month 1—31

85 Month unsigned int. Current month 1—12

86 Ye ar unsigned int. Current year 2000—2099

87 Day of w eek unsigned int. C urre nt day of the wee k 0—6

88 Day of year unsigned int. Current day of yea r 1—366

89 Autotune (Ao1) unsigned int.

90 Autotune (Ao2) unsigned int.

91

92

93 -100 Reserved , retu rns 0

If you w ant to find out more abou t Modbus over serial l ine, ple ase visit: http://www.modbus.org/docs/Modbus_over_serial_line_V1_02.pdf

Assi gn high p rior ity input to

analo gue output ( Ao2)

Time t o maximum output

(Ao2)

Analogue output override

va lu e ( Ao1 )

Analogue output override

value (Ao2)

unsigned int.

unsigned int.

signed int.

signed int.

CONTROLLER

Assigns high priority analogue or

temperature input to analogue output

Ao2. Active only if not in relation and

controlled output is selected.

Time f or the o utpu t to ris e to maximum

value. Active only if control function is

selected.

Proportional gain value for Ao2.

Active only if a PID functi on is selected.

Integrat ion per iod value for Ao2.

Active only if a PID functi on is selected.

Deri vative pe riod v alue for Ao2.

Active only if a PID functi on is selected.

Assigns a relation to analogue or digital

inpu t of relay 1

Assign relation to analogue or digital

inpu t of relay 2

Star ts au totune in PID co ntro l for

analo gue output Ao1

Star ts au totune in PID co ntro l for

analo gue output Ao2

Over ride v alue for analogue ou tput

Ao1. Active only if holding registers 7

and 8 are set to 1.

Over ride v alue for analogue ou tput

Ao2. Active on ly if holding registers 7

and 8 are set to 1.

0—3 2

0—10 0 s 60 s 60 = 60 s

1—1.000 10 10 = 1,0 gain

1—6.000 10 0

0—6.000 10

0—8 0

0—8 0

0—1 0

0—1 0

0—1.000 0

0—1.000 0

100 =

10 =

1.000 =

1.000 =

0 =

1 =

2 =

3 =

1 =

0 =

0 =

1 =

2 =

3 =

4 =

5 =

6 =

7 =

8 =

0 =

1 =

2 =

3 =

4 =

5 =

6 =

7 =

8 =

0 =

1 =

2 =

3 =

4 =

5 =

6 =

0 =

In progress (start autotune)

1 =

0 =

In progress (start autotune)

1 =

0 =

0 =

T1

T2

Ai1

Ai2

0,1 s

10 s

0 s

1 s

Not in use

Di1

Di2

Di3

Di4

T1

T2

Ai1

Ai2

Not in use

Di1

Di2

Di3

Di4

T1

T2

Ai1

Ai2

Sunday

Monday

Tuesday

Wednesday

ursday

Friday

Saturday

Stop

Stop

0 VDC

10,0 0 VDC

0 VDC

10,0 0 VDC

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 32 - 33

www.sentera.eu

back to the table of contents

Page 33

MULTIFUNCTIONAL LOGIC

MC S -1- LC D

CONTROLLER

TRANSPORT AND STOCK KEEPING INFORMATION

Avoid shocks and extreme conditions; stock in original packing.

WARRANTY INFORMATION AND RESTRICTIONS

Two years from the deliver y date agains t defects in manu factur ing. Any modifications

or alterations to the product after the date of publication relieve the manufacturer

of any responsibilities. e manufacturer bears no responsibility for any misprints or

mistakes in this data.

MAINTENANCE

In normal conditions this product is maintenance-free. If soiled, clean with a dry or

dampish cloth. In case of heavy pollution, clean with a non-aggressive product. In

these circumstances the unit should be disconnected from the supply. Pay attention

that no fluids enter the unit. Only reconnect it to the supply when it is completelydr y.

MIW- MC S -1-LCD- E N - 00 0 - 20 / 07 / 2016 33 - 33

back to the table of contents

www.sentera.eu

Loading...

Loading...