Sentera Controls EVSS1, EVSS Series, EVSS1 Series, EVSS-1-15-DM, EVSS-1-60-DM Mounting And Operating Instructions

...

ELECTRONIC FAN

SPEED CONTROLLER

EVSS

Mounting and operating instructions

WITH TK

ELECTRONIC FAN SPEED

EVSS

CONTROLLER WITH TK

Table of contents

SAFETY AND PRECAUTIONS 3

PRODUCT DESCRIPTION 4

ARTICLE CODES 4

INTENDED AREA OF USE 4

TECHNICAL DATA 4

STANDARDS 5

WIRING AND CONNECTIONS 5

OPERATIONAL DIAGRAMS 6

MOUNTING INSTRUCTIONS IN STEPS 8

VERIFICATION OF INSTALLATION INSTRUCTIONS 10

OPERATING INSTRUCTIONS 11

MODBUS REGISTER MAPS 12

TRANSPORT AND STORAGE 16

WARRANTY AND RESTRICTIONS 16

MAINTENANCE 16

MIW-EVSS-DM-EN-000 - 18 / 12 / 2018 2 - 16

www.sentera.eu

ELECTRONIC FAN SPEED

EVSS

CONTROLLER WITH TK

SAFETY AND PRECAUTIONS

Read all the information, the datasheet, mounting and operating instructions and

study the wiring and connection diagram before working with the product. For

personal and equipment safety, and for optimum product performance, make sure you

entirely understand the contents before installing, using, or maintaining this product.

For saf ety and li censing (CE ) reasons , unauthor ised conver sion and/ or modifi cations

of the product are inadmissible.

e product should not be exposed to abnormal conditions, such as: extreme

temperatures, direct sunlight or vibrations. Long-term exposure to chemical

vapours in high concentration can affect the product performance. Make sure the

work environment is as dry as possible; avoid condensation.

All installations shall comply with local health and safety regulations and local

electrical standards and approved codes. is product can only be installed by an

engineer or a technician who has expert knowledge of the product and safety

precautions.

Avoid contacts with energised electrical parts. Always disconnect the power

supply before connecting, servicing or repairing the product.

Always verify that you apply appropriate power supply to the product and use

appropriate wire size and characteristics. Make sure that all the screws and nuts

are well tightened and fuses (if any) are fitted well.

Recycling of equipment and packaging should be taken into consideration and these

should be disposed of in accordance with local and national legislation/regulations.

In case there are any questions that are not answered, please contact our technical

support or consult a professional.

MIW-EVSS-DM-EN-000 - 18 / 12 / 2018 3 - 16

www.sentera.eu

back to the table of contents

ELECTRONIC FAN SPEED

EVSS

CONTROLLER WITH TK

PRODUCT DESCRIPTION

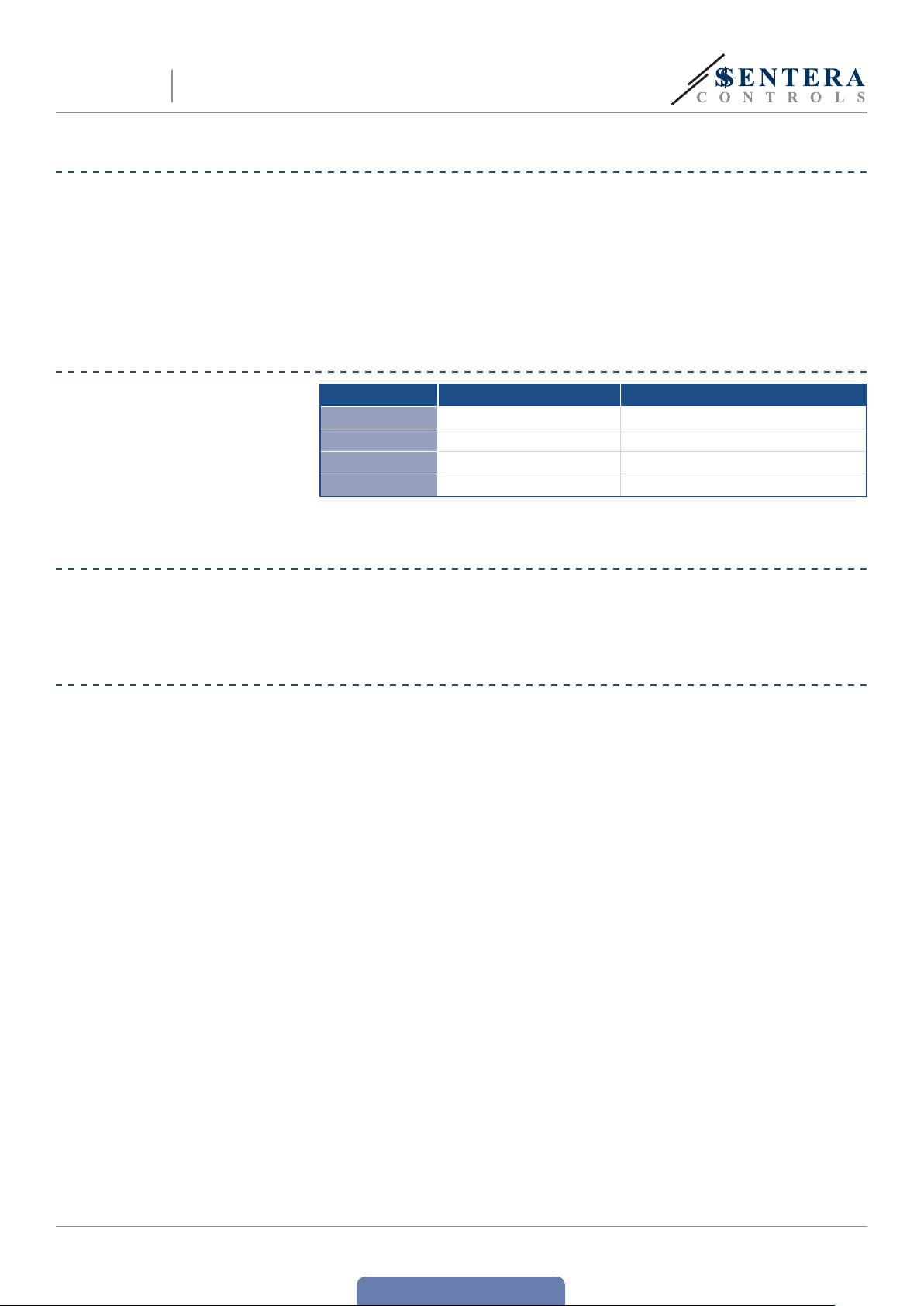

ARTICLE CODES

e EVSS1 is an electronic speed controller which controls the speed of singlephase (230 VAC /50—60 Hz) voltage controllable electric motors. It is equipped

with Modbus RTU (RS485) communication, an alarm relay output and thermal

contacts to provide overheating protection of motors with cut-out contacts. e

EVSS controller provides a wide range of functionalities: remote control options,

adjustable off level, min. and max. output voltage settings, and time-limited motor

operation initiated by a logic or switch signal.

Code Nominal current, [A] Fuse rating, [A]

EVSS -1-15 -DM 1,5 (5*20 mm) F 3,15 A H 250 VAC

EVSS -1-30 -DM 3,0 (5*20 mm) F 5,0 A H 250 VAC

EVSS -1- 60-DM 6,0 (5*20 mm) F 10,0 A H 250 VAC

E V SS -1100-DM 10,0 (6,3*32 mm) F 16,0 A H 250 VAC

INTENDED AREA OF USE

TECHNICAL DATA

■

Fan speed control in ventilation systems

■

For indoor use only

■

Power supply: 230 VAC ±10 %-50—60 Hz

■

Analog input:

►

voltage: 0—10 VDC/10—0 VDC

►

current: 0—20 mA/20—0 mA

■

Analog input modes: ascending or descending

■

Analog input functionality: Normal mode / Logic mode

■

Remote control input: normal or timer functionality

■

Regulated output: 30—100 % Us

■

Max. output load: depends on the version

■

Unregulated output, L1: 230 VAC (50/60 Hz)/max. 2 A

■

Alarm output (230 VAC / 1 A)

■

Min. output voltage setting, Umin: 30—70 % Us (69—161 VAC), selectable by

trimmer or via Modbus

■

Max. output voltage setting, Umax: 75—100 % Us (175—230 VAC), selectable by

trimmer or via Modbus

■

Off level, adjustable by trimmer or via Modbus:

►

0—4 VDC/0—8 mA for ascending mode

►

10—6 VDC/20—12 mA for descending mode

■

Kick start or soft start

■

Low voltage supply output: +12 VDC/1 mA for external potentiometer

■

Modbus communication

■

Operating indication:

►

continuous green: normal operation

►

blinking green: stand-by

■

Overvoltage and overcurrent protection

■

ermal inputs for motor overheating protection

MIW-EVSS-DM-EN-000 - 18 / 12 / 2018 4 - 16

back to the table of contents

www.sentera.eu

ELECTRONIC FAN SPEED

EVSS

CONTROLLER WITH TK

■

Motor overheating indication

■

Enclosure: plastic R-ABS, UL94-V0; grey colour (R AL 7035)

■

Protection standard: IP54 (according to EN 60529)

■

Operating ambient conditions:

►

►

■

Storage temperature: -40—50 °C

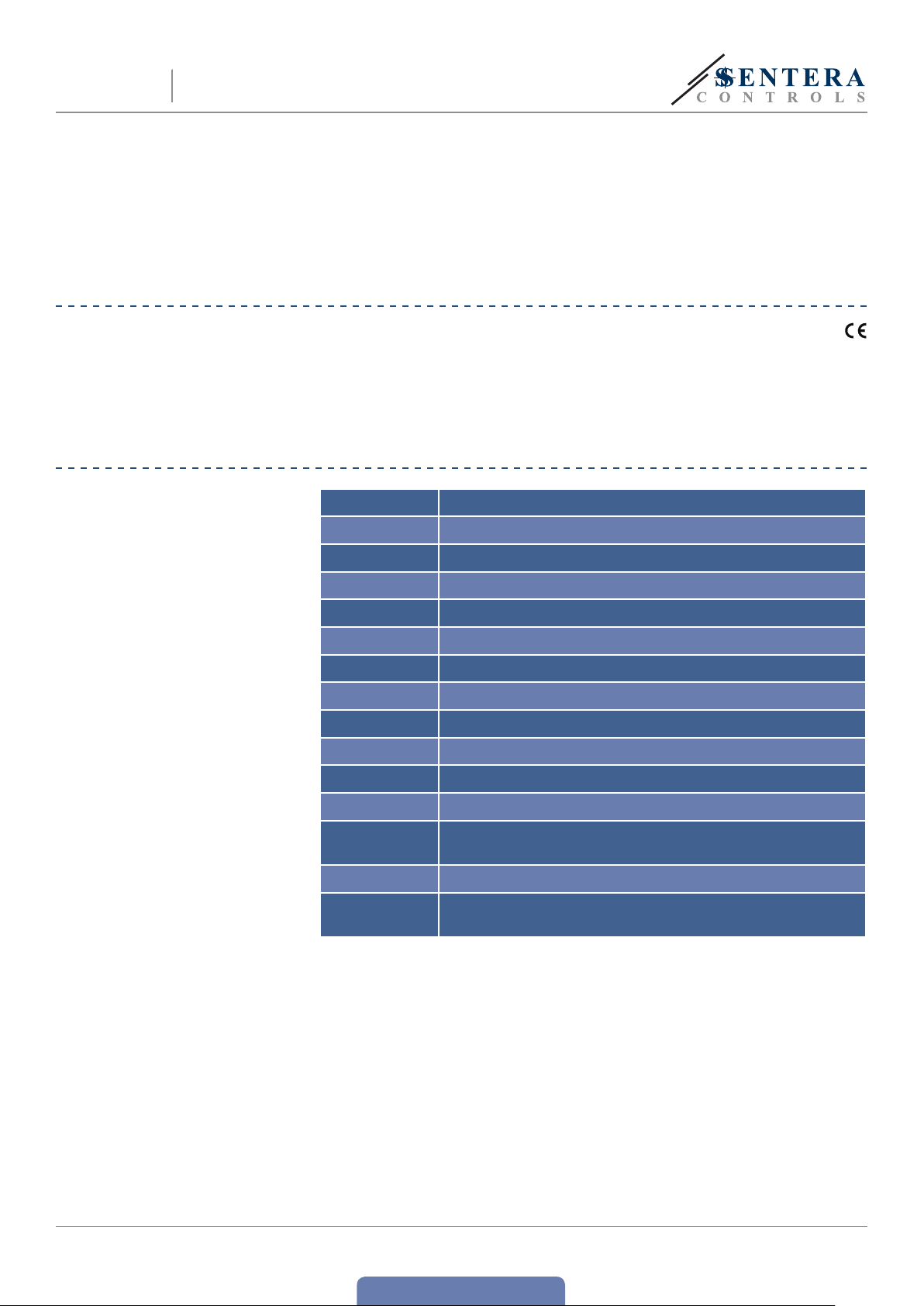

STANDARDS

■

Low Voltage Directive 2006/95/EC

■

EMC Directive 2004/108/EC: EN 61326

■

WEE E Di rective 2012/19/EU

■

RoHs Directive 2011/65/EU

WIRING AND CONNECTIONS

L Supply voltage 230 VAC ±10 % / 50—60 Hz

temperature: -20—40 °C

rel. humidity: < 95 % rH (non-condensing)

N Neutral

PE Earth terminal

L1 Unregulated output (230 VAC/max. 2 A)

U1, U2 Regulated output to the motor

TK, TK ermal contact

N Neutral

AL Alarm output (230 VAC / 1 A)

SW Remote control switch

A Modbus RTU (RS485) signal A

/B Modbus RTU (RS485) signal /B

+V Supply output +12 VDC/1 mA

Ai

GND Ground

Connections

Analog input (0—10 VDC/0—20 mA) or

(10—0 VDC/20—0 mA)

Cable cross section: max. 2,5 mm

Cable gland clamping range: 3—6 mm/ 5—10 mm

2

MIW-EVSS-DM-EN-000 - 18 / 12 / 2018 5 - 16

back to the table of contents

www.sentera.eu

[%]

[VDC]/[mA]

[%]

[VDC]/[mA]

Uout=Umin+

Aimax

Ai

(Umax-Umin)

Uout=Umax-

Aimax

Ai

(Umax-Umin)

/

U,

Uout=Umax+

Aimax-Off level

Ai-Off level

(Umax-Umin)

Uout=Umax-

Aimax-Off level

Ai-Off level

(Umax-Umin)

t [s]

Umax

Umin

0

Uout, [%]

100

75

70

30

10 VDC /

20 mA

Ai,

[VDC]/

[mA]

t [s]

Umax

Umin

Uout, [%]

100

75

70

30

10 VDC /

20 mA

0 VDC /

0 mA

Ai,

[VDC]/

[mA]

ELECTRONIC FAN SPEED

EVSS

CONTROLLER WITH TK

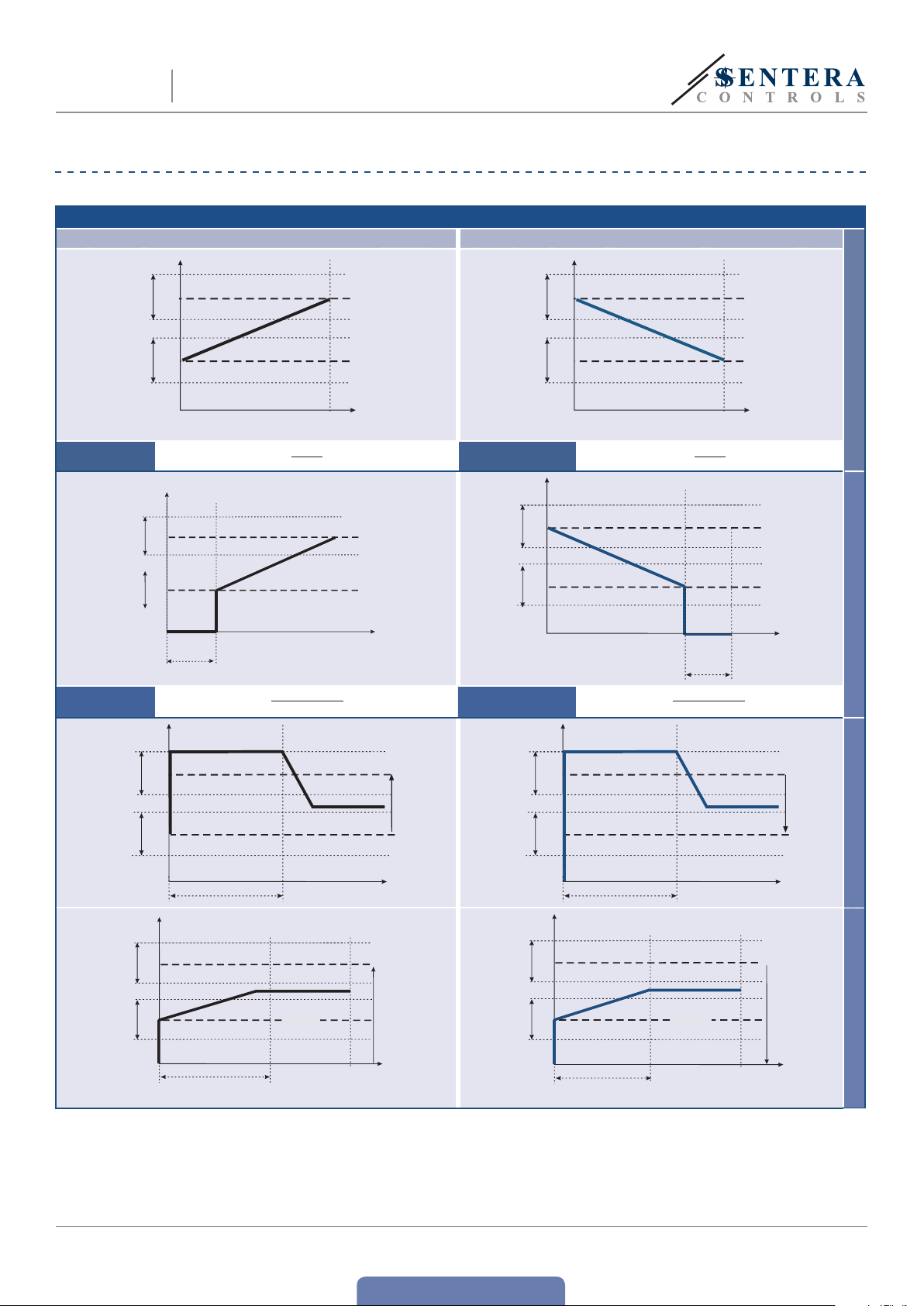

OPERATIONAL DIAGRAMS

Normal / Remote operating modes

Ascending input mode Descending input mode

U

out

100

Umax

range

Umin

range

Ascending mode

calculation formula

,

Umax

75

70

Umin

30

0

10 VDC

20 mA

Ai ,

Descending mode

calculation formula

U

Umax

range

Umin

range

out

100

,

Umax

75

70

Umin

30

0

10 VDC

20 mA

Ai ,

Off level disabled

100

Umax

range

75

70

Umin

range

30

Ascending mode

calculation formula

Uout, [%]

100

Umax

range

75

70

Umin

range

30

[%]out

Umax

Umin

Umax

Umin

0

0

Off level

range

Kick start time

Off level

4 VDC

8 mA

10 VDC

,Ai

20 mA

[VDC]

[mA]

Ai,10 VDC / 20 mA

0 VDC / 0 mA

t, [s]

U, [%]out

100

Umax

Umax

range

75

70

Umin

Umin

range

30

Descending mode

calculation formula

Uout, [%]

100

Umax

range

75

70

Umin

range

30

Umax

Umin

10 VDC

20 mA

0

Kick start time

Off level

6 VDC

12 mA

Off level range

0

[VDC] /

[mA]

0 VDC / 0 mA

Ai,10 VDC / 20 mA

t, [s]

,Ai

Off level enabled

Kick start enabled

Umax

range

Umin

range

Soft start time

MIW-EVSS-DM-EN-000 - 18 / 12 / 2018 6 - 16

Off level

www.sentera.eu

back to the table of contents

Umax

range

Umin

range

Off level

Soft start time

Soft start enabled

t [s]

Umax

Umin

0

Uout, [%]

100

75

70

30

10 VDC /

20 mA

Ai,

[VDC]/

[mA]

t [s]

Umax

Umin

Uout, [%]

100

75

70

30

10 VDC /

20 mA

0 VDC /

0 mA

Ai,

[VDC]/

[mA]

U

SW

Ai >2,4 VDC

ELECTRONIC FAN SPEED

EVSS

Ascending input mode Descending input mode

CONTROLLER WITH TK

Umax

range

Umin

range

100

Umax

range

Umin

range

75

70

30

Uout, [%]

Umax

Umin

0

Soft start time

Kick start time

Off level

Ai,10 VDC / 20 mA

0 VDC / 0 mA

t, [s]

Umax

range

Umin

range

100

Umax

range

Umin

range

Uout, [%]

75

70

30

Timer mode Logic mode

Remote

Switch,

[VDC]

5 VDC

2,5 VDC

Voltage

amplitude

range

out, [%]

100

Off level

Soft start & off level

Soft start time

Umax

Umin

0

Kick start time

75

0 VDC / 0 mA

Ai,10 VDC / 20 mA

t, [s]

Umax

range

Kick start & off level

0

Stand-by Operate

t, [s]

Switch control signal

0

Kick start time Operation timer

Controller is off

t [s]

Soft start enabled

ONON

OFF OFF

Soft

start

Timer

Output

Umax

Start

Holding

register

18

Soft start

duration

Operation time

Holding

register

21

Operation

timer

Holding

register

18

Soft start

duration

MIW-EVSS-DM-EN-000 - 18 / 12 / 2018 7 - 16

t

t

t

t

StopStartStop

Switch control signal

Output

www.sentera.eu

back to the table of contents

ON ON

Soft

start

Timer

Umax

Start

OFF OFF

Holding

register

18

Holding

register

21

Soft start

Operation

duration

timer

Start

Holding

register

18

Soft start

duration

Holding

register

Operation

timer

t

t

t

21

t

Stop

Kick start enabled

Ai control signal

4x

92

VR3

O

level

adj

Min.

speed

adj

Max.

speed

adj

ON

0 - 10v / 10 - 0v

0 - 10v / 0 - 20 mA

O level

NBT

Kickstart

1234

VR2VR1

1

ELECTRONIC FAN SPEED

EVSS

CONTROLLER WITH TK

MOUNTING INSTRUCTIONS IN STEPS

Before you start mounting the EVSS controller read carefully “Safety and

Precautions”. Choose a smooth surface for an installation location (a wall,

panel and etc.).

Follow these steps:

1. Switch off the power supply.

2. Open the enclosure cover and fix the unit to the wall or panel using the provided

dowels and screws. Mind the correct mounting position and unit dimensions.

(See Fig. 1 Mounting position and Fig. 2 Mounting dimensions.)

Fig. 1 Mounting dimensions Fig. 2 Mounting position

Correct Incorrect

124

4,50

102

205

Fig. 3 Wiring and connections

140

3. Connect the motor/fan.

4. e unregulated output (L1, N) can be used to connect a light indicator or to

control a damper actuator, a valve, etc. (if necessary). See Fig. 3.

Analog input

Power supply

230 VAC , 50—60 Hz

Unregulated output

230 VAC / max . 2 A.

MIW-EVSS-DM-EN-000 - 18 / 12 / 2018 8 - 16

v

220 / 240 VAC / 1 A

ermal

contact

Remot e contr ol switch

www.sentera.eu

Alarm output

Modbus RTU

Supply output

+12 VDC / 1 mA

0—10 VDC / 0—20 mA

back to the table of contents

ON

0 - 10v / 10 - 0v

0 - 10v / 0 - 20 mA

O level

Kickstart

1234

RX

EVSS

ELECTRONIC FAN SPEED

CONTROLLER WITH TK

5. Select the required analog input type and mode, start mode and OFF level

mode by the DIP switch on the board. (See Fig. 4 DIP switch settings.)

Fig. 4 DIP switch settings

6. e Network Bus Terminator (NBT ) is used to set the device as an end device

and by default the NBT is disconnected. It is put manually onto the pins to

be connected (see Fig. 5). To assure correct communication, the NBT jumper

needs to be activated in only two devices on the Modbus RTU network (see

Example 1 and Example 2).

Example 1 Example 2

Slave 1

RX

NBT

NBT

Slave 2

Master

ТX

NBT

Slave n

Master

Ascending/descending

mode selection

(DIP s witc h, position 1)

OFF level selection

(DIP s witc h, position 2)

Kick star t / soft star t

selection

(DIP s witc h, position 3)

Input mode selection

(DIP s witc h, position 4)

NBT

Slave 1

Slave 2

ТX

Slave n

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

NBT

ON - Descending mode:

10—0 VDC/20—0 mA

OFF - Ascending mode:

0—10 VDC/0—20 mA

ON - enab led

OFF - disabled

ON - Kic k star t

OFF - So ft start

ON - Current mode

(0—20 mA)

OFF - Voltage mode

(0 —10 VD C)

Fig. 5 Network bus

resistor jumper

ATTENTION

ATTENTION

On a Modbus RTU network, two bus terminators (NBTs) need to be activated

If an AC power supply is used with any of the units in a Modbus network, the

GND terminal should NOT BE CONNECTED to other units on the network or

via the CNVT‑USB‑RS485 converter. is may cause permanent damage to the

communication semiconductors and/or the computer!

7. Connect the power supply cable.

8. Adjust the max. speed by trimmer (if necessary). e default setting is Us

(230 VAC). See Fig. 6 Max. speed trimmer.

9. Adjust the min. speed by trimmer (if necessary). e default setting is 30 % Us

(69 VAC). See Fig. 7 Min. speed trimmer.

10. Adjust the OFF level value by trimmer (if necessary). e default setting is

0 VAC. See Fig. 8 Off level trimmer.

MIW-EVSS-DM-EN-000 - 18 / 12 / 2018 9 - 16

www.sentera.eu

back to the table of contents

VR3

O

level

Min.

speed

Max.

speed

VR2VR1

VR3

O

level

Min.

speed

Max.

speed

VR2VR1

VR3

O

level

Min.

speed

Max.

speed

VR2VR1

ELECTRONIC FAN SPEED

EVSS

Fig. 6 Max. speedtrimmer Fig. 7 Min. speed trimmer Fig. 8 Off leveltrimmer

CONTROLLER WITH TK

11. Close the enclosure and fix the cover.

12. Switch on the power supply.

13. Customise the factory settings to the desired ones, through 3SModbus

software (if necessar y). For the default factory settings see Table Modbus

register maps.

VERIFICATION OF INSTALLATION INSTRUCTIONS

Follow the instructions below:

1. Switch on the mains supply.

2. Set the NBT jumper, DIP switch, Max. trimmer, Min. trimmer and OFF level

trimmer to desired positions / values. e factory settings are as follows:

►

NBT jumper is open (Network bus termination resistor is disconnected)

►

Ascending mode: 0—10 VDC / 0—20 mA

►

Off level - OFF

►

Kick start disabled

►

Input voltage mode (0—10 VDC)

►

Min. setting of the Min. speed trimmer

►

Max. setting of the Max. speed trimmer

►

Min. setting of the Off level trimmer

3. Set the analog input signal to the maximum value of 10 VDC or 20 mA.

4. e connected motor will run at maximum speed or minimum speed depending

on the analog input mode (ascending / descending).

5. If OFF level is enabled and descending analog input mode is selected, the motor

will stop running.

6. Set the analog input signal to the maximum value of 0 VDC or 0 mA.

7. e connected fan will run at minimum speed or maximum speed depending on

the analog input mode (ascending / descending).

8. If OFF level is enabled and ascending analog input mode is selected, the motor

will stop running.

9. If OFF level is enabled and the input signal is equal to the value of the OFF level,

the speed of the motor will be the minimum speed in ascending mode or the

maximum speed in descending mode.

10. If the controller does not work according to the instructions above, the wiring

connec tions and settings need to be checked.

11. Check if both LEDs (Fig. 9) blink after you switch on your unit. If they do, your

unit has detected Modbus network. If they do not, check the connections again.

Fig. 9 Communication detection indication

MIW-EVSS-DM-EN-000 - 18 / 12 / 2018 10 - 16

back to the table of contents

www.sentera.eu

EVSS

ELECTRONIC FAN SPEED

CONTROLLER WITH TK

ATTENTION

e status of the LEDs can be checked only when the unit is energised. Take the

relevant safety measures!

OPERATING INSTRUCTIONS

OPERATION MODES

In Modbus mode you control the parameters: Umax, Umin, Kick star t / Soft start,

Off level enable / disable and Off level value through Modbus registers.

In Standalone mode you control the parameters: Umax, Umin, Kick start / Soft start,

Off level enable / disable and Off level value by means of the hardware settings (DIP

switch, trimmers, jumpers).

In Normal mode if Off level is disabled, Softstart / Kickstart is executed only once -

after the controller is supplied; otherwise Softstart / Kickstart is executed every

time the controller is switched on.

When Timer mode is selected, the controller receives a pulse control signal from the

remote control switch. When Logic mode is selected, the controller receives a pulse

control signal from the Ai input.

In both modes Timer mode and Logic mode the pulse width is to be more than 30

ms; otherwise the signal is filtered.

FRONT PANEL LED INDIC ATION

When the green LED on the front cover (Fig. 10) gives out a continuous light, the

controller operates in normal mode. When it blinks:

►

►

e red LED on the front cover (Fig. 10) indicates overheating of the motor. When

it is on, the controller stops the motor. To restart operation after eliminating the

cause for overheating, disconnect the unit from the mains supply for a few seconds

and then connect it again.

the controller operates in remote control mode, or

OFF level is enabled and the analog input signal is below the OFF level value.

Fig. 10 Operation indication

MIW-EVSS-DM-EN-000 - 18 / 12 / 2018 11 - 16

back to the table of contents

www.sentera.eu

ELECTRONIC FAN SPEED

EVSS

CONTROLLER WITH TK

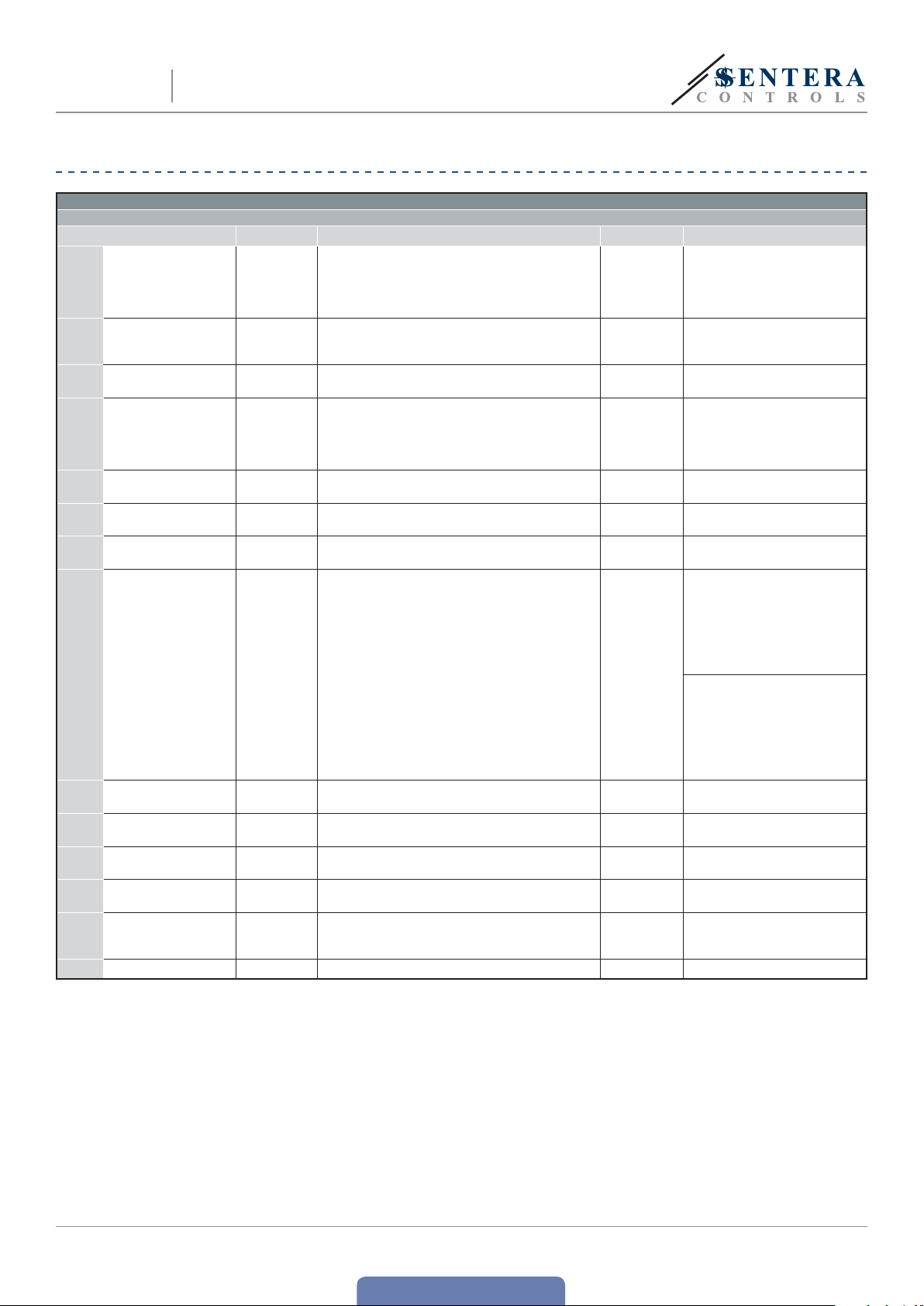

MODBUS REGISTER MAPS

INPUT REGISTERS

Data type Description Data Values

1 Analog input level unsigned int.

2 Current output voltage unsigned int. Actual output voltage

3 Analog input type unsigned int. Type of the selected analog input 0—1

4

5

6

7 Enable off level unsigned int. Enables off level 0—1

8 Off level value unsigned int.

9 Kick star t/soft star t unsigned int. Selects kick start or soft star t 0—1

10 Remote control input unsigned int. Remote control input 0—1

12 L1 c ont rol unsigned int. L1 c ont rol 0 —1

13 Alarm LED unsigned int. Alarm LED 0—1

14 ON/Stand-by LED unsigned int. ON/Stand-by LED 0—2

15-20 Reserved, retur n 0

Ascending/descending

input mode

Maximum output

voltage

Minimum output

voltage

unsigned int.

unsigned int. Maximum output voltage 75 —100

unsigned int. Minimum output voltage 30 —70

Analog input value depending on the selected analog

input type.

Ascending or descending analog input mode depending

on the selected analog input t ype.

Off level value depending on the selected analog

input type and ascending/descending analog input

mode.

0—100

30 —10 0

60 —100

0—1

0—40

MODBUS REGISTER MAPS

0 =

100 =

0 =

100 =

0 =

0

30 =

100 =

0 =

1 =

0 =

1 =

0 =

1 =

75 =

100 =

30 =

70 =

0 =

1 =

Ascending mode:

0 =

400 =

0 =

200 =

Descending mode:

100 =

60 =

100 =

60 =

0 =

1 =

0 =

1 =

0 =

1 =

0 =

1 =

0 =

1 =

2 =

0 VDC

10,0 VD C

or

0 mA

20,0 mA

0 % Us

30 % Us

100 % Us

0—20 mA

0—10 VDC

10— 0 VDC

0—10 VDC

or

20—0 mA

0—20 mA

75 % Us

100 % Us

30 % Us

70 % Us

Disabled

Enabled

Voltage

0 VDC

4,0 VDC

Current

0 mA

8,0 m A

Voltage

10,0 VD C

6,0 V DC

Current

20,0 mA

12, 0 m A

soft star t

kick start

Disabled

Enabled

Off

On

Off

On

Off

On

Stand-by

MIW-EVSS-DM-EN-000 - 18 / 12 / 2018 12 - 16

www.sentera.eu

back to the table of contents

ELECTRONIC FAN SPEED

EVSS

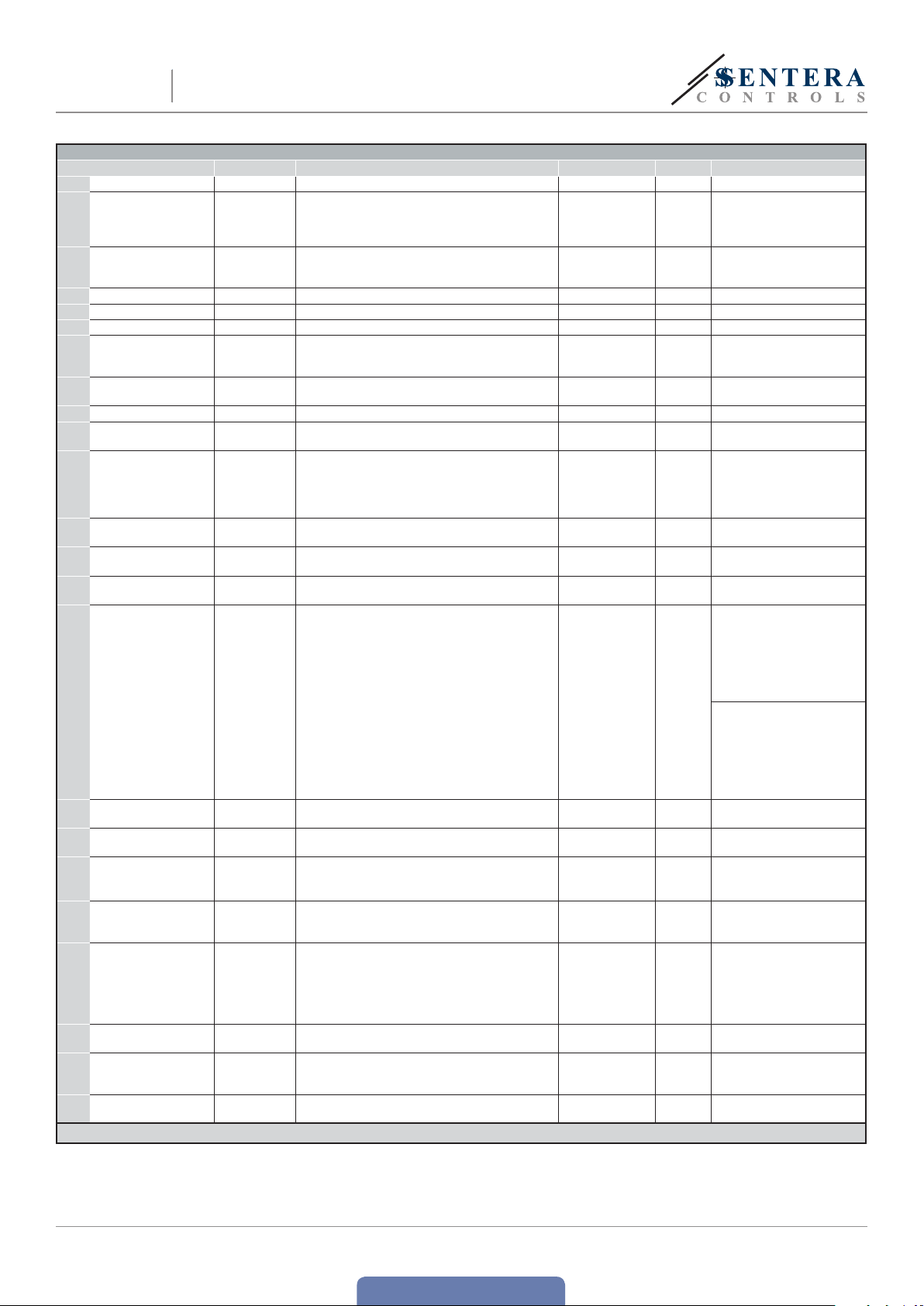

HOLDING REGISTERS

1 Device slave address unsigned int. Modbus device address 1—247 1

2 Modbus baud rate unsigned int. Modbus communication baud rate 1—4 2

3 Modbus parity unsigned int. Parity check mode 0—2 1

4 Device type unsigned int. Device type (Read only)

5 HW version unsigned int. Hardware version of the device (Read only) XXXX 0 x 0300 = HW versio n 3.00

6 FW version unsigned int. Firmware version of the device (Read only) XXXX 0 x 0140 = FW v ersion 1.40

7 Operating mode unsigned int.

8 Output override unsigned int.

9-10 Reserved, r eturn 0

11 Analog input type unsigned int.

Ascending/

12

descending analog

input mode

Maximum output

13

voltage

Minimum output

14

voltage

15 Enable off level unsigned int.

16 Off level value unsigned int.

17 Kic k star t/sof t start unsigned int.

Kick star t/soft star t

18

duration

Remote control

19

functionality

Analog input

20

functionality

21 Operation timer unsigned int.

22-

Reserved, return 0

30

31 Output override value unsigned int.

3240

If you want to find out more about Modbus over serial line, please visit: http://www.modbus.org/docs/Modbus_over_serial_line_V1_02.pdf

CONTROLLER WITH TK

Data type Description Data Default Values

EVSS-DM = 3005

unsigned int.

unsigned int.

unsigned int.

unsigned int.

unsigned int.

unsigned int.

Enables Modbus control and disables the DIP switch

and trimmers

Enables the direct control over the output. Always

settable. Active only if holding register 7 is set to 1.

Selects the analog input type of the device. Always

settable. Active only if holding register 7 is set to 1.

Ascending / descending analog input mode.

Depends on the selected analog input type. Always

settable. Active only if holding register 7 is set to 1.

Maximum settable output voltage. Always

settable. Active only if holding register 7 is set to 1.

Minimum settable output voltage. Always settable.

Active only if holding register 7 is set to 1.

Enables off level. Always set table. Active only if

holding register 7 is set to 1.

Off level value. Depends on the selected analog

input type and ascending / descending analog

input mode. Always settable. Active only if holding

register 7 is set to 1.

Selects kick start or so ft start. Always settable.

Active only if holding register 7 is set to 1.

Sets the duration time. Always settable. Active

only if holding register 7 is set to 1.

Sets the remote control input mode. Depends on

the selected kick start or soft start mode. Always

settable. Active only if holding register 7 is set to 1.

Sets the analog input functionality. Depends on the

selected kick start or soft start. Always settable.

Active only if holding register 7 is set to 1.

Sets the operation time of the device when Timer

mode by remote control input or Logic mode by

the analog input is selected. e operation time

is additional to the kick start/soft start duration

times. Always settable. Active only if holding

registers 7 and 19 or/and 20 are set to 1.

Override value for the analog output. Always

settable. Active only if holding register 8 is set to 1.

Reser ved, return 0

0—1 0

0—1 0

0—1 1

0—1 1

75 —100 100

30 —70 30

0—1 0

0—40

60 —100

0—1 1

0—60 10

0—1 0

0—1 0

0—20 0 60

0

30 —10 0

1 =

2 =

3 =

4 =

0 =

1 =

2 =

0 =

1 =

0 =

1 =

0 =

1 =

0 =

1 =

0 =

1 =

75 =

100 =

30 =

160 =

0 =

1 =

Ascending mode:

0 =

40 =

0 =

0

0

40 =

Descending mode:

100 =

60 =

100 =

60 =

0 =

1 =

0 =

60 =

0 =

1 =

0 =

1 =

0 =

200 =

0 =

30 =

100 =

19.200

38.400

57. 600

Standalone

Modbus mode

Disabled

Enabled

0—20 mA

0—10 VDC

10— 0 V DC

0—10 VDC

20—0 mA

0—20 mA

75 % Us

100 % Us

30 % Us

00 % Us

Disabled

Enabled

Voltage

4,0 VDC

Current

8,0 mA

Voltage

10,0 VD C

6,0 VDC

Current

20,0 mA

12, 0 m A

Sof t star t

Kick star t

Normal mode

Timer mode

Normal mode

Logic mode

0 % Us

30 % Us

100 % Us

9.600

8N1

8E1

8O1

mode

or

0 VDC

0 mA

0 s

60 s

0 s

200 s

MIW-EVSS-DM-EN-000 - 18 / 12 / 2018 13 - 16

www.sentera.eu

back to the table of contents

EVSS

ELECTRONIC FAN SPEED

CONTROLLER WITH TK

INPUT REGISTERS (See Table 1 Modbus register maps)

e input registers are read-only. Table 1 shows how the data is organized in the

input register sector. e measured data starts from address 1 (30001) and ends at

address 14 (30014). e other input registers are not used. When they are addressed,

they return 0.

All the data can be read by “Read Inputs Registers” command. Table1 shows what

the type of the returned data for each register is and the way it should be interpreted.

For example reading ‘300’ in input register 1 means that the measured analog input

signal is 3,0 VDC (or 6,0 mA), reading ‘50’ in input register 2 means that the output

voltage is 50 % Us (115 VAC).

Input register 1 (30001) shows the current value of measured analog input signal.

is value depends on the selected analog input type. When voltage input is

selected, the values vary in the range of 0—1.000 (0—10,0 VDC ). When current input

is selected, the values vary in the range of 0—1.000 (0—20,0 mA).

Input register 2 (30002) shows the current value of the output voltage. is input

register is overridden by holding register 31 if output override control (holding

register 8) is enabled. When output override control is disabled, this input register

shows the value of the output voltage according to the selected operating mode.

e output voltage values vary in the range of 30—100 % Us (69—230 VAC). Reading

‘0’ (0 VAC) indicates that the controller is off.

Input register 3 ( 30003) shows the type of the analog input

signal. is input register is defined by holding register 11 or by the

hardware setting of position 4 of the DIP switch. e values are ‘0’

(for0—20 mA) or ‘1’ (for 0—10 VDC).

Input register 4 ( 30004) shows the selected mode of the analog input. is input

register is defined by holding register 12 or the hardware setting of position 1 of the

DIP switch (Fig. 4), according to the selected operating mode. e values are ‘0’ (for

descending mode) or ‘1’ (for ascending mode).

Input register 5 ( 30005) shows the value of the maximum output voltage. is

input register is defined by holding register 13 or the hardware setting of the Max.

trimmer (Fig. 6), according to the selected operating mode. e register values vary

in range of 75—100 (75—100 % Us VAC).

Input register 6 ( 30006) shows the value of the minimum output voltage. is input

register is defined by holding register 14 or the hardware setting of Min. trimmer

(Fig. 7), according to the selected operating mode. e register values vary in range

30—70 % Us.

Input Register 7 (30007) gives information about the OFF level state. In Standalone

mode it contains the value set by position 2 of the DIP switch (Fig. 4). In Modbus

mode it contains the value of holding register 15. It could be ‘0’ (disabled) or ‘1’

(enabled).

Input Register 8 (30008) gives information about the OFF level value. In

Standalone mode it contains the value set by the OFF level trimmer (Fig. 8).

In Modbus mode it contains the value set by holding register 16. e register

values can vary from 0 to 40 (0—4,0 VDC / 0—8,0 mA) and from 60 to 100

(6,0—10,0 VDC / 12,0—20,0 mA). e values depend on the selected analog input

type and mode.

Input Register 9 (30009) gives information about the kick start or soft start

selection. In Standalone mode the value corresponds to the start type set by position

3 of the DIP switch. In Modbus mode it contains the value set by holding register 17.

e register values are ‘0’ (for soft start) or ‘1’ (for kick start).

Input Register 10 (30010) shows the state of the remote control input. When it is

disabled, the unit works in normal operating mode. When the remote control input is

enabled, the controller is in stand-by mode. e register values are ‘0’ (for disabled)

or ‘1’ (for enabled).

Input Register 11 (30011) shows the status of the alarm relay output. It is off when

the register value is ‘0’, and energised when the register value is ‘1’.

Input Register 12 (30012) shows the status of the unregulated output L1. When

MIW-EVSS-DM-EN-000 - 18 / 12 / 2018 14 - 16

back to the table of contents

www.sentera.eu

EVSS

ELECTRONIC FAN SPEED

CONTROLLER WITH TK

the analog input signal is below the value of the OFF level (if enabled) or when the

remote control input is disabled, the output voltage of the unregulated output L1 is

0 = OFF (0 VAC). Otherwise it is 1 = On (230 VAC).

Input Register 13 (30013) shows the status of the alarm LED (Fig.10). It indicates

motor overheating. When the register value is ‘0’ = Off, there is no overheating and

when the value is ‘1’ = On, the overheating is detected and the controller stops the

motor.

Input Register 14 (30014) shows the operating status of the unit. When the register

value is 0 (Off), the controller is switched off. e ON/Stand-by LED on the front

panel is off. See Fig. 10 Operating indication.

When the value is ‘1’ (On), the controller operates according to the control algorithm,

and the analog input signal is above the selected OFF level value (if enabled). e

ON/Stand-by LED (Fig. 10) gives out continuous light.

e ON/Stand-by LED blinks and the register value is 2 (Stand-by) when OFF level is

enabled and the analog input signal is below the OFF level value.

HOLDING REGISTERS (See Table 1 Modbus register maps)

ese registers are read / write registers and they can be managed with “Read

Holding Registers” command, “Write single register” and “Write Multiple Registers”

commands. ey are organised in parts containing different kind of information. e

holding registers that are not used are read only. Writing values on these registers

does not return Modbus error exception; however, it does not change anything

either!

■

Part 1:

is part contains information about the unit and Modbus communication settings.

Holding register 1 (40001) contains the address at which the controller replies to

the Modbus master unit. e default address is ‘1’. You can change it in two ways:

1. Send command “Write Single Register” with address ‘1’ and write the new

address value.

2. Connec t only your unit to a master controller or PC application and send the

command “Write Single Register” to address ‘0’ (Modbus broadcast address)

and write a new address value.

e next two registers (2 and 3) contain Modbus settings. Changing these registers

you change the communication settings. e default Modbus settings are 19200-E-1

as it is stated in the Modbus Protocol Specification.

e next three registers (4, 5 and 6) are read only. ey contain information about

the hardware and firmware versions.

Holding register 7 (40007) sets the operation mode of the controller. ere are two

options: Standalone mode and Modbus mode. In Standalone mode the controller is

fully controlled by the analog input signal and the selected hardware settings. In

Modbus mode the settings can be controlled by the Modbus master controller.

Holding register 8 (40008) is used for output override control. is setting is used

to override output voltage by a preselected value. is value has greater priority

over the calculated output voltage of the integrated control algorithm. Only kick

star t/soft start can change the output voltage value.

Holding registers 9 (40009) and 10 (40010) are not used. ey are read only.

■

Part 2:

Holding register 11 (40011) sets the analog input signal type. e default value is ‘1’

(0—10 VDC ). ‘0’ is for 0—20 mA.

Holding register 12 (40012) defines the ascending/descending analog input mode.

e default value is ‘1’ is for 0—10 VDC (ascending voltage signal). e register values

are ‘0’ for 10—0 VDC and ‘1’ for 0—10 VDC when voltage signal is selected, and ‘0’

for 20—0 mA and ‘1’ for 0—20 mA when current signal is selected.

Holding register 13 (40013) sets the maximum output voltage. e default value

is ‘100’ (100 % Us or 230 VAC). e register values vary in the range of 75—100

(75—100 % Us).

Holding register 14 (40014) sets the minimum output voltage. e default value is

‘30’ (30 % Us). e register values vary in the range of 30—70 (30—70 % Us).

MIW-EVSS-DM-EN-000 - 18 / 12 / 2018 15 - 16

back to the table of contents

www.sentera.eu

EVSS

ELECTRONIC FAN SPEED

CONTROLLER WITH TK

Holding register 15 (40015) contains the OFF level state. e default value is ‘0’

(disabled). ‘1’ is for enabled.

Holding register 16 (40016) defines the OFF level. is value depends on the

selected analog input type and mode. e register values vary in the ranges of

0—40 (0—4,0 VDC) for ascending voltage signal and 60—100 (6,0—10,0 VDC) for

descending voltage signal. When current signal is selected, the register values are in

ranges of 0—40 (0—8,0 mA) for ascending signal and 60—100 (12,0—20,0 mA) for

descending signal. e default value is ‘0’ (0 VDC).

Holding register 17 (40017) selects kick start or soft start. e default value is ‘1’

(kick start). ‘0’ value is for soft start.

Holding register 18 (40018) contains kick start or soft start duration time. e

default value is ‘10’ (10 seconds). e register values vary from ‘0’ to ‘60’ (0—60

seconds). is setting is accessible only in Modbus mode.

Holding register 19 (40019) selects the remote control input functionality. e

default value is ‘0’ for normal mode. Value ‘1’ is for timer mode. is setting is

accessible only in Modbus mode. OFF level mode is not used in timer mode.

Holding register 20 (40020) selects the analog input functionality. e default value

is ‘0’ for normal mode; ‘1’ is for logic mode. is setting is accessible only in Modbus

mode.

Holding register 21 (40021) contains the value of the operation timer. is holding

register is accessible only in timer mode and/or logic mode. e default value is

‘60’ (60 seconds). e register values can vary from 0 to 200 (0—200 seconds). is

setting is accessible only in Modbus mode. e working time is equal to the sum of

the kick star t/ soft start duration and the time value of the operation timer. When

a working time expires, only a remote control input or analog input can restart the

unit.

e next holding registers 22 (40022)—30 (40030) are not used. ey are read only.

Holding register 31 (40031) overrides the output voltage value in Modbus mode

when output override is enabled. e override value setting does not depend on the

other settings except on the kick start or soft start selection. e default value is

‘0’ (VAC). e register value can vary in the range of 30—100 (30—100 % Us). It can

be also ‘0’ (0 % Us).

e next holding registers 32 (40032)—40 (40040) are not used. ey are read only.

TRANSPORT AND STORAGE

Avoid shocks and extreme conditions; stock in original packing.

WARRANTY AND RESTRICTIONS

Two years from the delivery date against defects in manufactur ing. Any modifications

or alterations to the product after the date of publication relieve the manufacturer

of any responsibilities. e manufacturer bears no responsibility for any misprints or

mistakes in this data.

MAINTENANCE

In normal conditions this product is maintenance-free. If soiled, clean with a dry or

damp cloth. In case of heavy pollution, clean with a non-aggressive product. In these

circumstances the unit should be disconnected from the supply. Pay attention that

no fluids enter the unit. Only reconnect it to the supply when it is completelydry.

MIW-EVSS-DM-EN-000 - 18 / 12 / 2018 16 - 16

back to the table of contents

www.sentera.eu

Loading...

Loading...