Sentencia Chrono plus, Chrono Installation & Operating Instructions Manual

© 2014 erie water treatment OM-SentenciaChrono-Rev2014.09

Chrono & Chrono+

EN

Installation & Operating Instructions

WATER SOFTENER

FR

Instructions d’Installation & Emploi

ADOUCISSEUR D’EAU

DE

Installation- & Gebrauchsanleitung

WASSERENTHÄRTER

NL

Installatie & Gebruiksinstructies

WATERONTHARDER

EN English........................................................................................................................ Page 3

FR Français ...................................................................................................................... Page 11

DE Deutsch ...................................................................................................................... Seite 19

NL Nederlands ................................................................................................................. Pagina 27

TABLE OF CONTENT & INSTALLATION RECORD

Page 3

EN - English

Table of content & Installation record ..................................................................................Page 3

Warning & Safety instructions ..............................................................................................Page 4

Operating conditions & Requirements .................................................................................Page 5

Installation ...........................................................................................................................Page 6

Start-up ................................................................................................................................Page 7

Electromechanical control panel ..........................................................................................Page 8

Maintenance ........................................................................................................................Page 10

For future reference, fill in the following data

INSTALLATION RECORD

Serial Number:

______________________________________________

Model:

_______________________________________________________

Water Hardness inlet:

______________________________________

Water Hardness outlet:

_____________________________________

Water Pressure inlet:

_______________________________________

Regeneration Frequency:

________________________________ ___

Date of Installation:

_________________________________________

Company Name:

____________________________________________

Installer Name:

______________________________________________

Phone Number:

_____________________________________________

WARNING & SAFETY INSTRUCTIONS

EN - English

Page 4

· Before you begin the installation of the water softener, we advise you

read and carefully follow the instructions contained in this manual. It

contains important information about safety, installation, use and

maintenance of the product. The actual system that you have received,

may differ from the pictures/illustrations/descriptions in these

Instructions.

· Failure to follow the instructions could cause personal injury or damage

to the appliance or property. Only when installed, commissioned and

serviced correctly, the water softener will offer you many years of

trouble-free operation.

· The water softener is intended to 'soften' the water, meaning it will

remove hardness minerals; it will not necessarily remove other

contaminants present in the water. The water softener will not purify

polluted water or make it safe to drink!

· Installation of the water softener should only be undertaken by a

competent person, aware of the local codes in force. All plumbing and

electrical connections must be done in accordance with local codes.

· Before setting up the water softener, make sure to check it for any

externally visible damage; do not install or use when damaged.

· Use a hand truck to transport the water softener. To prevent accident or

injury, do not hoist the water softener over your shoulder. Do not lay the

water softener on its side.

· Keep these Instructions in a safe place and ensure that new users are

familiar with the content.

· The water softener is designed and manufactured in accordance with

current safety requirements and regulations. Incorrect repairs can result

in unforeseen danger for the user, for which the manufacturer cannot be

held responsible. Therefore repairs should only be undertaken by a

competent technician, familiar and trained for this product.

· In respect of the environment, this water softener should be disposed of

in accordance with Waste Electrical and Electronic Equipment

requirements. Refer to national/local laws and codes for correct recycling

of this water softener.

OPERATING CONDITIONS & REQUIREMENTS

Page 5

EN - English

·

OPERATING PRESSURE: min. 1,4 / max. 8,3 bar

- this system is configured to perform optimally at an operating

pressure of 3 bar (±½ bar); in case of a lower or higher operating

pressure the performance may be affected negatively!

- check water pressure regularly.

- take into account that night time water pressure may be

considerably higher than day time water pressure.

- install a pressure reducer ahead of the water softener if

necessary.

·

OPERATING TEMPERATURE: min. 2 / max. 48 °C

- do not install the water softener in an environment where high

ambient temperatures (e.g. unvented boiler house) or freezing

temperatures can occur.

- the water softener cannot be exposed to outdoor elements,

such as direct sunlight or atmospheric precipitation.

- do not install the water softener too close to a water heater;

keep at least 3 m of piping between the outlet of the water

softener and the inlet of the water heater; water heaters can

sometimes transmit heat back down the cold pipe into the

control valve; always install a check valve at the outlet of the

water softener.

·

ELECTRICAL CONNECTION: 230V-50Hz

- this water softener only works on 24VAC; it is equipped with a

230/24V-50Hz transformer; always use it in combination with

the supplied transformer.

- make sure to plug the transformer into a power outlet, which is

installed in a dry location, with the proper rating and overcurrent protection.

INSTALLATION

EN - English

Page 6

Picture 1

To facilitate the installation, you may want to remove the salt

lid and main cover from the water softener.

INLET & OUTLET

þ

Check the water pressure at the place of installation of

the water softener; it should never exceed 8,3 bar.

þ

In case of high concentration of impurities in the inlet

water, we recommend the installation of a sediment filter,

ahead of the water softener.

þ

We strongly recommend the use of flexible hoses to

connect the water softener to the water distribution system;

use hoses with a large diameter in order to limit the pressure

loss.

þ

If the water softener is not equipped with the factory

bypass (optional), we strongly recommend to install a 3valve bypass system (not included with this product!) to

isolate the water softener from the water distribution

system in case of repairs. It allows to turn off the water to

the water softener, while maintaining (untreated) water

supply to the user.

WITH FACTORY BYPASS (optional)

Picture 2

u = mains water supply (untreated water)

v = inlet of water softener (untreated water)

w = outlet of water softener (treated water)

x = house/application (treated water)

1. Screw the factory bypass onto the elbow connections of

the water softener (v&w); make sure to install the

gasket seals. Tighten the nuts firmly by hand.

2. Screw the connection kit with nuts onto the factory

bypass (u&x); make sure to install the gasket seals.

Tighten the nuts firmly by hand.

3. Connect the mains water supply to the adaptor on the

inlet port of the factory bypass (u).

4. Connect the house/application to the adaptor on the

outlet port of the factory bypass (x).

WITH 3-VALVE BYPASS SYSTEM (not included)

Picture 3

u = mains water supply (untreated water)

v = inlet of water softener (untreated water)

w = outlet of water softener (treated water)

x = house/application (treated water)

1. Install the 3-valve bypass system.

2. Screw the connection kit with nuts onto the elbow

connections of the water softener (v&w); make sure to

install the gasket seals. Tighten the nuts firmly by hand.

3. Connect the 3-valve bypass system to the adaptors on the

in (v) and out (w) elbow connections.

4. Connect the mains water supply to the inlet of the 3-valve

bypass system (u).

5. Connect the house/application to the outlet of the 3-valve

bypass system (x).

DRAIN

þ

We recommend the use of a stand pipe with air trap.

þ

To prevent backflow from the sewerage system into the

water softener, always make sure to have an air gap

between the end of the drain hose and the sewerage system

itself; as a rule of thumb, the air gap should be minimum 2x

the diameter of the drain hose.

þ

Always use separate drain hoses for the control valve

(evacuation of rinse water) and the softener cabinet's

overflow.

þ

Lay-out the drain hoses in such a way that pressure loss

is minimized; avoid kinks and unnecessary elevations.

þ

Make sure that the sewerage system is suitable for the

rinse water flow rate of the water softener.

Picture 4

1. Connect a 13 mm hose to the drain elbow connection of

the control valve (u); secure it by means of a clamp.

2. Run the drain hose to the sewerage system and connect

it to the stand pipe assuring sufficient air gap. This drain

line operates under pressure, so it may be installed higher

than the water softener.

3. Connect a 13 mm hose to the cabinet overflow elbow,

located at the back side of the water softener; secure it

by means of a clamp.

4. Run the drain hose to the sewerage system and connect

it to the stand pipe assuring sufficient air gap. This drain

line does NOT operate under pressure, so it may NOT be

installed higher than the water softener.

ELECTRICAL

Picture 5

1. Plug the transformers output lead into the socket on the

water softeners power cord; secure it by means of the

TwistLock clamp.

2. Plug the transformer into an electrical outlet.

START-UP

Page 7

EN - English

BRINE CABINET

1. Add water conditioner salt to the brine cabinet.

PRESSURIZING

2. Make sure the bypass system is in 'bypass' position.

3. Make sure the electronic controller of the water softener

is in service mode.

4. Open the mains water supply.

5. Open a cold treated water faucet nearby the water

softener and let the water run for a few minutes until all

air is purged and all foreign material that may have

resulted from the installation is washed out; close the tap.

6. Gently pressurize the water softener, by putting it into

service:

· factory bypass:

1. open the 'outlet' valve;

2. slowly open the 'inlet' valve.

· 3-valve bypass:

1. close the 'bypass' valve;

2. open the 'outlet' valve;

3. slowly open the 'inlet' valve.

7. After 2-3 minutes, open a cold treated water faucet

nearby the water softener and let the water run for a few

minutes until all air is purged from the installation and the

resin bed is rinsed (it is normal for the rinse water to show

some discoloration!); close the tap.

8. Check the water softener and all hydraulic connections

for leaks.

þ

After the first regenerations of the water softener, some

slight discoloration of the treated water might occur. This is

totally harmless and will disappear rapidly!

ELECTROMECHANICAL CONTROL PANEL

9. Program the electromechanical controller.

ADJUSTMENT RESIDUAL HARDNESS

WITH FACTORY BYPASS (optional)

Picture 6

10. Adjust the residual hardness of the water that leaves the

softener, by means of the adjusting screw, incorporated

in the ‘outlet’ valve of the factory bypass:

· to raise the residual hardness: turn the screw counter

clockwise; usually 1 turn corresponds to a residual

hardness of ±4 °f (±2 °d), 2 turns to ±8 °f (±4 °d).

· to reduce the residual hardness: turn the screw

clockwise.

PERFORM REGENERATION

11. Manually initiate a regeneration (refer to section

'ELECTROMECHANICAL CONTROL PANEL').

ELECTROMECHANICAL CONTROL PANEL

EN - English

Page 8

Picture 7

POWER FAILURE

In the event of a power failure, the settings will remain

unchanged, but the electromechanical clock will stop

working; consequently the time of day will not be maintained

and will need to be set again.

When the power failure occurs during the execution of an

automatic regeneration, the control valve will remain in the

regeneration position; when the power supply is reestablished, the control valve will resume the regeneration

from the point where it was interrupted.

SERVICE MODE

In service mode the drain plunger (G) will be closed. The

actuator (F) should NOT be visible.

REGENERATION MODE

In regeneration mode the drain plunger (G) will be pushed

down by the actuator (F). The actuator (F) will be visible.

The control valve can be reset to service mode at any time by

slowly turning the timer knob (H) counter clockwise until the

drain plunger (G) is released again by the actuator (F).

MANUAL REGENERATION

It is possible to manually initiate a regeneration:

1. Push in the skipper tab (E) that is aligned with the day

indicator (C).

2. Turn the timer knob (H) counter clockwise, until the time

in the time of day window (I) equals the time in the time

of regeneration window (B).

3. The time of day and the skipper tab (E) must be reset,

when the regeneration is terminated.

PROGRAMMING INSTRUCTIONS

Before starting the programming, make sure that the control

valve is in the service mode.

1. TIME OF REGENERATION:

· Turn the clock plate (A) until the desired time of

regeneration appears in the time of regeneration

window (B).

2. TIME OF DAY:

· Turn the timer knob (H) counter clockwise until the

correct time of day appears in the time of day window

(I).

3. DAYS OF REGENERATION:

þ

The regeneration frequency needs to be set in function

of:

- the exchange capacity of the water softener (= litres of

resin),

- the water hardness,

- the water usage.

þ

We recommend a regeneration frequency of min. 1x

regeneration per week.

The regeneration frequency, i.e. the number of days in service

after which the water softener needs to be regenerated, must

be calculated, by dividing the nominal exchange capacity of

the water softener by:

1. the local water hardness,

2. the peak daily water usage.

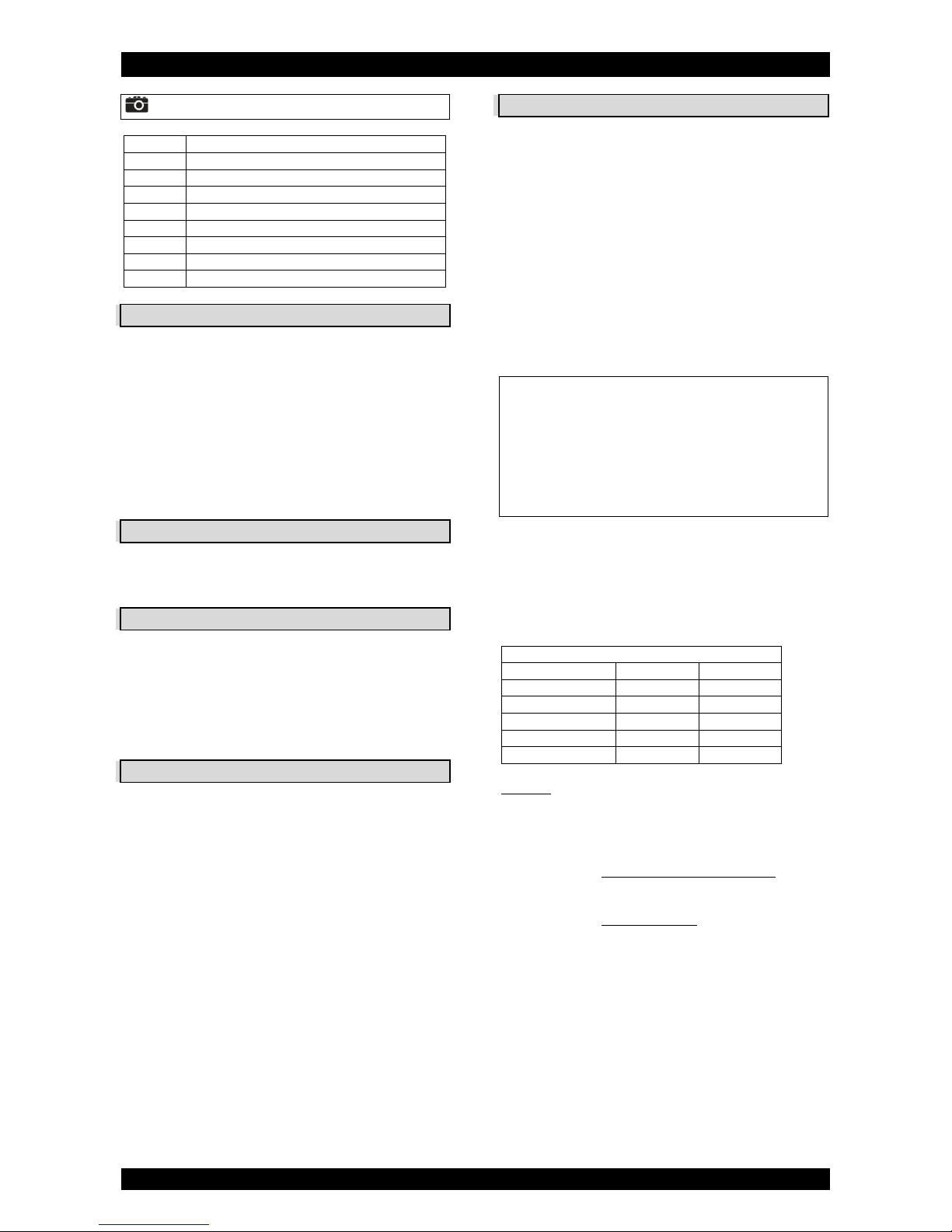

Nominal Exchange Capacity

Resin volume

m³x°f m³x°d

11 ltr 50 28 15 ltr 68 38 20 ltr 102 58 26 ltr 133 75 32 ltr 163 93

Example:

· 15 ltr resin

· Water hardness = 25 °f

· Peak daily water usage = 500 ltr/day = 0,5 m³/day

Þ Regen freq. = nominal exchange capacity

water hardn. x daily water usage

= 68 m³x°f

25 °f x 0,5 m³/day

= 5,4 days

Þ Regeneration every 5 days

To set the days at which a regeneration must take place:

· With all skipper tabs (E) pulled out, rotate the skipper

wheel (D) until day “1” is aligned with the day

indicator (C);

· push in skipper tabs (E) which correspond with the

desired days of regeneration.

A c

lock plate

B

time of regeneration window

C

day indicator

D 12-

days skipper wheel

E

skipper tabs

F actuator

G

drain plunger

H

timer knob

I

time of day window

MAINTENANCE

Page 9

EN - English

ROUTINE CHECKS

Regularly the user should perform a basic check to verify if the

water softener is functioning correctly, on the basis of the

following control points:

1. Check settings of electromechanical control panel.

2. Measure water hardness before/after water softener.

3. Check drain line from control valve; there shouldn’t be

any water flow (unless water softener is in regeneration).

4. Check drain line from cabinet overflow; there shouldn’t

be any water flow.

5. Check water softener and surrounding area; there

shouldn’t be any water leakages.

BYPASSING THE WATER SOFTENER

Occasionally it may be necessary to put the water softener

hydraulically in bypass, i.e. to isolate it from the water

distribution system; f.e.:

· in case of an urgent technical problem;

· when it is not necessary to supply treated water to the

house/application (refill swimming pool, irrigation,...).

WITH FACTORY BYPASS (optional)

Picture 8.a

SERVICE POSITION

u = inlet valve to water softener is OPEN

v = outlet valve from water softener is OPEN

Picture 8.b

BYPASS POSITION

u = inlet valve to water softener is CLOSED

v = outlet valve from water softener is CLOSED

Picture 8.c

MAINTENANCE POSITION

u = inlet valve to water softener is OPEN

v = outlet valve from water softener is CLOSED

WITH 3-VALVE BYPASS SYSTEM (not included)

Picture 9.a

SERVICE POSITION

u = bypass valve is CLOSED

v = inlet valve to water softener is OPEN

w = outlet valve from water softener is OPEN

Picture 9.b

BYPASS POSITION

u = bypass valve is OPEN

v = inlet valve to water softener is CLOSED

w = outlet valve from water softener is CLOSED

Picture 9.c

MAINTENANCE POSITION

u = bypass valve is OPEN

v = inlet valve to water softener is OPEN

w = outlet valve from water softener is CLOSED

WATER CONDITIONER SALT

Picture 10

The water softener needs 'brine' for its periodic

regenerations. This brine solution is made from water, that is

automatically dosed in the brine cabinet by the control valve,

and water conditioner salt. The user should make sure that

the brine cabinet is always kept full of water conditioner salt.

Therefore he should periodically check the salt level inside the

brine cabinet and refill it if necessary. The salt lid can be

removed completely to facilitate refilling.

Ideally the level of water conditioner salt inside the brine

cabinet is kept between 1/3 and 2/3. A lower level of water

conditioner salt can cause insufficient brine saturation,

resulting in a loss of softening capacity. A higher level of water

conditioner salt can cause salt bridging (hard crust or salt

bridges in the brine cabinet). When you suspect salt bridging:

· carefully pound on the outside of the brine cabinet to

break loose the salt bridges;

· using a broom (or like blunt tool) carefully push the salt to

break it apart;

· pour warm water over the top of the salt to dissolve it.

BRINE CABINET

To retain the appearance of the water softener, simply wipe

it with a damp cloth or clean it with a mild soap solution;

never use abrasive cleaners, ammonia or solvents.

RESIN CLEANER

Other contaminants (f.e. iron) present in the feed water can

cause the resin bed to foul up, resulting in a loss of softening

capacity. An approved resin cleaner can be used periodically

to thoroughly clean the resin bed.

SANITIZING THE WATER SOFTENER

This water softener is manufactured from premium quality

material and assembled in safe conditions to assure it is clean

and sanitary. If installed and serviced correctly, this water

softener will not infect or contaminate your water supply.

However, as in any 'device' plumbed-in in your water

distribution system, a proliferation of bacteria is possible,

especially in case of 'stagnant water'.

If the power supply to the water softener is disconnected for

a longer period of time, we recommend, when the power

supply is re-established, to manually initiate a complete

regeneration.

EN - English

Page 10

TABLE DES MATIÈRES & DONNÉES D’INSTALLATION

Page 11

FR - Français

Table des matières & Données d’installation ........................................................................Page 11

Mesures de précaution & Consignes de sécurité ..................................................................Page 12

Conditions de fonctionnement .............................................................................................Page 13

Installation ...........................................................................................................................Page 14

Mise en marche ...................................................................................................................Page 15

Panneau de commande électromécanique ..........................................................................Page 16

Entretien ..............................................................................................................................Page 18

Pour future référence, notez les données suivantes

DONNÉES D’INSTALLATION

Numéro de série:

____________________________________________

Modèle:

________________________________ ______________________

Dureté d’eau entrée:

_______________________________________

Dureté d’eau sortie:

________________________________________

Pression d’eau entrée:

______________________________________

Fréquence de régénération:

________________________________

Date d’installation:

________________________________ __________

Nom société:

________________________________________________

Nom installeur:

______________________________________________

Numéro de Tél.:

_____________________________________________

Loading...

Loading...