Sensys Networks VDS240 Installation Manual

APCC

Sensys Networks VDS240 Wireless Vehicle

Detection System

Access Point Controller Card (APCC) Installation Guide

P/N 152-240-030-005, Rev F

June 2015

Document Properties

This document is reference material for the Sensys Networks VDS240 wireless vehicle

detection system from Sensys Networks, Inc.

P/N 152-240-030-005 Rev F

Sensys Networks, Inc. makes no representation or warranties with respect to the

contents hereof and specifically disclaims any implied warranties of merchantability or

fitness for any particular purpose. Furthermore, Sensys Networks reserves the right to

revise this publication and to make changes from time to time in the content hereof

without obligation of Sensys Networks to notify any person or organization of such

revisions or changes.

© 2007 - 2015 – All rights reserved.

Sensys Networks and the Sensys Networks logo are trademarks of Sensys Networks,

Inc. All other products, names and services are trademarks or registered trademarks of

their respective owners.

Regulatory Statements

FCC Compliance Statement

This device complies with part 15 of the FCC rules. Operation is subject to the following

two conditions:

Any changes or modifications to this product not authorized by Sensys Networks could

void the EMC compliance and negate the authority to operate the product.

RF Exposure Statement

This device has been tested and meets the FCC RF exposure guidelines. It should be

installed and operated with a minimum distance of 20 cm between the radiator of RF

energy and the body of users, operators, or others.

Improper use or tampering with the device is prohibited and may not ensure

compliance with FCC exposure guidelines.

Warnings

No Safety Switching

Sensys Networks does not allow its equipment to be used for safety applications such

as controlling a mechanical gate or switching a train to avoid a collision.

(1) This device may not cause harmful interference.

(2) This device must accept any interference received, including interference that

may cause undesired operation.

Lithium Thionyl Chloride Batteries

N

OTE

:

Sensys Networks uses Lithium Thionyl Chloride batteries in the following products:

Sensors (VSN240-F, VSN240-T, VSN240-S, VSN240-M, VSN240-F-2,

VSN240-T-2)

Repeaters (RP240-BH-2, RP240-BH-LL-2, FLEX-RP-B-2, FLEX-RP-B-LL-2)

Lithium batteries are widely used in electronic products because they contain more

energy per unit -weight than conventional batteries. However, the same properties that

deliver high energy density also contribute to potential hazards if the batteries are

damaged. Improper use or handling of the batteries may result in leakage or release of

battery contents, explosion, or fire.

Following are the recommendations of the battery manufacturer for proper use and

handling of batteries in the Sensys Networks devices mentioned above:

DO NOT charge or attempt to recharge the batteries (they are NOT

rechargeable)

DO NOT crush or puncture batteries

DO NOT short-circuit the batteries

DO NOT force over-discharge of the batteries

DO NOT incinerate or expose batteries to excessive heating

DO NOT expose battery contents to water

DO dispose of batteries and devices containing batteries in accordance with

local regulations

Sensys Networks wireless sensors contain no serviceable parts and should never be

disassembled. Installation and removal of sensors from pavement should only be done by

trained personnel and care should be taken to insure that the sensor casing is not punctured

or crushed.

Additional safety information is available from the battery's manufacturer:

Sensor and repeater battery cell: http://www.ewtbattery.com/en/

DownView.asp?ID=9

Document Control

Sensys Networks continually reviews and revises its technical publications Please

address questions, suggestions, or corrections to support@sensysnetworks.com.

Sensys Networks Technical Publications

For additional information regarding Sensys Networks products and applications,

design guides, configuration guides, and best practices, refer to the Sensys Networks

technical documents library available at http://sensysnetworks.com/

resources?tech_docs.

Contact Information

Sensys Networks, Inc.

1608 Fourth Street, Suite 200

Berkeley, CA 94710 USA

+1 (510) 548-4620

www.sensysnetworks.com

Contents

Chapter 1: Introduction ............................................................................................... 1

What's Inside ..................................................................................................................................1

Chapter 2: Overview ................................................................................................... 3

Access Point Controller Card (APCC) ........................................................................................3

Contact Closure Expansion Card .........................................................................................3

Types of APCC Configurations ....................................................................................................4

APCC System ..........................................................................................................................4

APCC Serial Port Protocol (SPP) Digital Radio ..............................................................5

Isolator ...............................................................................................................................5

APCC Package Contents ............................................................................................................5

SPP Package Contents .................................................................................................................6

Universal Mounting Kit Contents ...........................................................................................7

Additional Parts and Equipment Required ................................................................................8

Chapter 3: APCC Installation Considerations ........................................................... 9

Identifying the SPP and Sensors ...................................................................................................9

SPP ............................................................................................................................................9

Wireless Sensors .....................................................................................................................10

Determining the Device Configuration ....................................................................................10

Configuration Worksheet .....................................................................................................10

Determining Slots and Contact Closures .................................................................................11

Mapping Wireless Sensors to Contact Closures .......................................................................12

Chapter 4: SPP Installation Considerations .............................................................. 13

Powering the SPP ........................................................................................................................13

Acquiring Power From a Traffic Controller .........................................................................13

Acquiring Power From Traffic Controller Using an Isolator ...............................................14

Voltages .................................................................................................................................15

Cabling ..................................................................................................................................15

Collecting Data From the APCC ...............................................................................................15

Determining the Location of the SPP ........................................................................................15

Optimal Location Criteria ....................................................................................................15

Chapter 5: APCC Installation Procedures ................................................................ 17

Overview ......................................................................................................................................17

Determining the Card ID and Setting it via Circuit-board Dip Switches SW1 and SW2 ......17

Factory Default Card ID .......................................................................................................18

Querying the Backplane for an Assigned Address ...........................................................18

Setting the Slot-Number With Circuit-board Dip Switch SW2 ...........................................19

Sensys Networks, Inc. Access Point Controller Card (APCC) v

Installation Guide

Exception ........................................................................................................................19

Setting the Shelf-Number With Circuit-board Dip Switch SW1 ........................................19

Determining the Controller Type and Setting it via Circuit-board Dip Switch SW1 .............19

Connecting the Cables to Each Device .................................................................................20

Cabling Summary .......................................................................................................................21

Chapter 6: SPP Installation Procedures .................................................................... 23

Tools Required for SPP Installation .............................................................................................23

Step-by-Step Procedures ...........................................................................................................24

Installing the Mounting Plate on Poles ...............................................................................24

Installing the Mounting Plate on Walls ...............................................................................25

Installing the Mounting Plate on Beams .............................................................................25

Determining the Type of SPP Radio Bulkhead Connector ..............................................26

SPP Radio Bulkhead Connector ...................................................................................26

Connecting the Cable to an SPP Radio with the Hex-head Connector .......................26

Components ...................................................................................................................26

Step-by-Step Procedures .....................................................................................................27

Proper Fit (little to no gap between edges of cut) ....................................................30

Improper Fit (gap between edges of cut) ..................................................................30

Proper Fit (bushing fully seated into guides) ...............................................................31

Improper Fit (bushing poorly seated into guides) ......................................................32

Proper Fit (recessed bushing, smooth face) ...............................................................33

Improper Fit (bushing not recessed, pinched edge, mushroomed face) ..............33

Removing the Cable Connection ......................................................................................33

Chapter 7: Configuration .......................................................................................... 35

Overview ......................................................................................................................................35

Configuration Methods ........................................................................................................36

Configuring Channels With the Front-Panel Interface ............................................................36

General Procedure ..............................................................................................................36

Saving the Configuration ..............................................................................................37

Enabling / Disabling a Channel ..........................................................................................37

Specifying the Channel Mode ............................................................................................38

Setting a Presence Mode Modifier (Optional) ..................................................................38

Using Delay and Extension ............................................................................................38

Specifying the Type of Communication Used by the Channel Status Monitor ............39

Starting TrafficDOT and Connecting to an APCC ...................................................................40

Configuring Channels with TrafficDOT ......................................................................................42

Entering controller card information ..................................................................................42

Configuring Channel State .................................................................................................43

Configuring Channel Mode ................................................................................................43

Configuring Presence Mode Modifier ................................................................................44

Configuring Channel Holdover Duration ...........................................................................44

Defining Sensor-to-Channel Mappings ....................................................................................44

Exiting TrafficDOT .........................................................................................................................45

Appendix A: X Mode LED Displays for Slot Numbers .............................................. 47

Examples ......................................................................................................................................48

vi Access Point Controller Card (APCC)

Installation Guide Sensys Networks, Inc.

Appendix B: Circuit-board Dip Switch SW1 Settings ............................................... 49

Settings for Shelf Number ...........................................................................................................49

Settings for TS1 and TS2 Controllers ...........................................................................................50

Appendix C: Circuit-board Dip Switch SW2 Settings .............................................. 51

Settings for Slot Number .............................................................................................................51

Appendix D: Pre-Installation Worksheets ................................................................ 53

Appendix E: Contact Closure Card External Interfaces ......................................... 55

Backplane Edge Connections ..................................................................................................56

IN RJ45 Connector Pin Assignments ..........................................................................................58

OUT RJ45 Connector Pin Assignments ......................................................................................58

Sensys Networks, Inc. Access Point Controller Card (APCC) vii

Installation Guide

viii Access Point Controller Card (APCC)

Installation Guide Sensys Networks, Inc.

Introduction

This guide provides information and procedures for installing Sensys Networks

Access Point Controller Card (APCC) and the APCC Serial Port Protocol (SPP)

digital radio in conjunction with the Sensys Networks VDS240 wireless vehicle

detection system. This document is intended to be used by Sensys Networks

customers, consultants, partners, dealers, and those who are interested in the

application of wireless communication technology to the challenges of traffic

detection, management, and control.

Chapter 1

What's Inside

This guide includes the following information:

Chapter 1: Introduction, defines the purpose and scope of the guide.

Chapter 2: Overview, provides an overview of the APCC and its additional

components. It also describes the contents of a product shipment.

Chapter 3: APCC Installation Considerations, provides the installation

considerations for the APCC.

Chapter 4: SPP Installation Considerations, provides the installation considerations

for the SPP.

Chapter 5: APCC Installation Procedures, provides instructions for installing and

cabling the APCC.

Chapter 6: SPP Installation Procedures, provides instructions for installing and

mounting the SPP.

Chapter 7: Configuration, provides instructions for configuring an APCC and

expansion cards.

Appendix A: X Mode LED Displays for Slot Numbers, depicts the channel LED

displays when an APCC operates in X mode.

Access Point Controller Card (APCC) 1

Sensys Networks, Inc. Installation Guide

Chapter 1

Appendix B: Circuit-board Dip Switch SW1 Settings, depicts SW1 settings that

identify the shelf number portion of the unique card address.

Appendix C: Circuit-board Dip Switch SW2 Settings, depicts combinations of switch

settings on the circuit-board dip switch SW2.

Appendix D: Pre-Installation Worksheets, provides worksheets for capturing

pre-installation information.

Appendix E: Contact Closure Card External Interfaces, provides the connector pin

assignments for the external interfaces of contact closure master and

expansion cards.

2 Access Point Controller Card (APCC)

Installation Guide Sensys Networks, Inc.

Overview

This chapter provides an overview of the APCC and its additional components.

The chapter also describes the contents of a product shipment.

Access Point Controller Card (APCC)

Chapter 2

The Sensys Networks VDS240 Wireless Vehicle Detection System detects the

presence and movement of vehicles with magneto-resistive sensors mounted in

the pavement. Wireless sensors continuously transmit detection data to the APCC

that collects and forwards data to remote traffic management systems or local

traffic signal controllers such as the CalTrans Type 170, Type 2070 ATC and

NEMA TS-1, and TS-2 controllers.

The Sensys Networks Access Point Controller Card (APCC), is a second generation

controller card that maintains low power consumption, supports multiple radios,

and allows for additional communication and processing power. The APCC, which

is compatible with all of Sensys Networks VDS240 Wireless Vehicle Detection

System products, receives and processes data from the sensors. The APCC then

relays the sensor detection data to a roadside traffic controller or remote server

traffic management system.

Contact Closure Expansion Card

Additional capacity (to handle more sensors or controller channels) is provided by

a contact closure expansion card (EX card). EX cards use the same form factor as

APCC cards and are daisy-chained to a CC interface on the APCC on the front-

panel RJ45 jacks or backplane connectors. Up to 63 EX cards can be used per

APCC card.

Access Point Controller Card (APCC) 3

Sensys Networks, Inc. Installation Guide

Chapter 2

Types of APCC Configurations

The APCC single-slot configuration consists of dual APCC radio ports, Sensys

Networks Expansion (EX) port, and contact closure interface via backplane to a

traffic controller. It also has dual USB 2.0 full speed host ports and 10/100Base-T

network access. The APCC dual-slot configuration adds an SD memory card, real-

time battery-backed clock, dual serial (DB9) interface, or an optional built in

cellular modem.

APCC System

The minimum APCC system consists of an APCC and one SPP radio. The system

can also consist of multiple SPP radios and an isolator that offers electrical

isolation up to 1500V, surge protection up to 1500V, and AC power cross

protection.

Figure 2.1. APCC configurations

Figure 2.2. APPC system configuration

4 Access Point Controller Card (APCC)

Installation Guide Sensys Networks, Inc.

APCC Serial Port Protocol (SPP) Digital Radio

The APCC, along with the SPP, maintains two-way wireless links to an

installation’s sensors and repeaters, establishes overall time synchronization, and

transmits configuration commands and message acknowledgements.

Figure 2.3. SPP digital radio

Isolator

The isolator is an optional component that provides the following services:

connects an SPP to the APCC

isolates and routes power from the controller backplane to the SPP

Overview

extends the communication for the APCC to and from the SPP at RS422

distance.

Figure 2.4. Isolator

APCC Package Contents

Each APCC is shipped with the items listed below. Verify that you have received all

of them. In the event that some items are missing, contact Sensys Networks or the

party that supplied the equipment to you.

The items in a Sensys Networks APCC shipment include:

An APCC

Access Point Controller Card Installation Guide (this document)

Information sheet

The Sensys Networks APCC is shipped with a factory default configuration suitable

for bench-testing the device and typically require further configuration to meet the

needs of specific applications. Hardware serial numbers are found on the

information sheet.

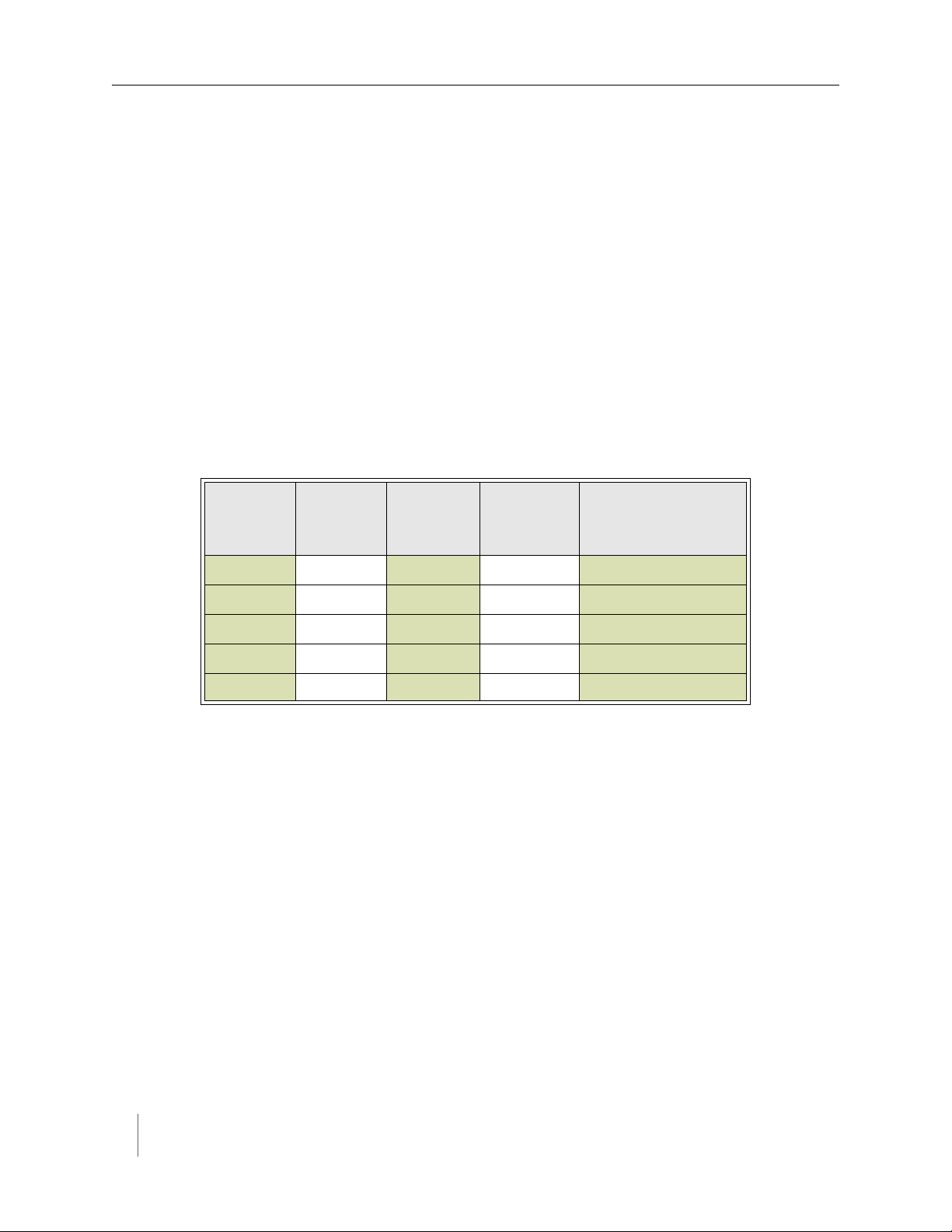

The APCC and EX cards are available in the models as shown below. Verify that

you have the correct model for your application.

Access Point Controller Card (APCC) 5

Sensys Networks, Inc. Installation Guide

Chapter 2

N

OTE

:

Product Description

APCC-M APCC Module

APCC-M-E APCC Module with Enhanced Ethernet

APCC-MP-E APCC Module with Peripheral Support and Enhanced Ethernet

APCC-MP-EG APCC Module with Peripheral Support and Enhanced Ethernet, GSM

APCC -MP-EV APCC with Peripheral Support and Enhanced Ethernet, Verizon

EX240 Expansion Card for Type 170, Type 2070, or NEMA TS1 or

TS2 traffic controllers

SPP Package Contents

Each SPP is shipped with the items listed below. Verify that you have received all

of them. In the event that some items are missing, contact Sensys Networks or the

party that supplied the equipment to you.

Table 1. APCC models

The items in an SPP shipment include:

An SPP

“Tool less” push/pull Ethernet bulkhead connector

Information sheet (one per device)

Item that is shipped separately:

Universal mounting kit (kit can be purchased from Sensys Networks)

SPP digital radios are shipped with a factory default configuration suitable for

bench-testing the device and applicable to many field environments. The

information sheet details the physical attributes of the SPP as well as key

configuration elements.

SPP information sheets contain the following elements:

Serial number – a globally unique identifier for the SPP

Default RF channel – a critical configuration property

Default IP address

Firmware release version

RF channel is essential for communicating and further configuring the wireless sensor

network. Save all information sheets for the party who will configure and use the network

after it is installed. Refer to the Configuration chapter of the Sensys Networks VDS240

Wireless Vehicle Detection System Reference Guide for more information about network

operations and configuration.

6 Access Point Controller Card (APCC)

Installation Guide Sensys Networks, Inc.

Universal Mounting Kit Contents

The following parts are included in the SPP mounting kit:

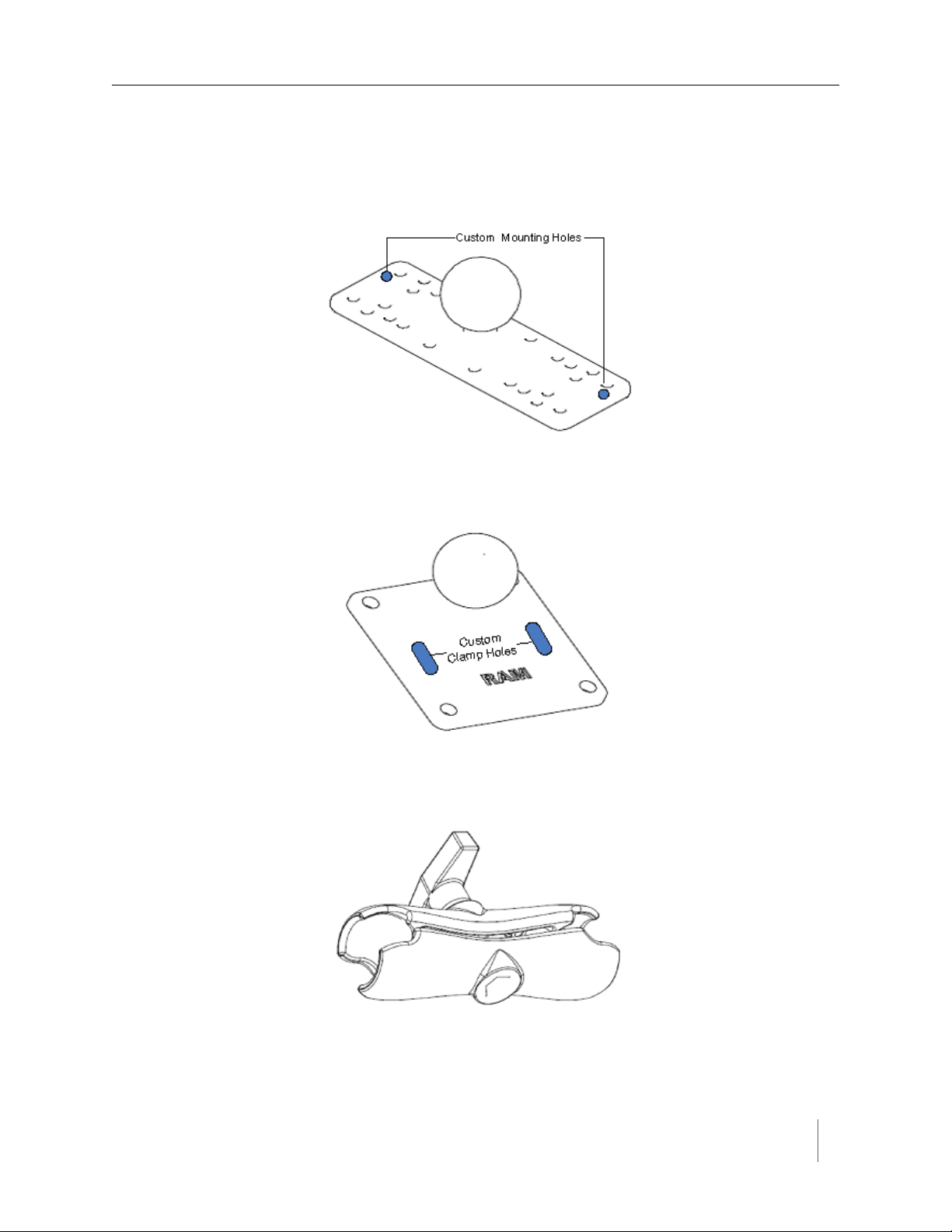

SPP ball plate (rectangular, attached to the SPP at the factory, refer to Figure

2.5)

Figure 2.5. Factory installed ball plate (rectangular)

Surface mounting ball plate (square, refer to Figure 2.6)

Overview

Figure 2.6. Surface (wall/beam/pole) mounting ball plate (square)

Double socket arm (refer to Figure 2.7)

Figure 2.7. Double socket arm

Access Point Controller Card (APCC) 7

Sensys Networks, Inc. Installation Guide

Chapter 2

N

OTE

:

5-foot clamp band

Clamp fastener

Additional Parts and Equipment Required

Additional parts and equipment required for installation and configuration of a

APCC include the following:

Standard Ethernet compatible, outdoor rated, 4-pair CAT5 (or better) cable

(refer to Notes below)

RJ45 jack kit and crimp tool

Cable ties

PC or laptop with Microsoft

(including 64-bit editions) and TrafficDOT, the system management software

tool from Sensys Networks.

The APCC is available with a range of options. Verify that the APCC you are using with the

contact closure card(s) is appropriate for that use.

®

Windows® XP Professional or Windows 7

Notes

1. Cabling – a minimum of one straight-through Ethernet cables are required.

2. Laptop PC and TrafficDOT software – if contact closure cards will be configured via TrafficDOT's GUI, a suitable host is required.

3. Contact closure card functions can be configured from the switches on the front panel eliminating the need for a laptop PC and TrafficDOT.

8 Access Point Controller Card (APCC)

Installation Guide Sensys Networks, Inc.

Chapter 3

APCC Installation Considerations

This chapter provides the installation considerations for the APCC. Prior to

installing an APCC ensure that the following aspects have been considered in the

site design.

1. Identify the devices that will be used with the APCC (refer to

and Sensors

2. Determine the configuration of the APCC (refer to

Configuration

3. Determine the number of available slots in the traffic controller's detector

shelf and which contact closures are required (refer to

Contact Closures

4. Develop the sensor-to-contact closure card mappings (refer to

Sensors to Contact Closures

).

).

).

).

Identifying the SPP and Sensors

SPP

Each APCC must connect to an SPP. This connection supplies power to the SPP

and passes command and configuration data to/from the APCC. There is a one-toone relationship between the APCC and master cards in a network.

Determine the location of the SPP relative to the cabinet that will hold the APCC

card. The Cat5 cable that connects to the SPP to the APCC, via an isolator, must

meet standard length limitations (2,000 ft with isolator) for RS422

communication.

Identifying the SPP

Determining the Device

Determining Slots and

Mapping Wireless

Access Point Controller Card (APCC) 9

Sensys Networks, Inc. Installation Guide

Chapter 3

NOTE:

NOTE:

Wireless Sensors

Each channel of an APCC interfaces a designated set of sensors to a designated

contact closure. Ensure information describing which sensor (or sensors) will

actuate a given APCC is available.

Wireless sensors have a unique identifier known as the Sensor ID. Use this identifier to

refer to sensors in design notes and plans.

Determining the Device Configuration

Configuration of an APCC is based on the following design decisions:

The number of APCC channels enabled

The operating mode (pulse or presence) of each channel

The use of and settings for any optional elements that modify the behavior of

channels operating in presence mode

The channel status communication method (LED-only) used by each channel

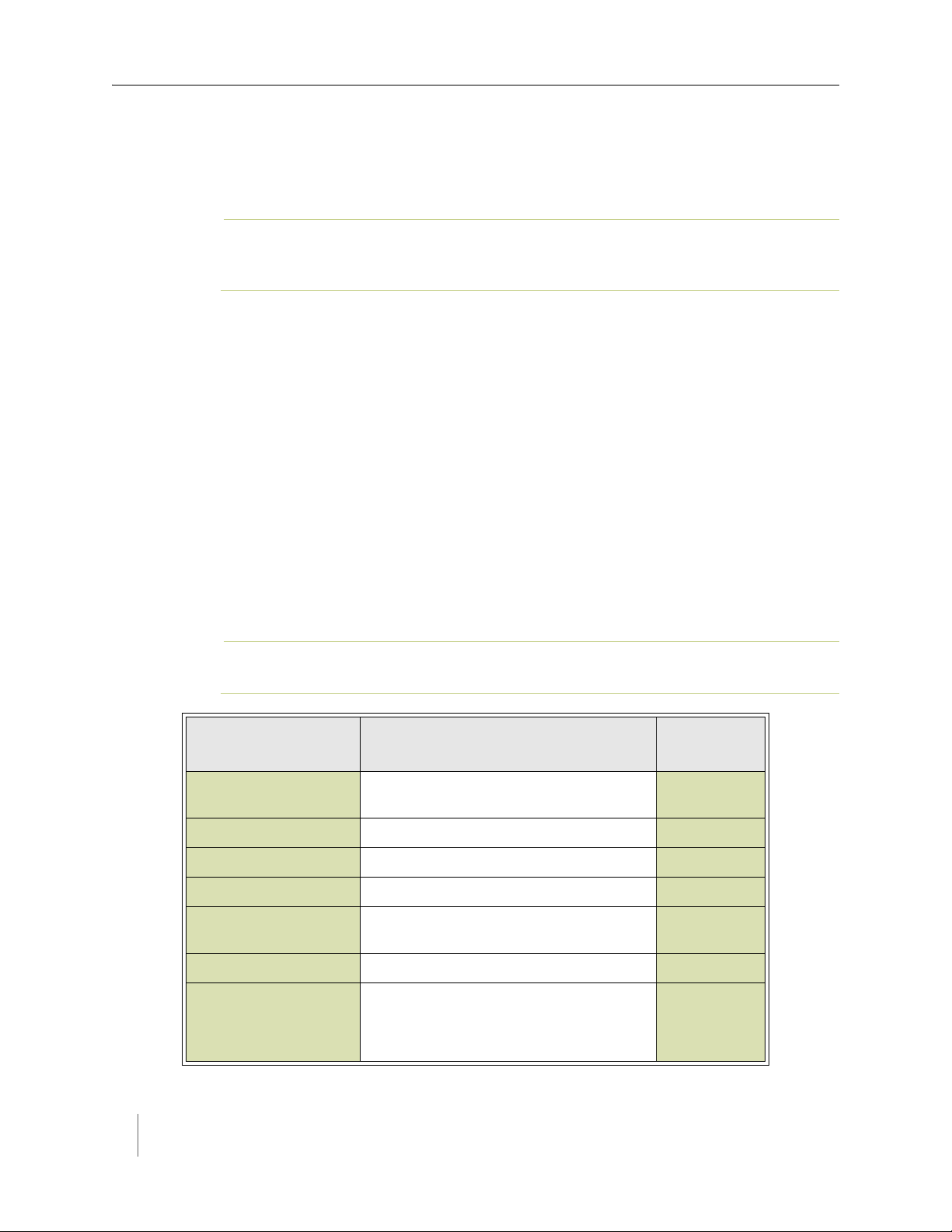

Configuration Worksheet

Each APCC supports up to four channels that are separately configured. Design

decisions can be captured in a Channel Configuration Worksheet such as the one

shown below.

Default values are shown in bold.

Configuration

Element

1. Card identifier (Defined by the traffic controller or

installer)

2. Channel 1, 2, 3, 4 1

3. Channel State Enabled | Disabled Enabled

4. Channel Mode Pulse | Presence Presence

4a. Presence Mode

Modifier

4b. Modifier Type None | Delay | Expansion Delay

(applicable only to channels in presence

mode)

Options

Example

Data

4c. Modifier Duration 0 – 31 seconds in 1 sec increments

(Delay, Delay16+)

0 – 7.5 seconds in 0.5 second increments

(Expansion)

10 Access Point Controller Card (APCC)

Installation Guide Sensys Networks, Inc.

5

APCC Installation Considerations

IMPORTANT!

Configuration

Element

5. Channel Holdover

Setting

6. Channel Status

Communications

Other Information

(Optional)

APCC identifier (from APCC) 192.2.68.100

Distance from APCC

(without Isolator)

List of wireless sensor for

the channel

Table 2. Channel configuration worksheet with example data (default values shown in bold)

0 -.75 seconds in .05 second increments 0

LED-only | LED and Tone LED

328 feet (100 meters) – 10BaseT 6 feet

(use SensorIDs of each sensor) 0707

Options

Example

Data

AC15

020D

Notes

1. Contact closure cards are addressed by the Card ID, a value dictated by the

controller or supplied by the installer.

2. Complete one worksheet for each channel.

3. Channel Holdover Setting should not be used; set it to zero.

4. The items listed in the section Other Information are not part of APCC

configuration. They are relevant to other aspects of installing and operating

the APCC.

Determining Slots and Contact Closures

Configuration of contact closure cards depends on (i) the availability of open slots

on the controller backplane and (ii) the use of any predefined functions or phases

for each slot – such as in the case of a standard CalTrans 322 shelf, where one

contact closure card and three contact closure EX cards are required (one card per

phase). Typically, a site survey of the traffic controller is required.

Shelf and slot information from the controller are used to create an identifier,

known as the Card ID, that uniquely defines an APCC in the network.

If using an APCC with an I/O board, it is essential that there is an empty slot directly to the left of

the APCC.

Access Point Controller Card (APCC) 11

Sensys Networks, Inc. Installation Guide

Chapter 3

Mapping Wireless Sensors to Contact Closures

The final installation consideration for contact closure cards are the assignment of

sensors to specific channels.

The four channels represent independent contact closures which, in turn, are

actuated by the vehicle detection events transmitted by a defined group of wireless

sensors. Each sensor may be associated with zero or one Card ID/Channel

combinations.

Up to 15 wireless sensors can be associated with the same card/channel, in which

case the sensors are logically “OR-ed” together – meaning that if any sensor on the

channel detects a vehicle, the corresponding contact closes.

The sensor-to-contact closure channel mappings are stored in a sensor database

that resides in memory. The sensor-to-contact closure channel mappings are

maintained within TrafficDOT.

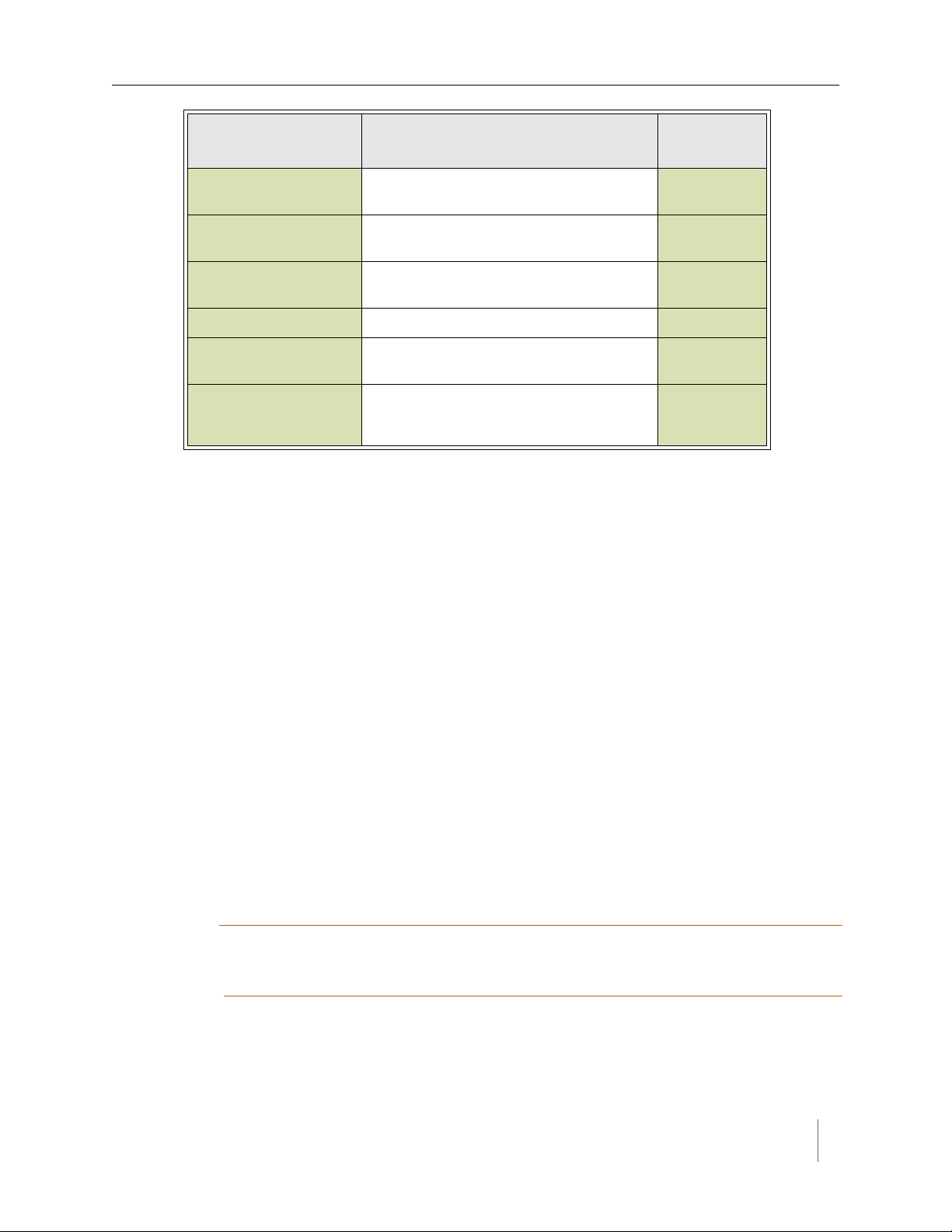

Defining the channel mappings is aided by the use of a Channel Mapping

Worksheet such as the one shown below.

Card ID

3-02 1 06C2 0 East bound, lane 1

3-02 1 06C3 0 East bound, lane 2

3-05 2 14C7 0 Advance C.3

3-06 3 0404 0 Stop bar A1

3-15 1 05D7 0 West bound, lane 1

Table 3. Sensor-to-channel mapping worksheet with sample data

Channel

(1 - 4)

Sensor ID

Channel

Extension

(opt.)

Location / Lane /

Description (opt.)

Notes

1. The worksheet assumes one sensor per row. Use as many rows as necessary to

assign all necessary sensors to channels.

2. Do not duplicate Sensor ID values. (A wireless sensor may only be assigned

once.)

3. The sample data above depicts representative Card ID values. Since these

values are rarely known prior to field installation, substitute a place-holder

value so that the installer will understand how the wireless sensors are

allocated to the channels.

4. Values for Channel Extension and Location are optional.

12 Access Point Controller Card (APCC)

Installation Guide Sensys Networks, Inc.

Loading...

Loading...