查询SCX100DN供应商

SCX - Series

Precision Compensated Pressure Sensors

FEATURES

· 0 - 1 psi to 0 - 150 psi

· Precision Temperature

Compensation

· Calibrated Zero and Span

· Small Size

· Low Noise

· High Accuracy

· High Impedance for

Low Power Applications

APPLICATIONS

· Medical Equipment

· Barometry

· Computer Peripherals

· Pneumatic Control

·HVAC

GENERAL DESCRIPTION

The SCX series sensors will provide a

very cost effective solution for pressure

applications that require high accuracy over

a wide temperature range. These internally

calibrated and temperature compensated

sensors were specifically designed to

provide an accurate and stable output over

a 0°C to 70°C temperature range. This series

is intended for use with non-corrosive, nonionic working fluids such as air, dry gases,

and the like.

Devices are available to measure absolute, differential, and gage pressures from

1psi (SCX01) up to 150psi (SCX150). The

Absolute (A) devices have an internal

vacuum reference and an output voltage

proportional to absolute pressure. The Differential (D) devices allow application of

pressure to either side of the pressure sensing diaphragm and can be used for gage

or differential pressure measurements.

The SCX devices feature an integrated

circuit sensor element and laser trimmed

thick film ceramic housed in a compact nylon

case. This package provides excellent

corrosion resistance and provides isolation

to external package stresses. The package

has convenient mounting holes and pressure ports for ease of use with standard

plastic tubing for pressure connection.

All SCX devices are calibrated for span

to within ±1% and provide a very low zero

pressure output of ±300 microvolts

maximum. Thus, for many applications,no

trimming networks are required in the signal

conditioning circuitry. If the application

requires extended temperature range ope-

Scale: 1c m

½ inch

ration, beyond 0 to 70°C, two pins which

provide an output voltage proportional to

temperature are available for use with

external circuitry.

The output of the bridge is ratiometric to

the supply voltage and operation from any

D.C. supply voltage up to +30 V is

acceptable.

Because these devices have very low

noise and excellent temperature

compensation, they are ideal for medical

and other high performance applications.

The 100 microsecond response time also

makes this series an excellent choice for

computer peripherals and pneumatic control

applications.

EQUIVALENT CIRCUIT

March 1998/053

ELECTRICAL CONNECTION

Pin 1) Temperature Output (+)

Pin 2) V

Pin 3) Output (+)

Pin 4) Ground

Pin 5) Output (-)

Pin 6) Temperature Output (-)

Note: The polarity indicated is for pressure applied to port B. (For absolute devices

pressure is applied to port A and the output polarity is reversed.)

Aubinger Weg 27, 82178 Puchheim, Germany

Phone 0049 - (0) 89 80 08 30, Fax 0049 - (0) 89 8 00 83 33

http://www.sensortechnics.com

S

SCX - Series

Precision Compensated Pressure Sensors

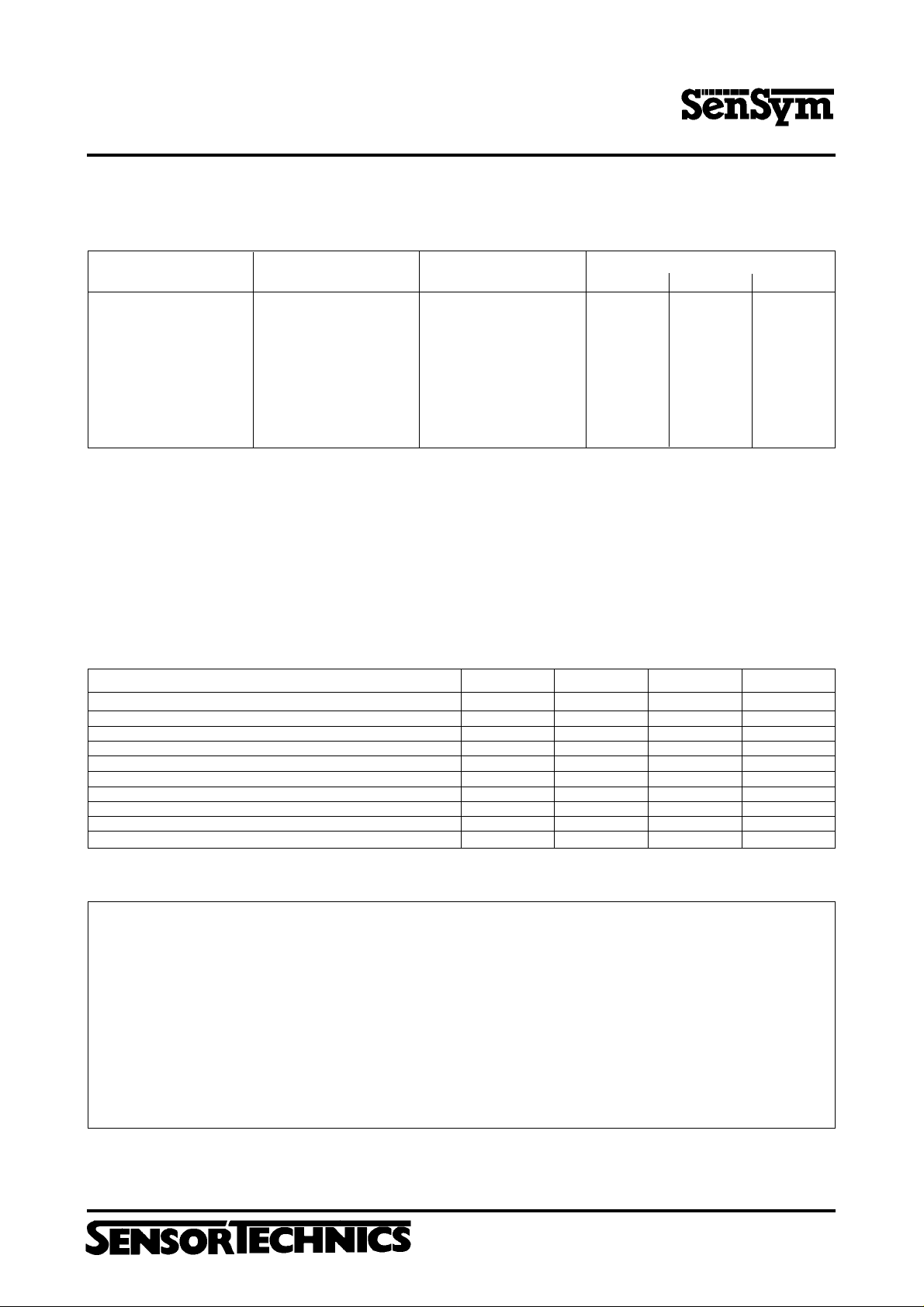

PRESSURE SENSOR CHARACTERISTICS

1

ST ANDARD PRESSURE RANGES

PART NUMBER

SCX01DN

SCX05DN

SCX15AN

SCX15DN

SCX30AN

SCX30DN

SCX100AN

SCX100DN

SCX150AN

SCX150DN

OPERA TING PRESSURE

0 - 1 psid

0 - 5 psid

0 - 15 psia

0 - 15 psid

0 - 30 psia

0 - 30 psid

0 - 100 psia

0 - 100 psid

0 - 150 psia

0 - 150 psid

PROOF PRESSURE*

* Maximum pressure above which causes permanent sensor failure

20 psid

20 psid

30 psia

30 psid

60 psia

60 psid

150 psia

150 psid

150 psia

150 psid

Min.

17.82 mV

59.4 mV

89.1 mV

89.1 mV

89.1 mV

89.1 mV

99.0 mV

99.0 mV

89.1 mV

89.1 mV

FULL-SCALE SP AN

Typ.

18 mV

60 mV

90 mV

90 mV

90 mV

90 mV

100 mV

100 mV

90 mV

90 mV

2

Max.

18.18 mV

60.6 mV

90.9 mV

90.9 mV

90.9 mV

90.9 mV

101.0 mV

101.0 mV

90.9 mV

90.9 mV

Maximum Ratings (For All Devices) Environmental Specifications (For All Devices)

Supply Voltage V

Common-mode Pressure 50 psig Compensated 0 to 70°C

S

+30 V

Lead Temperature Operating -40°C to +85°C

(Soldering, 4 seconds) 250°C Storage -55°C to +125°C

COMMON PERFORMANCE CHARACTERISTICS

Characteristic

Zero Pressure Offset

Combined Linearity and Hysteresis

Temperature Effect on Span (0-70°C)

Temperature Effect on Offset (0-70°C)

Repeatability

Input Impedance

Output Impedance

Common-mode Voltage

Response Time

5

6

7

8

9

Long Term Stability of Offset and Span

3

4

4

10

Temperature Range

DC

Humidity Limits 0 to 100 %RH

1

Min.

-300

---

---

---

---

---

---

5.8

---

---

Typ.

0

±0.1

±0.2

±100

±0.2

4.0

4.0

6.0

100

±0.1

Max.

+300

±0.5

±1.0

±500

±0.5

---

---

6.2

---

---

Unit

µV

%FSO

%FSO

µV

%FSO

kΩ

kΩ

V

DC

µsec

%FSO

SPECIFICA TION NOTES:

1. Reference conditions: Unless otherwise noted: Supply voltage, VS = 12 V, TA = 25°C, Common-mode Line Pressure = 0 psig,

Pressure Applied to Port B. For absolute devices only, pressure is applied to Port A and the output polarity is reversed.

2. Span is the algebraic difference between the output voltage at full-scale pressure and the output at zero pressure. Span is ratiometric to the supply voltage.

3. See Definition to T erms. Hysteresis - the maximum output difference at any point within the operating pressure range

for increasing and decreasing pressure.

4. Maximum error band of the offset voltage and the error band of the span, relative to the 25°C reading.

5. Maximum difference in output at any pressure with the operating pressure range and temperature within 0°C to +50°C after:

a) 1,000 temperature cycles, 0°C to +70°C

b) 1.5 million pressure cycles, 0 psi to full-scale span

6. Input impedance is the impedance between pins 2 and 4.

7. Output impedance is the impedance between pins 3 and 5.

8. This is the common-mode voltage of the output arms (Pins 3 and 5) for V

9. Response time for a 0 psi to full-scale span pressure step change, 10% to 90% rise time.

10. Long term stability over a one year period.

11. Maximum zero pressure offset for absolute devices is 0 ±500 µV.

= 12 VDC.

S

Aubinger Weg 27, 82178 Puchheim, Germany

Phone 0049 - (0) 89 80 08 30, Fax 0049 - (0) 89 8 00 83 33

http://www.sensortechnics.com

March 1998/053

Precision Compensated Pressure Sensors

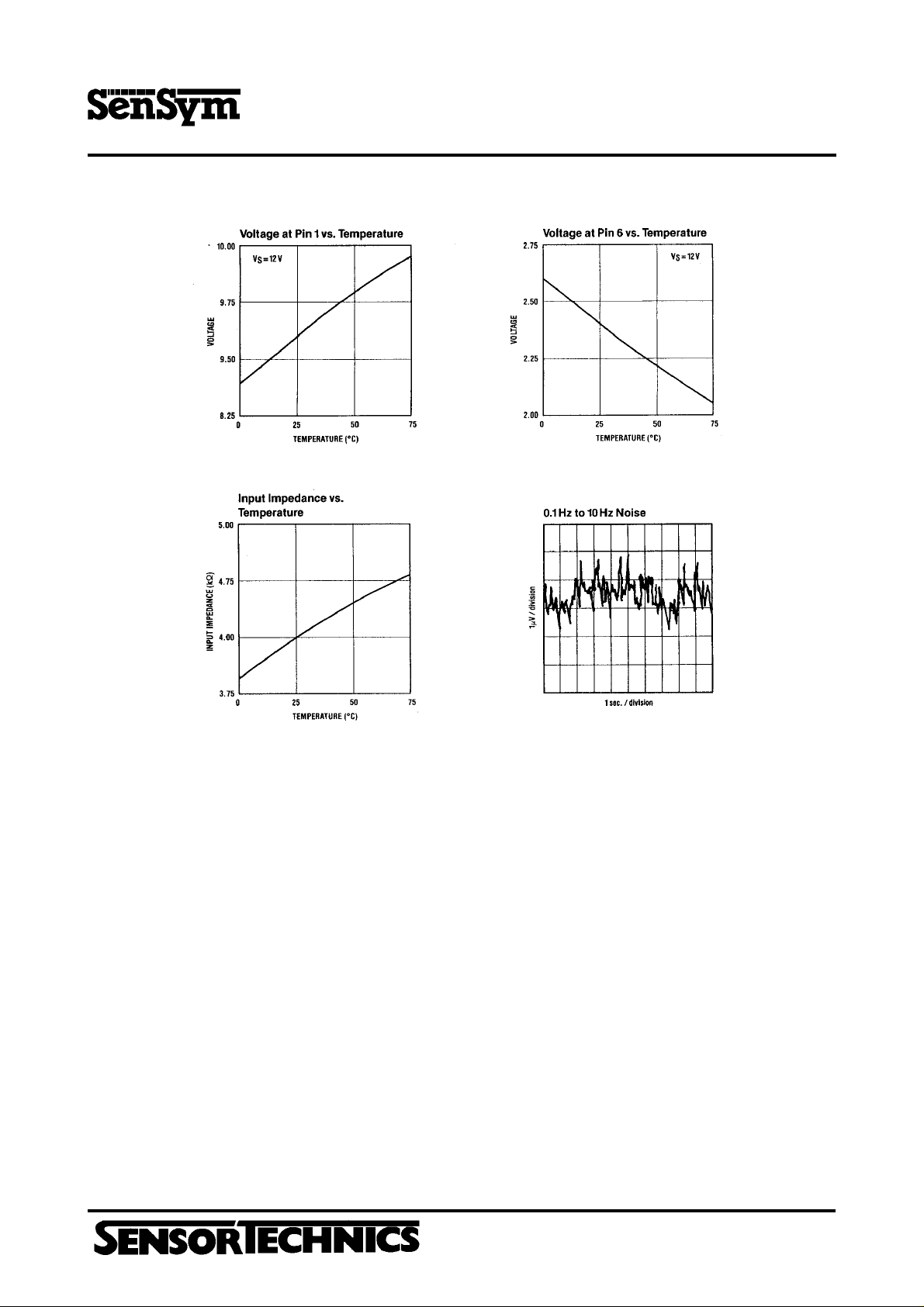

TYPICAL PERFORMANCE CHARACTERISTICS

SCX - Series

GENERAL DISCUSSION

The SCX series devices give a voltage output which is directly

proportional to applied pressure. The devices will give an increasing

positiv going output when increasing pressure is applied to

pressure port P

are reversed, the output will increase with decreases in pressure.

The devices are ratiometric to the supply voltage and changes in

the supply voltage will cause proportional changes in the offset

voltage and full-scale span. Since for absolute devices pressure

is applied to port P

User Calibration

The SCX devices are fully calibrated for offset and span and

should therefore require little if any user adjustment in most

applications. For precise span and offset adjustments, refer to the

applications section herein.

Vacuum Reference (Absolute Device)

Absolute sensors have a hermetically sealed vacuum reference

chamber. The offset voltage on these units is therefore measured

at vacuum, 0 psia. Since all pressure is measured relative to a

vacuum reference,all changes in barometric pressure or changes

in altitude will cause changes in the device output.

Media Compatibility

SCX devices are compatible with most non-corrosive gases.

March 1998/053

of the device. If the input pressure connections

B

, output polarity will be reversed.

A

Because the circuit is coated with a protective silicon gel, many

otherwise corrosive environments can be compatible with the

sensors. As shown in the physi-cal construction diagram below,

fluids must generally be compatible with silicon gel, plastic,

aluminium, RTV , silicon, and glass for use with Port B. For questions

concerning media compatibility, contact the factory.

MECHANICAL AND MOUNTING

CONSIDERATIONS

The SCX nylon housing is designed for convenient pressure

connection and easy PC board mounting. To mount the device

horizontally to a PC Board, the leads can be bent downward and

the package attached to the board using either tie wraps or

mounting screws. For pressure attachment, tygon or silicon tubing

is recommended.

All versions of the SCX sensors have two (2) tubes available for

pressure connection. For absolute devices, only port P

Applying pressure through the other port will result in pressure

dead ending into the backside of the silicon sensor and the device

will not give an output signal with pressure.

For gage applications, pressure should be applied the port P

is then the vent port which is left open to the atmosphere. For

P

A

differential pressure applications, to get proper output signal

polarity, port P

should be used as the low pressure port.

should be used as the high pressure port and P

B

Aubinger Weg 27, 82178 Puchheim, Germany

Phone 0049 - (0) 89 80 08 30, Fax 0049 - (0) 89 8 00 83 33

http://www.sensortechnics.com

is active.

A

. Port

B

A

Loading...

Loading...